1. Introduction

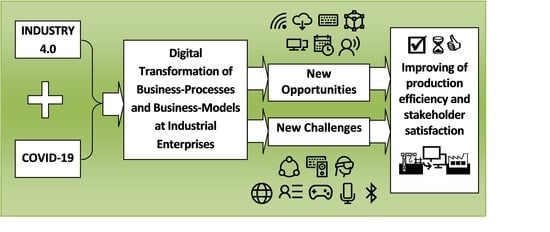

In the modern industry operating in the conditions of the digital transformation of the economy, the main priority of enterprise development is the formation and use of the potential of the available digitalization opportunities. The new path of development of all modern enterprises today is determined by the digital economy; therefore, in order to continue to function successfully in the market, enterprises should accept the challenges of digitalization of the economy and Industry 4.0. The formation of digital stability of industrial sector enterprises will ensure an increase in the stability of not only individual market economic entities, but also the industry as a whole. In this regard, it is necessary to conduct a comprehensive study of the broad possibilities of the impact of the digital transformation of the economy on the development of enterprises in modern industry.

- A.

Digitalization, digital transformation and Industry 4.0

The problems of digitalization of the economy and its industrial sector, in particular, the development of Industry 4.0 (in the meaning synonymous with the Fourth industrial revolution) have aroused a lively and growing interest of researchers in different countries in recent years, have been reflected in the documents of the World Economic Forum, UNESCO and other international organizations [

1,

2,

3]. In conformity with the reviews of publications on these themes introduced in the studies [

4,

5,

6], the number of published articles on Industry 4.0 from 2012 to 2018 increased from several units up to 1.5 thsd units per year; the total number of publications (articles) on the analyzed topic in journals indexed in the Scopus, Web of Science and Science Direct databases by 2019 amounted to 7.8 thsd units (including 4.6 thsd—these are articles about Industry 4.0, 1.2 thsd are articles about the fourth industrial revolution, the rest are publications about smart manufacturing, smart factories and smart industry).

The induce great interest this theme is also of a Russian researchers. The Russian Science Citation Index indexed for October 2021 (according to the authors of this article) about 56 thsd publications (articles, books, conference materials, dissertations), the title of which contains the term digitalization (in June 2020 they were 9 thsd, over the past year their number has increased more than 6 times), about 54 thsd publications on the request smart, about 22.5 thsd publications on the request digital transformation, 50 thsd publications about the fourth industrial revolution and Industry 4.0. Among the most significant publications are refs. [

7,

8,

9,

10,

11].

The key issue of most Russian studies on the analyzed theme is the challenges and opportunities that are relevant for national business in different sectors, as well as for various spheres of the economy and society in connection with the expansion of the scale and increasing rates of growth digitalization.

Fears cause impetuosity and unpredictability of technological and social changes as a consequence, catalyzed by the new industrial revolution, as well as the ability of society to withstand their negative consequences. In this regard, Russian researchers have a lot of questions about the readiness of the domestic economy, business (in particular, and especially industry) for the coming changes and about the prospects for ensuring the competitiveness of the industrial sector in the modern conditions.

On the background of a wide variety of publications by Russian researchers on the problems of digitalization of the economy and society, works on regional aspects of digital transformation of industry are relatively few and overwhelmingly descriptive, which suggests that research in this area is entry-level.

At the same time, it is the regional perspective of the digital transformation of industry that is especially interesting in relation to Russian specifics, since Russia is characterized by a very heterogeneous territorial distribution of industrial potential and a different degree of penetration of technologies Industry 4.0 into the activities of industrial enterprises in different regions.

In the context of the transition to the sixth technological order, Industry 4.0., the digitalization of the economy, there are profound changes in the directions and models of strategic development of countries, regions and business organizations. From the point of view of the size, pace of development and scale, these changes are of a historical nature [

12]. The values, goals and patterns of behavior of entrepreneurs, organizations, and society are changing. At the same time, the fight against progress is inevitable [

13]. The essence of Industry 4.0. is the accelerated integration of computing resources into industrial processes, as a result of which the main part of production will function autonomously, using artificial intelligence, robotics, digital technologies [

14]. For an adequate response to the new opportunities of digitalization opening up, on the one hand, and on the other hand, threats, enterprises, as business entities, must make timely changes to the targets of their development and the mechanisms for their implementation.

- B.

