The Complex Approach to Environmental and Technological Project Management to Enhance the Sustainability of Industrial Systems

Abstract

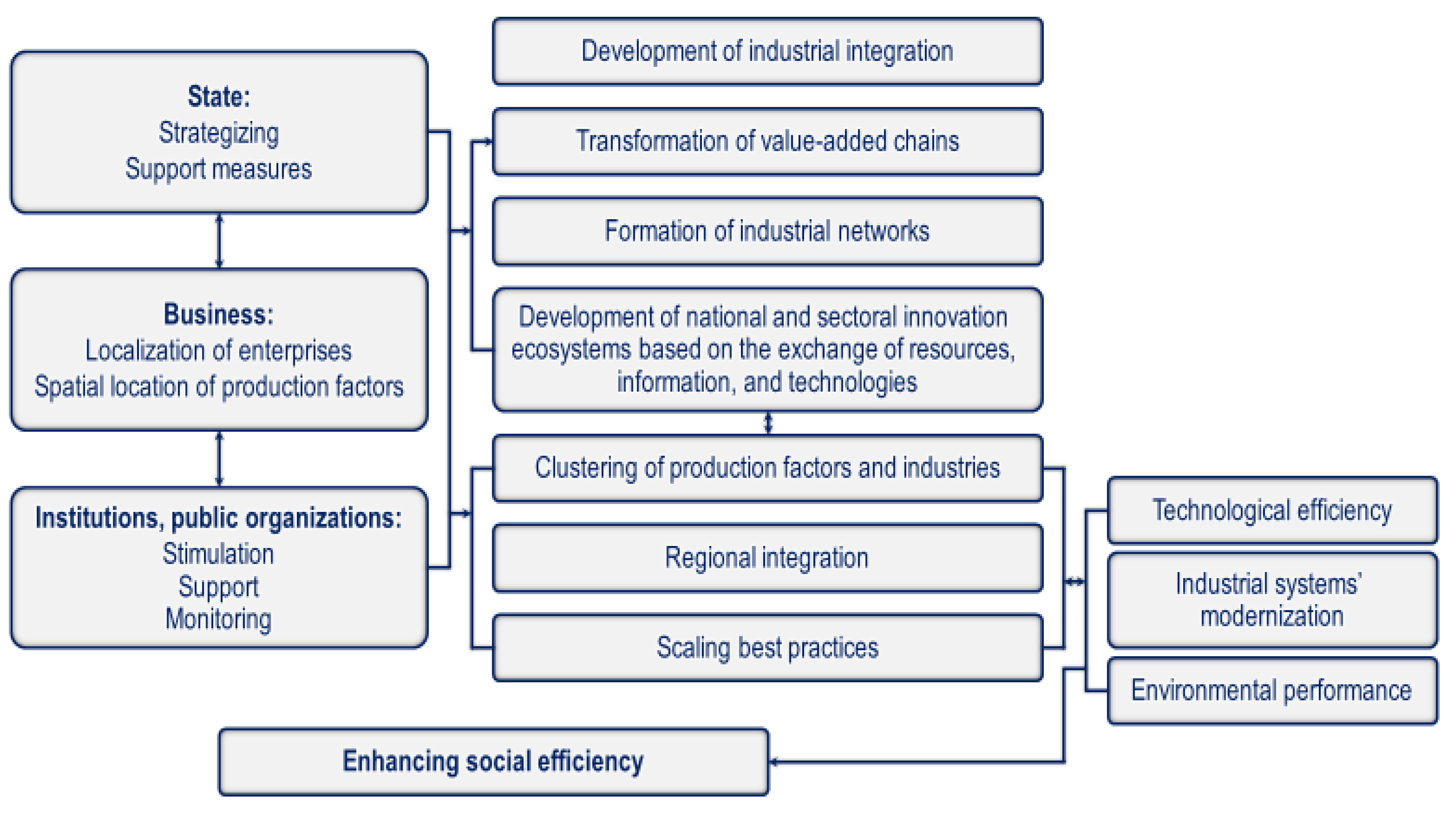

1. Introduction

2. Literature Review and Hypothesis Development

3. Research Methodology

- cross-sectoral technological and environmental project requirements;

- goals of numerous project actors and stakeholders with possible conflicts of interest;

- infrastructure development of those territories that are part of the project implementation.

- environmental impact assessment (of the potential partner industries) and strategic social and environmental assessment (of the planned symbiosis as a system);

- democracy in making mutually acceptable decisions for all project participants, i.e., recognition of the right to participate in the decision-making process of all interested parties.

