Conductive Electrifi and Nonconductive NinjaFlex Filaments based Flexible Microstrip Antenna for Changing Conformal Surface Applications

Abstract

1. Introduction

2. Materials and Methods

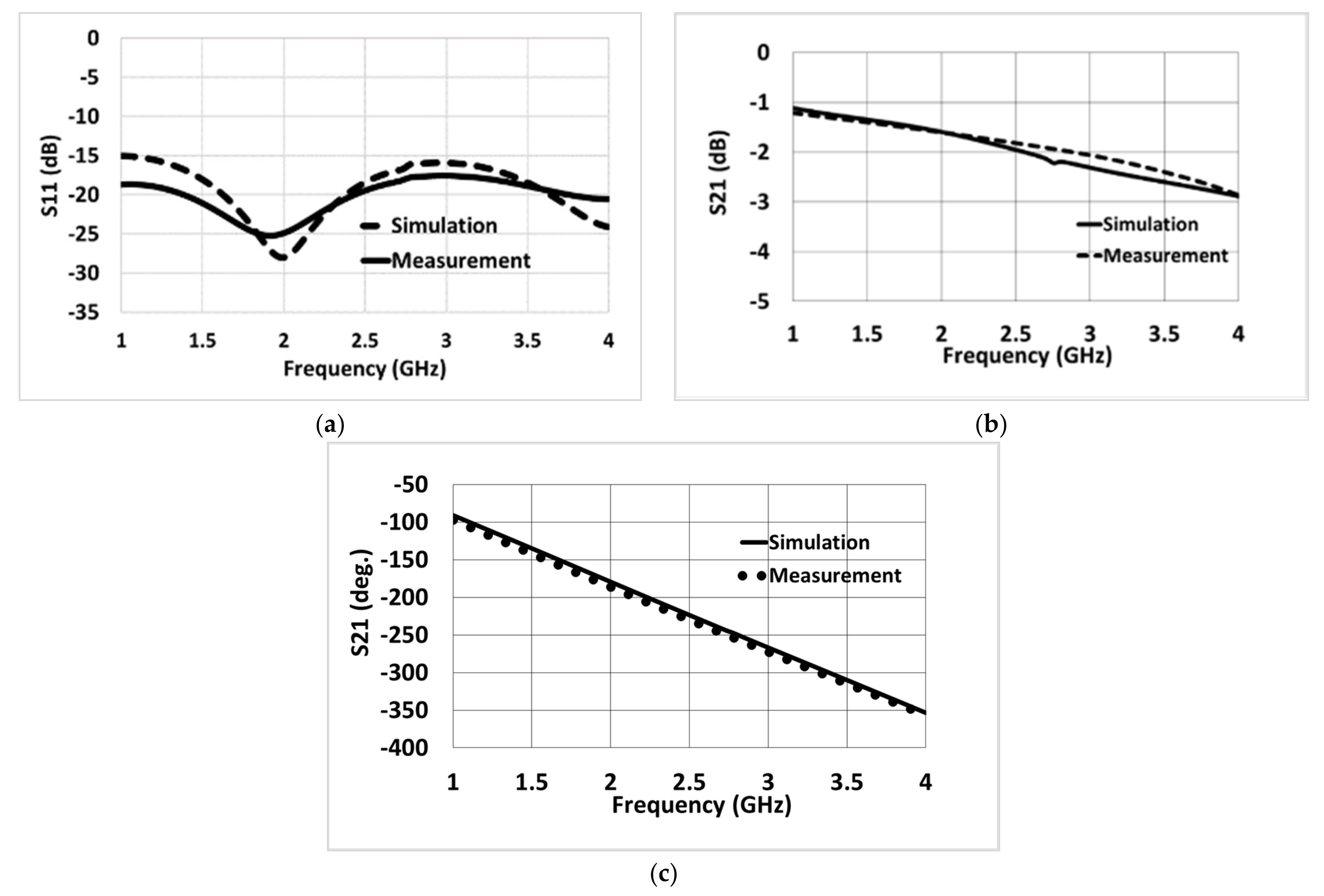

2.1. RF Characterization Analysis of a 50 Ω TL Made of Electrifi and NinjaFlex Filaments

- : resistance per unit length (Ω/m),

- : inductance per unit length (H/m)

- : capacitance per unit length (F/m), and

- : conductance per unit length (S/m).

