Innovative Wood Surface Treatments Based on Nanotechnology

Abstract

1. Introduction

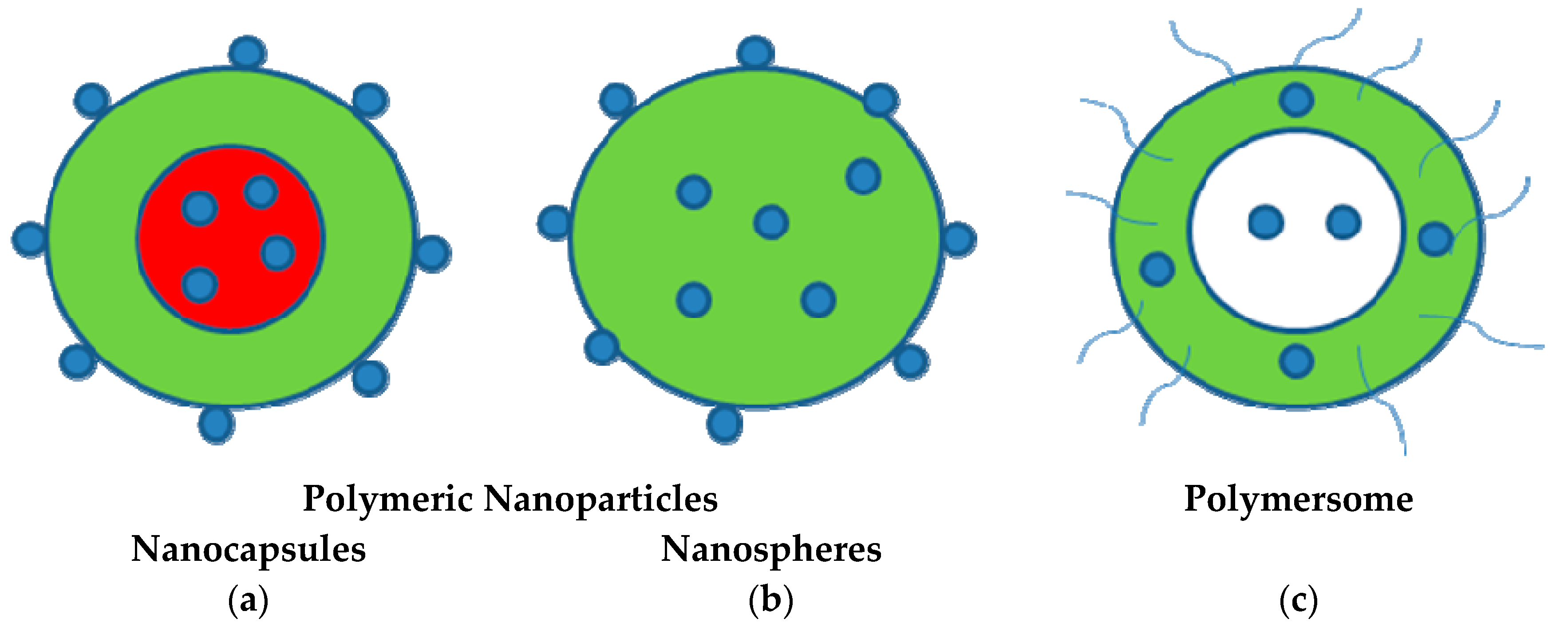

- through the impregnation of nano-based materials,

- as polymeric nanocarriers through the impregnation of nano-based materials,

- solution-based synthesis (like sol-gel or sonochemical)

2. Surface Treatment of Wood Based on Nanotechnology Coatings

2.1. Increased Durability

2.2. Improvement of Water Absorption

2.3. Improvement of Mechanical Properties

2.4. Improvement of UV Absorption

2.5. Improvement of Fire Resistance

- nanoclays (layered aluminosilicates). It has been reported that montmorillonite, a variety of bentonite clay, is the most effective and promising among the layered silicates. Its main characteristic is that it is able to split into individual nanosized plates [83].

