High-Performance Amorphous InGaSnO Thin-Film Transistor with ZrAlOx Gate Insulator by Spray Pyrolysis

Abstract

:1. Introduction

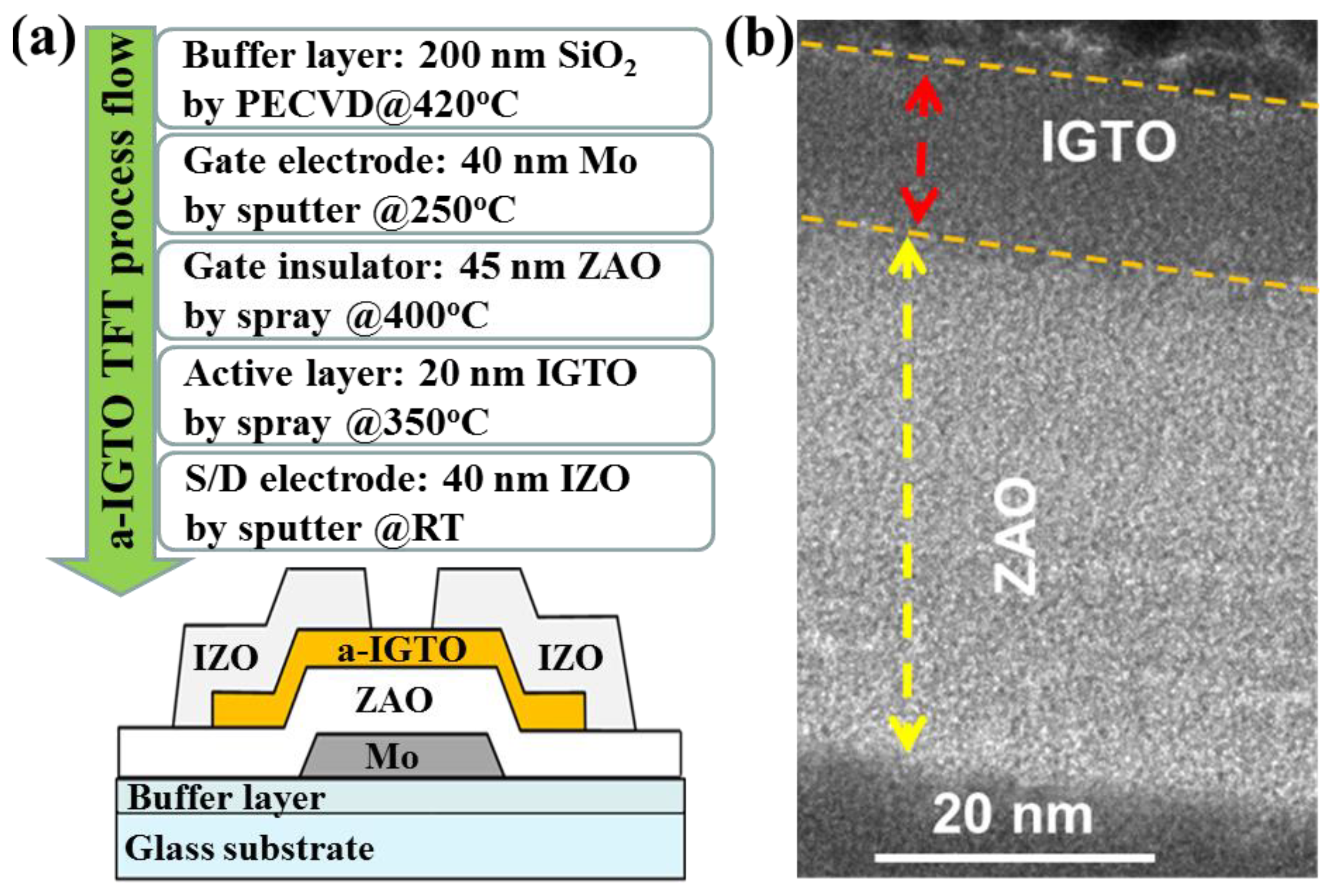

2. Materials and Methods

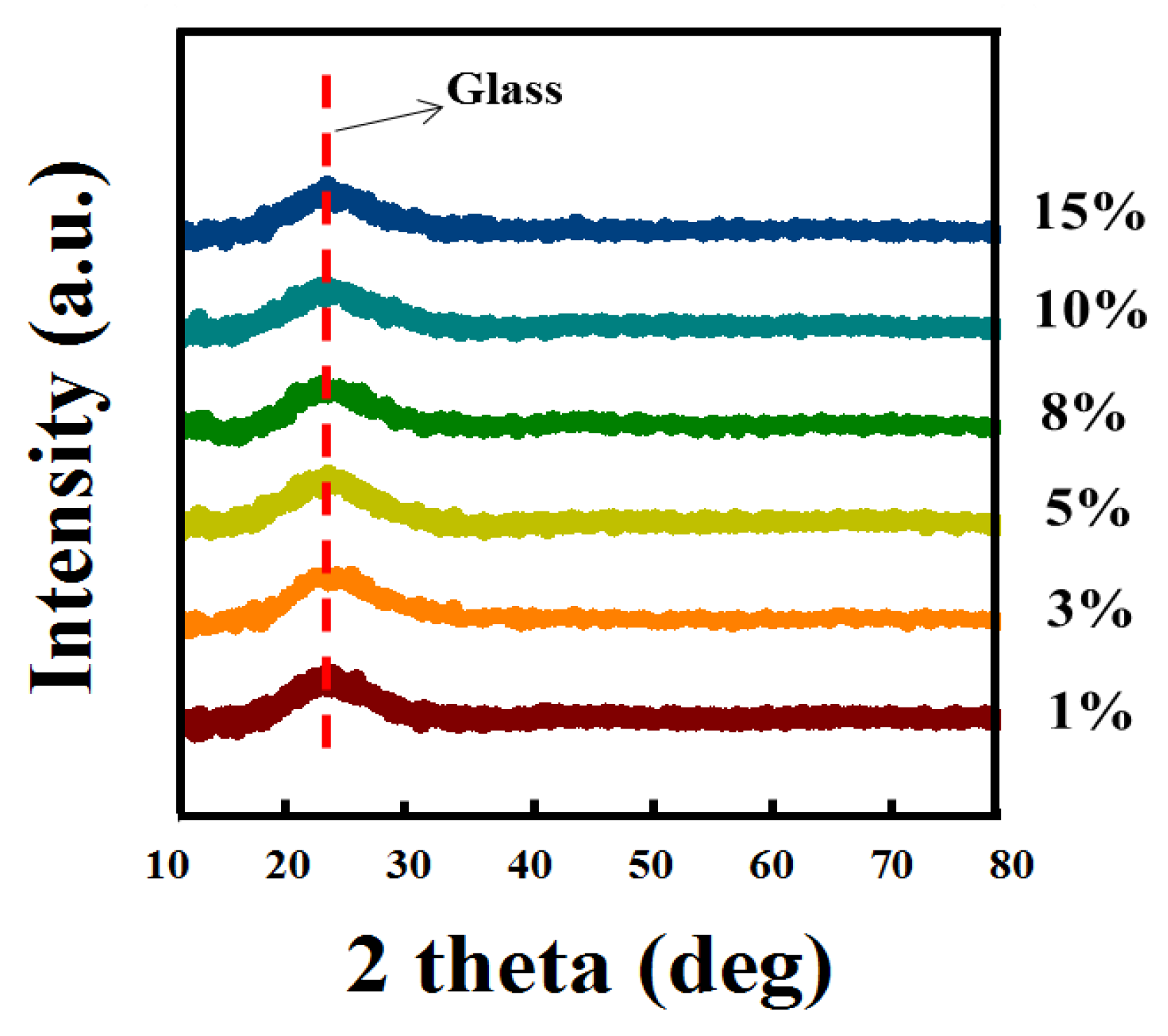

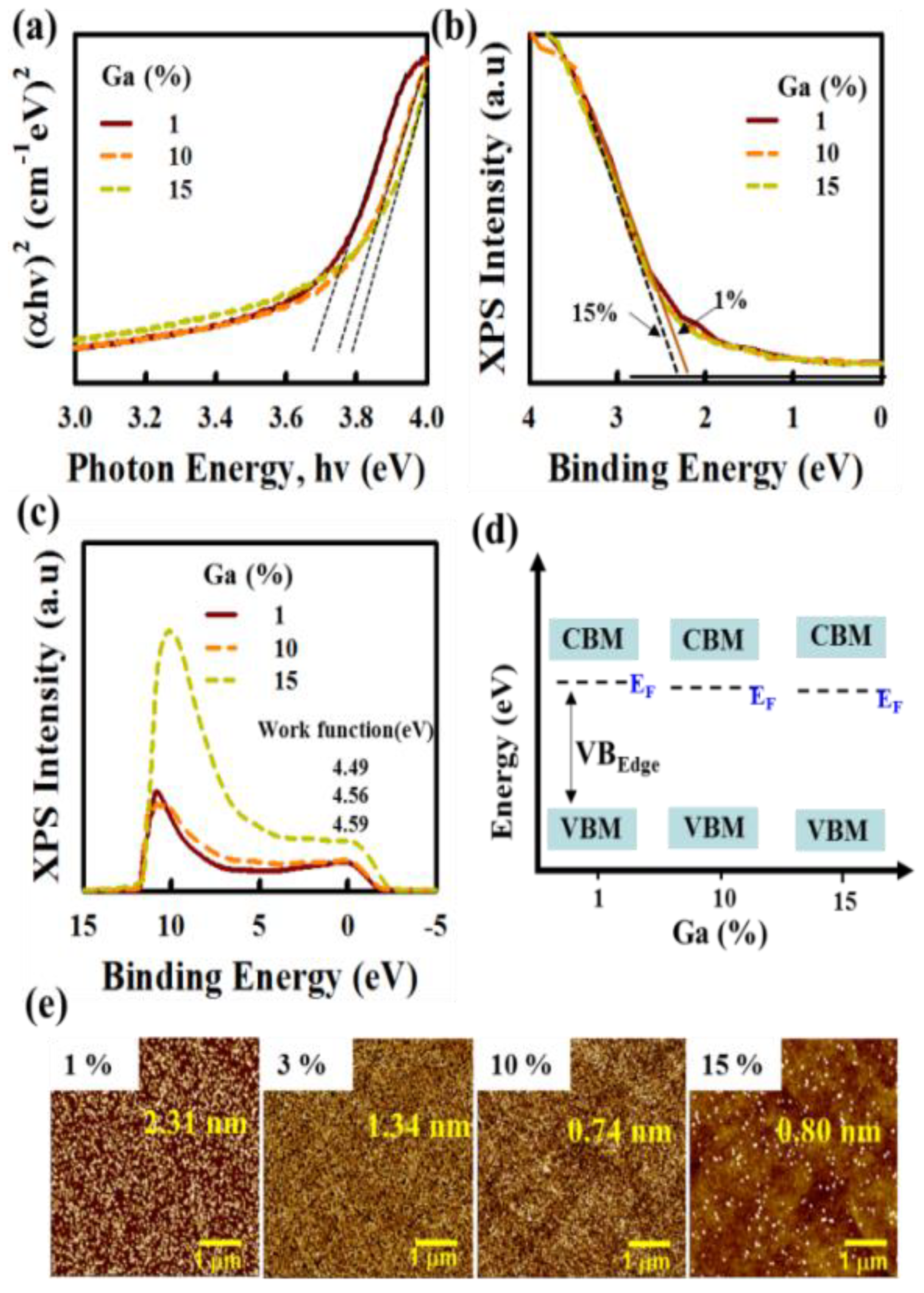

