1. Introduction

Rolling bearings are key components in rotating machinery. According to statistics, more than 30% of rotating machinery failures are the result of bearing failure [

1]. Therefore, detecting the bearing operating condition in real time is crucial for the reduction of potential mechanical accidents and economic losses brought about by bearing failure, while ensuring the safe running of machinery.

Existing fault diagnosis methods for rolling bearings can be broadly divided into two categories: model-driven and data-driven. Prior to the 1980s, rolling bearing fault diagnosis was implemented using knowledge models [

2]. The common processing method involves the determination of the bearing fault type by combining multiple statistical indicators or the conversion of the time domain signal of the bearing into a frequency domain signal in order to determine the spectral value, such as with the fast Fourier transform, wavelet transform, etc. However, the Fourier transform is a whole transformation, which lacks the time domain localization, and the wavelet transform requires large computations, making it difficult to realize real-time processing.

With the rapid growth of computing power in recent years, the development of data-driven fault diagnosis methods has also been promoted [

3,

4]. Data-driven methods construct a nonlinear mapping from the fault dimension to the feature dimension by learning large amounts of bearing data with known faults, without relying on additional prior knowledge and expert experience. In most cases, the verification of some machine learning methods, such as random forest [

5], support vector machines (SVM) [

6], and principal component analysis (PCA) [

7], is facilitated by the possibility to feed enough machine status data to the learning system in order for it to learn the characteristics of the data. However, these shallow neural networks are not effective in learning complex nonlinear mapping relations due to their limited learning capabilities. Deep learning (DL), which automatically learns the hierarchical features and correlations between data [

8,

9], has been widely used in various fields. Currently, DL is widely used in fault diagnosis due to its powerful feature learning capability [

10,

11]. Numerous deep learning methods, such as generative adversarial network (GAN) [

12], convolutional neural network (CNN) [

13,

14], and recurrent neural network (RNN) [

15], have been applied in fault diagnosis, with CNNs being the most widely used. Wang et al. proposed a multiscale CNN with a joint one-dimensional (1D) and two-dimensional (2D) feature extraction function that can distinguish correlations between adjacent and non-adjacent intervals in periodic signals [

16]. Xu et al. used CNN to extract features from the components of the variable mode decomposition (VMD) method for bearing fault diagnosis [

17]. Yang et al. performed bearing fault diagnosis by preprocessing the original signal with three different data processing methods and fusing the outputs of four CNNs with the use of a fuzzy fusion strategy [

18]. Cheng et al. proposed a method that used local binary convolutional layers instead of traditional convolutional layers and combined it with the continuous wavelet transform (CWT), which could effectively diagnose both bearing and gearbox compound faults [

19]. Fang et al. proposed a lightweight model for rotating machinery diagnosis based on dynamic convolution and separable convolution strategies [

20]. Ji et al. proposed an order-tracking method using 1DCNN in two steps for the fault diagnosis of variable condition signals [

21]. Gao et al. proposed the use of hierarchically trained CNNs to overcome the problem of unbalanced data distribution during fault diagnosis [

22]. Therefore, it is evident that PC-based CNNs have been widely applied in fault diagnosis. For this paper, the classical CNN network AlexNet has been selected to extract the bearing features and identify the bearing states.

With the rapid development of the internet and the internet of things, mechanical devices in industrial sites are continuously generating high-speed real-time data at an unprecedented rate, such as temperature, humidity, audio, video, etc. [

23,

24]. Data volume is gradually increasing, data types are more diverse, and data structures are increasingly more complex. Meanwhile, fault diagnosis for rotating machinery involves the following limitations. First, the scale of the data is too huge to upload to the server and be analyzed. Second, the data often have low information density. As the mechanical equipment usually works in normal conditions, the data generated have a great deal of redundancy, which makes it necessary to extract useful information from the data. Third, the timeliness of the data is extremely important. Whether it is a small machine for industrial production or an aircraft engine, both are tightly constructed machines, and the failure of a component (such as bearings) will quickly result in huge economic losses. Therefore, it is essential to analyze and process the data as soon as possible in order to provide an efficient diagnosis and a timely warning. Edge computing can analyze the real-time data directly on the edge side, thus avoiding data congestion and a delay in diagnosis caused by the uploading of data to the server [

25,

26]. For bearing fault diagnosis, IFD models deployed in embedded systems to identify the bearing status on the edge side not only reduce the network bandwidth pressure and energy consumption caused by the uploading of data to the server, but they also guarantee the timeliness of the data. They can help detect the abnormal status of a bearing in real time and prevent the loss of life and property caused by the fault.