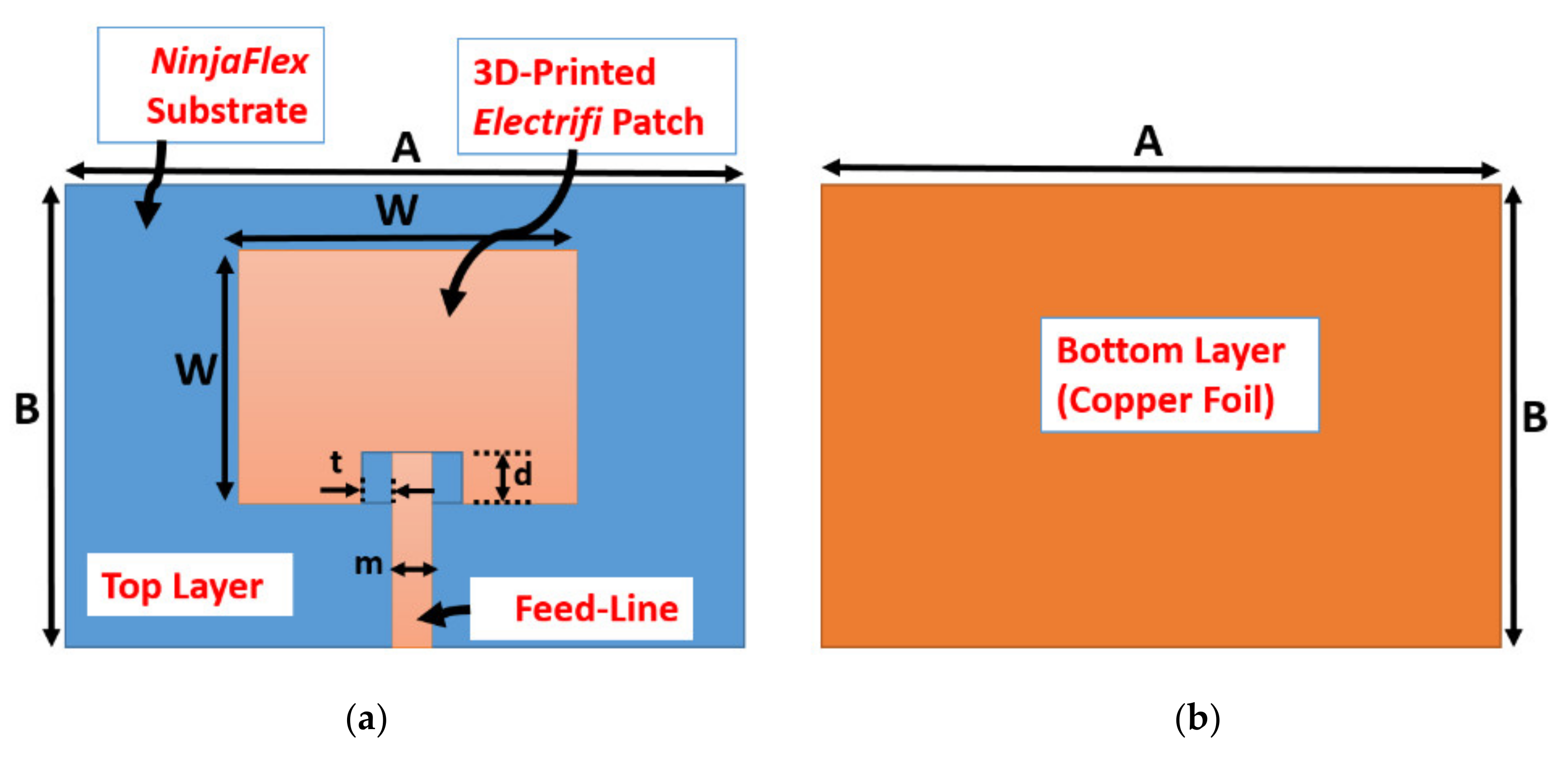

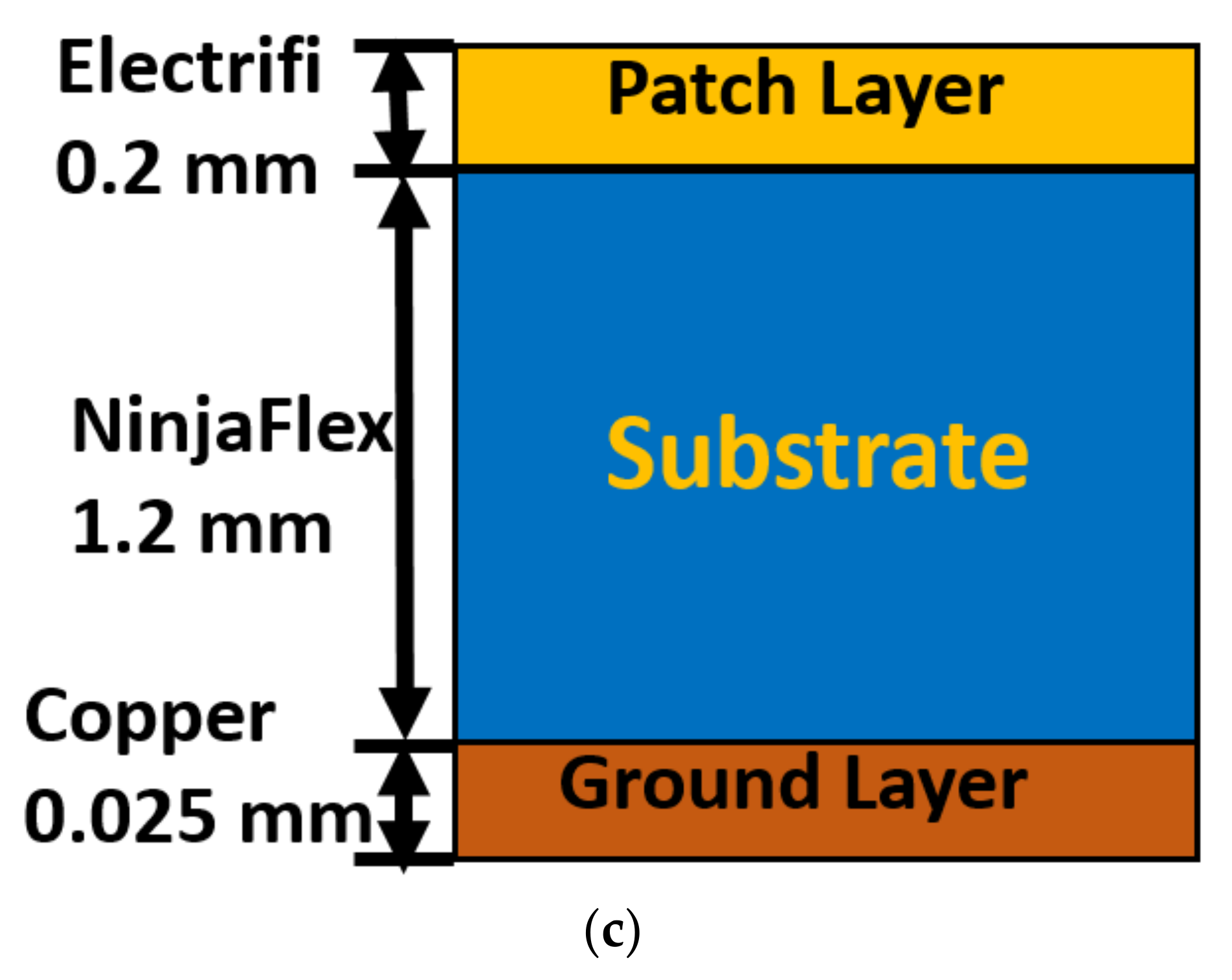

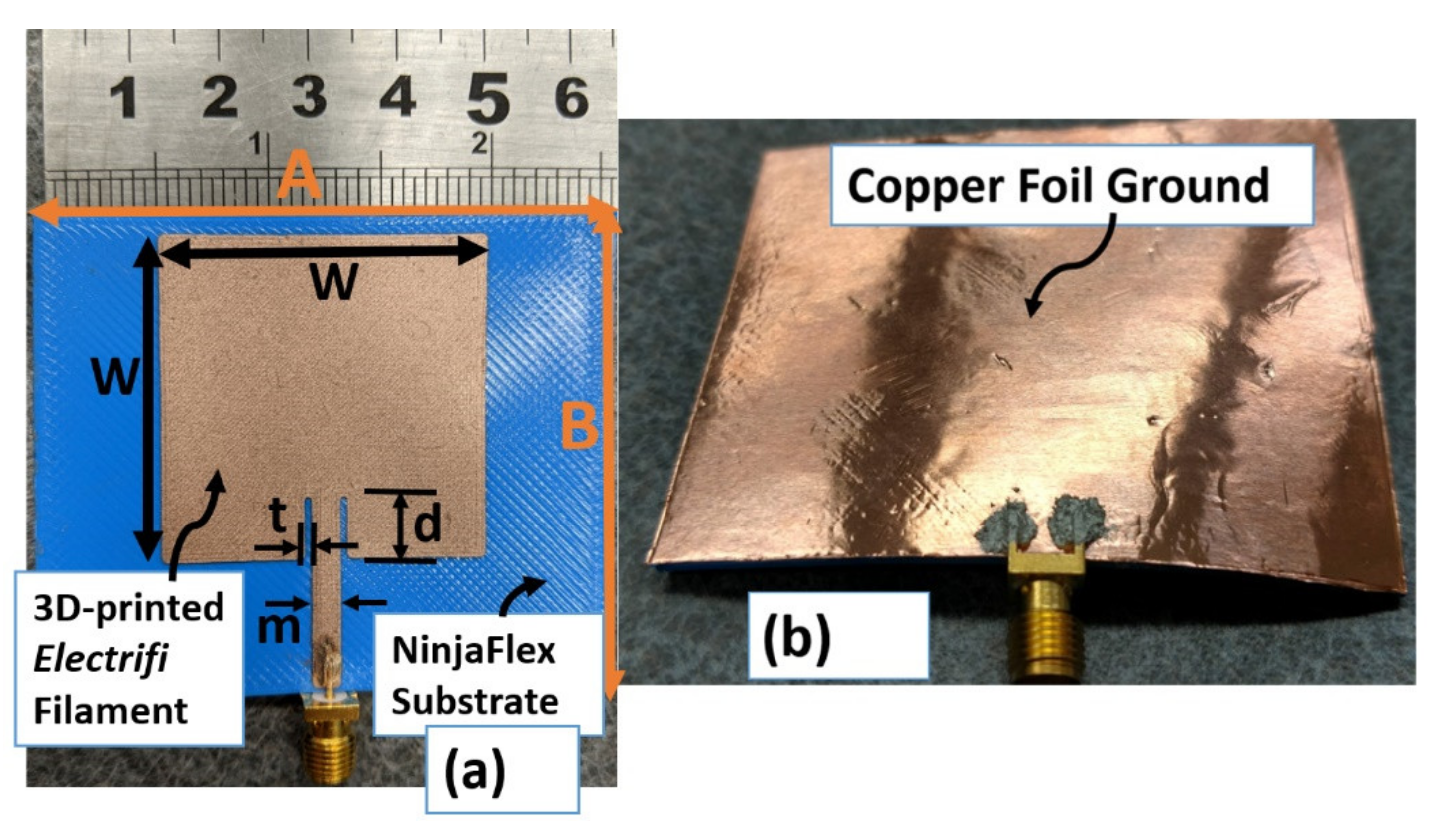

2.2. Prototyping of the 3D-Printed Microstrip Patch Antenna on Flexible NinjaFlex Substrate

