Development of a Quantitative Assessment Algorithm for Operational Risks in Mining Engineering

Abstract

1. Introduction

2. Materials and Methods

- Identification of additional operational risks: The authors developed a classification of operational risks by the form of their manifestation. The classification helps to identify critical areas where risks are most likely to occur.

- Risk decomposition for determining model parameters: The authors developed a risk decomposition matrix by types of production tasks and the nature of the influence of parameters on the project goal. This matrix helps to identify potential risk factors and select project parameters that significantly affect the probability of risk events.

- Building a mathematical model: using the parameters from the previous step, a functional model based on the IDEF0 notation was developed. This model was used to simulate and estimate probable damage from risk events, such as an emergency conveyor stop.

- Verification of the model: The validation process included regression analysis with quality control of equations according to three criteria and comparison of model results with time data to ensure that the mathematical model produces the correct result.

3. Results

3.1. Identification of Additional Operational Risks

3.2. Perform Risk Decomposition to Define Model Parameters

- Quantitative parameters—reflect the number of units of mining equipment, the number of personnel involved in the process, the amount of equipment, etc.;

- Physical property parameters—reflect the productivity of machinery, duration of operation, movement speed, mine working dimensions, total salary amounts of personnel, etc.;

- Schedule parameters—reflect on the panel the plant operating mode, blasting schedule, safety of blasting chambers, etc.;

- Location parameters—used to express the features of the mine geometry, the location of mine workings, the location of equipment parking areas, the location of capital construction facilities, and their impact on the features of the movement logistics within the mine.

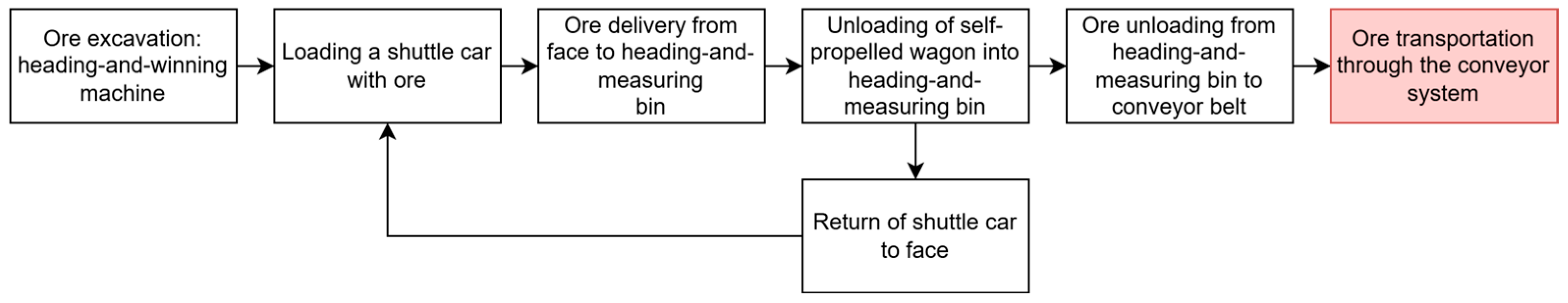

3.3. Construction of the Mathematical Model

- Calculation of the rollback distance:

- 2.

- Calculation of the extraction cycle duration, i.e., determination of the time of ore entering the hopper. Let us assume that the movement of the cargo flow along the conveyor after the ore enters the hopper is instantaneous:

- 3.

- Calculation of the end time of unloading the cargo flow onto the conveyor belt:

- 4.

- Calculation of the time taken to transport the cargo flow to the point of conveyor interconnection:

- 5.

