Modeling and Calibration of Active Thermal-Infrared Visual System for Industrial HMI

Abstract

:1. Introduction

- More adaptive to poor or changing lighting;

- Effective for detecting an object with low contrast but differences in temperature;

- Can detect surface information of objects as well as internal information.

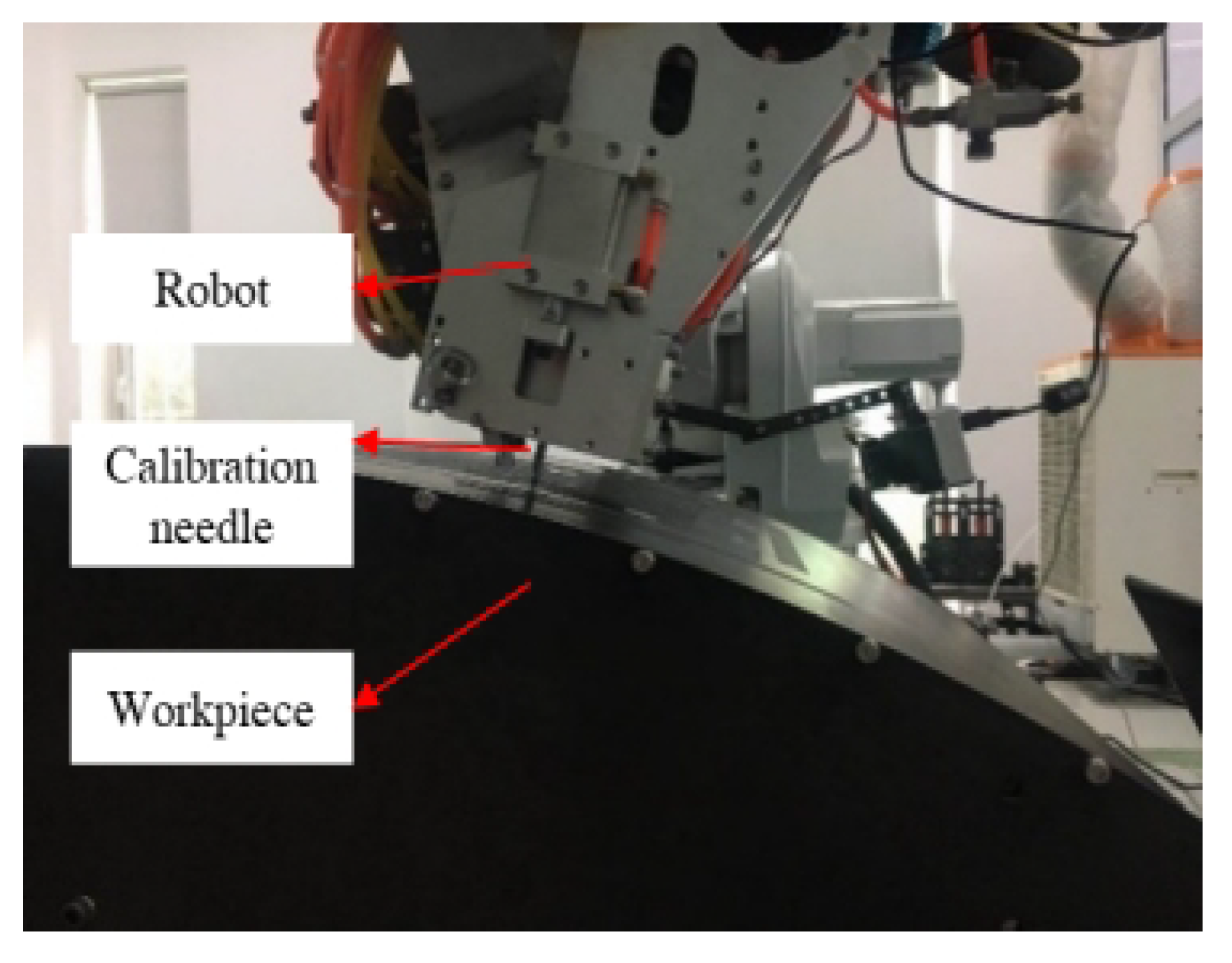

2. System Construction and Working Principle

3. Modeling of the Active Thermal-Infrared Visual Measurement System

4. Calibration Method

4.1. Calibration of System Parameters M

4.2. Calibration of System Parameters WTS(0)

4.3. Calibration Points Extraction Algorithm

| Algorithm 1: Sideline Extraction |

| Input: Image I Data container: edge point set Pe, line parameters set Lh, point set Pr Pe ← Canny (I); Lh ← Hough (IC); Lh ← Cluster (Lh); Lh ← SideDetection (Lh); For each line segment Lh: Pe ← EdgeScan (Lh); Lh ← Fitting (Pe); End Output: Lh |

