1. Introduction

Wireless power transmission (WPT) is a method of transferring electrical energy from a source to an electrical load without an electrical wire (conductor). The concept of wireless power transmission was introduced by Nikola Tesla in 1890 [

1]. However, the implementation of WPT technology has only been realized recently.

There are fundamentally two methods for transferring power from one station to another station: far-field and near-field power transfer [

2]. Far-field power transmissions are usually carried out using microwave, acoustic, or optical energy carriers, whereas near-field wireless power transmissions (WPTs) are mostly based on the concept of inductive coupling. For the successful operation of near-field inductive-based WPT, two inductive coils at the receiver and transmitter sides are required. When the transmitter coil is excited using an alternating current (AC), it induces a variable magnetic flux density. This flux density in turn induces an electromotive force (EMF) in the receiver coil according to Faraday’s law. Then, the variable EMF is converted to DC and utilized for various applications.

Wireless power transfer techniques have recently received considerable attention in applications such as power-up sensors, charging electronic devices, biomedical implants, integrated circuits, solar-powered satellites, charging electric vehicles, unmanned aerial vehicles (UAVs), and underwater applications [

2,

3,

4,

5,

6,

7,

8].

The key parameters that affect the power transfer efficiency (PTE) are the quality factor (Q), the mutual inductance, and the coupling coefficient (

k) [

6,

9,

10,

11,

12]. The shape and design of the transmitter and receiver coils also have an important role in improving the PTE [

6,

9,

13,

14].

Ali et al. [

6] compared two different configurations of a two-coil WPT system. The first configuration was based on two single wires: one on the transmitter side and the other on the receiver side. The inner and outer radii of the coil were 4.8 cm and 4.9 cm, respectively. They analyzed the power efficiency by varying the distance between the two coils. They then compared the PTE of this configuration with another configuration that had circular spiral coils with five turns on both the transmitter and receiver sides. For both configurations, they varied the distance between the receiver and transmitter from 4 cm to 7 cm and calculated the corresponding power efficiency at each distance. The spiral coil configuration had a higher PTE compared with the two single coils.

Similarly, Yan et al. [

9] used different configurations for the transmitter and receiver spiral coils to increase the efficiency of transmitted power for charging UAVs wirelessly. In the design, they applied an asymmetrical coil configuration for the transmitter and receiver coil. The transmitter coil was constructed from 2 concentric circular spiral coils with 25 turns in both coils. For the receiver coil, only one circular spiral coil which had the same size as the inner spiral transmitter coil was used. For the transmitter coil, the self-inductance of the coil was relatively higher compared with the conventional coil, while the resistance was not affected much. As a result, they achieved high-quality factors using this configuration.

Various coil-shape configurations for improved PTE have been investigated in the literature [

13,

14] and generally fall into two coil configuration categories: circular spiral and rectangular coils. The spiral coil design has a high coupling coefficient during the perfect alignment of the transmitter and receiver coils. However, the rectangular coil configuration has better performance during misalignment scenarios [

13]. As a result, the rectangular configuration is usually preferred for wireless charging vehicles. Kalwar et al. [

13] used a hybrid of the spiral and rectangular coil configurations to improve the efficiency of wireless power transfer during misalignment conditions. They applied one external rectangular coil and four symmetrically arranged inner spiral coils (quad-D quadrature) configurations.

Laksono et al. [

14] improved the previous design [

13] by incorporating a rectangular coil right at the center of the four circular spiral coils and obtained better power transfer efficiency in misalignment conditions. In their work, they compared the performances of three different design configurations. The first design was a pure rectangular coil with outer and inner dimensions of 36.5 cm × 26.5 cm and 30 cm × 20 cm, respectively. The second design consisted of one external rectangular coil having the same dimensions as the first design, with four symmetric inner spiral coils each having outer and inner diameters of 9.8 cm and 4.74 cm, respectively. The third coil consisted of all elements of the second configuration with an additional rectangular coil at the center with outer dimensions of 10 cm × 20 cm. Each coil configuration had 10 turns. Considering all three configurations, the third configuration provided the best efficiency during the misalignment of the receiver and transmitter coils.

