Smart and Sustainable Hair Products Based on Chitin-Derived Compounds

Abstract

:1. Introduction

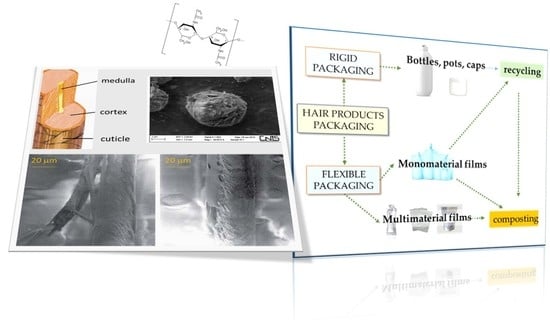

2. Waste, Climate Changing, and Wellbeing

3. The Hair

4. Chitin and Its Derived Compounds

5. Chitin Nanofibril-Nano-Lignin Complexes

6. Environmentally Friendly Packaging for Hair Products

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Reis Gavazzoni Dias, M.F. Hair cosmetics: An overview. Int. J. Trichol. 2015, 7, 2–15. [Google Scholar] [CrossRef] [PubMed]

- McDougall, A. What’s Next in Hair Care: Emerging Trends. 2019, Mintel Report, UK. Available online: www.mintel.com (accessed on 5 March 2021).

- Amberg, N.; Fogarassy, C. Green consumer behaviours in the cosmetic market. Resources 2019, 8, 137. [Google Scholar] [CrossRef] [Green Version]

- Cosmetic Europe. Environmental Sustainability. The Cosmetic Industry’s Contribution 2017–2019; Cosmetic Europe: Brussels, Belgium, 2019. [Google Scholar]

- UNEP. Plastic in Cosmetics; United Nation of Environmental Program: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Fever, D.; Lingvist, O.; Nordigarden, D. How the Packaging Industry Can Navigate the Coronavirus Pandemic. 2020 McKinsey & Company Report. Available online: www.mckinsey.com (accessed on 5 March 2021).

- MRS. Market Key Insight and COVID-19 Impact Analysis, 2020. Market Research Future Report. Available online: www.marketresearchfuture.com (accessed on 19 November 2020).

- Di Gesu, R. 6 Ways COVID-19 Spurred on Creative Beauty/Personal Care. 2020, Mintel Report. Available online: www.mintel.com (accessed on 19 November 2020).

- Coltelli, M.B.; Panariello, L.; Morganti, P.; Danti, S.; Baroni, A.; Lazzeri, A.; Fusco, A.; Donnarumma, G. Skin compatible biobased beauty masks prepared by extrusion. J. Funct. Biomater. 2020, 11, 23. [Google Scholar] [CrossRef] [Green Version]

- Morganti, P.; Yudin, V.E.; Morganti, G.; Coltelli, M.B. Trends in surgical and beauty masks for a cleaner environment. Cosmetics 2020, 7, 68. [Google Scholar] [CrossRef]

- MRFR. Cosmetic Packaging Market, 2020. COVID-19 Analysis, Application, Global Size, Share, Business Strategies, Huge Demand Value, Segments, Future Scope, Trends and Forecast Period 2018–2023. Market Research Future. Available online: report.www.marketresearchfuture.com (accessed on 11 November 2020).

- Reichert, C.L.; Bugnicourt, E.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A.; Canesi, I.; Braca, F.; Nartinez, B.M.; Alonso, R.; Agostinis, L.; et al. Biobased packaging: Materials, modifications, industrial applications and sustainability. Polymers 2020, 12, 1558. [Google Scholar] [CrossRef]

- Morganti, P.; Morganti, G. Surgical & beauty facial masks: The new waste problem of post COVID-19. Biomed. Sci. Tech. Res. 2020. [Google Scholar] [CrossRef]

- Morganti, P.; Morganti, G. Post-COVID-19: Opportunity to produce biodegradable goods & surgical masks to save the environment. J. Health Care Res. 2020, 1, 157–165. [Google Scholar] [CrossRef]

- Morganti, P.; Morganti, G. Textile & waste: Will be COVID-19 a catalyst for changing? J. Text. Eng. Fash. Tech. 2020, 2, 26–31. [Google Scholar]

- UN. Change of Climate Change Imprints, Climate Technology Centre & Network; United Nations Environment Program: New York, NY, USA, 2020. [Google Scholar]

- MGI. Climate Risk and Response in Asia. 2020, The MacKinsey Global Report Institute. Available online: www.makinsey.com (accessed on 29 August 2020).

