A Review on Small Power Rating PV Inverter Topologies and Smart PV Inverters

Abstract

:1. Introduction

2. Inverter Classifications

2.1. Stand-Alone Photovoltaic (PV) Systems

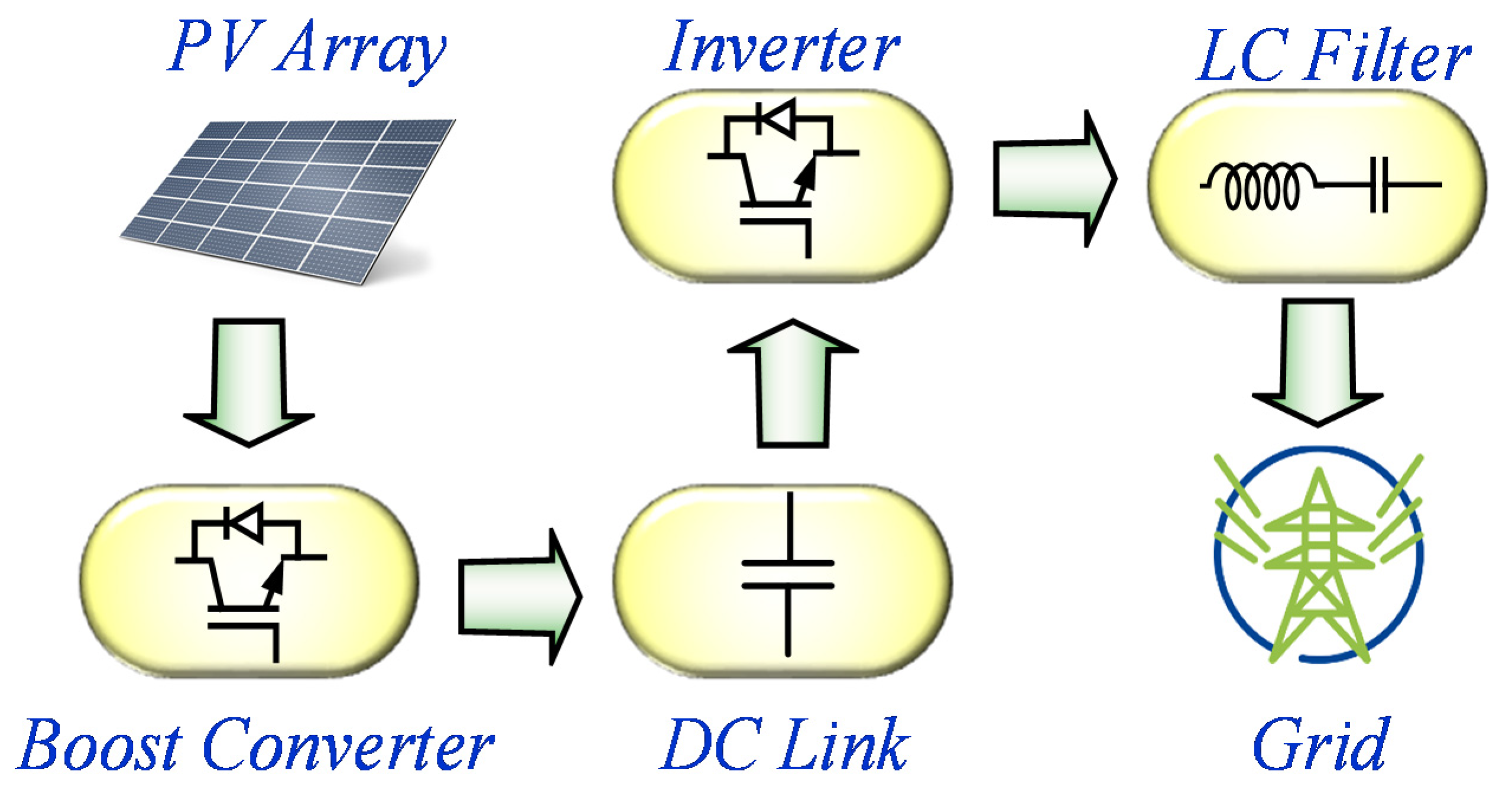

2.2. Grid-Connected PV Inverter

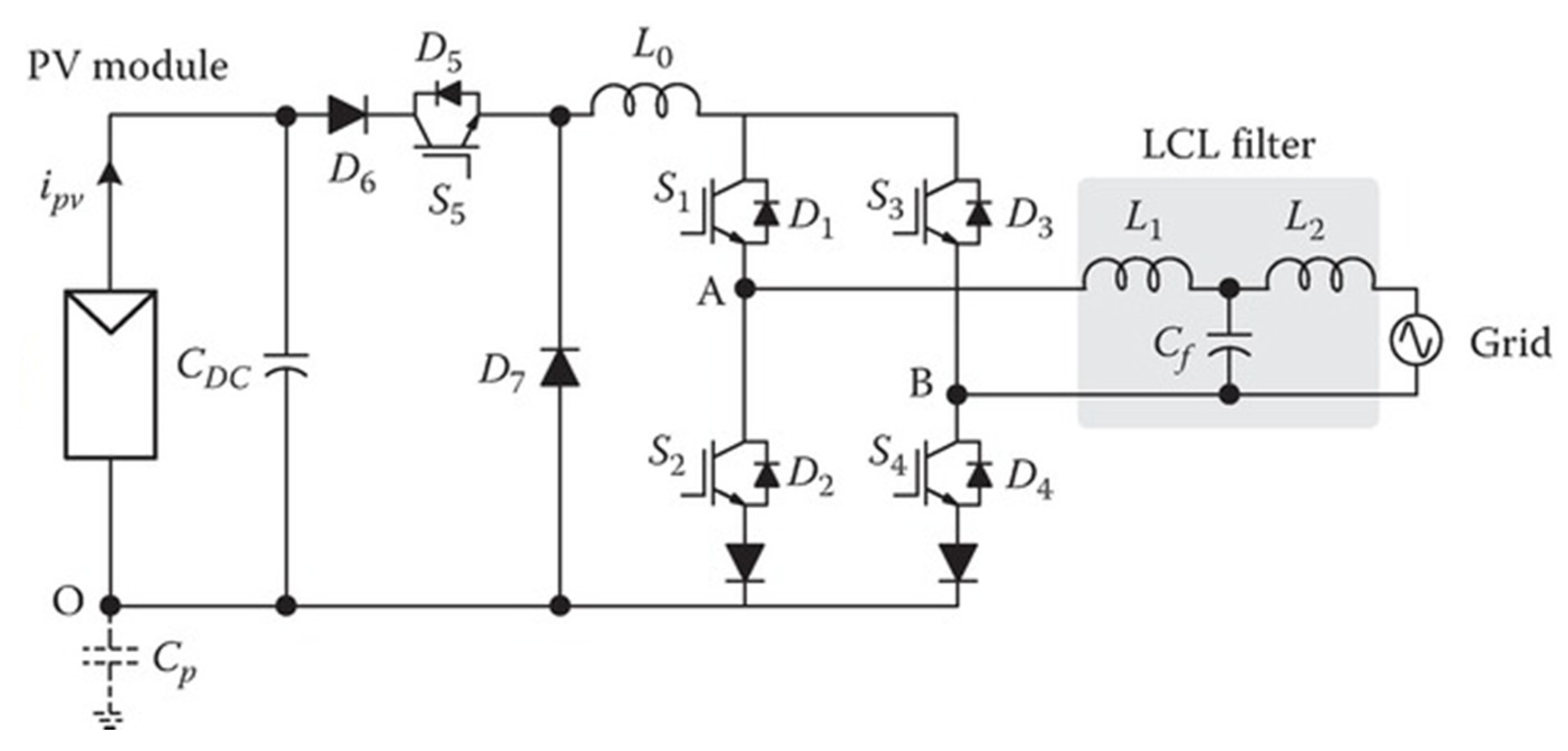

3. Transformerless Inverters

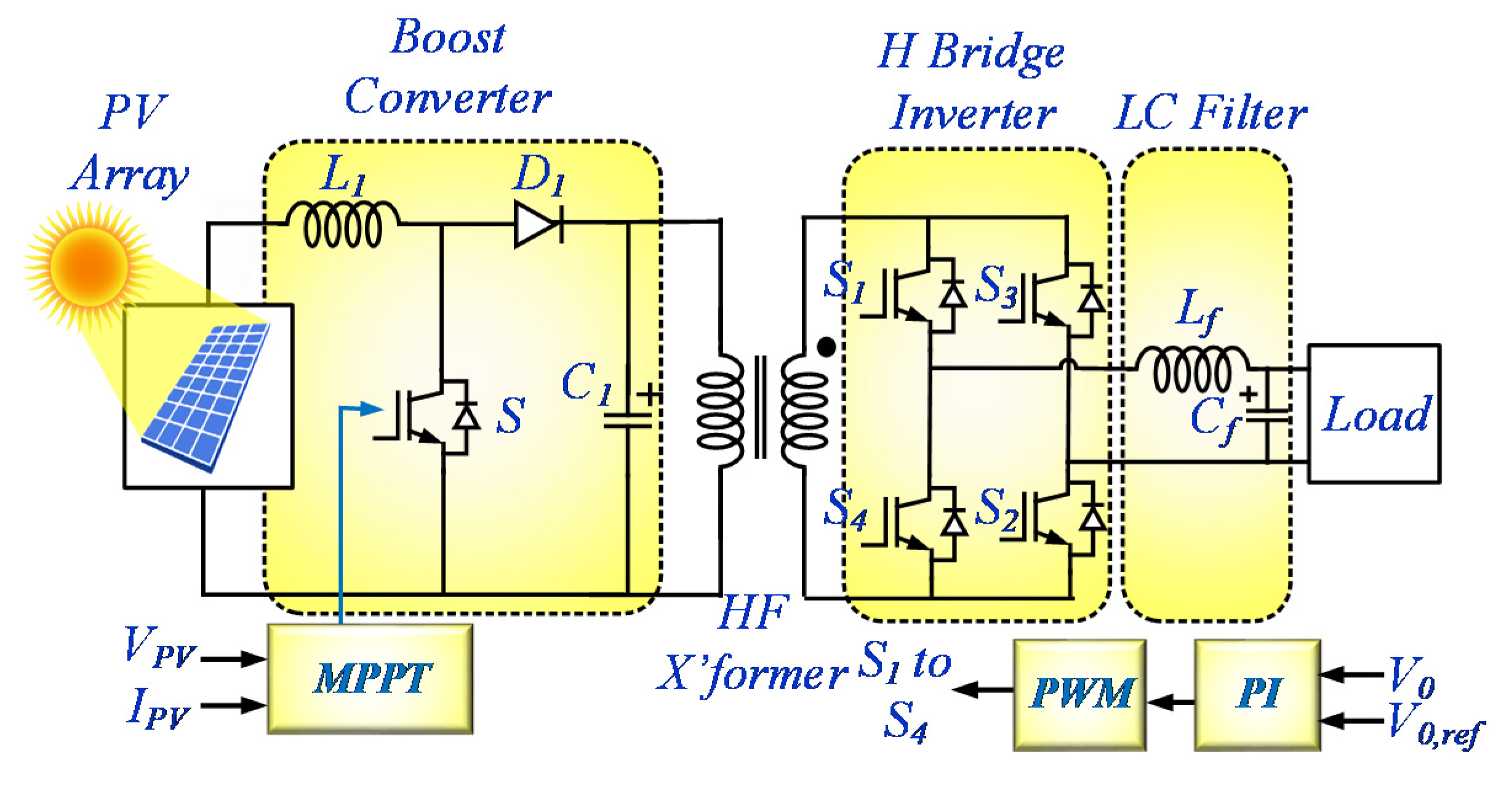

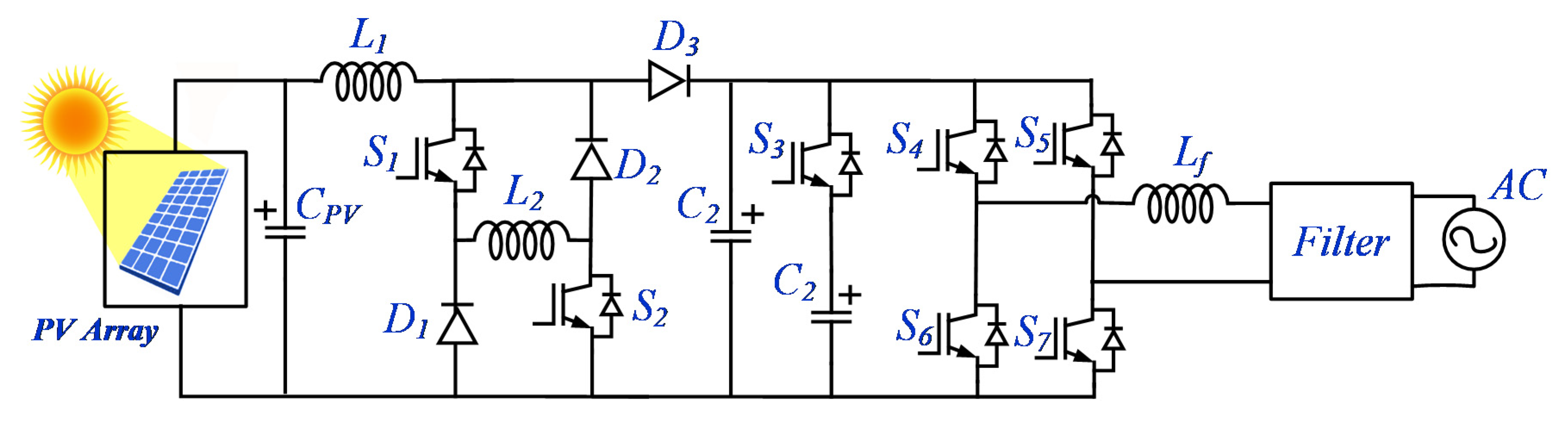

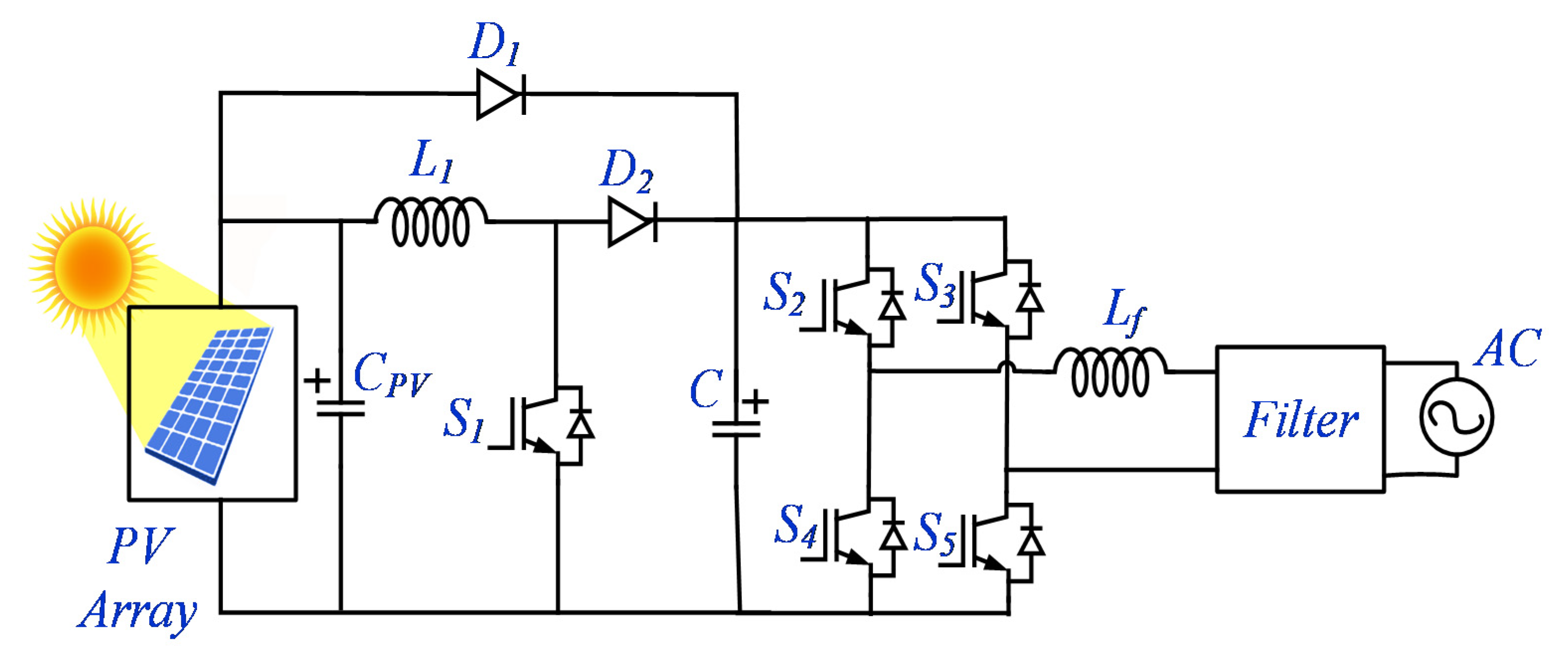

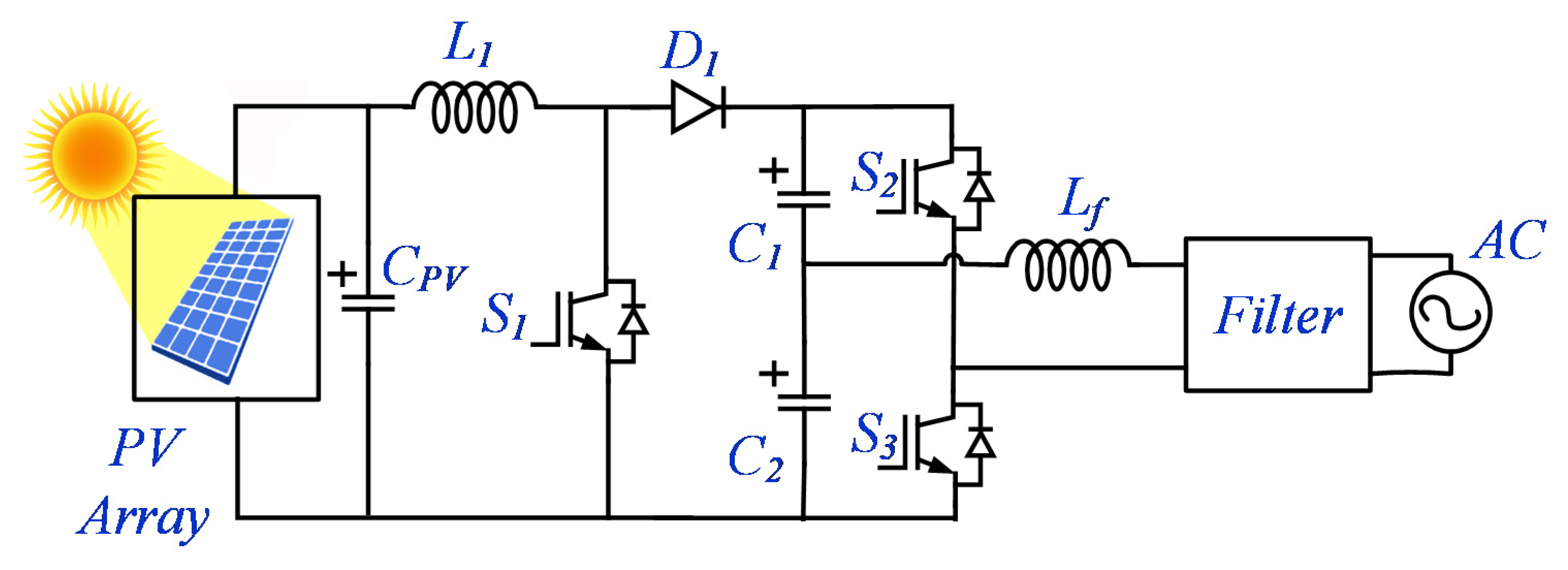

3.1. Two-Stage Topologies

3.2. Single-Stage Topologies

4. Grid-Connected Isolated Inverters

5. Multi-Stage Isolated Micro-Inverter

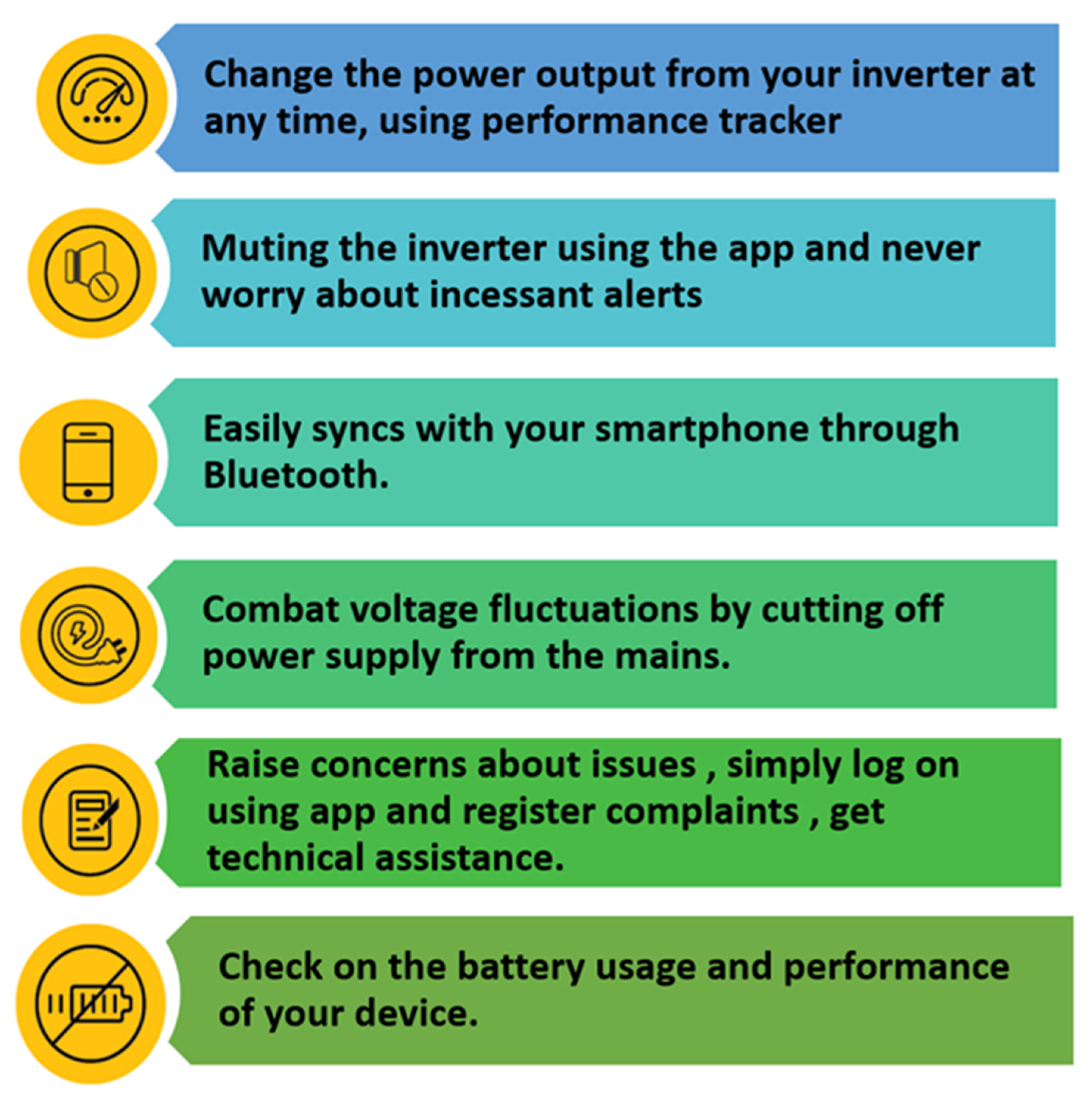

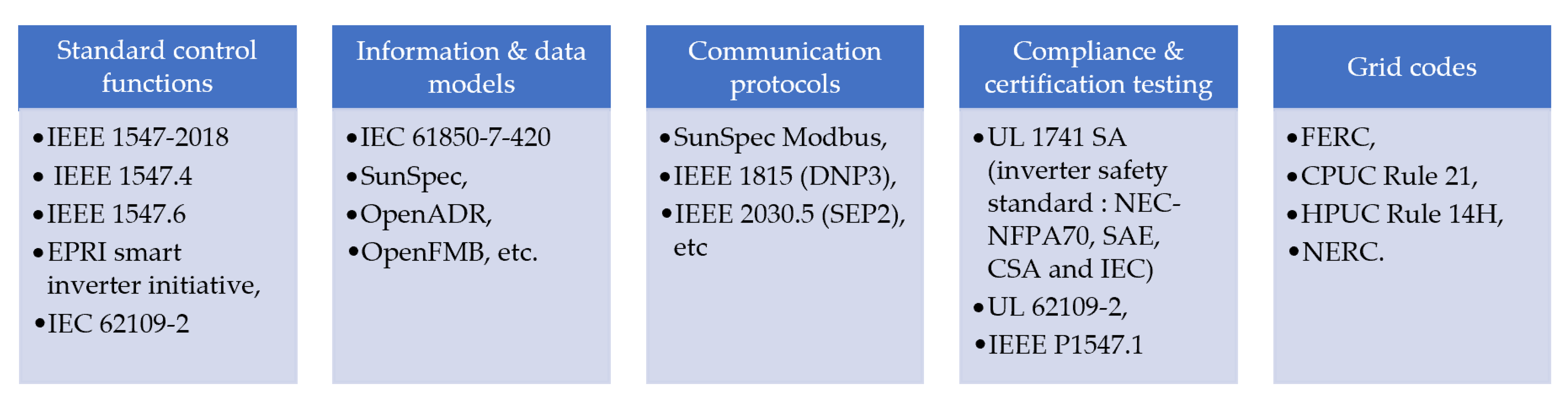

6. Smart Inverter

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Babu, T.S.; Rajasekar, N.; Sangeetha, K. Voltage band based improved particle swarm optimization technique for maximum power Point tracking in solar photovoltaic system. Renew. Sustain. Energy Rev. 2016, 15, 60–70. [Google Scholar]

- Babu, T.S.; Rajasekar, N.; Sangeetha, K. Modified particle swarm optimization technique based maximum power point tracking for uniform and under partial shading condition. Appl. Soft Comput. 2015, 32, 613–624. [Google Scholar] [CrossRef]

- Ram, J.P.; Babu, T.S.; Rajasekar, N. A comprehensive review on solar PV maximum power point tracking techniques. Renew. Sustain. Energy Rev. 2017, 67, 826–847. [Google Scholar] [CrossRef]

- Yang, Z.; Sen, P.C. A novel switch-mode dc-to-ac inverter with nonlinear robust control. IEEE Trans. Ind. Electron. 1998, 45, 602–608. [Google Scholar] [CrossRef]

- Kim, J.K.; Moon, G.W. Derivation, analysis, and comparison of non-isolated single switch high step-up converters with low voltage stress. IEEE Trans. Power Electron. 2015, 30, 1336–1344. [Google Scholar] [CrossRef]

- Balaji, C.; Chellammal, N.; Subranshu, S.D. A Non isolated Three-Port DC–DC Converter with Continuous Input and Output Currents Based on Cuk Topology for PV/Fuel Cell Applications. Electronics 2019, 8, 214. [Google Scholar]

- Wang, B.; Sechilariu, M.; Locment, F. Intelligent DC micro grid with smart grid communications: Control strategy consideration and design. IEEE Trans. Smart Grid 2012, 3, 2148–2156. [Google Scholar] [CrossRef]

- Veneri, O.; Capasso, C.; Lannuzzi, D. Experimental evaluation of DC charging architecture for fully-electrified low-power two-wheeler. Appl. Energy 2016, 162, 1428–1438. [Google Scholar] [CrossRef]

- Sun, Y.; Zhong, C.; Hou, X.; Yang, J.; Han, H.; Guerrero, G.M. Distributed cooperative synchronization strategy for multi-bus microgrids. Int. J. Electr. Power Energy Syst. 2017, 86, 18–28. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; He, X. Review of non-isolated high step-up DC/DC converters in photovoltaic grid-connected applications. IEEE Trans. Ind. Electron. 2011, 58, 1239–1250. [Google Scholar] [CrossRef]

- Davis, R.; Aathira, K.V. Developed non-isolated high step-up converter with low voltage stress. In Proceedings of the 2016 International Conference on Electrical, Electronics, and Optimization Techniques (ICEEOT), Chennai, India, 3–5 March 2016; pp. 1537–1540. [Google Scholar] [CrossRef]