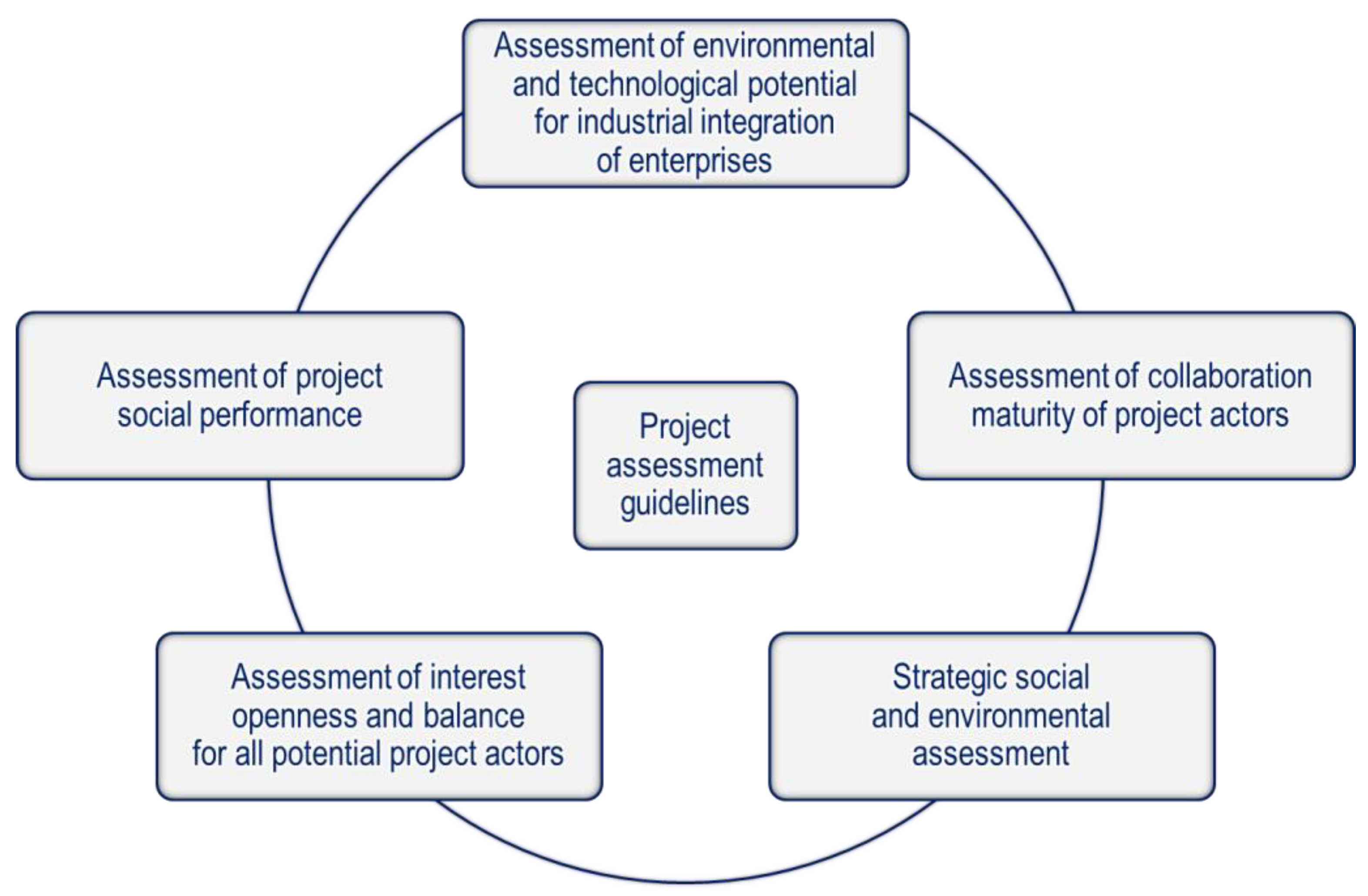

- Assessment of environmental and technological potential for industrial systems of enterprises involves technological capital; human capital; natural capital; secondary resources (waste to be recycled) as a special type of capital; processes; finance; and consumers for economic, environmental, and social subsystems in terms of the technological development both for an individual actor and for an industrial ecosystem. The internal company policy and potential of project actors should resemble the strategic direction of the implemented project.

- Assessment of collaboration maturity of the project actors presupposes goal openness of all project participants; an impeccable reputation; positive experience of long-term cooperation; and similarity of corporate cultures. We believe that cooperation and trust are the key factors for IETP implementation.

- Strategic social and environmental assessment entails implementing environmental industrial policy at the regional level. The project should contribute towards sustainable development of territories; enhancement of the resource efficiency and environmental performance of enterprises; and formation of a circular economy. Therefore, the project implementation should provide for crucial scientific, technological, and socio-economic effects for enterprises and industries.

- Assessment of interest openness and balance for all potential project actors involves considering various interests of enterprises and territories. Since these interests significantly differ in several aspects, goal alignment is vital for the IETP development and implementation.

- Assessment of project social performance.

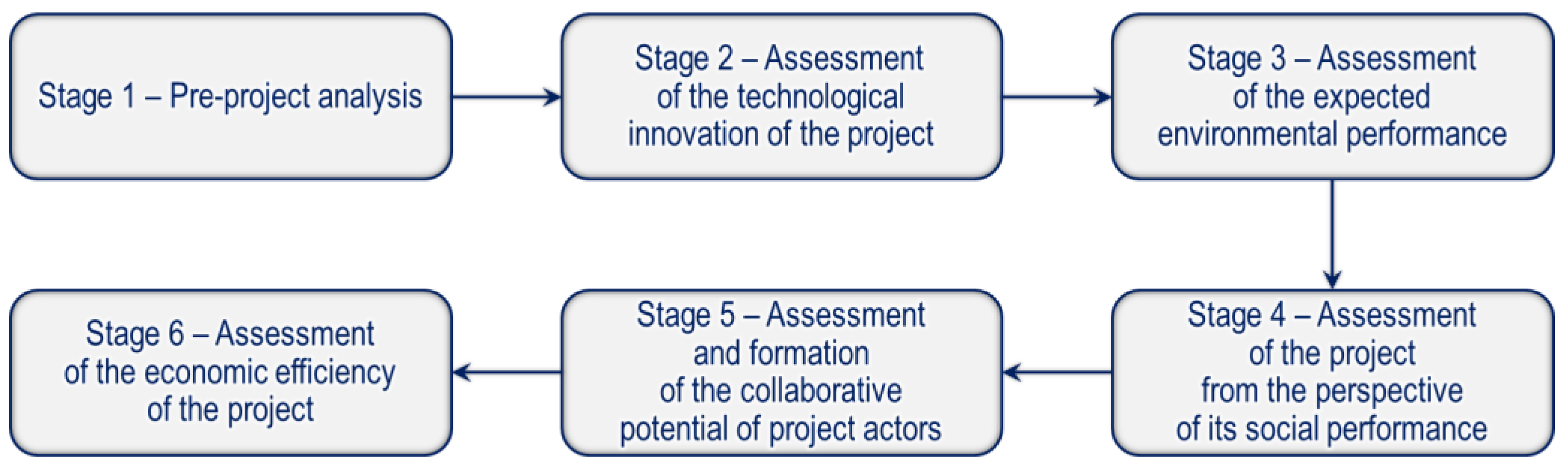

- Analysis of problems of enterprises, the industry, and the territory (expert analysis, analytics, forecast).

