Stabilizing of Mechanical Property of Amorphous In−Zn−O Thin Films with Hydrogen Flow

Abstract

:1. Introduction

2. Experimental Details

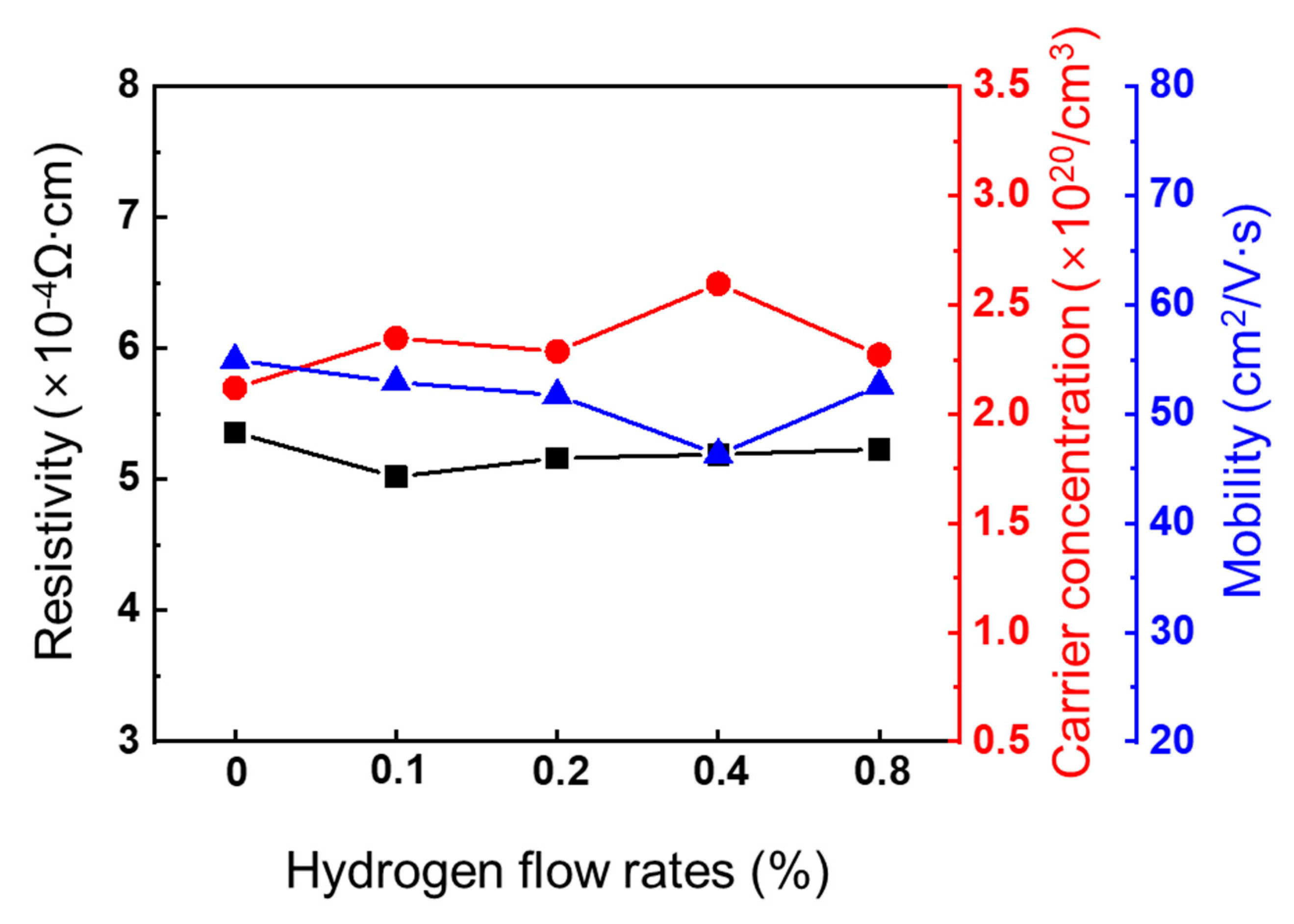

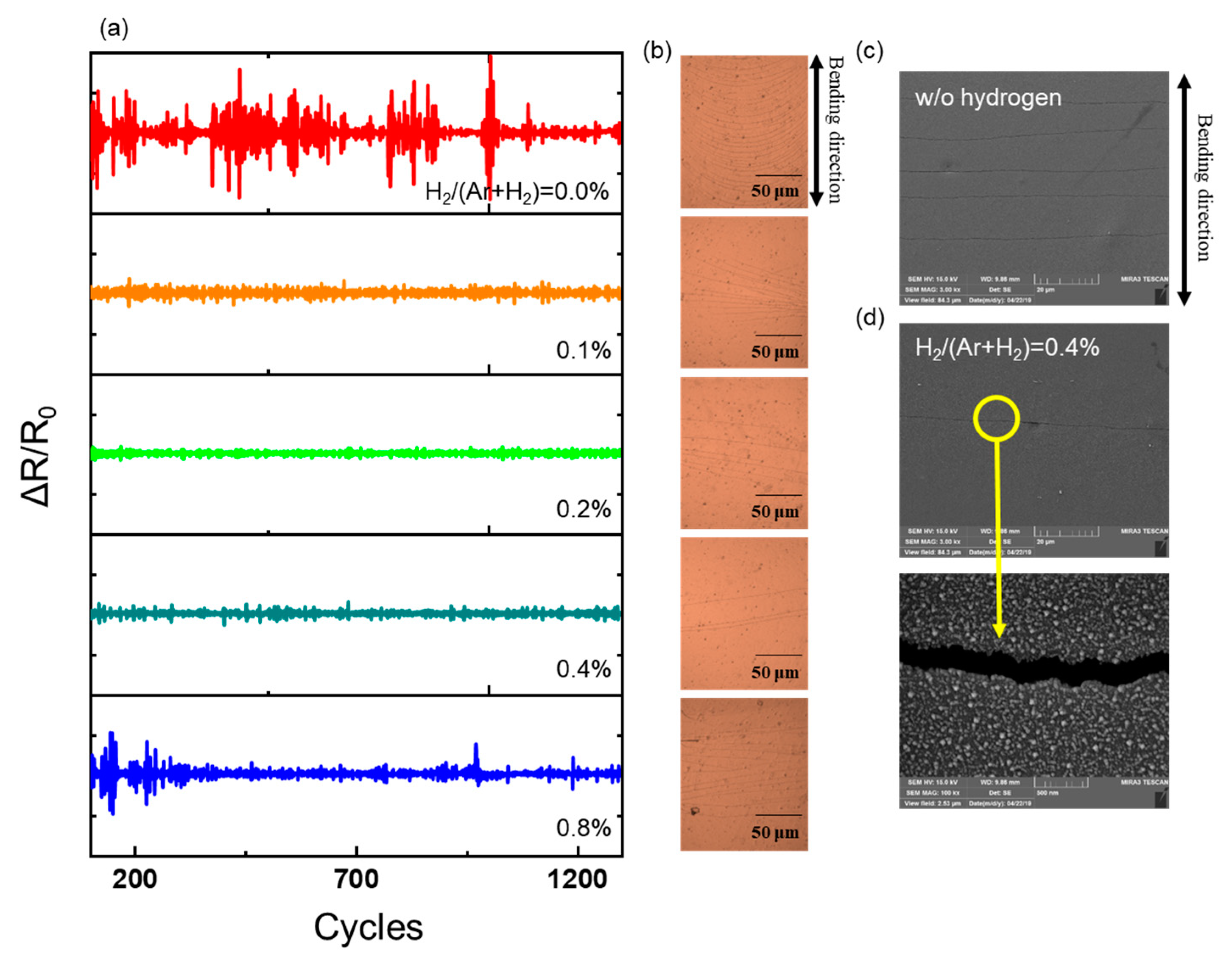

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Song, P.K.; Shigesato, Y.; Yasui, I.; Cleva, W.; Yang, W.O.; Paine, D.C. Study on Crystallinity of tin-doped Indium oxide films sputtering deposited by dc magnetron. Jpn. J. Appl. Phys. 1998, 37, 1870. [Google Scholar] [CrossRef]