So far, IFD technologies, based on signal analysis and machine learning, have achieved remarkable success in the field of condition monitoring of mechanical equipment [

27,

28,

29]. However, most of the research has been conducted on a PC, and it is difficult to deploy and execute IFD models in embedded systems due to their computational power, running memory, and storage capacity [

30]. Lu et al. implemented the inference and result display of the fault diagnosis algorithm using a stochastic resonance-based adaptive filter with two STM32F4 series MCUs [

31]. Lu et al. used two microcontroller units to synchronously collect the phase information and vibration signals of motor bearings in order to implement online fault diagnosis based on order analysis in embedded systems [

32]. Pham et al. built a CNN-based MobileNet-v2 model and transplanted it to Raspberry Pi 3 to carry out the fault classification of bearings [

33]. Chen et al. proposed a lightweight fault diagnosis system that employed the random forest algorithm and Hilbert transform on the Xilinx PYNQ-Z2 development board [

34]. Park et al. proposed LiReD, a lightweight, single-board, computer-based, real-time fault detection system, which consisted of two parts: a front-end for real-time monitoring based on Raspberry Pi 3 and a back-end for the training of LSTM-based networks [

35]. Most current approaches to deploying IFD models in embedded systems are based on high-performance microcontrollers, such as Raspberry Pi, which usually support machine learning languages, such as Python, thus facilitating the deployment of IFD models in microcontrollers, However, the convenience also comes with increased cost and limited applicability. Thus, deploying the IFD model on a more general and low-cost platform is a way to make edge IFD more widely applicable.

