Noise Reduction of Atomic Force Microscopy Measurement Data for Fitting Verification of Chemical Mechanical Planarization Model

Abstract

1. Introduction

2. FT and WT

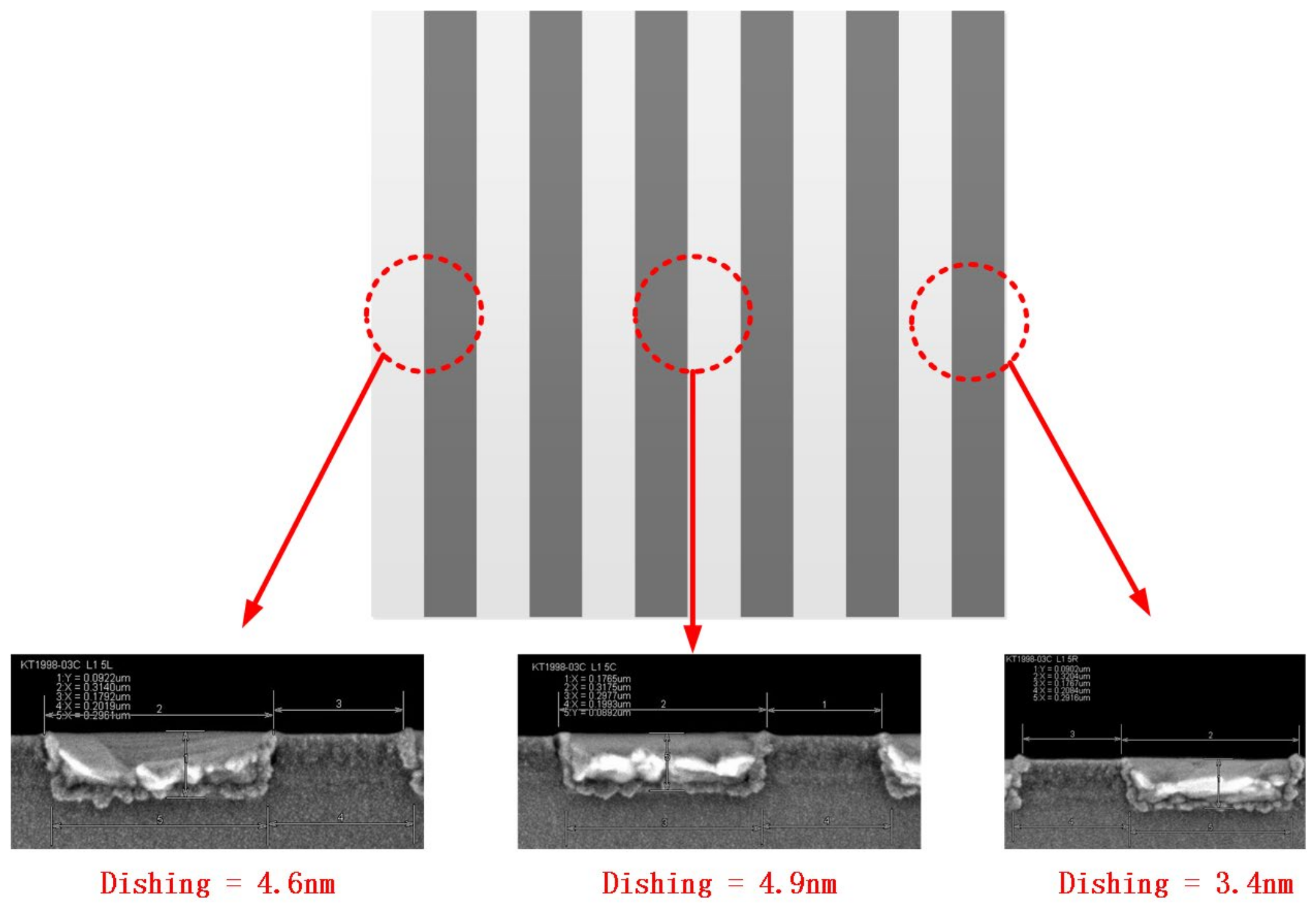

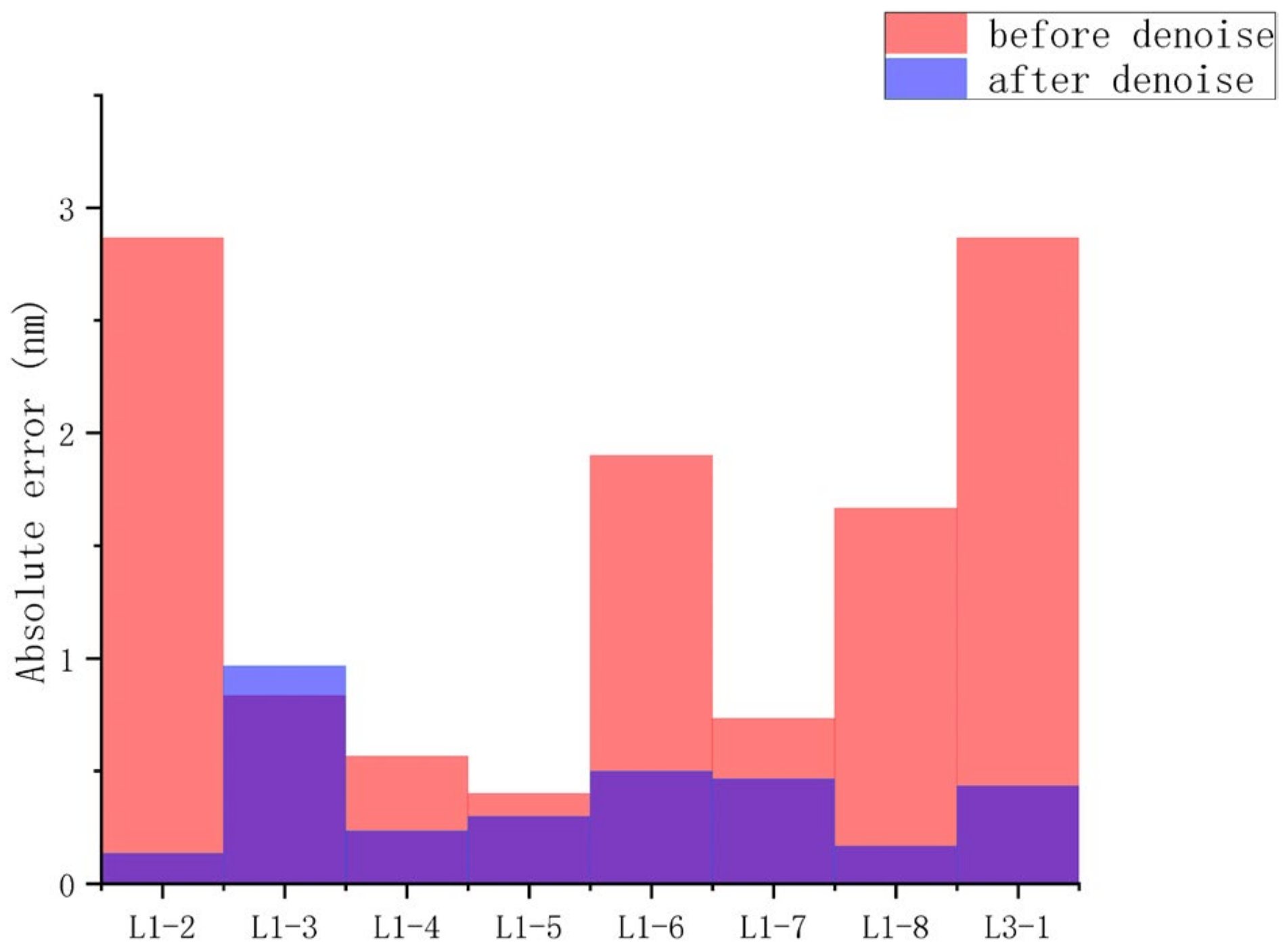

2.1. FT

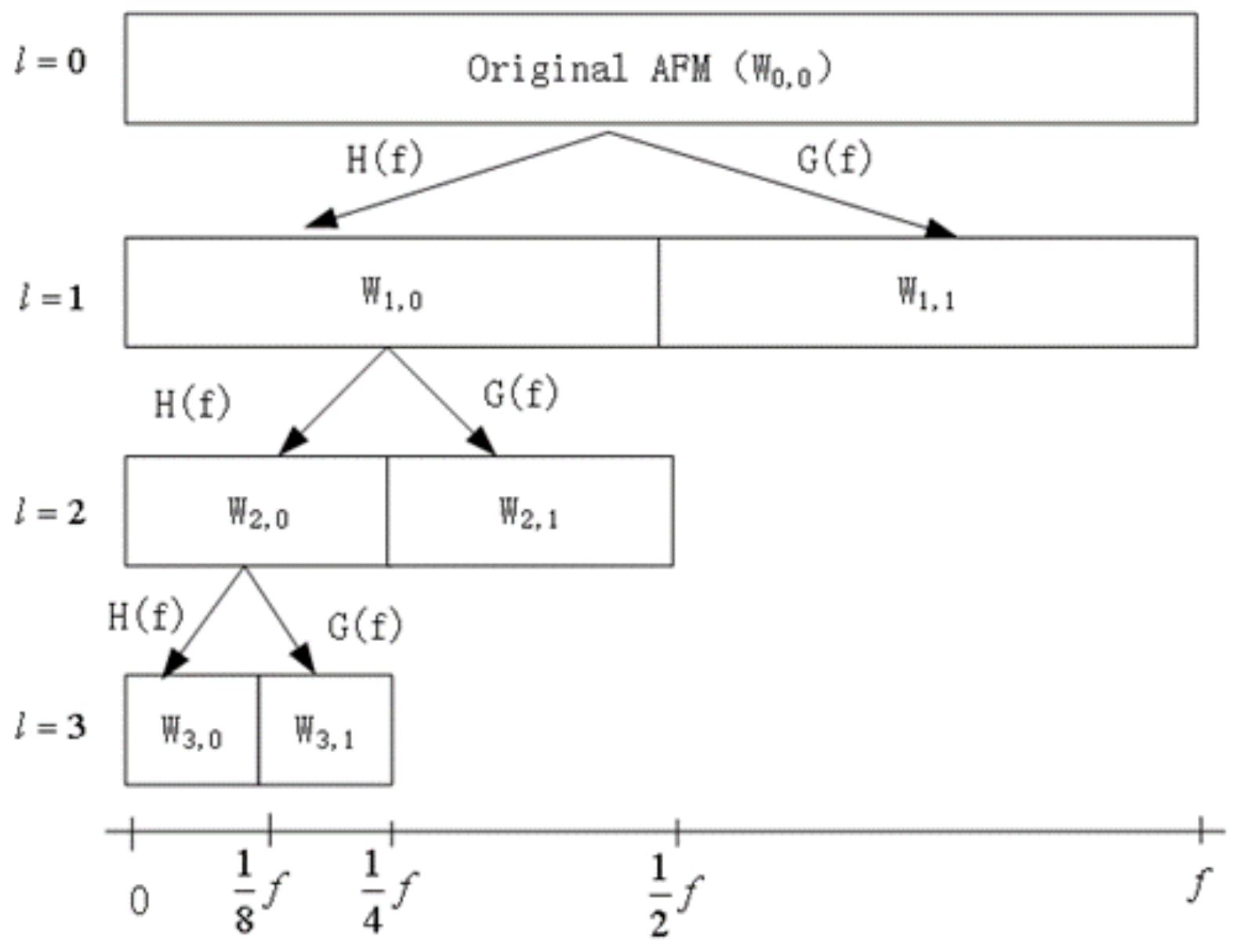