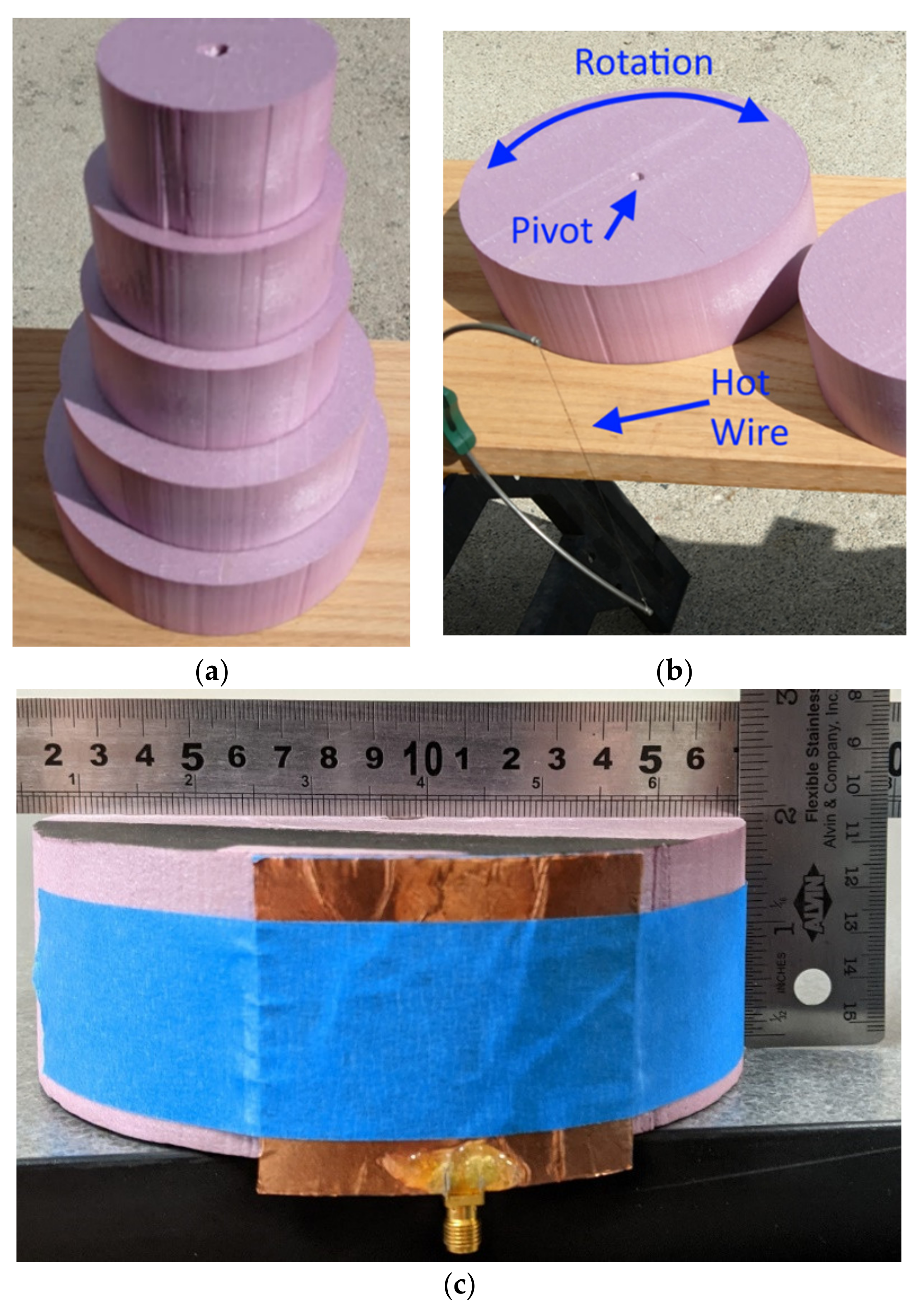

2.2.1. Processing of the Conformal Surfaces for Testing

3. Results

3.1. Reflection Coefficient (S11)

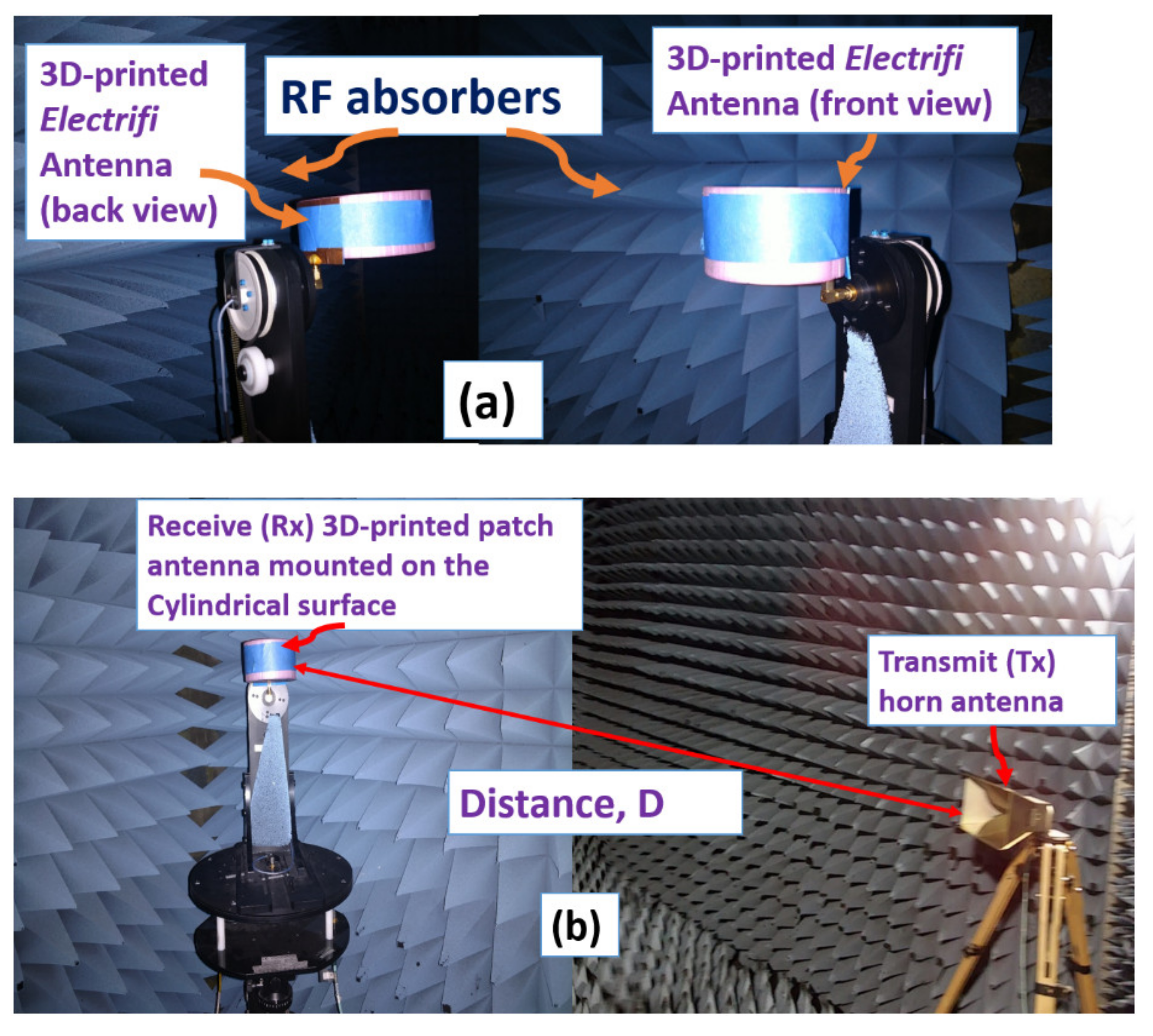

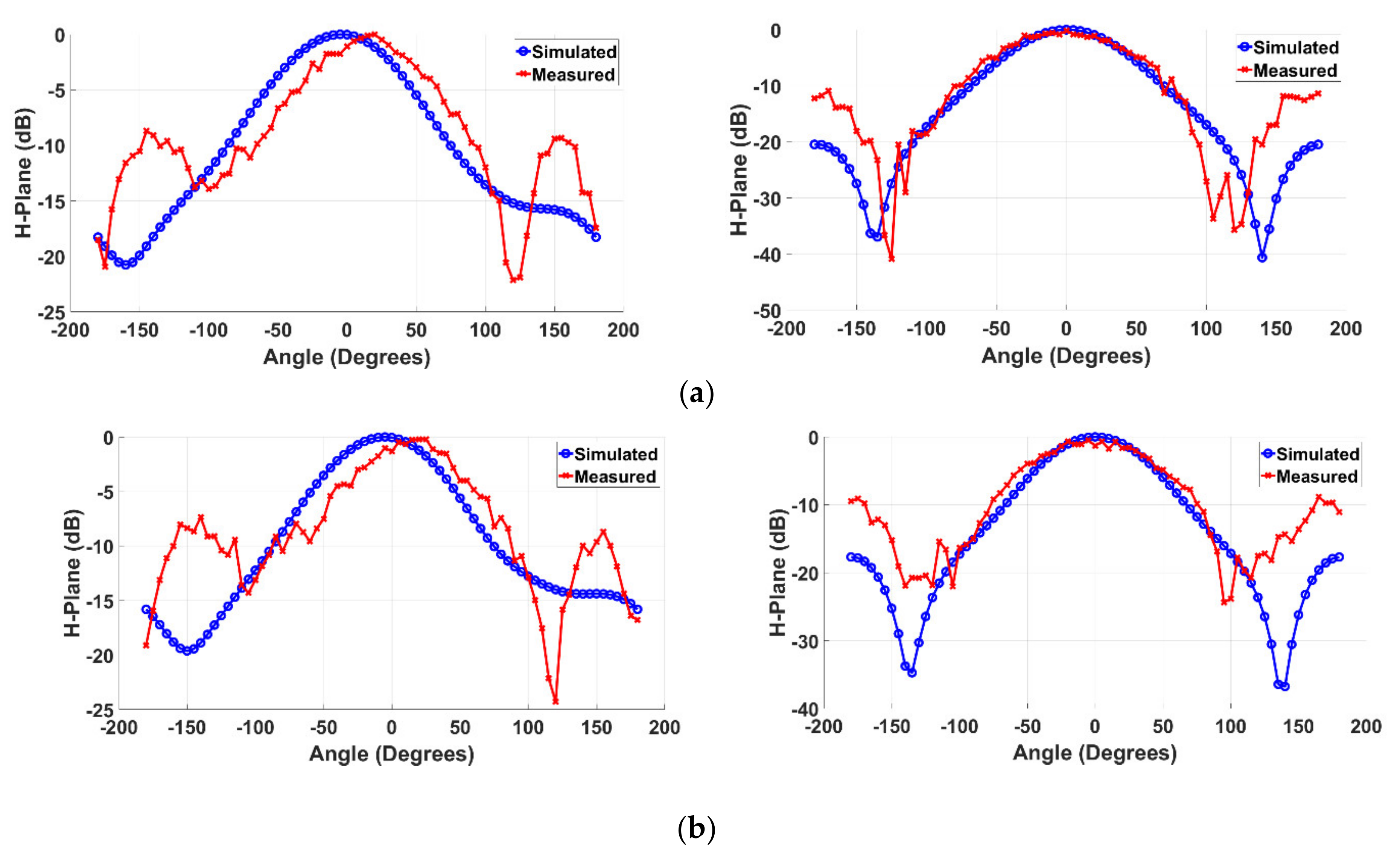