In their work related to WPT for electric vehicle charging, Tasnime Bouanou et al. [

15] investigated the effect of both the inner radius and the number of turns of the coil. They also investigated the effectiveness of three shapes of the coil: circular, rectangular, and hexagonal. They showed that the inner diameter and number of turns of the transmitter and the receiver coils have a significant impact on the coupling coefficient as well as their self-inductance and mutual inductances. The larger the inner radius and the number of coil turns, the better the coupling coefficient and the mutual inductance. However, the space occupied by the receiving coil in the vehicle chassis is limited. The comparison of the three shapes of the coils showed that the rectangular coil gave higher efficiency with a small difference compared with the circular and hexagonal coil. The combination of circular and rectangular coils gave the best results.

M. E. Thein et al. [

16] designed WPT transmitter and receiver coils. They studied the effect of the number of turns and the space between turns for the transmitter and receiver coils on the power transfer efficiency. Their study demonstrated that the power transfer efficiency improves with an increase in the number of turns for both coils and the space between the turns. Five coil designs were investigated: circular, rectangular, double-D, double-D quadrature (DDQ), and bipolar. The DDQ design showed the maximum power transfer efficiency, but its structure is more complex, utilizing more wires. The bipolar design showed the highest tolerance for misalignment between the transmitter and receiver coils.

Considering the effect of the transmitter and receiver shape, McDonough et al. [

17] analyzed WPT systems of circular and square coils. The analyses showed that the circular geometry provides better coupling in perfectly aligned coils, while during misalignment, the square type is better.

Taken together, it has been demonstrated that the inductive coupling coefficient and power transfer efficiency are highly affected by the number of turns, the distance between the consecutive turns, the shape of the turns, and the inner and outer diameters of both the receiver and transmitter coils. In the previous studies, only fixed shapes for the turns were investigated. However, in this work, quasi-elliptic curves are used to design WPT transmitter and receiver coils. For both the transmitter and receiver coils, the shape and location of each turn are varied by iteratively changing the quasi-elliptic parameter as well as the inner radius of the turns. The inner diameters of the transmitter and receiver coils are also investigated, searching for a configuration with a higher coupling coefficient between the transmitter and receiver coils. This optimization process results in coils with higher coupling coefficients and power transfer efficiency.