- Teodorescu, R.; Blaabjerg, F.; Liserre, M.; Loh, P. Proportional resonant controllers and filters for grid-connected voltage-source converters. IEEE Electr. Power Appl. 2006, 153, 750–762. [Google Scholar] [CrossRef] [Green Version]

- Blaabjerg, F.; Chen, Z.; Kjaer, S.B. Power electronics as efficient inter power generation systems. IEEE Trans. Power Electron. 2004, 19, 1184–1194. [Google Scholar] [CrossRef]

- Prabaharan, N.; Palanisamy, K. Analysis and integration of multilevel inverter configuration with boost converters in a photovoltaic system. Energy Convers Manag. 2016, 128, 327–342. [Google Scholar] [CrossRef]

- Kasa, N.; Iida, T.; Iwamoto, H. An inverter using buck-boost type chopper circuits for popular small-scale photovoltaic power system. In Proceedings of the IEEE IECON’99, San Jose, CA, USA, 29 November–3 December 1999; pp. 185–190. [Google Scholar]

- Nagao, M.; Harada, K. Power flow of photovoltaic system using buck-boost PWM power inverter. In Proceedings of the IEEE PEDS’97, Singapore, 26–29 May 1997; pp. 144–149. [Google Scholar]

- Rahman, M.F.; Zhong, L. A new, transformerless, photovoltaic array to utility grid interconnection. In Proceedings of the Second International Conference on Power Electronics and Drive Systems, Singapore, 26–29 May 1997; pp. 139–143. [Google Scholar]

- Veerachary, V.; Senjyu, T.; Uezato, K. Neural-network-based maximum-power-point tracking of coupled-inductor interleaved-boost-converter-supplied PV system using fuzzy controller. IEEE Trans. Ind. Electron. 2003, 50, 749–758. [Google Scholar] [CrossRef] [Green Version]

- Hsieh, Y.; Chen, J.; Liang, T.; Yang, L. Novel High Step-Up DC–DC Converter with Coupled-Inductor and Switched-Capacitor Techniques. IEEE Trans. Ind. Electron. 2012, 59, 998–1007. [Google Scholar] [CrossRef]

- Akkaya, R.; Kulaksız, A.A.; Aydoğdu, Ö. DSP implementation of a PV system with GA-MLP-NN based MPPT controller supplying BLDC motor drive. Energy Convers. Manag. 2007, 48, 210–218. [Google Scholar] [CrossRef]

- Choi, S.; Agelidis, V.G.; Yang, J.; Coutellier, D.; Marabeas, P. Analysis, design and experimental results of a floating-output interleaved-input boost-derived DC–DC high-gain transformer-less converter. IET Power Electron. 2011, 4, 168–180. [Google Scholar] [CrossRef]

- Cáceres, R.O.; Barbi, I. A boost dc-ac converter: Analysis, design, and experimentation. IEEE Trans. Power Electron. 1999, 14, 134–141. [Google Scholar] [CrossRef]

- Ashraf Gandomi, A.; Varesi, K.; Hosseini, S.H. “DC-AC buck and buck-boost inverters for renewable energy applications. In Proceedings of the 6th Power Electronics, Drive Systems & Technologies Conference (PEDSTC2015), Tehran, Iran, 3–4 February 2015; pp. 77–82. [Google Scholar] [CrossRef]

- Suroso; Winasis; Priswanto; Purnama, I.D. Design of 1 kW Buck-Boost Chopper with PI Control for Photovoltaic Power Conversion. IOP Conf. Series Mater. Sci. Eng. 2020, 982, 012022. [Google Scholar] [CrossRef]

- Wang, X.; Xiao, H.; Wei, Z.; Chen, C. An Improved Transformerless Photovoltaic Grid-Connected Soft-Switching Inverter. In Proceedings of the 14th IEEE Conference on Industrial Electronics and Applications (ICIEA), Xi’an, China, 19–21 June 2019; pp. 2338–2343. [Google Scholar] [CrossRef]

- Shen, J.-M.; Jou, H.-L.; Wu, J.-C. Novel Transformerless Grid-Connected Power Converter with Negative Grounding for Photovoltaic Generation System. IEEE Trans. Power Electron. 2012, 27, 1818–1829. [Google Scholar] [CrossRef]