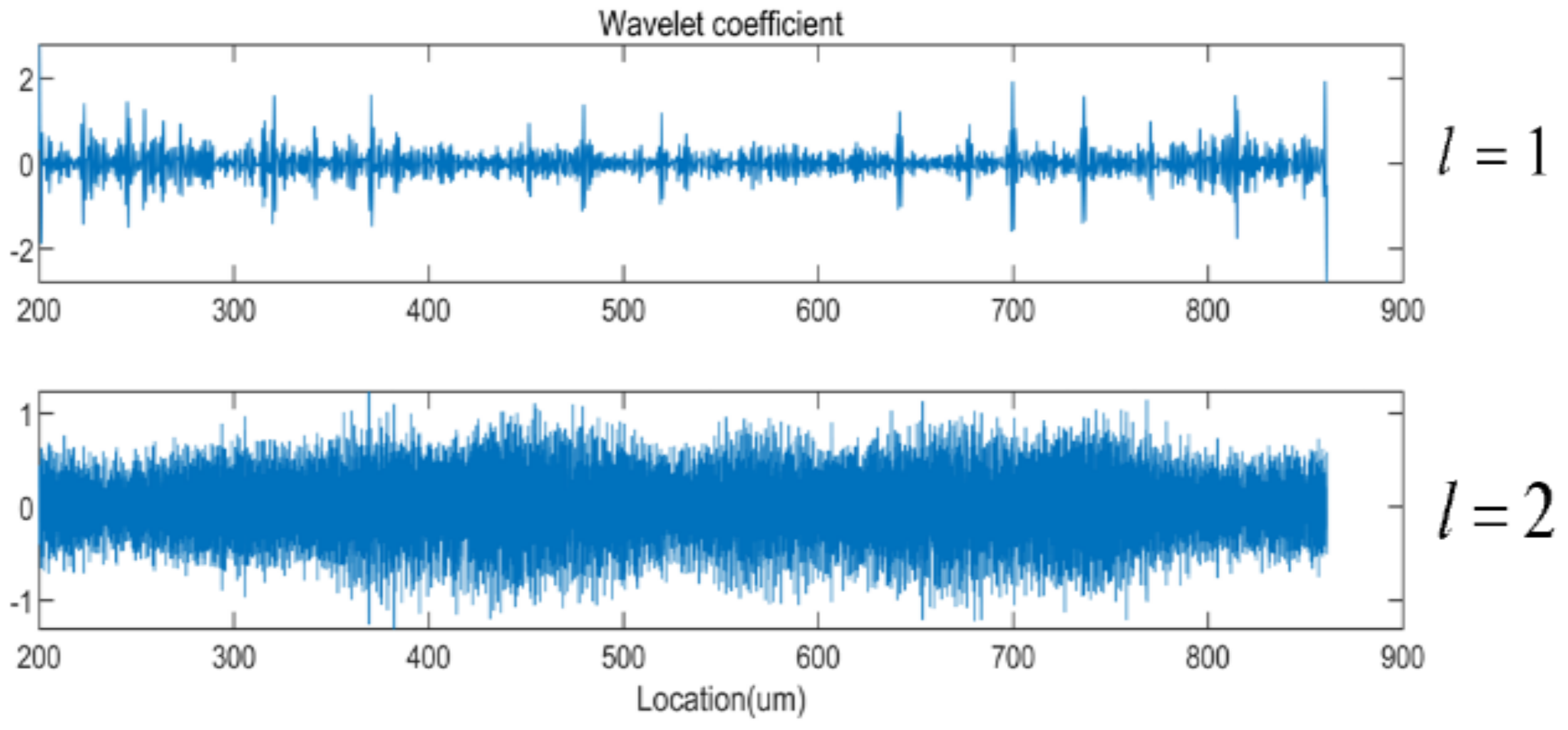

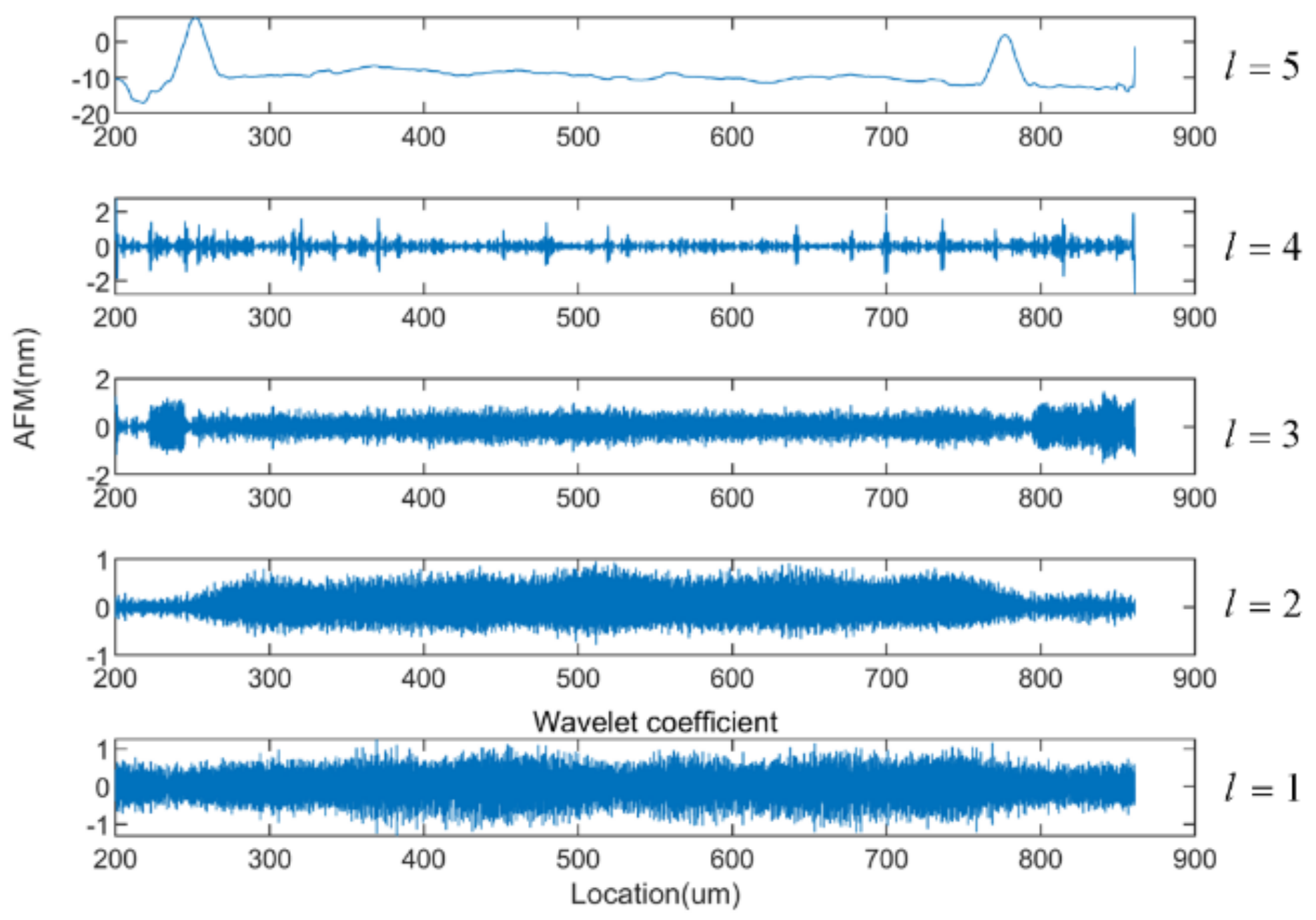

2.2. WT

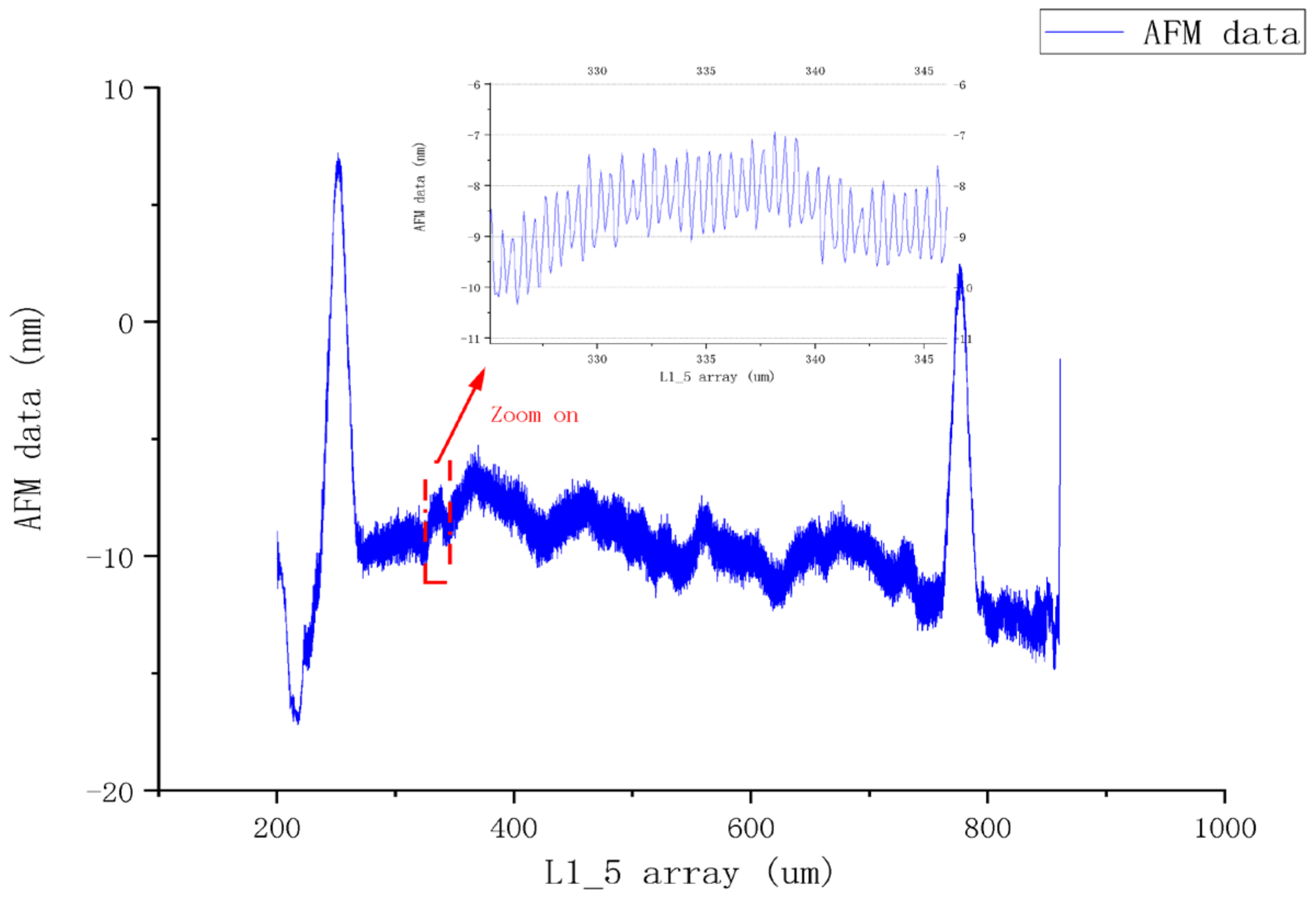

3. WT-FFT Signal Analysis Method

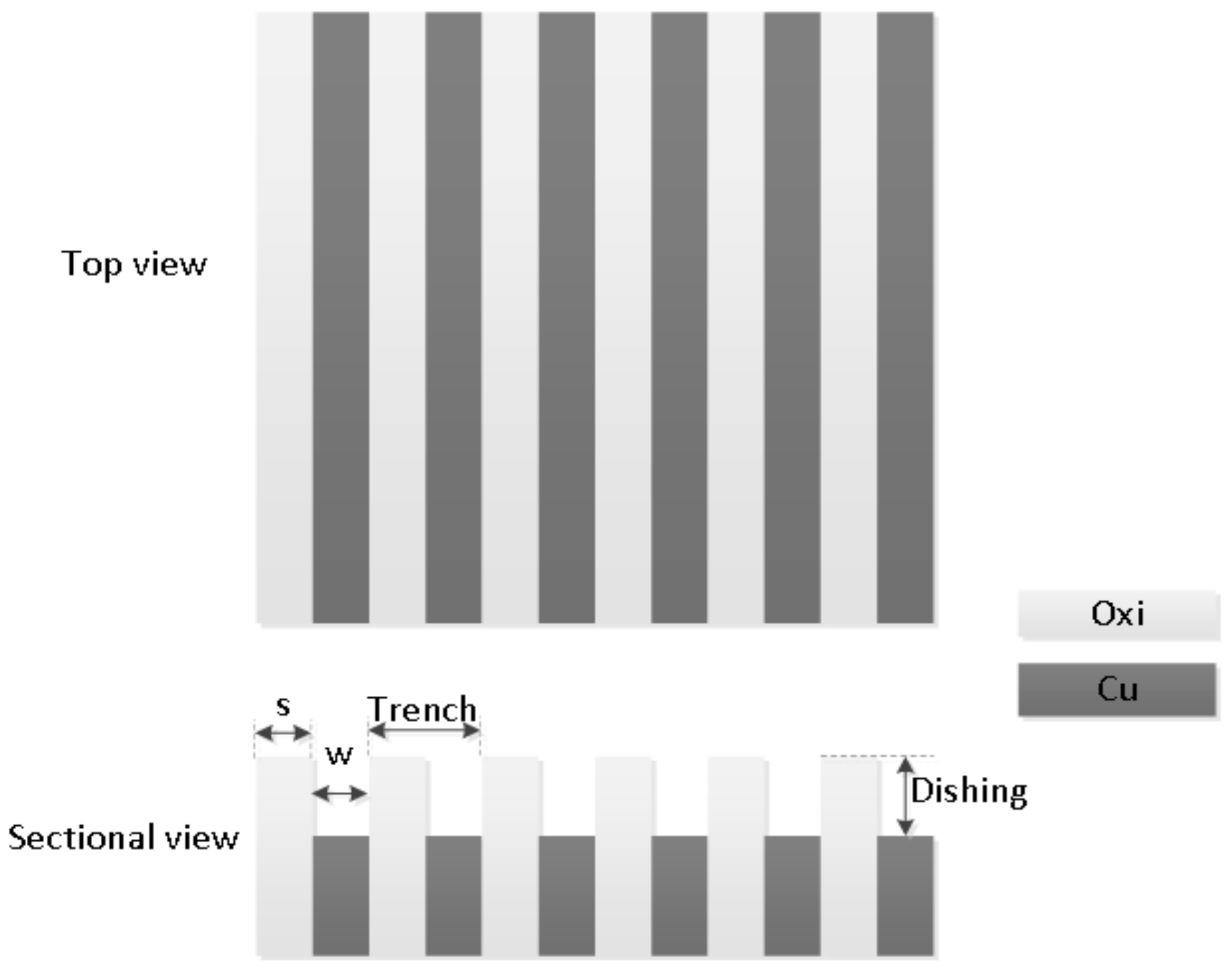

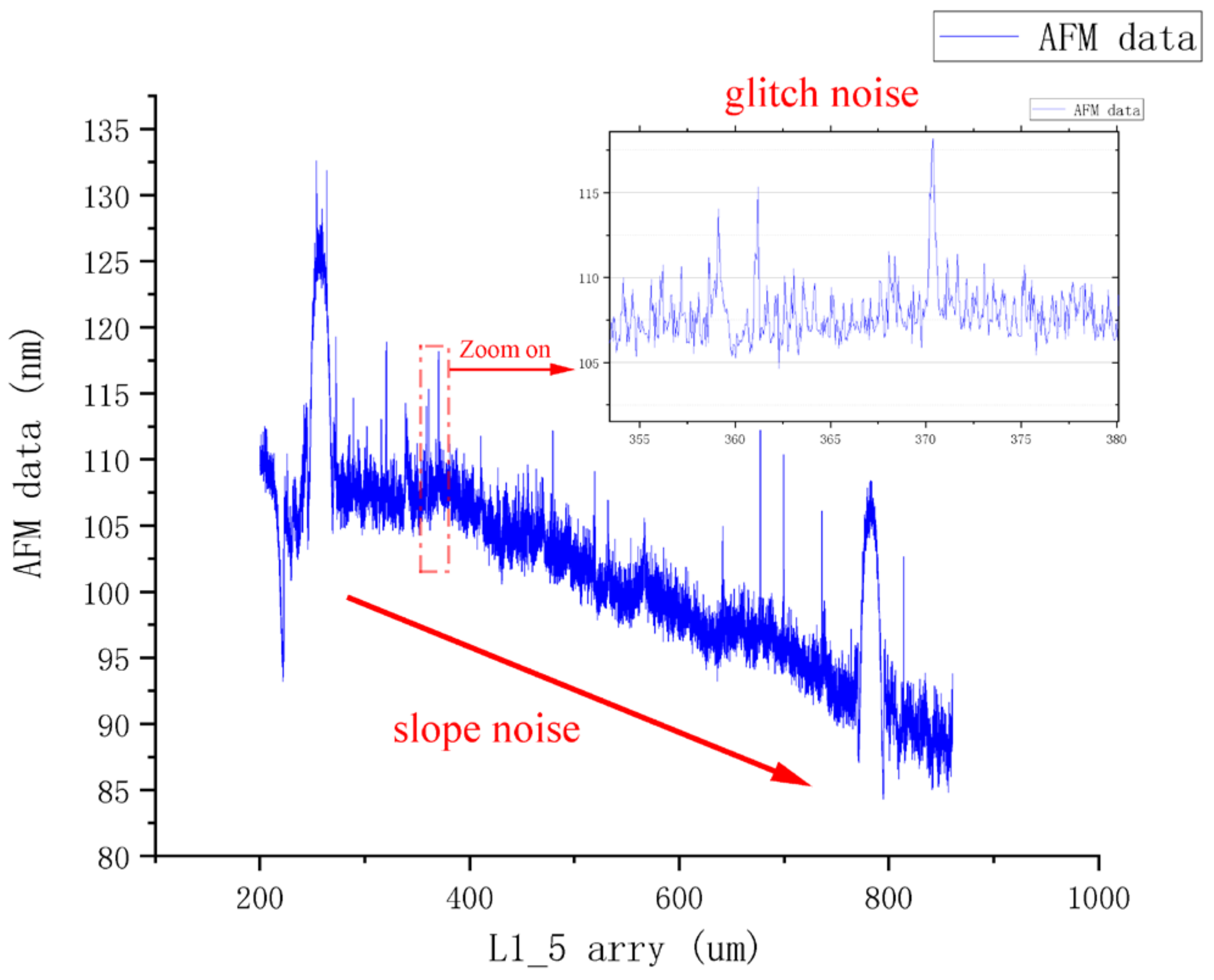

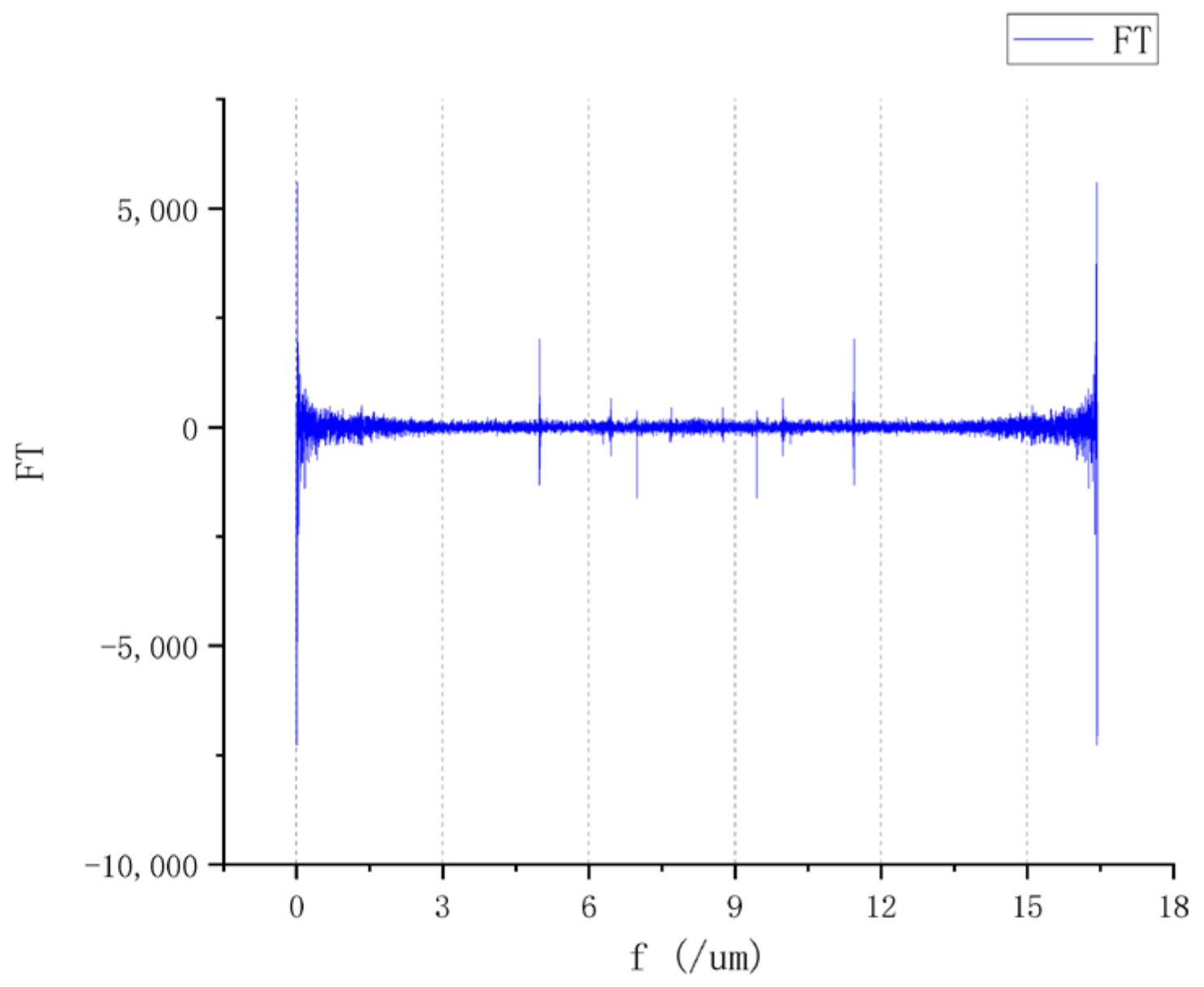

3.1. Frequency Domain Characteristics of Signals

- They exhibited significant energy concentration (peak) in the frequency domain. The instantaneous power of the signal was higher than that of the noise. Hence, hard thresholding could be used for noise reduction;

- More energy (amplitude) was distributed at low frequencies, and the noise at low frequencies was higher than the signal energy distributed at high frequencies;

- After dividing the multiple frequency bands, the noise energy distributed in each frequency band was relatively stable, which can be regarded as a Gaussian distribution.

- This denoising method can be applied via hard thresholding in the frequency domain owing to the high energy concentration in the frequency domain;

- With the different proportions of energy distributed in different frequency bands, a unified threshold in the entire frequency band cannot achieve precise noise elimination. Instead, multiple thresholds should be set in different frequency bands in the denoising method;

