The Influence of Design on Electrical Performance of AlGaN/GaN Lateral Schottky Barrier Diodes for Energy-Efficient Power Applications

Abstract

1. Introduction

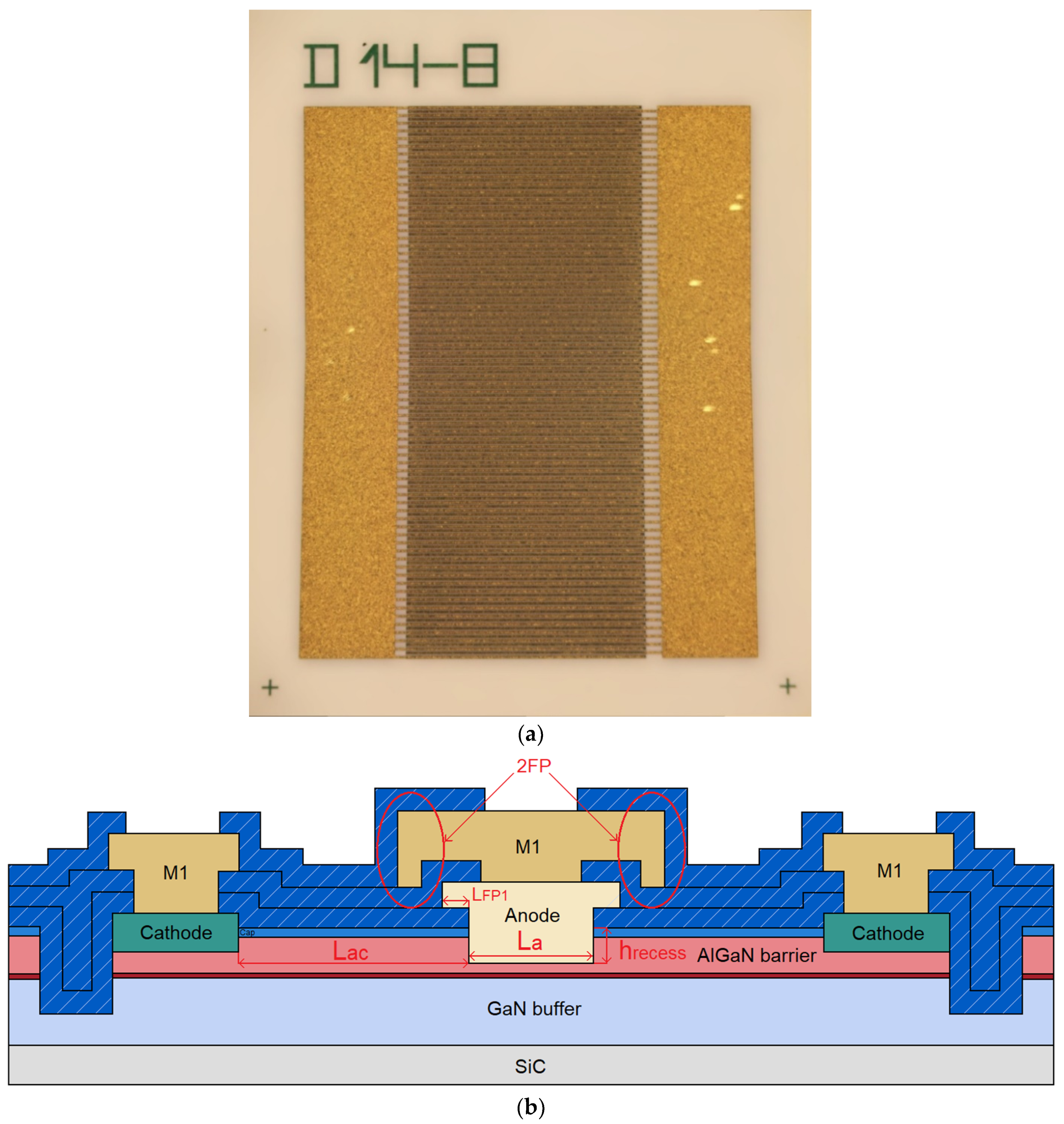

2. Materials and Methods

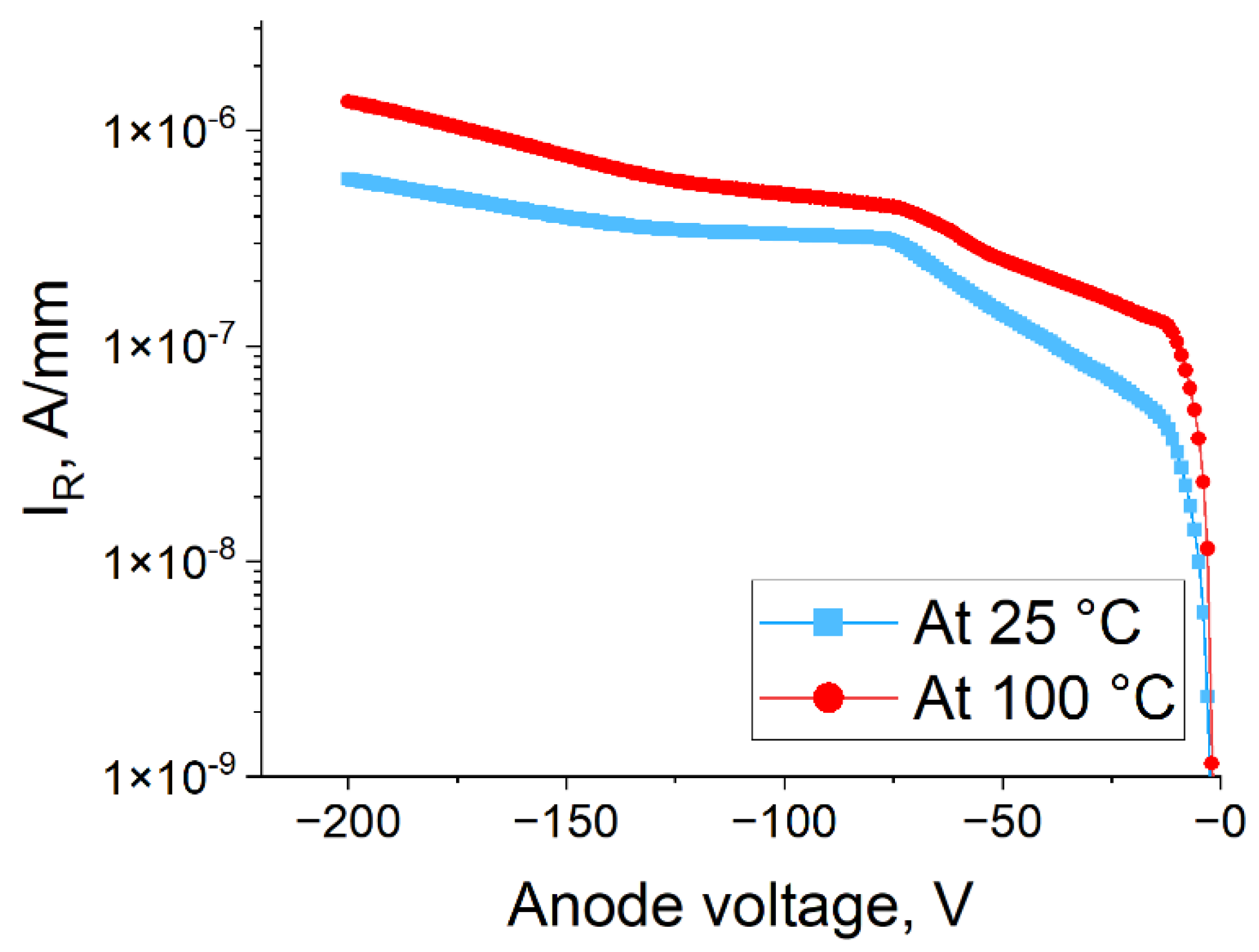

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tamura, Y.; Sakuma, H.; Morita, K.; Suzuki, M.; Yamamoto, Y.; Shimada, K.; Honma, Y.; Sohma, K.; Fujii, T.; Hasegawa, T. The first 0.14-dB/km loss optical fiber and its impact on submarine transmission. J. Light. Technol. 2018, 36, 44–49. [Google Scholar] [CrossRef]

- Erofeev, E.; Arykov, V.; Stepanenko, M.; Voevodin, A.; Kogai, A.; Kurikalov, V.J.S. 28 GHz Single-Chip Transmit RF Front-End MMIC for Multichannel 5G Wireless Communications. Symmetry 2020, 12, 1167. [Google Scholar] [CrossRef]

- Skubic, B.; Bottari, G.; Öhlén, P.; Cavaliere, F. The role of DWDM for 5G transport. In Proceedings of the 2014 The European Conference on Optical Communication (ECOC), Cannes, France, 21–25 September 2014; pp. 1–3. [Google Scholar]