- Duran-Gomez, J.L.; Garcia-Cervantes, E.; Lopez-Flores, D.R.; Enjeti, P.N.; Palma, L. Analysis and evaluation of a series-combined connected boost and buck-boost dc-dc converter for photovoltaic application. In Proceedings of the Twenty-First Annual IEEE Applied Power Electronics Conference and Exposition, APEC ’06, Dallas, TX, USA, 19–23 March 2006; pp. 19–23. [Google Scholar]

- Mallwitz, R. Circuit Apparatus for Transformerless Conversion of an Electric Direct Voltage into an Alternating Voltage. U.S. Patent 7,616,467, 10 November 2009. [Google Scholar]

- Zacharias, P.; Sahan, B. Device for Feeding Electric Energy into A power Grid and DC Converter for such a Device. U.S. Patent 8116103 B2, 14 February 2012. [Google Scholar]

- Araujo, S.V.; Zacharias, P.; Sahan, B. Novel grid-connected non isolated converters for photovoltaic systems with grounded generator. In Proceedings of the 2008 IEEE Power Electronics Specialists Conference, Rhodes, Greece, 15–19 June 2008; pp. 58–65. [Google Scholar]

- Schoenbauer, S.; Martin-Lopez, F.R. Single Inductor Buck Boost Converter with Positive and Negative Outputs. U.S. Patent 2010/0039080, 18 February 2010. [Google Scholar]

- Prasad, S.; Jain, S.; Agarwal, V. Universal single-stage grid connected inverter. IEEE Trans. Energy Convers. 2008, 23, 128–137. [Google Scholar] [CrossRef]

- Junior, L.G.; de Brito, M.A.G.; Sampaio, L.P.; Canesin, C.A. Single stage converters for low power stand-alone and grid-connected PV systems. In Proceedings of the 2011 IEEE International Symposium on Industrial Electronics, Gdansk, Poland, 27–30 June 2011; pp. 1112–1117. [Google Scholar]

- Nahavandi, A.; Roostaee, M.; Azizi, M.R. Single stage DC-AC boost converter. In Proceedings of the 7th Power Electronics and Drive Systems Technologies Conference (PEDSTC), Tehran, Iran, 16–18 February 2016; pp. 362–366. [Google Scholar] [CrossRef]

- Liang, T.; Shyu, J.; Chen, J. A novel DC/AC boost inverter. In Proceedings of the 2002 37th Intersociety Energy Conversion Engineering Conference, Washington, DC, USA, 29–31 July 2002; pp. 629–634. [Google Scholar]

- Swaminathan, N.; Lakshminarasamma, N. High Gain, High Frequency Link DC-AC Converter with Hybrid SPWM Scheme. In Proceedings of the 2018 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Madras, India, 18–21 December 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Vazquez, N.; Almazan, J.; Alvarez, J.; Aguilar, C.; Arau, J. Analysis and experimental study of the buck, boost and buck-boost inverters. In Proceedings of the 30th Annual IEEE Power Electronics Specialists Conference. Record. (Cat. No.99CH36321), Charleston, SC, USA, 1 July 1999; pp. 801–806. [Google Scholar]

- Kasa, N.; Ogawa, H.; Iida, T.; Iwamoto, H. A transformer-less inverter using buck-boost type chopper circuit for photovoltaic power system. In Proceedings of the IEEE 1999 International Conference on Power Electronics and Drive Systems, Hong Kong, China, 27–29 July 1999; pp. 653–658. [Google Scholar]

- Patel, H.; Agarwal, V. A single-stage single-phase transformer-less doubly grounded grid-connected PV interface. IEEE Trans. Energy Convers. 2009, 24, 93–101. [Google Scholar] [CrossRef]

