Impact of Rapid-Thermal-Annealing Temperature on the Polarization Characteristics of a PZT-Based Ferroelectric Capacitor

Abstract

:1. Introduction

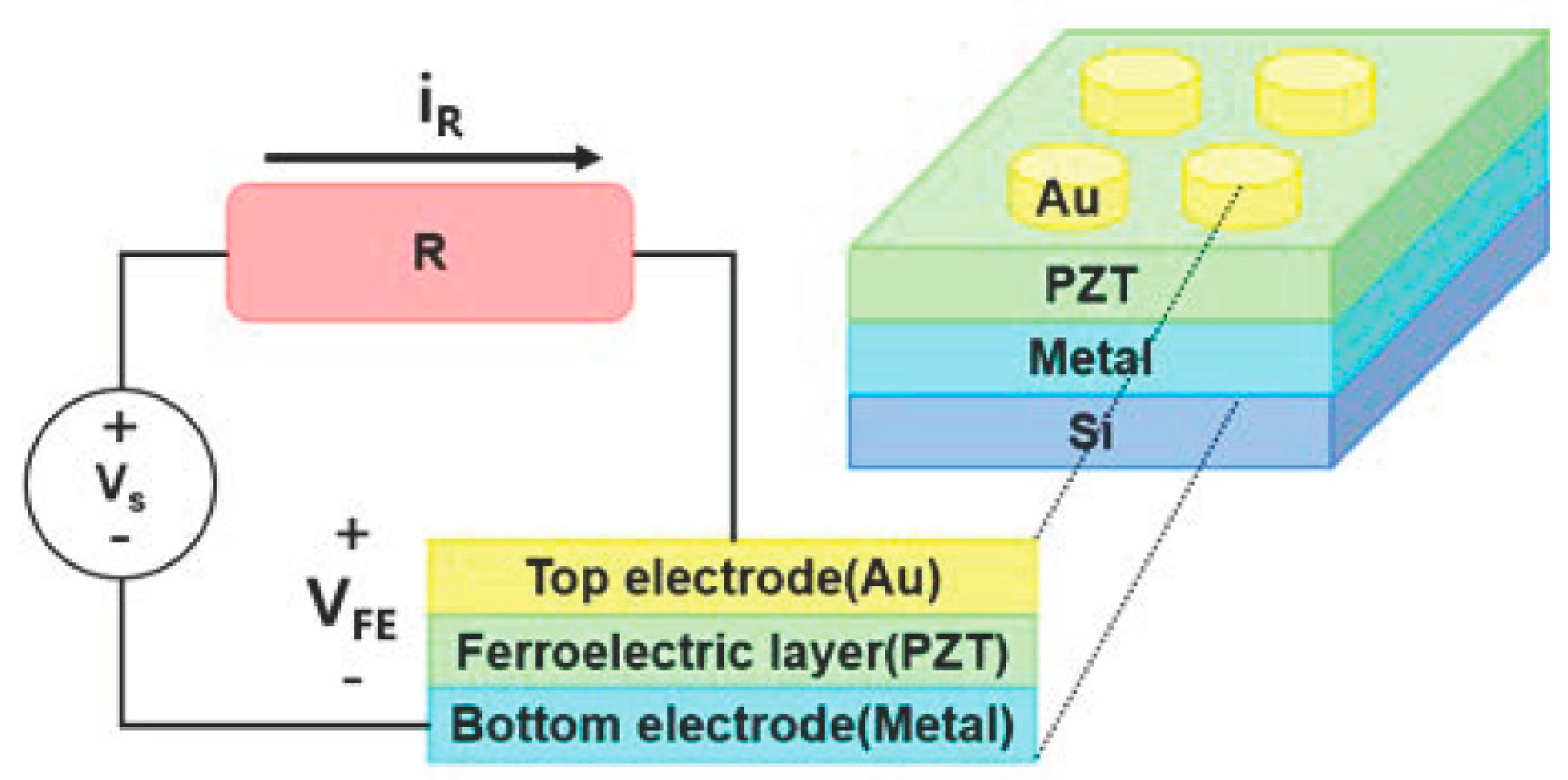

2. Fabrication and Measurement

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Izyumskaya, N.; Alivov, Y.-I.; Cho, S.-J.; Morkoç, H.; Lee, H.; Kang, Y.-S. Processing, structure, properties, and applications of PZT thin films. Crit. Rev. Solid State Mater. Sci. 2007, 32, 111–202. [Google Scholar] [CrossRef]