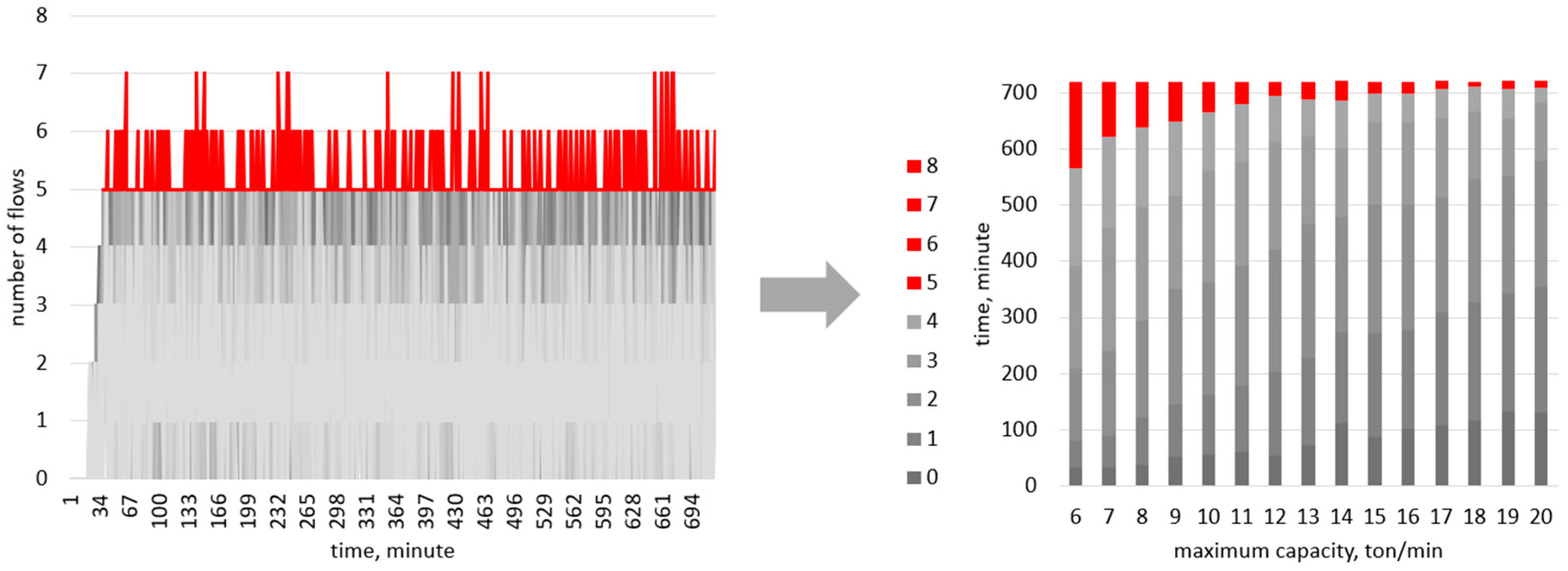

- Obtaining a time series N(t): the amount of cargo flows at the bottleneck is recorded once a minute:

- 6.

- Calculating the probability of a risk situation occurring:

3.4. Model Testing

4. Discussion

5. Conclusions

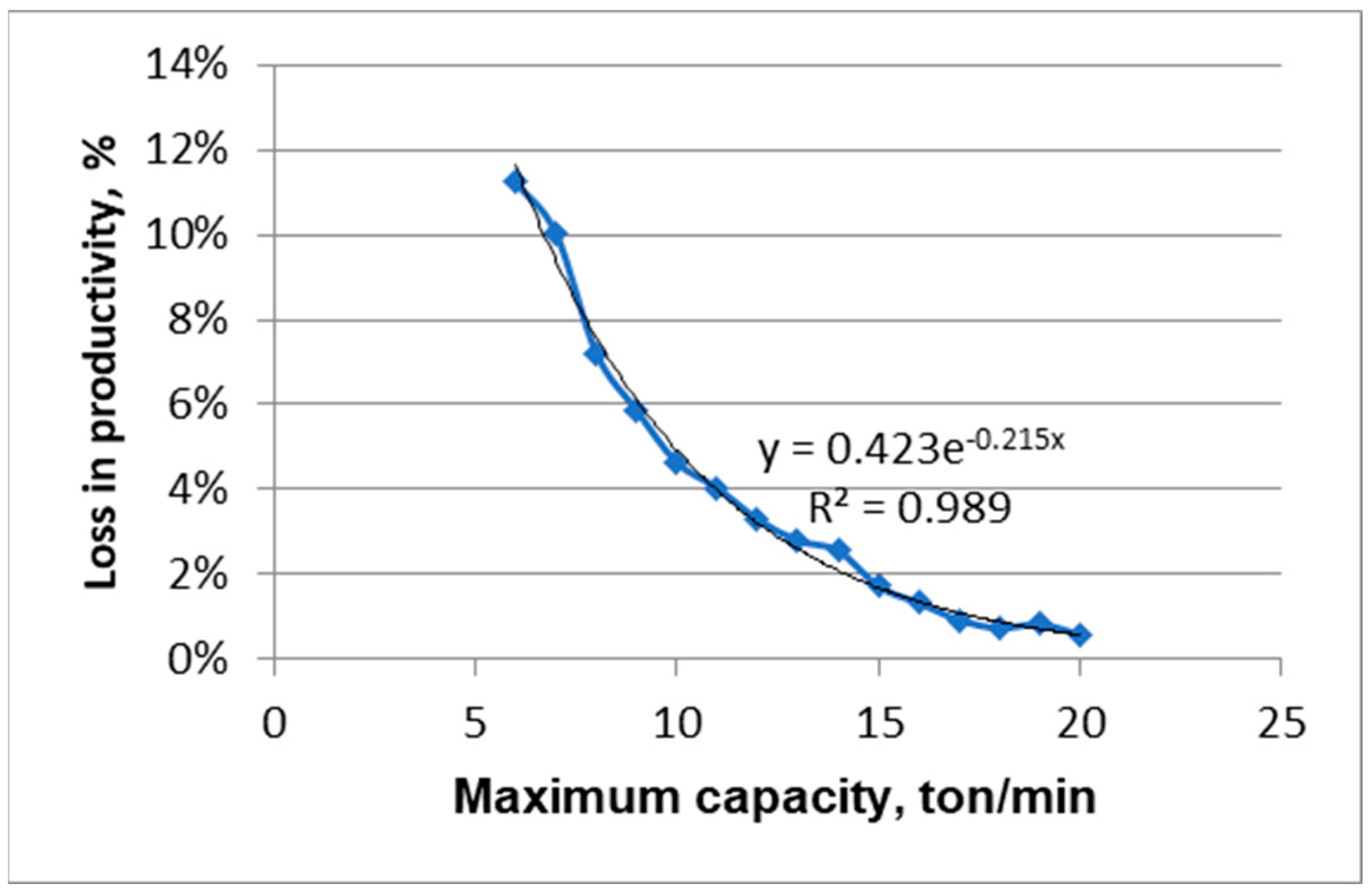

- The quantitative risk assessment shows that the risk occurrence probability (as an event resulting in a conveyor system emergency stop) is no more than 21.4%. At the same time, the occurrence of a risk situation entails a 44–73% drop in transporting productivity and, consequently, in annual revenue.

- The estimated probable damage amounts to 11.23% of the annual revenue loss. This indicates the need to develop measures to reduce the probability of risk occurrence, for example, by replacing the heading-and-measuring bin unit or introducing an automated system to control the speed of ore feeding to the conveyor.

- The main objective of operational risk assessment at the design stage is to verify the achievement of continuity in the production process. Hence, the risk factors are the values of the parameters laid down in the project.

- This paper proposes the classification of operational risks based on their manifestation in the production process. Within the framework of classification, risks are divided into four groups: shutdown, downtime, shortage, and violation of safe operation norms.

- This paper proposes to decompose the sources of risk according to the matrix “type of production task—nature of parameter influence on the process”. This study formulates nine types of production tasks and four types of influence parameters.

- The authors’ proposed methodology for assessing production and economic risks consists of the following stages: (a) risk identification using classification by the form of their manifestation in the production process; (b) risk decomposition by sources using the matrix “types of production tasks—nature of the influence of parameters on the process”; (c) determination of the parameters of the mathematical model—compiling a list of risk sources and determining the cause-and-effect relationships between them, which can lead to the manifestation of a risk event; (d) conducting experiments with the model to determine the amount of damage in the case of a risk event; and (e) calculating the probable damage from the risk occurrence.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Ansi, A.M.; Garad, A.; Ryabtsev, V. Intelligent Risk Analysis of Investment Projects in the Extractive Industry. J. Ind. Intell. 2024, 2, 42–53. [Google Scholar] [CrossRef]