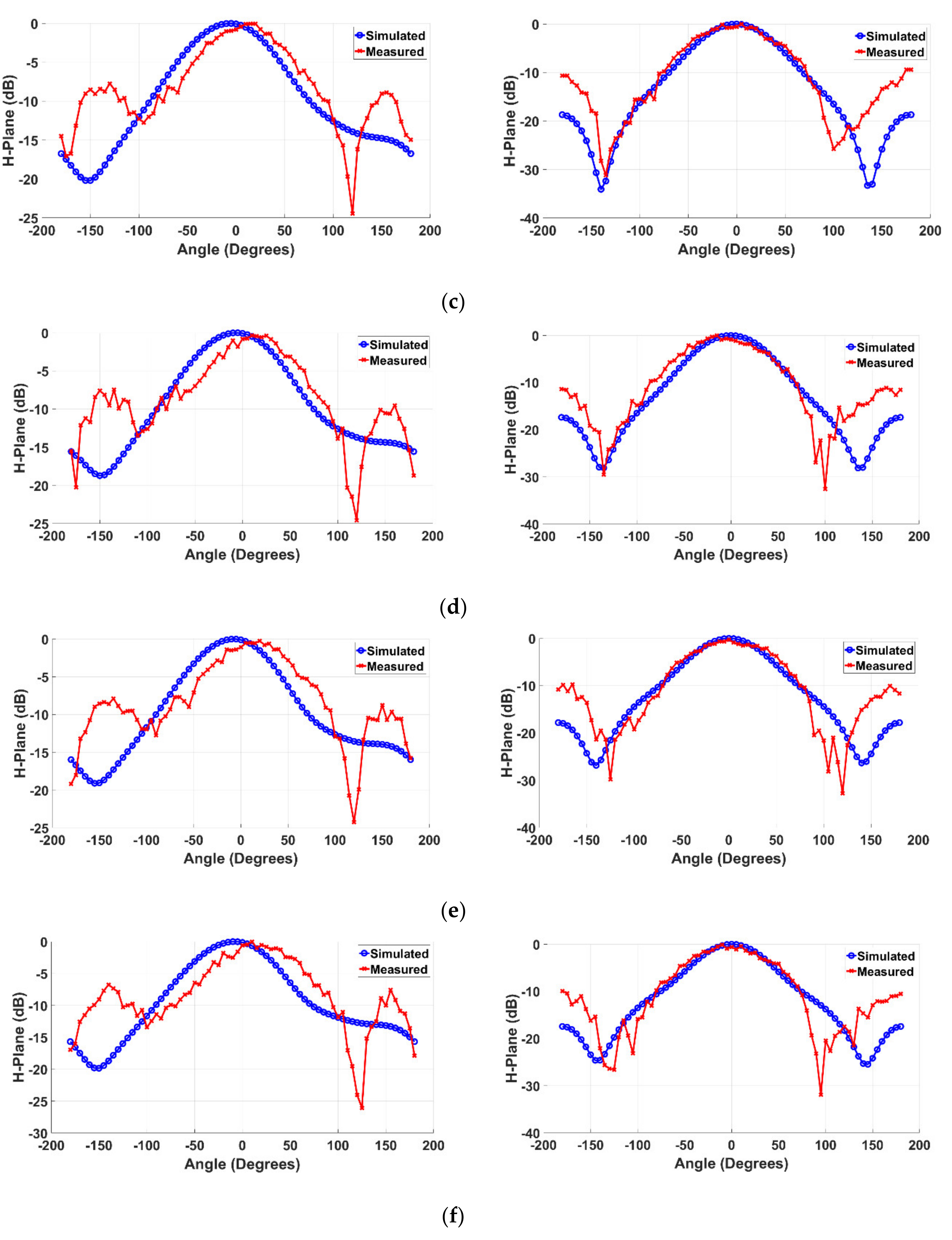

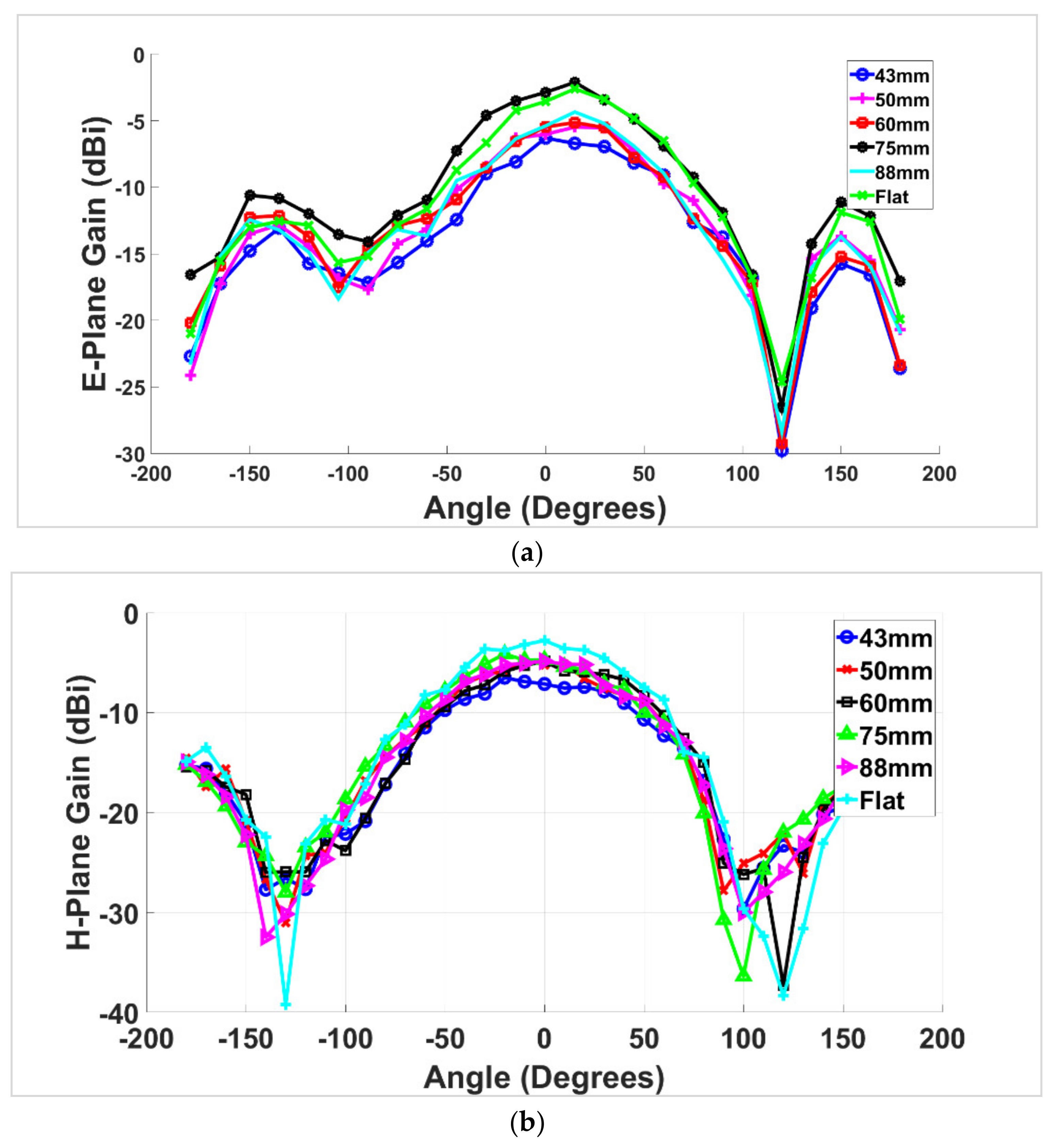

3.2. Description of Radiation Patterns

3.3. Analysis of Experimental Gain

3.4. Determination of Surface Current Distribution

4. Discussion

- A 50 Ω TL model was realized using an improved version of conductive Electrifi filament on 3D-printed NinjaFlex substrate, and later, the TL model was characterized to analyze RF propagation of the Electrifi filament showing attenuation and phase constant.

