Inverse Dynamics Modeling and Simulation Analysis of Multi-Flexible-Body Spatial Parallel Manipulators

Abstract

:1. Introduction

- (1)

- Unlike previous models, this model considers the effect of the elastic deformation of flexible links and joints on the system stability and trajectory accuracy. An accurate dynamic model is established based on the floating coordinate system method. The model includes the rigid-flexible coupling effect and the coupling between the flexible link and the flexible joint.

- (2)

- The rotation axis of the flexible link differs from other components. Therefore, the flexible link is a spatial link, having both translational and rotational energies. Simultaneously, the mass matrix is asymmetric, and the stiffness matrix is no longer constant.

- (3)

- According to the numerical model of the multi-flexible robot system, a simulation model is established using ADAMS software. The correctness of the simulation model is ensured by using the finite element method to discretize the flexible components to retain higher-order modal information of the model. Moreover, the first six modal information is retained during discretization. Simultaneously, the dynamic model of the end-effector with small displacement due to elastic deformation is established through boundary conditions and coordination matrix.

- (4)

- The dynamic system of multi-flexible-body robots is a highly nonlinear, strongly coupled, and high-dimensional model. Therefore, the established dynamic equation is a super-determined higher-order equation. The exact solution of the dynamic model is obtained by converting the dynamic equations into a set of differential equations to avoid the singularity of the Jacobian matrix and modify it through the Baumgarte stabilization method to obtain its numerical solution while improving its efficiency.

2. Multi-Flexible-Body Robots

3. Dynamic Analysis of Multi-Flexible-Body Spatial Parallel Manipulators

3.1. Dynamic Modeling of Flexible Joints

- (1)

- Using a flexible joint as an elastic constraint of a flexible link.

- (2)