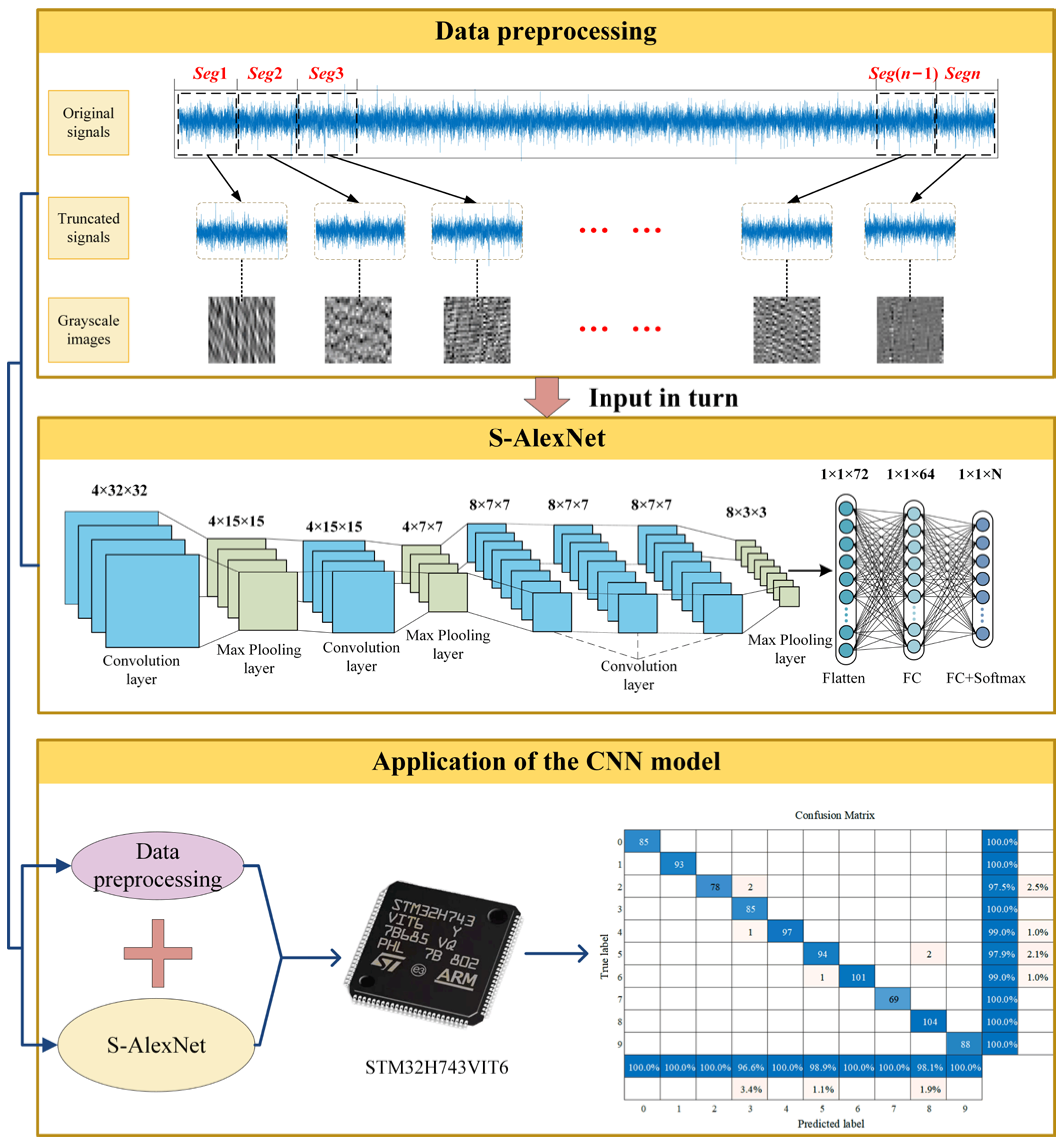

An edge intelligence diagnosis method for bearing faults, called S-AlexNet, which is based on a parameter transplantation CNN, is proposed in this paper [

36]. This work aims to deploy IFD models in low-cost MCUs in order to implement the monitoring and fault diagnosis of bearing status on the edge side. This method allows for onsite and real-time monitoring and identification of the bearing status by analyzing the obtained bearing vibration signals on the edge. Unlike traditional PC-based CNN [

37] fault diagnosis methods, this paper uses intelligent fault diagnosis algorithms deployed in embedded systems to achieve real-time bearing monitoring [

38]. By being close to the edge, the embedded system can greatly reduce the transfer pressure and cloud computing power consumption for data uploads to the cloud, while improving the real-time diagnostic performance. This method is highly applicable in electromechanical equipment fault diagnosis, particularly where it is inconvenient to transfer data to servers or where a real-time diagnosis is required.

The main technical contributions of this work are summarized as follows.

A lightweight CNN model, called S-AlexNet, which is easier to deploy in embedded systems, is proposed in this paper.

The S-AlexNet-based IFD model is deployed in embedded systems to identify the operating state of bearings on the edge side.

In the proposed method, model deployment does not require hardware to support artificial intelligence languages, such as Python, which greatly reduces the hardware cost and expands the application of the proposed method.

The rest of the paper is organized as follows:

Section 2 presents the embedded system-based CNN model.

Section 3 outlines the parameter training and transplantation methods for the embedded neural network models.

Section 4 validates the effectiveness of the proposed method through experimental data. Finally, our conclusions are summarized in

Section 5.

5. Conclusions and Future Research

An edge intelligent diagnosis method for bearing faults based on a parameter transplantation CNN was proposed in this paper. A model that fits the small and efficient character of embedded systems was designed and deployed in an embedded system to monitor the bearing status in real time. The method converted the raw vibration signals into grayscale images as model input, which was used directly for the bearing fault diagnosis on the edge side. The model was validated using the CWRU motor bearing dataset with an identification accuracy of 94.40%, and the dataset was collected using our self-built experimental bed with a 99.84% identification accuracy. The comparison of the results with those of published papers demonstrated that the proposed method has the advantages of good real-time performance, high accuracy, portability, and low cost, which compensate for the lack of current PC-based intelligent fault diagnosis methods and provides simple and effective solution for implementing bearing IFD on the edge side. Therefore, the proposed method has the potential for application in industrial production.

The limitations of this method in practical application are the following. Firstly, the types of faults are common ones, and, if a new fault appears, it will be misclassified as a known fault type. Secondly, it is necessary to collect sufficient tagged data each time a new model is acquired, which can be expensive in practical engineering. Further research could be conducted in the following areas based on these limitations. First, the mechanistic study of a fault should continue in order to find the unknown fault. Second, research on migration learning theory can be conducted to reduce the amount of data that need to be collected in order to train the model and reduce costs.