- The propagation constant () of the Electrifi filament from Section 2 was used in full-wave model to model a microstrip patch antenna using the fused filament fabrication (FFF) method of additive manufacturing on a flexible 3D-printed NinjaFlex substrate for conformal applications. This method introduced a low-cost and easy-to-fabricate 3D-printing method compared to existing solutions and methods for realizing complex and conformal RF structures.

- The fabricated 3D-printed Electrifi antenna was shown to have extraordinary flexibility and conformality performances. The conformal experimentation was performed through mounting the 3D-printed Electrifi antenna prototype on curved cylindrical surfaces of five different radii.

- The reflection coefficients, radiation patterns, and gains in Figure 10, Figure 11 and Figure 12 showed that the 3D-printed Electrifi antenna performed very well except for small discrepancies under different bending conditions, which would make it a very suitable candidate for various conformal applications.

- Due to the use of NinjaFlex material as the substrate, low gain was observed, in future different flexible substrates with lower loss might be used for better gain performance.

- The simulated current density results in Figure 14 showed that the current density remained in the center when the antenna geometry was flat, and the current tended to be more distributed towards the edges from the center as the curvature of the conformal surfaces increased.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- O’Donovan, P.L.; Rudge, A.W. Adaptive control of a flexible linear array. Electron. Lett. 1973, 9, 121–122. [Google Scholar] [CrossRef]

- Chung, D.J.; Bhattacharya, S.K.; Ponchak, G.E.; Papapolymerou, J. An 8×8 Lightweight Flexible Multilayer Antenna array. In Proceedings of the 2009 IEEE Antennas and Propagation Society International Symposium, Charleston, SC, USA, 1–5 June 2009; pp. 1–4. [Google Scholar]

- Hansen, R.C. Phased Array Antennas; Wiley: New York, NY, USA, 1998. [Google Scholar]

- Haupt, R.L. Antenna Arrays: A Computational Approach; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Roy, S.; Sajal, S.; Braaten, B.D. A phase correction technique based on spatial movements of antennas in real-time for designing self-adapting conformal array antennas. Microw. Opt. Technol. Lett. 2017, 59, 3002–3010. [Google Scholar] [CrossRef]

- Guo, J.L.; Li, J.Y. Pattern Synthesis of Conformal Array Antenna in the Presence of Platform Using Differential Evolution Algorithm. IEEE Trans. Antennas Propag. 2009, 57, 2615–2621. [Google Scholar]

- Zhu, S.; Langley, R. Dual-Band Wearable Textile Antenna on an EBG Substrate. IEEE Trans. Antennas Propag. 2009, 57, 926–935. [Google Scholar] [CrossRef]

- Wincza, K.; Gruszczynski, S. Influence of curvature Radius on Radiation Patterns in Multibeam Conformal Antennas. In Proceedings of the 36th European Microwave Conference, Manchester, UK, 10–15 September 2006; pp. 1410–1413. [Google Scholar]

- Josefsson, L.; Persson, P. Conformal Array Antenna Theory and Design; Wiley: Hoboken, NJ, USA, 2006. [Google Scholar]

- Klemm, M.; Troester, G. Textile UWB Antennas for Wireless Body Area Networks. IEEE Trans. Antennas Propag. 2006, 54, 3192–3197. [Google Scholar] [CrossRef]

- Kennedy, T.F.; Fink, P.W.; Chu, A.W.; Champagne, N.J.; Lin, G.Y.; Khayat, M.A. Body-Worn E-Textile Antennas: The Good, the Low Mass, the Conformal. IEEE Trans. Antennas Propag. 2009, 57, 910–918. [Google Scholar] [CrossRef]

- Salonen, P.; Rahmat-Samii, Y.; Schaffrath, M.; Kivikoski, M. Effect of Textile Materials on Wearable Antenna Performance: A Case Study of GPS Antennas. Proc. IEEE Int. Symp. Antennas Propag. Soc. 2004, 1, 459–462. [Google Scholar]

- Psychodakis, D.; Lee, G.Y.; Chen, C.C.; Volakis, J.L. Estimating Diversity for Body-Worn Antennas. In Proceedings of the 3rd European Conference on Antennas and Propagation (EuCAP), Berlin, Germany, 23–27 March 2009. [Google Scholar]

- Callus, P.J. Conformal Load-Bearing Antenna Structure for Australian Defense Force Aircraft; DSTO Platforms Sciences Laboratory: Victoria, Australia, 2007. [Google Scholar]

- Sbir.gov. Available online: https://www.sbir.gov/content/conformal-antennas-improved-signal-intelligence-0 (accessed on 1 November 2020).

- Liu, Y.; Yang, H.; Jin, Z.; Zhao, F.; Zhu, J. A Multibeam Cylindrically Conformal Slot Array Antenna Based on a Modified Rotman Lens. IEEE Tans. Antennas Propag. 2018, 66, 3441–3452. [Google Scholar] [CrossRef]

- Budhu, J.; Rahmat-Samii, Y.; Hodges, R.; Hofmann, U.C.; Ruffatto, D.F.; Carpenter, K. Three-Dimensionally Printed, Shaped, Engineered Material Inhomogenous Lens Antenna for Next-Generation Spaceborne Weather Radar Systems. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 2080–2084. [Google Scholar] [CrossRef]

- Zhao, Y.; Shen, Z.; Wu, W. Conformal SIW H-Plane Horn Antenna on a Conducting Cylinder. IEEE Antennas Wirel. Propag. Lett. 2015, 14, 1271–1274. [Google Scholar] [CrossRef]

- Nikolaou, S.; Ponchak, G.E.; Papapolymerou, J.; Tentzeris, M.M. Conformal Double Exponentially Tapered Slot Antenna (DETSA) on LCP for UWB Applications. IEEE Trans. Antennas Propag. 2006, 54, 1663–1669. [Google Scholar] [CrossRef]

- Bayram, Y.; Zhou, Y.; Shim, B.S.; Xu, S.; Zhu, J.; Kotov, N.A.; Volakis, J.L. E-TextileConductors and Polymer Composites for Conformal Lightweight Antennas. IEEE Trans. Antennas Propag. 2010, 58, 2732–2736. [Google Scholar] [CrossRef]