- Inventory of enterprises, industries, and territory resources based on assessment of their potential (expert assessment).

- Analysis of the existing business processes, logistical connections and information flows between enterprises and territories.

- Analysis of the infrastructure of the technological development of the territory.

- Formation of a project evaluation criteria system for meeting the objectives of all project actors.

- Determination of key characteristics of technological solutions and assessment of the project’s strategic technological perspective for all actors.

- Assessing the project by comparing threshold values of the project’s innovativeness with the trend indicators in development of maximum indicators of such characteristics of the market.

- Analysis of the projected outputs due to expected improvements in productivity, technological efficiency, and management systems.

- Assessment of resource consumption by the project actors (consumption of raw materials, energy, water, etc.).

- Assessment of the project compliance with BAT requirements; these requirements cover sectoral environmental performance and resource efficiency levels and, for some sectors, carbon intensity of products (see a more detailed description below).

- Assessment of the project’s environmental risks.

- Assessment of additional income for the project actors, which in the forecast will arise with waste recycling, water closed loops, etc.

- Assessment of the anticipated changes in the state of the environment (“environmental friendliness of the project”).

- Analysis of the expected changes in the territory’s infrastructure, job growth, business opportunities, etc.

- Forecast of the project’s impact on future generations’ development (scientific, educational, technological, and socio-economic effects for the territory).

- Assessment of the environmental and technological potential of industrial systems.

- Assessment of the collaboration maturity of the project actors.

- Assessment of the openness and balance of interests of all potential project actors.

- Formation of a system of goals and motivation for project implementation for the project actors.

- Cost-benefit analysis for each project actor.

- Analysis of the project’s economic feasibility for the actors and all project stakeholders (potential benefits from the project for some participants do not cause direct or indirect damage to other participants).