Industrial enterprises, automation business processes, information and computer technologies

Enterprises of the industrial sector, as a dynamic sector of the economy with a progressive nature of development, were able to adapt quickly enough to the ongoing changes in digitalization, forming a number of new IT ways of developing activities based on new directions of the digital economy. At the same time, a fairly large number of business tools in the modern digital environment remain in demand by enterprises of the industrial sector and have an undiscovered potential for using the opportunities of digitalization. The insufficient quality of the results of technological development of industrial enterprises is due to the limited use of new information technologies. There is a need to ensure the replacement of primary economic factors with secondary managerial ones, with a complex of corresponding impacts, as well as systematic regulation of the balance of the introduction of an expanded composition of technological factors of production. In this regard, the development of industrial enterprises may include the following stages relevant to the conditions of digitalization [

15]: modernization; low-tech unbalanced development; medium-tech balanced development; high-tech sustainable development. Therefore, the study of the possibilities of digitalization in industry is extremely important for the modern economy, since it allows us to ensure the development of the industrial sector on an innovative digital basis in the strategic perspective. Further research is required, providing for the development of a theoretical and practical basis for IT equipment and digital transformation of industrial enterprises in the conditions of wide opportunities for digitalization.

In the course of the research, the works in the field of comprehensive study of the possibilities of digitalization in the context of modern industry were analyzed. The study of the results of theoretical and practical studies of scientists at both the Russian and foreign levels allowed us to conclude that there is a fairly active study of the problems of various aspects of the possibilities of digitalization of the industrial sector of the economy: Schwab K. [

12], Mutaz et al. [

16], Rappa M. [

17], Camilleri M.A. [

18], Anokhina L. V. [

19], Zastupov A.V. [

20], Shchelkonogov A. E. [

15], Subaeva et al. [

21], Bushmeleva et al. [

22], Demyanova and Dimmieva [

23], Frolov et al. [

24], Streltsova et al. [

25], Toymentseva et al. [

26] and others.

The impact of digital business transformation on the activities of modern enterprises is becoming the subject of extensive discussions about the effectiveness of their work [

27]. Leading foreign researchers in the field of digital business transformation, based on the provisions of the concept Industry 4.0., are also actively studying the possibilities of digitalization and its impact on various aspects of enterprise activities. Scientists note that the implementation of solutions related to Industry 4.0. is a problem for industrial enterprises, regardless of their size or belonging to a large international organization [

28]. Researchers have identified the feasibility of using a closed-cycle business model by enterprises as an operational tool for improving competitiveness, based on the technologies of the Internet of Things and Industry 4.0., as stimulating factors [

29]. The complexity of innovative systems of different levels has been revealed at modern enterprises, which leads to the development of modern approaches to their modeling in the conditions of Industry 4.0. [

30].

Additionally, today research is already going in directions in certain areas of this study; there are the advanced studies of Sarkar and Seo, Dey et al., Tripathi et al., for example, automation policy to control work-in-process inventory in a smart production system [

31,

32], involvement of controllable lead time and variable demand for a smart manufacturing system under a supply chain management [

33], renewable energy supply chain management with flexibility and automation in a production system [

34], innovative agile model of smart lean–green approach for sustainability enhancement in Industry 4.0., etc. These works investigated interesting details, especially promising areas of digital transformation and automation business-process in enterprises activities. Therefore, in the works, the experts on a field of information technology, Sarkar et al. [

33], noted that the smart production process is developed under stochastic demand and flexible production rates. Sarkar and Seo [

34] obtained in researching the flexibility and automation in a production system an interesting conclusion that 43.05% more profit is obtained for the cooperation policy in the organization so that the profit associated with the coordination policy case is greater than that from the unequal power case. These conclusions also prove the need for future research in the field of digital technologies and automation a business process as new opportunities to improve the efficiency by introducing new ICT and automating activity of enterprises.

The automation business process and introducing ICT also have a separate area of research today [

35,

36]. The business process and ICT have a field of research especially in the contexts of COVID-19 [

37], robotization [

38], Industry 4.0 [

35], circular economy [

39] and other issues driven by business digitalization. Siderska J. notes that, in the area of robotization of business processes, there is still insufficient literature available on robotic process automation [

40,

41]. Suchanek, Bucki, and Korjenic [

42,

43] note that scientists also conduct research in the field of business process automation in order to optimize and increase business efficiency. Khan and Vorley note the importance of ICT technologies in the management and evaluation of processes [

44]. Viglioglia et al. explored the possibilities ICT potentialities to optimize the management of complex systems and to encourage sustainable development models [

45]. The above research also accentuate the importance and prospects of the research theme about assessment of the readiness of industrial enterprises for automation and digitalization of business processes.

