Optimization of Kiloampere Peltier Current Lead Using Orthogonal Experimental Design Method

Abstract

:1. Introduction

2. Model and Analysis Method

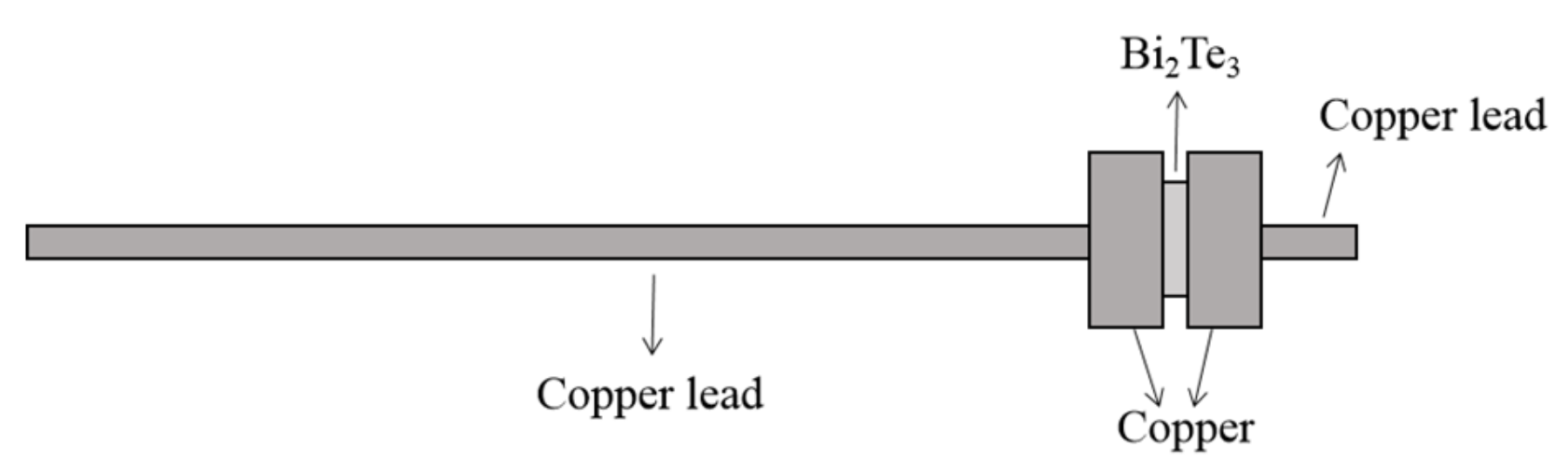

2.1. Model

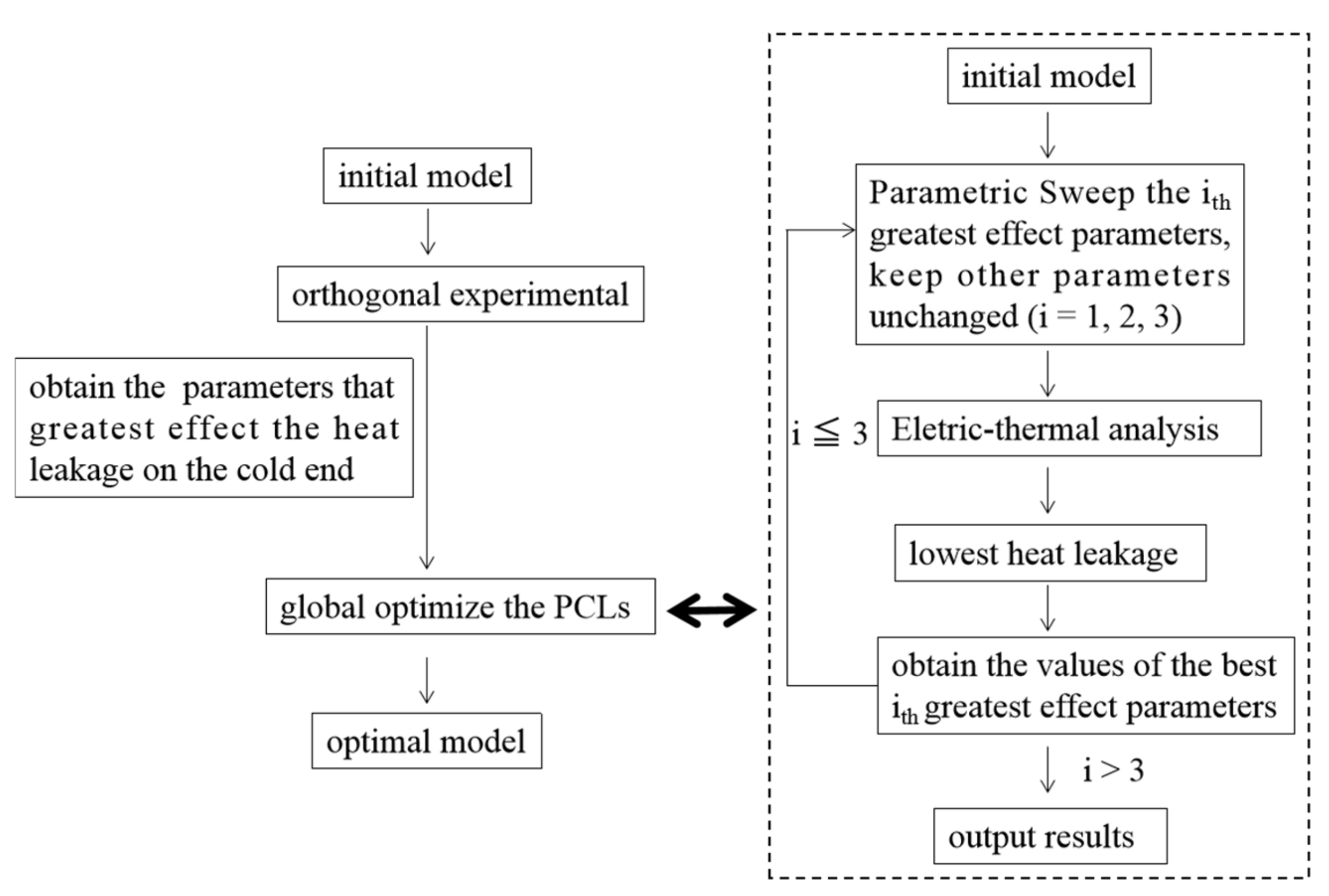

2.2. Optimization Procedure

3. Results and Discussions

3.1. Results of 120 A Peltier Current Lead Optimization

3.1.1. Orthogonal Experimental Design for 120 A PCLs

3.1.2. Orthogonal Experimental Results of 120 A PCLs

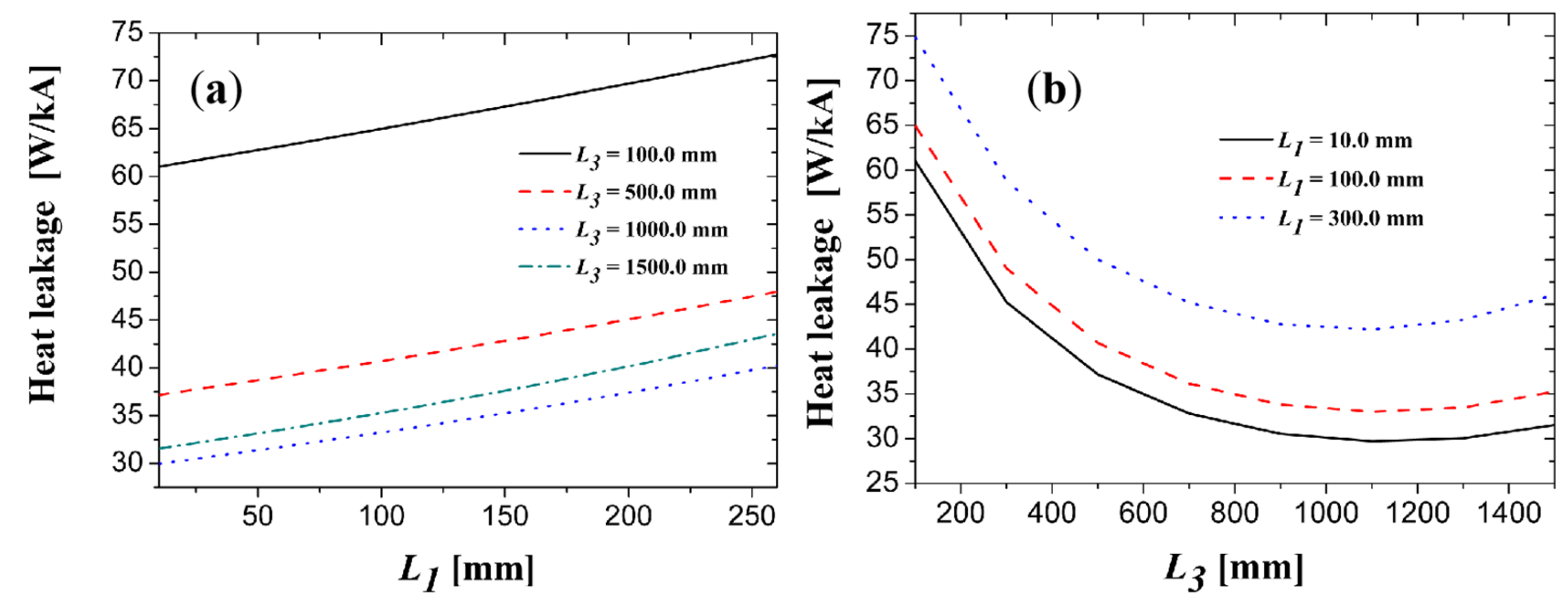

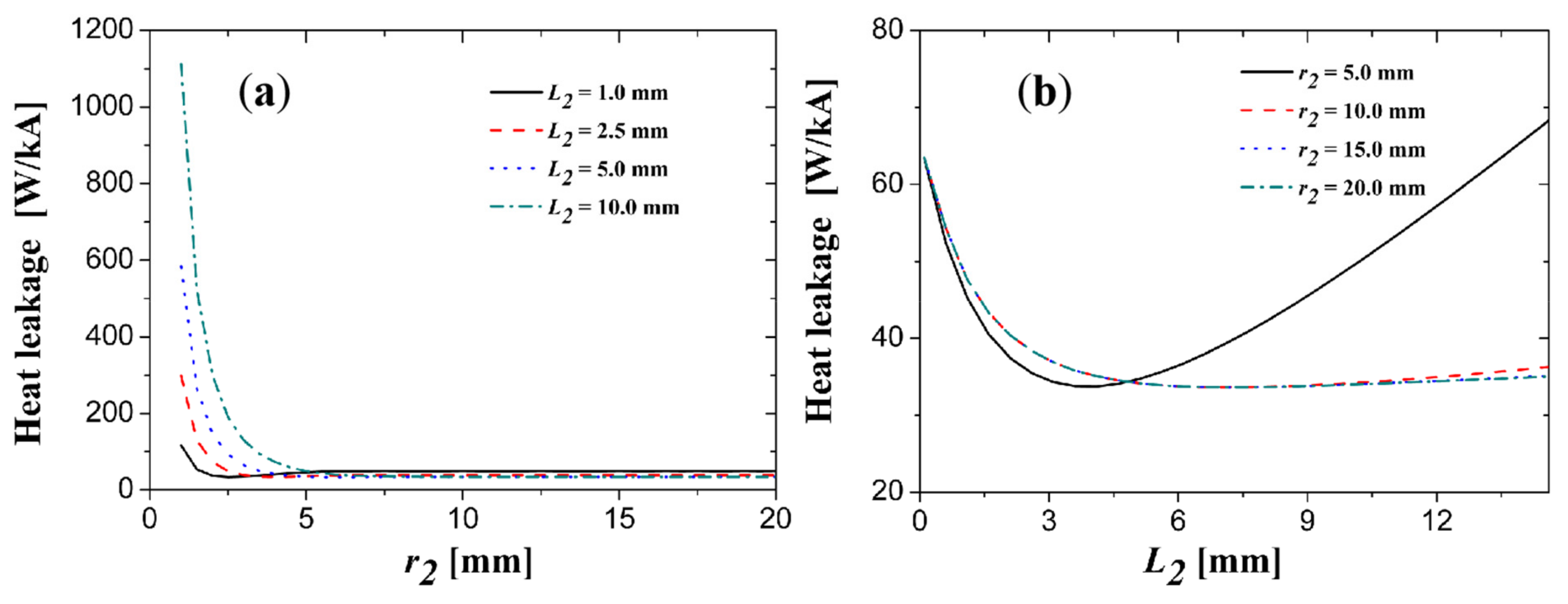

3.1.3. Global Optimization of the 120 A PCLs

3.2. Results of 1200 A Peltier Current Lead Optimization

3.2.1. Orthogonal Experimental Design for 1200 A PCLs