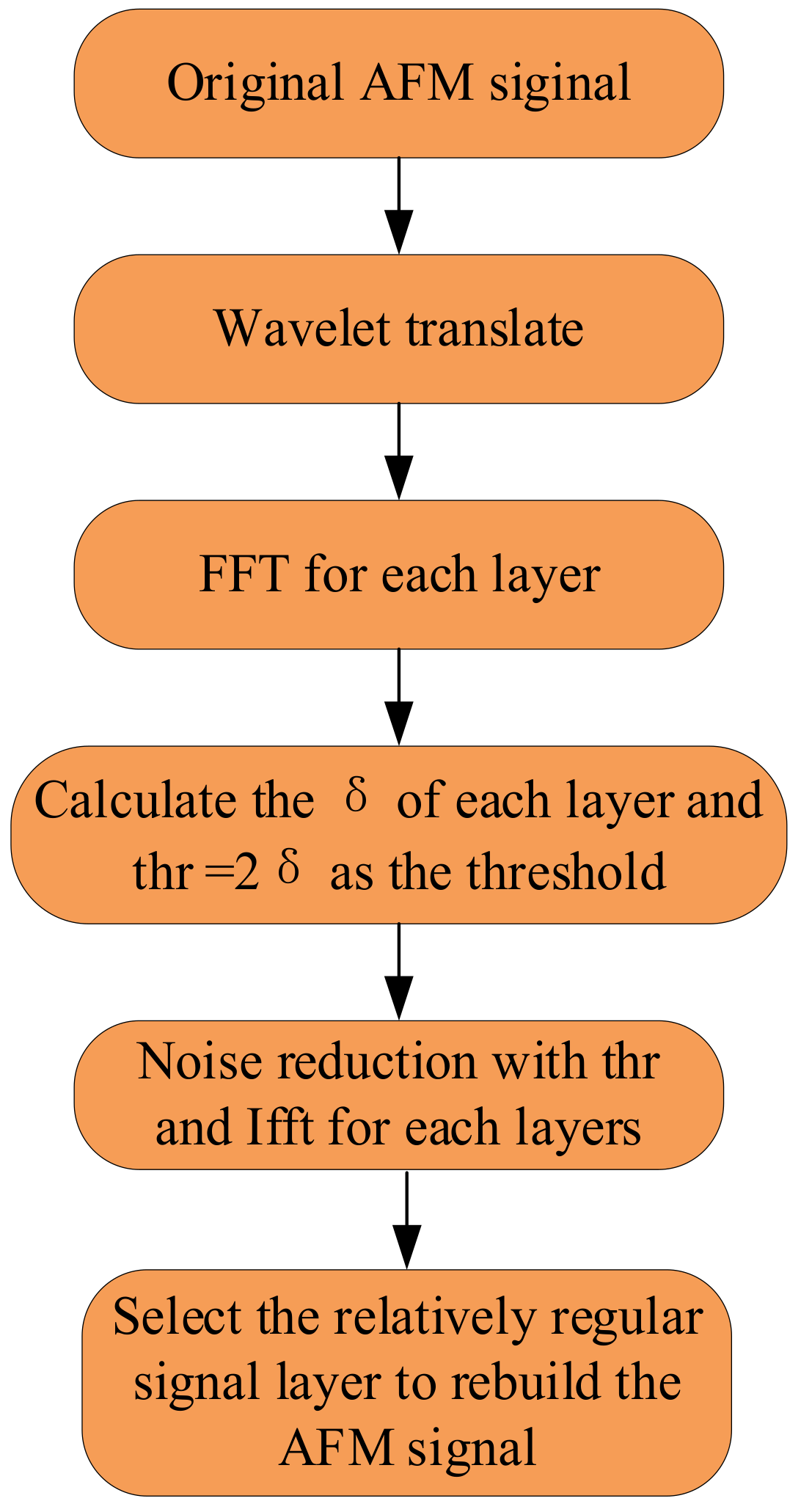

3.2. WT-FT Denoising Process

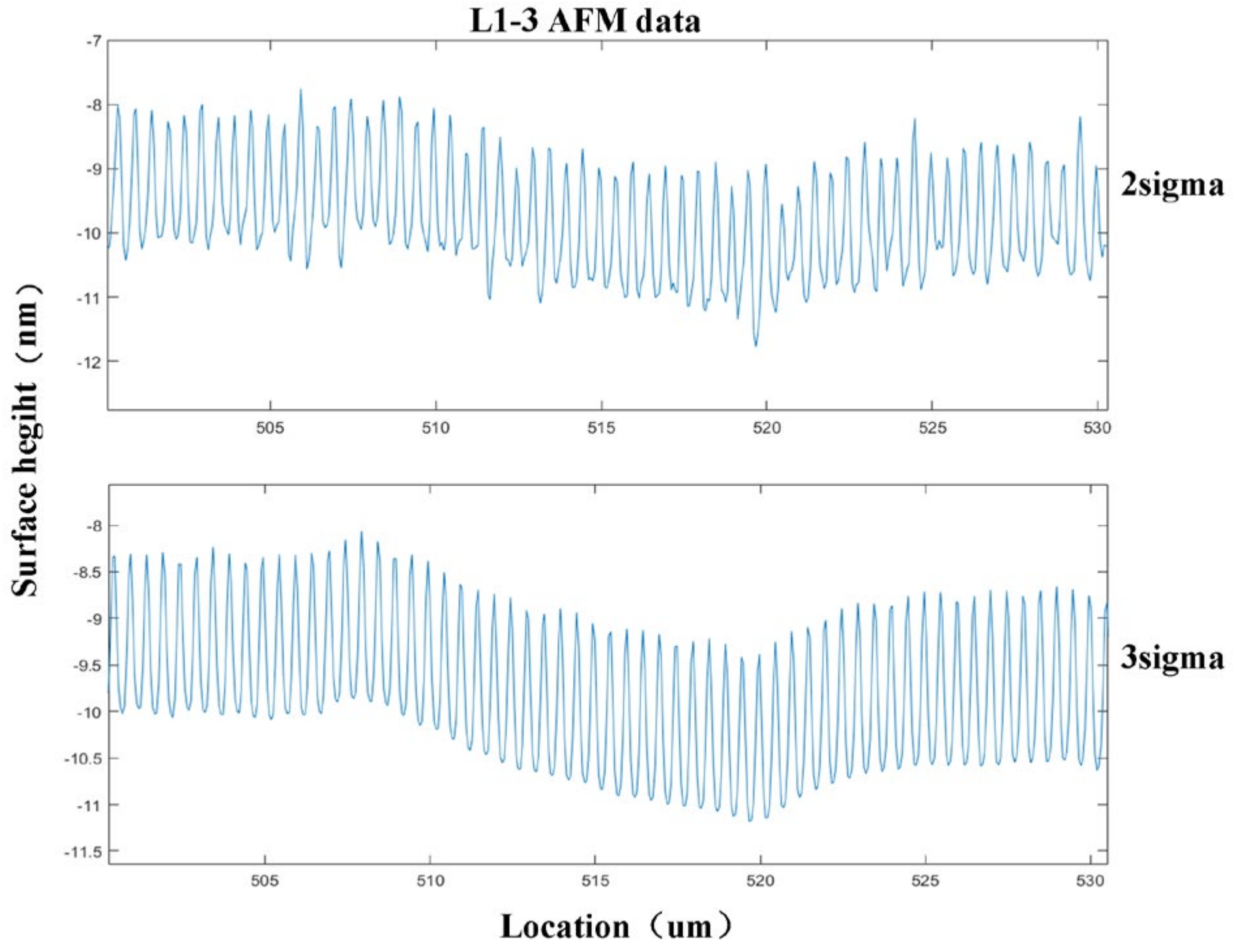

3.3. Noise Reduction Threshold Determination and Component Analysis

- (a)

- Threshold determination

- (b)

- Component screening

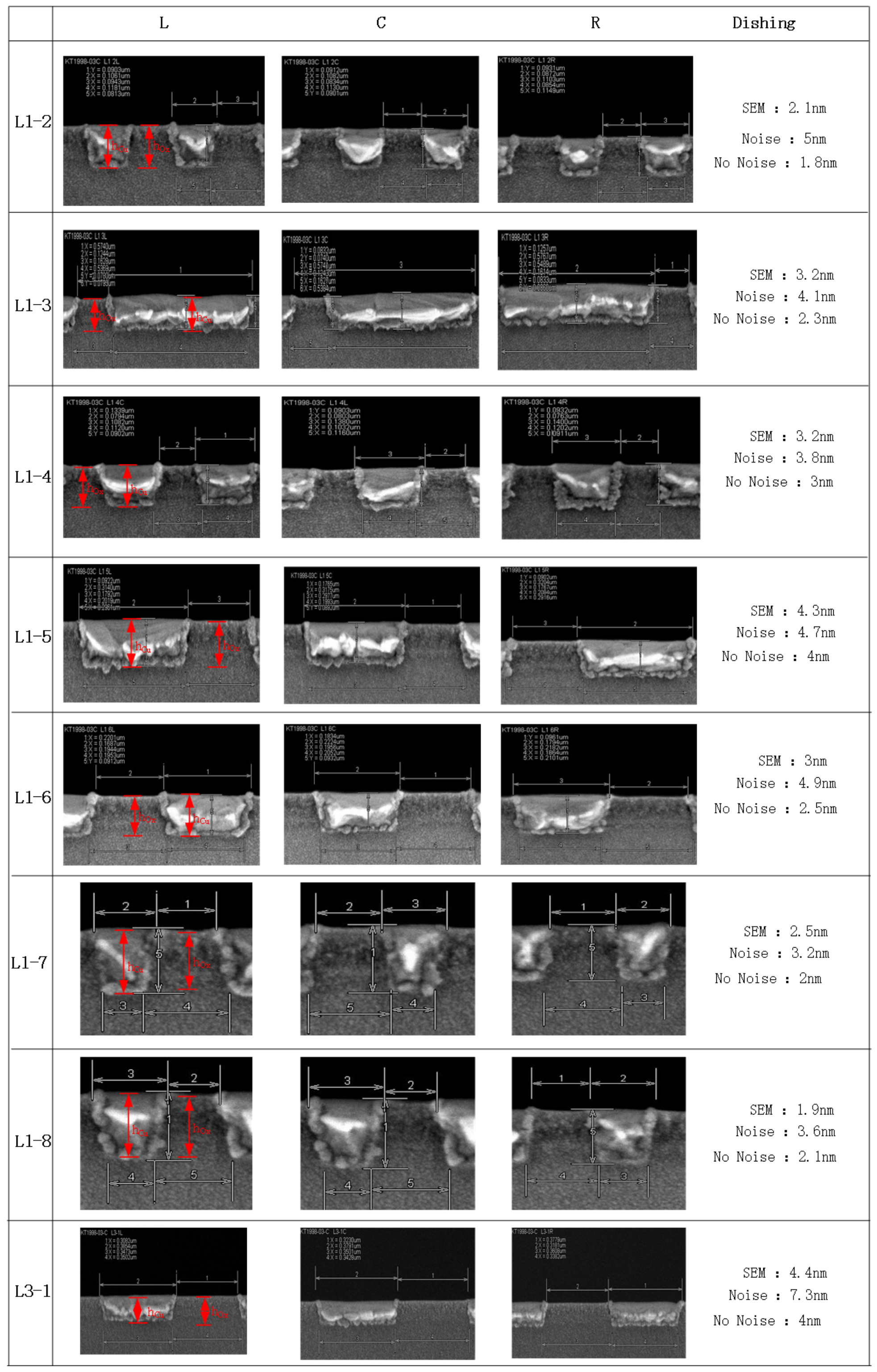

4. Data Denoising Verification and Analysis

5. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Xie, X. Physical Understanding and Modeling of Chemical Mechanical Planarization in Dielectric Materials. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2007. [Google Scholar]

