On the Applicability of ATR-FTIR Microscopy to Evaluate the Blending between Neat Bitumen and Bituminous Coating of Reclaimed Asphalt

Abstract

:1. Introduction

2. Materials and Methods

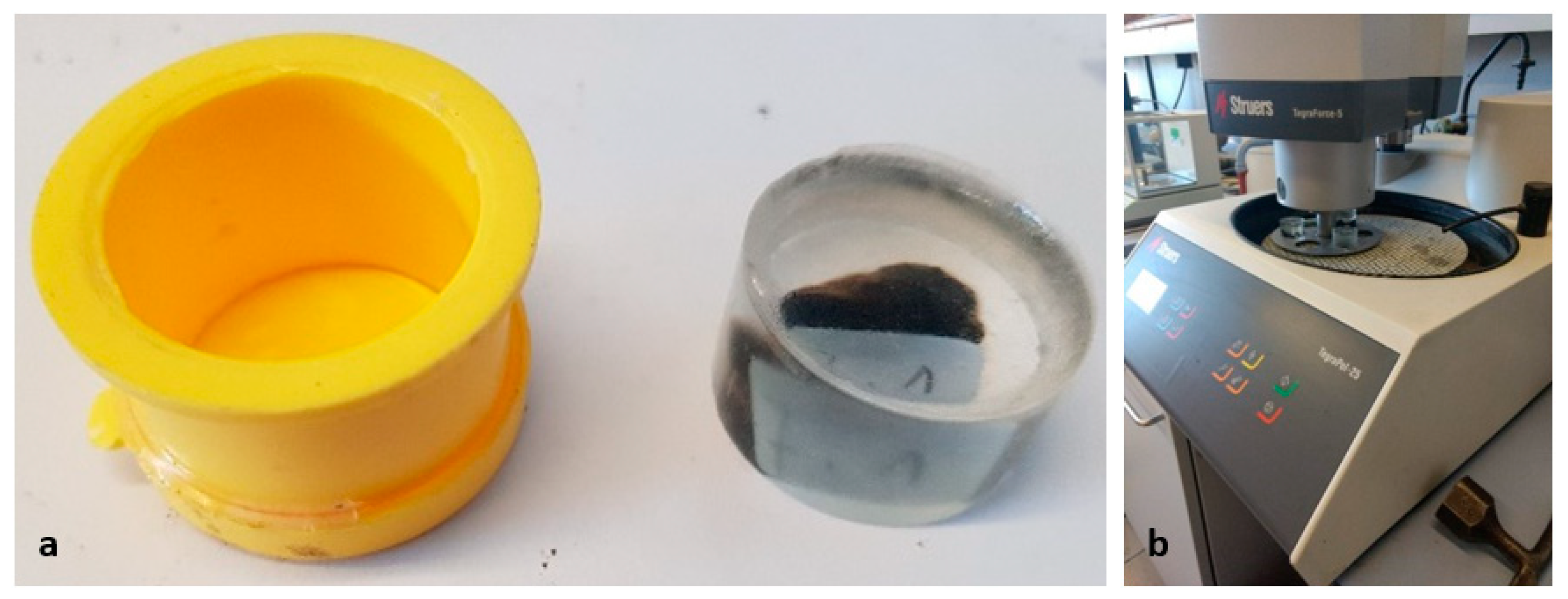

2.1. Sample Preparation

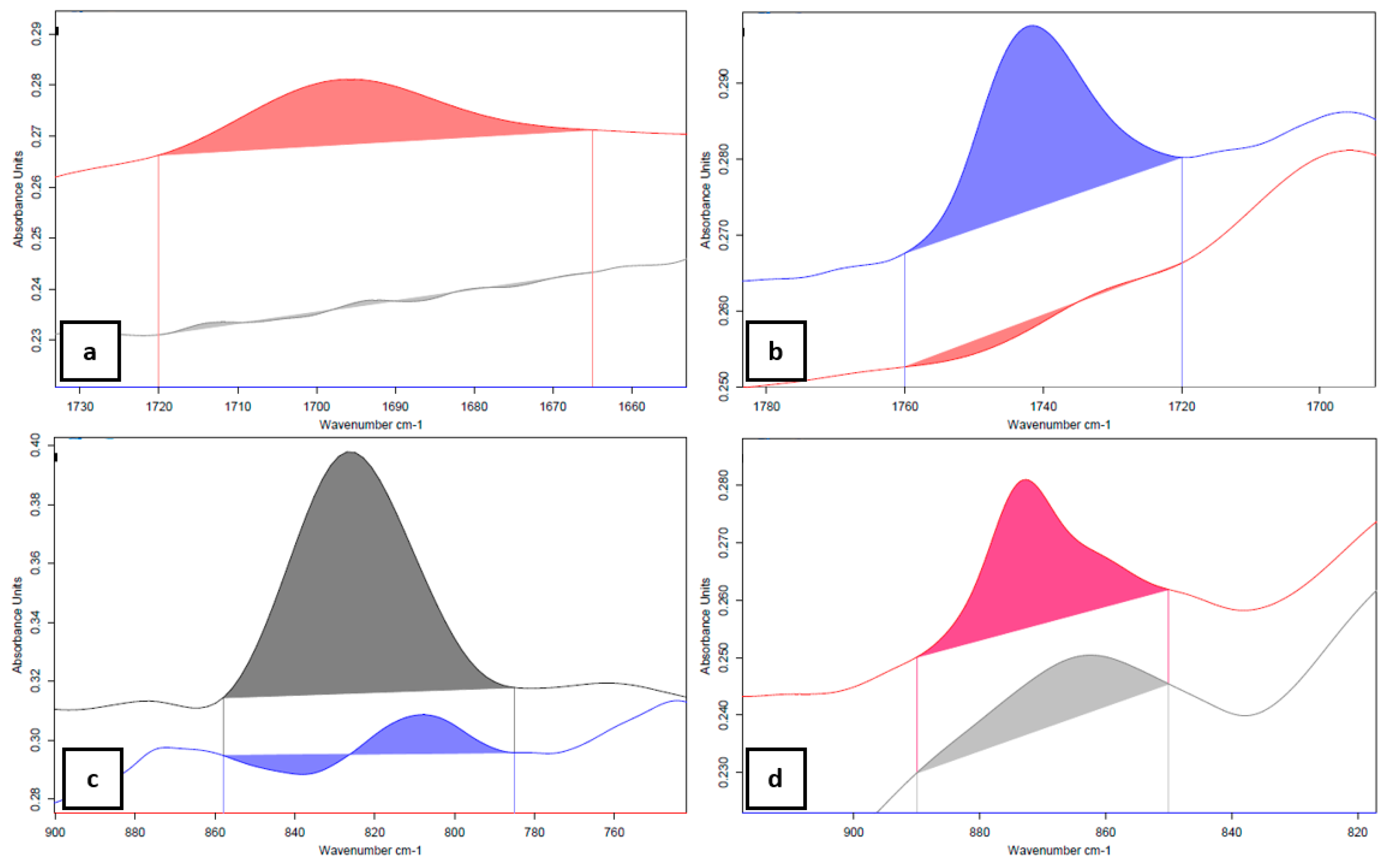

2.2. FTIR Instrumentation

2.3. Methodology

3. Results and Discussion

3.1. Chemical Imaging

3.2. Carbonyl Distribution as Indicator of Mobilization

- Epoxides lower than 0; values higher than 0 indicate a resin area.

- Alkyl group higher than 0; indication of bituminous area.

- Carbonyl higher than 0.

3.3. Bituminous Mortar Coating of the RA Granulates

4. Conclusions

- It is possible to trace carbonyls as an ageing indicator on actual RA granulates.

- The blending between RA mortar and neat bitumen can be characterized as only partial.

- Shorter mixing times and lower temperatures (2 min and 150 °C) can lead to large inactive RA mortar areas and a lower degree of blending.

- Higher temperature and longer mixing (5 min and 180 °C) may provide a higher degree of blending.

- Rejuvenation of bituminous coating can be traced based on the proposed method.

- The ageing index (carbonyls) for the rejuvenated area is lower than the sample areas covered with neat bitumen.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- NBN EN 13108-8:2016 Bituminous Mixtures—Material Specifications—Part 8: Reclaimed Asphalt; Bureau voor Normalisatie: Brussels, Belgium, 2016.

