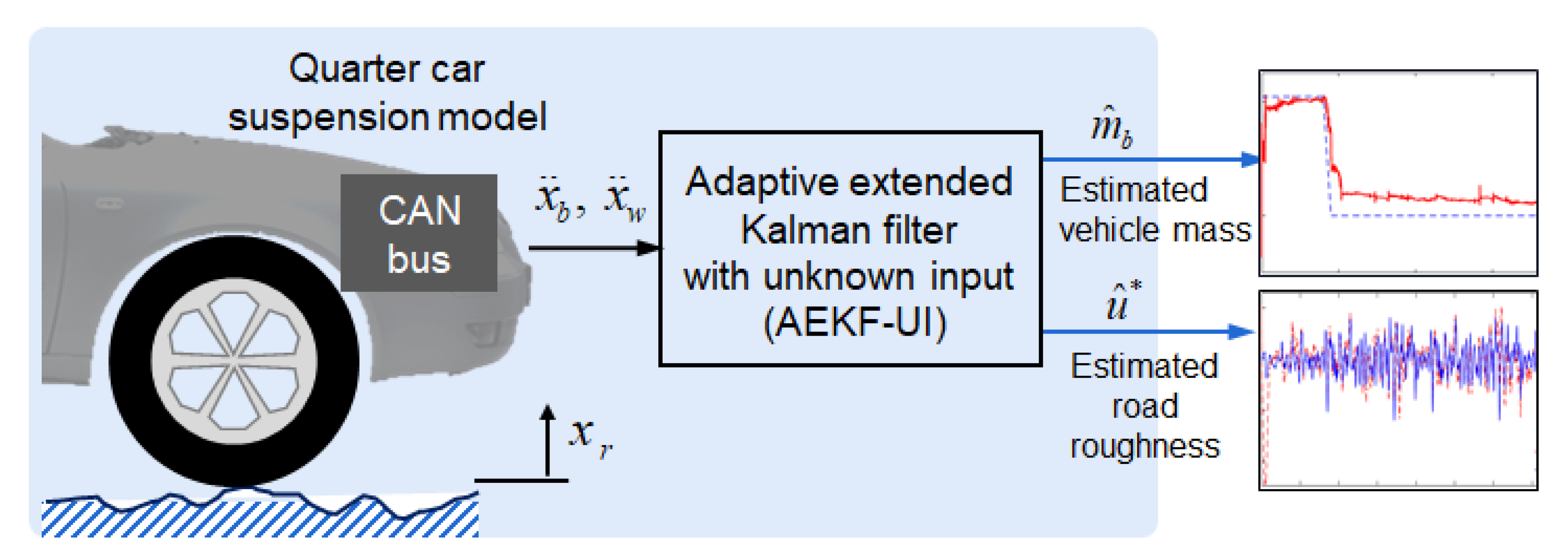

Simultaneous Estimation of Vehicle Mass and Unknown Road Roughness Based on Adaptive Extended Kalman Filtering of Suspension Systems