- Setter, N.; Damjanovic, D.; Eng, L.; Fox, G.; Gevorgian, S.; Hong, S.; Kingon, A.; Kohlstedt, H.; Park, N.; Stephenson, G. Ferroelectric thin films: Review of materials, properties, and applications. J. Appl. Phys. 2006, 100, 051606. [Google Scholar] [CrossRef]

- Kanno, I. Piezoelectric MEMS: Ferroelectric thin films for MEMS applications. Jpn. J. Appl. Phys. 2018, 57, 040101. [Google Scholar] [CrossRef] [Green Version]

- Noda, M.; Hashimoto, K.; Kubo, R.; Tanaka, H.; Mukaigawa, T.; Xu, H.; Okuyama, M. A new type of dielectric bolometer mode of detector pixel using ferroelectric thin film capacitors for infrared image sensor. Sens. Actuators A Phys. 1999, 77, 39–44. [Google Scholar] [CrossRef]

- Shih, W.-C.; Wu, M.-S. Theoretical investigation of the SAW properties of ferroelectric film composite structures. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1998, 45, 305–316. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.I.; Chatterjee, K.; Wang, B.; Drapcho, S.; You, L.; Serrao, C.; Bakaul, S.R.; Ramesh, R.; Salahuddin, S. Negative capacitance in a ferroelectric capacitor. Nat. Mater. 2015, 14, 182–186. [Google Scholar] [CrossRef] [PubMed]

- Salahuddin, S.; Datta, S. Use of negative capacitance to provide voltage amplification for low power nanoscale devices. Nano Lett. 2008, 8, 405–410. [Google Scholar] [CrossRef]

- Ku, H.; Shin, C. Comparative Study of Negative Capacitance in Ferroelectric Capacitors: P (VDF 0.75-TrFE 0.25) Versus Pb (Zr, Ti) O₃. J. Semicond. Technol. Sci. 2018, 18, 167–171. [Google Scholar] [CrossRef]

- Ku, H.; Shin, C. Comparative Study of Negative Differential Capacitance in Ferroelectric Capacitors: P (VDF 0.75-TrFE 0.25) and P (VDF 0.50-TrFE 0.50). J. Semicond. Technol. Sci. 2018, 18, 321–327. [Google Scholar] [CrossRef]

- Takada, Y.; Okamoto, N.; Saito, T.; Yoshimura, T.; Fujimura, N.; Higuchi, K.; Kitajima, A.; Shishido, R. Comparative Study of Hydrogen-and Deuterium-Induced Degradation of Ferroelectric (Pb, La)(Zr, Ti) O 3 Capacitors Using Time-of-Flight Secondary Ion Measurement. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2016, 63, 1668–1673. [Google Scholar] [CrossRef]

- Chae, B.; Yang, Y.; Lee, S.; Jang, M.; Lee, S.; Kim, S.; Baek, W.; Kwon, S. Comparative analysis for the crystalline and ferroelectric properties of Pb (Zr, Ti) O3 thin films deposited on metallic LaNiO3 and Pt electrodes. Thin Solid Film. 2002, 410, 107–113. [Google Scholar] [CrossRef]

- Velu, G.; Remiens, D.; Thierry, B. Ferroelectric properties of PZT thin films prepared by sputtering with stoichiometric single oxide target: Comparison between conventional and rapid thermal annealing. J. Eur. Ceram. Soc. 1997, 17, 1749–1755. [Google Scholar] [CrossRef]

- Li, J.; Yuan, N.; Li, K.; Tong, K.Y.; Chan, H.L.-W. A comparison of ferroelectric properties of sol-gel PLT films on different electrodes. Ferroelectrics 2001, 260, 195–200. [Google Scholar] [CrossRef]

- Vorotilov, K.; Yanovskaya, M.; Dorokhova, O. Effect of annealing conditions on alkoxy-derived PZT thin films. Microstructural and CV study. Integr. Ferroelectr. 1993, 3, 33–49. [Google Scholar] [CrossRef]