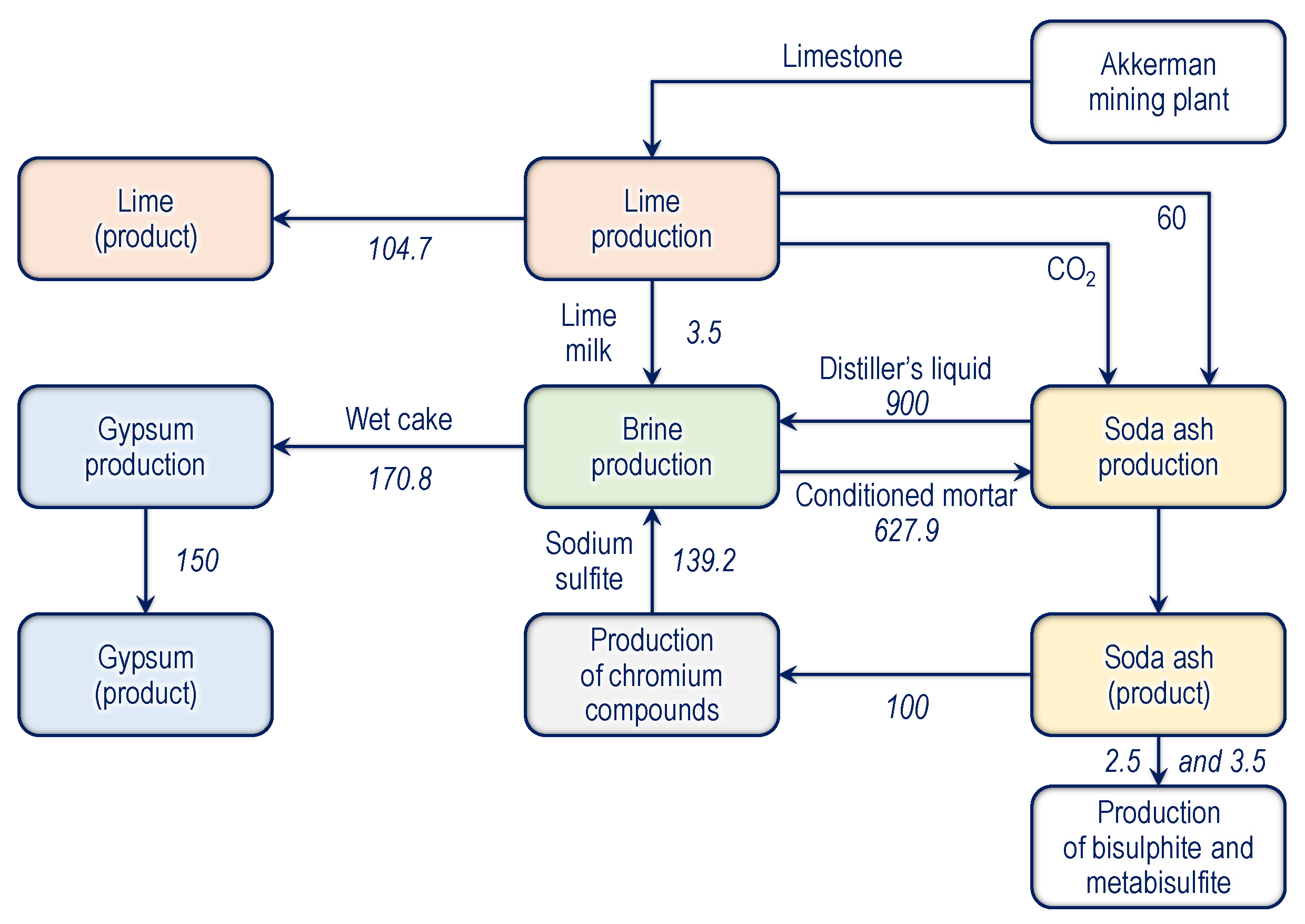

4. A Case Study of Industrial Symbioses in Novotroitsk Advanced Socio-Economic Development Territory

4.1. Data Sources and Experts Involved in Case Study Implementation

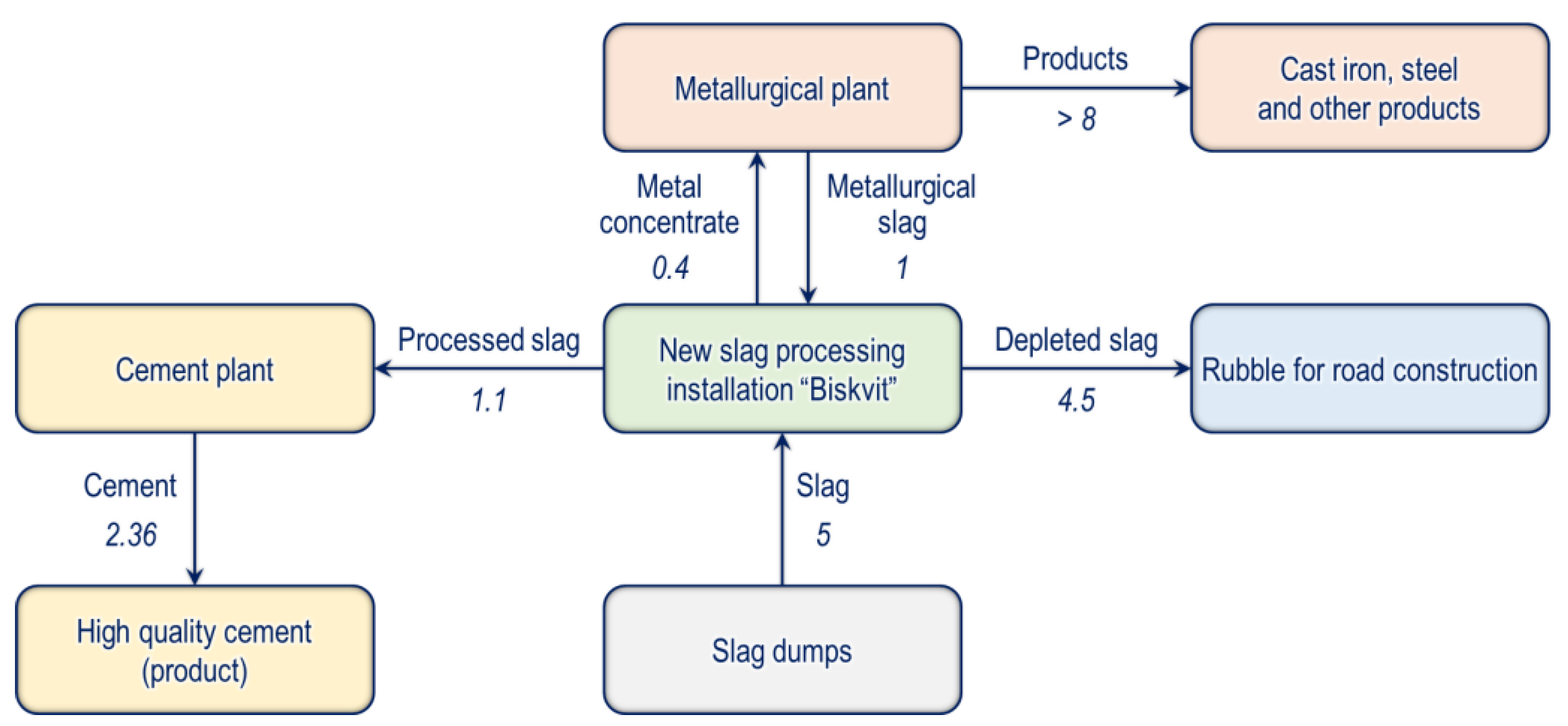

4.2. Case Study Results

- − reduction in specific heat energy consumption to 4.25 GJ per tonne of soda (the range of values established in BREF 19-2020 is 4.6–5.9 GJ per tonne of soda);

- − reduction in dolomite and limestone consumption by 160 thousand tonnes per year;

- − reduction in the specific amount of waste from 2.5 to 1.1 tonnes of sludge per 1 tonne of sodium monochromate generated in the main production;

- − extra absorption of over 60 thousand tonnes of CO2 [68].

- − increased employment levels (430 jobs with a more comfortable work environment created);

- − additional tax revenues of RUB 900 million for the regional budget;

- − increased accessibility and quality of services through the development of social infrastructure, including construction and repair of housing stock, transport development, further development and maintenance of urban municipal infrastructure (in 2022 the total area of refurbished premises was about 7.0 thousand m2; 24 residential buildings with 780 apartments were redeveloped);

- − solving socially significant issues and developing the town (historical part of the town was reconstructed; the Ice Palace built; over RUB 750 million was allocated for renovation of children’s educational institutions, healthcare, cultural, and sports facilities).

5. Discussion

6. Conclusions

- The article deals with a type of industrial symbiosis in which surplus resources or waste or by-products are exchanged between enterprises located close to each other (territorial proximity).

- Indicators selected for evaluation must be applicable to all potential participants in the symbiosis. Indicators can be calculated by quantitative characteristics or by qualitative characteristics through expert assessment.

- Indicator evaluations can be quantified, where the dynamics of the indicator are assessed, and scores are assigned. For qualitative indicators, a scale with a description of grades is proposed.