3.2.2. Orthogonal Experimental Results of 1200 A PCLs

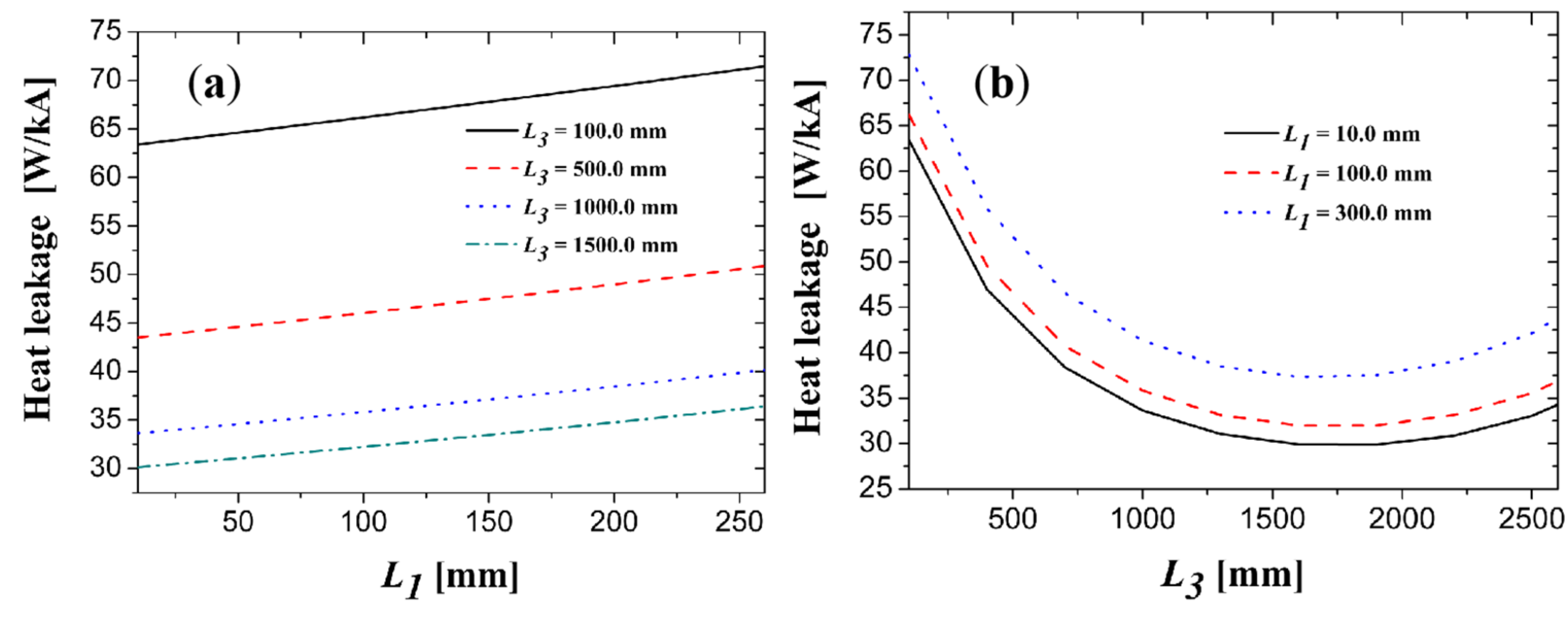

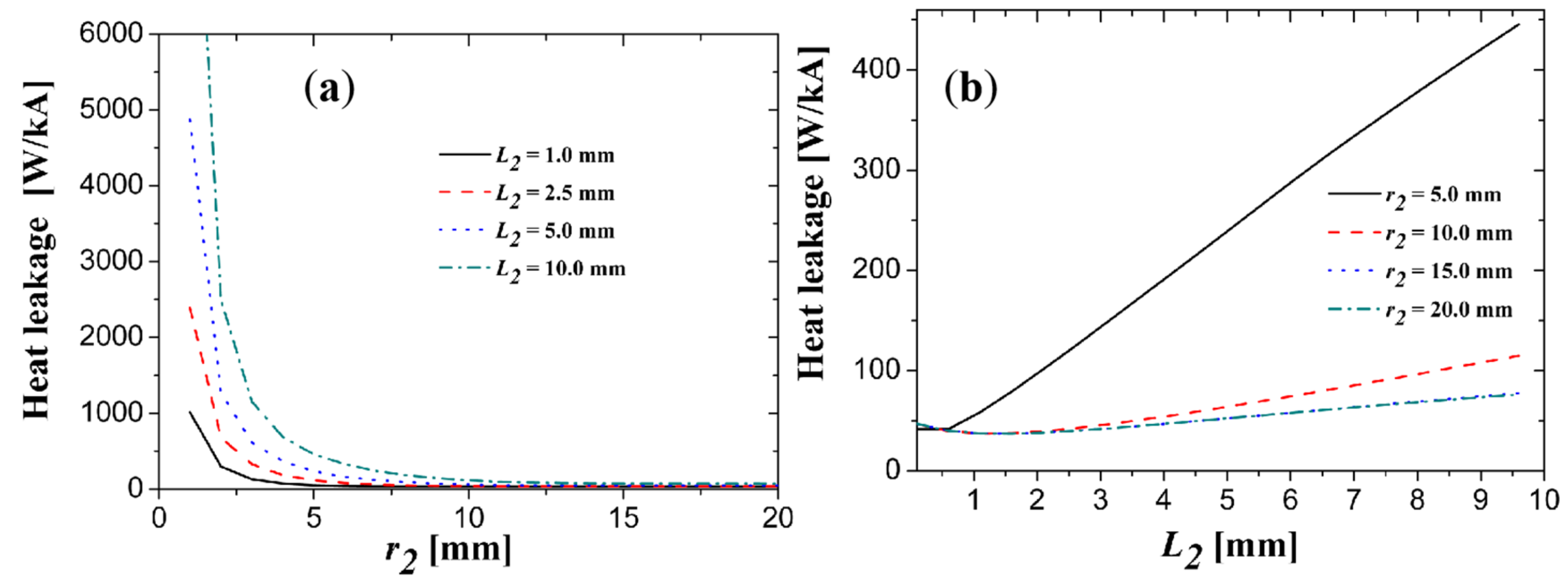

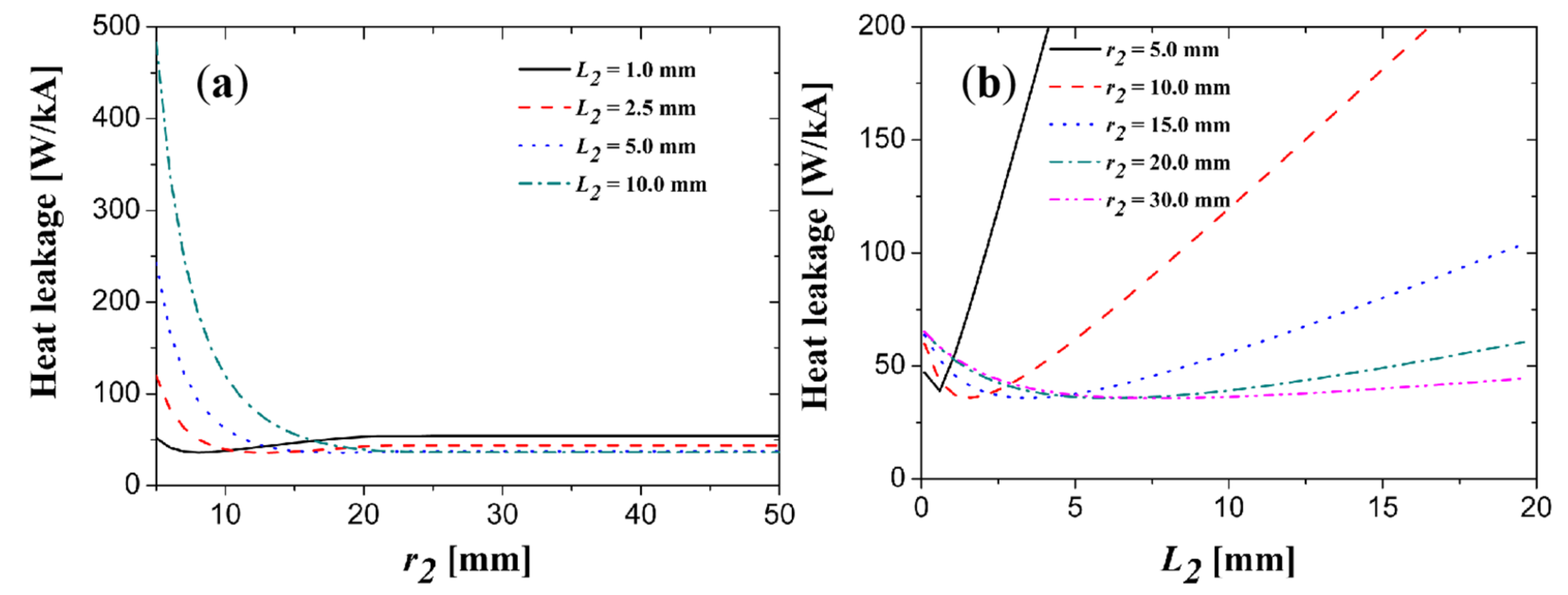

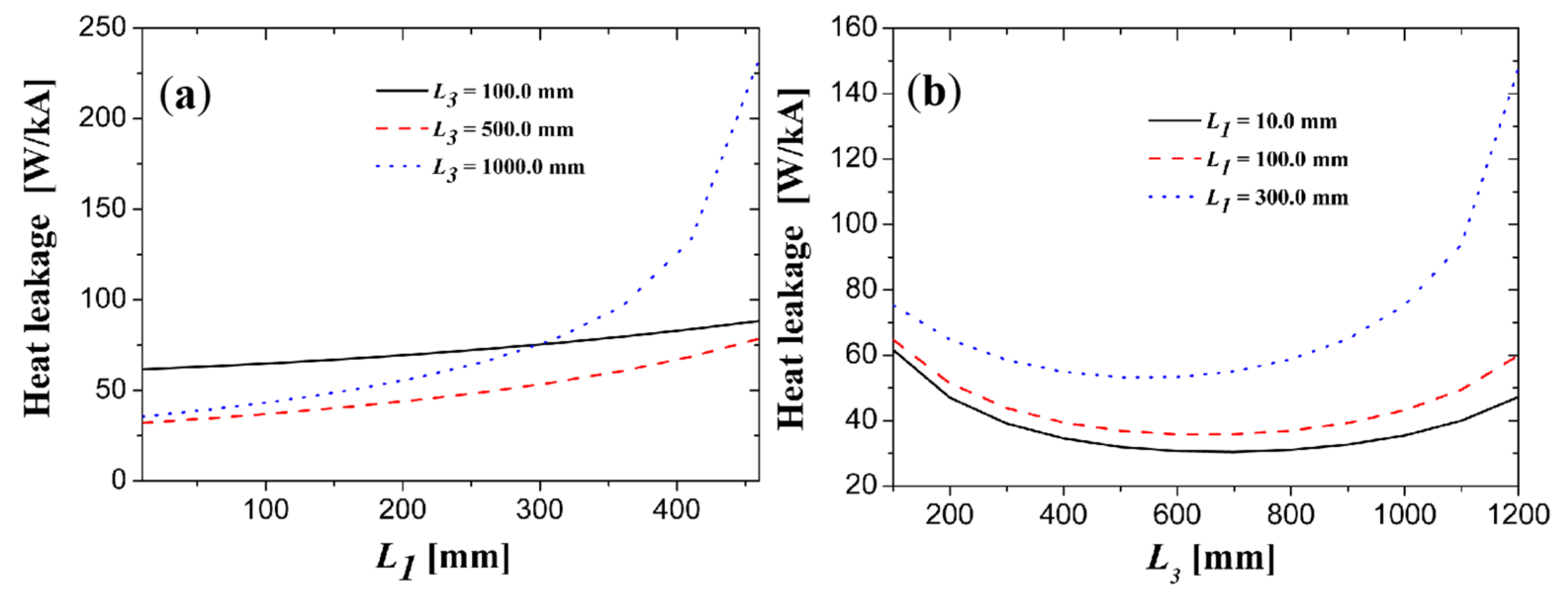

3.2.3. Global Optimization of the 1200 A PCLs

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix A.1. Orthogonal Experimental Schedule for 120 A PCLs

| Column Number | 1 | 2 | 4 | 8 | 15 | |

|---|---|---|---|---|---|---|

| Parameters | A: Copper Leads Radius (r1/mm) | B: Length of Warm end Copper Leads (L1/mm) | C: Length of Cold End Copper Leads (L3/mm) | D: Radius of Bi2Te3 (r2/mm) | E: Length of Bi2Te3 (L2/mm) | Simulation Results (W/kA) |

| Simulation 1 | 3.0 | 10.0 | 100.0 | 1.0 | 1.0 | 154.9 |