- The Conversation. Global Emissions to Hit 36.8 Billion Tonnes, Beating Last Year’s Record High. 4 December 2019. Available online: https://theconversation.com/global-emissions-to-hit-36-8-billion-tonnes-beating-last-years-record-high-128113 (accessed on 5 March 2021).

- EPA. Overview of Greenhouse Gases. United States Environmental Protection Agency: Washington, DC, USA, 2020. Available online: https://www.epa.gov/ghgemissions (accessed on 26 August 2020).

- CIEL. Plastic & Climate. The Hidden Costs of a Plastic Planet. 2019, Center for International Environmental Law (CIEL) Report. Available online: www.ciel.org/plasticaclimate (accessed on 26 August 2020).

- Greyhound, P. 22,000 Coffee Cups Disposed of in Ireland Every Hour. 2019, Greyhound Recycling. Available online: www.greyhound.ie (accessed on 29 August 2020).

- Hundertmar, K.T.; Mayer, M.; McNelly, C.; Simons, T.S.; Witte, C. How Plastics Waste Recycling Could Transform the Chemical Industry; McKinsey and Company: New York, NY, USA, 2018. [Google Scholar]

- Shridhar, A. Health by Generation—Understanding Health Lifestyles and Behaviours. Euromonitor International Report. Available online: https://go.euromonitor.com/white-paper-ch-2020-health-by-generation.html (accessed on 5 March 2021).

- Mason, A.; Garfeld, D.; Greenway, J. Naturally Beautiful: Millennials and Preferences in Beauty and Personal care Products. 2018. Available online: www.alixpartners.com (accessed on 29 August 2020).

- Jindal, S.; Kwek, S.; McDougall, A. Global Beauty and Personal Care Trends 2030. Mintel Report. 2020. Available online: www.mintel.com (accessed on 29 August 2020).

- Crabbe, M.; Lieberman, G.; Moriarty, S. Consumer Trends 2030. Mintel Report. 2020. Available online: www.mintel.com (accessed on 29 August 2020).

- Barbalova, I.; Oster, M. Health and Beauty in the Coronavirus Era. Euromonitor International Report. 2020. Available online: https://go.euromonitor.com/webinar-bpc-2020-covidhealthbeauty.html (accessed on 5 March 2021).

- Ridder, M. Cosmetics Industry -Statistics & Facts, 2020. Statista. Available online: https://www.statista.com/topics/3137/cosmetics-industry/ (accessed on 5 March 2021).

- Morganti, P.; Coltelli, M.B. A new carrier for advanced cosmeceuticals. Cosmetics 2019, 6, 10. [Google Scholar] [CrossRef] [Green Version]

- Riddell, J.; Johansson, J.A.; Ford, M.J.; Jahoda, C.A.B.; Klika, V.; Mort, R.L.; Headon, D.J. Hierarchical Patterning modes orchestrate hair follicle morphogenesis. PLoS Biol. 2017, 15, e2002117. [Google Scholar]

- Narisawa, Y.; Kohda, H. Arrector pili muscles surround human facial vellus hair follicles. Br. J. Dermatol. 1993, 129, 138–139. [Google Scholar] [CrossRef]

- Evans, D.J.; Laczki, M. Cleavage of integral surface lipids by aminolysis. Text. Res. J. 1997, 67, 435–444. [Google Scholar] [CrossRef]

- Tabor, D. Friction as a dissipative process. In Fundamentals of Friction Macroscopic and Microscopic Processes; Singer, I.L., Pollock, H.M., Eds.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2020; pp. 3–24. [Google Scholar]

- Yu, J.; Yu, D.; Checkla, D.M.; Freedberg, I.M.; Bertolino, A.P. Human hair keratins. J. Investig. Dermatol. 1993, 101, 56S–59S. [Google Scholar] [CrossRef]

- Zoak, C.; Dawber, R.P.R. Hair structure, function and physicochemical properties. In The Science of Hair Care; Zviak, C., Ed.; Marcel Dekker Inc.: New York, NY, USA, 1986; pp. 1–48. [Google Scholar]

- Benzarti, M.; Pailler-Mattei, C.; Jamart, J.; Zahouani, H. The effect of hydration in the mechanical behaviour of hair. Exp. Mech. 2014, 54, 1411–1419. [Google Scholar] [CrossRef]

- Robles Velasco, M.V.; de Sa Dias, T.C.; de Freitas, A.Z.; Vieira Junior, N.D.; Kaneko, M.T.; Rolim Baby, A. Hair fiber characteristics and method to evaluate hair physical and mechanical properties. Braz. J. Pharm. Sci. 2009, 42, 153–162. [Google Scholar] [CrossRef]

