Evaluation Research on Resilience of Coal-to-Liquids Industrial Chain and Supply Chain

Abstract

:1. Introduction

- (1)

- First, this paper presents an accurate definition and connotation explanation of the resilience of the CTL industrial chain and supply chain. It not only applies the resilience theory to the CTL field, but also systematically defines and explains the concept of the resilience of the CTL industrial chain and supply chain, which provides a clear theoretical foundation and conceptual framework for the subsequent research.

- (2)

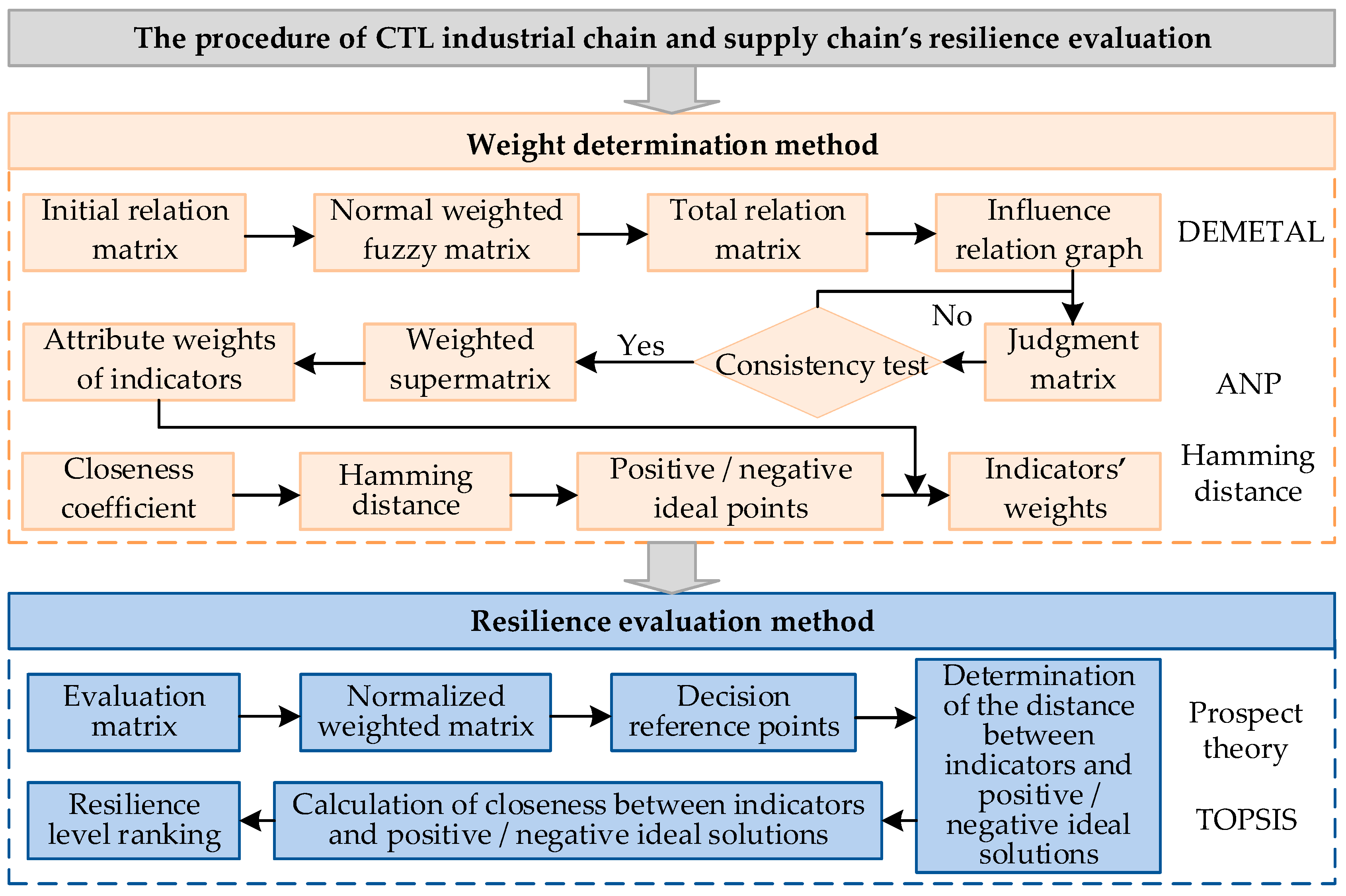

- Second, this paper proposes a set of evaluation frameworks for the resilience of the CTL industrial chain and supply chain. The framework incorporates an indicator system for factors such as rationality of CTL industrial layout, strategic CTL production capacity reserve, and construction of strategic CTL bases and determines the weights of the indicator system by using the interval type 2 fuzzy-decision-making trial and evaluation laboratory-analytic network process (IT2F-DEMATEL-ANP) method and conducts a resilience evaluation based on the interval type 2 fuzzy-prospect theory-technique for order preference by similarity to the ideal solution (IT2F-PT-TOPSIS), which can comprehensively and reasonably assess the resilience of CTL industrial chain and supply chain.

- (3)

- Finally, the results of the evaluation have led to the formulation of a series of strategies and suggestions designed to enhance the resilience of the CTL industrial chain and supply chain. These strategies not only consider optimization within the industry but also involve synergy with external factors such as government policies, market demand, and technological innovation. The implementation of these comprehensive measures will effectively enhance the resilience and sustainability of the CTL industrial chain and supply chain, which is of great significance in promoting energy supply security and economic stability.

2. Literature Review

2.1. Industrial Chain and Supply Chain of CTL

2.2. Resilience of the Industrial Chain and Supply Chain

2.2.1. Concept of Resilience

2.2.2. Application of Resilience in Industrial Chain and Supply Chain

2.2.3. Methods for Evaluating Resilience

2.3. Research Review

3. Evaluation Model of the CTL Industrial Chain and Supply Chain’s Resilience

3.1. Construction of Evaluation Indicator System for CTL Industrial Chain and Supply Chain’s Resilience

| Second-Level Indicators | Third-Level Indicators | Indicator Definition | Reference |

|---|---|---|---|

| Absorptive capacity A | Stability of raw material source A1 | The extent to which the company is able to reliably and consistently procure the raw materials required for production. | [37] |

| International crude oil price A2 | The profitability of CTL companies is influenced by the international crude oil price, which reflects the dynamics of supply and demand and determines the quality of production and the capacity for oil conversion. | [38] | |

| Revenue and profitability A3 | The capacity of a company to generate net income and profits from its business activities. | [39] | |

| Production cost A4 | The aggregate of direct and indirect costs incurred by a company in the production process. | [40] | |

| Degree of localization of key technologies A5 | The proportion of key technologies that are independently developed and domestically produced. | [41] | |

| Degree of localization of key equipment A6 | The share of key production equipment produced and supplied domestically. | [41] | |

| Capabilities of disaster defending and resistance A7 | The capacity of a company to respond to and recover from natural disasters and other emergencies. | [42] | |

| Adaptability B | Flexible production capacity B1 | The capacity of the CTL industrial chain and supply chain to respond expeditiously to fluctuations in demand in response to environmental changes and uncertain events. | [43] |

| CTL industry scale B2 | The capacity for production and the number of companies engaged in the CTL industry. | [40] | |

| Safety management level B3 | The level of construction, implementation, and monitoring of management systems in the company with respect to production safety. | [44] | |

| Equipment reliability B4 | The stability and reliability of the production equipment to function properly and accomplish the production tasks as expected. | [45] | |

| Rationality of CTL industrial layout B5 | The rationality of the geographic distribution and resource allocation of the CTL industry. | [5] | |

| Recovery capacity C | Sustainability C1 | The capacity of the CTL industrial chain and supply chain to achieve equilibrium between the disparate demands of environmental, social, and economic concerns while sustaining long-term growth. | [46] |

| Stability of supply and demand chain C2 | The ability of supply and demand chains to maintain stable operations against market volatility. | [47] | |

| CTL strategic capacity reserve C3 | A reserve of CTL capacity established to respond to market or production fluctuations. | [48] | |

| Technical talent C4 | The size and quality of the workforce with key technical knowledge and skills. | [49] | |

| Degree of industrial concentration C5 | The degree of concentration in the distribution of companies within the industry is indicative of the concentration of competition and resource allocation within the market. | [50] | |

| Self-learning capacity D | CTL strategic base construction D1 | The level of development of the CTL industrial base built to ensure national energy security. | [5] |

| Degree of industrial coupling D2 | The extent to which different industries are interdependent, cooperate, and engage in synergistic development. | [51] | |

| Industrial innovation output value D3 | The economic value and market competitiveness generated by the industry through technological innovation. | [52] | |

| Strength of policy support D4 | The efficacy of policy concessions, financial support, and administrative services provided by the government to facilitate industrial development. | [53] |