It should be noted that in the context of the study of the modern features of the digital transformation of the business of enterprises, today attention is also paid to the social aspects of digitalization. For example, the importance of the gender division of labor in the information and communication technology sectors [

46]; identification of the determinants of the attitude of decision makers on the adaptation of Industry 4.0, as well as factors hindering this adaptation, testifying to the need to form a positive attitude of employees making decisions in the field of adaptation to the concept of Industry 4.0 [

47]. Very important is an aspect of research in the field of professional competencies and qualification requirements for the implementation the concept of Industry 4.0 in modern enterprises, which is reflected in the works of Marcysiak and Pleskacz [

48], Shevyakova et al. [

49], Labanauskaitė et al. V. [

50], Anisimova [

51], etc. This indicates the importance of taking into account social factors and the need to assess the satisfaction of employees of industrial enterprises with the ongoing digital transformation.

A comparative study with the existing literature is presented in

Table 1.

The complex of the studied works and publications allows us to provide a basis for determining the possibilities of digitalization and the impact of digital transformation on the development of modern industrial enterprises.

The purpose of the study is to identify promising areas and potentially successful areas of using the opportunities of digitalization in the activities of modern enterprises of the industrial sector, based on the impact of the digital transformation of the economy. The scientific novelty of the obtained results lies in a number of well-founded scientific and practical provisions obtained in the course of the conducted research.

The study used methods of comparative and strategic analysis, mathematical statistics, marketing research, analysis of expert assessments, as well as a systematic approach to determining the impact of the conditions of digital transformation of the economy on the development of the activities of industrial enterprises.

The results of the study are to identify priority areas for the development of digitalization at the level of industrial enterprises, taking into account the current conditions of digital transformation. The use of digitalization opportunities in modern industry opens up great prospects for all market participants, since it is the industrial sector that is at the beginning of the market chain and serves as the basis for further creation of an effective consumer value chain. The system of digital technologies and digitalization of the economic business space today contribute to the formation of strategically significant competitive advantages of industrial enterprises and ensuring their competitiveness as a whole.

Thus, the novelty of this research it is concluded in identifying global and Russian trends, as well as opportunities for the digital transformation of industry, automation of business process, new opportunities for industrial enterprises in Russia under the fourth industrial revolution and pandemic COVID-19.

It is important that all studied enterprises belong to the non-resource sector of the industry, so that assessing the impact of digital transformation on the efficiency and competitiveness of these enterprises is free from the influence of market conditions. The scientific advantages of the this article, in contrast to other publications in this research area, also consist in the use of the methods of mathematical statistics and expert assessments for a comprehensive analysis of the situation and confirmation of hypotheses.

The practical value of the obtained results consists in the fact that the confirmed research hypotheses reflect both specific regional factors and systemic nationwide problems of digitalization of the Russian industry, allow us to outline the priority areas of digital transformation of business models not only of the studied enterprises industry of the region, but also the non-resource sector of the industry in general.

Based on the considered works, which indicate the relevance of various aspects of the study of the impact of digital business transformation in the modern industry, we hypothesize about the relationship of various factors of the use of information and communication technologies as the main tools of digitalization in the activities of industrial enterprises.

Hypothesis 0 (H0): The lack of positive correlations and differences, indicating the availability of statistically significant relationships between the obtained results of the research of assessment the readiness of industrial enterprises to automate business processes and the use of digital technologies in business.

Hypothesis 1 (H1): The assessment of changes in the efficiency of enterprises associated with the expansion of their use of information and computer technologies correlates with the preliminary readiness of industrial enterprises to use digital technologies in doing business.

Hypothesis 2 (H2): The degree of satisfaction with the use of ICT in the activities of modern manufacturing enterprises is interrelated with their use of specific ICT tools.

Hypothesis 3 (H3): Satisfaction with the use of ICT by industrial enterprises correlates with the degree of automation of the main business processes in their production activities.

Hypothesis 4 (H4): The level of satisfaction with the use of ICT in the activities of manufacturing enterprises is interrelated with the perception of their assessment of modern ICT tools that are most in demand in the future.

In this regard, the study should provide a final answer to the question of to what extent regional enterprises of the industrial sector are already prepared for the ongoing digital transformation of the economy, will be able to adapt to the irreversible conditions of digitalization and effectively use the achievements of the internationally significant concept Industry 4.0.

2. Materials and Methods

Considering the relevance and complexity of the problems of digital transformation of business, a marketing study was conducted in May 2021 to study the level of use of information and communication technologies in the activities enterprises of the Republic of Mordovia and to identify promising areas for using the opportunities of digitalization in the activities of industrial enterprises under the influence of the digital transformation of the economy.

In the study took part the largest and average industrial enterprises of the Republic of Mordovia: Lisma Ltd., Saransk television plant, Biokhimik, Lamzur, Dairy plant Saranskiy (Danone Russia), Novomilk Ltd., Elektrovypryamitel, Saranskkabel Ltd., Tsvetlit Ltd., EM-KAT Ltd., Saransk Instrument Works Europack Ltd., etc.

The questions were answered by senior and middle managers, representatives of R&D departments, specialists in the field of technical maintenance at the surveyed regional industrial enterprises-respondents.