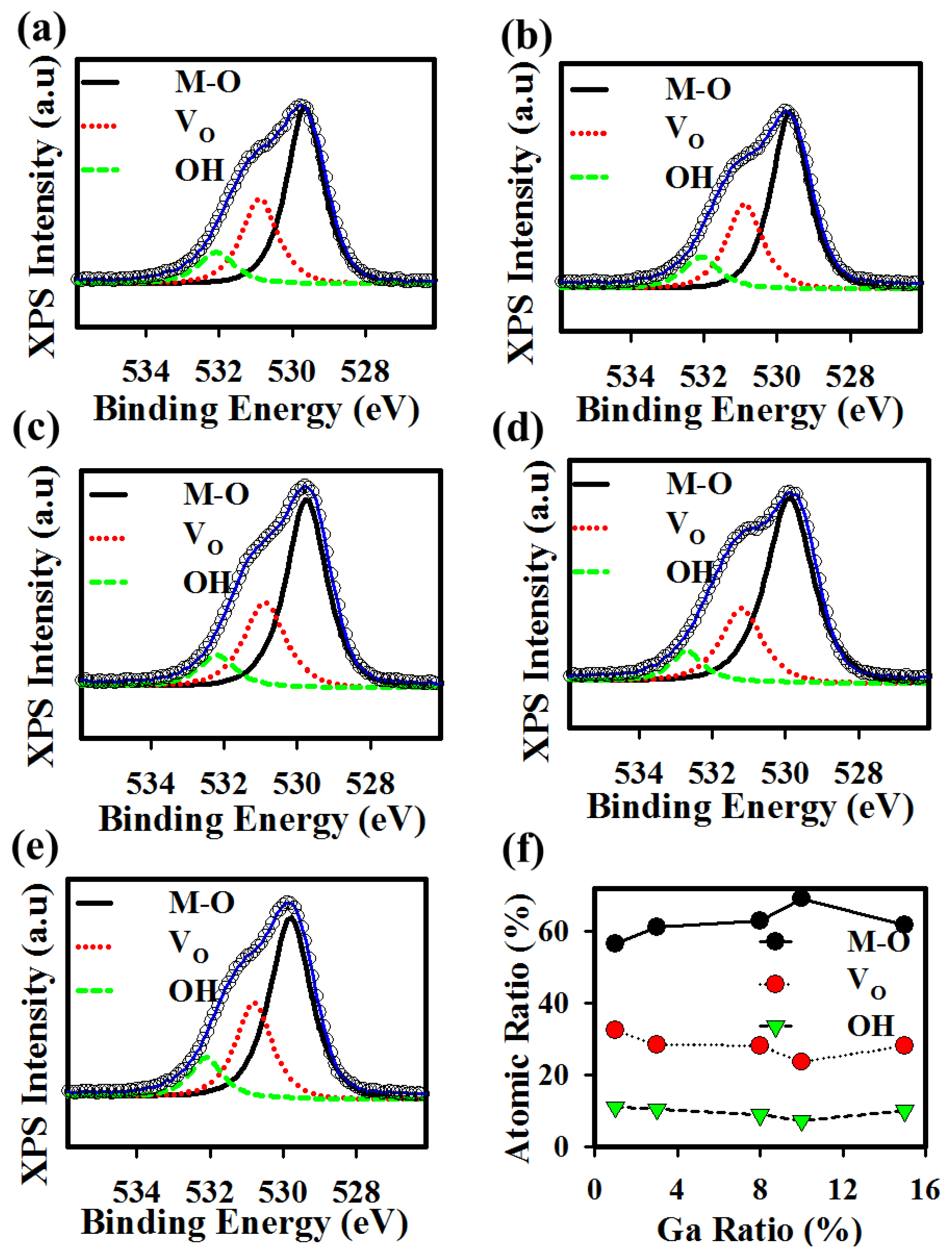

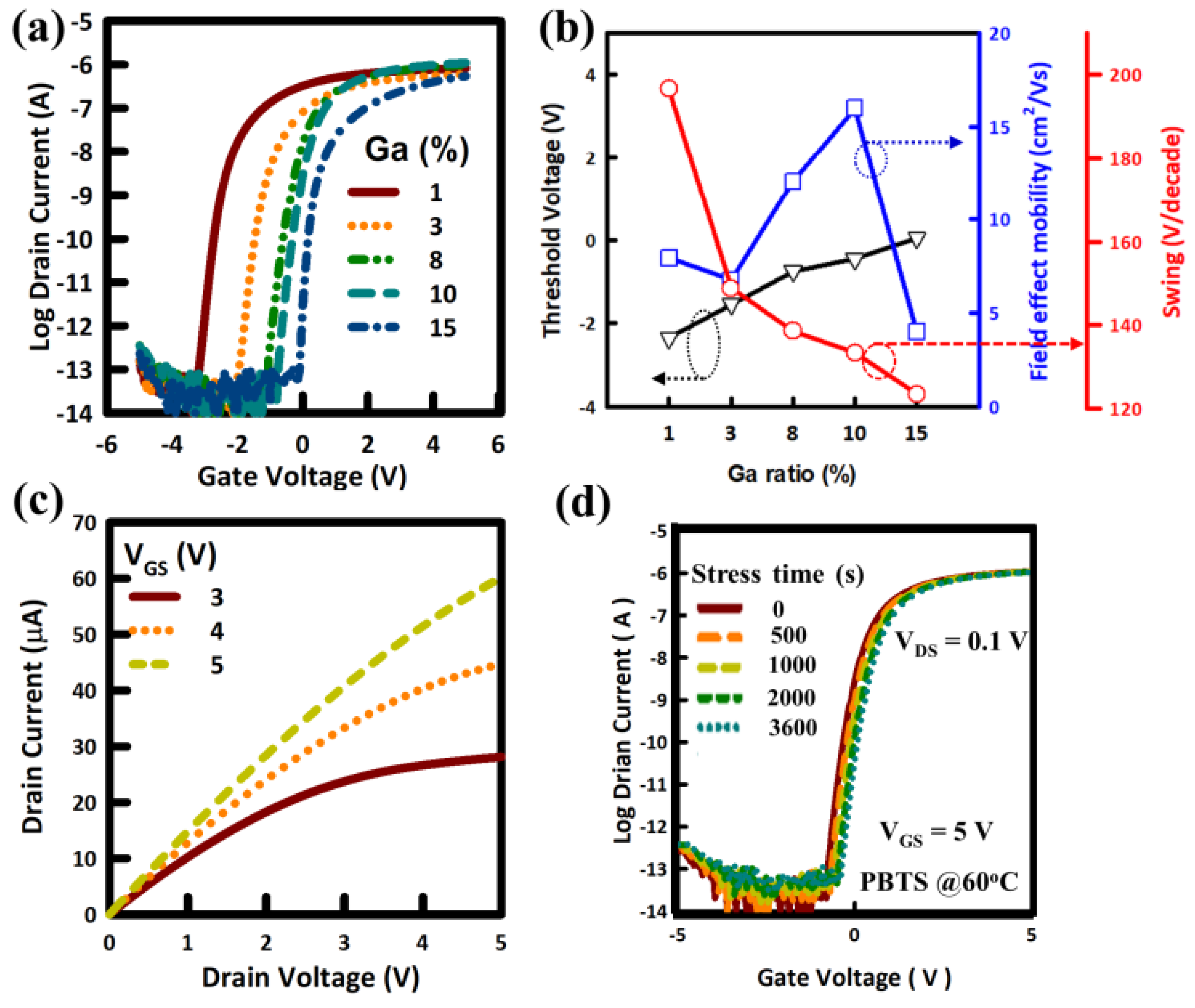

2.1. Results and Discussions

2.2. Materials and Thin-Film Characterization

3. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, L.; Li, J.; Zhang, X.W.; Jiang, X.Y.; Zhang, Z.L. High Performance ZnO-Thin-Film Transistor with Ta2O5 Dielectrics Fabricated at Room Temperature. Appl. Phys. Lett. 2009, 95, 23–26. [Google Scholar] [CrossRef]