| Simulation 2 | 3.0 | 10.0 | 100.0 | 30.0 | 30.0 | 76.1 |

| Simulation 3 | 3.0 | 10.0 | 1500.0 | 1.0 | 30.0 | 1608.3 |

| Simulation 4 | 3.0 | 10.0 | 1500.0 | 30.0 | 1.0 | 158.8 |

| Simulation 5 | 3.0 | 300.0 | 100.0 | 1.0 | 30.0 | 4920.0 |

| Simulation 6 | 3.0 | 300.0 | 100.0 | 30.0 | 1.0 | 74.1 |

| Simulation 7 | 3.0 | 300.0 | 1500.0 | 1.0 | 1.0 | 384.7 |

| Simulation 8 | 3.0 | 300.0 | 1500.0 | 30.0 | 30.0 | 351.9 |

| Simulation 9 | 30.0 | 10.0 | 100.0 | 1.0 | 30.0 | 5676.9 |

| Simulation 10 | 30.0 | 10.0 | 100.0 | 30.0 | 1.0 | 5816.0 |

| Simulation 11 | 30.0 | 10.0 | 1500.0 | 1.0 | 1.0 | 178.6 |

| Simulation 12 | 30.0 | 10.0 | 1500.0 | 30.0 | 30.0 | 215.8 |

| Simulation 13 | 30.0 | 300.0 | 100.0 | 1.0 | 1.0 | 183.9 |

| Simulation 14 | 30.0 | 300.0 | 100.0 | 30.0 | 30.0 | 244.6 |

| Simulation 15 | 30.0 | 300.0 | 1500.0 | 1.0 | 30.0 | 5507.5 |

| Simulation 16 | 30.0 | 300.0 | 1500.0 | 30.0 | 1.0 | 1066.6 |

Appendix A.2. Global Optimization of the PCLs for 120 A PCLs

Appendix A.2.1. The Simulation Case 2 for 120 A PCLs

Appendix A.2.2. The Simulation Case 3 for 120 A PCLs

Appendix A.3. Orthogonal Experimental Schedule for 1200 A PCLs

| Column Number | 1 | 2 | 4 | 8 | 15 | |

|---|---|---|---|---|---|---|

| Parameters | A: Copper Leads Radius (r1/mm) | B: Length of Warm End Copper Leads (L1/mm) | C: Length of Cold End Copper Leads (L3/mm) | D: Radius of Bi2Te3 (r2/mm) | E: Length of Bi2Te3 (L2/mm) | Simulation Results (W/kA) |