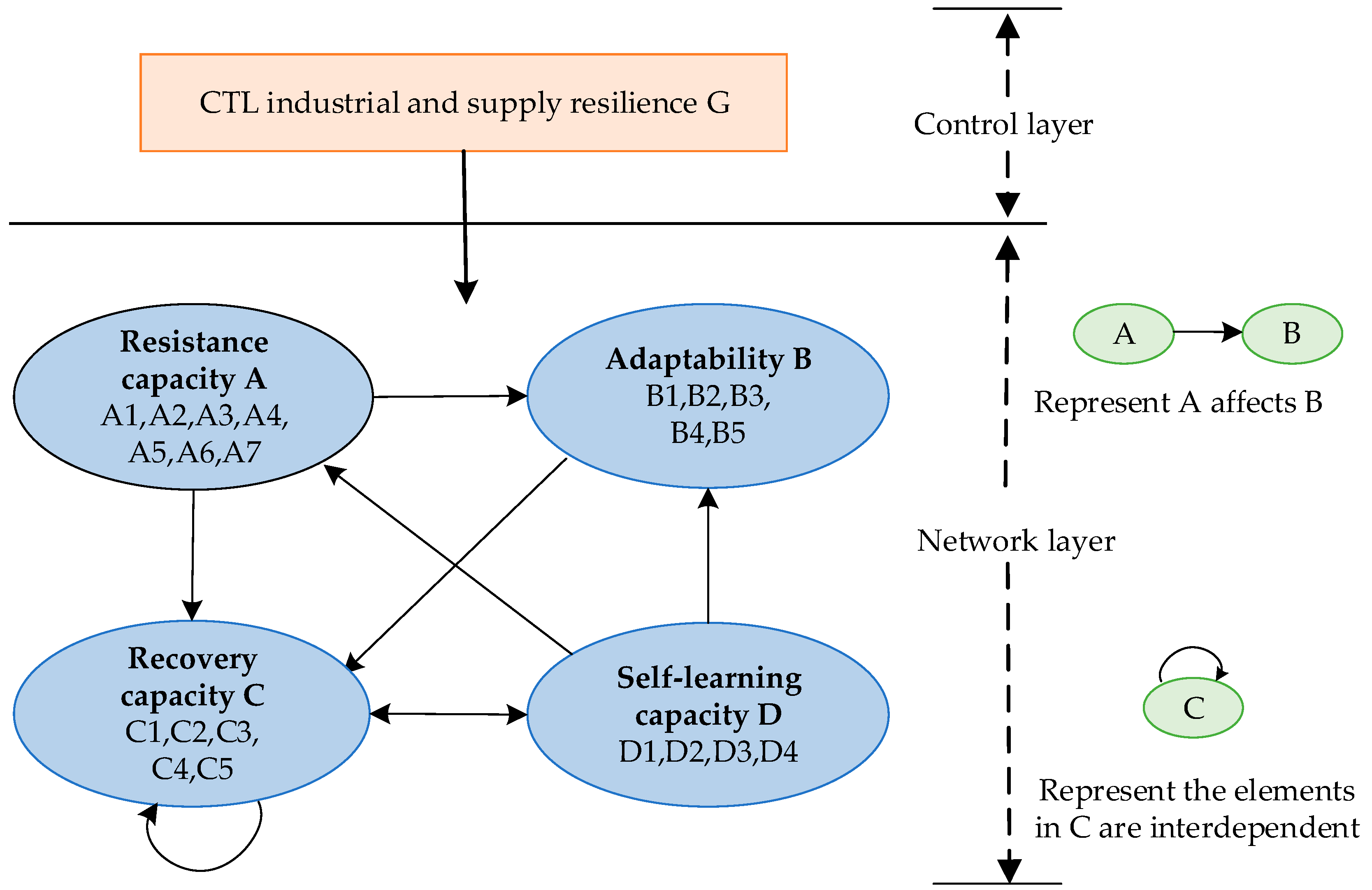

- (1)

- The term “absorption capacity” refers to the ability of the CTL industrial chain and supply chain to withstand or absorb external shocks when perturbations occur [54], which mainly includes two parts: resisting external risks and improving self-tolerance. Hence, seven indicators are selected, including the stability of production raw material sources, the international crude oil price, revenue and profitability, production costs, the degree of localization of key technologies, the degree of localization of key equipment, and the capacities of disaster defense and resistance.

- (2)

- The term “adaptability” is used to describe the ability of the CTL industrial chain and supply chain as a whole to adapt to changes in the environment and to make adjustments to maintain operational performance in the face of potential risks [55]. This paper primarily concentrates on two key areas: industry and enterprise. To this end, five key indicators are selected for analysis: flexible production capacity, CTL industry scale, safety management level, equipment reliability, and rationality of CTL industrial layout.

- (3)

- The term “recovery capacity” is used to describe the ability of individual nodes within the CTL industrial chain and supply chain to recover from disruptive events in a timely manner [56]. This recovery process is dependent on the resilience of five key aspects: sustainability, stability of supply and demand chains, strategic reserve of CTL production capacity, technical talent, and industrial concentration.

- (4)

- The term “self-learning capacity” represents a new equilibrium within the CTL industrial chain and supply chain, whereby these systems are stimulated to achieve higher levels of learning and innovation in response to adversity, pressure, and environmental constraints. As a result of this stimulation, higher levels of learning are realized [52]. This paper presents four indicators designed to evaluate the self-learning capacity of the CTL industrial chain and supply chain’s resilience. The indicators include the CTL strategic base construction, the degree of industrial coupling, the industrial innovation output value, and the strength of policy support.

3.2. Interval Type 2 Fuzzy Set (IT2FS)

3.2.1. Definition

3.2.2. The Algorithm of Trapezoidal Interval Type 2 Fuzzy Sets (IT2FSs)

- (1)

- Additive operation

- (2)

- Multiply operation

- (3)

- Scalar multiplication

- (4)

- Power operation

- (5)

- The distance between two trapezoidal IT2FSs [60]where , .

3.3. Procedure of Resilience Evaluation

3.4. Determination of Indicators’ Weights Based on IT2F-DEMATEL-ANP

3.4.1. IT2F-DEMATEL Method

3.4.2. IT2F-ANP Algorithm

3.5. Evaluation Method Based on IT2F-PT-TOPSIS

3.5.1. Prospect Theory

3.5.2. TOPSIS

4. Case Study

4.1. Calculation of Evaluation Indicators’ Weights

4.2. Calculation of CLT Industrial Chain and Supply Chain Resilience Level

5. Results Analysis and Policy Suggestions

- (1)

- The development of China’s CTL industrial chain and supply chain was still in its nascent stages in 2018. The stability of the political and economic environment domestically and internationally contributed to the overall stability of the industrial chain and supply chain throughout the year. Notwithstanding the numerous challenges encountered by the CTL project in 2018, including the fact that the core technology was subject to external restrictions, a shortage of talent, and deficiencies in corporate safety management, the stabilization of raw material sources and supply and demand chains, coupled with the active support of national policy, led to a remarkable development in the industrial chain and supply chain of CTL in 2018. This accomplishment not only exemplifies the capacity of the industrial chain and supply chain to adapt to alterations in the external environment but also illustrates the pivotal function of national policies in fostering industrial advancement.

- (2)

- In 2019, the CTL industrial chain and supply chain exhibited considerable advancement, and their resilience level demonstrated notable enhancement in comparison to 2018. This progress is primarily attributable to the robust policy support that has facilitated the standardized construction of strategic CTL bases. In this context, enterprises have implemented measures to enhance the recruitment and training of talent while simultaneously improving their safety management practices. Furthermore, the upstream and downstream synergistic effect of the industrial chain and supply chain has been reinforced, the construction of industrial supporting facilities has yielded preliminary outcomes, and the industrial coupling effect has commenced to emerge. These factors collectively contribute to the stability of the supply and demand chain, thereby significantly enhancing the flexible production capacity of enterprises. The aforementioned factors collectively indicate a notable enhancement in the resilience of CTL industrial chain and supply chain in 2019, when compared to the preceding year.

- (3)

- The global outbreak of the COVID-19 pandemic in 2020 had a profound impact on the CTL industrial chain and supply chain. First, there was a notable decline in energy demand due to the implementation of global epidemic prevention and control measures. Furthermore, the precipitous decline in crude oil prices had an additional detrimental impact on the market demand and profitability of CTL projects. In addition, in the context of significant and unpredictable shifts in the internal and external environments, the disaster prevention and resilience of the CTL industrial chain and supply chain have been revealed to be inadequate. The stability of the supply and demand chain has also been found to be insufficient. This deficiency results in shortcomings of the CTL industrial chain and supply chain in responding to changes in the external environment and adjusting their own strategies in a timely manner. Ultimately, these factors have collectively resulted in the lowest level of resilience observed in the CTL industrial chain and supply chain in 2020.

- (4)

- In 2021, with the advent of the post-epidemic era, the gradual recovery of the global economy and the rebound of energy demand have created new development opportunities for the CTL industrial chain and supply chain. In order to respond effectively to the adverse effects of the COVID-19 pandemic, the CTL industry is in urgent need of innovation and modernization to achieve its goal of sustainable development. Furthermore, synergistic collaboration with other energy sectors is of paramount importance in facilitating the transformation and green development of the entire energy industry. Such cross-field collaboration serves not only to enhance the resilience of the industrial chain and supply chain, but also represents a crucial pathway to achieving long-term, stable development. It is noteworthy that the resilience level of the CTL industrial chain and supply chain reached a peak in 2021. This provides crucial benchmarks and insights for subsequent years, indicating that the resilience and transformational capacity of the industrial chain and supply chain are pivotal in addressing global challenges.

- (5)

- The outbreak of the Russia-Ukraine conflict in 2022 triggered geopolitical tensions, resulting in unprecedented challenges to the management of the CTL industrial chain and supply chain. Despite some advancement in the capabilities of disaster defense and resistance, the volatility of the energy market and the sustained elevated costs of essential raw materials, such as coal, have exerted a considerable detrimental influence on the operational efficacy and profitability of the CTL industry. In addition, the rise in production costs serves to further intensify the test of sustainability in the supply chain and the equilibrium between supply and demand. Consequently, the CTL industry demonstrated a decline in resilience levels in 2022 when compared to 2021. This decline reflects the necessity to enhance the adaptability and resilience of the industrial chain and supply chain in order to effectively navigate a complex and volatile external environment.