- Bukke, R.N.; Saha, J.K.; Mude, N.N.; Kim, Y.; Lee, S.; Jang, J. Lanthanum Doping in Zinc Oxide for Highly Reliable Thin-Film Transistors on Flexible Substrates by Spray Pyrolysis. ACS Appl. Mater. Interfaces 2020, 12, 35164–35174. [Google Scholar] [CrossRef]

- Jeong, H.-J.; Ok, K.-C.; Park, J.; Lim, J.; Cho, J.; Park, J.-S. Stability Improvement of In-Sn-Ga-O Thin-Film Transistors at Low Annealing Temperatures. IEEE Electron Device Lett. 2015, 36, 1160–1162. [Google Scholar] [CrossRef]

- Fan, W.-T.; Liu, P.-T.; Kuo, P.-Y.; Chang, C.-M.; Liu, I.-H.; Kuo, Y. Numerical Analysis of Oxygen-Related Defects in Amorphous In-W-O Nanosheet Thin-Film Transistor. Nanomaterials 2021, 11, 3070. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Gutiérrez, C.A.; Avila-Avendano, C.; Solis-Cisneros, H.I.; Conde, J.; Sevilla-Camacho, P.Y.; Quevedo-López, M.A. Modeling and SPICE Simulation of the CdS/CdTe Neutron Detectors Integrated with Si-Poly TFTs Amplifiers. IEEE Trans. Nucl. Sci. 2022, 69, 1310–1315. [Google Scholar] [CrossRef]

- Shin, S.W.; Cho, J.E.; Lee, H.-M.; Park, J.-S.; Kang, S.J. Photoresponses of InSnGaO and InGaZnO thin-film transistors. RSC Adv. 2016, 6, 83529–83533. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, C.; Qin, H.; Peng, C.; Lu, M.; Chen, Z.; Zhao, Y. Steep Subthreshold Swing and Enhanced Illumination Stability InGaZnO Thin-Film Transistor by Plasma Oxidation on Silicon Nitride Gate Dielectric. Membranes 2021, 11, 902. [Google Scholar] [CrossRef]

- Bukke, R.N.; Avis, C.; Naik, M.N.; Jang, J. Remarkable Increase in Field Effect Mobility of Amorphous IZTO Thin-Film Tran-sistors with Purified ZrOx Gate Insulator. IEEE Electron Device Lett. 2018, 39, 371–374. [Google Scholar] [CrossRef]

- Yeom, H.-I.; Ko, J.B.; Mun, G.; Park, S.-H.K. High mobility polycrystalline indium oxide thin-film transistors by means of plasma-enhanced atomic layer deposition. J. Mater. Chem. C 2016, 4, 6873–6880. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Kim, D.; Lee, S.; Cho, J.; Park, H.; Jang, J. High Field Effect Mobility, Amorphous In-Ga-Sn-O Thin-Film Transistor with No Effect of Negative Bias Illumination Stress. IEEE Electron Device Lett. 2019, 40, 1443–1446. [Google Scholar] [CrossRef]

- Parthiban, S.; Kwon, J.Y. Role of Dopants as a Carrier Suppressor and Strong Oxygen Binder in Amorphous Indi-um-Oxide-Based Field Effect Transistor. J. Mater. Res. 2014, 29, 1585–1596. [Google Scholar] [CrossRef] [Green Version]

