1. Introduction

The increase in the price of a barrel of oil since 2020 has attracted oil and gas companies to focus on brownfields despite the decline in the production of wells in these fields. Traditionally, when these wells begin to decline, oil and gas companies abandon them due to the risk of unwanted water or gas production that is difficult to remediate [

1]. However, the subsea intervention in these wells became viable for production recovery due to the profit margin with the current oil and gas prices. This strategy was used by companies in Brazil, such as Trident, Perenco, and Karoon, to purchase brownfields from Petrobras.

In order to increase the production of brownfields, oil and gas companies seek companies capable of carrying out subsea interventions, to develop solutions that allow the growth of production safely. In this development scenario, these contracted companies develop products with the involvement of several suppliers who must follow the requirements defined by the engineering department. During this product development process, there is an initial stage in which suppliers prepare technical and commercial proposals, which are submitted to the company specializing in subsea intervention to evaluate whether they meet the requirements defined by the engineering department. However, when technical proposals from the suppliers have similar scopes of supply, each technical detail will be essential to identify the best recommendation.

The oil and gas extraction process is complex and involves many risks in terms of investment, environment, and human resources. The choice of a company with high technical capacity is of fundamental importance to the whole process. The decision-making group of an oil company needs to have precise and quality information to help in the decision-making process. A predominant factor, in this case, is the systematization of data, which is a critical factor for implementing artificial intelligence (A.I.) tools to support decision making. To avoid the analysis depending exclusively on human factors such as knowledge of the defined requirements, the possibility of using multicriteria decision analysis (MCDA) emerges to assist the decision-maker in choosing the most technically suitable supplier in the requested scope. In the last few years, we have observed a growth in the integration of machine learning methods with multicriteria methods to improve the elicitation of the weights attributed by decision-makers to the criteria used in decision support models: as an example, we cite the research developed by Souza Rodrigues et al. [

2] that developed an algorithm called Ranking Trees, which merges some steps of machine learning with the random forest technique, to elicit all parameter combinations of the ELECTRE II, III, and IV methods. This process presents the decision-maker with an optimized ranking of solutions, increasing the quality of the decision. Another example of decision-maker interaction with artificial intelligence is the work of Floriano et al. [

3], who developed the 3MO-AHP algorithm using the nondominated sorting genetic algorithm III (NSGA-III) to deal with the inconsistency problem of the AHP method. Another application can be observed in the research of Basilio et al. [

4], where they integrated the latent Dirichlet allocation (LDA) method with the ELECTRE-I method to identify criminal demands, helping decision-makers of police organizations to choose the best strategies to fight crime.

Regarding the oil and gas industry, an integration of A.I. and MCDA can be observed in the research developed by Eke et al. [

5] to identify and evaluate multiple options for decommissioning oil platforms. Furthermore, MCDA can be inserted into product development processes to predict software defects during development, as asserted by Özakıncı and Kolukısa Tarhan [

6]. The integration of artificial intelligence with operations research methods allows the decision-maker to virtually test and economically evaluate the attractiveness of adopting evolving technologies in full-field offshore developments, as reported by Basilio et al. [

7], using the method of “model-based systems metaheuristic engineering” (MBSME).

Basilio et al. [

8,

9,

10] reported that decision making is endogenous to humans. Throughout the day, we make numerous decisions consciously and unconsciously. We make decisions from the color of the tie we will wear to whether or not we will acquire some asset, for example. We want to reinforce the idea that we daily make simple and complex decisions in several knowledge areas [

8,

9,

10,

11,

12,

13] and that making decisions is inherent to human life. Decision support methods have been and will continue to be developed and improved to support managers in company decision making. Numerous methods have been developed over the last 50 years, such as AHP, TOPSIS, VIKOR, PROMETHEE, and ANP. As recorded by Basilio et al. [

8], these five methods are the most used in several areas of knowledge, the highlight being the AHP method. According to de Assis et al. [

9], “the literature reports the growth of new techniques and the integration with fuzzy sets and associations to reduce the discretion of the decision-maker regarding weight elicitation” (p. 2). Thus, decision-makers have at their disposal a myriad of methods such as MAUT, ELECTRE-MOr, SMART, UTA, MACBETH, ELECTRE, NAIADE, ORESTE, REGIME, ARGUS, TACTIC, EA FAHP, MELCHIOR, PAMSSEM, EVAMIX, QUALIFLEX, PCCA, MAPPAC, PRAGMA, PAC-MAN, IDRA, G-COPRAS, DRSA, SPOTIS, SIMUS, COMET, DARIA-TOPSIS, MABAC, MAIRCA, SF-AHP, WASPAS, TODIM, and SAPEVO-M [

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24].