| Simulation 1 | 10.0 | 10.0 | 100.0 | 5.0 | 1.0 | 69.7 |

| Simulation 2 | 10.0 | 10.0 | 100.0 | 50.0 | 50.0 | 196.5 |

| Simulation 3 | 10.0 | 10.0 | 1500.0 | 5.0 | 50.0 | 1254.7 |

| Simulation 4 | 10.0 | 10.0 | 1500.0 | 50.0 | 1.0 | 68.6 |

| Simulation 5 | 10.0 | 300.0 | 100.0 | 5.0 | 50.0 | 3482.7 |

| Simulation 6 | 10.0 | 300.0 | 100.0 | 50.0 | 1.0 | 74.0 |

| Simulation 7 | 10.0 | 300.0 | 1500.0 | 5.0 | 1.0 | 304.4 |

| Simulation 8 | 10.0 | 300.0 | 1500.0 | 50.0 | 50.0 | 357.8 |

| Simulation 9 | 80.0 | 10.0 | 100.0 | 5.0 | 50.0 | 3774.3 |

| Simulation 10 | 80.0 | 10.0 | 100.0 | 50.0 | 1.0 | 1845.0 |

| Simulation 11 | 80.0 | 10.0 | 1500.0 | 5.0 | 1.0 | 78.6 |

| Simulation 12 | 80.0 | 10.0 | 1500.0 | 50.0 | 50.0 | 63.2 |

| Simulation 13 | 80.0 | 300.0 | 100.0 | 5.0 | 1.0 | 83.0 |

| Simulation 14 | 80.0 | 300.0 | 100.0 | 50.0 | 50.0 | 67.5 |

| Simulation 15 | 80.0 | 300.0 | 1500.0 | 5.0 | 50.0 | 3617.8 |

| Simulation 16 | 80.0 | 300.0 | 1500.0 | 50.0 | 1.0 | 612.8 |

Appendix A.4. Global Optimization of the PCLs for 1200 A PCLs

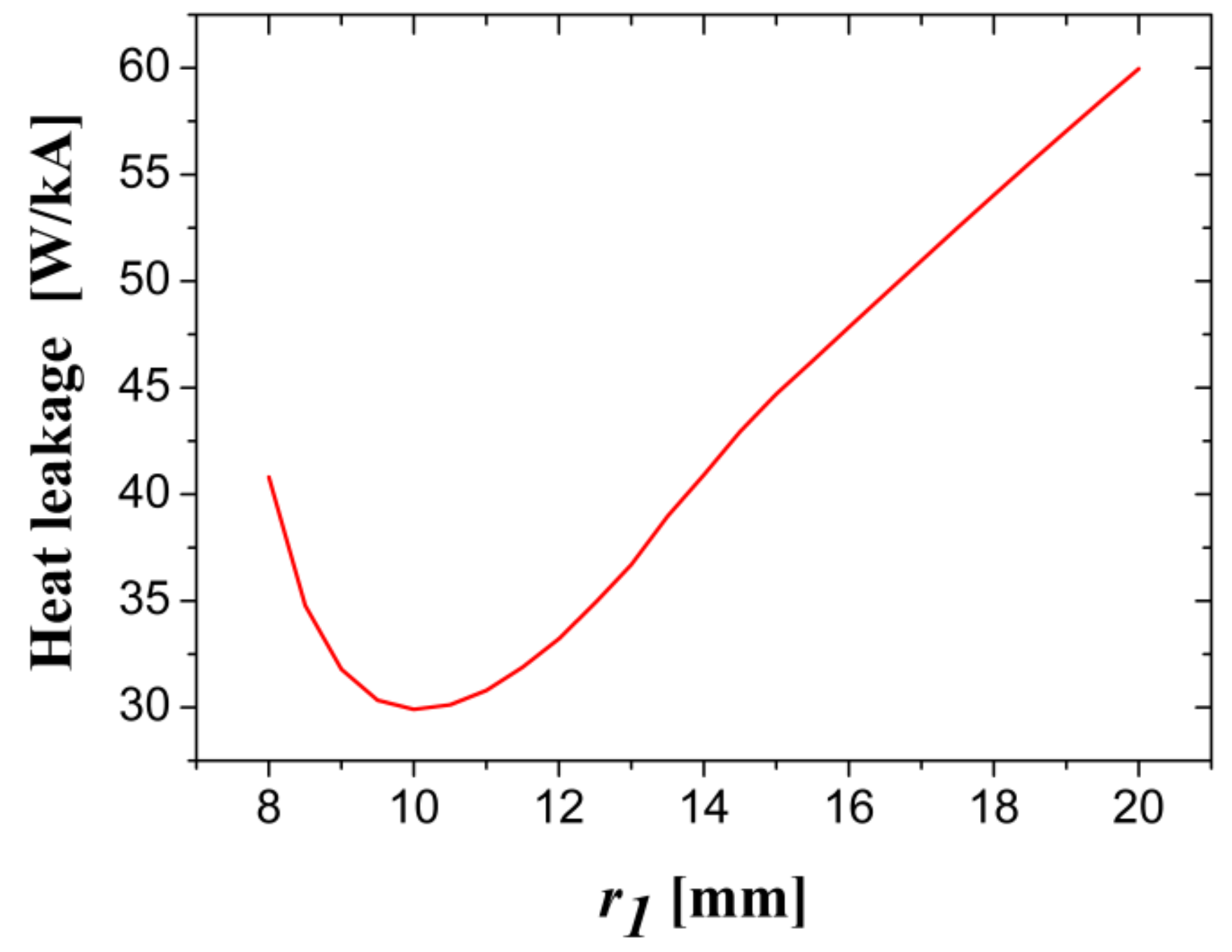

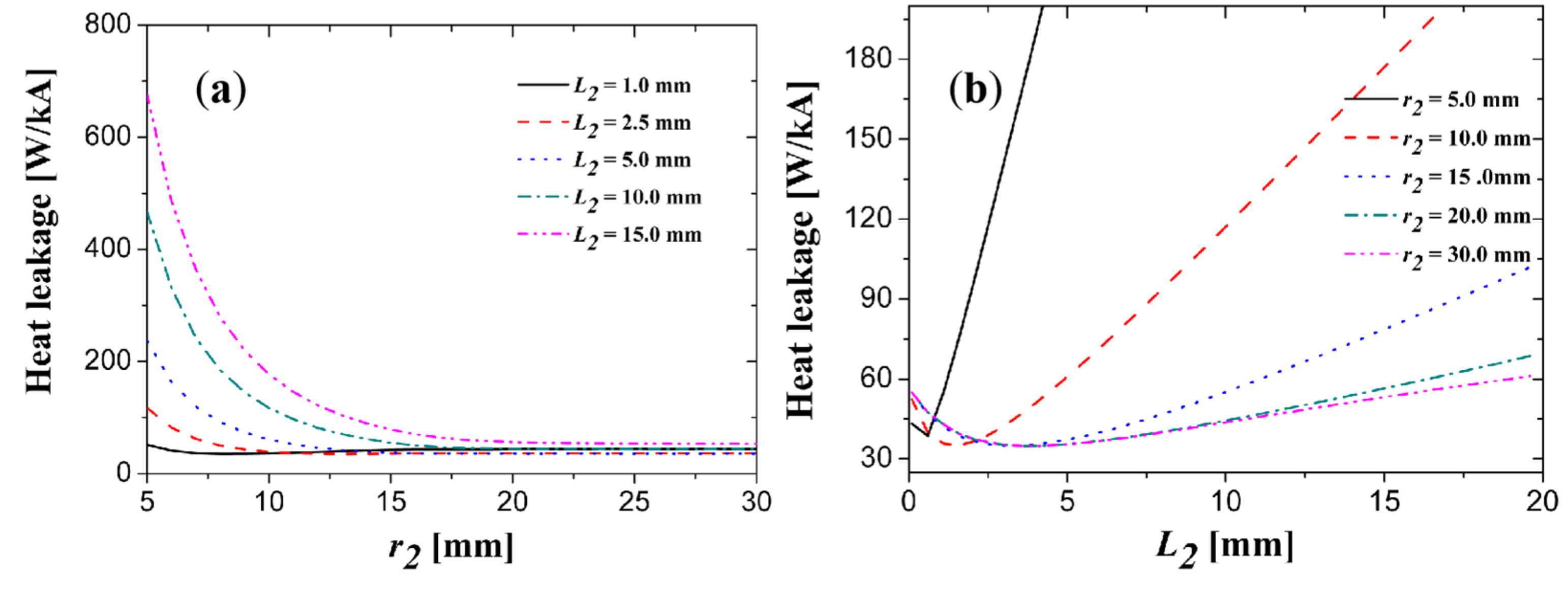

Appendix A.4.1. The Simulation Case 1 for 1200 A PCLs

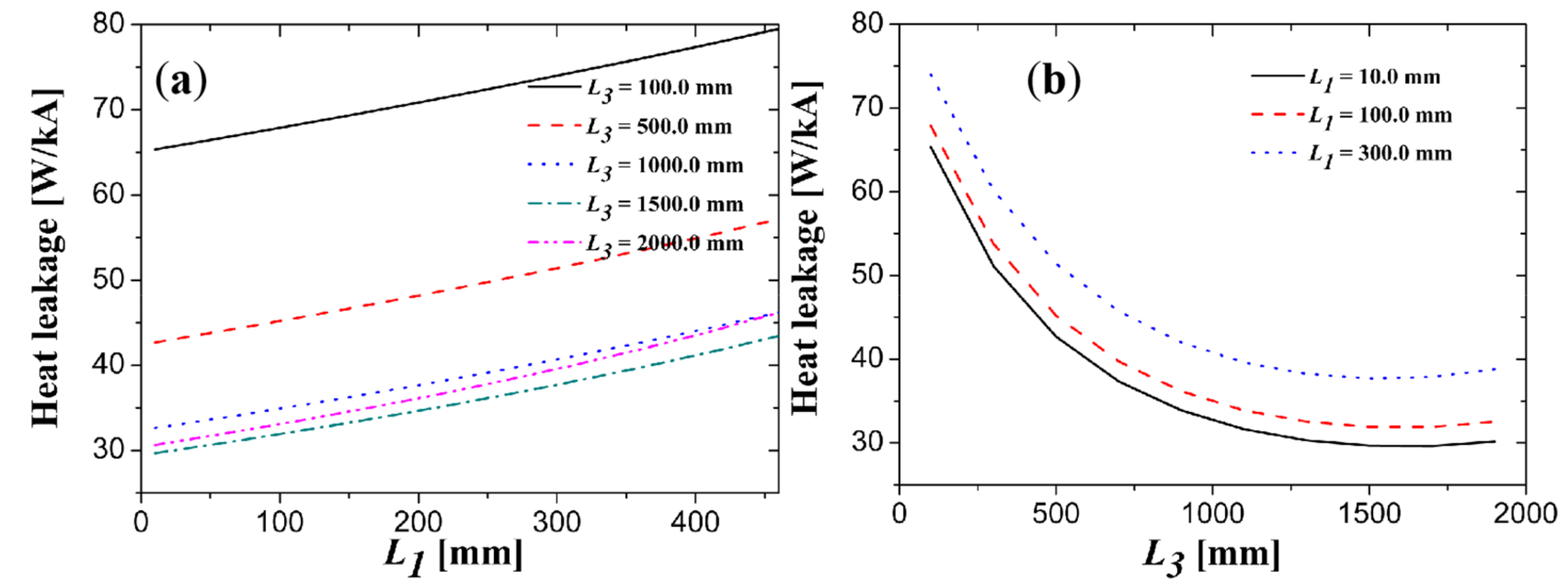

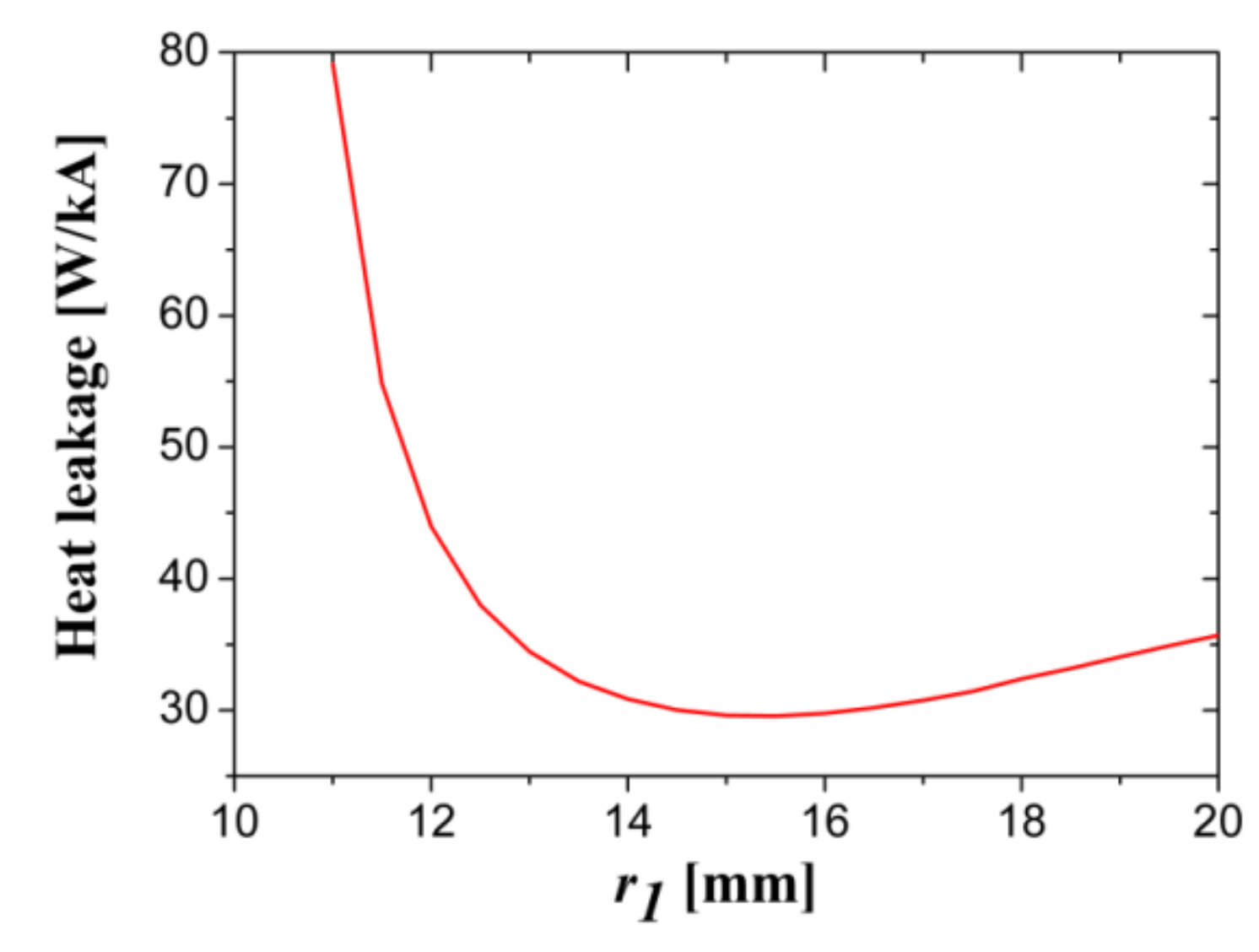

Appendix A.4.2. The Simulation Case 2 for 1200 A PCLs

Appendix A.4.3. The Simulation Case 3 for 1200 A PCLs