- Bukke, R.N.; Mude, N.N.; Islam, M.; Jang, J. Improvement of metal-oxide films by post atmospheric Ar/O2 plasma treatment for thin film transistors with high mobility and excellent stability. Appl. Surf. Sci. 2021, 568, 150947. [Google Scholar] [CrossRef]

- Kim, H.-A.; Kim, J.O.; Hur, J.S.; Son, K.-S.; Lim, J.H.; Cho, J.; Jeong, J.K. Achieving High Mobility in IGTO Thin-Film Transistors at a Low Temperature via Film Densification. IEEE Trans. Electron Devices 2018, 65, 4854–4860. [Google Scholar] [CrossRef]

- Mude, N.N.; Bukke, R.N.; Saha, J.K.; Avis, C.; Jang, J. Highly Stable, Solution-Processed Ga-Doped IZTO Thin Film Transistor by Ar/O2 Plasma Treatment. Adv. Electron. Mater. 2019, 5, 1–9. [Google Scholar] [CrossRef]

- Han, Y.-J.; Lee, S.H.; Bak, S.-Y.; Han, T.-H.; Kim, S.; Yi, M. Performance Improvement of ZnSnO Thin-Film Transistors with Low-Temperature Self-Combustion Reaction. Electronics 2021, 10, 1099. [Google Scholar] [CrossRef]

- Kim, H.; Maeng, S.; Lee, S.; Kim, J. Improved Performance and Operational Stability of Solution-Processed InGaSnO (IGTO) Thin Film Transistors by the Formation of Sn–O Complexes. ACS Appl. Electron. Mater. 2021, 3, 1199–1210. [Google Scholar] [CrossRef]

- Chen, S.; Li, Y.; Lin, Y.; He, P.; Long, T.; Deng, C.; Chen, Z.; Chen, G.; Tao, H.; Lan, L.; et al. Inkjet-Printed Top-Gate Thin-Film Transistors Based on InGaSnO Semiconductor Layer with Improved Etching Resistance. Coatings 2020, 10, 425. [Google Scholar] [CrossRef]

- Li, J.; Huang, C.X.; Zhao, C.Y.; Zhong, D.Y.; Zhang, J.H.; Li, X.F. Feasibility of Atomic Layer Deposited AlZrOx Film to Achieve High Performance and Good Stability of ZnSnO-TFT. IEEE Trans. Electron Devices 2017, 64, 4959–4964. [Google Scholar] [CrossRef]

- Zhu, L.; He, G.; Zhang, C.; Yang, B.; Xia, Y.; Alam, F.; Zhang, Y. Water-Derived All-Oxide Thin-Film Transistors with ZrAlOx Gate Dielectrics and Exploration in Digital Circuits. IEEE Trans. Electron Devices 2019, 66, 4198–4204. [Google Scholar] [CrossRef]

- Liu, W.-S.; Hsu, C.-H.; Jiang, Y.; Lai, Y.-C.; Kuo, H.-C. Improving Device Characteristics of Dual-Gate IGZO Thin-Film Transistors with Ar–O2 Mixed Plasma Treatment and Rapid Thermal Annealing. Membranes 2022, 12, 49. [Google Scholar] [CrossRef]

- Girtan, M.; Hrostea, L.; Boclinca, M.; Negulescu, B. Study of oxide/metal/oxide thin films for transparent electronics and solar cells applications by spectroscopic ellipsometry. AIMS Mater. Sci. 2017, 4, 594–613. [Google Scholar] [CrossRef]

- Saha, J.K.; Bukke, R.N.; Jang, J. Extremely Stable, High Performance Gd and Li Alloyed ZnO Thin Film Transistor by Spray Pyrolysis. Adv. Electron. Mater. 2020, 6, 1–11. [Google Scholar] [CrossRef]