- (1)

- It is imperative to enhance technological innovation, research, development, and localization. Although CENC’s large-scale indirect coal liquefaction system integration and complete set of clean operation technologies are generally at the international leading level, there is a need to increase the output of oleochemicals through continuous technological innovation and R&D. Furthermore, there is a necessity to improve the technological level of the CTL industry in order to cope with market changes and environmental pressures and to enhance the adaptability and competitiveness of the industry. It is recommended that investment in research and development be increased with regard to localized technologies. Furthermore, encouragement should be given to the cultivation and introduction of local technical talent, as well as to cooperation with domestic scientific research institutions. This will facilitate the acceleration of the transformation and application of technical achievements. Furthermore, cutting-edge technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analysis should be proactively integrated into the operational framework of CTL projects to enhance the efficiency and precision of the supply chain.

- (2)

- It is important to strengthen the framework of risk, emergency management, and risk response capacity. In the context of an increasingly dynamic international environment and energy market, it is crucial for CTL enterprises to recognize the importance of strengthening enterprise risk management at the key nodes of low-carbon transformation. This approach can effectively mitigate the impact on the entire supply chain network in the event of a risk occurrence while also leveraging the powerful momentum of industrial chain and supply chain resilience. For instance, in the coal mining stage, it would be prudent to reinforce the identification of potential disaster-causing factors in order to prevent the insufficient provision of raw materials due to the absence of such an identification process. Similarly, in the transportation link, the deployment of 5G, IoT, and other cutting-edge technologies can be leveraged to enhance the operational resilience of the supply chain. In the synthesis stage, it is essential to enhance the monitoring of the crucial equipment and procedures involved in the CTL conversion process. Furthermore, comprehensive drills must be conducted to address potential disasters, incidents, and emergencies. In the distribution stage, financial instruments such as futures and options can be employed for the purpose of price risk management and stabilizing market expectations.

- (3)

- It is imperative to reinforce the interconnectivity and collaborative efforts between the involved parties and to enhance the stability of the supply and demand chain. The success of the CTL project is contingent upon the full cooperation of the upstream and downstream sectors of the CTL industrial chain. Therefore, the CENC should not only reinforce the collaboration and innovation within the CTL project but also enhance the collaboration between the CTL industry and other related industries. For instance, the formation of a cross-enterprise collaboration platform, coupled with the refinery’s economies of scale, diverse oil sources, extensive blending capabilities, robust sales channels, and other advantages, can facilitate the sharing of information and integration of resources across the coal mining, transportation, CTL conversion, and sales sectors. Furthermore, collaboration with related industries, such as energy utilization and chemical product manufacturing, can facilitate the extension of the industrial chain, global integration of the supply chain, and high-end enhancement of the value chain. It is recommended that the stability of the supply and demand chain be enhanced through the implementation of a diversified sourcing strategy, the establishment of strategic reserves, and the optimization of flexible supply chain management, thereby improving responsiveness to market fluctuations.

- (4)

- It is recommended that policy support be increased and the industrial layout be optimized. The stability and longevity of policies are also significant factors in enhancing resilience. The government may establish an incentive mechanism based on energy supply, which could include raising carbon quotas during carbon trading, adjusting carbon trading prices, lowering the tax rate under the carbon tax policy, and raising the carbon subsidy rate under the carbon subsidy policy. The government must assume the role of a competent supervisor and implement irregular supervision and inspection of CTL industrial chain and supply chain enterprises. This will ensure that the actual level of risk and emergency management of enterprises is monitored. In addition, it is crucial to advocate for the centralized organization of the industry in regions that are endowed with resources and have developed robust infrastructure. This approach can enhance the efficiency of resource utilization and industrial collaboration, promote rationality in industrial layout, and reinforce the resilience of the entire CTL industrial chain and supply chain.

6. Conclusions

- (1)

- This paper presents a clear definition of the connotation of resilience of CTL industrial chain and supply chain, which is defined as the ability of the CTL industrial chain and supply chain system to withstand external shocks, such as those caused by climate, economic, technological, and societal factors, as well as internal disturbances and subsequent adaptations, recoveries, and renewals. This definition has yet to be fully explored in existing research on CTL [16]. The definition presented in this paper provides a new perspective for subsequent research.

- (2)

- The industrial chain and supply chain resilience evaluation framework of CTL industrial chain and supply chain, as outlined in this paper, not only encompasses the conventional elements of supply chain resilience but also introduces innovative indicators that have been overlooked in previous studies [68]. These include the rationality of the CTL industrial layout, the construction of strategic bases, and the strategic production capacity reserve. The incorporation of these indicators represents a valuable contribution to the existing evaluation of resilience within the specific context of the CTL industry, offering a more comprehensive framework for the development of the evaluation model.

- (3)

- By employing the TYPE 2-DEMATEL-ANP and TYPE 2-PT-TOPSIS methods to empirically analyze the resilience level of CTL industrial chain and supply chain from 2018 to 2022, this study elucidates the resilience performance and key influencing factors in different years. The majority of previous studies have employed cross-sectional data [69], whereas this paper places greater emphasis on the analysis of dynamic changes in time series data, thereby providing new insights into the long-term resilience of CTL industrial chain and supply chain. In light of the findings of the empirical analysis, this paper presents targeted policy recommendations that are closely aligned with the conclusions of this study. This approach ensures the scientific and practical relevance of the recommendations, with the aim of enhancing the overall resilience of the CTL industrial chain and supply chain.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, F.R.; Zhuang, L.; Cheng, S.S.; Zhang, Y.; Cheng, S.L. Spatiotemporal variation and convergence analysis of China’s regional energy security. Renew. Sustain. Energy Rev. 2024, 189, 113923. [Google Scholar] [CrossRef]

- Erker, S.; Stangl, R.; Stoeglehner, G. Resilience in the light of energy crises—Part I: A framework to conceptualise regional energy resilience. J. Clean. Prod. 2017, 164, 420–433. [Google Scholar] [CrossRef]

- Wang, X.P.; Shen, Y.; Su, C. Exploring the willingness and evolutionary process of public participation in community shared energy storage projects: Evidence from four first-tier cities in China. J. Clean. Prod. 2024, 472, 143462. [Google Scholar] [CrossRef]

- Li, Z.Y.; Pu, H.; Li, T.Z. Knowledge mapping and evolutionary analysis of energy storage resource management under renewable energy uncertainty: A bibliometric analysis. Front. Energy Res. 2024, 12, 1394318. [Google Scholar] [CrossRef]

- Guo, M.Y.; Xu, Y. Coal-to-liquids projects in China under water and carbon constraints. Energy Policy 2018, 117, 58–65. [Google Scholar] [CrossRef]

- Ribas, G.P.; Hamacher, S.; Street, A. Optimization under uncertainty of the integrated oil supply chain using stochastic and robust programming. Int. Trans. Oper. Res. 2010, 17, 777–796. [Google Scholar] [CrossRef]

- Emenike, S.N.; Falcone, G. A review on energy supply chain resilience through optimization. Renew. Sustain. Energy Rev. 2020, 134, 110088. [Google Scholar] [CrossRef]

- Wu, A.B.; Sun, Y.; Zhang, H.L.; Sun, L.H.; Wang, X.P.; Li, B.Y. Research on resilience evaluation of coal industrial chain and supply chain based on interval Type-2F-PT-TOPSIS. Processes 2023, 11, 556. [Google Scholar] [CrossRef]

- Wang, C.Y.; Zhu, L. Life cycle assessment of Coal-to-Liquid process. Environ. Dev. Sustain. 2021, 23, 14453–14471. [Google Scholar] [CrossRef]

- Zhou, L.; Chen, W.Y.; Zhang, X.L.; Qi, T.Y. Simulation and economic analysis of indirect Coal-to-Liquid technology coupling carbon capture and storage. Ind. Eng. Chem. Res. 2013, 52, 9871–9878. [Google Scholar] [CrossRef]

- Chang, S.Y.; Zhuo, J.K.; Meng, S.; Qin, S.Y.; Yao, Q. clean coal technologies in China: Current status and future perspectives. Engineering 2016, 2, 447–459. [Google Scholar] [CrossRef]

- World Bank. 2017 Energy Resilience Takes on Renewed Urgency. Available online: https://www.worldbank.org/en/news/feature/2017/11/10/energy-resilience-takes-on-renewed-urgency (accessed on 6 May 2024).

- Gasser, P.; Suter, J.; Cinelli, M.; Spada, M.; Burgherr, P.; Hirschberg, S.; Kadziński, M.; Stojadinović, B. Comprehensive resilience assessment of electricity supply security for 140 countries. Ecol. Indic. 2020, 110, 105731. [Google Scholar] [CrossRef]

- Xie, X.M.; Zhang, T.T.; Gu, J.C.; Huang, Z. Water footprint assessment of coal-based fuels in China: Exploring the impact of coal-based fuels development on water resources. J. Clean. Prod. 2018, 196, 604–614. [Google Scholar] [CrossRef]

- Qi, T.Y.; Zhou, L.; Zhang, X.L.; Ren, X.K. Regional economic output and employment impact of coal-to-liquids (CTL) industry in China: An input-output analysis. Energy 2012, 46, 259–263. [Google Scholar] [CrossRef]

- Zhou, X.Y.; Zhang, H.R.; Qiu, R.; Lv, M.Y.; Xiang, C.C.; Long, Y.; Liang, Y.T. A two-stage stochastic programming model for the optimal planning of a coal-to-liquids supply chain under demand uncertainty. J. Clean. Prod. 2019, 228, 10–28. [Google Scholar] [CrossRef]

- Sun, X.L.; Li, J.P.; Wu, D.S.; Yi, S.L. Energy geopolitics and chinese strategic decision of the energy-supply security: A Multiple-Attribute Analysis. J. Multi-Crit. Decis. Anal. 2011, 18, 151–160. [Google Scholar] [CrossRef]