- Alibakhshikenari, M.; Virdee, B.S.; See, C.; Shukla, P.; Moghaddam, S.M.; Zaman, A.U.; Shafqaat, S.; Akinsolu, M.O.; Liu, B.; Yang, J.; et al. Dual-polarized highly folded Bowtie antenna with slotted self-grounded structure for sub 6 GHz 5G applications. IEEE Trans. Antennas Propag. 2021, 1, 1–6. [Google Scholar] [CrossRef]

- Alibakhshikenari, M.; Virdee, B.S.; Azpilicueta, L.; Naser-Moghadasi, M.; Akinsolu, M.O.; See, C.H.; Liu, B.; Abd-Alhameed, R.A.; Falcone, F.; Huynen, I. A comprehensive survey of “metamaterial transmission-line based antennas: Design, challenges, and applications”. IEEE Access 2020, 8, 144778–144808. [Google Scholar] [CrossRef]

- Alibakhshikenari, M.; Babaeian, F.; Virdee, B.S.; Aïssa, S.; Azpilicueta, L.; See, C.H.; Althuwayb, A.A.; Huynen, I.; Abd-Alhameed, R.A.; Falcone, F. A comprehensive survey on “Various decoupling mechanisms with focus on metamaterial and metasurface principles applicable to SAR and MIMO antenna systems”. IEEE Access 2020, 8, 192965–193004. [Google Scholar] [CrossRef]

- Althuwayb, A.A.J.M.; Letters, O.T. Enhanced radiation gain and efficiency of a metamaterial-inspired wideband microstrip antenna using substrate integrated waveguide technology for sub-6 GHz wireless communication systems. Microwave Opt. Tech. Let. 2021, 63, 1892–1898. [Google Scholar] [CrossRef]

- Inamdar, M.A.; Kumaraswamy, H. Energy efficient 5G networks: Techniques and challenges. In Proceedings of the 2020 International Conference on Smart Electronics and Communication (ICOSEC), Tiruchirappalli, India, 10–12 September 2020; pp. 1317–1322. [Google Scholar]

- Roccaforte, F.; Fiorenza, P.; Greco, G.; Nigro, R.L.; Giannazzo, F.; Iucolano, F.; Saggio, M.J.M.E. Emerging trends in wide band gap semiconductors (SiC and GaN) technology for power devices. Microelectron. Eng. 2018, 187, 66–77. [Google Scholar] [CrossRef]

- Chowdhury, S.; Stum, Z.; Li, Z.D.; Ueno, K.; Chow, T.P. Comparison of 600V Si, SiC and GaN power devices. Mater. Sci. Forum 2014, 778–780, 971–974. [Google Scholar] [CrossRef]

- Hashizume, T.; Ootomo, S.; Oyama, S.; Konishi, M.; Hasegawa, H. Chemistry and electrical properties of surfaces of GaN and GaN/AlGaN heterostructures. J. Vac. Sci. Tech. Microelectron. Nanometer Struct. Process. Meas. Phenom. 2001, 19, 1675–1681. [Google Scholar] [CrossRef]

- Ambacher, O.; Smart, J.; Shealy, J.; Weimann, N.; Chu, K.; Murphy, M.; Schaff, W.; Eastman, L.; Dimitrov, R.; Wittmer, L. Two-dimensional electron gases induced by spontaneous and piezoelectric polarization charges in N-and Ga-face AlGaN/GaN heterostructures. J. Appl. Phys. 1999, 85, 3222–3233. [Google Scholar] [CrossRef]

- Chow, T.P.; Tyagi, R. Wide bandgap compound semiconductors for superior high-voltage power devices. In Proceedings of the 5th International Symposium on Power Semiconductor Devices and ICs, Monterey, CA, USA, 18–20 May 1993; pp. 84–88. [Google Scholar]

- Wu, Y.-F.; Kapolnek, D.; Ibbetson, J.P.; Parikh, P.; Keller, B.P.; Mishra, U. Very-high power density AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2001, 48, 586–590. [Google Scholar]

- Lenci, S.; De Jaeger, B.; Carbonell, L.; Hu, J.; Mannaert, G.; Wellekens, D.; You, S.; Bakeroot, B.; Decoutere, S.J.I.E.D.L. Au-free AlGaN/GaN power diode on 8-in Si substrate with gated edge termination. IEEE Electron Device Lett. 2013, 34, 1035–1037. [Google Scholar] [CrossRef]