- Bukke, R.N.; Jang, J. Gel-based precursors for the high-performance of n-channel GaInSnZnO and p-channel CuGaSnSO thin-film transistors. RSC Adv. 2021, 11, 34392–34401. [Google Scholar] [CrossRef] [PubMed]

- Bahubalindruni, P.G.; Martins, J.; Santa, A.; Tavares, V.; Martins, R.; Fortunato, E.; Barquinha, P. High-Gain Transimpedance Amplifier for Flexible Radiation Dosimetry Using InGaZnO TFTs. IEEE J. Electron Devices Soc. 2018, 6, 760–765. [Google Scholar] [CrossRef]

- Kim, D.H.; Cha, H.S.; Jeong, H.S.; Hwang, S.H.; Kwon, H.I. Effects of Active Layer Thickness on the Electrical Characteristics and Stability of High-Mobility Amorphous Indium–Gallium–Tin Oxide Thin-Film Transistors. Electronics 2021, 10, 1295. [Google Scholar] [CrossRef]

- Bukke, R.N.; Mude, N.N.; Bae, J.; Jang, J. Nano-Scale Ga O Interface Engineering for High-Performance of ZnO-Based Thin-Film Transistors. ACS Appl. Mater. Interfaces 2022, 14, 41508–41519. [Google Scholar] [CrossRef]

- Hernández-Gutiérrez, C.A.; Kudriavtsev, Y.; Cardona, D.; Hernández, A.G.; Camas-Anzueto, J.L. Optical, electrical, and chemical characterization of nanostructured InxGa1-xN formed by high fluence In+ ion implantation into GaN. Opt. Mater. 2021, 111, 110541. [Google Scholar] [CrossRef]

| Active/GI | TFT W/L [μm] | Mobility [cm2 V−1 s−1] | SS [mV dec−1] | Stability (ΔVTH, [V]) | Ref. |

|---|---|---|---|---|---|

| (a)IGTO/(a)AlOx | 200/10 | 3.00 | 210 | PBS (0.90) | [17] |

| (b)IGTO/(c)SiO2 | 1000/50 | 2.13 | 2440 | PBS (2.10) | [18] |

| (d)ZTO/(e)ZAO | 1000/100 | 12.50 | 150 | PBS (2.90) | [19] |

| (b)In2O3/(b)ZAO | 1000/100 | 10.14 | 100 | PBS (0.47) | [20] |

| (f)ZnO/(b)ZrOx | 50/10 | 12.76 | 260 | PBS (0.0) | [21] |

| (f)IGTO/(f)ZAO | 50/10 | 16.00 | 133 | PBTS (0.40) | This Work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, Y.; Bukke, R.N.; Kim, Y.; Ahn, K.; Bae, J.; Jang, J. High-Performance Amorphous InGaSnO Thin-Film Transistor with ZrAlOx Gate Insulator by Spray Pyrolysis. Electronics 2023, 12, 688. https://doi.org/10.3390/electronics12030688

Chang Y, Bukke RN, Kim Y, Ahn K, Bae J, Jang J. High-Performance Amorphous InGaSnO Thin-Film Transistor with ZrAlOx Gate Insulator by Spray Pyrolysis. Electronics. 2023; 12(3):688. https://doi.org/10.3390/electronics12030688

Chicago/Turabian StyleChang, Yeoungjin, Ravindra Naik Bukke, Youngoo Kim, Kiwan Ahn, Jinbaek Bae, and Jin Jang. 2023. "High-Performance Amorphous InGaSnO Thin-Film Transistor with ZrAlOx Gate Insulator by Spray Pyrolysis" Electronics 12, no. 3: 688. https://doi.org/10.3390/electronics12030688

APA StyleChang, Y., Bukke, R. N., Kim, Y., Ahn, K., Bae, J., & Jang, J. (2023). High-Performance Amorphous InGaSnO Thin-Film Transistor with ZrAlOx Gate Insulator by Spray Pyrolysis. Electronics, 12(3), 688. https://doi.org/10.3390/electronics12030688