Molecular Dynamics Study on the Tribological Properties of Phosphorene/Polyethylene Composites

Abstract

:1. Introduction

2. Methodology

3. Results and Discussion

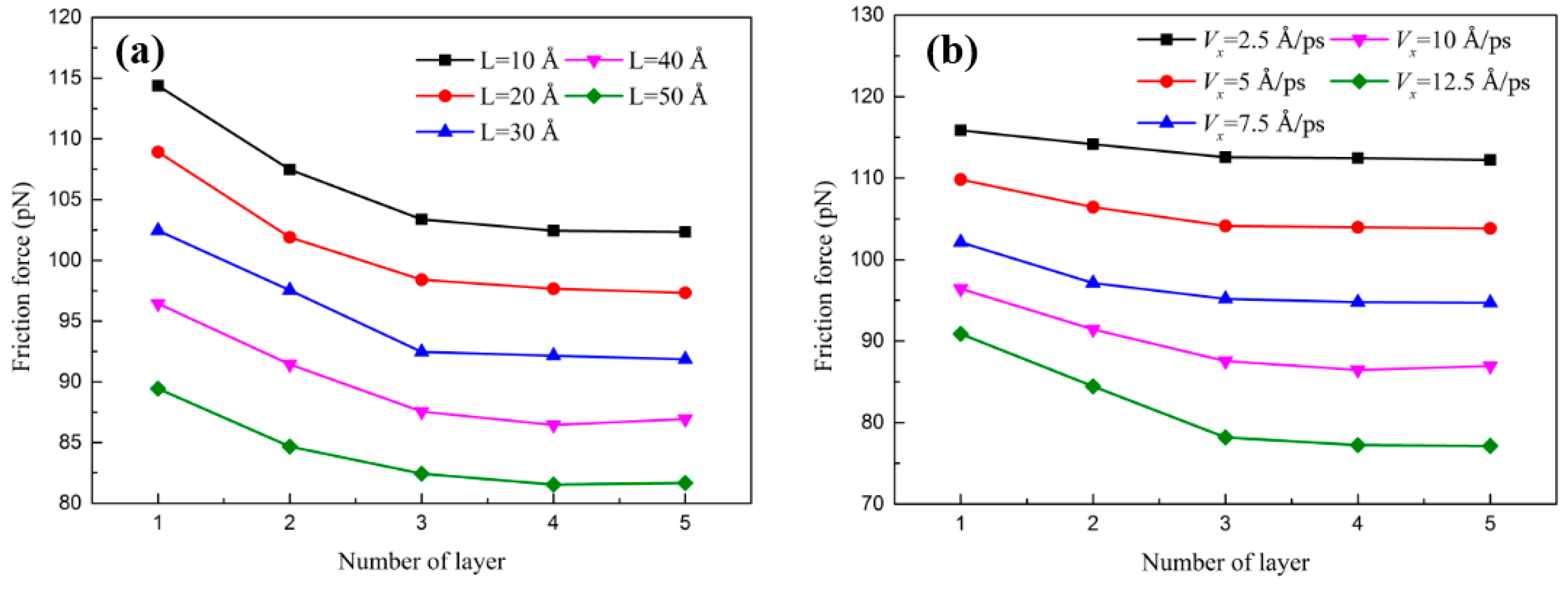

3.1. Friction Behavior

3.2. Microstructure Evolution

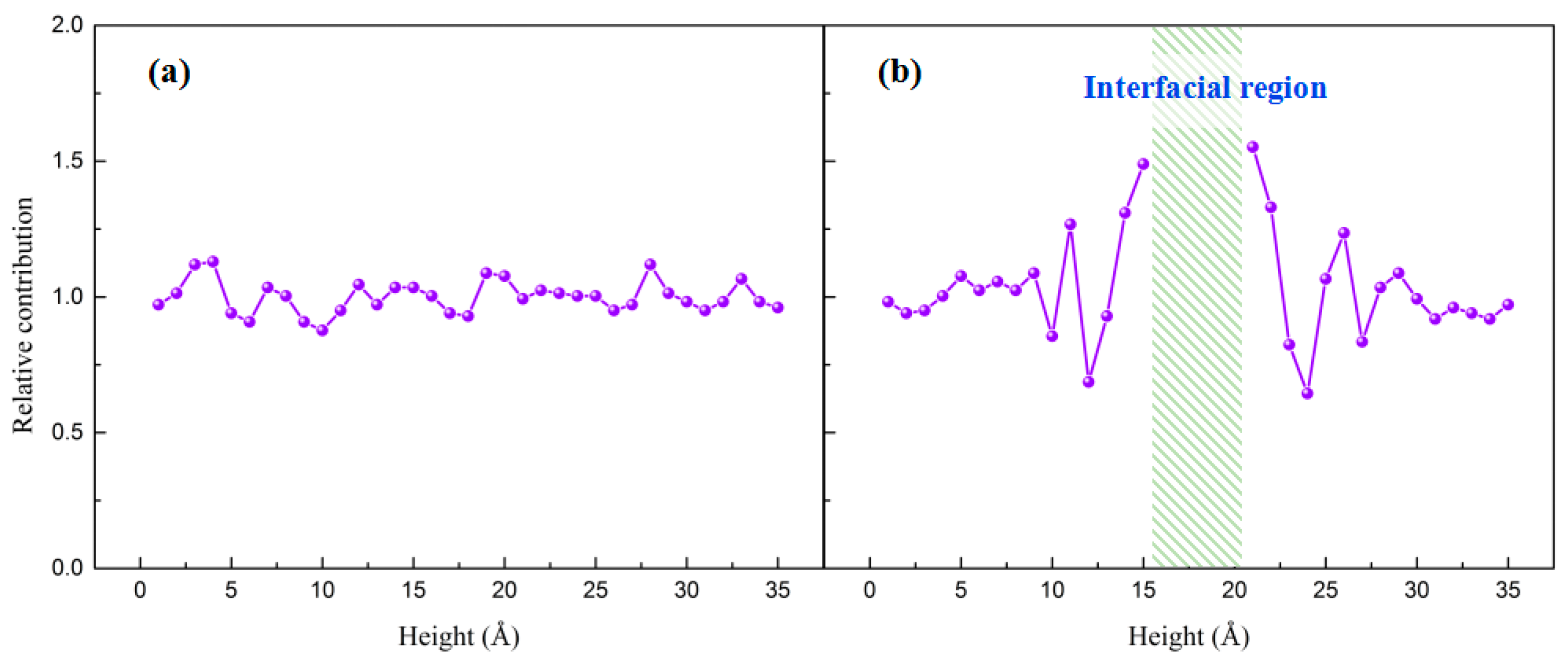

3.3. Mechanism Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wei, X.; Zhong, S.; Wang, J.; Zhang, Y.; Zhang, D. Enhanced tribological properties of polymer composite coating containing graphene at room and elevated temperatures. Coatings 2018, 8, 91. [Google Scholar]

- Peng, Y.; Fan, C.; Hu, L.; Peng, S.; Xie, P.; Wu, F.; Yi, S. Tunnel driving occupational environment and hearing loss in train drivers in China. Occup. Environ. Med. 2019, 76, 97–104. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.H.; Sun, Y.S.; Wang, W.S. Influences of carbon fabric/epoxy composites fabrication process on its friction and wear properties. J. Mater. Process. Technol. 2009, 209, 4553–4557. [Google Scholar] [CrossRef]