- Nguyen, M.P.; Ponomarenko, T.; Nguyen, N. Energy Transition in Vietnam: A Strategic Analysis and Forecast. Sustainability 2024, 16, 1969. [Google Scholar] [CrossRef]

- Ashkanani, S.; Franzoi, R. Gaps in Megaproject Management System Literature: A Systematic Overview. Eng. Constr. Archit. Manag. 2023, 30, 1300–1318. [Google Scholar] [CrossRef]

- Stoianova, A.D.; Trofimets, V. Ya.; Matrokhina, K.V. Technical Approach to Rating of Companies in the Arctic Zone Based on Sustainable Development Indicators. Min. Informational Anal. Bull. 2024, 6, 149–162. [Google Scholar] [CrossRef]

- Buch, A.C.; Niemeyer, J.C.; Marques, E.D.; Silva-Filho, E.V. Ecological Risk Assessment of Trace Metals in Soils Affected by Mine Tailings. J. Hazard. Mater. 2021, 403, 123852. [Google Scholar] [CrossRef] [PubMed]

- Marinina, O.; Malikov, A.; Lyubek, Y.; Pasternak, S.; Reshneva, E.; Stolbovskaya, N. Selection of Enhanced Oil Recovery Method on the Basis of Clustering Wells. Processes 2024, 12, 2082. [Google Scholar] [CrossRef]

- Myakotnykh, A.A.; Ivanova, P.V.; Ivanov, S.L. Criteria and Technological Requirements for Creation of a Bridge Platform to Extract Peat Raw Materials for Climate-Neutral Geotechnology. Min. Ind. J. (Gorn. Promishlennost) 2024, 4, 116–120. [Google Scholar] [CrossRef]

- Semenova, T.; Martínez Santoyo, J.Y. Increasing the Sustainability of the Strategic Development of Oil Producing Companies in Mexico. Resources 2024, 13, 108. [Google Scholar] [CrossRef]

- Calvo, G.; Valero, A. Strategic Mineral Resources: Availability and Future Estimations for the Renewable Energy Sector. Environ. Dev. 2022, 41, 100640. [Google Scholar] [CrossRef]

- Scammacca, O.; Mehdizadeh, R.; Gunzburger, Y. Territorial Mining Scenarios for Sustainable Land-Planning: A Risk-Based Comparison on the Example of Gold Mining in French Guiana. Sustainability 2022, 14, 10476. [Google Scholar] [CrossRef]

- Yongbin, Y. The Comprehensive Whole Process Risk Assessment Method of Mine Multi-Factor. World J. Manag. Sci. Technol. 2024, 3, 10. [Google Scholar] [CrossRef]

- Botyan, E.Y.; Lavrenko, S.A.; Pushkarev, A.E. Evaluation of Complicated Mining Exploitation Conditions Influence on Service Life of Open Pit Trucks Suspensions with Remote Monitoring Systems. Int. J. Eng. 2024, 37, 2268–2275. [Google Scholar] [CrossRef]

- Cherepovitsyn, A.E.; Dorozhkina, I.P.; Solov’eva, V.M. Forecasts of Rare-Earth Elements Consumption in Russia: Basic and Emerging Industries. Stud. Russ. Econ. Dev. 2024, 35, 688–696. [Google Scholar] [CrossRef]

- Trufanova, I.; Nevzorov, D. The Use of Conveyor Trains as External Transport for Enrichment Enterprises. Min. Informational Anal. Bull. 2023, 9–1, 64–78. [Google Scholar] [CrossRef]

- Maksarov, V.V.; Minin, A.O.; Romanov, P.I.; Nikiforov, I.P. Influence of High-Frequency Wave Action in a Tooling System on the Machining Quality of Corrosion-Resistant Aluminum Alloys. Metalloobrabotka 2022, 32–40. [Google Scholar] [CrossRef]

- Kantianis, D. Construction Project Crashing with Uncertain Correlated Normal and Crash Task Durations and Costs: An Integrated Stochastic Practical Approach. Eur. Proj. Manag. J. 2023, 13, 3–22. [Google Scholar] [CrossRef]