- Gong, X.; Sun, Y.; Du, Z.L. Geopolitical risk and China’s oil security. Energy Policy 2022, 163, 112856. [Google Scholar] [CrossRef]

- Hosseini, S.; Barker, K.; Ramirez-Marquez, J.E. A review of definitions and measures of system resilience. Reliab. Eng. Syst. Safe. 2016, 145, 47–61. [Google Scholar] [CrossRef]

- Holling, C.S. Resilience and stability of ecological systems. Annu. Rev. Ecol. Evol. Syst. 1973, 4, 1–23. [Google Scholar] [CrossRef]

- Su, P.; Yi, J.D.; Chen, X.W.; Xiao, Y. Visual analysis of psychological resilience research based on Web of Science database. Psychol. Res. Behav. Manag. 2023, 16, 465–481. [Google Scholar] [CrossRef]

- Saja, A.M.A.; Teo, M.; Goonetilleke, A.; Ziyath, A.M. An inclusive and adaptive framework for measuring social resilience to disasters. Int. J. Disast. Risk Reduct. 2018, 28, 862–873. [Google Scholar] [CrossRef]

- Wang, X.L.; Wang, L.; Zhang, X.R.; Fan, F. The spatiotemporal evolution of COVID-19 in China and its impact on urban economic resilience. China Econ. Rev. 2022, 74, 101806. [Google Scholar] [CrossRef] [PubMed]

- Hollnagel, E.; Woods, D.D.; Leveson, N. Resilience Engineering: Concepts and Precepts, 1st ed.; CRC Press: London, UK, 2006; p. 416. [Google Scholar] [CrossRef]

- Christopher, M.; Peck, H. Building the Resilient Supply Chain. Int. J. Logist. 2004, 15, 1–14. [Google Scholar] [CrossRef]

- Afgan, N.; Veziroglu, A. Sustainable resilience of hydrogen energy system. Int. J. Hydrogen Energy 2012, 37, 5461–5467. [Google Scholar] [CrossRef]

- Brusset, X.; Teller, C. Supply chain capabilities, risks, and resilience. Int. J. Prod. Econ. 2017, 184, 59–68. [Google Scholar] [CrossRef]

- Ambulkar, S.; Blackhurst, J.; Grawe, S. Firm’s resilience to supply chain disruptions: Scale development and empirical examination. J. Oper. Manag. 2015, 33–34, 111–122. [Google Scholar] [CrossRef]

- Yin, W.L.; Ran, W.X.; Zhang, Z. A configuration approach to build supply chain resilience: From matching perspective. Expert Syst. Appl. 2024, 249, 123662. [Google Scholar] [CrossRef]

- Cheek, W.; Chmutina, K. Measuring resilience in the assumed city. Int. J. Disaster Risk Sci. 2022, 13, 317–329. [Google Scholar] [CrossRef]

- Feng, Y.; Lee, C.C.; Peng, D.Y. Does regional integration improve economic resilience? Evidence from urban agglomerations in China. Sustain. Cities Soc. 2023, 88, 10427. [Google Scholar] [CrossRef]

- Månsson, A.; Johansson, B.; Nilsson, L.J. Assessing energy security: An overview of commonly used methodologies. Energy 2014, 73, 1–14. [Google Scholar] [CrossRef]

- Rathore, R.; Thakkar, J.J.; Jha, J.K. A quantitative risk assessment methodology and evaluation of food supply chain. Int. J. Logist. 2017, 28, 1272–1293. [Google Scholar] [CrossRef]

- Xun, X.L.; Yuan, Y.B. Research on the urban resilience evaluation with hybrid multiple attribute TOPSIS method: An example in China. Nat. Hazards 2020, 103, 557–577. [Google Scholar] [CrossRef] [PubMed]

- Cutter, S.L.; Barnes, L.; Berry, M.; Burton, C.; Evans, E.; Tate, E.; Webb, J. A place-based model for understanding community resilience to natural disasters. Glob. Environ. Chang. 2008, 18, 598–606. [Google Scholar] [CrossRef]

- Pei, J.J.; Liu, W.; Han, L. Research on evaluation index system of chinese city safety resilience based on Delphi Method and Cloud Model. Int. J. Environ. Res. Public Health 2019, 16, 3802. [Google Scholar] [CrossRef]

- Gong, C.Z.; Gong, N.J.; Qi, R.; Yu, S.W. Assessment of natural gas supply security in Asia Pacific: Composite indicators with compromise Benefit-of-the-Doubt weights. Resour. Policy 2020, 67, 101671. [Google Scholar] [CrossRef]

- Mohsin, M.; Zhou, P.; Iqbal, N.; Shah, S.A.A. Assessing oil supply security of South Asia. Energy 2018, 155, 438–447. [Google Scholar] [CrossRef]

- Kruyt, B.; van Vuuren, D.P.; de Vries, H.J.M.; Groenenberg, H. Indicators for energy security. Energy Policy 2009, 37, 2166–2181. [Google Scholar] [CrossRef]

- Parast, M.M. Toward a contingency perspective of organizational and supply chain resilience. Int. J. Prod. Econ. 2022, 250, 108667. [Google Scholar] [CrossRef]

- Fan, X.M.; Lu, M.Y. Influencing Factors and Evaluation of Supply Chain Resilience of Automobile Enterprises under New Coronavirus. J. Ind. Technol. Econ. 2020, 39, 21–28. [Google Scholar]

- Um, J.; Han, N. Understanding the relationships between global supply chain risk and supply chain resilience: The role of mitigating strategies. Supply Chain Manag. 2021, 26, 240–255. [Google Scholar] [CrossRef]

- Lui, J.G.; Jiang, X.H.; Zhao, J.L. Resilience of the supply chain system based on Interpretative Structural Modeling. J. Syst. Manag. 2015, 24, 617–623. [Google Scholar]

- Rajesh, R.; Ravi, V. Supplier selection in resilient supply chains: A grey relational analysis approach. J. Clean. Prod. 2015, 86, 343–359. [Google Scholar] [CrossRef]

- Aljabhan, B. Economic strategic plans with supply chain risk management (SCRM) for organizational growth and development. Alexandria Eng. J. 2023, 79, 411–426. [Google Scholar] [CrossRef]

- Mahdiraji, H.A.; Arzaghi, S.; Stauskis, G.; Zavadskas, E.K. A hybrid fuzzy BWM-COPRAS method for analyzing key factors of sustainable architecture. Sustainability 2018, 10, 1626. [Google Scholar] [CrossRef]

- Li, B.; Xiang, P.; Hu, M.; Zhang, C.; Dong, L. The vulnerability of industrial symbiosis: A case study of Qijiang Industrial Park, China. J. Clean. Prod. 2017, 157, 267–277. [Google Scholar] [CrossRef]

- Alikhani, R.; Torabi, S.A.; Altay, N. Retail supply chain network design with concurrent resilience capabilities. Int. J. Prod. Econ. 2021, 234, 108042. [Google Scholar] [CrossRef]

- Zhao, R.D.; Fang, C.L.; Liu, H.M.; Liu, X.X. Evaluating urban ecosystem resilience using the DPSIR framework and the ENA model: A case study of 35 cities in China. Sustain. Cities Soc. 2021, 72, 102997. [Google Scholar] [CrossRef]

- Vandermerwe, S.; Rada, J. Servitization of business: Adding value by adding services. Eur. Manag. J. 1988, 6, 314–324. [Google Scholar] [CrossRef]

- Rajesh, R. A fuzzy approach to analyzing the level of resilience in manufacturing supply chains. Sustain. Prod. Consum. 2019, 18, 224–236. [Google Scholar] [CrossRef]

- Stoverink, A.C.; Kirkman, B.L.; Mistry, S.; Rosen, B. Bouncing back together: Toward a theoretical model of work team resilience. Acad. Manag. Rev. 2020, 45, 395–422. [Google Scholar] [CrossRef]

- Sunmola, F.; Burgess, P.; Tan, A.; Chanchaichujit, J.; Balasubramania, S.; Mahmud, M. Prioritising Visibility Influencing Factors in Supply Chains for Resilience. Procedia Comput. Sci. 2023, 217, 1589–1598. [Google Scholar] [CrossRef]

- Biringer, B.; Vugrin, E.; Warren, D. Critical Infrastructure System Security and Resiliency, 1st ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar] [CrossRef]

- Nan, C.; Sansavini, G. A quantitative method for assessing resilience of interdependent infrastructures. Reliab. Eng. Syst. Saf. 2017, 157, 35–53. [Google Scholar] [CrossRef]

- Hosseini, S.; Ivanov, D.; Dolgui, A. Review of quantitative methods for supply chain resilience analysis. Transp. Res. Part E Transp. Res. E Logist. Transp. Rev. 2019, 125, 285–307. [Google Scholar] [CrossRef]

- Mendel, J.M.; John, R.I.; Liu, F. Interval Type-2 Fuzzy logic systems made simple. IEEE Trans. Fuzzy Syst. 2006, 14, 808–821. [Google Scholar] [CrossRef]

- Mendel, J.M.; John, R.I.B. Type-2 fuzzy sets made simple. IEEE Trans. Fuzzy Syst. 2002, 10, 117–127. [Google Scholar] [CrossRef]

- Lee, L.W.; Chen, S.M. A new method for fuzzy multiple attributes group decision-making based on the arithmetic operations of interval type-2 fuzzy sets. In Proceedings of the 2008 International Conference on Machine Learning and Cybernetics, Kunming, China, 12–15 July 2008. [Google Scholar]

- Ju, Y.B.; Ju, D.W.; Wang, A.H.; Ju, M.Y. GRP method for multiple attribute group decision making under trapezoidal interval type-2 fuzzy environment. J. Intell. Fuzzy Syst. 2017, 33, 3469–3482. [Google Scholar] [CrossRef]