- Larsen, T.; Andersen, T.L.; Thorning, B.; Horsewell, A.; Vigild, M.E. Comparison of friction and wear for an epoxy resin reinforced by a glass or a carbon/aramid hybrid weave. Wear 2007, 262, 1013–1020. [Google Scholar] [CrossRef]

- Yousif, B.F. Mechanical and wear properties of oil palm and glass fibres reinforced polyester composites. Int. J. Precis. Technol. 2007, 1, 213–222. [Google Scholar] [CrossRef]

- Pal, K.; Pal, S.K.; Das, C.K.; Kim, J.K. Effect of fillers on morphological and wear characteristics of NR/HSR blends with E-glass fiber. Mater. Des. 2012, 35, 863–872. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Gupta, A.; Sakthivel, T.; Seal, S. Recent development in 2D materials beyond graphene. Prog. Mater. Sci. 2015, 73, 44–126. [Google Scholar] [CrossRef]

- Lin, Q.; Qu, L.; Lü, Q.; Fang, C. Preparation and properties of graphene oxide nanosheets/cyanate ester resin composites. Polym. Test. 2013, 32, 330–337. [Google Scholar] [CrossRef]

- Wang, J.; Jia, H.; Tang, Y.; Ji, D.; Sun, Y.; Gong, X.; Ding, L. Enhancements of the mechanical properties and thermal conductivity of carboxylated acrylonitrile butadiene rubber with the addition of graphene oxide. J. Mater. Sci. 2013, 48, 1571–1577. [Google Scholar] [CrossRef]