- Kusakawa, M.; Nagayoshi, H.; Kamisako, K.; Kurokawa, K. Further improvement of a transformerless, voltage-boosting inverter for AC modules. Solar Energy Mater. Solar Cells 2001, 67, 379–387. [Google Scholar] [CrossRef]

- Cao, D.; Jiang, S.; Yu, X.; Peng, F.Z. Low-cost semi-Z-source inverter for single-phase photovoltaic systems. IEEE Trans. Power Electron. 2011, 26, 3514–3523. [Google Scholar] [CrossRef]

- Li, D.; Loh, P.C.; Zhu, M.; Gao, F.; Blaabjerg, F. Generalized multi cell switched-inductor and switched-capacitor Z-source inverters. IEEE Trans. Power Electron. 2013, 28, 837–848. [Google Scholar] [CrossRef]

- Kjaer, S.B.; Pedersen, J.K.; Blaabjerg, F. A review of single-phase grid-connected inverters for photovoltaic modules. IEEE Trans. Ind. Appl. 2005, 41, 1292–1306. [Google Scholar] [CrossRef]

- Kasa, N.; Iida, T.; Chen, L. Fly-back inverter controlled by sensorless current MPPT for photovoltaic power system. IEEE Trans. Ind. Electron. 2005, 52, 1145–1152. [Google Scholar] [CrossRef]

- Shimizu, T.; Wada, K.; Nakamura, N. Flyback type single-phase utility-interactive inverter with power pulsation decoupling on the DC input for an AC photovoltaic module system. IEEE Trans. Power Electron. 2006, 21, 1264–1272. [Google Scholar] [CrossRef]

- Hu, H.B.; Harb, S.; Fang, X.; Zhang, D.H.; Zhang, Q.; Shen, Z.J. A three-port flyback for PV micro inverter applications with power pulsation decoupling capability. IEEE Trans. Power Electron. 2016, 27, 3953–3964. [Google Scholar] [CrossRef]

- Hu, H.B.; Harb, S.; Kutkut, N.H.; Shen, Z.J.; Batarseh, I. A single-stage micro inverter without using electrolytic capacitors. IEEE Trans. Power Electron. 2013, 28, 2677–2687. [Google Scholar] [CrossRef]

- Sukesh, N.; Pahlevaninezhad, M.; Jain, P.K. Analysis and implementation of a single-stage flyback PV micro inverter with softswitching. IEEE Trans. Ind. Electron. 2014, 61, 1819–1833. [Google Scholar] [CrossRef]

- Zhang, Z.L.; He, X.F.; Liu, Y.F. An optimal control method for photovoltaic grid-tied interleaved flyback micro inverters to achieve high efficiency in wide load range. IEEE Trans. Power Electron. 2013, 28, 5074–5087. [Google Scholar] [CrossRef]

- Edwin, F.F.; Xiao, W.; Khadkikar, V. Dynamic modelling and control of interleaved flyback module-integrated converter for PV power applications. IEEE Trans. Ind. Electron. 2014, 61, 1377–1388. [Google Scholar] [CrossRef]

- Pathy, S.; Sridhar, R.; Hari, N.; Dash, S.S.; Subramani, C. A modified module integrated—Interleaved boost converter for standalone photovoltaic (PV) application. In Proceedings of the 2016 IEEE International Conference on Renewable Energy Research and Applications (ICRERA), Birmingham, UK, 20–23 November 2016; pp. 989–994. [Google Scholar] [CrossRef]

- Gao, M.; Chen, M.; Zhang, C.; Qian, Z. Analysis and implementation of an improved flyback inverter for photovoltaic AC module applications. IEEE Trans. Power Electron. 2013, 28, 2649–2663. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Ji, Y.-H.; Kim, J.-G.; Jung, Y.-C.; Won, C.-Y. A new control strategy for improving weighted efficiency in photovoltaic AC module-type interleaved flyback inverters. IEEE Trans. Power Electron. 2013, 28, 2688–2699. [Google Scholar] [CrossRef]

- Meneses, D.; Garcia, O.; Alou, P.; Oliver, J.; Cobos, J. Grid-connected forward microinverter with primary- parallel secondary-series transformer. IEEE Trans. Power Electron. 2015, 30, 4819–4830. [Google Scholar] [CrossRef] [Green Version]

- Tan, G.H.; Wang, J.Z.; Ji, Y.C. Soft-switching flyback inverter with enhanced power decoupling for photo voltaic applications. IET Electron. Power Appl. 2017, 1, 264–274. [Google Scholar] [CrossRef]

- Rodriguez, C.; Amaratunga, G.A. Long-life time power inverter for photovoltaic AC modules. IEEE Trans. Ind. Electron. 2008, 55, 2593–2601. [Google Scholar] [CrossRef]

- Jiang, S.; Cao, D.; Li, Y.; Peng, F.Z. Grid-connected boost-half-bridge photovoltaic micro inverter system using repetitive current control and maximum power point tracking. IEEE Trans. Power Electron. 2012, 27, 4711–4722. [Google Scholar] [CrossRef]

- Chiu, H.J.; Lo, Y.K.; Yang, C.Y.; Cheng, S.J.; Huang, C.M.; Chuang, C. C A module integrated isolated solar micro inverter. IEEE Trans. Ind. Electron. 2013, 60, 781–788. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Shin, S.-C.; Lee, J.-H.; Jung, Y.-C.; Won, C.-Y. Soft-switching current-fed push–pull converter for 250W AC module applications. IEEE Trans. Power Electron. 2014, 29, 863–872. [Google Scholar]

- LaBella, T.; Lai, J.S. A hybrid resonant converter utilizing a bidirectional GaNAC switch for high-efficiency PVapplications. IEEE Trans. Ind. Electron. 2015, 50, 3468–3475. [Google Scholar]

- Cha, W.J.; Cho, Y.W.; Kwon, J.M.; Kwon, B.H. Highly efficient micro inverter with soft- switching step-up converter and single-switch-modulation inverter. IEEE Trans. Ind. Electron. 2015, 62, 3516–3523. [Google Scholar]

- Korosec, L.; Konjedic, T.; Truntic, M.; Rodic, M.; Milanovic, M. PDM flyback PV micro inverter with HFAC-link and active de coupling circuit. Electron. Lett. 2015, 51, 516–517. [Google Scholar] [CrossRef]

- Chen, L.; Amirahmadi, A.; Zhang, Q.; Kutkut, N.; Batarseh, I. Design and implementation of three-phase two-stage grid-connected module integrated converter. IEEE Trans. Power Electron. 2013, 29, 3881–3892. [Google Scholar] [CrossRef]

- Arbab-Zavar, B.; Palacios-Garcia, E.J.; Vasquez, J.C.; Guerrero, J.M. Smart Inverters for Microgrid Applications: A Review. Energies 2019, 12, 840. [Google Scholar] [CrossRef] [Green Version]

- From Smart Meters to Smart Inverters: How DVI Is Optimizing the Distributed Grid Greentechmedia.com. 2018. Available online: https://www.greentechmedia.com/articles/read/DVIs-grid-edge-vision-from-smart-meters-to-smart-inverters (accessed on 15 April 2021).

- Xue, Y.; Guerrero, J.M. Smart inverters for utility and industry applications. In Proceedings of the PCIM Europe 2015, International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 19–20 May 2015; pp. 1–8. [Google Scholar]

- Mirafzal, B.; Adib, A. On grid-interactive smart inverters: Features and advancements. IEEE Access 2020, 8, 160526–160536. [Google Scholar] [CrossRef]

- Lulbadda, K.T.; Hemapala, K.T.M.U. The additional functions of smart inverters. Aims Energy 2019, 7, 971–988. [Google Scholar] [CrossRef]

| Figure | Vin | Vout (Vrms) | Power Rating | Frequency | Switching Timing | Efficiency |