References

- Dai, S.; Xiao, L.; Zhang, H.; Teng, Y.; Liang, X.; Song, N.; Cao, Z.; Zhu, Z.; Gao, Z.; Ma, T.; et al. Testing and Demonstration of a 10-kA HTS DC Power Cable. IEEE Trans. Appl. Supercond. 2014, 24, 99–102. [Google Scholar]

- Yamaguchi, S.; Koshizuka, H.; Hayashi, K.; Sawamura, T. Concept and Design of 500 Meter and 1000 Meter DC Superconducting Power Cables in Ishikari. IEEE Trans. Appl. Supercond. 2015, 25, 5402504. [Google Scholar] [CrossRef]

- Yang, B.; Kang, J.; Lee, S.; Choi, C.; Moon, Y. Qualification Test of a 80 kV 500 MW HTS DC Cable for Applying Into Real Grid. IEEE Trans. Appl. Supercond. 2015, 25, 5402705. [Google Scholar] [CrossRef]

- Sytnikov, V.E.; Bemert, S.E.; Krivetsky, I.V.; Karpov, V.N.; Romashov, M.A.; Shakarian, Y.G.; Nosov, A.A.; Fetisov, S.S. The Test Results of AC and DC HTS Cables in Russia. IEEE Trans. Appl. Supercond. 2016, 26, 5401304. [Google Scholar] [CrossRef]

- Xie, W.; Wei, B.G.; Yao, Z.F. Introduction of 35 kV km Level Domestic Second Generation High Temperature Superconducting Power Cable Project in Shanghai, China. J. Supercond. Nov. Magn. 2020, 33, 1927–1931. [Google Scholar] [CrossRef]

- Lee, C.; Son, H.; Won, Y.; Kim, Y.; Ryu, C.; Park, M.; Iwakuma, M. Progress of the First Commercial Project of High-Temperature Superconducting Cables by KEPCO in Korea. Supercond. Sci. Technol. 2020, 33, 44006. [Google Scholar] [CrossRef]