- Experts jointly assign weights to the indicators. Distribution of weighting coefficients can be done by the initiators of the study.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tolstykh, T.; Shmeleva, N.; Gamidullaeva, L.; Krasnobaeva, V. The Role of Collaboration in the Development of Industrial Enterprises Integration. Sustainability 2023, 15, 7180. [Google Scholar] [CrossRef]

- Tolstykh, T.; Gamidullaeva, L.; Shmeleva, N. Approach to the Formation of an Innovation Portfolio in Industrial Ecosystems Based on the Life Cycle Concept. J. Open Innov. Technol. Mark. Complex. 2020, 6, 151. [Google Scholar] [CrossRef]

- Tolstykh, T.; Shmeleva, N.; Gamidullaeva, L. Evaluation of Circular and Integration Potentials of Innovation Ecosystems for Industrial Sustainability. Sustainability 2020, 12, 4574. [Google Scholar] [CrossRef]

- Andrusenko, V.; Penzin, A. The relevance of assessing social performance of investment projects in managing state property. Real Estate Mark. Bull. RWAY 2015, 245, 133–141. [Google Scholar]

- Gamidullaeva, L.; Shmeleva, N.; Tolstykh, T.; Shmatko, A. An Assessment Approach to Circular Business Models within an Industrial Ecosystem for Sustainable Territorial Development. Sustainability 2022, 14, 704. [Google Scholar] [CrossRef]

- García-Sánchez, I.-M.; Somohano-Rodríguez, F.-M.; Amor-Esteban, V.; Gonzalez-Valdueza, B. Circular Economy Projects and Firm Disclosures in an Encouraging Institutional Environment. Sustainability 2022, 14, 1149. [Google Scholar] [CrossRef]

- Ranta, V.; Aarikka-Stenroos, L.; Ritala, P.; Mäkinen, S.J. Exploring institutional drivers and barriers of the circular economy: A cross-regional comparison of China, the US, and Europe. Resour. Conserv. Recycl. 2018, 135, 70–82. [Google Scholar] [CrossRef]

- Heckscher, E.; Ohlin, B. International and Inter-Regional Trade; Harvard University Press: Cambridge, MA, USA, 1933; Available online: https://www.abebooks.com/first-edition/Interregional-International-Trade-OHLIN-Bertil-Cambridge/372604098/bd (accessed on 10 February 2024).

- Baumol, W.J.; Blinder, A.S. Economics: Principles and Policy; Cengage Learning: Boston, MA, USA, 2009. [Google Scholar]

- Katz-Gerro, T.; Sintas, J.L. Mapping circular economy activities in the European Union: Patterns of implementation and their correlates in small and medium-sized enterprises. Bus. Strategy Environ. 2018, 28, 485–496. [Google Scholar] [CrossRef]

- Marshall, A. Industry and Trade, 4th ed.; MacMillan: London, UK, 1923. [Google Scholar]

- Chinitz, B. Contrasts in Agglomeration: New York and Pittsburgh. Am. Econ. Rev. 1961, 51, 363–374. [Google Scholar]

- Weber, A. Theory of the Location of Industries; Friedrich, C.J., Translator; The University of Chicago Press: Chicago, IL, USA, 1929. [Google Scholar]

- Christaller, W. Die Zentralen Orte in Süddeutschland (The Central Places in Southern Germany); Verlag von Gustav Fischer: Jena, Germany, 1933. [Google Scholar]

- Lösch, A. The Economics of Location; Woglom, W.H., Translator; Yale University Press: New Haven, CT, USA, 1954. [Google Scholar]

- Isard, W. Location and Space-Economy: A General Theory Relating to Industrial Location, Market Areas, Land Use, Trade, and Urban Structure; Published Jointly by the Technology Press of Massachusetts Institute of Technology and Wiley: Cambridge, MA, USA; New York, NY, USA, 1956. [Google Scholar]

- Friedman, J. Regional Development Policy: A Case Study of Venezuela; The MIT Press: Cambridge, MA, USA, 1966. [Google Scholar]

- Krugman, P. Increasing returns and economic geography. J. Political Econ. 1991, 99, 483–499. [Google Scholar] [CrossRef]

- Myrdal, G. Economic Theory and Underdeveloped Regions; University Paperbacks: London, UK; Methuen, MA, USA, 1957. [Google Scholar]

- Chertow, M.; Lombardi, R. Quantifying economic and environmental benefits of co-located firms. Environ. Sci. Technol. 2005, 39, 6535–6541. [Google Scholar] [CrossRef] [PubMed]

- Korhonen, J. Four ecosystem principles for an industrial ecosystem. J. Clean. Prod. 2001, 9, 253–259. [Google Scholar] [CrossRef]

- Uzzi, B. The sources and consequences of embeddedness for the economic performance of organizations: The network effect. Am. Sociol. Rev. 1996, 61, 674–698. [Google Scholar] [CrossRef]

- Solow, R.N. A contribution to the theory of economic growth. Q. J. Econ. 1956, 70, 65–94. [Google Scholar] [CrossRef]

- Ekins, P.; Hughes, N. UNEP Resource Efficiency: Potential and Economic Implications. A Report of the International Resource Panel; Roadmap to a Resource Efficient Europe 2011; European Commission: Brussels, Belgium, 2017; pp. 26–227. [Google Scholar]

- Stieglitz, J. People, Power, and Profits: Progressive Capitalism for an Age of Discontent; W. W. Norton & Company: New York, NY, USA, 2019; 366p. [Google Scholar]

- Schaltegger, S.; Burritt, R. Contemporary Environmental Accounting: Issues, Concepts and Practice; Greenleaf Publishing: Sheffield, UK, 2000. [Google Scholar]

- Liu, F.; Zhou, S.; Yang, Y.; Liu, C. Research on Industrial Ecological Efficiency Evaluation and Improvement Countermeasures Based on Data-Driven Evaluations from 30 Provinces and Cities in China. Sustainability 2022, 14, 8665. [Google Scholar] [CrossRef]

- Bian, J.; Zhang, Y.; Shuai, C.; Shen, L.; Ren, H.; Wang, Y. Have cities effectively improved ecological well-being performance? Empirical analysis of 278 Chinese cities. J. Clean. Prod. 2020, 245, 118913. [Google Scholar] [CrossRef]