|---|---|---|---|---|---|---|

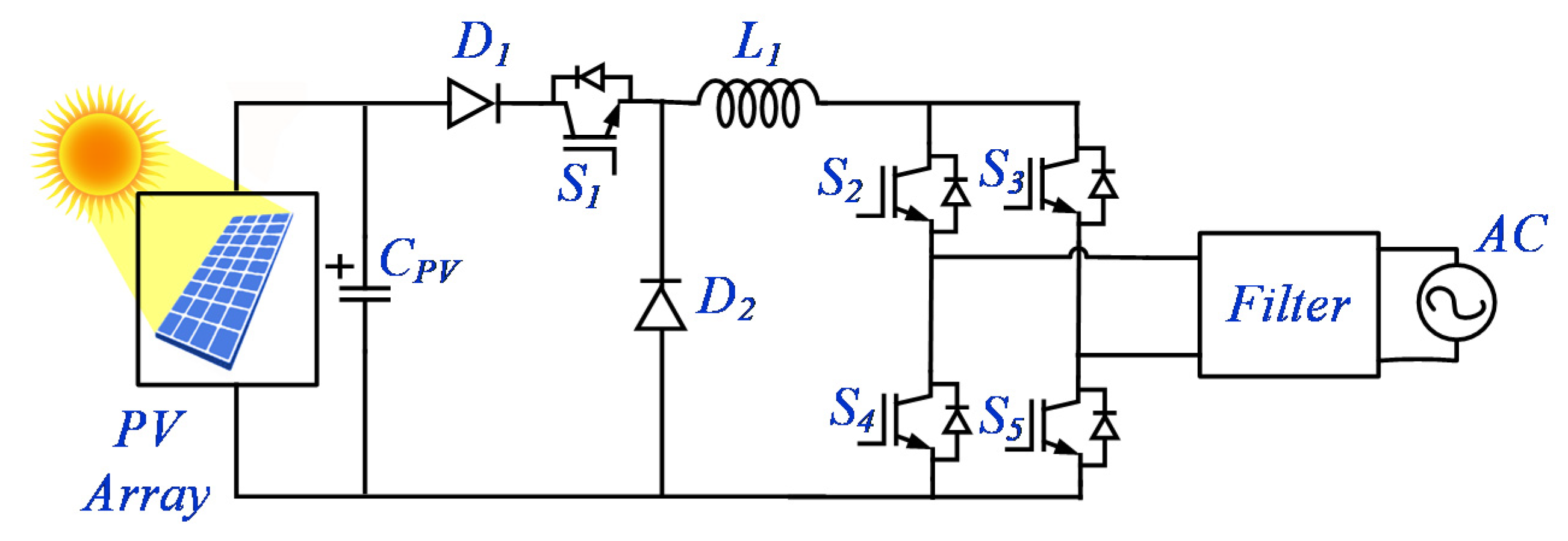

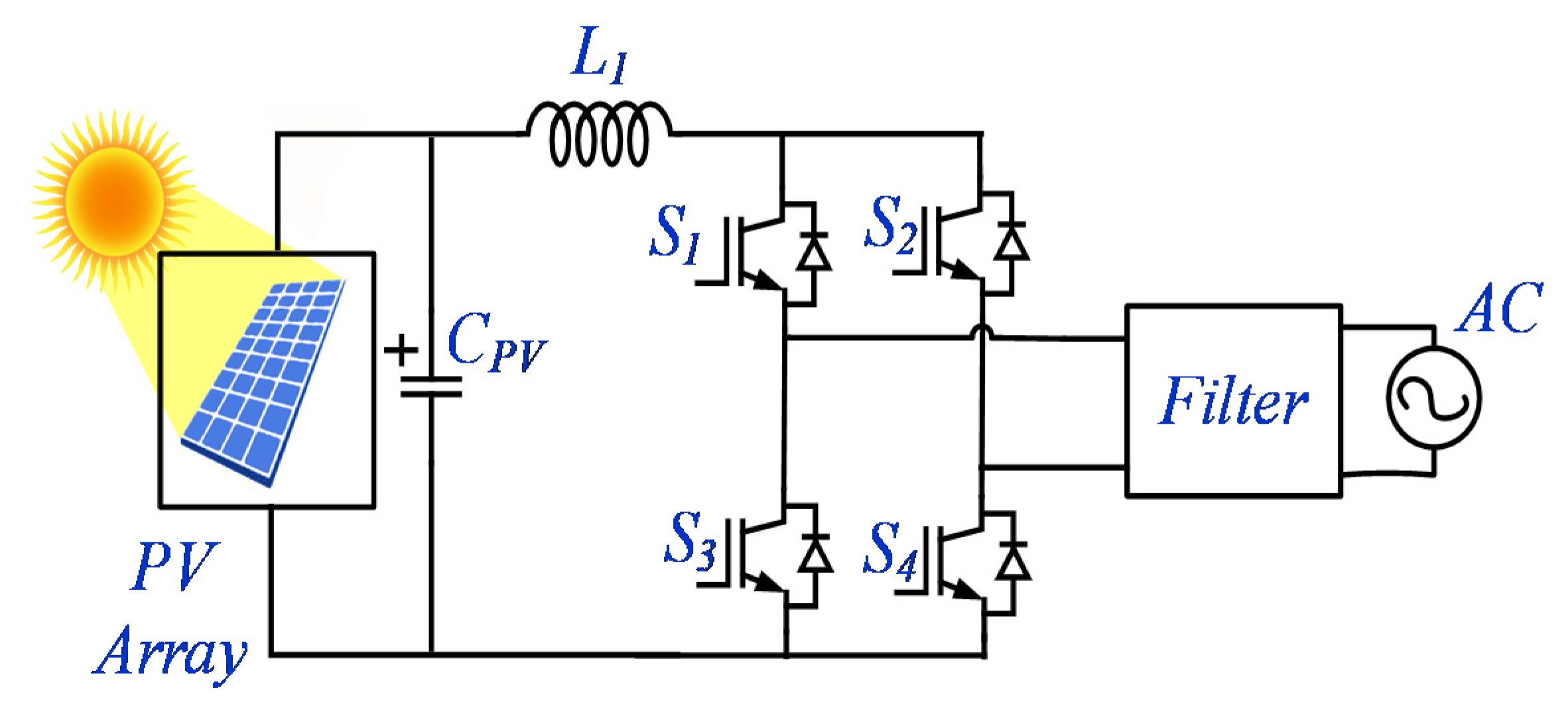

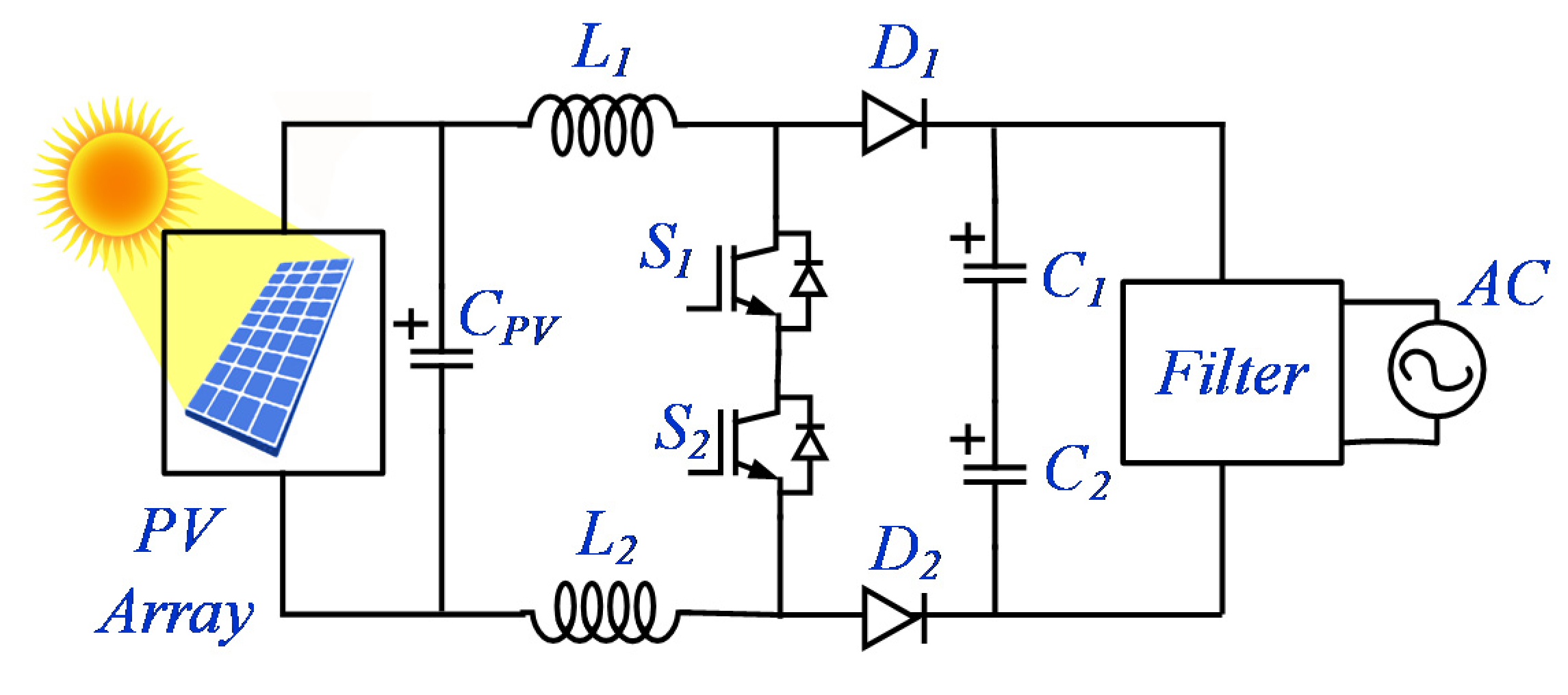

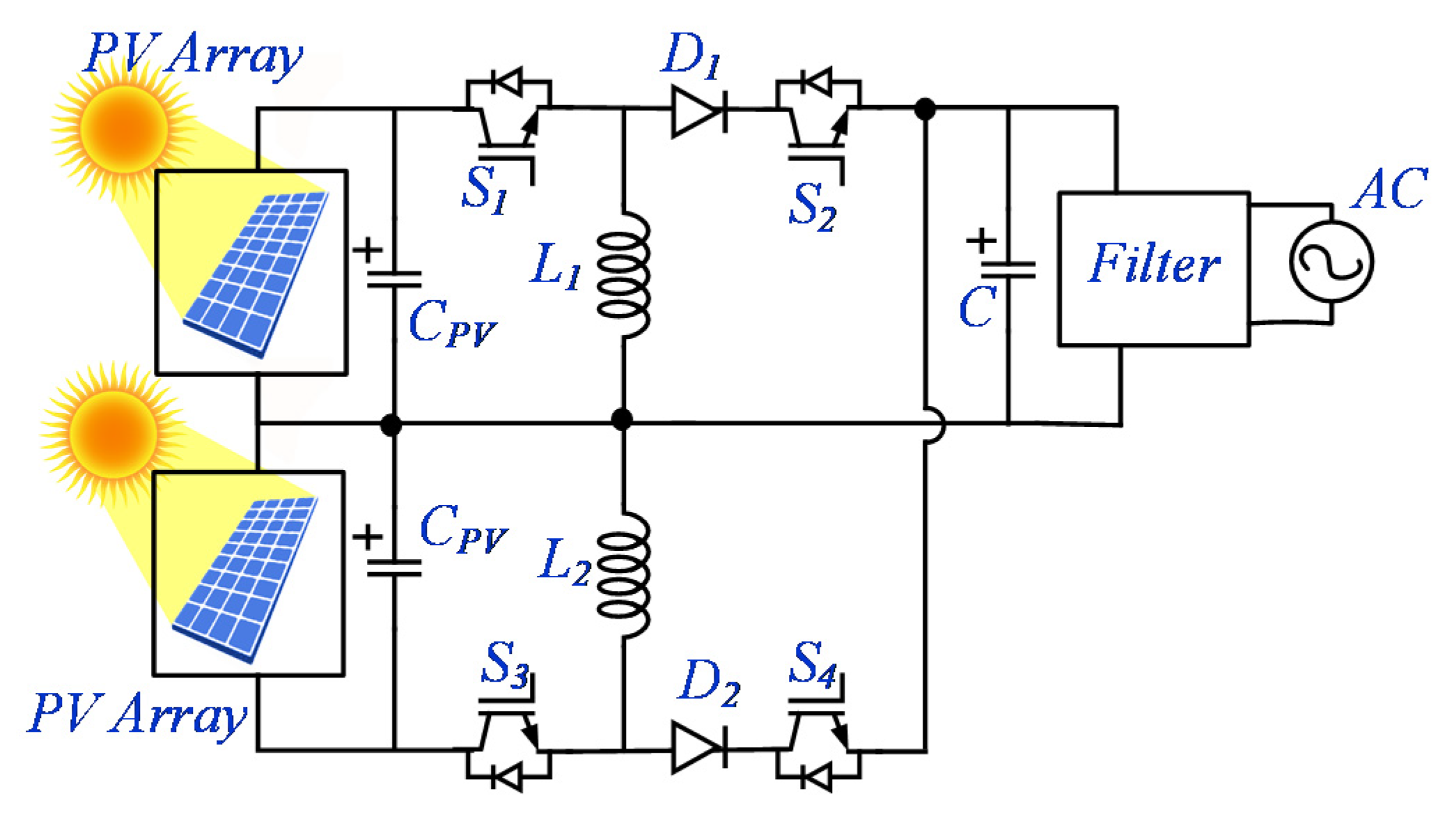

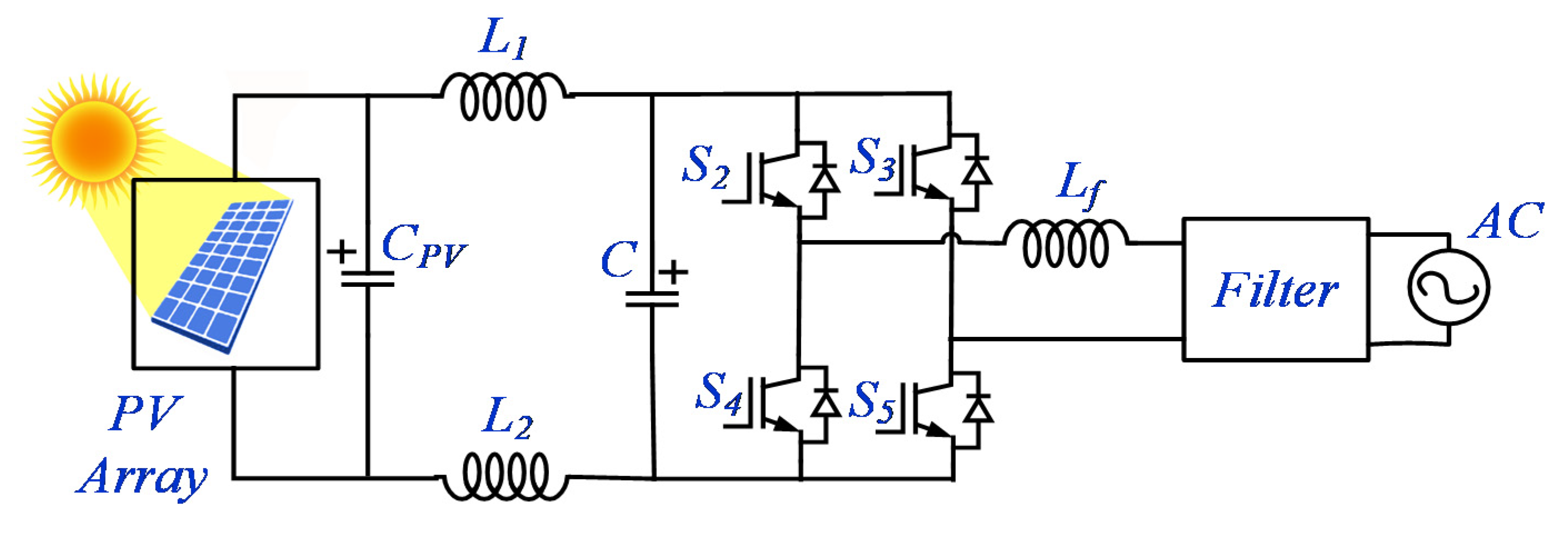

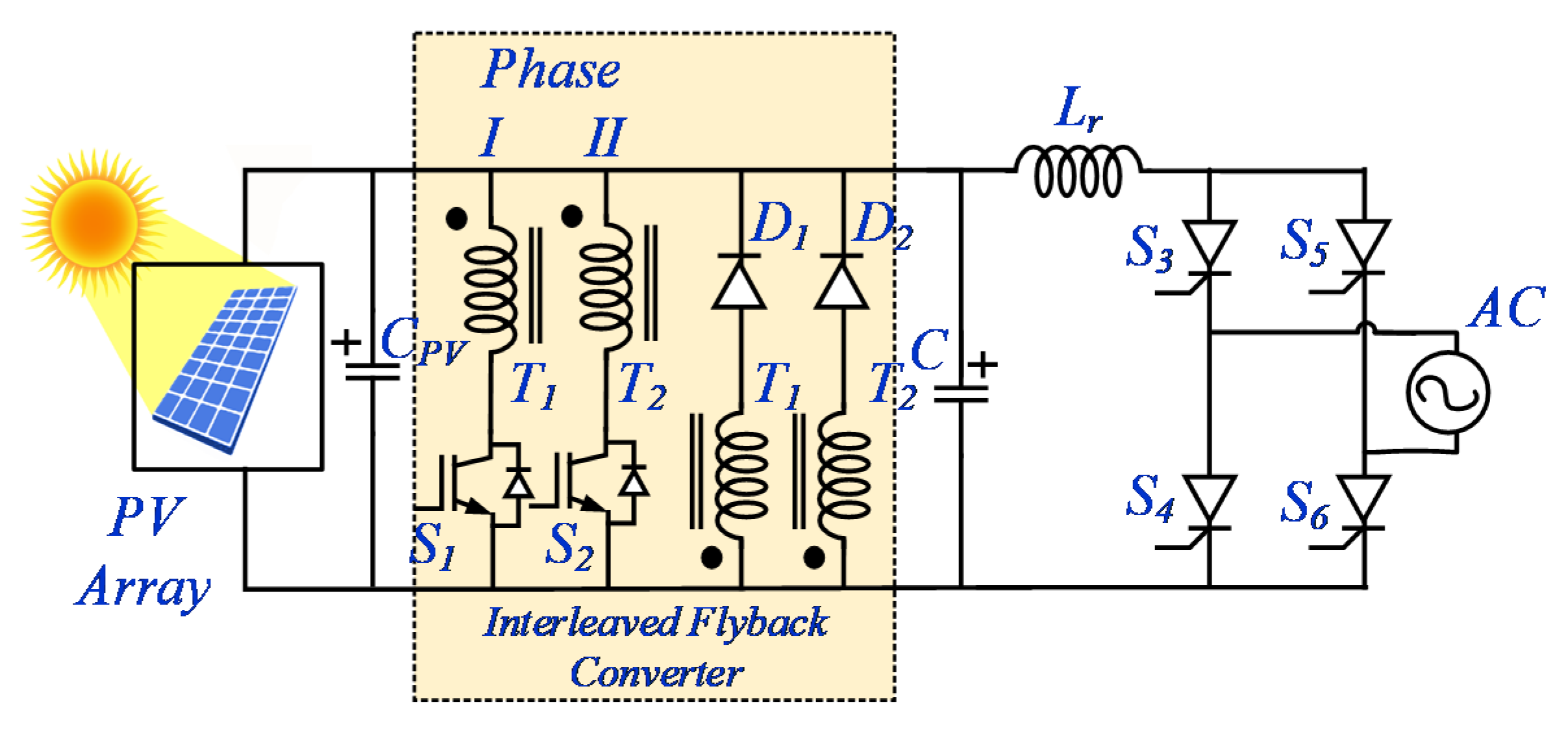

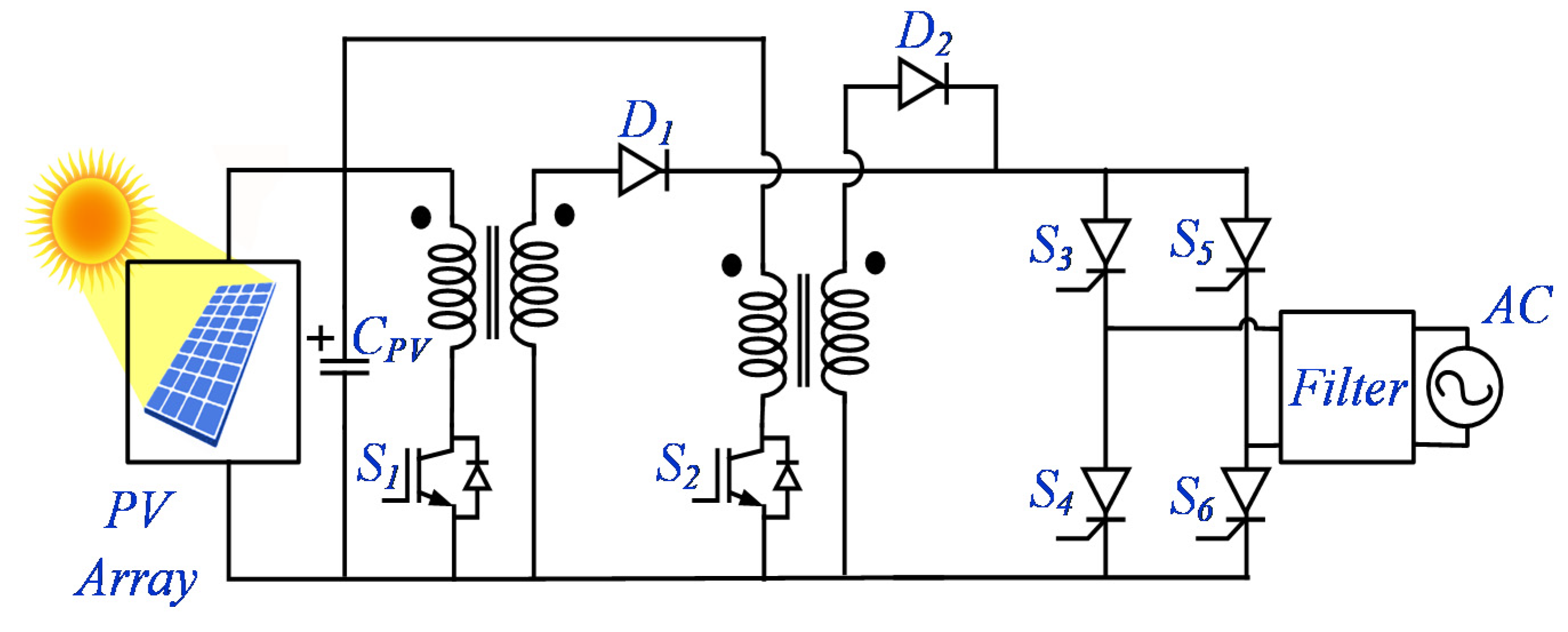

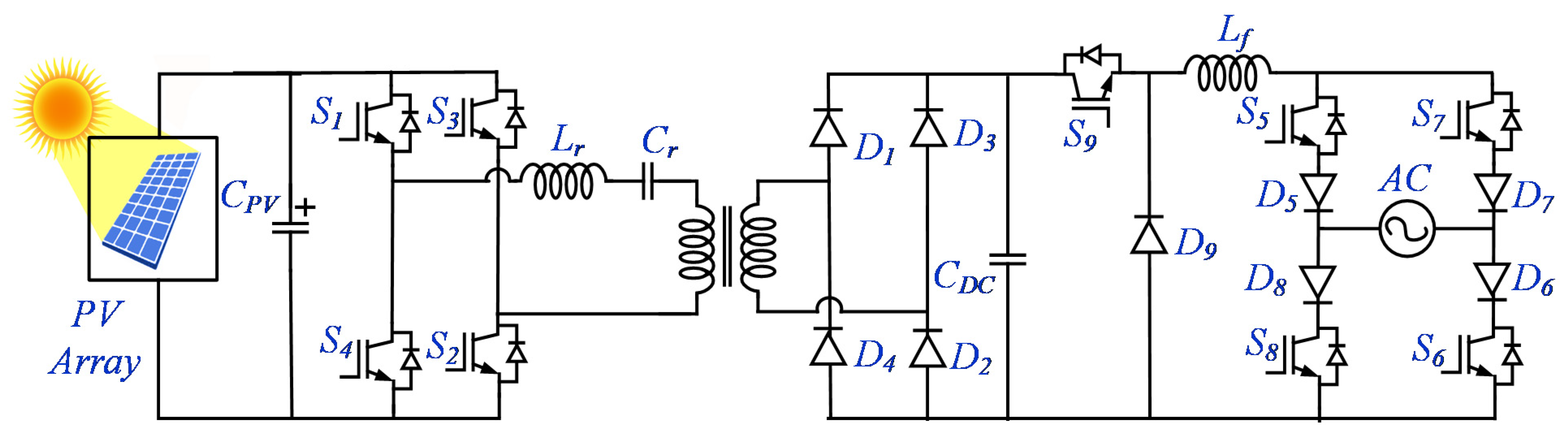

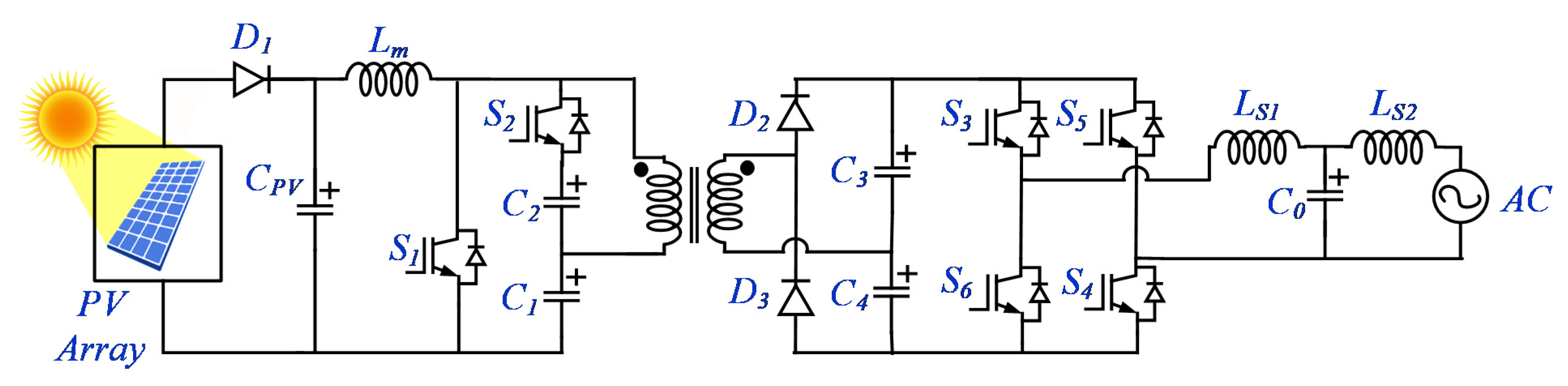