- nano oxides. Nanoparticles of titanium have applied for this purpose [84]. They create a fire retardant barrier on the wood surface which retards the spread of flame and suppresses smoke generation. Additionally, they produce water and gases when exposed to fire, which provide a cooling effect by snuffing out the oxygen. At the same time, char is created which, in turns, protects the wood surface from combustion [85,86,87]. Another nano-oxide with promising potential is ZnO [88].

- nanosilica sol and silicon compounds. Nano-SiO2 has been applied to wood by the sol-gel method and has demonstrated great potential [89].

- nanostructured carbon materials. Information on carbon nanotubes and graphenes as potential fire retardant materials is limited.

3. Summary of Points Raised and Advantages of Nanomaterials in Surface Treatment of Wood

4. Future Prospects of Nanotechnology

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press, Taylor and Francis Group: Boca Raton, FL, USA, 2012. [Google Scholar]

- Gerardin, P. New alternatives for wood preservation based on thermal and chemical modification of wood—A review. Ann. For. Sci. 2016, 73, 559–570. [Google Scholar] [CrossRef]

- Hill, C.A.S. Wood Modification—Chemical, Thermal and other Processes; John Wiley and Sons Ltd.: West Sussex, UK, 2006. [Google Scholar]

- Hon, D.N.S. Chemical Modification of Lignocellulosics; Marcel Dekker: New York, NY, USA, 2006. [Google Scholar]

- Rowell, R.M. The Chemistry of Solid Wood; ACS: Washington, DC, USA, 1984. [Google Scholar]

- Sanberg, D. Additives in Wood Products-Today and Future Development. In Environmental Impacts of Traditional and Innovative Forest-Based Bioproducts; Kutnar, A., Muthu, S.S., Eds.; Springer Science and Business Media: Singapore, 2016. [Google Scholar]

- Wegner, T.H.; Winandy, J.E.; Ritter, M.A. Nanotechnology opportunities in residential and non-residential construction. In Proceedings of the 2nd International Symposium on Nanotechnology in Construction, Bilbao, Spain, 13–16 November 2005; pp. 23–31. [Google Scholar]

- Wegner, T.H.; Jones, P. Advancing cellulose-based nanotechnology. Cellulose 2005, 13, 115–118. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Bikiaris, D.N.; Mitropoulos, A.C.; Kyzas, G.Z. Nanomaterials and chemical modification technologies for enhanced wood properties: A review. Nanomaterials 2019, 9, 607. [Google Scholar] [CrossRef] [PubMed]

- Papadopoulos, A.N. Chemical modification of solid wood and wood raw materials for composites production with linear chain carboxylic acid anhydrides: A brief Review. BioResources 2010, 5, 499–506. [Google Scholar]

- Teng, T.; Arip, M.; Sudesh, K.; Lee, H. Conventional technology and nanotechnology in wood preservation: A review. BioResources 2018, 13, 9220–9252. [Google Scholar] [CrossRef]

- Hill, C.A.S.; Papadopoulos, A.N. A review of methods used to determine the size of the cell wall microvoids of wood. J. Inst. Wood Sci. 2001, 15, 337–345. [Google Scholar]

- Polleti Papi, M.A.; Caetano, F.R.; Berganini, M.F.; Marcolino-Junior, L.H. Facile synthesis of a silver nanoparicles/polypyrrole nanocomposite for non-enzymatic glucose determination. Mater. Sci. Eng. 2017, 75, 88–94. [Google Scholar] [CrossRef]

- Gupta, A.; Srivastana, R. Zinc oxide nanoleaves: A scalable disperser assisted sonochemical approach for synthesis and an antibacterial application. Ultrason. Sonochem. 2018, 41, 47–58. [Google Scholar] [CrossRef]

- Moya, R.; Zuniga, A.; Berrocal, A.; Vega, J. Effect of silver nanoparticles synthesized with NPsAg-ethylene glycol on brown decay and white decay fungi of nine tropical woods. J. Nanosci. Nanotechnol. 2017, 17, 5233–5240. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Royas, O.J.; Lucia, L.A. Green modification of surface characteristics of cellulose materials at the molecular or nano scale: A review. BioResources 2015, 10, 6095–6206. [Google Scholar] [CrossRef]