- Staron, P.; Banach, M.; Kowalski, Z. Keratin-origins, properties, applications. CHEMIK 2011, 65, 1019–1026. [Google Scholar]

- Zhang, Y.; Alsop, R.J.; Soomro, A.; Yang, F.G.; Rheinstandter, M.C. Effect of shampoo, conditioner and permanent waving on the molecular structure of human hair. PeerJ 2015, 3, e1296. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Robinson, V.N.E. A study of damaged hair. J. Soc. Cosmet. Chem. 1976, 27, 155–161. [Google Scholar] [CrossRef] [PubMed]

- Cruz, C.F.; Martins, M.; Egipto, J.; Osorio, H.; Ribeiro, A.; Cavaco-Paulo, A. Changing the shape of hair with keratin peptides. RSC Adv. 2017, 7, 5181–51592. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Ezazi, N.Z.; Liu, L.; Aidary, R.; Xiang, W.; Borghei, M.; Santos, H.A.; Rojas, O.J. Microfibers synthesized by wet-spinning of chitin nanomaterials: Mechanical, structural and cell proliferation properties. RSC Adv. 2020, 10, 29450–29459. [Google Scholar] [CrossRef]

- Abd El-Hack, M.; El-Saadoy, M.T.; Shafi, M.E.; Zabermawi, N.M.; Arif, M.; Batiha, G.E.; Khafaga, A.F.; Abd El-Hakim, Y.; Al-Sagheer, A.A. Antimicrobial and antioxidant properties of chitosan and its derivatives and their applications: A review. Int. J. Biol. Macromol. 2020, 164, 2726–2744. [Google Scholar] [CrossRef]

- Hart, H. Minireview of waste shell-derived materials’ application. Sustain. Circ. Econ. 2020, 38, 514–527. [Google Scholar] [CrossRef]

- Harland, D.P.; Walls, R.J.; Vernon, J.A.; Dyer, J.M.; Woods, J.L.; Bell, F. Three-dimensional architecture of macrofibrils in the human scalp hair. J. Struct. Biol. 2014, 185, 397–404. [Google Scholar] [CrossRef]

- Panariello, L.; Coltelli, M.B.; Buchignani, M.; Lazzeri, A. Chitosan and nano-structured chitin for biobased anti-microbial treatments onto cellulose based materials. Eur. Polym. J. 2019, 113, 328–339. [Google Scholar] [CrossRef]

- Muriel, J.M.; O’Neill, A.; Kerr, J.P.; Kleinhans-Welte, E.; Lovering, R.M.; Bloch, R.S. Keratin is an integral part of the intermediate filament network in murine skeletal muscle. Am. J. Physiol. Cell Physiol. 2020, 318, C215–C224. [Google Scholar] [CrossRef] [PubMed]

- Welte, E. Keratins in Skeletal Muscle: Effects of Altering Expression of Type I/Type II Keratin Pairs. Master’s Thesis, Department of Physiology, University of Maryland, Baltimore, MD, USA, 2014. [Google Scholar]

- Rittie, L. Cellular mechanisms of skin repair in humans and other mammals. J. Cell Commun. Signal. 2016, 10, 103–120. [Google Scholar] [CrossRef] [Green Version]

- Biagini, A.; Zizzi, F.; Santomassi, F.; Orlando, F.; Lucarini, G.; Mattioli-Belmonte, M.; Tucci, M.G.; Morganti, P. Cutaneous absorption of chitin associated with natural synergistic molecules(lutein). J. Appl. Cosmetol. 1999, 26, 69–80. [Google Scholar]

- Galbraith, H. Fundamental hair follicle biology and fine fibre production in animals. Animal 2010, 4, 1490–1509. [Google Scholar] [CrossRef] [Green Version]

- Coloumbe, P.A.; Omary, M.B. Hard and soft principles defining the structure, function and regulation of keratin intermediate filaments. Curr. Opin. Cell. Biol. 2002, 14, 110–122. [Google Scholar] [CrossRef]

- Sellan, K.; Rajan, S.; Suganya, T.; Parameshwari, G.; Antonysamy, M. Immunocosmeceuticals by anti-hair antibodies. Chron. Young Sci. 2013, 4, 81–85. [Google Scholar]

- Speck, O.; Speck, T. An overview of bioinspired and biomimetic self-repairing materials. Biomimetics 2019, 4, 26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Morganti, P.; Morganti, G. Natural polymers for natural hair: The smart use of an innovative carrier. In Nanocosmetics: Fundamantals, Applications and Toxicity; Nanda, A., Nanda, S., Nguyen, T.A., Rajendran, S., Slimani, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 267–286. [Google Scholar]