- Robaina-Alves, M.; Moutinho, V.; Macedo, P. A new frontier approach to model the eco-efficiency in European countries. J. Clean. Prod. 2015, 103, 562–573. [Google Scholar] [CrossRef]

- Wang, X.; Ding, H.; Liu, L. Eco-efficiency measurement of industrial sectors in China: A hybrid super-efficiency DEA analysis. J. Clean. Prod. 2019, 229, 53–64. [Google Scholar] [CrossRef]

- Rodriguez, C.M.; Rodas, C.F.R.; Munoz, J.C.C.; Casas, A.F. A multi-criteria approach for comparison of environmental assessment methods in the analysis of the energy efficiency in agricultural production system. J. Clean. Prod. 2019, 228, 1464–1471. [Google Scholar] [CrossRef]

- Zhang, R.-L.; Liu, X.-H. Evaluating ecological efficiency of Chinese industrial enterprise. Renew Energy 2021, 178, 679–691. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, H.; Chen, B.; Yang, N. Social network analysis and network connectedness analysis for industrial symbiotic systems: Model development and case study. Front. Earth Sci. 2013, 7, 169–181. [Google Scholar] [CrossRef]

- Huang, M.; Ding, R.J.; Xin, C.H. Impact of technological innovation and industrial-structure upgrades on ecological efficiency in China in terms of spatial spillover and the threshold effect. Integr. Environ. Assess. Manag. 2021, 17, 852–865. [Google Scholar] [CrossRef] [PubMed]

- Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on Industrial Emissions (Integrated Pollution Prevention and Control). Available online: http://data.europa.eu/eli/dir/2010/75/oj (accessed on 2 February 2024).

- OECD. Controlling Best Industrial Establishing Available Pollution, Techniques (BAT) Activity 2: For Preventing Approaches and to Best Available Techniques Around the World, Environment, Health and Safety, Environment Directorate, OECD. 2018. Available online: https://www.oecd.org/chemicalsafety/risk-management/approaches-to-establishing-best-available-techniques-around-the-world.pdf (accessed on 16 February 2024).

- Valderrama, C.; Granados, R.; Cortina, J.L.; Gasol, C.M.; Guillem, M.; Josa, A. Implementation of best available techniques in cement manufacturing: A life-cycle assessment study. J. Clean. Prod. 2012, 25, 60–67. [Google Scholar] [CrossRef]

- Berseneva, M.L.; Vasilovskaya, G.V.; Klindukh, N.Y.; Terekhova, I.I.; Gumennaya, E.Y. Metallurgical Waste in Construction Industry. KEM 2020, 839, 155–159. [Google Scholar] [CrossRef]

- Davankov, A.Y.; Dvinin, D.Y. Features of The Conceptual Construct and Methodology of Socio-Ecological and Economic Research, Cognitive, Pragmatic and Cultural Aspects. In European Proceedings of Social and Behavioural Sciences; European Publisher: Veliky Novgorod, Russia, 2020; Volume 86, pp. 31–318. [Google Scholar] [CrossRef]

- Tian, J.; Huang, W.; Peng, J.; Fu, S.; Wang, J. How technological innovation influences carbon neutrality? The perspective of spatial spillover effect and attenuation boundary. J. Environ. Plann. Man. 2023. [Google Scholar] [CrossRef]

- Nilsson, A.E.; Avango, D.; Rosqvist, G. Social-ecological-technological systems consequences of mining: An analytical framework for more holistic impact assessments. Extr. Ind. Soc. 2021, 8, 101011. [Google Scholar] [CrossRef]

- Cherepovitsyn, A.E.; Tcvetkov, P.S.; Evseeva, O.O. Critical analysis of methodological approaches to assessing sustainability of arctic oil and gas projects. J. Min. Inst. 2021, 249, 463–479. [Google Scholar] [CrossRef]

- Del-Aguila-Arcentales, S.; Alvarez-Risco, A.; Jaramillo-Arévalo, M.; De-la-Cruz-Diaz, M.; de las Mercedes Anderson-Seminario, M. Influence of Social, Environmental and Economic Sustainable Development Goals (SDGs) over Continuation of Entrepreneurship and Competitiveness. J. Open Innov. Technol. Mark. Complex. 2022, 8, 73. [Google Scholar] [CrossRef]

- Zentner, E.; Kecinski, M.; Letourneau, A.; Davidson, D. Ignoring Indigenous peoples-climate change, oil development, and Indigenous rights clash in the Arctic National Wildlife Refuge. Clim. Chang. 2019, 155, 533–544. [Google Scholar] [CrossRef]

- Ibrahim, M.A. Risk of spontaneous and anthropogenic fires in waste management chain and hazards of secondary fires. Resour. Conserv. Recycl. 2020, 159, 104852. [Google Scholar] [CrossRef]

- Medina-Mijangos, R.; Ajour El Zein, S.; Guerrero-García-Rojas, H.; Seguí-Amórtegui, L. The economic assessment of the environmental and social impacts generated by a light packaging and bulky waste sorting and treatment facility in Spain: A circular economy example. Environ. Sci. Eur. 2021, 33, 78. [Google Scholar] [CrossRef]

- Padilla-Rivera, A.; Morgan-Sagastume, J.M.; Noyola, A.; Güereca, L.P. Addressing social aspects associated with wastewater treatment facilities. Environ. Impact Assess. Rev. 2016, 57, 101–113. [Google Scholar] [CrossRef]

- Serreli, M.; Petti, L.; Raggi, A.; Simboli, A.; Iuliano, G. Social life cycle assessment of an innovative industrial wastewater treatment plant. Int. J. Life Cycle Assess. 2021, 26, 1878–1899. [Google Scholar] [CrossRef]