Abstract

:1. Introduction

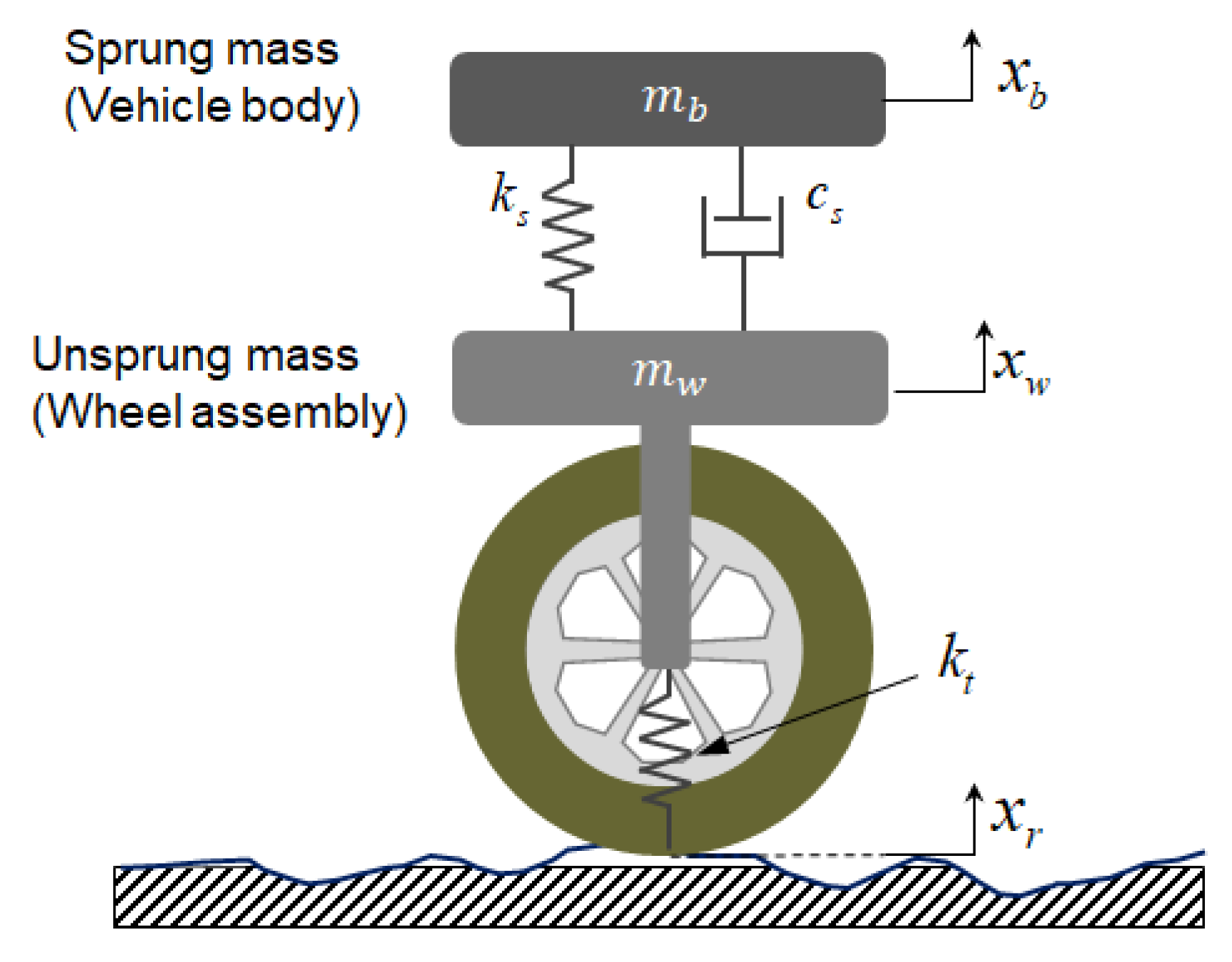

2. Quarter-Car Suspension Model

3. Adaptive Extended Kalman Filter with Unknown Input Estimation

3.1. Overview

- Initialization of the filter at k = 0

- Prediction stage

- Unknown input estimation

- Correction stage

3.2. Forgetting Factor Update

4. Simulation of AKEF-UI Algorithm

5. Experimental Validation

5.1. Experimental Setup and Results

5.2. Robustness Analysis

6. Conclusions

- First, we conclude that it is possible to provide a cost-effective alternative means of measuring vehicle mass in real-time by using conventional vehicle sensors (i.e., two accelerometers mounted on the sprung and unsprung mass of the suspension system) because the proposed system can capture sudden decreases in car mass (e.g., a sudden sprung mass change from 240 kg to 220 kg).

- Secondly, we demonstrated that the time-varying car mass and unknown road inputs can be estimated simultaneously through simulations and experiments

- Lastly, the proposed vehicle mass estimation algorithm is robust because it uses a constantly updated weight value treatment of the forgetting factors to ignore errors in the estimation model. By introducing a forgetting factor, AEKF-UI can provide robust adaptation in the Kalman filter during estimation with the consideration of the fluctuation of unknown input and time-varying parameters.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, X.Y.; Wang, J. Multiple-vehicle longitudinal collision avoidance and impact mitigation by active brake control. In Proceedings of the 2012 IEEE Intelligent Vehicles Symposium, Madrid, Spain, 3–7 June 2012; pp. 680–685. [Google Scholar]

- Krtolica, R.; Hrovat, D. Optimal active suspension control based on a half-car model. In Proceedings of the 29th IEEE Conference on Decision and Control, Honolulu, HI, USA, 5–7 December 1990; pp. 2238–2243. [Google Scholar]

- Yin, D.; Sun, N.; Hu, J.S. A wheel slip control approach integrated with electronic stability control for decentralized drive electric vehicles. IEEE Trans. Ind. Inform. 2019, 15, 2244–2252. [Google Scholar] [CrossRef]

- Lin, N.; Zong, C.; Shi, S. The Method of Mass Estimation Considering System Error in Vehicle Longitudinal Dynamics. Energies 2019, 12, 52. [Google Scholar] [CrossRef]