- Kim, D.H.; Park, M.R.; Lee, G.H. Preparation of high quality ITO films on a plastic substrate using RF magnetron sputtering. Surf. Coat. Technol. 2006, 201, 927–931. [Google Scholar] [CrossRef]

- Sannicolo, T.; Lagrange, M.; Cabos, A.; Celle, C.; Simonato, J.P.; Bellet, D. Metallic Nanowire-Based Transparent Electrodes for Next Generation Flexible Devices: A Review. Small 2016, 12, 6052–6075. [Google Scholar] [CrossRef] [PubMed]

- Oh, B.Y.; Jeong, M.C.; Moon, T.H.; Lee, W.; Myoung, J.M.; Hwang, J.Y.; Seo, D.S. Transparent conductive Al-doped ZnO films for liquid crystal displays. J. Appl. Phys. 2006, 99, 124505. [Google Scholar] [CrossRef]

- Leterrier, Y.; Médico, L.; Demarco, F.; Månson, J.A.E.; Betz, U.; Escolà, M.F.; Olsson, M.K.; Atamny, F. Mechanical integrity of transparent conductive oxide films for flexible polymer-based displays. Thin Solid Film 2004, 460, 156–166. [Google Scholar] [CrossRef]

- Kang, J.W.; Jeong, W.I.; Kim, J.J.; Kim, H.K.; Kim, D.G.; Lee, G.H. High-Performance Flexible Organic Light-Emitting Diodes Using Amorphous Indium Zinc Oxide Anode. Electrochem. Solid-State Lett. 2007, 10, J75–J78. [Google Scholar] [CrossRef]

- Hwang, T.H.; Cui, W.H.; Yang, I.S.; Kwon, O.K. A highly area-efficient controller for capacitive touch screen panel systems. IEEE Trans. Consum. Electron. 2010, 56, 1115–1122. [Google Scholar] [CrossRef]

- Lee, J.; Han, T.H.; Park, M.H.; Jung, D.Y.; Seo, J.; Seo, H.K.; Cho, H.; Kim, E.; Chung, J.; Choi, S.Y.; et al. Synergetic electrode architecture for efficient graphene-based flexible organic light-emitting diodes. Nat. Commun. 2016, 7, 1–9. [Google Scholar] [CrossRef]

- Mohl, M.; Dombovari, A.; Vajtai, R.; Ajayan, P.M.; Kordas, K. Self-assembled large scale metal alloy grid patterns as flexible transparent conductive layers. Sci. Rep. 2015, 5, 1–8. [Google Scholar] [CrossRef]

- Sahu, B.B.; Long, W.; Han, J.G. Highly conductive flexible ultra thin ITO nanoclusters prepared by 3-D confined magnetron sputtering at a low temperature. Scr. Mater. 2018, 149, 98–102. [Google Scholar] [CrossRef]

- Kim, M.J.; Song, P.K. High Crystallization of Ultra-Thin Indium Tin Oxide Films Prepared by Direct Current Magnetron Sputtering with Post-Annealing. Sci. Adv. Mater. 2016, 8, 622. [Google Scholar] [CrossRef]

- Kim, S.; Yoon, J.h.; Bang, J.; Song, P. Effect of hydrogen on mechanical stability of amorphous In–Sn–O thin films for flexible electronics. Thin Solid Films 2019, 669, 275–280. [Google Scholar] [CrossRef]