5. Experiments

5.1. Extraction of Calibration Points in the Thermal-Infrared Image

5.2. Calibration of System Parameters M

5.3. Calibration of System Parameters WTS(0)

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rasheed, A.; Zafar, B.; Rasheed, A.; Ali, N.; Sajid, M.; Dar, S.H.; Habib, U.; Shehryar, T.; Mahmood, M.T. Fabric Defect Detection Using Computer Vision Techniques: A Comprehensive Review. Math. Probl. Eng. 2020, 2020, 8189403. [Google Scholar] [CrossRef]

- Li, B. Research on geometric dimension measurement system of shaft parts based on machine vision. EURASIP J. Image Video Process. 2018, 2018, 101. [Google Scholar] [CrossRef]

- Liu, S.; Liu, J.; Jin, P.; Wang, X. Tube measurement based on stereo-vision: A review. Int. J. Adv. Manuf. Technol. 2017, 92, 2017–2032. [Google Scholar] [CrossRef]

- Shirmohammadi, S.; Ferrero, A. Camera as the instrument: The rising trend of vision based measurement. IEEE Instrum. Meas. Mag. 2014, 17, 41–47. [Google Scholar] [CrossRef]

- Das, M.P.; Matthies, L.; Daftry, S. Online Photometric Calibration of Automatic Gain Thermal Infrared Cameras. IEEE Robot. Autom. Lett. 2021, 6, 2453–2460. [Google Scholar] [CrossRef]

- Griffith, B.; Türler, D.; Goudey, H. IR Thermographic Systems: A Review of IR Imagers and Their Use; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2001. [Google Scholar]

- Teutsch, M.; Mueller, T.; Huber, M.; Beyerer, J. Low resolution person detection with a moving thermal infrared camera by hot spot classification. In Proceedings of the 2014 IEEE Conference on Computer Vision and Pattern Recognition Workshops, Washington, DC, USA, 23–28 June 2014; pp. 209–216. [Google Scholar]

- Brehar, R.; Nedevschi, S. Pedestrian detection in infrared images using HOG, LBP, gradient magnitude and intensity feature channels. In Proceedings of the 17th International IEEE Conference on Intelligent Transportation Systems (ITSC), Qingdao, China, 8–11 October 2014; pp. 1669–1674. [Google Scholar]

- Li, J.; Gong, W.; Li, W.; Liu, X. Robust pedestrian detection in thermal infrared imagery using the wavelet transform. Infrared Phys. Technol. 2010, 53, 267–273. [Google Scholar] [CrossRef]

- Buchlin, J.M. Convective heat transfer and IR thermography (IRTh). J. Appl. Fluid Mech. 2010, 3, 55–62. [Google Scholar]

- Hung, Y.; Chen, Y.; Ng, S.P.; Liu, L.; Huang, Y.; Luk, B.L.; Ip, R.; Wu, L.; Chung, P. Review and comparison of shearography and active thermography for nondestructive evaluation. Mater. Sci. Eng. R Rep. 2009, 64, 73–112. [Google Scholar] [CrossRef] [Green Version]

- Denkena, B.; Schmidt, C.; Völtzer, K.; Hocke, T. Thermographic online monitoring system for Automated Fiber Placement processes. Compos. Part B Eng. 2016, 97, 239–243. [Google Scholar] [CrossRef]

- Horn, B. Robot Vision; MIT Press: Cambridge, MA, USA, 1986. [Google Scholar]

- Cigliano, P.; Lippiello, V.; Ruggiero, F.; Siciliano, B. Robotic Ball Catching with an Eye-in-Hand Single-Camera System. IEEE Trans. Control Syst. Technol. 2015, 23, 1657–1671. [Google Scholar] [CrossRef] [Green Version]