- Mahmood, M.; Orazalin, N. Green governance and sustainability reporting in Kazakhstan’s oil, gas, and mining sector: Evidence from a former USSR emerging economy. J. Clean. Prod. 2017, 164, 389–397. [Google Scholar] [CrossRef]

- Amor-Esteban, V.; Galindo-Villardin, V.; Garcia-Sanchez, I.-M. Useful information for stakeholder engagement: A multivariate proposal of an industrial corporate social responsibility practices index. Sustain. Dev. 2018, 26, 620–637. [Google Scholar] [CrossRef]

- Lam, H.K.; Yeung, A.C.; Cheng, T.C.E.; Humphreys, P.K. Humphreys, Corporate environmental initiatives in the Chinese context: Performance implications and contextual factors. Int. J. Prod. Econ. 2016, 180, 48–56. [Google Scholar] [CrossRef]

- Xu, Y.; Zhao, X.; Wang, J.; Xie, P. Clarifying the dispute of corporate social responsibility: Evidence from green technological innovation. Technol. Soc. 2023, 75, 102392. [Google Scholar] [CrossRef]

- Valdez-Juárez, L.E.; Castillo-Vergara, M. Technological Capabilities, Open Innovation, and Eco-Innovation: Dynamic Capabilities to Increase Corporate Performance of SMEs. J. Open Innov. Technol. Mark. Complex. 2021, 7, 8. [Google Scholar] [CrossRef]

- Choi, P.K. A Need for Co-Evolution between Technological Innovations and Social Innovations. J. Open Innov. Technol. Mark. Complex. 2020, 6, 54. [Google Scholar] [CrossRef]

- Bogdanov, A.A. Tectology: Universal Organizational Science; Economics: Moscow, Russia, 1989. [Google Scholar]

- von Bertalanffy, L. Research on General Systems Theory; Progress: Moscow, Russia, 1969. [Google Scholar]

- Jolly, R. Systems Thinking for Business: Capitalize on Structures Hidden in Plain Sight; Systems Solutions Press: Paducah, KY, USA, 2015. [Google Scholar]

- Skobelev, D.O. Information and methodological support to the implementation of Best Available Techniques in the Russian Federation. Upravlenie 2019, 7, 5–15. (In Russian) [Google Scholar] [CrossRef]

- Skobelev, D.; Guseva, T.; Chechevatova, O.; Begak, M.; Tsevelev, V. Chartered experts in Best Available Techniques in Russia: Key principles and first practices. In Proceedings of the 18th International Multidisciplinary Scientific GeoConference SGEM, Vienna, Austria, 3–6 December 2018; pp. 183–190. [Google Scholar]

- Hjort, M.; Skobelev, D.; Almgren, R.; Guseva, T.; Koh, T. Best available techniques and sustainable development goals. In Proceedings of the 19th International Multidisciplinary Scientific GeoConference SGEM 2019, Albena, Bulgaria, 28 June–7 July 2019; pp. 185–192. [Google Scholar] [CrossRef]

- ISO 1400-3:2022; Environmental Performance Evaluation. Green Debt Instruments. Part 3: Taxonomy. ISO: Geneva, Switzerland, 2022.

- Skobelev, D.O. Building the infrastructure for transforming Russian industry towards better resource efficiency and environmental performance. Procedia Environ. Sci. Eng. Manag. 2021, 8, 483–493. Available online: https://www.procedia-esem.eu/pdf/issues/2021/no2/19_51_Skobelev_21.pdf (accessed on 2 March 2024).

- Guseva, T.; Potapova, E.; Tikhonova, I.; Molchanova, Y.; Begak, M. Training Russian Practitioners in Best Available Techniques and Integrated Environmental Permits. In Proceedings of the 18th International Multidisciplinary Scientific GeoConference SGEM 2018, Albena, Bulgaria, 2–8 July 2018; pp. 313–320. [Google Scholar] [CrossRef]

- Hellweg, S.; Benetto, E.; Huijbregts, M.A.; Verones, F.; Wood, R. Life-cycle assessment to guide solutions for the triple planetary crisis. Nat. Rev. Earth Environ. 2023, 4, 471–486. [Google Scholar] [CrossRef]

- Resolution of the Government of the Russian Federation No. 871 of 24 July 2017 on Creation of the Territory of Advanced Socio-Economic Development in Novotroitsk. 2017. Available online: http://publication.pravo.gov.ru/Document/View/0001201707270047 (accessed on 16 September 2023). (In Russian)

- Petrosyan, V.; Tikhonova, I.; Epifantsev, A.; Shchelchkov, K.; Tsvetkova, E. Developing an Industrial Symbiosis of Chemical Industries: A Case Study. Ecol. Ind. Russ. 2021, 25, 28–33. (In Russian) [Google Scholar] [CrossRef]

- Novotroitsk Plant of Bisulphite and Metabisulphite Ltd. 2023. Available online: https://nzbp.ru/?language=en (accessed on 10 February 2024). (In Russian).

- Tikhonova, I.; Guseva, T.; Potapova, E.; Shchelchkov, K. Forming Circular Economy Links in Chemical Industry: Lime, Caustic Ash, Salt and Gypsum Production in the Urals. In Proceedings of the 21st International Multidisciplinary Scientific GeoConference SGEM 2021, Albena, Bulgaria, 14–22 August 2021; pp. 229–235. [Google Scholar] [CrossRef]

- Baidy, R.; Ghosh, S.K.; Parlikar, U.V. Co-processing of industrial waste in cement kiln—A robust system for material and energy recovery. Procedia Environ. Sci. 2016, 31, 309–317. [Google Scholar] [CrossRef]

- Gao, T.; Shen, L.; Shen, M.; Liu, L.; Chen, F. Analysis of material flow and consumption in cement production process. J. Clean. Prod. 2015, 112, 553–565. [Google Scholar] [CrossRef]