For collect information was used the CAWI method (computer web interview), which involves obtaining respondents answers to 30 developed questions related to various areas of research in the field of assessing the level of use of information and communication technologies in the activities of enterprises.

To analyze the information the methods of comparative and strategic analysis, mathematical statistics, expert assessments and a systematic approach to determining the impact of the conditions of digital transformation of the economy on the development of enterprise activities were used.

In our opinion, the most accurate determination of the strength of proximity and the direction of the correlation relationship between the hierarchies of various signs and factors obtained in the course of the study allows the method of rank correlation Ch. Spearman. Spearman’s rank correlation coefficient is a quantitative assessment of the statistical study of the relationship between the established parameters and is used in nonparametric methods. Spearman’s rank linear correlation indicator

rs shows the degree of difference between the sum of squares of the differences between the ranks obtained by observation from the case of lack of connection and is determined by the formula:

The Spearman coefficient makes it possible to determine the closeness and direction of the correlation between two values. The result of the Spearman linear correlation coefficient can be in the range «1» and «−1» and be positive and negative, characterizing the direction of the relationship between the two features measured in the rank scale. If the correlation coefficient is «0» then there is practically no relationship between the values. If the correlation coefficient turns out to be close to 1, this corresponds to a high level of communication between variables, while at rs 1 there is a strictly direct connection, and at rs − 1 there is an inverse connection. With a direct connection, the resultant attribute increases with an increase in the factorial attribute, with the inverse connection—the increase of the factorial attribute leads to a decrease in the values of the resultant attribute.

In this regard in order to establish the most significant correlations and confirm the hypotheses obtained as a result of the study of the impact of the digital transformation of the economy on the development of industrial enterprises of the Republic of Mordovia, calculations were carried out using one of the most important methods of mathematical statistics the linear correlation of Spearman.

The limitations and assumptions of the research were determined as analysis of mostly industrial enterprises, the scope of the research was limited to the region of the Republic of Mordovia, as well as the limited timing. For a better assessment of the readiness of enterprises for modern automation and digitalization of business processes, it would be possible to additionally use such a qualitative research method as an in-depth interview. In connection with the assumption of elimination these limitations it is advisable to conduct future research of various aspects the impact of digitalization conditions on the activities of enterprises in various fields in a more representative sample group of national and international scale.

The notation of this research is as follows:

ICT—Information and communication technologies;

CAWI—Computer web interview method;

rs—result of the Spearman linear correlation coefficient;

N—number of ranked features (indicators);

d—difference between the ranks of two variables for each subject;

d2—sum of the squares of the rank differences;

H0—Hypothesis 0;

H1—Hypothesis 1;

H2—Hypothesis 2;

H3—Hypothesis 3;

H4—Hypothesis 4.

3. Results

The study of the digital transformation of the economy and its impact on the development of industrial enterprises at the national and regional levels allowed us to obtain the following results.

At this moment, the impact of the digital transformation of the economy and the development of the concept of Industry 4.0 as a whole are the subject of extensive discussions, both at the Russian and regional levels. Experts of the leading international world-class consulting company McKinsey note that timely implementation of digital transformations in industry is an important strategic task for Russia [

11]. Despite the fact that some industries are approaching the world level in terms of digitalization, Russia still lags behind the leading European countries in many key industries. The industrial sector has poorly mastered even the ICT of previous generations (automated design systems, management and accounting, production management, electronic document management, planning and management of supply chains, etc.), therefore, enterprises have a significant potential to increase efficiency. Russian companies have a great chance to reduce the technological gap from foreign leaders by using the most advanced digital solutions. In order to use the new opening prospects, it is important for enterprises to act from the position of integration, consistency and efficiency. Russian companies of all industries need to develop digital strategies for their behavior in the market and the implementation of the full range of opportunities, to convey the importance of new digital tools to employees of enterprises at all levels, to form a digital culture and digital business sustainability. The top management of the industrial sector should change the approach to making managerial decisions due to which the significance of the introduction of modern ICTs is often leveled due to the low level of automation. In this regard, it is important for the management of Russian companies to have an idea of what problems in the field of ICT application are typical for the current situation of the enterprise and what trends in the use of digital technologies will have the greatest impact on the industrial sector and will allow them to benefit from making new decisions. The experience of developed countries demonstrates that it is possible to master new ICTs simultaneously with the digital transformation of business and the introduction of the concept of Industry 4.0.

The results of modern research by specialists show that business entities of the Russian economy on the way to transition to a digital society of the future faced the same problems and limitations as most countries of the world [

52]. Russia, later than the largest Western economies, embarked on the path of digital transformation, but under the influence of the development of ICT, domestic enterprises began to gradually join the programs of industrial transformation, restructuring of business models and processes. At the same time, the risks faced by Russian enterprises are becoming increasingly complex, and the application of the provisions of the Industry 4.0 concepts in domestic practice is limited and fragmented [

53].