- Hu, J.; Stoffels, S.; Lenci, S.; Bakeroot, B.; De Jaeger, B.; Van Hove, M.; Ronchi, N.; Venegas, R.; Liang, H.; Zhao, M. Performance optimization of Au-free lateral AlGaN/GaN Schottky barrier diode with gated edge termination on 200-mm silicon substrate. IEEE Trans. Electron Devices 2016, 63, 997–1004. [Google Scholar] [CrossRef]

- Zhou, Q.; Jin, Y.; Shi, Y.; Mou, J.; Bao, X.; Chen, B.; Zhang, B. High reverse blocking and low onset voltage AlGaN/GaN-on-Si lateral power diode with MIS-gated hybrid anode. IEEE Electron. Device Lett. 2015, 36, 660–662. [Google Scholar] [CrossRef]

- Bahat-Treidel, E.; Hilt, O.; Zhytnytska, R.; Wentzel, A.; Meliani, C.; Wurfl, J.; Trankle, G.J.I.E.D.L. Fast-switching GaN-based lateral power Schottky barrier diodes with low onset voltage and strong reverse blocking. IEEE Electron. Device Lett. 2012, 33, 357–359. [Google Scholar] [CrossRef]

- Treidel, E.B.; Hilt, O.; Wentzel, A.; Würfl, J.; Tränkle, G. Fast GaN based Schottky diodes on Si (111) substrate with low onset voltage and strong reverse blocking. Phys. Status Solidi 2013, 10, 849–852. [Google Scholar] [CrossRef]

- Lee, J.-G.; Park, B.-R.; Cho, C.-H.; Seo, K.-S.; Cha, H.-Y. Low turn-on voltage AlGaN/GaN-on-Si rectifier with gated ohmic anode. IEEE Electron. Device Lett. 2013, 34, 214–216. [Google Scholar] [CrossRef]

- Matioli, E.; Lu, B.; Palacios, T. Ultralow leakage current AlGaN/GaN Schottky diodes with 3-D anode structure. IEEE Trans. Electron Devices 2013, 60, 3365–3370. [Google Scholar] [CrossRef]

- Hsueh, K.-P.; Peng, L.-Y.; Cheng, Y.-H.; Wang, H.-Y.; Wang, H.-C.; Kao, H.-L.; Chiu, H.-C. Improved reverse recovery characteristics of low turn-on voltage AlGaN/GaN Schottky barrier diodes with anode edge AlON spacers. J. Alloys Compd. 2017, 703, 204–209. [Google Scholar] [CrossRef]

- Gao, J.; Jin, Y.; Xie, B.; Wen, C.P.; Hao, Y.; Shen, B.; Wang, M. Low ON-Resistance GaN Schottky Barrier Diode with High VON Uniformity Using LPCVD Si3N4 Compatible Self-Terminated, Low Damage Anode Recess Technology. Mater. Sci. Biol. 2018, 39, 859–862. [Google Scholar]

- Charles, M.; Baines, Y.; Bouis, R.; Papon, A. The characterization and optimization of GaN cap layers and SiN cap layers on AlGaN/GaN HEMT structures grown on 200 mm GaN on silicon. Phys. Status Solid 2018, 255, 1700406. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, J.; Zhang, W.; Zhang, Y.; Duan, X.; Ning, J.; Hao, Y. Investigation of an AlGaN-channel Schottky barrier diode on a silicon substrate with a molybdenum anode. Semicond. Sci. Technol. 2021, 36, 044003. [Google Scholar] [CrossRef]

- Basler, M.; Reiner, R.; Moench, S.; Waltereit, P.; Quay, R.; Kallfass, I.; Ambacher, O. Large-area lateral AlGaN/GaN-on-Si field-effect rectifier with low turn-on voltage. IEEE Electron. Device Lett. 2020, 41, 993–996. [Google Scholar] [CrossRef]

- Kang, X.; Zheng, Y.; Wu, H.; Wei, K.; Sun, Y.; Zhang, G.; Liu, X. Thin barrier gated-edge termination AlGaN/GaN Schottky-barrier-diode with low reverse leakage and high turn-on uniformity. Semicond. Sci. Tech. 2021, 36, 094001. [Google Scholar] [CrossRef]

- Soni, A.; Amogh, K.; Shrivastava, M. Design guidelines and performance tradeoffs in recessed AlGaN/GaN Schottky barrier diodes. IEEE Trans. Electron Devices 2020, 67, 4834–4841. [Google Scholar] [CrossRef]