- Kim, S.; Shin, K.; Yoo, C.; Huh, K. Development of algorithms for commercial vehicle mass and road grade estimation. Int. J. Automot. Technol. 2017, 18, 1077–1083. [Google Scholar] [CrossRef]

- Zhao, M.; Yang, F.; Sun, D.; Han, W.; Xie, F.; Chen, T. A joint dynamic estimation algorithm of vehicle mass and road slope considering braking and turning. In Proceedings of the 2018 Chinese Control And Decision Conference (CCDC), Shenyang, China, 9–11 June 2018; pp. 5868–5873. [Google Scholar] [CrossRef]

- Reina, G.; Paiano, M.; Blanco-Claraco, J.L. Vehicle parameter estimation using a model-based estimator. Mech. Syst. Signal Process. 2017, 87, 227–241. [Google Scholar] [CrossRef]

- Holm, E.J. Vehicle mass and road grade estimation using Kalman filter. Inst. Syst. Dep. Electr. Eng. 2011, 16, 1–38. [Google Scholar]

- Kidambi, N.; Harne, R.L.; Fujii, Y.; Pietron, G.M.; Wang, K.W. Methods in vehicle mass and road grade estimation. SAE Int. J. Passeng. Cars-Mech. Syst. 2014, 7, 981–991. [Google Scholar] [CrossRef]

- Jo, A.; Jeong, Y.; Lim, H.; Yi, K. Vehicle mass and road grade estimation for longitudinal acceleration controller of an automated bus. J. Auto-Veh. Saf. Assoc. 2020, 12, 14–20. [Google Scholar]

- Mahyuddin, M.N.; Na, J.; Herrmann, G.; Ren, X.; Barber, P. Adaptive Observer-Based Parameter Estimation With Application to Road Gradient and Vehicle Mass Estimation. IEEE Trans. Ind. Electron. 2014, 61, 2851–2863. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Ai, Z.; Feng, Y.; Zhang, J.; Murphey, Y.L. Estimation of Electric Mining Haul Trucks’ Mass and Road Slope Using Dual Level Reinforcement Estimator. IEEE Trans. Veh. Technol. 2019, 68, 10627–10638. [Google Scholar] [CrossRef]

- Jordan, J.; Hirsenkorn, N.; Klanner, F.; Kleinsteuber, M. Vehicle mass estimation based on vehicle vertical dynamics using a multi-model filter. In Proceedings of the 17th International IEEE Conference on Intelligent Transportation Systems (ITSC), Qingdao, China, 8–11 October 2014; pp. 2041–2046. [Google Scholar] [CrossRef]

- Boada, B.L.; Boada, M.J.L.; Zhang, H. Sensor Fusion Based on a Dual Kalman Filter for Estimation of Road Irregularities and Vehicle Mass under Static and Dynamic Conditions. IEEE/ASME Trans. Mechatron. 2019, 24, 1075–1086. [Google Scholar] [CrossRef]

- Cai, Y. Kalman filtering–based real-time inertial profiler. J. Surv. Eng. 2017, 143, 04017017. [Google Scholar] [CrossRef]

- Doumiati, M.; Martinez, J.; Sename, O.; Dugard, L.; Lechner, D. Road profile estimation using an adaptive Youla–Kučera parametric observer: Comparison to real profilers. Control Eng. Pract. 2017, 61, 270–278. [Google Scholar] [CrossRef]

- Pham, T.P.; Sename, O.; Phan, C.; Tran, G.Q.B. H∞ observer for road profile estimation in an automotive semi-active suspension system using two accelerometers. In Proceedings of the 10th International Conference on Mechatronics and Control Engineering, (ICMCE 2021), Qingdao, China, 8–11 October 2014. [Google Scholar]

- Kang, S.-W.; Kim, J.-S.; Kim, G.-W. Road roughness estimation based on discrete Kalman filter with unknown input. Veh. Syst. Dyn. 2019, 57, 1530–1544. [Google Scholar] [CrossRef]

- Kim, G.W.; Kang, S.W.; Kim, J.S.; Oh, J.S. Simultaneous estimation of state and unknown road roughness input for vehicle suspension control system based on discrete Kalman filter. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2020, 234, 1610–1622. [Google Scholar] [CrossRef]

- Im, S.J.; Oh, J.S.; Kim, G.W. Simultaneous Estimation of Unknown Road Roughness Input and Tire Normal Forces Based on a Long Short-Term Memory Model. IEEE Access 2022, 10, 16655–16669. [Google Scholar] [CrossRef]