When a particular MCDM method is finally recommended for a specific application, it is observed that its solution accuracy and ranking performance are seriously influenced by the value of its control parameter, as stated by Kahraman et al. [

25]. The general objective of this research is to apply the hybrid method SWARA-MOORA-3NAG in analyzing technical proposals of subsea intervention equipment for ordering suppliers according to the engineering requirements defined in the initial stage of the projects of an oil and gas company. The choice for this method is due to the report by Hermogens [

26], which states that the new proposal works, considering the original ordering of the MOORA method. According to Hermogenes [

26], the new approach simplified the process. The SWARA-MOORA-3NAG also uses two more normalizations in its model; thus, in addition to presenting the results considering a single ordination, without disregarding MOORA and Tchebycheff’s ordination, the three normalizations applied to the model guarantee more excellent safety in decision making. As a contribution, the method eliminates the need to perform sensitivity analysis on the results, as reported by Hermogens [

26]. The engineering department of this company performs this technical analysis, and there is no inclusion of the cost and delivery time criteria in the ordering, limiting the investigation to the technical scope of the proposals received by the suppliers.

In order to achieve the general objective, the following specific objectives were defined: (1) to identify the problems encountered in the analysis of the technical proposals of the suppliers; (2) to propose a multicriteria decision analysis method to assist engineers in this analysis; and (3) to apply the SWARA-MOORA-3NAG method and analyze the results obtained with its implementation.

This article is structured as follows:

Section 2 briefly describes the methods.

Section 3 presents the description of the problem.

Section 4 reports the main applications of multicriteria methods applied to the oil and gas sector.

Section 5 describes the proposed solution with the application of the SWARA-MOORA-3NAG method. The main discussions are summarized in

Section 6.

2. Literature Review

The bibliographic research carried out in the Scopus database was fundamental to the literature review since the MCDA methods can assist in ordering suppliers in the technical scope according to the established engineering requirements. The need to combine existing MCDA methods with the particularities of each project is important to achieve success, as performed by Janowska-Renkas et al. [

27] in the combination of the methods EA FAHP (extent analysis fuzzy analytic hierarchy process) and FuzzyTOPSIS (fuzzy technique for order preference by similarity to an ideal solution) in the optimal selection of high-performance concrete for monolithic beam structures of bridges.

Numerous MCDA methods have been developed in recent decades and are currently applied in various domains, such as their use to prioritize the redesign of streets in Quebec City, Canada [

28]. The benefits of implementing these methods can also be found at the national level in Pakistan, where its application in energy shortages to order renewable sources of green hydrogen can help the country find the solutions for this problem [

29].

Different sectoral investments in energy must be made in more suitable areas of cities, and recent concepts such as smart cities are also using MCDA methods for selecting locations for electric vehicle charging stations [

30]. In addition, it was observed that for energy-efficient home projects, a concept adopted by smart cities, there is an increase in environmental impact in the construction and demolition phases, and MCDA methods can order solutions so that this impact is as small as possible [

31]. Complementing this discussion, we can report on the work of Wang et al. [

32], who used a combination of DEA window analysis and the Malmquist index approach to assess the efficiency of the cybersecurity industry.

MCDA methods can also be associated with product development projects, such as prioritizing technical design and engineering requirements using the quality function deployment (QFD) tool to ensure quality during product and service development to meet customer needs [

33]. The QFD tool transforms these customer requirements into technical requirements and evaluates the product parameters of the competitor’s product to meet customer requirements by increasing their satisfaction [

34]. One of the possibilities of applying the QFD tool was proposed by Vongvit et al. [

35], by using Fuzzy-QFD technique to insert design changes in a 3-axis CNC (computerized numerical control) machine to make it a 5-axis machine that meets customer requirements.

Among the options for using MCDA methods, we highlight the proposal of a model for evaluating business projects for admission to an incubator, in which there is the possibility of classification in order of selection priority through the combination of momentum methods to build prospective scenarios and the AHP-TOPSIS-2N method to classify alternatives [

36]. In the case of startups, Simões et al. [

37] use the combination of cognitive mapping and the decision expert (DEX) technique to evaluate the growth potential of startups, bringing together a panel of experienced entrepreneurs and business investors to identify and articulate the criteria to be considered in the evaluation and classification of these startups.