- Morganti, P.; Danti, S.; Coltelli, M.B. Chitin and lignin to produce biocompatible tissues. Res. Clin. Dermatol. 2018, 1, 5–11. [Google Scholar] [CrossRef]

- Danti, S.; Trombi, L.; Fusco, A.; Azimi, B.; Lazzeri, A.; Morganti, P.; Coltelli, M.B.; Donnarumma, G. Chitin nanofibrils and nanolignin as functional agents in skin regeneration. Int. J. Mol. Sci. 2019, 20, 2669. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Morganti, P. Use of chitin nanofibrils from biomass for an innovative bioeconomy. In Nanofabrication Using Nanomaterials; Ebothe, J., Ahmed, W., Eds.; One Central Press: Manchester, UK, 2016; pp. 1–22. [Google Scholar]

- Morganti, P.; Del Ciotto, P.; Stoller, M.; Chianese, A. Antibacterial and antiinflammatory green nanocomposites. Chem. Eng. Trans. 2016, 47, 61–64. [Google Scholar] [CrossRef]

- Donnarumma, G.; Fusco, A.; Morganti, P.; Palombo, M.; Anniboletti, T.; Del Ciotto, P.; Baroni, A.; Chianese, A. Advanced medications made by green nanocomposites. Int. J. Res. Nano Sci. 2018, 5, 261–270. [Google Scholar]

- Morganti, P.; Fusco, A.; Paoletti, I.; Perfetto, B.; Del Ciotto, P.; Donnarumma, G. Anti-inflammatory, immunomodulatory, and tissue repair activity on human keratinocytes by green innovative nanocomposites. Materials 2017, 10, 843. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, S.C.; Yoo, E.; Won, K. Preparation and Application of Light-colored Lignin for Broad-spectrum Sunscreens. Polymers 2020, 12, 699. [Google Scholar] [CrossRef] [Green Version]

- Morganti, P. Chitin nanofibrils: A natural multifunctional polymer. Physicochemical characteristics, effectiveness and safeness. In Nanobiotechnology; Phoenix, D.A., Ahmed, W., Eds.; One Central Press: Manchester, UK, 2016. [Google Scholar]

- Morganti, P. The meaning of nanodimension involving the cosmetic chemist from lab to the industry process. J. Sci. Res. Rep. 2015, 4, 79–100. [Google Scholar] [CrossRef]

- Coltelli, M.B.; Aglietto, M. Riutilizzo dei Materiali Polimerici; Nuova Cultura: Rome, Italy, 2015; pp. 39–73. [Google Scholar]

- Cinelli, P.; Coltelli, M.B.; Signori, F.; Morganti, P.; Lazzeri, A. Cosmetic packaging to save the environment: Future perspectives. Cosmetics 2019, 6, 26. [Google Scholar] [CrossRef] [Green Version]

- Landfill of Waste. Amendments Adopted by the European Parliament on 14 March 2017 on the Proposal for a Directive of the European Parliament and of the Council Amending Directive 1999/31/EC on the Landfill of Waste. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52017AP0071&rid=9 (accessed on 12 April 2019).

- Ehilen, O.; Obadoni, B.; Imade, F.; Eseigbe, D.; Mensah, J.K. The effect of detergents on the germination and growth of Amaranthus hybridus L. and Solanum lycopersicon L. Niger. Ann. Nat. Sci. 2017, 16, 100–108. [Google Scholar]

- Fatoba, P.O.; Olorunmaiye, K.S.; Adepoju, A.O. Effects of soaps and detergents wastes on seed germination, flowering and fruiting of tomato (Lycopersico nesculentum) and okra (Abelmoschus esculentus) plants. Ecol. Environ. Conserv. 2011, 17, 7–11. [Google Scholar]

- Alvarenga, P.; Palma, P.; Goncalves, A.P.; Fernandes, R.M.; Cunha-Queda, A.C.; Duarte, E.; Vallini, G. Evaluation of chemical and ecotoxicological characteristics of biodegradable organic residues for application to agricultural land. Environ. Int. 2007, 33, 505–513. [Google Scholar] [CrossRef]

- Position of European Bioplastics Concerning Bioplastics and the Circular Economy. Available online: https://www.pac.gr/bcm/uploads/bioplastics-and-the-circular-economy.pdf (accessed on 6 January 2019).