- Scrivenera, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Shmeleva, N.V. Methodological approaches to assessing the resource efficiency of industrial ecosystem. Models, systems, networks in economics. Technol. Nat. Soc. 2023, 1, 70–84. (In Russian) [Google Scholar] [CrossRef]

- Cui, T.; Wu, Y.; Tong, Y. Exploring ideation and implementation openness in open innovation projects: IT-enabled absorptive capacity perspective. Inf. Manag. 2018, 55, 576–587. [Google Scholar] [CrossRef]

- Costa, J.; Carrizo, M. Public Policies, Open Innovation Ecosystems and Innovation Performance. Analysis of the Impact of Funding and Regulations. J. Open Innov. Technol. Mark. Complex. 2022, 8, 210. [Google Scholar] [CrossRef]

- Song, X.; Geng, Y.; Dong, H.; Chen, W. Social network analysis on industrial symbiosis: A case of Gujiao eco-industrial park. J. Clean. Prod. 2018, 193, 414–423. [Google Scholar] [CrossRef]

- Fan, Y.; Qiao, Q.; Xian, C.; Xiao, Y.; Fang, L. A modified ecological footprint method to evaluate environmental impacts of industrial parks. Resour. Conserv. Recycl. 2017, 125, 293–299. [Google Scholar] [CrossRef]

- Brondi, C.; Cornago, S.; Ballarino, A.; Avai, A.; Pietraroia, D.; Dellepiane, U.; Niero, M. Sustainability-based Optimization Criteria for Industrial Symbiosis: The Symbioptima Case. In Proceedings of the 25th CIRP Conference on Life Cycle Engineering, CIRP LCE 2018, Copenhagen, Denmark, 30 April–2 May 2018; ITIA-CNR—Institute for Industrial Technologies and Automation: Milan, Italy, 2018; pp. 855–860. [Google Scholar]

- Lopes, A.P.V.B.V.; de Carvalho, M.M. Evolution of the open innovation paradigm: Towards a contingent conceptual model. Technol. Forecast. Soc. Change 2018, 132, 284–298. [Google Scholar] [CrossRef]

- Streimikiene, D.; Mikalauskiene, A.; Kiausiene, I. The Impact of Value Created by Culture on Approaching the Sustainable Development Goals: Case of the Baltic States. Sustainability 2019, 11, 6437. [Google Scholar] [CrossRef]

| Indicators | Industrial Enterprises | Industrial Symbiosis | Savings, Million RUB |

|---|---|---|---|

| Thermal energy consumption, million GJ | 8.97 | 3.19 | 1702.15 |

| Slag usage, million tonnes | – | 1.00 | – |

| Consumption of primary resources (limestone, clay, gypsum), million tonnes | 3.78 | 1.88 | 820.8 |

| Cement production, million tonnes | 2.36 | 2.36 | – |

| CO2-equivalent, million tonnes | 1.6 | 0.75 | 850.0 |

| Total: | 3372.95 |

| Social and Environmental Impacts | Scale of Impact | Types of Impact | Qualitative/Quantitative | Source |

|---|---|---|---|---|

| State | ||||

| Implementing strategic initiatives and national programmes, including transition to green economy | macrolevel | environmental | +/− | official databases |

| Scaling successful experience of circular economy-related projects (industrial symbioses) through network integration | meso and micro levels | environmental and social | +/− | field surveys |

| Improving technological independence | macrolevel | technological | +/− | official databases |

| Increasing tax payments to budgets at all levels | macro and meso levels | economic | −/+ | official databases |

| Public | ||||

| Increasing service availability and quality | macro and meso levels | environmental | +/− | official databases |

| Improving state of the environment and decreasing “visual pollution” | macro and meso levels | environmental | +/− | official databases |

| Implementing national projects—“Environmental Protection” and “Circular Economy”. | macro and meso levels | environmental and social | +/+ | official databases |

| Territory (region) | ||||

| Increasing production of construction materials needed to develop the town of Novotroitsk and its surroundings | meso and micro levels | economic | −/+ | regional official databases |

| Developing infrastructure | meso and micro levels | economic and social | −/+ | regional official databases |

| Increasing employment levels in the region | meso and micro levels | economic and social | −/+ | regional official databases |

| Industrial enterprises | ||||

| Enhancing resource efficiency | micro level | environmental and economic | −/+ | Sustainable enterprise development report (SDR) |

| Cutting costs of raw materials | micro level | economic | −/+ | operational report |

| Reducing GHG emissions | micro level | environmental and economic | −/+ | SDR |

| Developing high-tech jobs | micro level | economic and social | −/+ | SDR |

| Developing human capital | micro level | economic and social | −/+ | SDR |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gamidullaeva, L.; Shmeleva, N.; Tolstykh, T.; Guseva, T.; Panova, S. The Complex Approach to Environmental and Technological Project Management to Enhance the Sustainability of Industrial Systems. Systems 2024, 12, 261. https://doi.org/10.3390/systems12070261

Gamidullaeva L, Shmeleva N, Tolstykh T, Guseva T, Panova S. The Complex Approach to Environmental and Technological Project Management to Enhance the Sustainability of Industrial Systems. Systems. 2024; 12(7):261. https://doi.org/10.3390/systems12070261

Chicago/Turabian StyleGamidullaeva, Leyla, Nadezhda Shmeleva, Tatyana Tolstykh, Tatiana Guseva, and Svetlana Panova. 2024. "The Complex Approach to Environmental and Technological Project Management to Enhance the Sustainability of Industrial Systems" Systems 12, no. 7: 261. https://doi.org/10.3390/systems12070261

APA StyleGamidullaeva, L., Shmeleva, N., Tolstykh, T., Guseva, T., & Panova, S. (2024). The Complex Approach to Environmental and Technological Project Management to Enhance the Sustainability of Industrial Systems. Systems, 12(7), 261. https://doi.org/10.3390/systems12070261