- Qu, S.J.; Zhou, Y.Y.; Ji, Y.; Dai, Z.H.; Wang, Z.L. Robust maximum expert consensus modeling with dynamic feedback mechanism under uncertain environments. J. Ind. Manag. Optim. 2024. [Google Scholar] [CrossRef]

- Dou, Y.J.; Sarkis, J. A multiple stakeholder perspective on barriers to implementing China RoHS regulations. Resour. Conserv. Recyl. 2013, 81, 92–104. [Google Scholar] [CrossRef]

- Saaty, R.W. The analytic hierarchy process—What it is and how it is used. Math. Model. 1987, 9, 161–176. [Google Scholar] [CrossRef]

- Chen, S.M.; Lee, L.W. Fuzzy multiple attributes group decision-making based on the interval type-2 TOPSIS method. Expert Syst. Appl. 2010, 37, 2790–2798. [Google Scholar] [CrossRef]

- Kahneman, D.; Tversky, A. Prospect theory: An analysis of decision under risk. Econometrica 1979, 47, 263–291. [Google Scholar] [CrossRef]

- Tversky, A.; Kahneman, D. Advances in prospect theory: Cumulative representation of uncertainty. J. Risk Uncertain. 1992, 5, 297–323. [Google Scholar] [CrossRef]

- Tzeng, G.H.; Huang, J.J. Multiple Attribute Decision Making: Methods and Applications, 1st ed.; Chapman and Hall/CRC: New York, NY, USA, 2011; pp. 1–333. [Google Scholar]

- Yang, J.; Zhou, K.; Hu, R. City-level resilience assessment of integrated energy systems in China. Energy Policy 2024, 193, 114294. [Google Scholar] [CrossRef]

- Yang, C.; Li, S.; Huang, D.; Lo, W. Performance evaluation of carbon-neutral cities based on Fuzzy AHP and HFS-VIKOR. Systems 2024, 12, 173. [Google Scholar] [CrossRef]

- Pu, H.; Wang, X.; Li, T.; Su, C. Dynamic control of low-carbon efforts and process innovation considering knowledge accumulation under dual-carbon policies. Comput. Ind. Eng. 2024, 196, 110526. [Google Scholar] [CrossRef]

- Su, C.; Deng, J.; Li, X.; Cheng, F.; Huang, W.; Wang, C.; He, W.; Wang, X. Research on the game strategy of mutual safety risk prevention and control of industrial park enterprises under Blockchain Technology. Systems 2024, 12, 351. [Google Scholar] [CrossRef]

| Syboml | Definition |

|---|---|

| Type 1 fuzzy set | |

| Membership function | |

| Primary variable | |

| Minor variable | |

| Interval Type 2 fuzzy set | |

| Upper trapezoid membership function | |

| Lower trapezoid membership function | |

| , | Upper and lower reference points of interval type 2 fuzzy set |

| Denotes the membership value of the element in the upper trapezoidal membership function | |

| Denotes the membership value of the element in the lower trapezoidal membership function | |

| The distance between interval type 2 fuzzy sets and | |

| The distance between indicator and positive ideal solution | |

| The distance between indicator and positive ideal solution | |

| A | Weighted initial fuzzy matrix |

| The relation matrices given by k experts | |

| The degree of influence of indicator i on indicator j given by expert k | |

| Normalized weighted initial fuzzy matrix | |

| The level of influence of indicator i on indicator j | |

| Total relation matrix | |

| Defuzzied value of | |

| Indicators on control layer | |

| Element group on network layer | |

| Elements in element group | |

| Consistency indicator | |

| q | The maximum order of a matrix in the consistency test |

| CR | Consistency ratio |

| RI | Average random consistency index |

| Largest eigenvalue | |

| Eigenvector corresponding to the largest eigenvalue | |

| Supermatrix | |

| Weighted matrix | |

| Weighted supermatrix | |

| Weight of attributes | |

| The collection of positive ideal points | |

| Ideal points of indicators | |

| The collection of negative ideal points | |

| Ideal points of indicators | |

| Evaluation value | |

| Closeness coefficient | |

| Prospect value | |

| Probability weight function | |

| is value function, denotes the difference between attribute and the reference point | |

| The sensitivity of decision-makers to benefits | |

| The sensitivity of decision-makers to losses | |

| The sensitivity of decision-makers to benefits | |

| Evaluation of the j-th indicator by the i-th expert | |

| Semantic evaluation matrix | |

| Normalized semantic evaluation matrix | |

| Weighted normalized semantic evaluation matrix | |

| Positive ideal solution of evaluation value | |

| Negative ideal solution of evaluation value | |

| Closeness to the optimal ideal solution | |

| Resilience level in a given year |

| Linguistic Variable | IT2FS |

| Very high influence (VHI) | [(0.8,0.9,0.9,1;1,1), (0.85,0.9,0.9,0.95;0.9,0.9)] |

| High influence (HI) | [(0.6,0.7,0.7,0.8;1,1), (0.65,0.7,0.7,0.75;0.9,0.9)] |

| Low influence (LI) | [(0.4,0.5,0.5,0.6;1,1), (0.45,0.5,0.5,0.55;0.9,0.9)] |

| Very low influence (VLI) | [(0.2,0.3,0.3,0.4;1,1), (0.25,0.3,0.3,0.35;0.9,0.9)] |

| No influence (NI) | [(0,0.1,0.1,0.1;1,1), (0,0.1,0.1,0.05;0.9,0.9)] |

| Linguistic Variable | IT2FS |

|---|---|

| Absolutely strong (AS) | [(7,8,9,9;1,1), (7.2,8.2,8.8,9;0.8,0.8)] |

| (1/AS) | [(0.11,0.11,0.12,0.14;1,1), (0.11,0.11,0.12,0.14;0.8,0.8)] |

| Very strong (VS) | [(5,6,8,9;1,1), (5.2,6.2,7.8,8.8;0.8,0.8)] |

| (1/VS) | [(0.11,0.13,0.17,0.2;1,1), (0.11,0.13,0.16,0.19;0.8,0.8)] |

| Fairly strong (FS) | [(3,4,6,7;1,1), (3.2,4.2,5.8,6.8;0.8,0.8)] |

| (1/FS) | [(0.14,0.17,0.25,0.33;1,1), (0.15,0.17,0.24,0.31;0.8,0.8)] |

| Slightly strong (SS) | [(1,2,4,5;1,1), (1.2,2.2,3.8,4.8;0.8,0.8)] |

| (1/SS) | [(0.2,0.25,0.5,1;1,1), (0.21,0.26,0.45,0.83;0.8,0.8)] |

| Equal (E) | [(1,1,1,1;1,1), (1,1,1,1;1,1)] |

| (1/E) | [(1,1,1,1;1,1), (1,1,1,1;1,1)] |

| Linguistic Variable | IT2FS |

|---|---|

| Very poor (VP) | [(0,0,0,1;1,1), (0,0,0,0.5;0.9,0.9)] |

| Poor (P) | [(0,1,1,3;1,1), (0.5,1,1,2;0.9,0.9)] |

| Moderately poor (MP) | [(1,3,3,5;1,1), (2,3,3,4;0.9,0.9)] |

| Fair (F) | [(3,5,5,7;1,1), (4,5,5,6;0.9,0.9)] |

| Moderately good (MG) | [(5,7,7,9;1,1), (6,7,7,8;0.9,0.9)] |

| Expert 1 | A | B | C | D |

|---|---|---|---|---|

| A | 0.00 | LI | LI | NI |

| B | NI | 0.00 | HI | NI |

| C | NI | VLI | 0.00 | NI |

| D | NI | LI | HI | 0.00 |

| A | B | C | D | |

|---|---|---|---|---|

| A | 0 | [(0.18,0.23,0.23,0.27;1,1), (0.20,0.23,0.23,0.25;0.9,0.9)] | [(0.20,0.24,0.24,0.29;1,1), (0.22,0.24,0.24,0.27;0.9,0.9)] | [(0.07,0.12,0.12,0.15;1,1), (0.09,0.12,0.12,0.13;0.9,0.9)] |

| B | [(0.09,0.14,0.14,0.17;1,1), (0.11,0.14,0.14,0.15;0.9,0.9)] | 0 | [(0.22,0.26,0.26,0.31;1,1), (0.24,0.26,0.26,0.28;0.9,0.9)] | [(0.07,0.12,0.12,0.15;1,1) (0.09,0.12,0.12,0.13;0.9,0.9)] |

| C | [(0.09,0.14,0.14,0.17;1,1), (0.11,0.14,0.14,0.15;0.9,0.9)] | [(0.13,0.17,0.17,0.22;1,1), (0.15,0.17,0.17,0.19;0.9,0.9)] | 0 | [(0.07,0.12,0.12,0.15;1,1), (0.09,0.12,0.12,0.13;0.9,0.9)] |

| D | [(0.14,0.19,0.19,0.23;1,1), (0.16,0.19,0.19,0.20;0.9,0.9)] | [(0.29,0.33,0.33,0.38;1,1), (0.31,0.33,0.33,0.36;0.9,0.9)] | [(0.31,0.35,0.35,0.40;1,1), (0.33,0.35,0.35,0.37;0.9,0.9)] | 0 |