- Aziz, M.A.; Roy, S.; Berge, L.A.; Ullah, I.; Braaten, B.D. A Conformal CPW Folded Slot Antenna Array Printed on a Kapton Substrate. In Proceedings of the European Microwave Conference, Prague, Czech Republic, 26–30 March 2012. [Google Scholar]

- Liyakath, R.A.; Takshi, A.; Mumcu, G. Multilayer Stretchable Conductors on Polymer Substrates for Conformal and Reconfigurable Antennas. IEEE Antennas Wirel. Propag Lett. 2013, 12, 603–606. [Google Scholar] [CrossRef]

- Auyeung, R.C.Y.; Nurnberger, M.W.; Wendland, D.J.; Pique, A.; Arnold, A.R.; Schuette, L.C. Laser Fabrication of GPS Conformal Antennas. In Proceedings of the Photon Processing in Microelectronics and Photonics III, San Jose, CA, USA, 26–29 January 2004. [Google Scholar]

- Toriz-Garcia, J.J.; Cowling, J.J.; Williams, G.L.; Bai, Q.; Seed, N.L.; Tennant, A.; McWilliam, R.; Purvis, A.; Soulard, F.B.; Ivey, P.A. Fabrication of a 3D Electrically Small Antenna Using Holographic Photolithography. J. Micromech. Microeng. 2013, 23, 055010. [Google Scholar] [CrossRef]

- Dorlé, A.; Gillard, R.; Menargues, E.; Vorst, M.V.D.; Rijk, E.D.; Martín-Iglesias, P.; Garcia- Vigueras, M. Additive Manufacturing of Modulated Triple-Ridge Leaky-Wave Antenna. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 2123–2127. [Google Scholar] [CrossRef]

- Dimitriadis, A.I.; Debogović, T.; Costa, J.R.; Fernandes, C.A.; Mosig, J.R. Polymer-Based Additive Manufacturing of High-Performance Waveguide and Antenna Components. Proc. IEEE 2017, 105, 668–676. [Google Scholar] [CrossRef]

- Silva, J.S.; García-Vigueras, M.; Debogović, T.; Costa, J.R.; Fernandes, C.A.; Mosig, J.R. Sterolithography-Based Antennas for Satellite Communications in Ka-Band. Proc. IEEE 2017, 105, 655–667. [Google Scholar] [CrossRef]

- Vorst, M.V.D.; Gumpinger, J. Applicability of 3D Printing Techniques for Compact Ku-Band Medium/High-Gain Antennas. In Proceedings of the 10th European Conference on Antennas and Propagation (EuCAP), Davos, Switzerland, 10–15 April 2016; pp. 1–4. [Google Scholar]

- Garcia- Vigueras, M.; Menargues, E.; Debogović, T.; Rijk, E.D.; Mosig, J.R. Cost-Effective Dual-Polarized Leaky-Wave antennas Enabled by Three-Dimensional Printing. IET Microw. Antennas Propag. 2017, 11, 1985–1991. [Google Scholar] [CrossRef]

- Li, Z.; Huang, J.; Yang, Y.; Yang, S.; Zhang, J.; Yuan, P.; Zhang, J. Additive Manufacturing of Conformal Microstrip Antenna Using Piezoelectric Nozzle Array. Appl. Sci. 2020, 10, 3082. [Google Scholar] [CrossRef]

- Goh, G.L.; Ma, J.; Chua, K.L.; Shweta, A.; Yeong, W.Y.; Zhang, Y.P. Inkjet-printed patch antenna emitter for wireless communication application. Virtual Phys. Prototyp. 2016, 11, 289–294. [Google Scholar] [CrossRef]

- McKerricher, G.; Titterington, D.; Shamim, A. A fully inkjet-printed 3-D honeycomb-inspired patch antenna. IEEE Antennas Wirel. Propag. Lett. 2015, 15, 544–547. [Google Scholar] [CrossRef]

- Menéndez, L.G.; Kim, O.S.; Persson, F.; Nielsen, M.; Breinbjerg, O. 3D Printed 20/30-GHz Dual-Band Offset Stepped-Reflector Antenna. In Proceedings of the 2015 9th European Conference on Antennas and Propagationc (EuCAP), Libson, Portugal, 12–17 April 2015; pp. 1–2. [Google Scholar]

- Shang, X.; Penchev, P.; Guo, C.; Lancaster, M.J.; Dimov, S.; Dong, Y.; Favre, M.; Billod, M.; Rijk, E.D. W-Band Waveguide Filters Fabricated by Laser Micromachining and 3D Printing. IEEE Trans. Microw. Theor. Techniq. 2016, 64, 2572–2580. [Google Scholar] [CrossRef]

- Johnson, K.; Zemba, M.; Conner, B.P.; Walker, J.; Burden, E.; Rogers, K.; Cwiok, K.R.; Macdonald, E.; Cortes, P. Digital Manufacturing of Pathologically-Complex 3D Printed Antennas. IEEE Access. 2019, 7, 39378–39389. [Google Scholar] [CrossRef]

- Zhang, S. Three-Dimensional Printed Millimetre Wave Dielectric Resonator Reflectarray. IET Microw. Antennas Propag. 2017, 11, 2005–2009. [Google Scholar] [CrossRef]

- Piekarz, I.; Sorocki, J.; Slomian, I.; Wincza, K.; Gruszczynski, S. Experimental Verification of 3D Printed Low-Conductivity Graphene-Enhanced PLA Absorbers for Back Lobe Suppression in Aperture-Coupled Antennas. In Proceedings of the 2018 IEEE-APS Topical Conference on Antennas and Propagation in Wireless Communications (APWC), Cartenga des Indias, Colombia, 10–14 September 2018; pp. 780–782. [Google Scholar]

- Li, Y.; Ge, L.; Wang, J.; Da, S.; Cao, D.; Wang, J.; Liu, Y. 3D Printed High-Gain Wideband Waveguide Fed Horn Antenna Arrays for Millimeter-Wave Applications. IEEE Trans. Antennas Propag. 2019, 67, 2868–2877. [Google Scholar] [CrossRef]

- Mirzaee, M.; Noghanian, S. High Frequency Characterization of Wood-Fill PLA for Antenna Additive Manufacturing Application. Elec. Lett. 2016, 52, 1656–1658. [Google Scholar] [CrossRef]

- Electrifi Conductive Filament, multi3dllc. Available online: https://www.multi3dllc.com/product/Electrifi/ (accessed on 24 January 2021).

- BlackMagic3D. Available online: https://www.blackmagic3d.com/ (accessed on 30 June 2020).

- Proto-Pasta. Available online: https://www.proto-pasta.com/ (accessed on 30 June 2020).

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive Manufacturing: Scientific and Technological Challenges, Market Uptake and Opportunities. 2018. Available online: https://doi.org/10.1016/j.mattod.2017.07.001 (accessed on 30 June 2020).