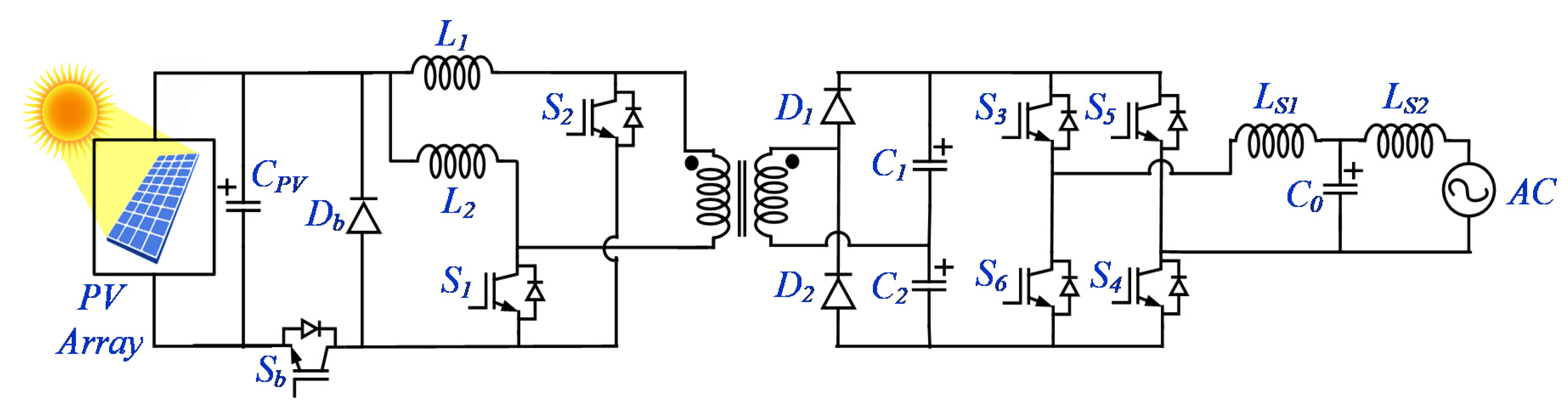

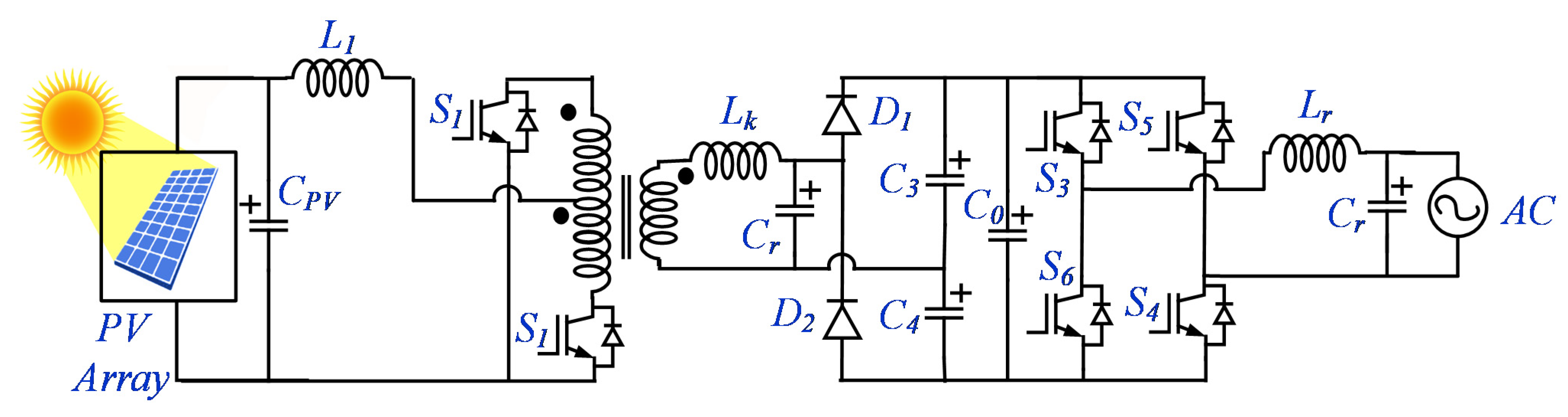

| Figure 7 | 160 | 210 | 1500 | 20 | 0.05 | 94 |

| Figure 8 | 140 | 200 | 1600 | 20 | 0.05 | 96.5 |

| Figure 9 | 160 | 120 | 270 | 30 | 0.033 | - |

| Figure 10 | 120 | 230 | 980 | 6.26 | 0.15 | - |

| Figure 11 | 150 | 115 | 930 | 18 | 0.055 | 96.7 |

| Figure | Vin | Vout | Power Rating | Frequency | Switching Timing | Efficiency |