The process of transformational changes in Russia is in its infancy, which is due to the prevalence of vertical ties in a business, closed information, distrust of the external environment, as well as technological lag and underdevelopment of the digital infrastructure. For activation, the process of digital transformation will require a transforming business management, personnel capable of working in new conditions and the appropriate infrastructure [

55].

Today, the Russian Federation is making active attempts to overcome the difficulties and barriers of digital transformation of enterprises. The adopted long—term comprehensive program to create conditions for ensuring the leadership of Russian companies—the National Technology Initiative, the national program Digital Economy of Russia 2024, Strategy for the Development of the Information Society 2030 can contribute to the digital development of the industrial sector of the Russian Federation in order to form the foundations of an institutional and infrastructural nature, eliminate existing obstacles and restrictions in the conditions of the transition of the Russian Federation to the digital economy [

54].

Modern industrial informatization is associated with the dynamic development of the market of information products and services, which has had a great impact on the activities of regional industrial enterprises as the most important components of the national industrial sector of the Russian Federation. The study of the situation of the establishment and experience of the introduction of ICT in certain regions can demonstrate a cross-section of the overall level of digitalization of regional industrial enterprises. Thus, the Republic of Mordovia is a full-fledged representative of the territory established by enterprises of various industries. The image of positioning of the «Sample of the province» of the Republic of Mordovia formed over the years allows us to project an example of the situation of ICT equipment at industrial enterprises in the region as an average indicator of digitalization of the business of regional enterprises of the industrial sector as a whole of the Russian Federation.

The state of the level of ICT penetration into the work of industrial enterprises of the Republic of Mordovia can be described as satisfactory. The use of ICT in the conditions of digitalization and the COVID19 pandemic is constantly increasing, but it requires constant solution of new tasks for automation of production and improving the efficiency of business as a whole.

Considering the automated business processes of manufacturing enterprises of the Republic of Mordovia (

Figure 1), it should be noted that manufacturing enterprises use ICT in such areas as—Document flow 24%, Customer relationship management (CRM)—17%, Accounting—20%, Production management—15%, Supplier relationship management—9%, Logistics—7%, Management accounting—5%, Warehouse processes—2%, Forecasting—1%.

Based on the percentage ratio, it can be seen that document management, accounting and production management currently occupy the most important place in manufacturing enterprises. Document management is one of the most important tools necessary to ensure a successful business as a whole and interaction between various market participants.

Examining the ICT tools used at the enterprises of the Republic of Mordovia, it can be noted (

Figure 2) that manufacturing enterprises note the following options: E-mail—30%, Tools for online communication—19%, Electronic document management systems—14%, Tools for automated communication with customers—13%, Tools for accounting for working hours and monitoring the activities of employees—8%, Logistics management systems—7%, Tools for video conferences—5%, File hosting—3%, Virtual infrastructure—1%.

Currently, such ICT tools as e-mail, electronic document management systems and tools for online communications are most often used at the production enterprises of the Republic of Mordovia. At the same time, the main node of business processes remains within the framework of the unchanged scheme adopted at this enterprise. Information technologies significantly transform business, reduce costs, and involve intellectual products in circulation.

At the moment, ICT tools are being dynamically modernized and it is important for enterprises of the Republic of Mordovia to use the most up-to-date technologies that make the workflow more convenient and faster, which ensures the potential success of well-established work and as a result, is a way to get the greatest profit.

Figure 3 shows the ICT tools that according to the respondents of the production enterprises of the Republic of Mordovia will be in demand in the near future.

Figure 3 shows the following percentage, based on the analysis of the opinions of representatives of manufacturing enterprises of the Republic of Mordovia on the demand for new ICT tools: Corporate mobile applications—17%, Logistics management systems—16%, Virtual infrastructure—14%, Tools for automated work with clients—11%, Working time monitoring the activities of employees tracking tools—10%, Electronic document management systems—8%, Tools for remote monitoring of equipment—8%, Tools for collecting and data analysis—6%, File hosting—5%, Tools for video conferencing—5%. Based on the data, it can be concluded that Mordovian enterprises are considering more advanced ICT tools that become more relevant over time. The majority of enterprises preferred corporate mobile applications (17%), the most unpopular were tools for video conferencing, due to the fact that the system for using these technologies is already quite well-established.

Next, we analyzed the current digital ICT, which, in the opinion of the respondents of industrial enterprises of the Republic of Mordovia are most relevant in their activities (

Figure 4).