- Anthonissen, J. Bituminous Pavements in Flanders: Quantifying the Effect of RAP on the Environmental Impact. Ph.D. Thesis, University of Antwerp, Antwerpen, Belgium, May 2017. [Google Scholar]

- Margaritis, A.; Van den bergh, W. Evaluation of Flemish bituminous mixtures’ performance containing RAP: Statistical analysis and modelling. In Proceedings of the 13th ISAP Conference, Fortaleza, Ceará, Brazil, 19–21 June 2018. [Google Scholar]

- Van den bergh, W.; Kara, P.; Anthonissen, J.; Margaritis, A.; Jacobs, G.; Couscheir, K. Recommendations and strategies for using reclaimed asphalt pavement in the Flemish Region based on a first life cycle assessment research. IOP Conf. Ser. Mater. Sci. Eng. 2017, 236, 012088. [Google Scholar] [CrossRef] [Green Version]

- McDaniel, R.S.; Anderson, R.M. Recommended Use of Reclaimed Asphalt Pavement in the Superpave Mix Design Method: Technician’s Manual; National Research Council (US), Transportation Research Board: Washington, DC, USA, 2001. [Google Scholar]

- Mogawer, W.; Bennert, T.; Daniel, J.S.; Bonaquist, R.; Austerman, A.; Booshehrian, A. Performance characteristics of plant produced high RAP mixtures. Road Mater. Pavement Des. 2012, 13, 183–208. [Google Scholar] [CrossRef]

- Cavalli, M.C.; Partl, M.N.; Poulikakos, L.D. Measuring the binder film residues on black rock in mixtures with high amounts of reclaimed asphalt. J. Clean. Prod. 2017, 149, 665–672. [Google Scholar] [CrossRef]

- Margaritis, A.; Jacobs, G.; Hasheminejad, N.; Blom, J.; Van den bergh, W. Influence of mixing procedures on the performance of asphalt mixtures with high reclaimed asphalt content. In Proceedings of the 7th International Conference on Bituminous Mixtures and Pavements, Thessaloniki, Greece, 12–14 June 2019. [Google Scholar]

- Kriz, P.; Grant, D.L.; Veloza, B.A.; Gale, M.J.; Blahey, A.G.; Brownie, J.H.; Shirts, R.D.; Maccarrone, S. Blending and diffusion of reclaimed asphalt pavement and virgin asphalt binders. Road Mater. Pavement Des. 2014, 15, 78–112. [Google Scholar] [CrossRef]

- Rad, F.Y.; Sefidmazgi, N.R.; Bahia, H. Application of diffusion mechanism: Degree of blending between fresh and recycled asphalt pavement binder in dynamic shear rheometer. Transp. Res. Rec. 2014, 2444, 71–77. [Google Scholar] [CrossRef]

- Bennert, T.; Dongré, R. Backcalculation method to determine effective asphalt binder properties of recycled asphalt pavement mixtures. Transp. Res. Rec. 2010, 2179, 75–84. [Google Scholar] [CrossRef]

- Bowers, B.F.; Huang, B.; Shu, X.; Miller, B.C. Investigation of reclaimed asphalt pavement blending efficiency through GPC and FTIR. Constr. Build. Mater. 2014, 50, 517–523. [Google Scholar] [CrossRef]

- Xu, J.; Hao, P.; Zhang, D.; Yuan, G. Investigation of reclaimed asphalt pavement blending efficiency based on micro-mechanical properties of layered asphalt binders. Constr. Build. Mater. 2018, 163, 390–401. [Google Scholar] [CrossRef]

- Huang, B.; Li, G.; Vukosavljevic, D.; Shu, X.; Egan, B.K. Laboratory investigation of mixing hot-mix asphalt with reclaimed asphalt pavement. Transp. Res. Rec. 2005, 1929, 37–45. [Google Scholar] [CrossRef]

- AbuHassan, Y.; Alin, M.; Iqbal, T.; Nazzal, M.; Abbas, A.R. Effect of extraction solvents on rheological properties of recovered asphalt binders. J. Transp. Eng. Part B Pavements 2019, 145, 04018064. [Google Scholar] [CrossRef]

- Van den bergh, W. The Effect of Ageing on the Fatigue and Healing Properties of Bituminous Mortars. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, December 2011. [Google Scholar]

- Marsac, P.; Piérard, N.; Porot, L.; Van den bergh, W.; Grenfell, J.; Mouillet, V.; Pouget, S.; Besamusca, J.; Farcas, F.; Gabet, T.; et al. Potential and limits of FTIR methods for reclaimed asphalt characterisation. Mater. Struct. 2014, 47, 1273–1286. [Google Scholar] [CrossRef]

- Hofko, B.; Alavi, M.Z.; Grothe, H.; Jones, D.; Harvey, J. Repeatability and sensitivity of FTIR ATR spectral analysis methods for bituminous binders. Mater. Struct. 2017, 50, 187. [Google Scholar] [CrossRef] [Green Version]