- Shrivastava, P.; Soon, T.K.; Idris, M.Y.I.B.; Mekhilef, S.; Adnan, S.B.R.S. Combined state of charge and state of energy estimation of lithium-ion battery using dual forgetting factor-based adaptive extended Kalman filter for electric vehicle applications. IEEE Trans. Veh. Technol. 2021, 70, 1200–1215. [Google Scholar] [CrossRef]

- Türkay, S.; Akçay, H. A study of random vibration characteristics of the quarter-car model. J. Sound Vib. 2005, 282, 111–124. [Google Scholar] [CrossRef]

- Hurel, J.; Mandow, A.; García-Cerezo, A. Kinematic and dynamic analysis of the McPherson suspension with a planar quarter-car model. Veh. Syst. Dyn. 2013, 51, 1422–1437. [Google Scholar] [CrossRef]

- Kalman, R.E. A new approach to linear filtering and prediction problems. J. Basic Eng. 1960, 82, 35–54. [Google Scholar] [CrossRef]

- Gelb, A. Nonlinear Estimation. In Applied Optimal Estimation, 6th ed.; MIT Press: Massachusetts, MA, USA, 1974; pp. 182–199. [Google Scholar]

- Xia, Q.; Rao, M.; Ying, Y.; Shen, X. Adaptive fading Kalman filter with an application. Automatica 1994, 30, 1333–1338. [Google Scholar] [CrossRef]

- Yang, J.N.; Lin, S.; Huang, H. An adaptive extended Kalman filter for structural damage identification. Struct. Control. Health Monit. 2006, 13, 849–867. [Google Scholar] [CrossRef]

- Varshney, D.; Bhushan, M.; Patwardhan, S.C. State and parameter estimation using extended Kitanidis Kalman filter. J. Process. Control 2019, 76, 98–111. [Google Scholar] [CrossRef]

- Huang, C.; Wang, Z.; Zhao, Z.; Wang, L.; Lai, C.S.; Wang, D. Robustness evaluation of extended and unscented Kalman filter for battery state of charge estimation. IEEE Access 2018, 6, 27617–27628. [Google Scholar] [CrossRef]

- Lee, D.H.; Yoon, D.S.; Kim, G.W. New indirect tire pressure monitoring system enabled by adaptive extended Kalman filtering of vehicle suspension systems. Electronics 2021, 10, 1359. [Google Scholar] [CrossRef]

| Symbol | Parameters | Value |

|---|---|---|

| Tire sprung constant | 233,350 N/m | |

| Unsprung mass | 56.9 kg | |

| Damping coefficient | 925.8 Ns/m | |

| Suspension sprung constant | 29,114 N/m |

| Tire Stiffness (N/m) | MRMSE | Relative Error to Nominal |

|---|---|---|

| 198,347.5 (−15%) | 3.25 | 19.4% |

| 233,350 (nominal) | 2.72 | - |

| 268,352.5 (+15%) | 2.83 | 4.04% |

| Variance | MRMSE (from 5 s) | Relative Error to Nominal |

|---|---|---|

| 0.273 | 4.99 | 83.4% |

| 0.248 (nominal) | 2.72 | - |

| 0.223 | 4.91 | 80.5% |

| Tire Stiffness (N/m) | MRMSE | Relative Error to Nominal |

|---|---|---|

| 198,347.5 (−15%) | 3.73 | 49.8% |

| 233,350 (nominal) | 2.49 | - |

| 268,352.5 (+15%) | 3.38 | 35.7% |

| Variance | MRMSE (from 5 s) | Relative Error to Nominal |

|---|---|---|

| 0.273 | 3.67 | 47.4% |

| 0.248 (nominal) | 2.49 | - |

| 0.223 | 1.93 | −22.5% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Kim, B.-G.; Oh, J.-S.; Kim, G.-W. Simultaneous Estimation of Vehicle Mass and Unknown Road Roughness Based on Adaptive Extended Kalman Filtering of Suspension Systems. Electronics 2022, 11, 2544. https://doi.org/10.3390/electronics11162544

Yang H, Kim B-G, Oh J-S, Kim G-W. Simultaneous Estimation of Vehicle Mass and Unknown Road Roughness Based on Adaptive Extended Kalman Filtering of Suspension Systems. Electronics. 2022; 11(16):2544. https://doi.org/10.3390/electronics11162544

Chicago/Turabian StyleYang, Haolin, Bo-Gyu Kim, Jong-Seok Oh, and Gi-Woo Kim. 2022. "Simultaneous Estimation of Vehicle Mass and Unknown Road Roughness Based on Adaptive Extended Kalman Filtering of Suspension Systems" Electronics 11, no. 16: 2544. https://doi.org/10.3390/electronics11162544