- Roco, M.C. Nanotechnology’s Future. Sci. Am. 2006, 295, 39. [Google Scholar] [CrossRef] [PubMed]

- De Filpo, G.; Palermo, A.M.; Rachiele, F.; Nicoletta, F.P. Preventing fungal growth in wood by titanium dioxide nanoparticles. Int. Biodeterior. Biodegrad. 2014, 85, 217–222. [Google Scholar] [CrossRef]

- Civardi, C.; Schwarze, F.; Wick, P. Micronized copper wood protection: An efficiency and potential health and risk assessment for copper based nanoparticles. Environ. Pollut. 2015, 200, 20–32. [Google Scholar] [CrossRef] [PubMed]

- Goffredo, G.B.; Accoroni, S.; Totti, T.; Romagnoli, T.; Valentini, L.; Munafò, P. Titanium dioxide based nanotreatments to inhibit microalgal fouling on building stone surfaces. Build. Environ. 2017, 112, 209–222. [Google Scholar] [CrossRef]

- Khoee, S.; Haslemi, A. Synthesis and characterization of IUdR loaded PEG/PCL/PEG polymersome in mixed DCM/DMF solvent: Experimental and molecular dynamics insights into the role of solvent composition and star architecture in drug dispersion and diffusion. Eur. J. Pharm. Sci. 2018, 114, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yan, L.; Heiden, P.; Laks, P. Use of nanaparticles for controlled release of biocides in solid wood. J. Appl. Polym. Sci. 2001, 79, 458–465. [Google Scholar] [CrossRef]

- Liu, Y.; Laks, P.; Heiden, P. Controlled release of biocides in solid wood. Efficacy against brown rot wood decay fungus. J. Appl. Polym. Sci. 2002, 86, 596–607. [Google Scholar] [CrossRef]

- Mishra, P.M.; Giagli, K.; Tsalagas, D.; Mishra, H.; Talegaonkar, S.; Gryc, V.; Wimmer, R. Changing face of wood science in modern era: Contribution of Nanotechnolgy. Recents Pat. Nanotechnol. 2018, 12, 13–21. [Google Scholar] [CrossRef]

- Petric, M. Surface modification of wood: A critical review. Rev. Adhes. Adhes. 2013, 1, 216–247. [Google Scholar] [CrossRef]

- Morones, J.R.; Elechiguerra, J.L.; Camacho, A.; Holt, K.; Kouri, J.B.; Ramirez, J.T.; Yacaman, M.J. The Bactericidal Effect of Silver Nanoparticles. Nanotechnology 2005, 16, 2346–2353. [Google Scholar] [CrossRef]

- Mantanis, G.I.; Terzi, E.; Kartal, S.N.; Papadopoulos, A.N. Evaluation of mold, decay and termite resistance of pine wood treated with zinc and copper based nanocompounds. Int. Biodeterior. Biodegrad. 2014, 90, 140–144. [Google Scholar] [CrossRef]

- Reinprecht, L.; Vidholdova, Z.; Kozienka, M. Decay inhibition of lime wood with zinc oxide nanoparticles used in combination with acrylic resin. Acta Fac. Xylologiae Zvolen 2015, 57, 43–52. [Google Scholar]

- Reinprecht, L.; Vidholdova, Z. Biological resistance and application properties of particleboards containing nano-zinc oxide. Adv. Mater. Sci. Eng. 2018, 2018, 2680121. [Google Scholar] [CrossRef]

- Kartal, S.N.; Green, F.; Clausen, C.A. Do the unique properties of nanometals affect leachability or efficacy against fungi and termites? Int. Biodeterior. Biodegrad. 2009, 63, 490–495. [Google Scholar] [CrossRef]

- Bak, M.; Nemeth, R. Effect of different nanoparticle treatments on the decay resistance of wood. BioResources 2018, 13, 7886–7899. [Google Scholar] [CrossRef]

- Bak, M.; Molnar, F.; Nemeth, R. Improvement of dimensional stability of wood by silica nanoparticles. Wood Mater. Sci. Eng. 2018, 14, 48–58. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.; Zhang, H. Light Curing Nano Composite Coating. International Patent Application No. CN101423678A, 6 May 2009. [Google Scholar]