- Park, T.H. Characterization and Modeling of Pattern Dependencies in Copper Interconnects for Integrated Circuits. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2002. [Google Scholar]

- Tugbawa, T.E.; Park, T.H.; Boning, D.S. Integrated chip-scale simulation of pattern dependencies in copper electroplating and copper chemical mechanical polishing processes. In Proceedings of the IEEE 2002 International Interconnect Technology Conference (Cat. No.02EX519), Burlingame, CA, USA, 5 June 2002. [Google Scholar] [CrossRef]

- Geng, C.; Liu, B.; Nakatake, S. Density Optimization for Analog Layout Based on Transistor-Array. IEICE Trans. Fundam. Electron. Commun. Comput. Sci. 2019, E102, 1720–1730. [Google Scholar] [CrossRef]

- Ghulghazaryan, R.; Wilson, J.; Abouzeid, A. FEOL CMP modeling: Progress and challenges. In Proceedings of the 2015 International Conference on Planarization/CMP Technology, Chandler, AZ, USA, 30 September–2 October 2015; pp. 1–4. [Google Scholar]

- Tugbawa, T.; Park, T.; Boning, D.; Pan, T.; Li, P.; Hymes, S.; Brown, T.; Camilletti, L. A mathematical model of pattern dependencies in Cu CMP processes. In Proceedings of the CMP Symposium, Electrochemical Society Meeting, Honolulu, HA, USA, 17–22 October 1999; pp. 605–615. [Google Scholar]

- Francisco, L.; Mao, R.; Katakamsetty, U.; Verma, P.; Pack, R.C. Multilayer CMP hotspot modeling through deep learning. In Design-Process-Technology Co-Optimization Manufacturability XIII; SPIE: Bellingham, WA, USA, 2019; Volume 10962, pp. 202–213. [Google Scholar] [CrossRef]

- Tripathi, S.; Monvoisin, A.; Dornfeld, D.; Doyle, F.M. CMP Modeling as a part of Design for Manufacturing. In Proceedings of the International Conference on Planarization/CMP Technology, Dresden, Germany, 25–27 October 2007; pp. 1–6. [Google Scholar]

- Liew, S.W.; Leong, L.S.; Whsu, R.; Chong, Y.S. Poly CMP Process Challenges for Embedded Array Devices. In Proceedings of the 2021 32nd Annual SEMI Advanced Semiconductor Manufacturing Conference (ASMC), Milpitas, CA, USA, 10–12 May 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Ruan, W.; Chen, L.; Ma, T.; Fang, J.; Zhang, H.; Ye, T. Optimization of a Cu CMP process modeling parameters of nanometer integrated circuits. J. Semicond. 2012, 33, 086001. [Google Scholar] [CrossRef]

- Tanwar, K.; Canaperi, D.; Lofaro, M.; Tseng, W.-T.; Patlolla, R.; Penny, C.; Waskiewicz, C. BEOL Cu CMP process evaluation for advanced technology nodes. J. Electrochem. Soc. 2013, 160, D3247. [Google Scholar] [CrossRef]

- Toffoli, A.; Maitrejean, S.; De Pontcharra, J.D.; De Crécy, F.; Bouchu, D.; Arnaud, L.; Boulanger, F. Test structure for characterizing metal thickness in damascene CMP technology. In Proceedings of the 2008 IEEE International Conference on Microelectronic Test Structures, Edinburgh, UK, 24–27 March 2008; pp. 210–213. [Google Scholar] [CrossRef]

- Gomez, C.; Su, R.; de Groot, P.; Leach, R. Noise Reduction in Coherence Scanning Interferometry for Surface Topography Measurement. Nanomanuf. Metrol. 2020, 3, 68–76. [Google Scholar] [CrossRef]

- Jones, L.; Yang, H.; Pennycook, T.J.; Marshall, M.S.J.; Van Aert, S.; Browning, N.D.; Castell, M.R.; Nellist, P.D. Smart align-A new tool for robust non-rigid registration of scanning microscope data. Adv. Struct. Chem. Imaging 2015, 1, 8. [Google Scholar] [CrossRef]

- Lapshin, R.V. Automatic drift elimination in probe microscope images based on techniques of counter-scanning and topography feature recognition. Meas. Sci. Technol. 2007, 907, 907–927. [Google Scholar] [CrossRef]

- Dukic, M.; Adams, J.D.; Fantner, G.E. Piezoresistive AFM cantilevers surpassing standard optical beam deflection in low noise topography imaging. Sci. Rep. 2015, 5, 16393. [Google Scholar] [CrossRef] [PubMed]

- Zhan, H.; Tan, X.; Xie, G.; Guo, D. Load-dependent energy dissipation induced by the tip–membrane friction on suspended 2D materials. Phys. Chem. Chem. Phys. 2021, 23, 19819–19826. [Google Scholar] [CrossRef] [PubMed]

- Yi, S.; Li, T.; Zou, Q. Active control of acoustics-caused nano-vibration in atomic force microscope imaging. Ultramicroscopy 2018, 195, 101–110. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Fang, Y.; Fan, Z.; Wang, C.; Liu, C. An automated vertical drift correction algorithm for AFM images based on morphology prediction. Micron 2021, 140, 102950. [Google Scholar] [CrossRef] [PubMed]

- Tsimbinos, J.; Lever, K.V. Input Nyquist sampling suffices to identify and compensate nonlinear systems. IEEE Trans. Signal Process. 1998, 46, 2833–2837. [Google Scholar] [CrossRef] [PubMed]

- Hara, T. Openloop Gain Criteria of Sampled-data Control Systems with Mechanical Resonant modes above the Nyquist Frequency. In Proceedings of the 2006 SICE-ICASE International Joint Conference, Busan, Republic of Korea, 18–21 October 2006; pp. 2771–2776. [Google Scholar] [CrossRef]

- Münch, B.; Trtik, P.; Marone, F.; Stampanoni, M. Stripe and ring artifact removal with combined wavelet—Fourier filtering. Opt. Express 2009, 17, 8567–8591. [Google Scholar] [CrossRef] [PubMed]

- Sifuzzaman, M.; Islam, M.R.; Ali, M.Z. Application of wavelet transform and its advantages compared to Fourier transform. J. Phys. Sci. 2009, 13, 121–134. [Google Scholar]

- Mallat, S.G. A theory for multiresolution signal decomposition: The wavelet representation. IEEE Trans. Pattern Anal. Mach. Intell. 1989, 11, 674–693. [Google Scholar] [CrossRef]

- Mallat, S. A Wavelet Tour of Signal Processing; Elsevier: Amsterdam, The Netherlands, 1999. [Google Scholar]

- Shi, J.; Liu, X.; Zhang, N. On uncertainty principle for signal concentrations with fractional Fourier transform. Signal Process. 2012, 92, 2830–2836. [Google Scholar] [CrossRef]

- Labuda, A.; Lysy, M.; Paul, W.; Miyahara, Y.; Grütter, P.; Bennewitz, R.; Sutton, M. Stochastic noise in atomic force microscopy. Phys. Rev. E 2012, 86, 031104. [Google Scholar] [CrossRef] [PubMed]