- Ford, S.; Despeisse, M. Additive Manufacturing and Sustainability: An Exploratory Study of the Advantages and Challenges. 2016. Available online: https://www.researchgate.net/publication/302589689_Additive_manufacturing_and_sustainability_an_exploratory_study_of_the_advantages_and_challenges (accessed on 30 June 2020).

- Chua, C.K.; Leong, K.F.; Lim, C.S. Rapid Prototyping: Principles and Applications; World Scientific: Hackensack, NJ, USA, 2003; Volume 1. [Google Scholar]

- Turner, B.N.; Strong, R.; Gold, S.A. A Review of Melt Extrusion Additive Manufacturing Processes: I. Process Design and Modeling. Rapid Prototyp. J. 2014. [Google Scholar] [CrossRef]

- Roy, S.; Qureshi, M.B.; Asif, S.; Braaten, B.D. A Model for 3D-Printed Microstrip Transmission Lines Using Conductive Electrifi Filament. In Proceedings of the 2017 IEEE International Symposium on Antennas and Propagation & USNC/URSI National Radio Science Meeting, San Diego, CA, USA, 9–14 July 2017; pp. 1099–1100. [Google Scholar]

- Mitra, D.; Striker, R.; Braaten, B.D.; Aqueeb, A.; Kabir, K.S.; Roy, S. On the Design of an Improved Model of Additively Manufactured Microstrip Transmission Lines for Radio Frequency Applications. In Proceedings of the 2019 IEEE International Conference on Electro Information Technology (EIT), Brookings, SD, USA, 20–22 May 2019; pp. 182–184. [Google Scholar]

- Pizarro, F.; Salazar, R.; Rajo-Iglesias, E.; Rodríguez, M.; Fingerhuth, S.; Hermosilla, G. Parametric Study of 3D Additive Printing Parameters Using Conductive Filaments on Microwave Topologies. IEEE Access 2019, 7, 106814–106823. [Google Scholar] [CrossRef]

- Colella, R.; Chietera, F.; Catarinucci, L.; Casula, A.; Montisci, G.; Gatto, G.; Michel, A.; Nepa, P.; Rogier, H. Electromagnetic Analysis and Performance Comparison of Fully 3D-Printed Antennas. In Proceedings of the 2019 PhotonIcs & Electromagnetics Research Symposium—Spring (PIERS-Spring), Rome, Italy, 17–20 December 2019; pp. 964–970. [Google Scholar]

- Basic Copper. Available online: https://basiccopper.com/6x61milcofol.html (accessed on 10 March 2021).

- DIY 3D Printer, Creality 3D. Available online: https://www.creality3d.cn/creality-cr-10-3d-printer-p00096p1.html/ (accessed on 20 February 2019).

- Striker, R.; Mitra, D.; Braaten, B.D.; Kabir, K.S.; Roy, S. On the Manufacturing Process of a Single-Step Fully 3D Printed Conformal Patch Antenna. In Proceedings of the 2020 IEEE International Conference on Electro Information Technology (EIT), Chicago, IL, USA, 31 July–1 August 2020; pp. 288–292. [Google Scholar]

- Roy, S.; Qureshi, M.B.; Asif, S.; Sajal, S.; Braaten, B.D. A Study of Microstrip Transmission Lines on Substrates Created Using Additive Manufacturing and Flexible or Semi-Rigid Filaments. In Proceedings of the 2017 IEEE International Conference on Electro Information Technology (EIT), Lincoln, NE, USA, 14–17 May 2017; pp. 200–205. [Google Scholar]

- 3MTM Super 77TM Multipurpose Spray Adhesive. Available online: https://www.3m.com/ (accessed on 1 November 2020).

- Ansys, Inc. Available online: https://www.ansys.com/ (accessed on 20 December 2019).

- Knott, E.F. Dielectric constant of plastic foams. IEEE Trans. Ant. Propag. 1993, 41, 1167–1171. [Google Scholar] [CrossRef]

- Waldron, I.; Makarov, S.N. Measurement of dielectric permittivity and loss tangent for bulk foam samples with suspended ring resonator method. In Proceedings of the 2006 IEEE Antennas and Propagation Society International Symposium, Albuquerque, NM, USA, 9–14 July 2006; pp. 3175–3178. [Google Scholar]

- TDK RF Solutions. Available online: https://www.tdkrfsolutions.com/ (accessed on 13 January 2020).

- Roberson, D.A.; Espalin, D.; Wicker, R.B. 3D printer selection: A decision-making evaluation and ranking model. Virtual Phys. Prototyp. 2013, 8, 201–212. [Google Scholar] [CrossRef]

| Printing Parameters | for Electrifi | for NinjaFlex |

|---|---|---|

| Nozzle diameter (mm) | 0.4 | 0.5 |

| Print speed (mm/s) | 15 | 15 ~ 40 |

| Print temp. (°C) | 130~140 | 240 |

| Bed temp. (°C) | 23 | 60 |

| Layer height (mm) | 0.2 | 0.25 |

| Extrusion multiplier | 1.15 | 1 |

| Outline shells | 2 | 3 |

| Infill percentage (%) | 100 | 100 |

| Equipment | Details |

|---|---|

| Coaxial cable | Micro-coax 26.5 GHz cable with assembly part number UFA210A-0-0240-30070U (12-feet) |

| Network analyzer | Keysight E5071C 300 kHz–20 GHz ENA series network analyzer |

| Horn antenna | TDK HRN-0118 1 GHz–18 GHz |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitra, D.; Roy, S.; Striker, R.; Burczek, E.; Aqueeb, A.; Wolf, H.; Kabir, K.S.; Ye, S.; Braaten, B.D. Conductive Electrifi and Nonconductive NinjaFlex Filaments based Flexible Microstrip Antenna for Changing Conformal Surface Applications. Electronics 2021, 10, 821. https://doi.org/10.3390/electronics10070821

Mitra D, Roy S, Striker R, Burczek E, Aqueeb A, Wolf H, Kabir KS, Ye S, Braaten BD. Conductive Electrifi and Nonconductive NinjaFlex Filaments based Flexible Microstrip Antenna for Changing Conformal Surface Applications. Electronics. 2021; 10(7):821. https://doi.org/10.3390/electronics10070821

Chicago/Turabian StyleMitra, Dipankar, Sayan Roy, Ryan Striker, Ellie Burczek, Ahsan Aqueeb, Henry Wolf, Kazi Sadman Kabir, Shengrong Ye, and Benjamin D. Braaten. 2021. "Conductive Electrifi and Nonconductive NinjaFlex Filaments based Flexible Microstrip Antenna for Changing Conformal Surface Applications" Electronics 10, no. 7: 821. https://doi.org/10.3390/electronics10070821

APA StyleMitra, D., Roy, S., Striker, R., Burczek, E., Aqueeb, A., Wolf, H., Kabir, K. S., Ye, S., & Braaten, B. D. (2021). Conductive Electrifi and Nonconductive NinjaFlex Filaments based Flexible Microstrip Antenna for Changing Conformal Surface Applications. Electronics, 10(7), 821. https://doi.org/10.3390/electronics10070821