| A | B | C | D | |

|---|---|---|---|---|

| A | 0.0000 | 0.3977 | 0.4815 | 0.0000 |

| B | 0.0000 | 0.0000 | 0.4509 | 0.0000 |

| C | 0.0000 | 0.0000 | 0.3263 | 0.4077 |

| D | 0.4044 | 0.5348 | 0.6638 | 0.0000 |

| Expert 1 | B1 | B2 | B3 | B4 | B5 |

|---|---|---|---|---|---|

| B1 | E | 1/VS | E | E | 1/SS |

| B2 | VS | E | VS | VS | SS |

| B3 | E | 1/VS | E | E | 1/FS |

| B4 | E | 1/VS | E | E | 1/FS |

| B5 | SS | 1/SS | FS | FS | E |

| Expert | Indicator | Fuzzy Attribute Weights |

|---|---|---|

| Expert 1 | B1 | [(0.1757,0.1706,0.1707,0.1768;1,1), (0.1742,0.1701,0.1702,0.1749;0.8,0.8)] |

| B2 | [(0.0847,0.0814,0.0855,0.0923;1,1), (0.0835,0.0814,0.0846,0.0906;0.8,0.8)] | |

| B3 | [(0.2424,0.2419,0.2316,0.2196;1,1), (0.2427,0.2413,0.2333,0.2227;0.8,0.8)] | |

| B4 | [(0.1806,0.1854,0.1898,0.1918;1,1), (0.1820,0.1860,0.1895,0.1914;0.8,0.8)] | |

| B5 | [(0.3166,0.3207,0.3223,0.3195;1,1), (0.3176,0.3212,0.3224,0.3203;0.8,0.8)] | |

| Expert 2 | B1 | [(0.0626,0.0618,0.0657,0.0712;1,1), (0.0623,0.0619,0.0649,0.0698;0.8,0.8)] |

| B2 | [(0.1400,0.1384,0.1408,0.1455;1,1), (0.1395,0.1383,0.1403,0.1442;0.8,0.8)] | |

| B3 | [(0.1899,0.1895,0.1879,0.1868;1,1), (0.1899,0.1893,0.1882,0.1871;0.8,0.8)] | |

| B4 | [(0.2523,0.2542,0.2532,0.2508;1,1), (0.2530,0.2542,0.2536,0.2515;0.8,0.8)] | |

| B5 | [(0.3551,0.3562,0.3524,0.3457;1,1), (0.3553,0.3562,0.3530,0.3474;0.8,0.8)] | |

| Expert 3 | B1 | [(0.0591,0.0582,0.0699,0.0872;1,1), (0.0586,0.0586,0.0679,0.0825;0.8,0.8)] |

| B2 | [(0.1034,0.1106,0.1347,0.1604;1,1), (0.1048,0.1122,0.1313,0.1537;0.8,0.8)] | |

| B3 | [(0.1682,0.1729,0.2047,0.2414;1,1), (0.1685,0.1746,0.1999,0.2318;0.8,0.8)] | |

| B4 | [(0.0976,0.0999,0.1175,0.1381;1,1), (0.0978,0.1008,0.1148,0.1328;0.8,0.8)] | |

| B5 | [(0.5717,0.5583,0.4732,0.3729;1,1), (0.5704,0.5538,0.4861,0.3992;0.8,0.8)] |

| Indicator | Defuzzified Weight | Normalized Weight | Objective Weight |

|---|---|---|---|

| A | 0.09 | 0.29 | |

| A1 | 0.03 | 0.06 | 0.02 |

| A2 | 0.04 | 0.09 | 0.03 |

| A3 | 0.06 | 0.15 | 0.04 |

| A4 | 0.04 | 0.09 | 0.03 |

| A5 | 0.17 | 0.39 | 0.11 |

| A6 | 0.05 | 0.11 | 0.03 |

| A7 | 0.05 | 0.12 | 0.03 |

| B | 0.09 | 0.28 | |

| B1 | 0.03 | 0.10 | 0.03 |

| B2 | 0.04 | 0.12 | 0.04 |

| B3 | 0.06 | 0.20 | 0.06 |

| B4 | 0.07 | 0.22 | 0.06 |

| B5 | 0.11 | 0.36 | 0.10 |

| C | 0.11 | 0.35 | |

| C1 | 0.04 | 0.08 | 0.03 |

| C2 | 0.19 | 0.40 | 0.14 |

| C3 | 0.05 | 0.11 | 0.04 |

| C4 | 0.11 | 0.24 | 0.08 |

| C5 | 0.08 | 0.17 | 0.07 |

| D | 0.02 | 0.08 | |

| D1 | 0.05 | 0.17 | 0.01 |

| D2 | 0.06 | 0.19 | 0.01 |

| D3 | 0.07 | 0.23 | 0.02 |

| D4 | 0.13 | 0.41 | 0.03 |

| Indicator | Expert 1 | Expert 2 | Expert 3 | Indicator | Expert 1 | Expert 2 | Expert 3 |

|---|---|---|---|---|---|---|---|

| A1 | VG | G | VG | B5 | MG | F | F |

| A2 | G | G | F | C1 | G | MG | MG |

| A3 | MG | F | F | C2 | G | G | MG |

| A4 | MG | F | MG | C3 | G | MP | F |

| A5 | VG | MG | G | C4 | G | F | F |

| A6 | VG | MG | MG | C5 | F | MP | G |

| A7 | VG | F | G | D1 | F | VP | G |

| B1 | F | MP | MP | D2 | G | F | F |

| B2 | G | F | MP | D3 | MG | MG | F |

| B3 | MG | MP | MG | D4 | MG | MP | F |

| B4 | VG | MG | MG | - | - | - | - |

| Indicator | Expert 1 | Expert 2 | Expert 3 | Indicator | Expert 1 | Expert 2 | Expert 3 |

| A1 | G | G | G | B5 | MG | F | F |

| A2 | G | F | F | C1 | G | MG | MG |

| A3 | F | G | F | C2 | G | MG | MG |

| A4 | G | F | F | C3 | G | MP | F |

| A5 | VG | MG | G | C4 | G | F | F |

| A6 | VG | MG | MG | C5 | G | F | F |

| A7 | VG | G | MG | D1 | F | MP | F |

| B1 | MG | F | F | D2 | G | MG | F |

| B2 | G | MP | F | D3 | MG | MG | F |

| B3 | VG | MG | MG | D4 | MG | F | F |

| B4 | VG | MG | MG | - | - | - | - |

| Indicator | Expert 1 | Expert 2 | Expert 3 | Indicator | Expert 1 | Expert 2 | Expert 3 |

|---|---|---|---|---|---|---|---|

| A1 | F | G | MG | A2 | VG | MG | MG |

| A3 | G | MG | MG | A4 | F | MP | F |

| A5 | VG | G | G | A6 | VG | G | MG |

| A7 | G | G | MG | B1 | F | F | MG |

| B2 | G | F | MP | B3 | G | G | MG |

| B4 | VG | G | MG | B5 | MG | F | F |

| C1 | G | F | MP | C2 | MP | F | F |

| C3 | G | MP | F | C4 | G | F | F |

| C5 | F | F | G | D1 | MP | F | F |

| D2 | G | MG | F | D3 | MG | G | MG |

| D4 | G | MP | MG | - | - | - | - |

| Indicator | Expert 1 | Expert 2 | Expert 3 | Indicator | Expert 1 | Expert 2 | Expert 3 |

|---|---|---|---|---|---|---|---|

| A1 | G | G | G | B5 | MG | F | F |

| A2 | VG | G | MG | C1 | MG | MG | MG |

| A3 | VG | G | G | C2 | G | MG | MG |

| A4 | F | F | MG | C3 | G | MP | F |

| A5 | VG | G | G | C4 | G | F | MG |

| A6 | VG | VG | MG | C5 | G | MG | F |

| A7 | G | VG | MG | D1 | G | MP | F |

| B1 | G | VG | MG | D2 | G | MG | F |

| B2 | G | F | F | D3 | G | MG | MG |

| B3 | G | G | MG | D4 | G | MP | MG |

| B4 | VG | G | MG | - | - | - | - |

| Indicator | Expert 1 | Expert 2 | Expert 3 | Indicator | Expert 1 | Expert 2 | Expert 3 |