- Tomita, R.; Ueda, S.; Kawada, T.; Mitsuzono, H.; Horio, K. Analysis of Dependence of Breakdown Voltage on Gate–Drain Distance in AlGaN/GaN HEMTs with High-k Passivation Layer. IEEE Trans. Electron Devices 2021, 68, 1550–1556. [Google Scholar] [CrossRef]

- Floros, K.; Li, X.; Guiney, I.; Cho, S.J.; Hemakumara, D.; Wallis, D.J.; Wasige, E.; Moran, D.A.; Humphreys, C.J.; Thayne, I. Dual barrier InAlN/AlGaN/GaN-on-silicon high-electron-mobility transistors with Pt-and Ni-based gate stacks. Appl. Mater. Sci. 2017, 214, 1600835. [Google Scholar] [CrossRef][Green Version]

- Jingzhan Semiconductor. Available online: http://en.enkris.com/ (accessed on 8 September 2021).

- Shin, J.-H.; Park, J.; Jang, S.; Jang, T.; Sang Kim, K. Metal induced inhomogeneous Schottky barrier height in AlGaN/GaN Schottky diode. Appl. Phys. Lett. 2013, 102, 243505. [Google Scholar] [CrossRef]

| Anode Configuration | IF, mA/mm | IR, μA/mm | C, pF/mm |

|---|---|---|---|

| LA = 11 μm, no 2FP | 43.3 | 40.66 | 3.03 |

| LA = 11 μm, 2FP | 50.4 | 30.72 | 3.63 |

| LA = 6 μm, 2FP | 47.6 | 36.96 | 3.34 |

| Diode Configuration | Structure 1 (SiN Cap, Al0.23Ga0.77N) | Structure 2 (GaN Cap, Al0.25Ga0.75N) | ||

|---|---|---|---|---|

| IF, mA/mm | IR, μA/mm | IF, mA/mm | IR, μA/mm | |

| Ni SC, 15 nm recess | 159 | 69.9 | 135.85 | 11.5 |

| Pt SC, 15 nm recess | 73.24 | 1.1 | 44.45 | 71.3 |

| Pt SC, 40 nm recess | 59.7 | 0.04 | 107.05 | 53 |

| Paper | Wafer | Fab | VON, V | VF, V | IR, µA/mm | VBR, V |

|---|---|---|---|---|---|---|

| IMEC ‘16 [16] | Si | CMOS | ~0.55 | 1.2 | 0.01 | 600 |

| Hongik ‘13 [20] | Si | RF | 0.37 | 1.53 | 1 | 1440 |

| UESTC ‘15 [17] | Si | RF | ~0.6 | 1.3 | 1 | 1100 |

| CAS ‘21 [27] | Si | RF | 0.57 | 1.3 | 0.02 | 1780 |

| FIASSP ‘20 [26] | Si | RF | 0.2 | 2.0 | 0.1 | 676 |

| MIT ‘13 [21] | Si | RF | 0.85 | 1.4 | 10−4 | 127 |

| FBH ‘12 [18] | SiC | RF | 0.43 | 1.5 | 0.2 | 1000 |

| AUT ‘20 [28] | Si | RF | 0.8 | 1.8 | 1 | 1620 |

| XIDIAN ‘20 [25] | Si | RF | 0.5 | 1.1 | 1 | 1300 |

| This work | SiC | RF | 0.6 | 1.6 | 0.04 | 300 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Polyntsev, E.; Erofeev, E.; Yunusov, I. The Influence of Design on Electrical Performance of AlGaN/GaN Lateral Schottky Barrier Diodes for Energy-Efficient Power Applications. Electronics 2021, 10, 2802. https://doi.org/10.3390/electronics10222802

Polyntsev E, Erofeev E, Yunusov I. The Influence of Design on Electrical Performance of AlGaN/GaN Lateral Schottky Barrier Diodes for Energy-Efficient Power Applications. Electronics. 2021; 10(22):2802. https://doi.org/10.3390/electronics10222802

Chicago/Turabian StylePolyntsev, Egor, Evgeny Erofeev, and Igor Yunusov. 2021. "The Influence of Design on Electrical Performance of AlGaN/GaN Lateral Schottky Barrier Diodes for Energy-Efficient Power Applications" Electronics 10, no. 22: 2802. https://doi.org/10.3390/electronics10222802

APA StylePolyntsev, E., Erofeev, E., & Yunusov, I. (2021). The Influence of Design on Electrical Performance of AlGaN/GaN Lateral Schottky Barrier Diodes for Energy-Efficient Power Applications. Electronics, 10(22), 2802. https://doi.org/10.3390/electronics10222802