- Kumar, A.; Ryparova, P.; Skapin, A.S.; Humar, M.; Pavlic, M.; Tywoniak, J.; Hajek, P.; Zigon, J.; Petric, M. Influence of surface modification of wood with octadecyltrichlorosilane on its dimensional stability and resistance against Coniophora puteana and molds. Cellulose 2016, 23, 3249–3263. [Google Scholar] [CrossRef]

- Kumar, A.; Ryparova, P.; Petric, M.; Tywoniak, J.; Hajek, P. Coating of wood by means of electrospun nanofibers based on PVA/SiO2 and its hydrophobization with octadecyltrichlorosilane (OTS). Holzforschung 2016, 71, 225–231. [Google Scholar] [CrossRef]

- Wang, C.; Chen, M.; Chen, S.; Chen, B. High Hardness Abrasive Resistance Bicomponent Waterborne Wood Lacquer and Preparation Method Thereof. International Patent Application No. CN101445695A, 3 June 2009. [Google Scholar]

- Chen, X.; Jiang, J.; Xiao, G. High-Glossiness, Scratch-Resistant, Wear-Resistant and Environment-Friendly Waterborne Wood Varnish and Preparation Method Thereof. International Patent Application No. CN102676035B, 18 June 2014. [Google Scholar]

- Chen, H.; Guangyu, H.; Xiaoqiang, S.; Yong, H.; Gorge, W.; Yunfeng, C. Preparation of Method of Modified Ultroviolet Light Solid Wooden Articles Paint by in-Situ Method. International Patent Application No. CN101045833A, 4 November 2007. [Google Scholar]

- Thomas, S.C.; Harshita, N.; Mishra, P.K.; Talegaonkar, S. Ceramic Nanoparticles: Fabrication Methods and Applications in Drug Delivery. Curr. Pharm. Des. 2015, 21, 6165–6188. [Google Scholar] [CrossRef]

- Hui, B.; Li, Y.; Huang, Q.; Li, G.; Li, J.; Cai, L. Fabrication of smart coatings based on wood substrates with photoresponsive behavior and hydrophobic performance. Mater. Des. 2015, 84, 277–284. [Google Scholar] [CrossRef]

- Leong, M. Nano Composite Photocatalytic Coating. International Patent Application No. US20070000407A1, 4 January 2007. [Google Scholar]

- Liu, J.; Jin, K.; Huang, J. Nanometre Ag Antibacterial Aqueous Wood-Ware Paint and Its Preparation Method. International Patent Application No. CN100387666C, 14 May 2008. [Google Scholar]

- Gao, F. Novel Nano Modified Antimicrobial Water-Based Woodware Paint. International Patent Application No. CN103059669A, 24 April 2013. [Google Scholar]

- Gao, F. Preparation Method of Novel Nano Modified Antibiosis Aqueous Woodenware Paint. International Patent Application No. CN103073964A, 1 May 2013. [Google Scholar]

- He, W.; Xu, J. Environment Friendly Waterborne Paint and Preparation Thereof. International Patent Application No. CN101486863A, 22 July 2009. [Google Scholar]

- Du, L.; Li, R.; Miao, G.; Liu, H.; Liu, H. Nano Antibacterial Water Woodenware Paint and Preparing Method Thereof. International Patent Application No. CN101016431A, 15 August 2007. [Google Scholar]

- Ong, I.W.; Wilson, C.B. Antimicrobial Radiation Cur-Able Coating. U.S. Patent US7098256B2, 29 August 2006. [Google Scholar]

- Ottersbach, P.; Anders, C. Process for the Preparation of Antimicrobial Plastics. U.S. Patent US5967714A, 19 October 1999. [Google Scholar]

- Ottersbach, P.; Sosna, F. Antimikrobielle Polymere und Polymer-Blends aus Polymeren Alkylacrylamiden. U.S. Patent DE10024270A1, 22 November 2001. [Google Scholar]