- Karlsson, R.; Isacsson, U. Application of FTIR-ATR to characterization of bitumen rejuvenator diffusion. J. Mater. Civ. Eng. 2003, 15, 157–165. [Google Scholar] [CrossRef]

- Mikhailenko, P.; Bertron, A.; Ringot, E. Methods for analyzing the chemical mechanisms of bitumen aging and rejuvenation with FTIR spectrometry. In Proceedings of the 8th RILEM International Symposium on Testing and Characterization of Sustainable and Innovative Bituminous Materials, Ancona, Italy, 7–9 October 2015; pp. 203–214. [Google Scholar]

- Lamontagne, J.; Durrieu, F.; Planche, J.P.; Mouillet, V.; Kister, J. Direct and continuous methodological approach to study the ageing of fossil organic material by infrared microspectrometry imaging: Application to polymer modified bitumen. Anal. Chim. Acta 2001, 444, 241–250. [Google Scholar] [CrossRef]

- Nivitha, M.R.; Prasad, E.; Krishnan, J.M. Ageing in modified bitumen using FTIR spectroscopy. Int. J. Pavement Eng. 2016, 17, 565–577. [Google Scholar] [CrossRef]

- Lopes, M.; Mouillet, V.; Bernucci, L.; Gabet, T. The potential of attenuated total reflection imaging in the mid-infrared for the study of recycled asphalt mixtures. Constr. Build. Mater. 2016, 124, 1120–1131. [Google Scholar] [CrossRef]

- Vassaux, S.; Gaudefroy, V.; Boulangé, L.; Soro, L.J.; Pévère, A.; Michelet, A.; Barragan-Montero, V.; Mouillet, V. Study of remobilization phenomena at reclaimed asphalt binder/virgin binder interphases for recycled asphalt mixtures using novel microscopic methodologies. Constr. Build. Mater. 2018, 165, 846–858. [Google Scholar] [CrossRef]

- Rinaldini, E.; Schuetz, P.; Partl, M.N.; Tebaldi, G.; Poulikakos, L.D. Investigating the blending of reclaimed asphalt with virgin materials using rheology, electron microscopy and computer tomography. Compos. Part B Eng. 2014, 67, 579–587. [Google Scholar] [CrossRef]

- Jiang, Y.; Gu, X.; Zhou, Z.; Ni, F.; Dong, Q. Laboratory observation and evaluation of asphalt blends of reclaimed asphalt pavement binder with virgin binder using SEM/EDS. Transp. Res. Rec. 2018, 2672, 69–78. [Google Scholar] [CrossRef]

- Nahar, S.N.; Mohajeri, M.; Schmets, A.J.M.; Scarpas, A.; van de Ven, M.F.C.; Schitter, G. First observation of blending-zone morphology at interface of reclaimed asphalt binder and virgin bitumen. Transp. Res. Rec. 2013, 2370, 1–9. [Google Scholar] [CrossRef]

- Mohajeri, M.; Molenaar, A.A.A.; Van de Ven, M.F.C. Experimental study into the fundamental understanding of blending between reclaimed asphalt binder and virgin bitumen using nanoindentation and nano-computed tomography. Road Mater. Pavement Des. 2014, 15, 372–384. [Google Scholar] [CrossRef]

- Lu, X.; Talon, Y.; Redelius, P. Aging of bituminous binders–laboratory tests and field data. In Proceedings of the 4th Eurasphalt Eurobitume Congress, Copenhagen, Denmark, 21–23 May 2008; pp. 1–12. [Google Scholar]

- Erkens, S.; Porot, L.; Gläser, R.; Glover, C.J. Aging of bitumen and asphalt concrete: Comparing state of the practice and ongoing developments in the United States and Europe. In Proceedings of the Transportation Research Board 95th Annual Meeting, Washington, DC, USA, 10–14 January 2016. [Google Scholar]

- NBN EN 12697-11:2012 Bituminous Mixtures-Test Methods-Part 11: Determination of the Affinity between Aggregate and Bitumen; Bureau voor Normalisatie: Brussels, Belgium, 2012.

- NBN EN 12697-35:2016 Bituminous Mixtures-Test Methods-Part 35: Laboratory Mixing; Bureau voor Normalisatie: Brussels, Belgium, 2016.