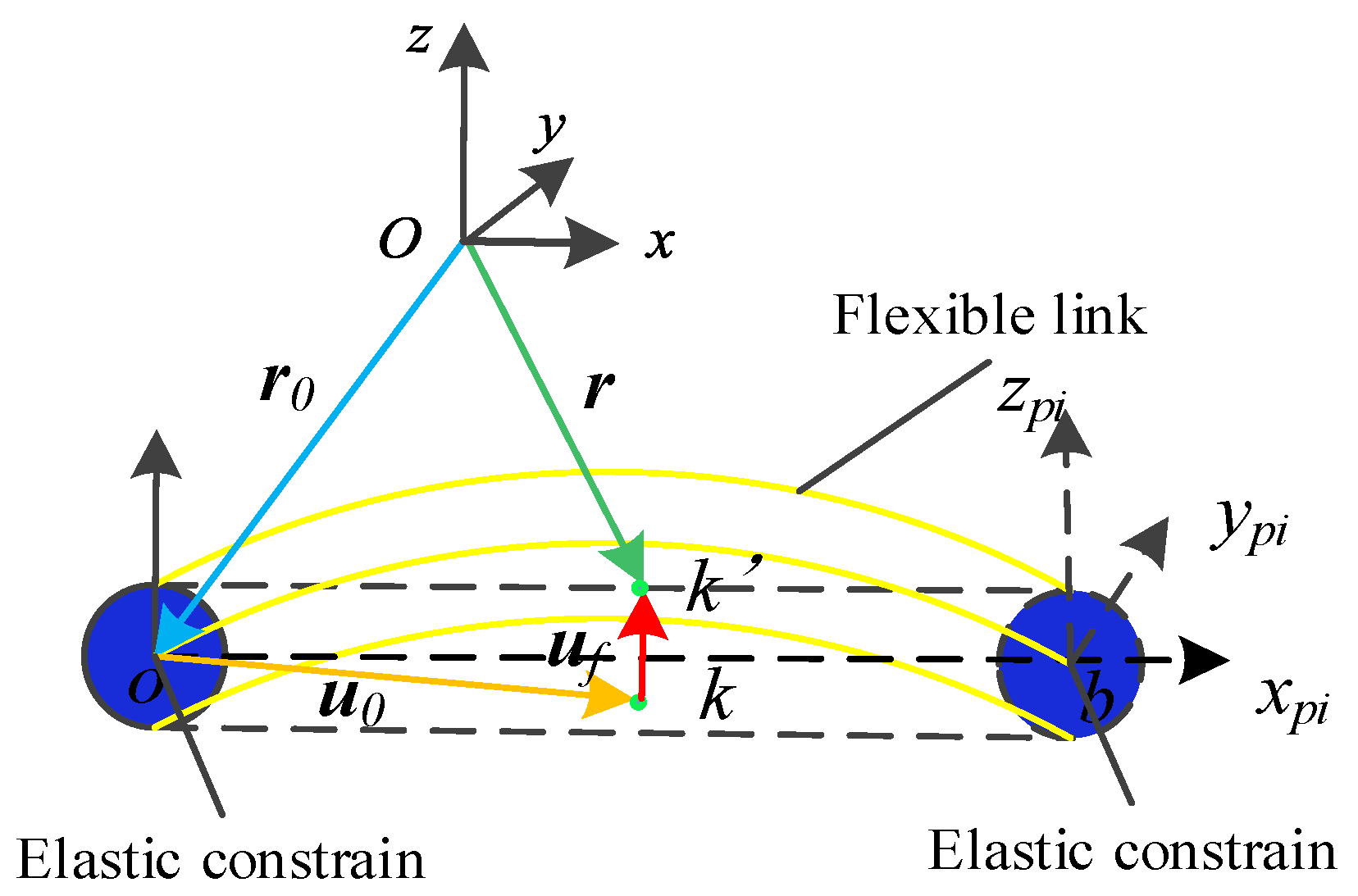

- The flexible link and joint system are simplified as multi-flexible-body systems of two flexible components and a simply supported beam with unilateral elastic constraints.

- (3)

- The connection between the flexible joint and the rigid link adopts a rigid constraint connection.

- (4)

- The axis of the flexible joint is coaxial with the rotational axis of the connecting link.

3.2. Dynamic Modeling of Flexible Link

3.3. Dynamic Modeling of Rigid Links

3.4. Dynamic Modeling of Multiple Flexible Kinematic Chains

3.5. Multi-Flexible-Body Robot System

3.6. Algorithm of Multi-Flexible-Body Robot System

4. Inverse Dynamics Simulation Model of Multi-Flexible-Body Robots

4.1. Rigid Simulation Model Validation

- Use the point drive motion in the ADAMS/Force module to load the motion trajectory given by Equation (23) to the geometric center of the end-effector. A running time of 5 s and a step size of 0.005 s was set for the simulation. By using inverse dynamics simulation, the variation relationship of each driving torque of the kinematic with time could be obtained, as shown in Figure 6.

4.2. Verification of Multi-Flexible-Body Simulation Model

5. Simulation Analysis

5.1. Positive Dynamics Analysis of the Multi-Flexible-Body Robot

5.2. Inverse Dynamics Analysis of Multi-Flexible-Body Robots

6. Conclusions

- (1)

- In this paper, a multi-flexible-body spatial parallel robot was numerically simulated through a co-simulation between ADAMS and SOLIDWORKS. The correctness of the derived dynamic equations and the effectiveness of the simulation mode were verified. The simulation results were consistent with the actual working conditions.

- (2)

- The elastic deformation of flexible joints and links in the motion process considerably affects the motion trajectory of the system’s end-effector. Therefore, the flexibility of the links and joints cannot be ignored when establishing an accurate dynamic model for a multi-flexible-body spatial parallel robot.

- (3)

- During the system operation, the coupling effect between the flexible joint and rigid link and between the flexible joint and flexible link is complex. Therefore, the effect of the higher-order mode on the motion trajectory of the system should be considered.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fang, W.Y.; Guo, X.; Liang, L.; Zhang, D. Dynamics, simulation, and control of robots with flexible joints and flexible links. Chin. J. Theor. Appl. Mech. 2020, 54, 965–974. (In Chinese) [Google Scholar]

- Zhang, F.L.; Yuan, Z.H. Flexible space robot modeling and characteristic analysis based on Recursive Gibbs-Appell. J. Aerosp. Power 2020, 1–16. [Google Scholar] [CrossRef]

- Zhang, Q.; Mills, J.K.; Cleghorn, W.L.; Jin, J.; Zhao, C. Trajectory and vibration suppression of a 3-PRR parallel manipulator with flexible links. Multibody Syst. Dyn. 2015, 33, 27–60. [Google Scholar] [CrossRef]

- Ssyahkarajy, M.; Mohamed, Z.; Mohd Faudzi, A.A. Review of modelling and control of flexible-link manipulators. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2016, 230, 861–873. [Google Scholar] [CrossRef]

- Virgili-Llop, J.; Drew, J.V.; Zappulla II, R.; Romano, M. Laboratory experiments of resident space object capture by a spacecraft- manipulator system. Aerosp. Sci. Technol. 2017, 71, 530–545. [Google Scholar] [CrossRef]

- Korayem, M.H.; Dehkordi, S.F.; Mehrjooee, O. Nonlinear analysis of open-chain flexible manipulator with time- dependent structure. Adv. Space Res. 2022, 69, 1027–1049. [Google Scholar] [CrossRef]