- Feng, L.; Li, S.; Li, Y. Super-hydrophobic surfaces: From natural to artificial. Adv. Mater. 2002, 14, 1857–1860. [Google Scholar] [CrossRef]

- Liu, S.; Ye, R. Nano Polyacrylate Emulsion for Water-Based Wood Coating and Method for Preparing Same. International Patent Application No. CN101638451A, 3 February 2010. [Google Scholar]

- Polo, A.; Diamanti, M.V.; Bjarnsholt, T.; Hoiby, N.; Villa, F.; Pedeferri, M.P.; Cappitelli, F. Effects of Photoactivated Titanium Dioxide Nanopowders and Coating on Plank-tonic and Biofilm Growth of Pseudomonas aeruginosa. Photochem. Photobiol. 2011, 87, 1387–1394. [Google Scholar] [CrossRef] [PubMed]

- Gladis, F.; Eggert, A.; Karsten, U.; Schumann, R. Prevention of Biofilm Growth on Man-Made Surfaces: Evaluation of Antialgal Activity of Two Biocides and Photocatalytic Nanoparticles. Biofouling 2010, 26, 89–101. [Google Scholar] [CrossRef] [PubMed]

- Clausen, C.A.; Kartal, S.N.; Arango, R.A.; Green, F. The Role of Particle Size of Particulate Nano-zinc OxideWood Preservatives on Termite Mortality and Leach Resistance. Nanoscale Res. Lett. 2011, 6, 427. [Google Scholar] [CrossRef]

- Nikolic, M.; Lawther, J.M.; Sanadi, A.R. Use of nanofilers in wood coating: A scientific review. J. Coat. Technol. Res. 2015, 12, 445–461. [Google Scholar] [CrossRef]

- Mantanis, G.; Papadopoulos, A.N. The sorption of water vapour of wood treated with a nanotechnology compound. Wood Sci. Technol. 2010, 44, 515–522. [Google Scholar] [CrossRef]

- Soltani, M.; Najafi, A.; Bakar, E. Water repellent effect and dimensional stability of beech wood impregnated with nano-zinc oxide. BioResources 2013, 8, 6280–6287. [Google Scholar] [CrossRef]

- Civardi, C.; Schlagenhauf, L.; Kaiser, J.P.; Hirsch, C.; Mucchino, C.; Wichser, A.; Wick, P.; Schwarze, F.W.M.R. Release of copper amended particles from micronized copper pressure treated wood during mechanical abrasion. J. Nanotechnol. 2016, 14, 77. [Google Scholar] [CrossRef]

- Akhtari, M.; Ganjipour, M. Effect of nano-silver and nano-copper and nano zinc oxide on Paulownia wood exposed to white rot fungus. Agric. Sci. Dev. 2013, 2, 116–119. [Google Scholar]

- Akhtari, M.; Nicholas, D. Evaluation of particulate zinc and copper as wood preservatives for termite control. Eur. J. Wood Wood Prod. 2013, 71, 395–396. [Google Scholar] [CrossRef]

- Bauer, F.; Mehnert, R. UV curable acrylate nanoparticles: Properties and applications. J. Polym. Res. 2005, 12, 483–491. [Google Scholar] [CrossRef]

- Zou, H.; Wu, S.; Shen, J. Polymer/Silica Nanocomposites: Preparation, Characterization, Properties, and Applications. Chem. Rev. 2008, 108, 3893–3957. [Google Scholar] [CrossRef] [PubMed]

- Fernando, R. Nanomaterial Technology Applications in Coatings. JCT CoatingsTech 2004, 1, 32–38. [Google Scholar]

- Khudyakov, I.V.; Zopf, D.R.; Turro, N. Polyurethane Nanocomposites. Des. Monomers Polym. 2009, 12, 279–290. [Google Scholar] [CrossRef]

- Bayani, S.; Taghiyari, H.R.; Papadopoulos, A.N. Physical and mechanical properties of thermally-modified beech wood impregnated with silver nano-suspension and their relationship with the crystallinity of cellulose. Polymers 2019, 11, 1538. [Google Scholar] [CrossRef]