- Lee, Y.-J.; Lim, B.-W.; Kim, J.-H.; Kim, T.-W.; Oh, B.Y.; Heo, G.-S.; Kim, K.-Y. Thin Transparent W-Doped Indium-Zinc Oxide (WIZO) layer on glass. J. Nanosci. Nanotechnol. 2012, 12, 5604–5608. [Google Scholar] [CrossRef] [PubMed]

- Choi, K.-H.; Jeong, J.-A.; Kim, H.-K.; Lee, J.-Y.; Lee, J.-H.; Bae, H.-D.; Tak, Y.-H.; Lee, S.-H.; Leem, D.-S.; Kim, J.-J. Characteristics of Ni-Doped IZO Layers grown on izo anode for enhancing hole injection in OLEDs. J. Electrochem. Soc. 2008, 155, J340–J344. [Google Scholar] [CrossRef]

- Zhang, Q.; Di, Y.; Huard, C.M.; Guo, L.J.; Wei, J.; Guo, J. Highly stable and stretchable graphene-polymer processed silver nanowires hybrid electrodes for flexible displays. J. Mater. Chem. C 2015, 3, 1528–1536. [Google Scholar] [CrossRef]

- Alzoubi, K.; Hamasha, M.M.; Lu, S.; Sammakia, B. Bending fatigue study of sputtered ITO on flexible substrate. J. Display Techn. 2011, 7, 593–600. [Google Scholar] [CrossRef]

- Ohya, Y.; Nakaoawa, Z. Grain-boundary microcracking due to thermal expansion anisotropy in aluminum titanate ceramics. J. Am. Ceram. Soc. 1987, 70, 184–186. [Google Scholar] [CrossRef]

- Ohya, Y.; Nakagawa, Z. Crack healing and bending strength of aluminum titanate ceramics at high temperature. J. Am. Ceram. Soc. 1998, 71, 232–233. [Google Scholar] [CrossRef]

- Lin, H.; Pope, D.P. The influence of grain boundary geometry on intergranular crack propagation in Ni3Al. Acta Metall. Mater. 1993, 41, 553–562. [Google Scholar]

- Fortunato, E.; Raniero, L.; Siva, L.; Gonçalves, A.; Pimentel, A.; Barquinha, P.; Águas, H.; Pereira, L.; Gonçalves, G.; Ferreira, I.; et al. Highly stable transparent and conducting gallium-doped zinc oxide thin films for photovoltaic applications. Sol. Energy Mater. Sol. Cells 2008, 92, 1605–1610. [Google Scholar] [CrossRef]

- Minami, T.; Nanto, H.; Takata, S. Highly Conductive and Transparent Aluminum Doped Zinc Oxide Thin Films Prepared by RF Magnetron Sputtering. Jap. J. Appl. Phys. 1984, 23, L280. [Google Scholar] [CrossRef]

- Kang, Y.M.; Kwon, S.H.; Choi, J.H.; Cho, Y.J.; Song, P.K. Properties of Ce-doped ITO films deposited on polymer substrate by DC magnetron sputtering. Thin Solid Films 2010, 518, 3081–3084. [Google Scholar] [CrossRef]

- Choi, S.R.; Cho, S.H.; Kim, S.I.; Kang, Y.M.; Yoon, H.H.; Kim, K.H.; Song, P.K. Microstructure and Electrical Properties of Yb- or Sm-Doped Indium–Tin-Oxide Films Prepared by DC Magnetron Sputtering. Jpn. J. Appl. Phys. 2009, 48, 05EC04. [Google Scholar] [CrossRef]

- Jeong, S.; Ha, Y.G.; Moon, J.; Facchetti, A.; Marks, T.J. Role of gallium doping in dramatically lowering amorphous-oxide processing temperatures for solution-derived indium zinc oxide thin-film transistor. Adv. Mater. 2010, 22, 1346–1350. [Google Scholar] [CrossRef] [PubMed]