In several industries, MCDA has been widely applied, as we can report in sustainable supplier selection (SSS), where Dang et al. [

38] integrated spherical fuzzy analytical hierarchical process (SF-AHP) and grey complex proportional assessment (G-COPRAS) to assess and choose a possible supplier based on their capability to adapt to the COVID-19 epidemic sustainably.

In the oil and gas industry, as presented by Barata et al. [

39], MCDA methods can be used to classify the degree of organizational sustainability of supplier companies, highlighting the advanced level of maturity of these companies in the context of sustainability. Additionally, in this same industry, Miri Lavasani et al. [

40] emphasize the importance of using the AHP method to estimate the weights needed to group the sources of nonpar proportional risks to identify acceptable risks in offshore wells. Among the various options of existing MCDA methods, this research addresses the application of the hybrid method SWARA-MOORA-3NAG in analyzing technical proposals for subsea intervention projects in the oil and gas industry.

3. Methodology

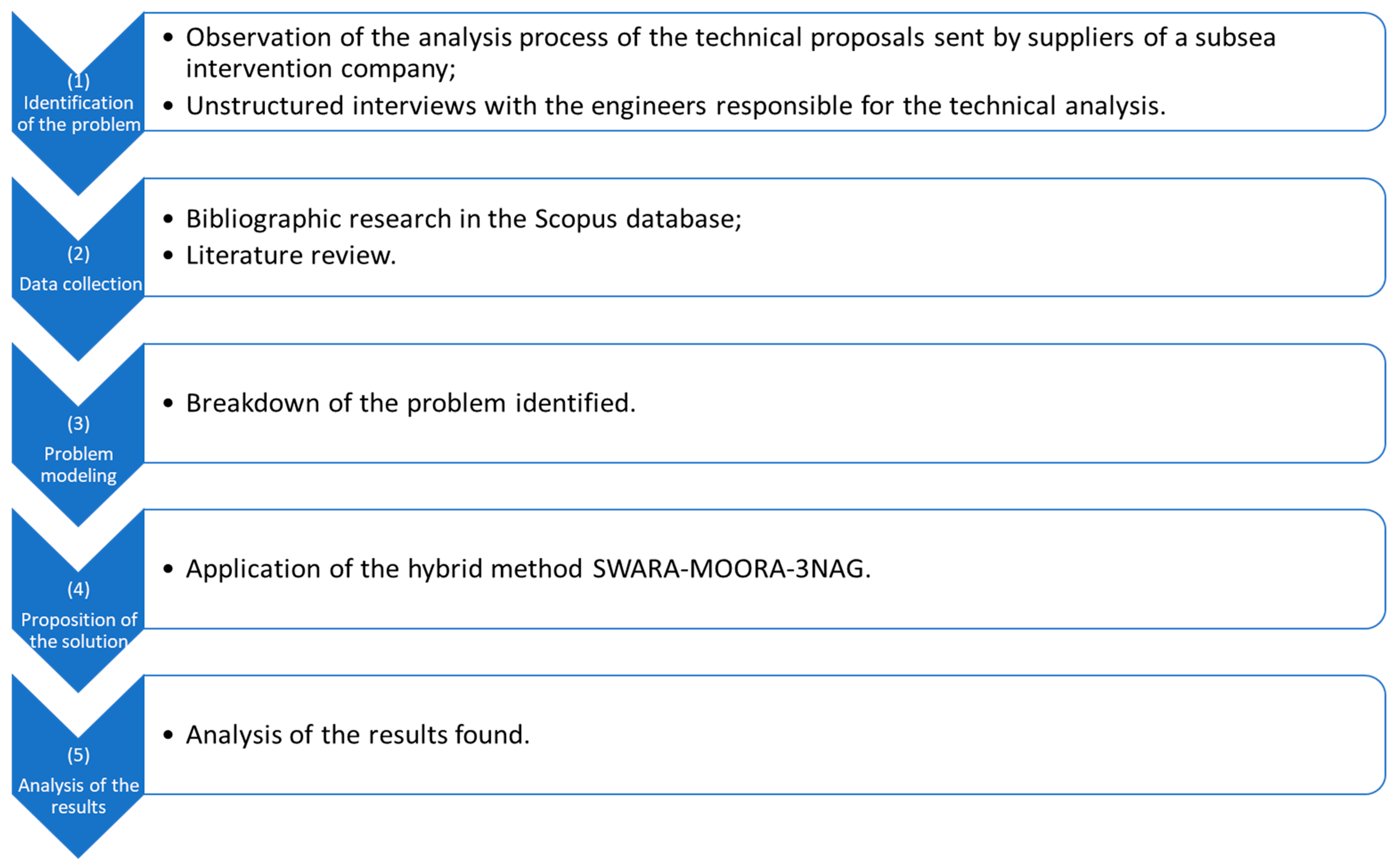

The methodology applied to this research was elaborated to identify the problem, present solutions to solve it, and finally, determine whether the proposed solution met the research objective.

Figure 1 shows the structure of the methodology used.

The first step is identifying the problem by observing the company’s current process analyzed in this research. Through this observation, it was determined that the ordering of suppliers performed by the engineering department, in the analysis of technical proposals, presented criteria in which there were no weights to be associated with technical requirements, and that they could impact the decision of the best supplier for the projects of subsea intervention. This observation was confirmed in unstructured interviews with three engineers responsible for these technical analyses, who emphasized the need to apply improvements in this analysis. This interview was conducted on 8 November 2022, with the question, “What is your assessment of the methodology of analysis of technical proposals sent by suppliers used by the company currently?” Although they agree that the current methodology helps identify the requirements requested, these engineers commented that different weights should be inserted in the criteria adopted due to the degree of importance of each requirement.

Then, with the problem identified, it was necessary to conduct bibliographic research that associated MCDA methods with product development. This bibliographical research was carried out using the Scopus database in November 2022 with the search string “requirements” and “design” and “multi-criteria decision analysis (MCDA)”, in which the 15 most recent articles were chosen, including the five most cited articles in this database. The reading of these papers facilitated the literature review on the theme proposed by this research, to identify the applications of MCDA methods in the product development processes in several industries.