Based on the analysis of

Figure 4, it can be seen that a large share of manufacturing enterprises of the Republic of Mordovia noted that one of the relevant technologies for them is business process automatic systems (32%). In addition, autonomous machines and devices (28%), cloud technologies (28%), and artificial intelligence technologies (21%) are also highlighted. Less popular are digital technologies such as robotics (16%), voice technologies (15%), and blockchain technology (8%). These results can be attributed to the fact that the introduction of digital technologies is leading to important changes in the organization of management and operation workflows. Through the use of the latest technologies in the field of digital economy, the speed of data processing and the quality of the information provided at the enterprises of the Republic of Mordovia are increasing. Therefore, manufacturing enterprises of the Republic of Mordovia strive to use, first of all, the latest technologies for automating business processes.

In this regard, the industrial enterprises of the Republic of Mordovia mostly note that business process automation systems and autonomous machines and devices are the most relevant in their field of activity, since unexpected resource shortages and even regular scheduled maintenance activities can negatively affect work due to downtime, reduced productivity and increased risk. Prescription services based on new ICT help industrial enterprises of the Republic of Mordovia to prevent these problems. At the same time, data and forecasts are used to determine the time of the necessary preventive maintenance.

Next, we considered a list of aspects that contributed to the change in the situation and the impact of digital transformation in the world (

Figure 5).

Analyzing the data in

Figure 5, it can be seen that 49% of enterprises-respondents in the production sector believe that the world is currently changing rapidly precisely because of the development of IT and digitalization. According to the study, it can be seen that remote work and changes in the field of communications (17%), the crisis, negative economic and social trends (12%), the transformation of the economy and business (7%), robotization and the development of artificial intelligence (4%), unemployment, job creation (3%), value changes, awareness (3%), state pressure on citizens, increased control (2%), the global nature of changes (1%), changes in the field of medicine, health care (1%), changes in in the field of education, and training (1%).

The COVID-19 pandemic has affected most of the industrial enterprises of the Republic of Mordovia. The consequences of influencing the workflow are discussed in

Figure 6.

Based on the analysis of

Figure 6, it is clear how the pandemic COVID-19 affected the activities of companies. The majority of respondents in the production sector have partially switched to remote work (33%). There are also some companies that operate in the same mode (31%), were forced to suspend their activities (12%), did not switch to remote work, but were forced to significantly change business processes (23%). This is due to the fact that outbreaks of the coronavirus are still occurring, people are infected daily in every city, that is, at present, humanity has not yet overcome the virus and, in order to warn employees of various enterprises as much as possible, organizations are forced to partially switch to remote work. Due to the fact that enterprises can partially perform work remotely, a large number of people are safe from the virus.

Next, the changes that occurred at the respondents production enterprises of Republic of Mordovia were analyzed (

Figure 7).

Analyzing the data, it can be noted that 25% of the surveyed enterprises did not need to expand the technological infrastructure. Additionally, 18% of the enterprises studied had a need for additional data storage resources, 17% had a need for new communication channels, 15% had a need to purchase additional server equipment, 13% had a need to purchase additional production equipment, and 12% had a need to purchase additional software for existing equipment.

Based on the above data, it can be concluded that in most cases, the technological infrastructure at production enterprises was well developed and did not need additional improvement, and the purchase of various additional equipment and programs was also less necessary. This means that the technological ICT sphere of activity was well developed at the enterprise even before the quarantine COVID-19.

Next, an assessment of the changes that have occurred in the organization of Republic of Mordovia in connection with the expansion of the use of ICT is considered (

Figure 8).

Based on the graph data, it can be seen that the efficiency of activity has slightly increased in 27% of the surveyed enterprises, significantly increased in 21% of enterprises, and the same number of enterprises has not changed. The efficiency of activity decreased slightly in 17% of the surveyed enterprises, and significantly decreased in 14% of enterprises. Based on the above data, it can be concluded that due to the use of information and computer technologies, the activities of most enterprises of production activity have improved, which means that all innovations and technological implementations have benefited enterprises of the production sphere of activity. In addition, some of the work at the enterprises went into remote mode, thanks to which it began to be performed much faster.

Next, we consider the business processes that have become the most popular in the production sector (

Figure 9).

According to the data shown in the diagram it can be seen that 21% of the surveyed enterprises in the production sector noted a significant spread of electronic digital signatures in their work. Additionally, 20% of the surveyed enterprises have increased the speed of solving everyday tasks. Electronic document management with clients and counterparties has become very widespread in 15% of enterprises, and decisions on the introduction of new technologies have been made faster (15%). Remote work of some of the staff has also become the norm for 15% of the surveyed enterprises. No changes occurred in 14% of enterprises. Based on the above statistics, it can be concluded that almost all enterprises of the Republic of Mordovia have undergone changes in the work of information and computer technologies and information business processes have also been improved. Due to the changes that have taken place at the enterprises of the production sector of the Republic of Mordovia, various organizational processes have also been improved, as a result of which the production processes at these enterprises have been modernized and become more autonomous.