- Banerjee Chattapadhyay, D.; Putta, J.; Rao, P.R.M. Risk Identification, Assessments, and Prediction for Mega Construction Projects: A Risk Prediction Paradigm Based on Cross Analytical-Machine Learning Model. Buildings 2021, 11, 172. [Google Scholar] [CrossRef]

- Zhu, J. Application of Artificial Intelligence Data Mining Algorithm in Enterprise Management Risk Assessment. Int. J. Inf. Syst. Supply Chain Manag. 2024, 17, 1–19. [Google Scholar] [CrossRef]

- Lu, Y.; Gong, P.; Tang, Y.; Sun, S.; Li, Q. BIM-Integrated Construction Safety Risk Assessment at the Design Stage of Building Projects. Autom. Constr. 2021, 124, 103553. [Google Scholar] [CrossRef]

- Chen, S.; Zeng, Y.; Majdi, A.; Salameh, A.A.; Alkhalifah, T.; Alturise, F.; Ali, H.E. Potential Features of Building Information Modelling for Application of Project Management Knowledge Areas as Advances Modeling Tools. Adv. Eng. Softw. 2023, 176, 103372. [Google Scholar] [CrossRef]

- Koteleva, N.I.; Valnev, V.V.; Korolev, N.A. Augmented Reality as a Means of Metallurgical Equipment Servicing. Tsvetnye Met. 2023, 4, 14–23. [Google Scholar] [CrossRef]

- Myakotnykh, A.A.; Ivanova, P.V.; Ivanov, S.L. On Classification of Peat Extraction Complexes. Min. Ind. J. (Gorn. Promishlennost) 2023, 6, 137–142. [Google Scholar] [CrossRef]

- Shabalov, M.Y.; Zhukovskiy, Y.L.; Buldysko, A.D.; Gil, B.; Starshaia, V.V. The Influence of Technological Changes in Energy Efficiency on the Infrastructure Deterioration in the Energy Sector. Energy Rep. 2021, 7, 2664–2680. [Google Scholar] [CrossRef]

- Koteleva, N.; Valnev, V. Automatic Detection of Maintenance Scenarios for Equipment and Control Systems in Industry. Appl. Sci. 2023, 13, 12997. [Google Scholar] [CrossRef]

- Zhukovsky, Y.; Suslikov, P. Assessment of the Potential Effect of Applying Demand Management Technology at Mining Enterprises. Sustain. Dev. Mt. Territ. 2024, 16, 895–908. [Google Scholar] [CrossRef]

- Iakhiaev, D.; Grigorishchin, A.; Zaikov, K.; Bezdudnaya, A.; Ukhanova, A.; Tsvetkova, A.; Fadeev, A. Methodological Approach to Assessing the Digital Infrastructure of the Northern Regions of the Russian Federation. J. Infrastruct. Policy Dev. 2024, 8, 8747. [Google Scholar] [CrossRef]

- RACHID, S.; TAHA, Y.; BENZAAZOUA, M. Environmental Evaluation of Metals and Minerals Production Based on a Life Cycle Assessment Approach: A Systematic Review. Miner. Eng. 2023, 198, 108076. [Google Scholar] [CrossRef]

- Radebe, N.; Chipangamate, N. Mining Industry Risks, and Future Critical Minerals and Metals Supply Chain Resilience in Emerging Markets. Resour. Policy 2024, 91, 104887. [Google Scholar] [CrossRef]

- Wang, J.; Sifamen, V. Exploring Industrial Hazards and Implementing Risk Control Measures in the Mining Sector. J. Infrastruct. Policy Dev. 2024, 8, 6255. [Google Scholar] [CrossRef]

- Nevskaya, M.; Shabalova, A.; Kosovtseva, T.; Nikolaychuk, L. Applications of Simulation Modeling in Mining Project Risk Management: Criteria, Algorithm, Evaluation. J. Infrastruct. Policy Dev. 2024, 8, 5375. [Google Scholar] [CrossRef]

- Karchina, E.I.; Ivanova, M.V.; Volokhina, A.T.; Glebova, E.V.; Vikhrov, A.E. Improving the procedure for group expert assessment in the analysis of professional risks in fuel and energy companies. J. Min. Inst. 2024, 270, 994–1003. [Google Scholar]

- ISO 310000:2018; Risk Managment. International Organization for Standardization: Geneva, Switzerland, 2018.