- Mansour, S.; Binford, D.; Vest, R. The dependence of ferroelectric and fatigue behaviors of PZT films on annealing conditions. Integr. Ferroelectr. 1992, 1, 43–56. [Google Scholar] [CrossRef]

- Hu, H.; Peng, C.; Krupanidhi, S. Effect of heating rate on the crystallization behavior of amorphous PZT thin films. Thin Solid Film. 1993, 223, 327–333. [Google Scholar] [CrossRef]

- Hu, G.; Wilson, I.; Xu, J.; Cheung, W.; Wong, S.; Wong, H. Structure control and characterization of SrBi 2 Ta 2 O 9 thin films by a modified annealing method. Appl. Phys. Lett. 1999, 74, 1221–1223. [Google Scholar] [CrossRef]

- Oh, C.; Tewari, A.; Kim, K.; Kumar, U.S.; Shin, C.; Ahn, M.; Jeon, S. Comprehensive study of high pressure annealing on the ferroelectric properties of Hf0. 5Zr0. 5O2 thin films. Nanotechnology 2019, 30, 505204. [Google Scholar] [CrossRef]

- Kamenshchikov, M.; Solnyshkin, A.; Pronin, I. Peculiarities of CV characteristics of PZT films depending on annealing temperature. Ferroelectrics 2017, 508, 108–114. [Google Scholar] [CrossRef]

- Dang, E.K.; Gooding, R.J. Theory of the effects of rapid thermal annealing on thin-film crystallization. Phys. Rev. Lett. 1995, 74, 3848–3851. [Google Scholar] [CrossRef]

- Wu, Z.; Pascual, R.; Vasant Kumar, C.V.R.; Amd, D.; Sayer, M. Rapid Thermal Processing of Ferroelectric Thin Films. MRS Online Proc. Libr. 1991, 224, 305–310. [Google Scholar] [CrossRef]

- Bhaskar, A.; Chang, H.; Chang, T.; Cheng, S. Effect of microwave annealing temperatures on lead zirconate titanate thin films. Nanotechnology 2007, 18, 395704. [Google Scholar] [CrossRef] [Green Version]

- Okazaki, K.; Nagata, K. Effects of grain size and porosity on electrical and optical properties of PLZT ceramics. J. Am. Ceram. Soc. 1973, 56, 82–86. [Google Scholar] [CrossRef]

- Zhu, M.W.; Wang, Z.J.; Chen, Y.N.; Kobayashi, T.; Maeda, R. Effect of heating rate on microstructure and electrical properties of sol–gel derived lead zirconate titanate films crystallized by rapid thermal annealing. Thin Solid Film. 2013, 540, 73–78. [Google Scholar] [CrossRef]

- Nagashima, K.; Aratani, M.; Funakubo, H. Orientation dependence of ferroelectricity of epitaxially grown Pb(ZrxTi1−x)O3 thin films prepared by metalorganic chemical vapor deposition. J. Appl. Phys. 2001, 89, 4517–4522. [Google Scholar] [CrossRef]

- Gong, W.; Li, J.; Chu, X.; Gui, Z.; Li, L. Preparation and characterization of sol-gel derived (100)-textured Pb(Zr,Ti)O-3 thin films: PbO seeding role in the formation of preferential orientation. Acta Mater. 2004, 52, 2787–2793. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, H.; Shin, C. Impact of Rapid-Thermal-Annealing Temperature on the Polarization Characteristics of a PZT-Based Ferroelectric Capacitor. Electronics 2021, 10, 1324. https://doi.org/10.3390/electronics10111324

Yu H, Shin C. Impact of Rapid-Thermal-Annealing Temperature on the Polarization Characteristics of a PZT-Based Ferroelectric Capacitor. Electronics. 2021; 10(11):1324. https://doi.org/10.3390/electronics10111324

Chicago/Turabian StyleYu, Hanyeong, and Changhwan Shin. 2021. "Impact of Rapid-Thermal-Annealing Temperature on the Polarization Characteristics of a PZT-Based Ferroelectric Capacitor" Electronics 10, no. 11: 1324. https://doi.org/10.3390/electronics10111324

APA StyleYu, H., & Shin, C. (2021). Impact of Rapid-Thermal-Annealing Temperature on the Polarization Characteristics of a PZT-Based Ferroelectric Capacitor. Electronics, 10(11), 1324. https://doi.org/10.3390/electronics10111324