The third stage was modeling the problem identified, to describe it in detail with the help of tools such as rich picture and mind map. The fourth step was structuring the solution by applying the hybrid method SWARA-MOORA-3NAG. Finally, the results were analyzed in the last step so that the ordering proposed by the hybrid method chosen was adjusted for the process of the analyzed company.

4. Description of the Problem

Ordering suppliers in the public administration’s bidding processes or the quotation stages in remote administration is fundamental for choosing products or services that meet the customer’s expectations. However, in some processes, the criterion weight of the cost and lead time sent by these suppliers is greater than other technical criteria. In this scenario, the contracting company can opt for the lowest cost and shorter lead time without having a detailed technical analysis that ensures the reliability of what is being offered. Generally, the technical analysis is performed by a team with technical knowledge, who compares the requirements requested in the technical specification with the technical proposal of the supplier. The cost and lead time analysis depends on evaluating other teams, such as the supply chain and projects.

In order to analyze this scenario in the company chosen for this research, it was observed that the engineering department is responsible for elaborating a technical specification of the product to be developed with all the requirements of the project. This technical specification is sent to the supply chain department, which directs it to the suppliers to submit the commercial and technical proposals. While technical proposals are analyzed by engineering, the commercial proposals are verified by supply chain and project departments.

Based on the process of the company analyzed, it was found that the ordering of suppliers indicated by the engineering team had a technical characteristic in which fulfilling the requested requirements was fundamental to the project’s success. However, the proposed ordering was based on requirements that had the same weight, through a document generated in Microsoft Excel, as shown in

Table 1. Additionally, the definitions of the requirements proposed in this research are based on the documentation already used by the company analyzed, following systems engineering principles. The evaluation of suppliers followed the requirements list included in the technical specification document sent to the vendors.

The score entered ranges from 0 to 100, according to the requirements requested by engineering in the technical specification sent to the supplier. For example, if there are 100 design requirements and the vendor has submitted a technical proposal with 87 requirements met, the score will be 87. In addition, the technical analysis of suppliers consists of the structuring of seven requirements that must be checked in the technical proposal received. The engineering department prepared the description of each condition according to

Table 2.