However, certain obstacles may arise on the path of digital transformation in the Republic of Mordovia industry (

Figure 10).

The survey results show that the most global obstacle to the digital transformation of the production enterprises of the Republic of Mordovia is the lack of funding (38%), the second most important obstacle is the lack of qualified personnel (30%), and the third is the lack of clear standards and regulatory and methodological framework. Most modern organizations face similar problems, which reduces the efficiency and profitability of their activities. The lack of data on the effectiveness of digitalization (26%) and the unwillingness of counterparties to switch to new interaction models (22%), as well as the lack of market incentives (20%), also significantly affect the production enterprises of the Republic of Mordovia. The least impact is caused by an undeveloped infrastructure (15%), a lack of understanding of what digitalization is and a lack of qualified external consultants (11%).

In this regard, despite the difficulties, the industrial enterprises of the Republic of Mordovia demonstrate an understanding of the problems of digitalization, therefore, enterprises can work on them and level the existing obstacles. Consider the stimulus of digital transformation in the activities of manufacturing enterprises of the Republic of Mordovia (

Figure 11).

From the presented data, it can be noted that in 22% of the production enterprises of the Republic of Mordovia, the digital transformation is stimulated by the creation of digital platforms, ecosystems, and databases. Targeted financing is present in 19% of production enterprises, trainings and master classes in the production sector are allocated in 15% of cases. The availability of information about existing business process automation systems is an incentive for the activities of 13% of production enterprises, the availability of standards in regulatory and methodological documents is 11% of enterprises. The need to maintain market positions in the production sector is an incentive for digital transformation in 9% of enterprises, assistance in planning and management in 7% of production enterprises of the Republic of Mordovia. Therefore, it should be noted that it is important for manufacturing enterprises to establish relationships with customers by creating digital platforms and databases, conduct various trainings to unite staff and also pay attention to business financing.

Further, the possibilities of industrial enterprises of the Republic of Mordovia were investigated, which allow paying attention to these factors (

Figure 12).

According to the diagram, in the production sector of the Republic of Mordovia in 28% of cases, such a possibility of digital transformation is highlighted as an opportunity to increase the efficiency of the organization. The possibility of entering new markets is noted in 19% of manufacturing enterprises, the possibility of increasing demand for the manufactured product in the production sector is highlighted by 19% of enterprises of the Republic of Mordovia. Additionally, for enterprises there is the possibility of implementing the «product as a service» model and providing services in 16% for manufacturing enterprises, the possibility of mastering the production of new products is typical for 12% of manufacturing enterprises.

In this regard, the main opportunities of the production enterprises of the Republic of Mordovia are the growth of demand for their products, increasing profitability and increasing the efficiency of the company. Additional opportunities also arose in connection with the support of the state during the COVID-19 quarantine. The following are the opinions of the industrial enterprises of the respondents of the Republic of Mordovia related to the statements regarding their readiness to use digital technologies (

Figure 13).

The diagram shows that 34% of manufacturing enterprises of the Republic of Mordovia tend to be incentivized to optimize existing business processes, reduce costs, 28% of manufacturing enterprises are in the period of the formation of new skills and habits of using digital technologies, 23% of manufacturing enterprises are characterized by a period of uncertainty and complete misunderstanding the future. Additionally, 8% of manufacturing enterprises need a driver to use digital technologies, and 7% of manufacturing enterprises need a complete business restructuring.

A special role is played by the degree of satisfaction among the respondents from manufacturing enterprises of the Republic of Mordovia in the use of ICT in their activities (

Figure 14).

The result of the survey of respondents of manufacturing enterprises in the use of ICT in their activities: 33%—Partially satisfied, 29%—Generally satisfied, 12%—Completely satisfied and 8% of respondents—Difficult to answer. Taking into account the rather high score of 18%—Completely not satisfied, the results of the study as a whole demonstrate partial satisfaction with the work in using ICT in the activities of industrial enterprises of the Republic of Mordovia.

4. Discussion

It should be noted that initially we put forward several hypotheses about the presence of statistically significant links between the obtained results of the study of the use of information and communication technologies in the activities of enterprises and the impact of digital transformation.

In the process of the study of the impact of the digital transformation of the economy on the development of industrial enterprises of the Republic of Mordovia, the most significant correlations were established for a number of interdependencies obtained as a result of calculations carried out using the method Ch. Spearman.