- Doukas, D.I. Superconducting Transmission Systems: Review, Classification, and Technology Readiness Assessment. IEEE Trans. Appl. Supercond. 2019, 29, 5401205. [Google Scholar] [CrossRef]

- Chen, W.; Song, P.; Jiang, H.; Zhu, J.H.; Zou, S.N.; Qu, T.M. Investigations on Quench Recovery Characteristics of High-Temperature Superconducting Coated Conductors for Superconducting Fault Current Limiters. Electronics 2021, 10, 259. [Google Scholar] [CrossRef]

- Hong, Z.; Sheng, J.; Yao, L.; Gu, J.; Jin, Z. The Structure, Performance and Recovery Time of a 10 kV Resistive Type Superconducting Fault Current Limiter. IEEE Trans. Appl. Supercond. 2013, 23, 5601304. [Google Scholar]

- Qiu, Q.Q.; Xiao, L.Y.; Zhang, J.Y.; Zhang, Z.F.; Song, N.H.; Jing, L.W.; Zha, W.H.; Du, X.J.; Teng, Y.P.; Zhou, Z.H.; et al. Design and Test of 40-kV/2-kA DC Superconducting Fault Current Limiter. IEEE Trans. Appl. Supercond. 2020, 30, 2988068. [Google Scholar] [CrossRef]

- Dai, S.T.; Ma, T.; Xue, C.; Zhao, L.Q.; Huang, Y.; Hu, L.; Wang, B.Z.; Zhang, T.; Xu, X.F.; Cai, L.L.; et al. Development and Test of a 220 kV/1.5 kA Resistive Type Superconducting Fault Current Limiter. Phys. C 2019, 565, 1253501. [Google Scholar] [CrossRef]

- Hao, L.N.; Huang, Z.; Dong, F.L.; Qiu, D.R.; Shen, B.Y.; Jin, Z.J. Study on Electrodynamic Suspension System with High-Temperature Superconducting Magnets for a High-Speed Maglev Train. IEEE Trans. Appl. Supercond. 2019, 29, 3600105. [Google Scholar] [CrossRef]

- Lee, H.W.; Kim, K.C.; Lee, J. Review of maglev train technologies. IEEE Trans. Magn. 2006, 42, 1917–1925. [Google Scholar]

- Deng, Z.G.; Zhang, W.H.; Zheng, J.; Wang, B.; Ren, Y.; Zheng, X.X.; Zhang, J.H. A High-Temperature Superconducting Maglev-Evacuated Tube Transport (HTS Maglev-ETT) Test System. IEEE Trans. Appl. Supercond. 2017, 27, 3602008. [Google Scholar] [CrossRef]

- Deng, Z.G.; Zhang, W.H.; Zheng, J.; Ren, Y.; Jiang, D.H.; Zheng, X.X.; Zhang, J.H.; Gao, P.F.; Lin, Q.X.; Song, B.; et al. A High-Temperature Superconducting Maglev Ring Test Line Developed in Chengdu, China. IEEE Trans. Appl. Supercond. 2016, 26, 3602408. [Google Scholar] [CrossRef]

- Wang, Y.; Chan, W.K.; Schwartz, J. Self-Protection Mechanisms in No-Insulation (RE) Ba2Cu3Ox High Temperature Superconductor Pancake Coils. Supercond. Sci. Technol. 2016, 29, 45007. [Google Scholar] [CrossRef]

- Wang, Y.W.; Weng, F.J.; Li, J.W.; Souc, J.; Gomory, F.; Zou, S.N.; Zhang, M.; Yuan, W.J. No-Insulation High-Temperature Superconductor Winding Technique for Electrical Aircraft Propulsion. IEEE Trans. Transp. Electrif. 2020, 6, 1613–1624. [Google Scholar] [CrossRef]

- Jun, Z.; Feng, X.; Wei, C.; Yijun, D.; Jin, C.; Wenbin, T. The Study and Test for 1MW High Temperature Superconducting Motor. IEEE/CSC ESAS Eur. Supercond. News Forum 2013, 23, 6–9. [Google Scholar]

- Gamble, B.; Snitchler, G.; MacDonald, T. Full Power Test of a 36.5 MW HTS Propulsion Motor. IEEE Trans. Appl. Supercond. 2010, 21, 1083–1088. [Google Scholar] [CrossRef]

- Sivasubramaniam, K.; Zhang, T.; Lokhandwalla, M.; Laskaris, E.; Bray, J.; Gerstler, B.; Shah, M.; Alexander, J. Development of a High Speed HTS Generator for Airborne Applications. IEEE Trans. Appl. Supercond. 2009, 19, 1656–1661. [Google Scholar] [CrossRef]

- Song, X.; Bührer, C.; Brutsaert, P.; Krause, J.; Ammar, A.; Wiezoreck, J.; Hansen, J.; Rebsdorf, A.V.; Dhalle, M.; Bergen, A. Designing and Basic Experimental Validation of the World’s First MW-Class Direct-Drive Superconducting Wind Turbine Generator. IEEE Trans. Energy Convers. 2019, 34, 2218–2225. [Google Scholar] [CrossRef]

- Filipenko, M.; Kühn, L.; Gleixner, T.; Thummet, M.; Lessmann, M.; Möller, D.; Böhm, M.; Schröter, A.; Häse, K.; Grundmann, J. Concept Design of a High Power Superconducting Generator for Future Hybrid-Electric Aircraft. Supercond. Sci. Technol. 2020, 33, 054002. [Google Scholar] [CrossRef]

- Komiya, M.; Aikawa, T.; Sasa, H.; Miura, S.; Iwakuma, M.; Yoshida, T.; Sasayama, T.; Tomioka, A.; Konno, M.; Izumi, T. Design Study of 10 MW REBCO Fully Superconducting Synchronous Generator for Electric Aircraft. IEEE Trans. Appl. Supercond. 2019, 29, 5204306. [Google Scholar] [CrossRef]

- Seifert, W.; Ueltzen, M.; Muller, E. One-Dimensional Modelling of Thermoelectric Cooling. Phys. Status Solidi A Appl. Mat. 2002, 194, 277–290. [Google Scholar] [CrossRef]

- Sato, K.; Okumura, H.; Yamaguchi, S. Numerical Calculations for Peltier Current Lead Designing. Cryogenics 2001, 41, 497–503. [Google Scholar] [CrossRef]

- Xiangchun, X. On the Optimal Design of Gas-Cooled Peltier Current Leads. IEEE Trans. Appl. Supercond. 2003, 13, 48–53. [Google Scholar] [CrossRef]

- Jeong, E.S. Optimization of Conduction-Cooled Peltier Current Leads. Cryogenics 2005, 45, 516–522. [Google Scholar] [CrossRef]

- Chen, G.; Wang, Y.; Pi, W.; Shi, C.; Li, T.; Li, J.; Zhang, H. Experimental Investigation on 100 A-Class PCL for DC HTS Devices. IEEE Trans. Appl. Supercond. 2016, 26, 4800805. [Google Scholar] [CrossRef]

- Michael, P.C.; Galea, C.A.; Bromberg, L. Cryogenic Current Lead Optimization Using Peltier Elements and Configurable Cooling. IEEE Trans. Appl. Supercond. 2015, 25, 4801805. [Google Scholar] [CrossRef]

- Miyata, S.; Yoshiwara, Y.; Watanabe, H.; Yamauchi, K.; Makino, K.; Yamaguchi, S. Evaluation of Thermoelectric Performance of Peltier Current Leads Designed for Superconducting Direct-Current Transmission Cable Systems. IEEE Trans. Appl. Supercond. 2016, 26, 5401604. [Google Scholar] [CrossRef]

- Dai, S.; Liu, M.; Ma, T.; Zhang, T.; Hu, L.; Wang, B.; Wang, Y. Experimental Study on Heat-leakage of 100 A-Class PCL with Varying Cross Section. IEEE Trans. Appl. Supercond. 2019, 29, 4800104. [Google Scholar] [CrossRef]

- Chen, G.; Wang, Y.; Pi, W.; Kan, C.; Fu, Y.; Shi, C.; Li, T.; Li, J. Heat Leakage Analysis on Peltier Current Leads of Different Structures. IEEE Trans. Appl. Supercond. 2016, 26, 8801504. [Google Scholar] [CrossRef]

- Liu, M.; Wang, Y.; Dai, S.; Wang, J.; Peng, C.; Chen, H.; Jiang, Z.; Hu, Y. Experimental Study on 1 kA-Class Peltier Current Lead for Superconducting DC Devices. IEEE Trans. Appl. Supercond. 2019, 29, 4802504. [Google Scholar] [CrossRef]

- COMSOL. COMSOL Multiphysics®, v.5.3. 2017. Available online: https://www.comsol.com/release/5.3 (accessed on 15 April 2021).