|---|---|---|---|---|---|---|---|

| A1 | MG | F | F | B5 | G | F | F |

| A2 | VG | VG | MG | C1 | MG | F | MP |

| A3 | VG | VG | G | C2 | MG | MG | MG |

| A4 | F | F | MG | C3 | G | F | F |

| A5 | VG | G | G | C4 | MG | G | G |

| A6 | VG | VG | MG | C5 | G | MG | G |

| A7 | VG | G | VG | D1 | G | F | F |

| B1 | G | VG | MG | D2 | G | G | G |

| B2 | G | F | F | D3 | MG | G | G |

| B3 | G | G | G | D4 | VG | G | G |

| B4 | VG | G | MG | - | - | - | - |

| Indicator | Results |

|---|---|

| A1 | [(0.1390,0.1621,0.1621,0.1679;1,1), (0.1507,0.1621,0.1621,0.1651;0.9,0.9)] |

| A2 | [(0.1481,0.2076,0.2076,0.2491;1,1), (0.1782,0.2076,0.2076,0.2287;0.9,0.9)] |

| A3 | [(0.1510,0.2375,0.2375,0.3232;1,1), (0.1944,0.2375,0.2375,0.2804;0.9,0.9)] |

| A4 | [(0.1167,0.1732,0.1732,0.2291;1,1), (0.1451,0.1732,0.1732,0.2012;0.9,0.9)] |

| A5 | [(0.7824,0.9858,0.9858,1.1102;1,1), (0.8851,0.9858,0.9858,1.0494;0.9,0.9)] |

| A6 | [(0.1809,0.2344,0.2344,0.2772;1,1), (0.2080,0.2344,0.2344,0.2563;0.9,0.9)] |

| A7 | [(0.1864,0.2490,0.2490,0.2885;1,1), (0.2185,0.2490,0.2490,0.2694;0.9,0.9)] |

| B1 | [(0.0384,0.0948,0.0948,0.1490;1,1), (0.0671,0.0948,0.0948,0.1220;0.9,0.9)] |

| B2 | [(0.0966,0.1797,0.1797,0.2468;1,1), (0.1401,0.1797,0.1797,0.2139;0.9,0.9)] |

| B3 | [(0.0986,0.2294,0.2294,0.3506;1,1), (0.1663,0.2294,0.2294,0.2905;0.9,0.9)] |

| B4 | [(0.3744,0.4852,0.4852,0.5738;1,1), (0.4304,0.4852,0.4852,0.5304;0.9,0.9)] |

| B5 | [(0.3651,0.5741,0.5741,0.7812;1,1), (0.4699,0.5741,0.5741,0.6778;0.9,0.9)] |

| C1 | [(0.1629,0.2216,0.2216,0.2714;1,1), (0.1923,0.2216,0.2216,0.2467;0.9,0.9)] |

| C2 | [(0.8717,1.1530,1.1530,1.3450;1,1), (1.0126,1.1530,1.1530,1.2498;0.9,0.9)] |

| C3 | [(0.1047,0.1947,0.1947,0.2675;1,1), (0.1518,0.1947,0.1947,0.2319;0.9,0.9)] |

| C4 | [(0.3309,0.5057,0.5057,0.6555;1,1), (0.4190,0.5057,0.5057,0.5815;0.9,0.9)] |

| C5 | [(0.1877,0.3490,0.3490,0.4795;1,1), (0.2721,0.3490,0.3490,0.4156;0.9,0.9)] |

| D1 | [(0.0000,0.0000,0.0000,0.0348;1,1), (0.0000,0.0000,0.0000,0.0229;0.9,0.9)] |

| D2 | [(0.0582,0.0889,0.0889,0.1152;1,1), (0.0737,0.0889,0.0889,0.1022;0.9,0.9)] |

| D3 | [(0.0750,0.1113,0.1113,0.1472;1,1), (0.0932,0.1113,0.1113,0.1293;0.9,0.9)] |

| D4 | [(0.0772,0.1477,0.1477,0.2130;1,1), (0.1138,0.1477,0.1477,0.1806;0.9,0.9)] |

| Indicator | Results |

|---|---|

| A1 | [(0.1175,0.1511,0.1511,0.1679), (0.1343,0.1511,0.1511,0.1595;0.9,0.9)] |

| A2 | [(0.1116,0.1707,0.1707,0.2212), (0.1414,0.1707,0.1707,0.1962;0.9,0.9)] |

| A3 | [(0.1689,0.2582,0.2582,0.3347), (0.2140,0.2582,0.2582,0.2969;0.9,0.9)] |

| A4 | [(0.1167,0.1732,0.1732,0.2291), (0.1451,0.1732,0.1732,0.2012;0.9,0.9)] |

| A5 | [(0.7824,0.9858,0.9858,1.1102), (0.8851,0.9858,0.9858,1.0494;0.9,0.9)] |

| A6 | [(0.1809,0.2344,0.2344,0.2772), (0.2080,0.2344,0.2344,0.2563;0.9,0.9)] |

| A7 | [(0.2033,0.2689,0.2689,0.3137), (0.2361,0.2689,0.2689,0.2915;0.9,0.9)] |

| B1 | [(0.0948,0.1490,0.1490,0.2028), (0.1220,0.1490,0.1490,0.1759;0.9,0.9)] |

| B2 | [(0.0966,0.1797,0.1797,0.2468), (0.1401,0.1797,0.1797,0.2139;0.9,0.9)] |

| B3 | [(0.3506,0.4544,0.4544,0.5373), (0.4031,0.4544,0.4544,0.4967;0.9,0.9)] |

| B4 | [(0.3744,0.4852,0.4852,0.5738), (0.4304,0.4852,0.4852,0.5304;0.9,0.9)] |

| B5 | [(0.3651,0.5741,0.5741,0.7812), (0.4699,0.5741,0.5741,0.6778;0.9,0.9)] |

| C1 | [(0.1629,0.2216,0.2216,0.2714), (0.1923,0.2216,0.2216,0.2467;0.9,0.9)] |

| C2 | [(0.7792,1.0604,1.0604,1.2986), (0.9200,1.0604,1.0604,1.1802;0.9,0.9)] |

| C3 | [(0.1047,0.1947,0.1947,0.2675), (0.1518,0.1947,0.1947,0.2319;0.9,0.9)] |

| C4 | [(0.4388,0.6152,0.6152,0.7383), (0.5280,0.6152,0.6152,0.6777;0.9,0.9)] |

| C5 | [(0.2707,0.4138,0.4138,0.5364), (0.3429,0.4138,0.4138,0.4758;0.9,0.9)] |

| D1 | [(0.0262,0.0532,0.0532,0.0790), (0.0401,0.0532,0.0532,0.0661;0.9,0.9)] |

| D2 | [(0.0689,0.0994,0.0994,0.1253), (0.0843,0.0994,0.0994,0.1125;0.9,0.9)] |

| D3 | [(0.0750,0.1113,0.1113,0.1472), (0.0932,0.1113,0.1113,0.1293;0.9,0.9)] |

| D4 | [(0.1114,0.1751,0.1751,0.2383), (0.1434,0.1751,0.1751,0.2068;0.9,0.9)] |

| Indicator | Results |

|---|---|

| A1 | [(0.0792,0.1143,0.1143,0.1440), (0.0969,0.1143,0.1143,0.1293;0.9,0.9)] |

| A2 | [(0.1707,0.2212,0.2212,0.2615), (0.1962,0.2212,0.2212,0.2418;0.9,0.9)] |

| A3 | [(0.2375,0.3232,0.3232,0.3958), (0.2804,0.3232,0.3232,0.3597;0.9,0.9)] |

| A4 | [(0.0576,0.1167,0.1167,0.1732), (0.0879,0.1167,0.1167,0.1451;0.9,0.9)] |

| A5 | [(0.8753,1.0719,1.0719,1.1499), (0.9742,1.0719,1.0719,1.1113;0.9,0.9)] |

| A6 | [(0.2023,0.2549,0.2549,0.2871), (0.2289,0.2549,0.2549,0.2714;0.9,0.9)] |

| A7 | [(0.2033,0.2689,0.2689,0.3137), (0.2361,0.2689,0.2689,0.2915;0.9,0.9)] |

| B1 | [(0.0948,0.1490,0.1490,0.2028), (0.1220,0.1490,0.1490,0.1759;0.9,0.9)] |

| B2 | [(0.0966,0.1797,0.1797,0.2468), (0.1401,0.1797,0.1797,0.2139;0.9,0.9)] |

| B3 | [(0.3607,0.4771,0.4771,0.5565), (0.4190,0.4771,0.4771,0.5171;0.9,0.9)] |

| B4 | [(0.4188,0.5276,0.5276,0.5943), (0.4738,0.5276,0.5276,0.5617;0.9,0.9)] |

| B5 | [(0.3651,0.5741,0.5741,0.7812), (0.4699,0.5741,0.5741,0.6778;0.9,0.9)] |

| C1 | [(0.0803,0.1494,0.1494,0.2052), (0.1165,0.1494,0.1494,0.1779;0.9,0.9)] |

| C2 | [(0.2898,0.5875,0.5875,0.8717), (0.4423,0.5875,0.5875,0.7302;0.9,0.9)] |

| C3 | [(0.1047,0.1947,0.1947,0.2675), (0.1518,0.1947,0.1947,0.2319;0.9,0.9)] |

| C4 | [(0.3309,0.5057,0.5057,0.6555), (0.4190,0.5057,0.5057,0.5815;0.9,0.9)] |

| C5 | [(0.2707,0.4138,0.4138,0.5364), (0.3429,0.4138,0.4138,0.4758;0.9,0.9)] |

| D1 | [(0.0262,0.0532,0.0532,0.0790), (0.0401,0.0532,0.0532,0.0661;0.9,0.9)] |

| D2 | [(0.0689,0.0994,0.0994,0.1253), (0.0843,0.0994,0.0994,0.1125;0.9,0.9)] |

| D3 | [(0.0995,0.1354,0.1354,0.1658), (0.1175,0.1354,0.1354,0.1507;0.9,0.9)] |

| D4 | [(0.1024,0.1797,0.1797,0.2399), (0.1434,0.1797,0.1797,0.2105;0.9,0.9)] |

| Indicator | Results |

|---|---|

| A1 | [(0.1175,0.1511,0.1511,0.1679), (0.1343,0.1511,0.1511,0.1595;0.9,0.9)] |

| A2 | [(0.1909,0.2405,0.2405,0.2709), (0.2160,0.2405,0.2405,0.2561;0.9,0.9)] |