- Tubis, A.; Werbińska-Wojciechowska, S.; Wroblewski, A. Risk Assessment Methods in Mining Industry—A Systematic Review. Appl. Sci. 2020, 10, 5172. [Google Scholar] [CrossRef]

- Rashid, A.; Ayub, M.; Ullah, Z.; Ali, A.; Sardar, T.; Iqbal, J.; Gao, X.; Bundschuh, J.; Li, C.; Khattak, S.A.; et al. Groundwater Quality, Health Risk Assessment, and Source Distribution of Heavy Metals Contamination around Chromite Mines: Application of GIS, Sustainable Groundwater Management, Geostatistics, PCAMLR, and PMF Receptor Model. Int. J. Environ. Res. Public Health 2023, 20, 2113. [Google Scholar] [CrossRef] [PubMed]

- Galkina, N.V.; Kravchuk, I.L.; Smolin, A.V.; Peryatinski, A.Y. An Approach to the Economic Assessment of Production Risk at a Mining Enterprise. NEWS Ural State Min. Univ. 2022, 4, 151–158. [Google Scholar] [CrossRef]

- Deveci, M.; Varouchakis, E.A.; Brito-Parada, P.R.; Mishra, A.R.; Rani, P.; Bolgkoranou, M.; Galetakis, M. Evaluation of Risks Impeding Sustainable Mining Using Fermatean Fuzzy Score Function Based SWARA Method. Appl. Soft Comput. 2023, 139, 110220. [Google Scholar] [CrossRef]

- Mishra, P.C.; Mohanty, M.K. A Review of Factors Affecting Mining Operation. World J. Eng. 2020, 17, 457–472. [Google Scholar] [CrossRef]

- Amirudin, A.; Sukwika, T.; Ramli, S. Analysis of Performance and Safety Risks in the Nickel Mining Sector. Indones. J. Glob. Health Res. 2024, 6, 723–734. [Google Scholar]

- Massel, L.; Komendantova, N.; Massel, A.; Tsvetkova, A.; Zaikov, K.; Marinina, O. Resilience of Socio-Ecological and Energy Systems: Intelligent Information Technologies for Risk Assessment of Natural and Technogenic Threats. J. Infrastruct. Policy Dev. 2024, 8, 4700. [Google Scholar] [CrossRef]

| Risk Manifestation | Example of a Risk |

|---|---|

| Mining transport logistic issues, formation of “traffic jams” | Risk of incorrect localization of ore dumps; risk of mining equipment not being able to pass through due to restrictions related to the geometric dimensions of mine shafts |

| Downtime of machinery and equipment | Risk of incorrect blasting schedules; risk of excessive amount of mining equipment |

| Insufficient productivity of machinery and equipment | Risk of insufficient number of loading and delivery vehicles to transport ore; risk of insufficient width of conveyor belt |

| Violation of safety regulations | Risk of disruption in the ventilation system; risk of disruption of the power supply system |

| Production Task | Quantity | Properties | Timetable | Placement |

|---|---|---|---|---|

| Organization of excavation and cleaning works | 4 faces per panel, 8 heading-and-winning machines, 8 shuttle cars, 20 conveyors in the system | heading-and-winning machine capacity, shuttle car speed, ore weight per cycle, heading-and-measuring bin capacity, belt speed | shift duration, duration of loading and unloading operations | advance per cycle, rolling shoulder, conveyor positioning |

| # | Parameter | Symbol | Value |

|---|---|---|---|

| 1 | shift duration, min | l | 720 |

| 2 | number of faces, heading-and-winning machines, shuttle cars | i | 1...8 |

| 3 | number of cargo flows, number of mining cycles | j | Computed parameter |

| 4 | heading-and-winning machine advancement per cycle, m | x1 | 0.5 |

| 5 | rolling shoulder, m | d | Computed parameter |

| 6 | start time of a new cycle, min | t0 | 1.6 |

| 7 | shuttle car speed, m/min | x2 | normal (0.51, 98.75) |

| 8 | loading and unloading time, min | x3 | normal (0.21, 5.62) |

| 9 | moment of cargo flow movement starts on the conveyor, min | ts | Computed parameter |