- Hicks, C.R. Fundamental Concepts in the Design of Experiments, 4th ed.; Oxford University Press: Oxford, UK, 1993. [Google Scholar]

| Symbol | Quantity | Values (mm) | Column Number | |

|---|---|---|---|---|

| Level 1 | Level 2 | |||

| A: r1 | Radius of copper leads | 3.0 | 30.0 | 1 |

| B: L1 | Length of warm end copper leads | 10.0 | 300.0 | 2 |

| C: L3 | Length of cold end copper leads | 100.0 | 1500.0 | 4 |

| D: r2 | Radius of Bi2Te3 | 1.0 | 30.0 | 8 |

| E: L2 | Length of Bi2Te3 | 1.0 | 30.0 | 15 |

| Column Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Parameters | A: Copper Leads Radius (r1/mm) | B: Length of Warm end Copper Leads (L1/mm) | A × B | C: Length of Cold End Copper Leads (L3/mm) | A × C | B × C | D × E | D: Radius of Bi2Te3 (r2/mm) | A × D | B × D | C × E | C × D | B × E | A × E | E: Length of Bi2Te3 (L2/mm) |

| Mean value 1 | 966.0 | 1736.5 1 | 1125.0 | 2143.2 | 1524.1 | 2379.2 | 223.7 | 2326.7 | 1801.2 | 1169.4 | 1738.9 | 1591.0 | 2166.4 | 1552.0 | 1002.1 |

| Mean value 2 | 2361.2 | 1591.6 | 2202.3 | 1184.0 | 1803.1 | 948.0 | 3103.5 | 1000.5 | 1526.0 | 2157.8 | 1588.3 | 1736.2 | 1160.8 | 1775.1 | 2325.1 |

| Sample range | 1395.3 | 143.9 | 1077.3 | 959.2 | 279.1 | 1431.2 | 2879.8 | 1326.2 | 275.3 | 988.5 | 150.6 | 145.3 | 1005.6 | 223.2 | 1323.1 |

| Symbol | Quantity | Optimized Parameters | ||

|---|---|---|---|---|

| Case 1 | Case 2 | Case 3 | ||

| A: r1 | Radius of copper leads (mm) | 3.0 | 4.0 | 5.5 |

| B: L1 | Length of warm end copper leads (mm) | 10.0 | 10.0 | 10.0 |

| C: L3 | Length of cold end copper leads (mm) | 700.0 | 1100.0 | 1900.0 |

| D: r2 | Radius of Bi2Te3 (mm) | 10.0 | 10.0 | 10.0 |

| E: L2 | Length of Bi2Te3 (mm) | 1.0 | 3.5 | 7.0 |

| Lowest heat leakage (W/kA) | 30.1 | 29.7 | 29.8 | |

| Heat leakage with pure copper (W/kA) | 43.2 | 45.6 | 47.9 | |

| Reduction rate of cold end heat leakage | 30.4% | 34.8% | 37.7% | |

| Symbol | Quantity | Values (mm) | Column Number | |

|---|---|---|---|---|

| Level 1 | Level 2 | |||

| A: r1 | Radius of Copper leads | 10.0 | 80.0 | 1 |

| B: L1 | Length of warm end copper leads | 10.0 | 300.0 | 2 |

| C: L3 | Length of cold end copper leads | 100.0 | 1500.0 | 4 |

| D: r2 | Radius of Bi2Te3 | 5.0 | 50.0 | 8 |

| E: L2 | Length of Bi2Te3 | 1.0 | 50.0 | 15 |

| Column Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Parameters | A: Copper Leads Radius (r1/mm) | B: Length of Warm End Copper Leads (L1/mm) | A × B | C: Length of Cold end Copper Leads (L3/mm) | A × C | B × C | D × E | D: Radius of Bi2Te3 (r2/mm) | A × D | B × D | C × E | C × D | B × E | A × E | E: Length of Bi2Te3 (L2/mm) |

| Mean value 1 | 726.0 | 918.8 | 746.3 | 1199.1 | 1024.4 | 1347.3 | 152.6 | 1583.1 | 962.5 | 786.1 | 920.6 | 1064.0 | 1198.5 | 1004.9 | 392.0 |

| Mean value 2 | 1267.8 | 1075.0 | 1247.5 | 794.7 | 969.4 | 647.5 | 1841.2 | 410.7 | 1031.3 | 1207.6 | 1073.2 | 929.8 | 795.4 | 988.9 | 1601.8 |

| Sample range | 541.7 | 156.2 | 501.2 | 404.3 | 55.0 | 700.7 | 1688.7 | 1172.4 | 68.8 | 421.5 | 152.5 | 134.2 | 403.1 | 16.1 | 1209.8 |

| Symbol | Quantity | Optimized Parameters | ||

|---|---|---|---|---|

| Case 1 | Case 2 | Case 3 | ||

| A: r1 | Radius of Copper leads (mm) | 10.0 | 15.5 | 20.0 |

| B: L1 | Length of warm end copper leads (mm) | 10.0 | 10.0 | 10.0 |

| C: L3 | Length of cold end copper leads (mm) | 700.0 | 1700.0 | 2900.0 |

| D: r2 | Radius of Bi2Te3 (mm) | 15.0 | 20.0 | 30.0 |

| E: L2 | Length of Bi2Te3 (mm) | 1.5 | 3.5 | 7.5 |

| Lowest heat leakage (W/kA) | 29.9 | 29.6 | 29.8 | |

| Heat leakage with pure copper (W/kA) | 45.1 | 43.8 | 44.6 | |

| Reduction rate of cold end heat leakage | 33.7% | 32.5% | 33.2% | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Zou, S.; Deng, S.; Lai, L.; Gu, C. Optimization of Kiloampere Peltier Current Lead Using Orthogonal Experimental Design Method. Electronics 2021, 10, 1054. https://doi.org/10.3390/electronics10091054

Liu L, Zou S, Deng S, Lai L, Gu C. Optimization of Kiloampere Peltier Current Lead Using Orthogonal Experimental Design Method. Electronics. 2021; 10(9):1054. https://doi.org/10.3390/electronics10091054

Chicago/Turabian StyleLiu, Linying, Shengnan Zou, Shutong Deng, Lingfeng Lai, and Chen Gu. 2021. "Optimization of Kiloampere Peltier Current Lead Using Orthogonal Experimental Design Method" Electronics 10, no. 9: 1054. https://doi.org/10.3390/electronics10091054

APA StyleLiu, L., Zou, S., Deng, S., Lai, L., & Gu, C. (2021). Optimization of Kiloampere Peltier Current Lead Using Orthogonal Experimental Design Method. Electronics, 10(9), 1054. https://doi.org/10.3390/electronics10091054