If all the requirements proposed by the engineering team had the same weight, there would be no need to use the MCDA methods since the analysis methodology proposed by engineering would meet the ordering requirements. However, it was found that this method was problematic because the non-inclusion of all project documentation by the supplier, such as the design databook, could not have the same weight as meeting the design requirements. It was observed that some suppliers chose not to provide the design databook due to some information that was considered as the intellectual property of each supplier, and it differentiated them from its competitors. Therefore, the ordering proposed by engineering could be improved so that there was the inclusion of weights by requirements, and in this case, the MCDA methods become fundamental to assist the engineering department in choosing the best technical proposal.

To assist in this stage of the identification of problems, two structuring tools were used: rich picture and mind map. The rich picture was fundamental for the macro analysis of the problem, in which the interruption of an oil well’s production allows the implementation of several solutions for subsea intervention so that it returns to its maximum production, as shown in

Figure 2.

Additionally, the mind map (e.g.,

Figure 3) was essential for the visualization of the requirements that are fundamental to the engineering department in the analysis of the technical proposal sent by suppliers, so that the best solution is chosen for the return to production of the oil well.

6. Discussion of the Results and Final Considerations

After the definition of the weights, the data in

Table 1 were included in the software so that the ordering and normalization of the SWARA-MOORA-3NAG method could be performed. After the software was run, the criteria weights were obtained according to

Table 5.

Table 6 shows the absolute orderings in each normalization and the overall absolute ordering, indicating that supplier C presented the best technical proposal to the engineering department.

Note that the normalizations of the three absolute orderings did not change the overall absolute ordering, keeping vendor C as the first option, vendor B as the second, and vendor A as the last option. Comparing

Table 3 with

Table 1 presented in

Section 4 of this paper, it is observed that prior to implementing the hybrid method, the ordering made by the engineering department would choose supplier A as the best option, since the criterion used had the same weight for all the requirements evaluated in the technical proposal. Therefore, the application of the hybrid method SWARA-MOORA-3NAG made it possible to insert the weights of the criteria to be ordered so that the decision-maker can use this information to differentiate supplier C from supplier B since, according to

Table 1, suppliers B and C had the same score in the analysis previously made by the engineering department.

This research applied the concepts of the hybrid method SWARA-MOORA-3NAG in the analysis of technical proposals of subsea intervention equipment to meet the following specific objectives: (1) to identify the problems encountered in the analysis of the technical proposals of suppliers; (2) to propose a multicriteria decision analysis method to assist engineers in this analysis; and (3) to apply the SWARA-MOORA-3NAG method and analyze the results obtained with its implementation.

The identification of the problem showed that the analysis of technical proposals carried out by the engineering department of the analyzed company required improvements in the choice of the most technically suitable supplier according to the requirements requested. In addition, the proposition of the multicriteria decision analysis method SWARA-MOORA-3NAG, as well as the theoretical basis applied to this method, allowed a new analysis methodology to be carried out by the engineers. Finally, applying the SWARA-MOORA-3NAG method presented a new absolute ordering different from the previous ordering process used by the engineering department.

Additionally, the relationship between humans and A.I. (artificial intelligence), as MCDA methods, should exist in a social system in which humans will always actively participate in some decision-making loops that will influence the operations of A.I. [

45]. Then, carefully questioning and evaluating whether A.I. deployment is beneficial from a team perspective is important when applying the MCDA methods in the current process [

46,

47,

48,

49,

50,

51,

52]. Even if the SWARA-MOORA-3NAG aids in the decision making of the best supplier to attend the technical requirements, the definition of the weight for each requirement depends on the human factor with proper technical knowledge.

The contributions of this research to the organizational scope of the company can be verified in the analysis processes carried out after the insertion of SWARA-MOORA-3NAG, emphasizing the importance of defining the weights of the criteria to engineers to assist in decision making. In relation to the academic field, this research contributed to the approach of a new hybrid method of MCDA in the oil and gas industry, presenting results that can be analyzed by several researchers for new applications. Compared to other MCDA methods, SWARA-MOORA-3NAG contributes to eliminating the possibility of doubts because of the proposal to run three normalizations, bringing more confidence to decision-makers in the scope proposed in this research.

It is important to highlight that this study is limited to a process of the engineering department of the company analyzed, and the cost and delivery time criteria were not inserted as criteria of the hybrid method applied, because they were not part of the scope of technical analysis performed by the engineering department. Finally, the researcher interested in applying this methodology can evaluate scenarios in other departments, such as the project or supply chain, to apply SWARA-MOORA-3NAG with the inclusion of the cost and delivery time criteria and evaluate whether it will affect the overall absolute ordering presented in this article.