- Cong, P.; Hao, H.; Zhang, Y.; Luo, W.; Yao, D. Investigation of diffusion of rejuvenator in aged asphalt. Int. J. Pavement Res. Technol. 2016, 9, 280–288. [Google Scholar] [CrossRef] [Green Version]

- Baghaee Moghaddam, T.; Baaj, H. The use of rejuvenating agents in production of recycled hot mix asphalt: A systematic review. Constr. Build. Mater. 2016, 114, 805–816. [Google Scholar] [CrossRef]

- Bruker Optik GmbH. OPUS/IR Reference Manual, version 7; Bruker Optik GmbH: Billerica, MA, USA, 2014; pp. 347–350. [Google Scholar]

- Bressi, S.; Cavalli, M.C.; Partl, M.N.; Tebaldi, G.; Dumont, A.G.; Poulikakos, L.D. Particle clustering phenomena in hot asphalt mixtures with high content of reclaimed asphalt pavements. Constr. Build. Mater. 2015, 100, 207–217. [Google Scholar] [CrossRef]

| Sample Name | RA Granulate | Neat Bitumen | Rejuvenator | Treatment Description |

|---|---|---|---|---|

| GRA | ✔ | – | – | Untreated RA granulates (fraction 10/12 mm) |

| GRAB | ✔ | ✔ | – | RA granulates covered with neat bitumen (fraction 10/12 mm) |

| MRAB | ✔ | ✔ | – | RA granulates, covered with neat bitumen, obtained from mixed AC-14 with GRA |

| GRAR | ✔ | – | ✔ | Rejuvenated RA granulates |

| Component | Percentage |

|---|---|

| RA aggregates 0/14 | 55.7% |

| Limestone 4/8 | 18.4% |

| Limestone 2/6.3 | 6.4% |

| Limestone 0/2 | 18.5% |

| Limestone filler | 1.0% |

| RA bitumen | 3.0% |

| Neat bitumen (168 ⅟10 mm) | 1.3% |

| Bond & Functional Group | Peak Point (cm−1) | Baseline Limits (cm−1) | Presence in Material |

|---|---|---|---|

| C–H stretch (alkyl bonds) | 2920, 2848 | 2990–2820 | Bitumen & Resin |

| C=O stretch area (carboxylic acids) | 1741 | 1760–1720 | Rejuvenator |

| C=O stretch area (carbonyl) | 1700 | 1720–1665 | Aged bitumen |

| C–O vibration (carbonate) | 875 | 890–850 | Limestone |

| C–O–C (ring vibration of epoxides) | 829 | 858–785 | Resin |

| Percentage | Percentiles | Carbonyl Level |

|---|---|---|

| 100.0% | maximum | 27.94 |

| 97.5% | 97.5 percentile | 7.16 |

| 75.0% | third quartile | 2.00 |

| 50.0% | second quartile (median) | 1.34 |

| 25.0% | first quartile | 0.67 |

| 2.5% | 2.5 percentile | 0.09 |

| 0.0% | minimum | 0.01 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Margaritis, A.; Tofani, G.; Jacobs, G.; Blom, J.; Tavernier, S.; Vuye, C.; Van den bergh, W. On the Applicability of ATR-FTIR Microscopy to Evaluate the Blending between Neat Bitumen and Bituminous Coating of Reclaimed Asphalt. Coatings 2019, 9, 240. https://doi.org/10.3390/coatings9040240

Margaritis A, Tofani G, Jacobs G, Blom J, Tavernier S, Vuye C, Van den bergh W. On the Applicability of ATR-FTIR Microscopy to Evaluate the Blending between Neat Bitumen and Bituminous Coating of Reclaimed Asphalt. Coatings. 2019; 9(4):240. https://doi.org/10.3390/coatings9040240

Chicago/Turabian StyleMargaritis, Alexandros, Giorgio Tofani, Geert Jacobs, Johan Blom, Serge Tavernier, Cedric Vuye, and Wim Van den bergh. 2019. "On the Applicability of ATR-FTIR Microscopy to Evaluate the Blending between Neat Bitumen and Bituminous Coating of Reclaimed Asphalt" Coatings 9, no. 4: 240. https://doi.org/10.3390/coatings9040240

APA StyleMargaritis, A., Tofani, G., Jacobs, G., Blom, J., Tavernier, S., Vuye, C., & Van den bergh, W. (2019). On the Applicability of ATR-FTIR Microscopy to Evaluate the Blending between Neat Bitumen and Bituminous Coating of Reclaimed Asphalt. Coatings, 9(4), 240. https://doi.org/10.3390/coatings9040240