- Vidas, S.; Lakemond, R.; Denman, S.; Fookes, C.; Sridharan, S.; Wark, T. A Mask-Based Approach for the Geometric Calibration of Thermal-Infrared Cameras. IEEE Trans. Instrum. Meas. 2012, 61, 1625–1635. [Google Scholar] [CrossRef] [Green Version]

- Saponaro, P.; Sorensen, S.; Rhein, S.; Kambhamettu, C. Improving calibration of thermal stereo cameras using heated calibration board. In Proceedings of the 2015 IEEE International Conference on Image Processing (ICIP), Quebec City, QC, Canada, 27–30 September 2015; pp. 4718–4722. [Google Scholar]

- Zhang, Z. Flexible Camera Calibration by Viewing a Plane from Unknown Orientations. In Proceedings of the 7th IEEE International Conference on Computer Vision (ICCV’99), Kerkyra, Greece, 20–27 September 1999; pp. 666–673. [Google Scholar]

- Lagüela, S.; González-Jorge, H.; Armesto, J.; Arias, P. Calibration and verification of thermographic cameras for geometric measurements. Infrared Phys. Technol. 2011, 54, 92–99. [Google Scholar] [CrossRef]

- Luhmann, T.; Piechel, J.; Roelfs, T. Geometric calibration of thermographic cameras, International Archives of Photogrammetry, Remote Sensing and Spatial Information Sciences. Int. Soc. Photogramm. Remote Sens. 2010, XXXVIII, 411–416. [Google Scholar]

- St-Laurent, L.; Prévost, D.; Maldague, X. Fast and accurate calibration-based thermal/colour sensors registration. In Proceedings of the 10th Quantitative InfraRed Thermography Conference, Paper QIRT2010-126 Québec, Quebec, QC, Canada, 24–29 June 2010; pp. 1–8. [Google Scholar]

- Dias, A.; Brás, C.; Martins, A.; Almeida, J.; Silva, E. Thermographic and visible spectrum camera calibration for marine robotic target detection. In Proceedings of the 2013 OCEANS-San Diego, San Diego, CA, USA, 23–27 September 2013; pp. 1–5. [Google Scholar]

- Yang, R.; Yang, W.; Chen, Y.; Wu, X. Geometric calibration of IR camera using trinocular vision. J. Light. Technol. 2011, 29, 3797–3803. [Google Scholar] [CrossRef]

- Ellmauthaler, A.; da Silva, E.A.; Pagliari, C.L.; Gois, J.N.; Neves, S.R. A novel iterative calibration approach for thermal infrared cameras. In Proceedings of the2013 20th IEEE International Conference on Image Processing (ICIP), Melbourne, VIC, Australia, 15–18 September 2013; pp. 2182–2186. [Google Scholar]

- Yang, R.; Chen, Y. Design of a 3-D Infrared Imaging System Using Structured Light. IEEE Trans. Instrum. Meas. 2010, 60, 608–617. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Garcia, D.; Ibarra-Castanedo, C.; Maldague, X. Highly accurate geometric calibration for infrared cameras using inexpensive calibration targets. Measurement 2017, 112, 105–116. [Google Scholar] [CrossRef]

- Chen, M.; Jiang, M.; Liu, X.; Wu, B. Intelligent Inspection System Based on Infrared Vision for Automated Fiber Placement. In Proceedings of the 2018 IEEE International Conference on Mechatronics and Automation (ICMA), Changchun, China, 5–8 August 2018; pp. 918–923. [Google Scholar]

- Szajna, A.; Stryjski, R.; Woźniak, W.; Chamier-Gliszczyński, N.; Kostrzewski, M. Assessment of Augmented Reality in Manual Wiring Production Process with Use of Mobile AR Glasses. Sensors 2020, 20, 4755. [Google Scholar] [CrossRef] [PubMed]

- Szajna, A.; Stryjski, R.; Woźniak, W.; Chamier-Gliszczyński, N.; Królikowski, T. The Production quality control process, enhanced with augmented reality glasses and the new generation computing support system. Procedia Comput. Sci. 2020, 176, 3618–3625. [Google Scholar] [CrossRef]