- Gouliaev, V.I.; Zavrazhina, T.V. Dynamics of a flexible multi-link cosmic robot- manipulator. J. Sound Vib. 2001, 243, 641–657. [Google Scholar] [CrossRef]

- Shafei, A.; Shafei, H. Oblique impact of multi- flexible- link systems. J. Vib. Control 2016, 2, 25–34. [Google Scholar] [CrossRef]

- Hu, J.F.; Zhang, X.M.; Zhu, D.C.; Chen, Q. Dynamic modeling of flexible parallel robot. Trans. Chin. Soc. Agric. Mach. 2011, 42, 208–213. [Google Scholar]

- Li, L.; Liu, Z.Y.; Hong, J.Z. Model reduction of rigid-flexible coupling dynamics of hub-beam system. J. Econ. Dyn. Control 2015, 13, 6–10. [Google Scholar]

- Meng, D.; She, Y.; Xu, W.; Lu, W.; Liang, B. Dynamic modeling and vibration characteristics analysis of flexible-link and flexible-joint space manipulator. Multibody Syst. Dyn. 2018, 43, 321–347. [Google Scholar] [CrossRef]

- Fu, X.; Chen, L. Output feedback finite-dimensional repetitive learning control on virtual force link and flexible-joint space robot. Chin. J. Space Sci. 2021, 41, 819–827. (In Chinese) [Google Scholar]

- Zhang, X.Y.; Liu, X.F.; Cai, G.P.; Liu, C.K. Dynamic modeling of a flexible-link flexible-joint manipulator. J. Econ. Dyn. Control 2022, 20, 25–39. [Google Scholar]

- Kunming, Z.; Youmin, H.; Wenyong, Y. A novel parallel recursive dynamic modelling method for robot with flexible bar-groups. Appl. Math. Model 2020, 77, 267–288. [Google Scholar]

- Wang, J. Modified models for revolute joints coupling flexibility of links in multibody systems. Multibody Syst. Dyn. 2019, 45, 37–55. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhao, X.; Liu, L.; Dai, T. Dynamics analysis of spatial parallel robot with rigid and flexible links. Math. Biosci. Eng. 2020, 17, 7101–7129. [Google Scholar] [CrossRef] [PubMed]

- Spong, M.W. Modeling and control of elastic joint robots. J. Dyn. Syst. Meas. Control 1987, 109, 310–319. [Google Scholar] [CrossRef]

- Zhang, Q.Y.; Zhao, X.H.; Liu, L.; Dai, T.D. Adaptive sliding mode neural network control and flexible vibration suppression of a flexible spatial parallel robot. Electronics 2021, 10, 212. [Google Scholar] [CrossRef]

- Huang, Z.; Kong, L.F.; Fang, Y.F. Mechanism Theory and Control of Parallel Robot; Machinery Industry Press: Beijing, China, 1997. [Google Scholar]

- Zhang, Q.Y. Research on Nonlinear Mathematical Modeling and Intelligent Control Algorithm of Flexible Spatial Closed—Chain Robot; Tianjin University of Technology: Tianjin, China, 2021. [Google Scholar]

| Parameter | Mass/kg | Length/m | Density(kg/m3) | Poisson’s Ration | Elastic Modulus/(Pa) |

|---|---|---|---|---|---|

| Driving link | 2 | 0.4 | 7801 | 0.29 | 2.07 × 1011 |

| Intermediate link | 0.3 | 0.1 | 7801 | 0.29 | 2.07 × 1011 |

| Flexible link | 1.5 | 0.8 | 2740 | 0.33 | 2.07 × 1011 |

| End-effector | 2.6 | 0 | 7801 | 0.29 | 2.07 × 1011 |

| Flexible joint | 0.07 | 0.04 | 2740 | 0.33 | 2.07 × 1011 |

| Kinematic Pair | Component |

|---|---|

| Rotating pair | Driving link, fixed platform |

| Rotating pair | Intermediate link, driving link |

| Rotating pair | Driven link, intermediate link |

| Hook hinge | Moving platform, driven link |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Zhao, X. Inverse Dynamics Modeling and Simulation Analysis of Multi-Flexible-Body Spatial Parallel Manipulators. Electronics 2023, 12, 2038. https://doi.org/10.3390/electronics12092038

Zhang Q, Zhao X. Inverse Dynamics Modeling and Simulation Analysis of Multi-Flexible-Body Spatial Parallel Manipulators. Electronics. 2023; 12(9):2038. https://doi.org/10.3390/electronics12092038

Chicago/Turabian StyleZhang, Qingyun, and Xinhua Zhao. 2023. "Inverse Dynamics Modeling and Simulation Analysis of Multi-Flexible-Body Spatial Parallel Manipulators" Electronics 12, no. 9: 2038. https://doi.org/10.3390/electronics12092038