- Hara, H.; Hanada, T.; Shiro, T.; Yatabe, T. Properties of indium zinc oxide thin films on heat withstanding plastic substrate. J. Vac. Sci. Technol. A Vac. Surf. Film 2004, 22, 1726. [Google Scholar] [CrossRef]

- Ni, J.; Yan, H.; Wang, A.; Yang, Y.; Stern, C.L.; Metz, A.W.; Jin, S.; Wang, L.; Marks, T.J.; Ireland, J.R.; et al. MOCVD-derived highly transparent, conductive zinc- and tin-doped indium oxide thin films: Precursor synthesis, metastable phase film growth and characterization, and application as anodes in polymer light-emitting diodes. J. Am. Chem. Soc. 2005, 127, 5613–5624. [Google Scholar] [CrossRef] [PubMed]

- Choi, W.S.; Jo, H.; Kwon, M.S.; Jung, B.J. Control of electrical properties and gate bias stress stability in solution-processed a-IZO TFTs by Zr doping. Curr. Appl. Phys. 2014, 14, 1831–1836. [Google Scholar]

- Wan, D.; Liu, X.; Xu, L.; Liu, C.; Xiao, X.; Guo, S.; Liao, L. The Study for Solution-Processed Alkali Metal-Doped Indium-Zinc Oxide Thin-Film Transistors. IEEE Electron Device Lett. 2016, 37, 50–52. [Google Scholar] [CrossRef]

- Byeon, J.; Kim, S.; Lim, J.H.; Song, J.Y.; Park, S.H.; Song, P. Thermoelectric and electrical properties of micro-quantity Sn-doped amorphous indium-zinc oxide thin films. Jpn. J. Appl. Phys. 2017, 56, 010304. [Google Scholar] [CrossRef]

- Bang, J.; Matsuishi, S.; Hosono, H. Hydrogen anion and subgap states in amorphous In-Ga-Zn-O thin films for TFT applications. Appl. Phys. Lett. 2017, 110, 232105. [Google Scholar] [CrossRef]

- Walle, C.V.D. Hydrogen as a cause of doping in zinc oxide. Phys. Rev. Lett. 2000, 85, 1012–1015. [Google Scholar] [CrossRef] [PubMed]

- Assali, L.V.C.; Leite, J.R. Microscopic mechanism of hydrogen passivation of acceptor shallow levels in silicon. Phys. Rev. Lett. 1985, 55, 980–982. [Google Scholar] [CrossRef] [PubMed]

- Stutzmann, M. The defect density in amorphous silicon. Philos. Mag. B 1989, 60, 531–546. [Google Scholar] [CrossRef]

- He, C.R.; Wang, W.G.; Wang, J.; Xue, Y. Effect of alumina on the curvature, Young’s modulus, thermal expansion coefficient and residual stress of planar solid oxide fuel cells. J. Power Sources 2011, 196, 7639–7644. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-h.; Yoon, J.; Jin, S.-H.; Bang, J.; Song, P. Stabilizing of Mechanical Property of Amorphous In−Zn−O Thin Films with Hydrogen Flow. Coatings 2019, 9, 485. https://doi.org/10.3390/coatings9080485

Kim S-h, Yoon J, Jin S-H, Bang J, Song P. Stabilizing of Mechanical Property of Amorphous In−Zn−O Thin Films with Hydrogen Flow. Coatings. 2019; 9(8):485. https://doi.org/10.3390/coatings9080485

Chicago/Turabian StyleKim, Seo-han, Janghee Yoon, Sung-Ho Jin, Joonho Bang, and Pungkeun Song. 2019. "Stabilizing of Mechanical Property of Amorphous In−Zn−O Thin Films with Hydrogen Flow" Coatings 9, no. 8: 485. https://doi.org/10.3390/coatings9080485