- Pan, B.; Zhang, S.; Li, W.; Zhao, J.; Liu, J.; Zhang, Y.; Zhang, Y. Tribological and mechanical investigation of MC nylon reinforced by modified graphene oxide. Wear 2012, 294–295, 395–401. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Q.; Wang, T.; Pan, G. Preparation and tribological properties of graphene oxide/nitrile rubber nanocomposites. J. Mater. Sci. 2012, 47, 730–738. [Google Scholar] [CrossRef]

- Peng, Y.; Wu, Y.; Wang, K.; Gao, G.; Ahzi, S. Synergistic reinforcement of polyamide-based composites by combination of short and continuous carbon fibers via fused filament fabrication. Compos. Struct. 2019, 207, 232–239. [Google Scholar] [CrossRef]

- Peng, Y.; Ma, W.; Wang, S.; Wang, K.; Gao, G. Investigation of the fracture behaviors of windshield laminated glass used in high-speed trains. Compos. Struct. 2019, 207, 29–40. [Google Scholar] [CrossRef]

- Chen, W.H.; Yu, C.F.; Chen, I.C.; Cheng, H.C. Mechanical property assessment of black phosphorene nanotube using molecular dynamics simulation. Comput. Mater. Sci. 2017, 133, 35–44. [Google Scholar] [CrossRef]

- Low, T.; Rodin, A.S.; Carvalho, A.; Jiang, Y.; Wang, H.; Xia, F.; Neto, A.H.C. Tunable optical properties of multilayers black phosphorus thin films. Phys. Rev. B 2014, 90, 075434. [Google Scholar] [CrossRef]

- Bai, L.; Liu, B.; Srikanth, N.; Tian, Y.; Zhou, K. Nano-friction behavior of phosphorene. Nanotechnology 2017, 28, 355704. [Google Scholar] [CrossRef] [PubMed]

- Gong, H.; Zhu, P.; Si, L.; Zhang, X.; Xie, G. “M-shape” nanoscale friction anisotropy of phosphorene. Comput. Mater. Sci. 2018, 150, 364–368. [Google Scholar] [CrossRef]

- Hanlon, D.; Backes, C.; Doherty, E.; Cucinotta, C.S.; Berner, N.C.; Boland, C.; Lee, K.; Harvey, A.; Lynch, P.; Gholamvand, Z.; et al. Liquid exfoliation of solvent-stabilized few-layer black phosphorus for applications beyond electronics. Nat. Commun. 2015, 6, 8563. [Google Scholar] [CrossRef]

- Zandbergen, H.W.; Vicarelli, L.; Groenendijk, D.J.; Alvarez, J.V.; Island, J.O.; van der Zant, H.S.J.; Prada, E.; Narasimha-Acharya, K.L.; Blanter, S.I.; Buscema, M.; et al. Isolation and characterization of few-layer black phosphorus. 2D Mater. 2014, 1, 025001. [Google Scholar]

- Frankland, S.J.V.; Harik, V.M.; Odegard, G.M.; Brenner, D.W.; Gates, T.S. The stress-strain behavior of polymer-nanotube composites from molecular dynamics simulations. Compos. Sci. Technol. 2003, 63, 1655–1661. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Wang, Q. A molecular dynamics simulation study on enhancement of mechanical and tribological properties of polymer composites by introduction of graphene. Carbon 2017, 111, 538–545. [Google Scholar] [CrossRef]

- He, E.; Wang, S.; Li, Y.; Wang, Q. Enhanced tribological properties of polymer composites by incorporation of nano-SiO2 particles: A molecular dynamics simulation study. Comput. Mater. Sci. 2017, 134, 93–99. [Google Scholar] [CrossRef]

- Chen, S.J.; Li, C.Y.; Wang, Q.; Duan, W.H. Reinforcing mechanism of graphene at atomic level: Friction, crack surface adhesion and 2D geometry. Carbon 2017, 114, 557–565. [Google Scholar] [CrossRef]

- Rezaei, M.; Shirzad, A.; Ebrahimi, N.G.; Kontopoulou, M. Surface modification of ultra-high-molecular-weight polyethylene. II. Effect on the physicomechanical and tribological properties of ultra-high-molecular-weight polyethylene/poly(ethylene terephthalate) composites. J. Appl. Polym. Sci. 2006, 99, 2352–2358. [Google Scholar] [CrossRef]

- Selyutin, G.E.; Gavrilov, Y.Y.; Voskresenskaya, E.N.; Zakharov, V.A.; Nikitin, V.E.; Poluboyarov, V.A. Composite materials based on ultra high molecular polyethylene: Properties, application prospects. Chem. Sustain. Dev. 2010, 18, 301–314. [Google Scholar]