- Taghiyari, H.; Esmailpour, A.; Papadopoulos, A. Paint Pull-Off Strength and Permeability in Nanosilver-Impregnated and Heat-Treated Beech Wood. Coatings 2019, 9, 723. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, A.; Song, X.; Liu, X. Synthesis and Characterization of Waterborne UV-Curable Polyurethane Nanocomposites Based on the Macromonomer Surface Modification of Colloidal Silica. Prog. Org. Coat. 2013, 76, 1032–1039. [Google Scholar] [CrossRef]

- Ji, X.; Guo, M. Facile surface hydrophobization of medium-density fiberboard (MDF) by silver deposition. Holzforschung 2016, 71, 337–340. [Google Scholar] [CrossRef]

- de Cademartori, P.H.G.; Stafford, L.; Blanchet, P.; Magalhaes, W.L.E.; de Muniz, C.I.B. Enhancing the water repellency of wood surfaces by atmospheric pressure cold plasma deposition of fluorocarbon film. RSC Adv. 2017, 7, 29159–29169. [Google Scholar] [CrossRef]

- Xuan, L.; Fu, Y.; Liu, Z.; Wei, P.; Wu, L. Hydrophobicity and Photocatalytic Activity of a Wood Surface Coated with a Fe3+-Doped SiO2/TiO2 Film. Materials 2017, 10, 2594. [Google Scholar] [CrossRef]

- Kumar, A.; Stanek, K.; Ryparova, P.; Hajek, P.; Tywoniak, J. Hydrophobic treatment of wood fibrous thermal insulator by octadecyltrichlorosilane and its influence on hygric properties and resistance against moulds. Compos. Part B Eng. 2016, 106, 285–293. [Google Scholar] [CrossRef]

- Mantanis, G.; Papadopoulos, A.N. Reducing the thickness swelling of wood based panels by applying a nanotechnology compound. Eur. J. Wood Prod. 2010, 68, 237–239. [Google Scholar] [CrossRef]

- Nik Salleh, N.G.; Sofian Alias, M.; Glasel, H.J.; Mehnert, R. High Performance Radiation Curable Hybrid Coatings. Radiat. Phys. Chem. 2013, 84, 70–73. [Google Scholar] [CrossRef]

- Mishra, P.K.; Gregor, T.; Wimmer, R. Utilising Brewer’s Spent Grain as a source of cellulose nanofibres following separation of protein-based biomass. BioResources 2016, 12, 107–116. [Google Scholar] [CrossRef]

- Baumgart, R.J.; Kanagasabapathy, S. Hydrophobic Self-Cleaning Coating Compositions. U.S. Patent US20110094417A1, 28 April 2011. [Google Scholar]

- Liao, S.C.; Lin, H.F.; Chen, J.M. Superhydrophobic and Self-Cleaning Powders and Fabrication Method Thereof. U.S. Patent US20090025508A1, 29 January 2009. [Google Scholar]

- Mahltig, B.; Böttcher, H.; Rauch, K.; Dieckmann, U.; Nitsche, R.; Fritz, T. Optimized UV protecting coatings by combination of organic and inorganic UV absorbers. Thin Solid Film. 2005, 485, 108–114. [Google Scholar] [CrossRef]

- Zayat, M.; Garcia-Parejo, P.; Levy, D. Preventing UV-Light Damage of Light Sensitive Materials Using a Highly Protective UV-Absorbing Coating. Chem. Soc. Rev. 2007, 36, 1270–1281. [Google Scholar] [CrossRef]

- de Meijer, M. Review on the Durability of Exterior Wood Coatings with Reduced VOC-Content. Prog. Org. Coat. 2001, 43, 217–225. [Google Scholar] [CrossRef]

- Evans, P.D.; Thay, P.D.; Schmalzl, K.J. Degradation of Wood Surfaces During Natural Weathering. Effects on Lignin andCellulose and on the Adhesion of Acrylic Latex Primers. Wood Sci. Technol. 1996, 30, 411–422. [Google Scholar] [CrossRef]