|---|---|---|---|---|---|---|

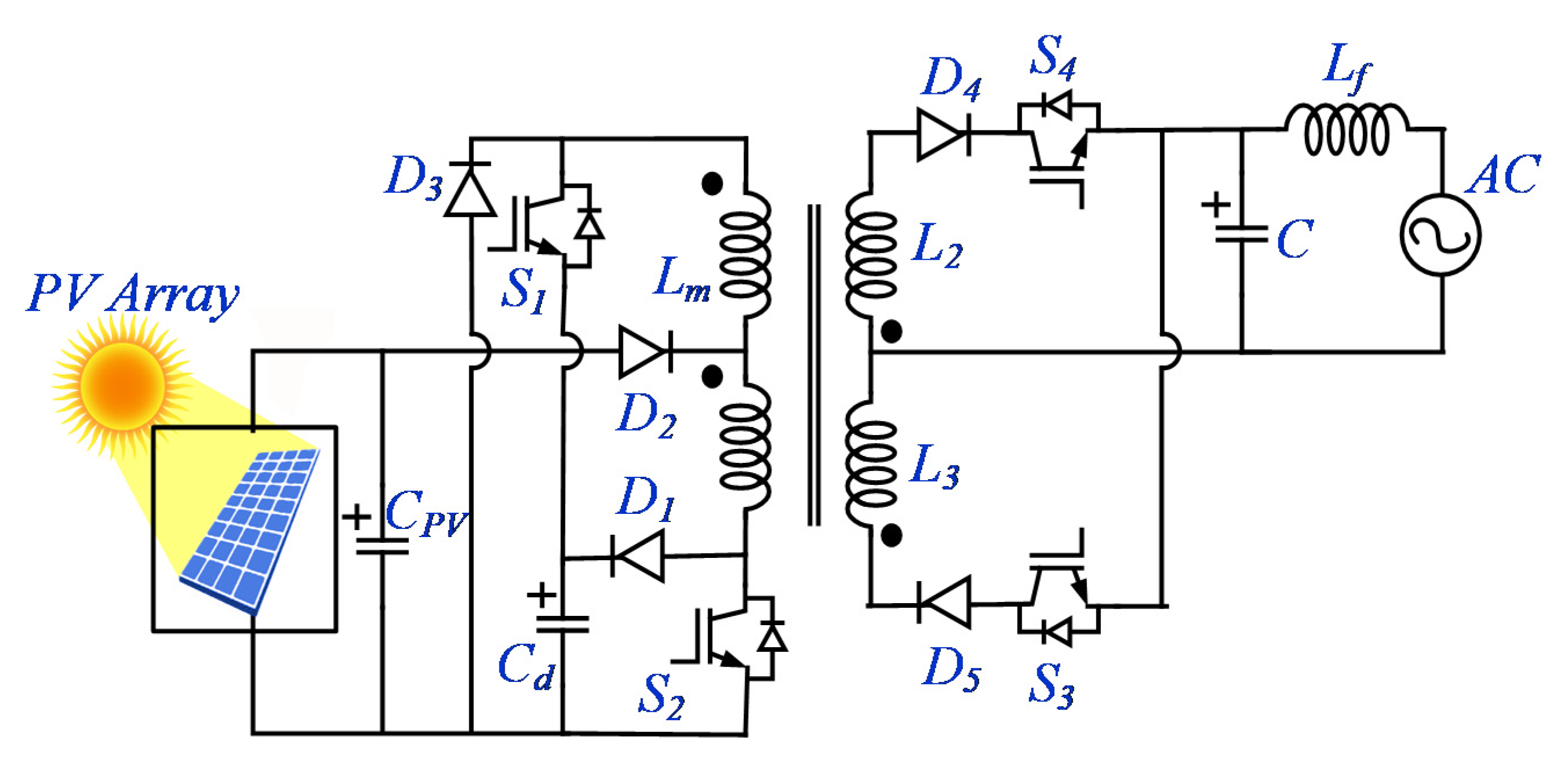

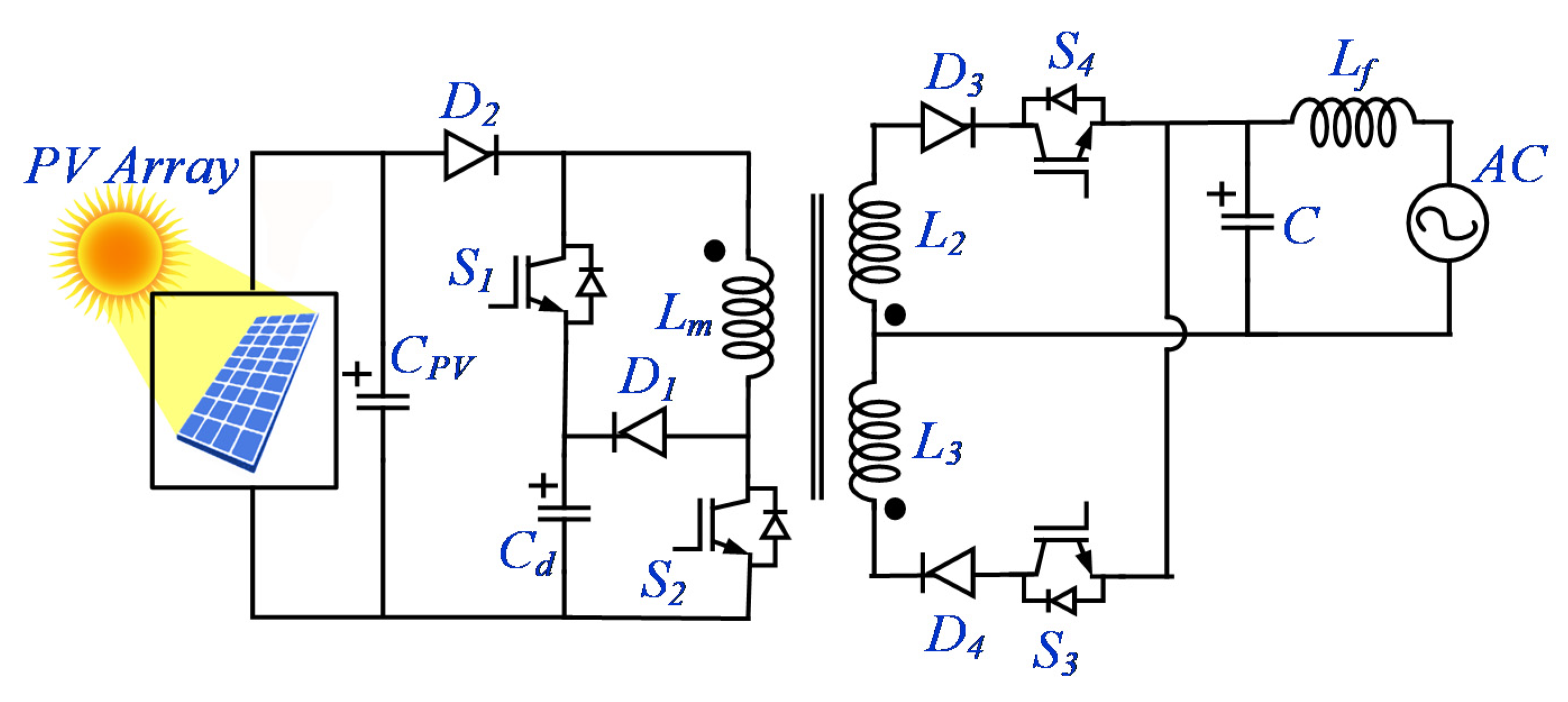

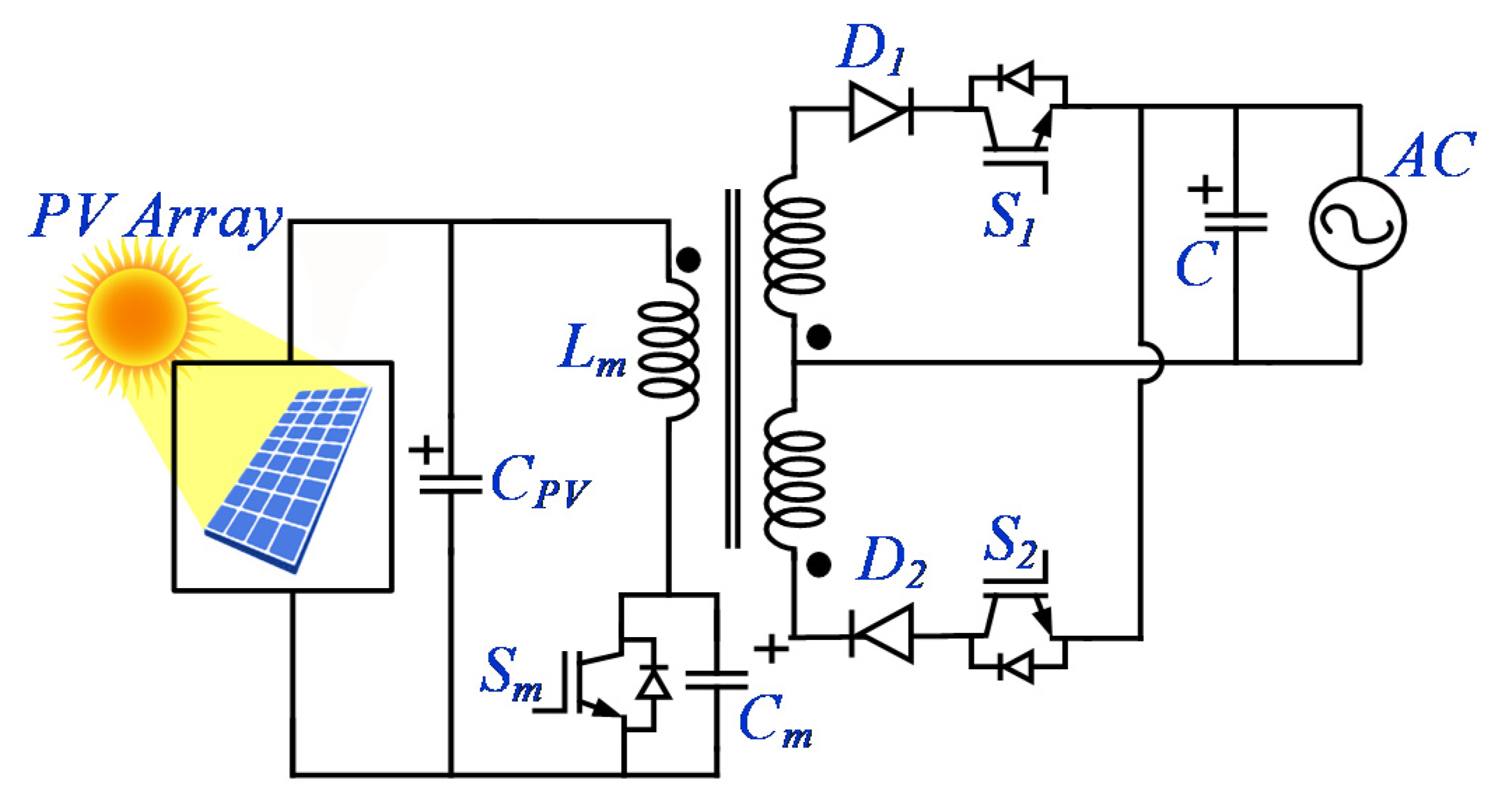

| Figure 12 | 50 | 100 | 150 | 10 | 0.1 | - |

| Figure 13 | 16.8 | 110 | 200 | 10 | 0.1 | 70 |

| Figure 14 | 20 | 230 | 170 | 10 | 0.1 | 85 |

| Figure 15 | 200–350 | 230 | 1000 | - | - | 93.6 |

| Figure 16 | 60–75 | 120 | 180 | 15 | 0.15 | - |

| Figure 17 | 50 | 120 | 200 | - | - | 75 |

| Figure 18 | 40–50 | 90–110 | 500 | 9.2 | 0.092 | 80–90 |

| Figure 19 | 50–250 | 120 | 950 | 5 | 0.05 | - |

| Figure 20 | 150 | 120 | 200 | 20 | 0.2 | 94–95 |

| Figure | Power | Mode of Operation | Number of Switches | Cost | THD | Efficiency | Life Span |

|---|---|---|---|---|---|---|---|

| Figure 21 | 300 | DCM | 3 | Low | - | 89.1 | Short |

| Figure 22 | 100 | DCM | 4 | Medium | - | 70.2 | Long |

| Figure 23 | 100 | DCM | 4 | Medium | <1.7% | 90.51 | Long |

| Figure 24 | 100 | Modified DCM | 4 | Medium | <1.9% | 90.12 | Long |

| Figure 25 | 250 | 2φAnd 1φDCM | 3 | Low | - | 94.1 | Short |

| Figure 26 | 200 | DCM | 6 | Medium | <3.79% | 94.21 | Short |

| Figure 27 | 200 | CCM | 6 | Medium | <4% | 95.1 | Short |

| Figure 28 | 200 | BCM | 6 | Medium | <2.46% | 94.2 | Short |

| Figure 29 | 250 | DCM | 8 | Medium | - | 95.1 | Short |

| Topology | Merits | Demerits | Reference |

|---|---|---|---|

| Boost | High gain, low Total Harmonic Distortion | Less efficiency, high switching losses, and high voltage and current stresses | [32,33] |

| Buck-Boost | High gain, the dead time during Pulse Width Modulation (PWM) eliminated, common-mode leakage current removed | Increased inductor size, High current stress on inductors | [34,36,39] |

| Z source | High gain | high conduction losses and voltage stresses, expensive | [41] |

| Fly-back | Availability of galvanic isolation, eliminate power pulsation, | High Electro Magnetic Interference (EMI), low efficiency, increased cost, size, and weight | [43] |

| Figure | Power | Mode of Operation | Number of Switches | Cost | THD | Efficiency | Life Span |