- Sun, H. The COMPASS force field: Parameterization and validation for phosphazenes. Comput. Theor. Polym. Sci. 1998, 8, 229–246. [Google Scholar] [CrossRef]

- Sun, H. COMPASS: An ab initio force-field optimized for condensed-phase applications—Overview with details on alkane and benzene compounds. J. Phys. Chem. B 1998, 102, 7338–7364. [Google Scholar] [CrossRef]

- Lordi, V.; Yao, N. Molecular mechanics of binding in carbon-nanotube-polymer composites. J. Mater. Res. 2000, 15, 2770–2779. [Google Scholar] [CrossRef]

- Chen, W.H.; Chen, I.C.; Cheng, H.C.; Yu, C.F. Influence of structural defect on thermal-mechanical properties of phosphorene sheets. J. Mater. Sci. 2017, 52, 3225–3232. [Google Scholar] [CrossRef]

- Liu, F.; Hu, N.; Ning, H.; Liu, Y.; Li, Y.; Wu, L. Molecular dynamics simulation on interfacial mechanical properties of polymer nanocomposites with wrinkled graphene. Comput. Mater. Sci. 2015, 108, 160–167. [Google Scholar] [CrossRef]

- Humphrey, W.; Dalke, A.; Schulten, K. VMD: Visual molecular dynamics. J. Mol. Graph. 1996, 14, 33–38. [Google Scholar] [CrossRef]

- Bai, L.; Srikanth, N.; Korznikova, E.A.; Baimova, J.A.; Dmitriev, S.V.; Zhou, K. Wear and friction between smooth or rough diamond-like carbon films and diamond tips. Wear 2017, 372–373, 12–20. [Google Scholar] [CrossRef]

- Ensafi, A.A.; Chamjangali, M.A. Sequential flow injection determination of iodate and periodate with spectrophotometric detection. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2003, 59, 2897–2903. [Google Scholar] [CrossRef]

- Krylov, S.Y.; Frenken, J.W. The crucial role of temperature in atomic scale friction. J. Phys. Condens. Matter 2008, 20, 354003. [Google Scholar] [CrossRef]

- Liu, X.; Wood, J.D.; Chen, K.S.; Cho, E.; Hersam, M.C. In situ thermal decomposition of exfoliated two-dimensional black phosphorus. J. Phys. Chem. Lett. 2015, 6, 773–778. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; He, E.; Wang, Q. The effect of sliding velocity on the tribological properties of polymer/carbon nanotube composites. Carbon 2016, 106, 106–109. [Google Scholar] [CrossRef]

- Bai, L.; Sha, Z.D.; Srikanth, N.; Pei, Q.X.; Wang, X.; Srolovitz, D.J.; Zhou, K. Friction between silicon and diamond at the nanoscale. J. Phys. D. Appl. Phys. 2015, 48, 255303. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Wang, Q. Enhancement of tribological properties of polymer composites reinforced by functionalized graphene. Compos. Part B Eng. 2017, 120, 83–91. [Google Scholar] [CrossRef]

- Hölscher, H.; Ebeling, D.; Schwarz, U.D. Friction at atomic-scale surface steps: Experiment and theory. Phys. Rev. Lett. 2008, 101, 246105. [Google Scholar] [CrossRef]

- Luo, T.; Lloyd, J.R. Enhancement of thermal energy transport across graphene/graphite and polymer interfaces: A molecular dynamics study. Adv. Funct. Mater. 2012, 22, 2495–2502. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Y.; Li, J.; Tang, X.; Yang, W.; Chen, X.; Fan, C.; Wang, K. Molecular Dynamics Study on the Tribological Properties of Phosphorene/Polyethylene Composites. Coatings 2019, 9, 342. https://doi.org/10.3390/coatings9050342

Peng Y, Li J, Tang X, Yang W, Chen X, Fan C, Wang K. Molecular Dynamics Study on the Tribological Properties of Phosphorene/Polyethylene Composites. Coatings. 2019; 9(5):342. https://doi.org/10.3390/coatings9050342

Chicago/Turabian StylePeng, Yong, Jiahao Li, Xianqiong Tang, Wei Yang, Xuanzhen Chen, Chaojie Fan, and Kui Wang. 2019. "Molecular Dynamics Study on the Tribological Properties of Phosphorene/Polyethylene Composites" Coatings 9, no. 5: 342. https://doi.org/10.3390/coatings9050342

APA StylePeng, Y., Li, J., Tang, X., Yang, W., Chen, X., Fan, C., & Wang, K. (2019). Molecular Dynamics Study on the Tribological Properties of Phosphorene/Polyethylene Composites. Coatings, 9(5), 342. https://doi.org/10.3390/coatings9050342