Therefore, a statistically significant correlation was established between the assessment of changes in the performance of industrial enterprises-respondents of the Republic of Mordovia, associated with the expansion of the use of information and communications technologies—A (based on the indicators of

Figure 8) and the assessment of their readiness to use digital technologies in business B (based on the indicators of

Figure 13). The definition on Spearman method in this linear correlation is presented in

Table 2.

The Spearman correlation obtained according to

Table 2 (

rs = 0.975) between A and B is positive and statistically significant, this means that H0 is rejected, the hypothesis H1 is accepted about a close positive relationship between the assessment of changes in the efficiency activity of industrial enterprises-respondents of the Republic of Mordovia associated with the expansion of the use of information and communicate technologies and the assessment of the readiness of enterprises to use digital technologies in doing business. This correlation indicates that enterprises that timely take into account the trends of digitalization and consequently highly assess the readiness for digital transformation of business, and as a result subsequently demonstrate a higher assessment of changes in the efficiency of their work associated with the expansion of the use of ICT.

In addition, a statistically significant correlation was established between the degree of satisfaction of respondents of manufacturing enterprises of the Republic of Mordovia with the use of ICT in their activities—A (based on the indicators of

Figure 14) and the real assessment of the use of the main ICT tools—B (based on the indicators of

Figure 2). The definition of this Spearman linear correlation is presented in

Table 3.

The Spearman correlation obtained according to

Table 3 (

rs = −3) between A and B is negative and statistically significant, this means that H0 is rejected, the hypothesis H2 is accepted about a close but inverse relationship between the degree of satisfaction with the use of ICT and the assessment of the use of specific ICT tools in the activities of respondents of production enterprises of the Republic of Mordovia. This correlation indicates that the ICT tools used in industrial enterprises have a negative impact on the satisfaction of respondents with the production enterprises of the Republic of Mordovia. In our opinion, this correlation is explained by the revealed predominant so far used of traditional ICT by enterprises (e-mail, electronic document management, etc.) and the weak implementation of modern ICT tools (systems for recording working hours and monitoring employees activities, logistics management systems, video conference tools, file hosting, virtual infrastructure, etc.). These results and the hypothesis are confirmed by the revealed high statistically significant correlation between the degree of satisfaction of respondents of RM manufacturing enterprises with the use of ICT in activity—A (based on the indicators of

Figure 14) and the assessment of the main automated business processes of respondents-RM manufacturing enterprises—B (based on the indicators of

Figure 1). The definition of this Spearman linear correlation is presented in

Table 4.

The Spearman correlation obtained according to

Table 4 (

rs = −3) between A and B is negative and statistically significant, this means that H0 is rejected, the hypothesis H3 is accepted about a close but inverse relationship between the degree of satisfaction with the use of ICT and the assessment of the main automated business processes in the activities of production enterprises of the Republic of Mordovia. This correlation indicates that automated business processes at industrial enterprises have a negative impact on the satisfaction of respondents of manufacturing enterprises of the Republic of Mordovia. In our opinion, this correlation is explained by the revealed predominant so far automation of enterprises only of basic business processes (document management, accounting, CRM, etc.). At the same time, automation of other modern business processes of the enterprise (production management, relations with suppliers, logistics, warehouse processes, forecasting, etc.) is currently needed, which can significantly increase employee satisfaction, due to the large number of advantages of modern labor automation.

It should be noted that the results obtained also confirm our hypothesis about the identification of a statistically significant correlation between the degree of satisfaction of respondents of manufacturing enterprises of the Republic of Mordovia with the use of ICT in their activities—A (based on the indicators of

Figure 14) and the assessment by respondents of manufacturing enterprises of the Republic of Mordovia of ICT tools that, in their opinion, will be in demand in the near future—B (based on the indicators of

Figure 3). The definition of this Spearman linear correlation is presented in

Table 5.

The Spearman correlation obtained according to

Table 5 (

rs = −5.25) between A and B is negative and statistically significant, this means that H0 is rejected, the hypothesis H4 is accepted about a close but inverse relationship between the degree of satisfaction with the use of ICT and the assessment of ICT tools that will be in demand in the near future in the activities of industrial enterprises of the Republic of Mordovia. This statistically significant negative correlation indicates that, according to respondents, the most popular ICT tools (corporate mobile applications, logistics management systems, virtual infrastructure, etc.) are still used to the least extent at enterprises and on the contrary the least relevant in the near future ICT tools ones are used, which is confirmed by the data of the above study.

Thus, the results of the study of the use of ICT in the activities of industrial enterprises of the Republic of Mordovia demonstrate both positive and negative dynamics. Industrial companies of Mordovia prefer to implement IT solutions with the possibility of scaling them in the future. These studies confirm the increasing trend of the introduction of ICT and the need for an integrated approach in building the IT infrastructure of industrial sector enterprises.