- Labuda, A.; Lysy, M.; Gruetter, P. Stochastic simulation of tip-sample interactions in atomic force microscopy. Appl. Phys. Lett. 2012, 1, 053121. [Google Scholar] [CrossRef]

- Jain, A.; Gupta, R. Gaussian filter threshold modulation for filtering flat and texture area of an image. In Proceedings of the 2015 International Conference on Advances in Computer Engineering and Applications, Ghaziabad, India, 19–20 March 2015; pp. 760–763. [Google Scholar]

- Starck, J.-L.; Murtagh, F.; Gastaud, R. A new entropy measure based on the wavelet transform and noise modeling [image compression]. IEEE Trans. Circuits Syst. II Analog. Digit. Signal Process. 1998, 45, 1118–1124. [Google Scholar] [CrossRef]

- Hughes, M.S. Analysis of ultrasonic waveforms using Shannon entropy. In Proceedings of the IEEE 1992 Ultrasonics Symposium Proceedings, Tucson, AZ, USA, 20–23 October 1992; Volume 2, pp. 1205–1209. [Google Scholar] [CrossRef]

- Hughes, M.S. Analysis of digitized waveforms using Shannon entropy. J. Acoust. Soc. Am. 1993, 93, 892–906. [Google Scholar] [CrossRef]

- Hughes, M.S. Analysis of digitized waveforms using Shannon entropy. II. High-speed algorithms based on Green’s functions. J. Acoust. Soc. Am. 1994, 95, 2582–2588. [Google Scholar] [CrossRef]

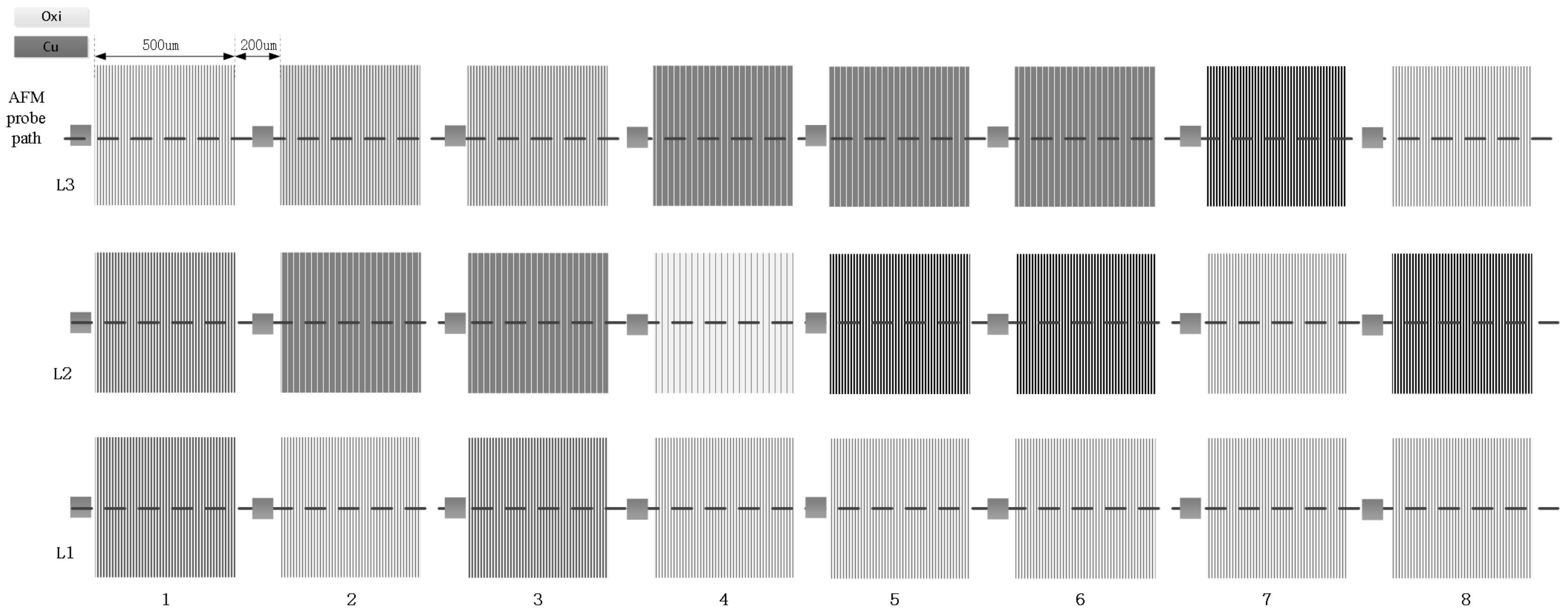

| Array | Line Width (μm) | Line Space (μm) | Pitch (μm) | Density |

|---|---|---|---|---|

| L1_1 | 1.000 | 1.000 | 2.000 | 0.500 |

| L1_2 | 0.100 | 0.100 | 0.200 | 0.500 |

| L1_3 | 0.560 | 0.140 | 0.700 | 0.800 |

| L1_4 | 0.150 | 0.065 | 0.215 | 0.698 |

| L1_5 | 0.300 | 0.200 | 0.500 | 0.600 |

| L1_6 | 0.200 | 0.200 | 0.400 | 0.500 |

| L1_7 | 0.045 | 0.090 | 0.135 | 0.333 |

| L1_8 | 0.075 | 0.075 | 0.150 | 0.500 |

| L2_1 | 2.000 | 3.000 | 5.000 | 0.400 |

| L2_2 | 4.000 | 1.000 | 5.000 | 0.800 |

| L2_3 | 4.000 | 2.000 | 6.000 | 0.667 |

| L2_4 | 3.000 | 9.000 | 12.000 | 0.250 |

| L2_5 | 4.500 | 4.500 | 9.000 | 0.500 |

| L2_6 | 1.120 | 0.280 | 1.400 | 0.800 |

| L2_7 | 0.100 | 0.400 | 0.500 | 0.200 |

| L2_8 | 0.045 | 0.045 | 0.090 | 0.500 |

| L3_1 | 0.350 | 0.350 | 0.700 | 0.500 |

| L3_2 | 0.500 | 0.500 | 1.000 | 0.500 |

| L3_3 | 0.800 | 0.800 | 1.600 | 0.500 |

| L3_4 | 2.000 | 2.000 | 4.000 | 0.500 |

| L3_5 | 4.500 | 1.000 | 5.500 | 0.818 |

| L3_6 | 2.000 | 1.300 | 3.300 | 0.606 |

| L3_7 | 0.700 | 0.300 | 1.000 | 0.700 |

| L3_8 | 1.000 | 4.000 | 5.000 | 0.200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, B.; Chen, L.; Chen, R.; Ji, R.; Wang, Y. Noise Reduction of Atomic Force Microscopy Measurement Data for Fitting Verification of Chemical Mechanical Planarization Model. Electronics 2023, 12, 2422. https://doi.org/10.3390/electronics12112422

Ren B, Chen L, Chen R, Ji R, Wang Y. Noise Reduction of Atomic Force Microscopy Measurement Data for Fitting Verification of Chemical Mechanical Planarization Model. Electronics. 2023; 12(11):2422. https://doi.org/10.3390/electronics12112422

Chicago/Turabian StyleRen, Bowen, Lan Chen, Rong Chen, Ruian Ji, and Yali Wang. 2023. "Noise Reduction of Atomic Force Microscopy Measurement Data for Fitting Verification of Chemical Mechanical Planarization Model" Electronics 12, no. 11: 2422. https://doi.org/10.3390/electronics12112422

APA StyleRen, B., Chen, L., Chen, R., Ji, R., & Wang, Y. (2023). Noise Reduction of Atomic Force Microscopy Measurement Data for Fitting Verification of Chemical Mechanical Planarization Model. Electronics, 12(11), 2422. https://doi.org/10.3390/electronics12112422