|---|---|---|---|---|---|---|---|

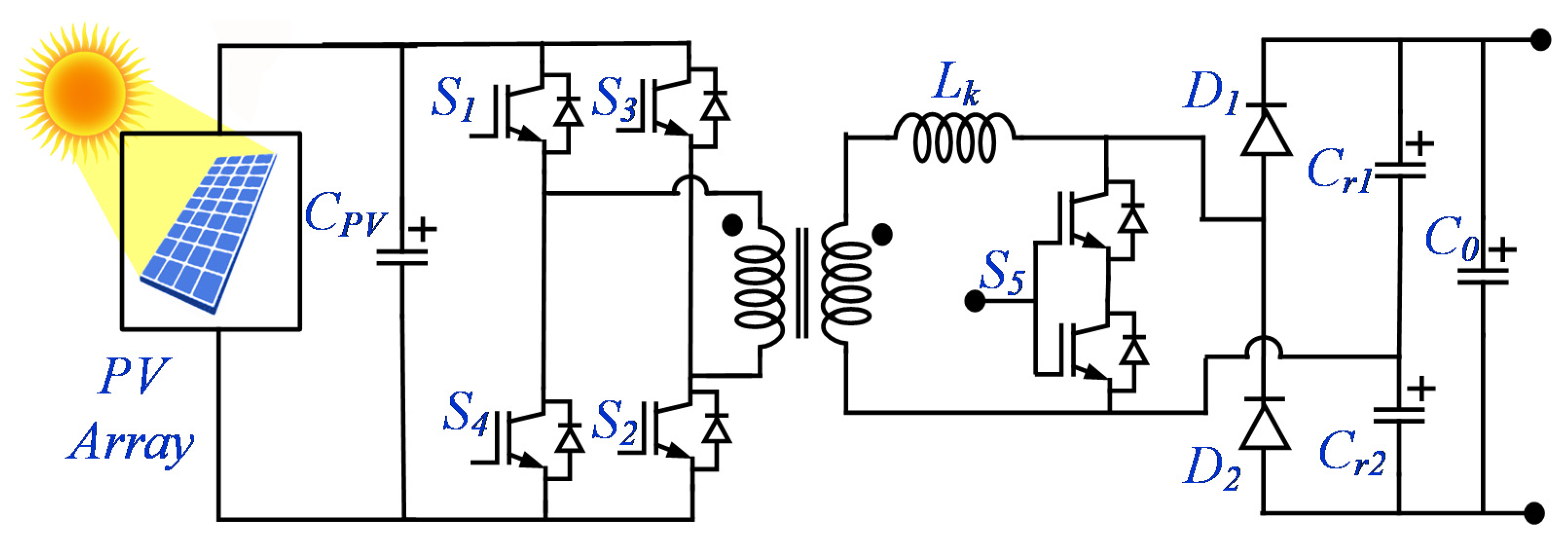

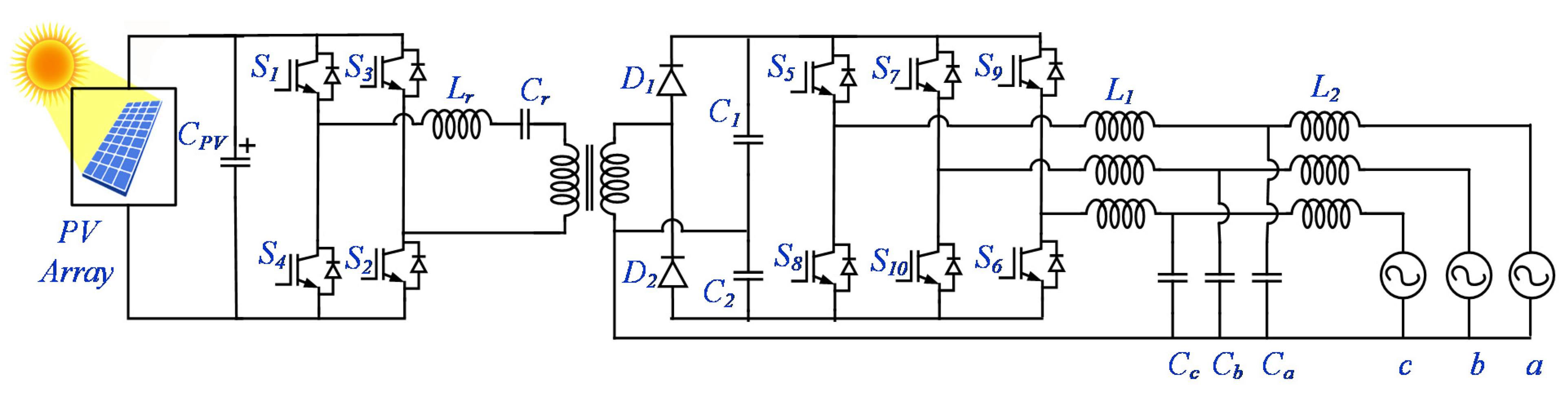

| Figure 32 | 500 | DCM | 4 | Medium | <1.7% | 90.1 | Long |

| Figure 33 | 150 | - | 9 | High | <1.9% | 90 | Long |

| Figure 34 | 210 | - | 6 | High | - | 94.1 | Long |

| Figure 35 | 250 | - | 7 | High | <3.79% | 94.1 | Short |

| Figure 36 | 250 | - | 6 | High | <4% | 95.4 | Short |

| Figure 37 | 400 | - | 6 | High | <2.46% | 94.1 | Short |

| Figure 38 | 100 | - | 6 | High | - | 95.1 | Short |

| Topology | Controller | Application |

|---|---|---|

| Full bridge | Deadbeat | Uninterrupted Power Supply (UPS) |

| Two-stage half-bridge inverter | Proportional-Resonant (PR) current control | Fuel cell |

| Z source inverter | Repetitive, PR current control, Selective compensator, Capacitor current, Droop control, Fractional-order repetitive control | Distributed Generation (DG), UPS, PV and Wind |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vairavasundaram, I.; Varadarajan, V.; Pavankumar, P.J.; Kanagavel, R.K.; Ravi, L.; Vairavasundaram, S. A Review on Small Power Rating PV Inverter Topologies and Smart PV Inverters. Electronics 2021, 10, 1296. https://doi.org/10.3390/electronics10111296

Vairavasundaram I, Varadarajan V, Pavankumar PJ, Kanagavel RK, Ravi L, Vairavasundaram S. A Review on Small Power Rating PV Inverter Topologies and Smart PV Inverters. Electronics. 2021; 10(11):1296. https://doi.org/10.3390/electronics10111296

Chicago/Turabian StyleVairavasundaram, Indragandhi, Vijayakumar Varadarajan, Pitta Janakiram Pavankumar, Ramesh Kumar Kanagavel, Logesh Ravi, and Subramaniyaswamy Vairavasundaram. 2021. "A Review on Small Power Rating PV Inverter Topologies and Smart PV Inverters" Electronics 10, no. 11: 1296. https://doi.org/10.3390/electronics10111296

APA StyleVairavasundaram, I., Varadarajan, V., Pavankumar, P. J., Kanagavel, R. K., Ravi, L., & Vairavasundaram, S. (2021). A Review on Small Power Rating PV Inverter Topologies and Smart PV Inverters. Electronics, 10(11), 1296. https://doi.org/10.3390/electronics10111296