- Auclair, N.; Bernard, R.; Vincent, B.; Pierre, B. Improvementof Photoprotection of Wood Coatings by Using Inorganic Nanoparticles as Ultraviolet Absorbers. For. Prod. J. 2011, 61, 20–27. [Google Scholar]

- Vakhitova, L.N. Fire retardant nanocoating for wood protection. In Nanotechnology in Eco-Efficient Construction; Woodhead Publishing: Cambridge, UK, 2019. [Google Scholar]

- Wu, H.; La Parola, V.; Pantaleo, G.; Puleo, F.; Venezia, A.M.; Liotta, L.F. Ni-based catalysts for low temperature methane steam reforming: Recent results on Ni-Au and comparison with other bimetallic systems. Catalysts 2013, 3, 563–583. [Google Scholar] [CrossRef]

- Weichelt, F.; Emmler, R.; Flyunt, R.; Beyer, E.; Buchmeiser, M.R.; Beyer, M. ZnO-Based UV Nanocomposites for Wood Coatings in Outdoor Applications. Macromol. Mater. Eng. 2010, 29, 130–136. [Google Scholar] [CrossRef]

- Cristea, M.V.; Riedl, B.; Blanchet, P. Effect of Addition of Nanosized UV Absorbers on the Physico-mechanical and Thermal Properties of an Exterior Waterborne Stain for Wood. Prog. Org. Coat. 2011, 72, 755–762. [Google Scholar] [CrossRef]

- Sow, C.; Riedl, B.; Blanchet, P. UV-Waterborne Polyurethane-Acrylate Nanocomposite Coatings Containing Alumina and Silica Nanoparticles for Wood: Mechanical, Optical, and Thermal Properties Assessment. J. Coat. Technol. Res. 2010, 8, 211–221. [Google Scholar] [CrossRef]

- Bueno, A.B.F.; Banon, M.V.N.; Morentín, L.; García, M.J.M. Treatment of natural woodveneers with nanooxides to improve their fire behaviour. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 2nd International Conference on Structural Nano Composites, Madrid, Spain, 20–21 May 2014; IPO Publishing Ltd.: Bristol, UK, 2014. [Google Scholar]

- Malthig, B.; Swaboda, C.; Roessler, A.; Bottcher, H. Functionalising wood by nanosol application. J. Mater. Chem. 2008, 18, 3180–3192. [Google Scholar] [CrossRef]

- Teizer, J.; Venugopal, M.; Teizer, W.; Felkl, J. Nanotechnology and Its Impact on Construction: Bridging the Gap Between Researchers and Industry Professionals. J. Constr. Eng. Manag. 2012, 138, 594–604. [Google Scholar] [CrossRef]

- Bauer, C.; Buchgeister, J.; Hischier, R.; Poganietz, W.R.; Schebek, L.; Warsen, J. Towards a framework for life cycle thinking in the assessment of nanotechnology. J. Clean. Prod. 2018, 16, 910–926. [Google Scholar] [CrossRef]

- Jiang, F.; Li, T.; Li, Y.; Zhang, Y.; Gong, A.; Dai, J.; Hitz, E.; Luo, W.; Hu, L. Wood-Based Nanotechnologies toward Sustainability. Adv. Mater. 2018, 30, 1703453. [Google Scholar] [CrossRef]

- Monteiro-Riviere, N.A.; Inman, A.O.; Wang, Y.Y.; Nemanich, R.J. Surfactant effects on carbon nanotube interactions with humanepidermal keratinocytes. Nanomedicine. Nanomedicine 2005, 1, 293–299. [Google Scholar] [CrossRef]

- Wiesner, M.R. Decreasing uncertainties in assessing environmental exposure, risk, and ecological implications of nanomaterials. Environ. Sci. Technol. 2009, 43, 6458–6462. [Google Scholar] [CrossRef]