2. Materials and Methods

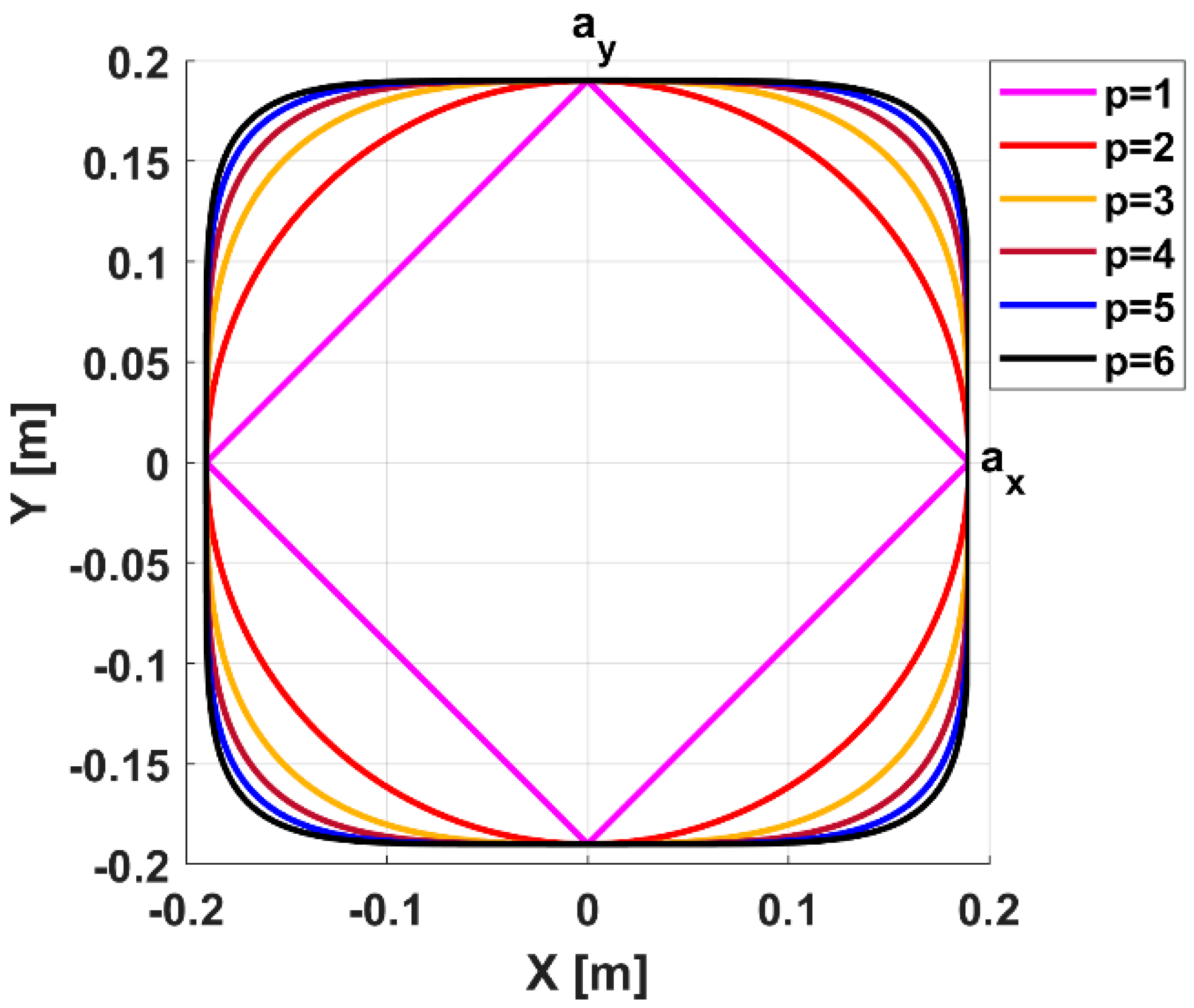

The turns of the WPT transmitter and receiver coils were assumed to have quasi-elliptical shapes which were symmetric with respect to the origin. As an example, in the XY plane, the geometry of a single turn can be mathematically represented using Equations (1)–(4). The turn has different geometries depending on the elliptical parameter

, as shown in

Figure 1:

Both the transmitter and receiver coils were assumed to have a specific number of turns

, and the distance between the coils (

was set to 15 cm. The minimum distance between the consecutive turns in each coil was constrained to 7 mm. As demonstrated in

Figure 2, the turns occupied the locations between the inner radius

and the outer radius

. The outer radius was fixed and set to 190 mm. A spiral connection was applied to connect the separated turns by gradually changing the radius of a single turn in Equations (1)–(4) from its current value to the next outer turn radius value.

In the optimization process of the coils, the inner radius

was varied from 0 up to

with 100 steps

= 100), where

is the turn-to-turn distance (

). At a specific

, the 19 turns were distributed uniformly between

and

. The quasi-elliptical parameter

was ranging from 1 up to 6 with 20 steps (

= 20). The transmitter and receiver coils can be different in size and configuration, but in this paper, they were assumed to be the same size and configuration. In the brute searching process, the optimizer changes the parameters

and

one at a time with many iterations. At any iteration of certain values of

and

, the self and mutual inductances of the transmitter and receiver coils were calculated using the Neuman formula [

18], which is given as

where

and

are the elements’ vectors on the transmitter and receiver coils, respectively,

is the distance between these elements, and

is the permeability of free space, which is equal to

.

The coupling coefficient

between the transmitter and receiver coils was also calculated and stored. After the simulation, the coil configurations with the maximum coupling coefficient were selected. The resistance of the coil (if needed) was calculated in terms of the material resistivity of the coil, length of the coil, and cross section of the coil’s track. The detailed optimization algorithm is demonstrated in the flow chart diagram (see

Figure 3).

To compute the magnetic fields from the designed coil for any further processing, the coil was conventionally considered as a thin wire track. Accordingly, the magnetic field generated by the coil at any arbitrary target point can be calculated using the Biot–Savart law in terms of the line current as follows [

18]:

where

is the element’s vector on the coil,

is a vector from the coil element to the target point,

is the distance between the coil element and the target point, and

is the current passing through the coil.

Figure 4 shows an equivalent circuit of a WPT system which includes both the transmitter and receiver coils. The same circuit was constructed in Ansys, where AC analysis was performed to compute the efficiency of the power transmission. For the optimized transmitter and receiver coils, the values of both capacitors

and

at the resonance frequency

were calculated as follows:

where

and

are the self-inductances of the optimized transmitter and receiver coils, respectively. These inductances were obtained from the optimization process using Equation (5). The value of the voltage source

was set to 220 V

RMS, and the frequency of the source was 85 kHz, following the WPT standards [

19].