- Kostrzewski, M.; Chamier-Gliszczyński, N.; Królikowski, T. Selected reflections on formal modeling in Industry 4.0. Procedia Comput. Sci. 2020, 176, 3293–3300. [Google Scholar] [CrossRef]

| Real Value (mm) | Measured Value (mm) | Absolute Error (mm) | Relative Error (%) | |

|---|---|---|---|---|

| A1B1 | 20.0 | 20.1 | 0.1 | 0.50 |

| B1C1 | 40.0 | 39.9 | 0.1 | 0.25 |

| C1D1 | 20.0 | 19.7 | 0.3 | 1.50 |

| D1A1 | 40.0 | 39.8 | 0.2 | 0.50 |

| A2B2 | 40.0 | 40.1 | 0.1 | 0.25 |

| B2C2 | 20.0 | 19.8 | 0.2 | 1.00 |

| C2D2 | 40.0 | 39.9 | 0.1 | 0.25 |

| D2A2 | 20.0 | 19.8 | 0.2 | 1.00 |

| A3B3 | 30.0 | 30.1 | 0.1 | 0.33 |

| B3C3 | 50.0 | 50.0 | 0.0 | 0.00 |

| C3D3 | 30.0 | 29.9 | 0.1 | 0.33 |

| D3A3 | 50.0 | 50.0 | 0.0 | 0.00 |

| Index | Calibration Needle Data (mm) | Infrared Vision System Data (mm) | Difference (mm) | |||||

|---|---|---|---|---|---|---|---|---|

| XW | YW | ZW | XW | YW | ZW | |||

| 1 | A1 | 511.8 | 403.4 | 256.9 | 511.7 | 404.3 | 256.9 | 0.14 |

| A2 | 532.2 | 349.9 | 248.4 | 532.0 | 349.9 | 248.5 | 0.22 | |

| A3 | 419.1 | 298.5 | 327.3 | 419.3 | 298.4 | 327.2 | 0.24 | |

| 2 | A1 | 511.9 | 403.5 | 256.8 | 511.7 | 404.3 | 256.9 | 0.30 |

| A2 | 532.3 | 349.7 | 248.3 | 532.1 | 349.9 | 248.4 | 0.30 | |

| A3 | 419.2 | 298.5 | 327.3 | 419.3 | 298.4 | 327.2 | 0.17 | |

| 3 | A1 | 511.8 | 403.5 | 256.9 | 511.7 | 404.3 | 256.9 | 0.22 |

| A2 | 532.3 | 349.8 | 248.3 | 532.1 | 349.9 | 248.4 | 0.24 | |

| A3 | 419.2 | 298.6 | 327.4 | 419.3 | 298.4 | 327.2 | 0.30 | |

| Real Value (mm) | Measurement Value (mm) | Error (mm) | ||||

|---|---|---|---|---|---|---|

| Needle | Traditional Method | Proposed Method | Needle | Traditional Method | Proposed Method | |

| 25 | 25.9 | 25.6 | 25.0 | 0.9 | 0.6 | 0.0 |

| 30 | 30.3 | 30.5 | 30.1 | 0.3 | 0.5 | 0.1 |

| 35 | 35.2 | 35.4 | 35.9 | 0.2 | 0.4 | 0.1 |

| 40 | 40.6 | 40.6 | 40.2 | 0.6 | 0.6 | 0.2 |

| 45 | 45.6 | 45.9 | 45.0 | 0.6 | 0.1 | 0.0 |

| 50 | 50.4 | 50.3 | 49.9 | 0.4 | 0.3 | 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, M.; Tian, S.; He, F.; Fu, Q.; Gu, Q.; Wu, B. Modeling and Calibration of Active Thermal-Infrared Visual System for Industrial HMI. Electronics 2022, 11, 1230. https://doi.org/10.3390/electronics11081230

Chen M, Tian S, He F, Fu Q, Gu Q, Wu B. Modeling and Calibration of Active Thermal-Infrared Visual System for Industrial HMI. Electronics. 2022; 11(8):1230. https://doi.org/10.3390/electronics11081230

Chicago/Turabian StyleChen, Mengjuan, Simeng Tian, Fan He, Qingqin Fu, Qingyi Gu, and Baolin Wu. 2022. "Modeling and Calibration of Active Thermal-Infrared Visual System for Industrial HMI" Electronics 11, no. 8: 1230. https://doi.org/10.3390/electronics11081230

APA StyleChen, M., Tian, S., He, F., Fu, Q., Gu, Q., & Wu, B. (2022). Modeling and Calibration of Active Thermal-Infrared Visual System for Industrial HMI. Electronics, 11(8), 1230. https://doi.org/10.3390/electronics11081230