- Roco, M.C.; Bainbridge, W. Societal Implications of Nanoscience and Nanotechnology; Nanoscale Science, Engineering, and Technology Workshop Report; National Science Foundation: Arlington, VA, USA, 2001. [Google Scholar]

| Method | Key Wood Properties |

|---|---|

| Chemical or enzymatic grafting | Resistance to weathering Decay resistance Activation of wood surface Wettability Hydrophobicity |

| Plasma treatments | Wettability Hydrophobicity Activation of wood surface |

| Exposure to microwaves | Improved penetration |

| Mechanical treatments (surface densification) | Hardness, resistance to abrasion |

| Surface chemical modifications | Wettability Hydrophobicity Activation of wood surface |

| Sol-gel methods and deposition of nanoparticles | Resistance to weathering Decay resistance Fire retardancy |

| Property | Advantages | Disadvantages |

|---|---|---|

| Water absorption | The impregnation of nanomaterials reduces the pore size and space available within the cell wall, which is used for the absorption of water molecules. In this way, a rough hydrophobic surface is created. | There is increasing concern about the environmental risks of nanomaterials. Experience from the past reminds us that new breakthrough technologies may not be more environmentally friendly than traditional technologies. It is certain that incomplete knowledge about nanomaterials delays their broad application. Their potential impact on both health and the environment should be addressed by applying tools such as a life-cycle assessment. |

| UV-protection | Damaging solar rays are absorbed by the coating and the wood surface is protected. UV absorbers can be added in higher concentrations without altering the transparency of the coating, since their size is significantly smaller than that of other absorbers | |

| Fire resistance | The application of nanoparticles, either alone or in combination with fire retardants, is able to reduce the ignitability of wood. They create a fire retardant barrier on the wood surface which retards the spread of flames and suppresses the generation of smoke. | |

| Durability | Nanoparticles increase the decay resistance of wood by reducing moisture availability. This happens either by preventing the absorption of moisture or by blocking the flow path of liquid. | |

| Mechanical properties | The incorporation of inorganic particles into organic polymers, as fillers, is a common practice applied to improve the mechanical properties of wood. In this way, the rigidity and hardness of the inorganic particles is combined effectively with the polymer’s processability. The dispersion of inorganic materials causes an increase in the surface area, and consequently, the ratio of the interfacial area is also increased; this significantly influences the properties of the raw material. |

| Property Improved | Nanomaterial Used | Reference |

|---|---|---|

| Water absorption | nano-elulsion | [45] |

| TiO2 | [46,48] | |

| nano silica | [32,47,51,55,58] | |

| spherical metal oxide | [49] | |

| SiO2, ZnO, TiO2 | [50,57] | |

| AgNPs | [52,57,72] | |

| CuO | [19] | |

| UV-protection | TiO2 | [46,48,78,79] |

| ZnO | [80,81,82] | |

| acrylate nanoparticles | [61] | |

| nano silica | [67] | |

| Fire resistance | TiO2 | [84,85] |

| ZnO | [88] | |

| SiO2 | [89] | |

| Durability | Ag | [36] |

| Ag, TiO2 | [37,38] | |

| Ag, TiO2, ZnO | [39,59] | |

| ZnO, B2O6Zn3, CuO | [14,19,27,28,29,30,31,32,51] | |

| AgNPs | [15,30,52,59] | |

| TiO2 | [18,20,53,54,55] | |

| Mechanical properties | AgNPs | [65,66] |

| nano silica | [67,73] | |

| CuO | [58] | |

| ceramic nanoparticles | [75,76,77] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papadopoulos, A.N.; Taghiyari, H.R. Innovative Wood Surface Treatments Based on Nanotechnology. Coatings 2019, 9, 866. https://doi.org/10.3390/coatings9120866

Papadopoulos AN, Taghiyari HR. Innovative Wood Surface Treatments Based on Nanotechnology. Coatings. 2019; 9(12):866. https://doi.org/10.3390/coatings9120866

Chicago/Turabian StylePapadopoulos, Antonios N., and Hamid R. Taghiyari. 2019. "Innovative Wood Surface Treatments Based on Nanotechnology" Coatings 9, no. 12: 866. https://doi.org/10.3390/coatings9120866

APA StylePapadopoulos, A. N., & Taghiyari, H. R. (2019). Innovative Wood Surface Treatments Based on Nanotechnology. Coatings, 9(12), 866. https://doi.org/10.3390/coatings9120866