AC analysis was performed for the WPT circuit in

Figure 3 using Ansys Maxwell 3D and Simplorer. In this analysis, the frequency of the source was varied from 25 kHz to 150 kHz at steps of 1 Hz. The coils were optimized using MATLAB and then imported to Ansys Maxwell to conduct an electromagnetic simulation. Finally, the model output of Ansys Maxwell 3D was linked to Ansys Simplorer to carry out the AC circuit analysis.

3. Results and Discussion

After the optimization process, the optimal value of the coupling coefficient was selected from the searching space of both the inner radius

and the quasi-elliptical parameter

.

Figure 5 shows a 3D mesh of the obtained coupling coefficients as a function of

and

.

Figure 6 demonstrates the optimized transmitter and receiver coils. As mentioned in the method section, both the transmitter and receiver coils were assumed to have the same configuration. However, the approach followed in this paper is flexible to using a different configuration.

Table 1 lists the parameters and their respective values for the optimized WPT coils. The capacitance of the transmitter coil

and the capacitance of the receiver coil

were obtained using Equations (7) and (8), respectively.

For cross-validation, the inductances of the optimized coils were calculated using Ansys Maxwell 3D. The values of the self-inductance, mutual inductances, and coupling coefficient were comparable to the corresponding values computed using the optimization algorithm in MATLAB.

The Ansys Maxwell and Simplorer AC circuit analysis of the WPT circuit including the designed transmitter and receiver coils is illustrated in

Figure 7, where the highest efficiency was located at the resonance frequency of 85 kHz.

The selected number of turns (19 turns), the distance between the coils (15 cm), and the dimensions of the coils used in the simulations were selected arbitrarily. However, they were comparable to the dimensions in some published works in the same field [

20,

21]. The approach suggested in this paper is viable to design WPT of any desirable dimensions and number of coil turns. The suggested approach was tested initially with different dimensions and numbers of turns.

In the result, the optimizer gave a large inner radius

(as shown in

Figure 6 and

Table 1) in the optimized coils, and that large value improved the coupling coefficient and the mutual inductance between the transmitter and the receiver coils, as investigated in [

15,

22], where the magnetic flux between the coils was at its maximum. The idea of a quasi-elliptic shape was borrowed from [

23], which contributes to giving high flexibility to create any arbitrary geometries between the circular and rectangular (or square) shapes. In previous studies [

15,

16,

17], pure circular, rectangular, or square turn shapes were used, where each has its own drawbacks. The achieved quasi-elliptical parameter

from the suggested approach in this paper gave a geometry combining the features of circular and rectangular (or square) shapes, which we believe had a better coupling coefficient and a better transfer efficiency. After achieving the optimized parameters

and

, the self-inductances of the transmitter and the receiver coils were computed accordingly, and from them, the mutual inductance and the capacitors were calculated. The suggested approach has been applied initially in different structures with different dimensions and numbers of turns. When involving the two optimization parameters

and

, the searching space was always convex, as shown in

Figure 5, with one global maximum. However, we believe that using more parameters in the optimization will add complexity to the search space, and that will be investigated in future work.

This study investigated the application of quasi-elliptic curves in designing the transmitter and receiver coils of WPT circuits. The findings of the study suggest that the optimization of the geometry and positions of the quasi-elliptic curves resulted in coils with a high coupling coefficient.

4. Conclusions

WPT has gained importance in many daily applications. The transmitter and receiver are essential parts of the WPT system. The coupling coefficient has a significant contribution to transmission efficiency. A new approach to designing WPT transmitter and receiver coils involving a high coupling coefficient was introduced in this paper. The final designed coils using this method have quasi-elliptical shapes, which are easy to manufacture. The geometry of the turn varies from rhombus to circular to rectangular shapes, according to the quasi-elliptic parameter () value. This approach will be helpful for WPT designers to design flexible shapes for coils. Furthermore, the approach is flexible, as more constraints such as the number of turns, the distance between turns, the length of the coil, the inductance and resistance of the coil, and the gap between the transmitter and receiver coils may be incorporated into the design optimization. In this work, the designed receiver and transmitter coils were assumed to be perfectly aligned. In future work, more parameters will be added to the optimization, and the misalignment scenarios will be further explored. Adding ferrite and aluminum ferrite bars or plates to guide the magnetic flux and reduce the leakage flux should also be investigated.