| A3 | [(0.3232,0.3958,0.3958,0.4246), (0.3597,0.3958,0.3958,0.4103;0.9,0.9)] |

| A4 | [(0.1167,0.1732,0.1732,0.2291), (0.1451,0.1732,0.1732,0.2012;0.9,0.9)] |

| A5 | [(0.8753,1.0719,1.0719,1.1499), (0.9742,1.0719,1.0719,1.1113;0.9,0.9)] |

| A6 | [(0.2200,0.2640,0.2640,0.2871), (0.2424,0.2640,0.2640,0.2760;0.9,0.9)] |

| A7 | [(0.2211,0.2785,0.2785,0.3137), (0.2501,0.2785,0.2785,0.2965;0.9,0.9)] |

| B1 | [(0.1813,0.2284,0.2284,0.2572), (0.2051,0.2284,0.2284,0.2431;0.9,0.9)] |

| B2 | [(0.1393,0.2130,0.2130,0.2761), (0.1765,0.2130,0.2130,0.2449;0.9,0.9)] |

| B3 | [(0.3607,0.4771,0.4771,0.5565), (0.4190,0.4771,0.4771,0.5171;0.9,0.9)] |

| B4 | [(0.4188,0.5276,0.5276,0.5943), (0.4738,0.5276,0.5276,0.5617;0.9,0.9)] |

| B5 | [(0.3651,0.5741,0.5741,0.7812), (0.4699,0.5741,0.5741,0.6778;0.9,0.9)] |

| C1 | [(0.1456,0.2216,0.2216,0.2714), (0.1923,0.2216,0.2216,0.2467;0.9,0.9)] |

| C2 | [(0.7792,1.0604,1.0604,1.2986), (0.9200,1.0604,1.0604,1.1802;0.9,0.9)] |

| C3 | [(0.1047,0.1947,0.1947,0.2675), (0.1518,0.1947,0.1947,0.2319;0.9,0.9)] |

| C4 | [(0.3923,0.5658,0.5658,0.7128), (0.4797,0.5658,0.5658,0.6400;0.9,0.9)] |

| C5 | [(0.3210,0.3210,0.3210,0.3210), (0.3210,0.3210,0.3210,0.3210;0.9,0.9)] |

| D1 | [(0.0348,0.0647,0.0647,0.0889), (0.0505,0.0647,0.0647,0.0771;0.9,0.9)] |

| D2 | [(0.0689,0.0994,0.0994,0.1253), (0.0843,0.0994,0.0994,0.1125;0.9,0.9)] |

| D3 | [(0.0995,0.1354,0.1354,0.1658), (0.1175,0.1354,0.1354,0.1507;0.9,0.9)] |

| D4 | [(0.1024,0.1797,0.1797,0.2399), (0.1434,0.1797,0.1797,0.2105;0.9,0.9)] |

| Indicator | Results |

|---|---|

| A1 | [(0.0597,0.0939,0.0939,0.1278), (0.0769,0.0939,0.0939,0.1109;0.9,0.9)] |

| A2 | [(0.2076,0.2491,0.2491,0.2709), (0.2287,0.2491,0.2491,0.2605;0.9,0.9)] |

| A3 | [(0.3514,0.4099,0.4099,0.4246), (0.3809,0.4099,0.4099,0.4174;0.9,0.9)] |

| A4 | [(0.0985,0.1732,0.1732,0.2291), (0.1451,0.1732,0.1732,0.2012;0.9,0.9)] |

| A5 | [(0.8753,1.0719,1.0719,1.1499), (0.9742,1.0719,1.0719,1.1113;0.9,0.9)] |

| A6 | [(0.2200,0.2640,0.2640,0.2871), (0.2424,0.2640,0.2640,0.2760;0.9,0.9)] |

| A7 | [(0.2689,0.3137,0.3137,0.3249), (0.2915,0.3137,0.3137,0.3194;0.9,0.9)] |

| B1 | [(0.1813,0.2284,0.2284,0.2572), (0.2051,0.2284,0.2284,0.2431;0.9,0.9)] |

| B2 | [(0.1393,0.2130,0.2130,0.2761), (0.1765,0.2130,0.2130,0.2449;0.9,0.9)] |

| B3 | [(0.4035,0.5188,0.5188,0.5764), (0.4611,0.5188,0.5188,0.5476;0.9,0.9)] |

| B4 | [(0.4188,0.5276,0.5276,0.5943), (0.4738,0.5276,0.5276,0.5617;0.9,0.9)] |

| B5 | [(0.4084,0.6242,0.6242,0.8091), (0.5172,0.6242,0.6242,0.7177;0.9,0.9)] |

| C1 | [(0.0718,0.1374,0.1374,0.1981), (0.1058,0.1374,0.1374,0.1680;0.9,0.9)] |

| C2 | [(0.6966,0.6966,0.6966,0.6966), (0.6966,0.6966,0.6966,0.6966;0.9,0.9)] |

| C3 | [(0.1510,0.2309,0.2309,0.2992), (0.1913,0.2309,0.2309,0.2654;0.9,0.9)] |

| C4 | [(0.5203,0.6882,0.6882,0.8028), (0.6044,0.6882,0.6882,0.7459;0.9,0.9)] |

| C5 | [(0.4257,0.4257,0.4257,0.4257), (0.4257,0.4257,0.4257,0.4257;0.9,0.9)] |

| D1 | [(0.0666,0.0934,0.0934,0.1120), (0.0801,0.0934,0.0934,0.1029;0.9,0.9)] |

| D2 | [(0.1023,0.1315,0.1315,0.1461), (0.1169,0.1315,0.1315,0.1388;0.9,0.9)] |

| D3 | [(0.1113,0.1472,0.1472,0.1718), (0.1293,0.1472,0.1472,0.1596;0.9,0.9)] |

| D4 | [(0.2383,0.2919,0.2919,0.3131), (0.2653,0.2919,0.2919,0.3026;0.9,0.9)] |

| Years | 2018 | 2019 | 2020 | 2021 | 2022 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| + | − | + | − | + | − | + | − | + | − | |

| A1 | 0.00 | 0.08 | 0.04 | 0.06 | 0.13 | 0.03 | 0.04 | 0.06 | 0.17 | 0.00 |

| A2 | 0.12 | 0.04 | 0.20 | 0.00 | 0.08 | 0.06 | 0.03 | 0.08 | 0.00 | 0.09 |

| A3 | 0.39 | 0.00 | 0.35 | 0.03 | 0.21 | 0.09 | 0.05 | 0.16 | 0.00 | 0.17 |

| A4 | 0.00 | 0.07 | 0.00 | 0.07 | 0.15 | 0.00 | 0.00 | 0.07 | 0.02 | 0.06 |

| A5 | 0.20 | 0.00 | 0.20 | 0.00 | 0.00 | 0.09 | 0.00 | 0.09 | 0.00 | 0.09 |

| A6 | 0.08 | 0.00 | 0.08 | 0.00 | 0.03 | 0.03 | 0.00 | 0.04 | 0.00 | 0.04 |

| A7 | 0.17 | 0.00 | 0.12 | 0.00 | 0.12 | 0.00 | 0.12 | 0.00 | 0.00 | 0.07 |

| B1 | 0.31 | 0.00 | 0.20 | 0.06 | 0.20 | 0.06 | 0.00 | 0.14 | 0.00 | 0.14 |

| B2 | 0.10 | 0.00 | 0.10 | 0.00 | 0.10 | 0.00 | 0.00 | 0.04 | 0.00 | 0.04 |

| B3 | 0.62 | 0.00 | 0.15 | 0.22 | 0.15 | 0.22 | 0.11 | 0.24 | 0.00 | 0.27 |

| B4 | 0.11 | 0.00 | 0.11 | 0.00 | 0.00 | 0.05 | 0.00 | 0.05 | 0.00 | 0.05 |

| B5 | 0.12 | 0.00 | 0.12 | 0.00 | 0.12 | 0.00 | 0.12 | 0.00 | 0.00 | 0.06 |

| C1 | 0.00 | 0.09 | 0.00 | 0.09 | 0.19 | 0.02 | 0.02 | 0.09 | 0.21 | 0.00 |

| C2 | 0.00 | 0.50 | 0.22 | 0.43 | 1.12 | 0.00 | 0.22 | 0.43 | 0.95 | 0.20 |

| C3 | 0.10 | 0.00 | 0.10 | 0.00 | 0.10 | 0.00 | 0.10 | 0.00 | 0.00 | 0.05 |

| C4 | 0.41 | 0.00 | 0.19 | 0.11 | 0.41 | 0.00 | 0.29 | 0.07 | 0.00 | 0.18 |

| C5 | 0.28 | 0.00 | 0.19 | 0.08 | 0.19 | 0.08 | 0.26 | 0.10 | 0.00 | 0.13 |

| D1 | 0.22 | 0.00 | 0.11 | 0.06 | 0.11 | 0.06 | 0.08 | 0.07 | 0.00 | 0.10 |

| D2 | 0.11 | 0.00 | 0.09 | 0.02 | 0.09 | 0.02 | 0.09 | 0.02 | 0.00 | 0.05 |

| D3 | 0.10 | 0.00 | 0.10 | 0.00 | 0.04 | 0.03 | 0.04 | 0.03 | 0.00 | 0.04 |

| D4 | 0.33 | 0.00 | 0.27 | 0.04 | 0.27 | 0.04 | 0.27 | 0.04 | 0.00 | 0.15 |

| 0.32 | 0.41 | 0.19 | 0.50 | 0.35 | ||||||

| Rank | 4 | 2 | 5 | 1 | 3 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, A.; Li, P.; Sun, L.; Su, C.; Wang, X. Evaluation Research on Resilience of Coal-to-Liquids Industrial Chain and Supply Chain. Systems 2024, 12, 395. https://doi.org/10.3390/systems12100395

Wu A, Li P, Sun L, Su C, Wang X. Evaluation Research on Resilience of Coal-to-Liquids Industrial Chain and Supply Chain. Systems. 2024; 12(10):395. https://doi.org/10.3390/systems12100395

Chicago/Turabian StyleWu, Anbo, Pingfan Li, Linhui Sun, Chang Su, and Xinping Wang. 2024. "Evaluation Research on Resilience of Coal-to-Liquids Industrial Chain and Supply Chain" Systems 12, no. 10: 395. https://doi.org/10.3390/systems12100395

APA StyleWu, A., Li, P., Sun, L., Su, C., & Wang, X. (2024). Evaluation Research on Resilience of Coal-to-Liquids Industrial Chain and Supply Chain. Systems, 12(10), 395. https://doi.org/10.3390/systems12100395