- Cinelli, P.; Coltelli, M.B.; Mallegni, N.; Morganti, P.; Lazzeri, A. Degradability and Sustainability of Nanocomposites Based on Polylactic Acid and Chitin Nano Fibrils. Chem. Eng. Trans. 2017, 60, 115–120. [Google Scholar]

- Aklog, Y.F.; Egusa, M.; Kaminaka, H.; Izawa, H.; Morimoto, M.; Saimoto, H.; Ifuku, S. Protein/CaCO3/chitin nanofiber complex prepared from crab shells by simple mechanical treatment and its effect on plant growth. Int. J. Mol. Sci. 2016, 17, 1600. [Google Scholar] [CrossRef] [PubMed]

- Boukhlifi, F.; Mamouni, F.Z.; Razouk, R. Chitin/Chitosan’s Bio-Fertilizer: Usage in Vegetative Growth of Wheat and Potato Crops; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef] [Green Version]

- Coltelli, M.B.; Cinelli, P.; Gigante, V.; Aliotta, L.; Morganti, P.; Panariello, L.; Lazzeri, A. Chitin nanofibrils in poly(lactic acid) (PLA) nanocomposites: Dispersion and thermo-mechanical properties. Int. J. Mol. Sci. 2019, 20, 504. [Google Scholar] [CrossRef] [Green Version]

- Herrera, N.; Salaberria, A.M.; Mathew, A.P.; Oksman, K. Plasticized polylactic acid nanocomposite films with cellulose and chitin nanocrystals prepared using extrusion and compression molding with two cooling rates: Effects on mechanical, thermal and optical properties. Compos. Part A 2016, 83, 89–97. [Google Scholar] [CrossRef] [Green Version]

- Coltelli, M.B.; Aliotta, L.; Vannozzi, A.; Morganti, P.; Panariello, L.; Danti, S.; Neri, S.; Fernandez-Avila, C.; Fusco, A.; Donnarumma, G.; et al. Properties and skin compatibility of films based on poly(lactic acid) (PLA) bionanocomposites incorporating chitin nanofibrils (CN). J. Funct. Biomater. 2020, 11, 21. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aliotta, L.; Vannozzi, A.; Canesi, I.; Cinelli, P.; Coltelli, M.B.; Lazzeri, A. Poly(lactic acid) (PLA)/Poly(butylene succinate-co-adipate) (PBSA) compatibilized binary biobased blends: Melt fluidity, morphological, thermo-mechanical and micromechanical analysis. Polymers 2021, 13, 218. [Google Scholar] [CrossRef]

- Narancic, T.; Verstichel, S.; Reddy Chaganti, S.; Morales-Gamez, L.; Kenny, S.T.; De Wilde, B.; Babu Padamati, R.; O’Connor, K.E. Biodegradable plastic blends create new possibilities for end-of-life management of plastics but they are not a panacea for plastic pollution. Environ. Sci Technol. 2018, 52, 10441–10452. [Google Scholar] [CrossRef]

- Avio, C.G.; Gorbi, S.; Regoli, P. Plastics and microplastics in the oceans: From emerging pollutants to emerged threat. Mar. Environ. Res. 2016, 102, 1–10. [Google Scholar] [CrossRef]

- Gavigan, J.; Kefela, T.; Macadam-Somer, I.; Suh, S.; Geyer, R. Synthetic microfiber emissions to landrival those to waterbodies and are growing. PLoS ONE 2020, 15, e0237839. [Google Scholar] [CrossRef] [PubMed]

- OECD. Environment at a Glance—OECD Indicators; OECD Publishing: Paris, France, 2020. [Google Scholar] [CrossRef]

- OECD. OECD Economic Outlook; OECD Publishing: Paris, France, 2020; Volume 2020. [Google Scholar] [CrossRef]

- Morganti, P.; Morganti, G.; Colao, C. Biofunctional textiles for aging skin. Biomedicines 2019, 7, 51. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morganti, P.; Morganti, G.; Coltelli, M.-B. Smart and Sustainable Hair Products Based on Chitin-Derived Compounds. Cosmetics 2021, 8, 20. https://doi.org/10.3390/cosmetics8010020

Morganti P, Morganti G, Coltelli M-B. Smart and Sustainable Hair Products Based on Chitin-Derived Compounds. Cosmetics. 2021; 8(1):20. https://doi.org/10.3390/cosmetics8010020

Chicago/Turabian StyleMorganti, Pierfrancesco, Gianluca Morganti, and Maria-Beatrice Coltelli. 2021. "Smart and Sustainable Hair Products Based on Chitin-Derived Compounds" Cosmetics 8, no. 1: 20. https://doi.org/10.3390/cosmetics8010020

APA StyleMorganti, P., Morganti, G., & Coltelli, M.-B. (2021). Smart and Sustainable Hair Products Based on Chitin-Derived Compounds. Cosmetics, 8(1), 20. https://doi.org/10.3390/cosmetics8010020