| 10 | ore weight, ton | x4 | 16 |

| 11 | heading-and-measuring bin capacity, ton/minute | x5 | 6...20 |

| 12 | moment of cargo flows full discharge to the conveyor, min | te | Computed parameter |

| 13 | location of conveyors—taken into account as the length of each conveyor, m | x6 | 50...1135 |

| 14 | belt speed, m/min | x7 | 189 |

| 15 | number of cargo flows in case of their merge | n | Computed parameter |

| 16 | capacity of conveyor network (without stops), ton | ab | Computed parameter |

| 17 | capacity of conveyor network (with stops), ton | a | Calculation |

| 18 | loss in productivity, % | Δa | Computed parameter |

| 19 | risk, RUB | risk | Computed parameter |

| 20 | annual revenue, RUB | revenue | Computed parameter |

| Max. Capacity of Heading-and-Measuring Bin | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ∑N(t) | n ≥ 5 | 154 | 97 | 82 | 72 | 54 | 39 | 26 | 32 | 34 | 21 | 21 | 13 | 8 | 13 | 10 |

| z(n(1)..nt),% | 21.4 | 13.5 | 11.4 | 10.0 | 7.5 | 5.4 | 3.6 | 4.4 | 4.7 | 2.9 | 2.9 | 1.8 | 1.1 | 1.8 | 1.4 |

| Maximum Capacity of Heading-and-Measuring Bin, Ton/Min | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight extracted, ton | 14,736 | 14,752 | 14,752 | 14,768 | 14,800 | 14,880 | 14,816 | 14,784 | 14,720 | 14,736 | 14,864 | 14,848 | 14,832 | 14,752 | 14,832 |

| Carried weight, ton (no stops) | 13,856 | 13,888 | 13,904 | 13,920 | 13,984 | 14,064 | 14,032 | 13,936 | 13,904 | 13,936 | 14,064 | 14,080 | 14,064 | 13,984 | 14,064 |

| Carried weight, ton (with stops) | 4544 | 3792 | 5104 | 5248 | 5648 | 5216 | 5312 | 5040 | 4080 | 5920 | 6480 | 7664 | 7904 | 5648 | 6960 |

| Decrease in productivity, % | 67 | 73 | 63 | 62 | 60 | 63 | 62 | 64 | 71 | 58 | 54 | 46 | 44 | 60 | 51 |

| Risk probability (by distribution), % | 16.72 | 13.81 | 11.41 | 9.42 | 7.79 | 6.43 | 5.31 | 4.39 | 3.63 | 3.00 | 2.48 | 2.04 | 1.69 | 1.40 | 1.15 |

| risk, % | 11.23 | 10.04 | 7.22 | 5.87 | 4.64 | 4.05 | 3.30 | 2.80 | 2.56 | 1.72 | 1.33 | 0.93 | 0.74 | 0.83 | 0.58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nevskaya, M.; Shabalova, A.; Nikolaichuk, L.; Kirsanova, N. Development of a Quantitative Assessment Algorithm for Operational Risks in Mining Engineering. Resources 2025, 14, 53. https://doi.org/10.3390/resources14040053

Nevskaya M, Shabalova A, Nikolaichuk L, Kirsanova N. Development of a Quantitative Assessment Algorithm for Operational Risks in Mining Engineering. Resources. 2025; 14(4):53. https://doi.org/10.3390/resources14040053

Chicago/Turabian StyleNevskaya, Marina, Anna Shabalova, Liubov Nikolaichuk, and Natalya Kirsanova. 2025. "Development of a Quantitative Assessment Algorithm for Operational Risks in Mining Engineering" Resources 14, no. 4: 53. https://doi.org/10.3390/resources14040053

APA StyleNevskaya, M., Shabalova, A., Nikolaichuk, L., & Kirsanova, N. (2025). Development of a Quantitative Assessment Algorithm for Operational Risks in Mining Engineering. Resources, 14(4), 53. https://doi.org/10.3390/resources14040053