Unveiling the Sub-10 GHz Performance of SMA Connectors: A Comparative Analysis

Abstract

:1. Introduction

1.1. Similar Works

1.2. Motivation and Relevance

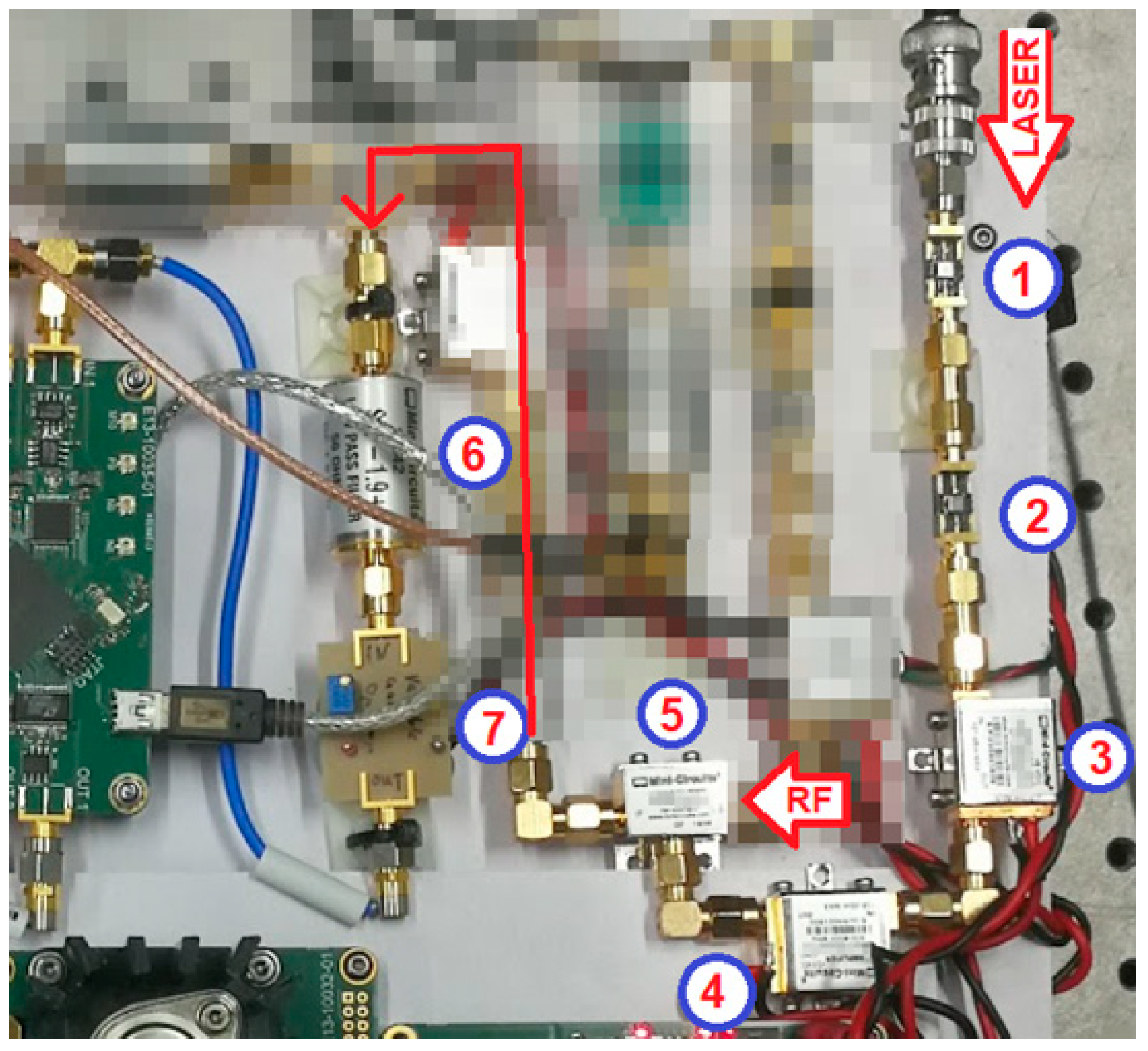

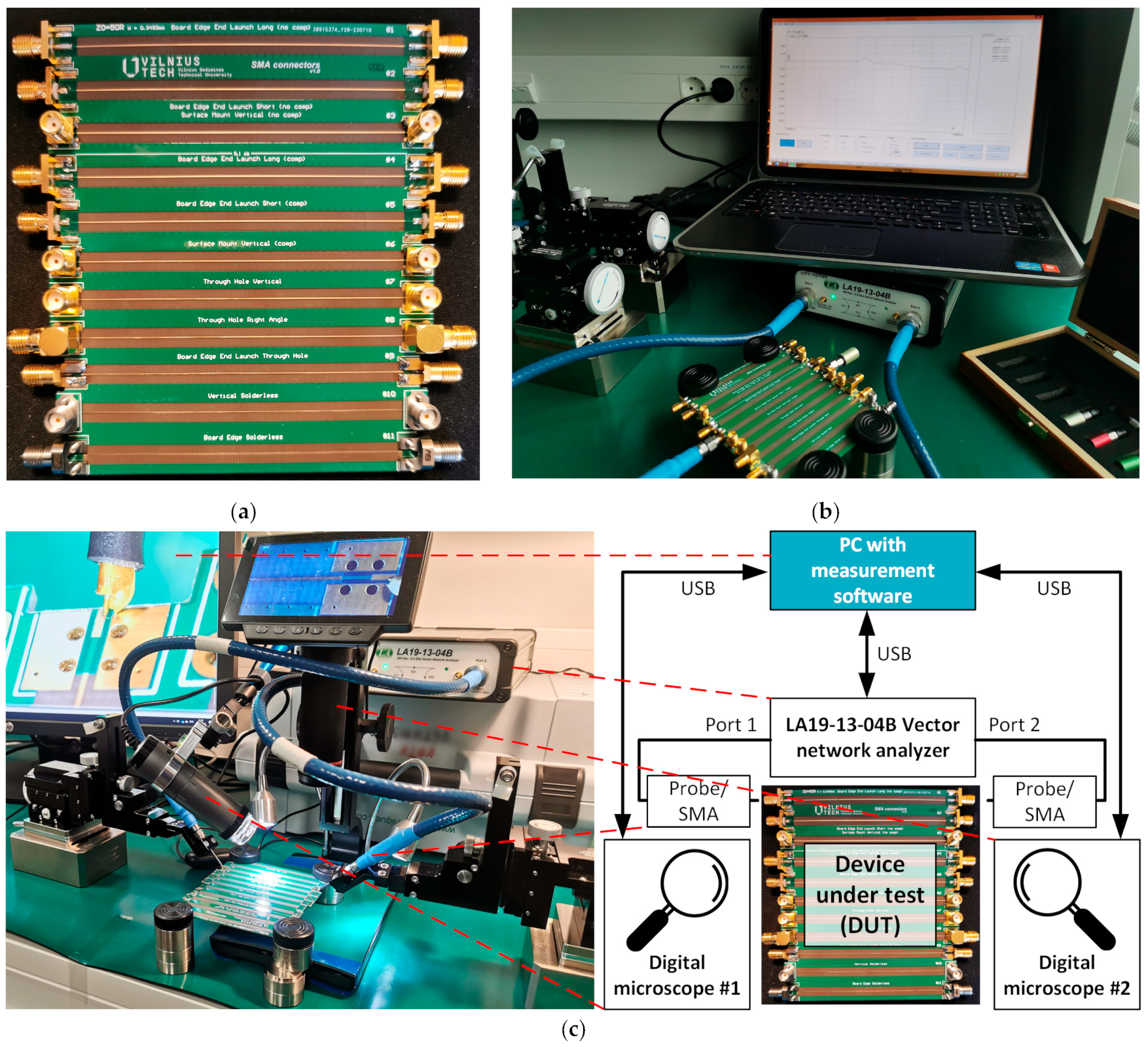

2. Measurement Set-Up

3. Measurement Results and Discussion

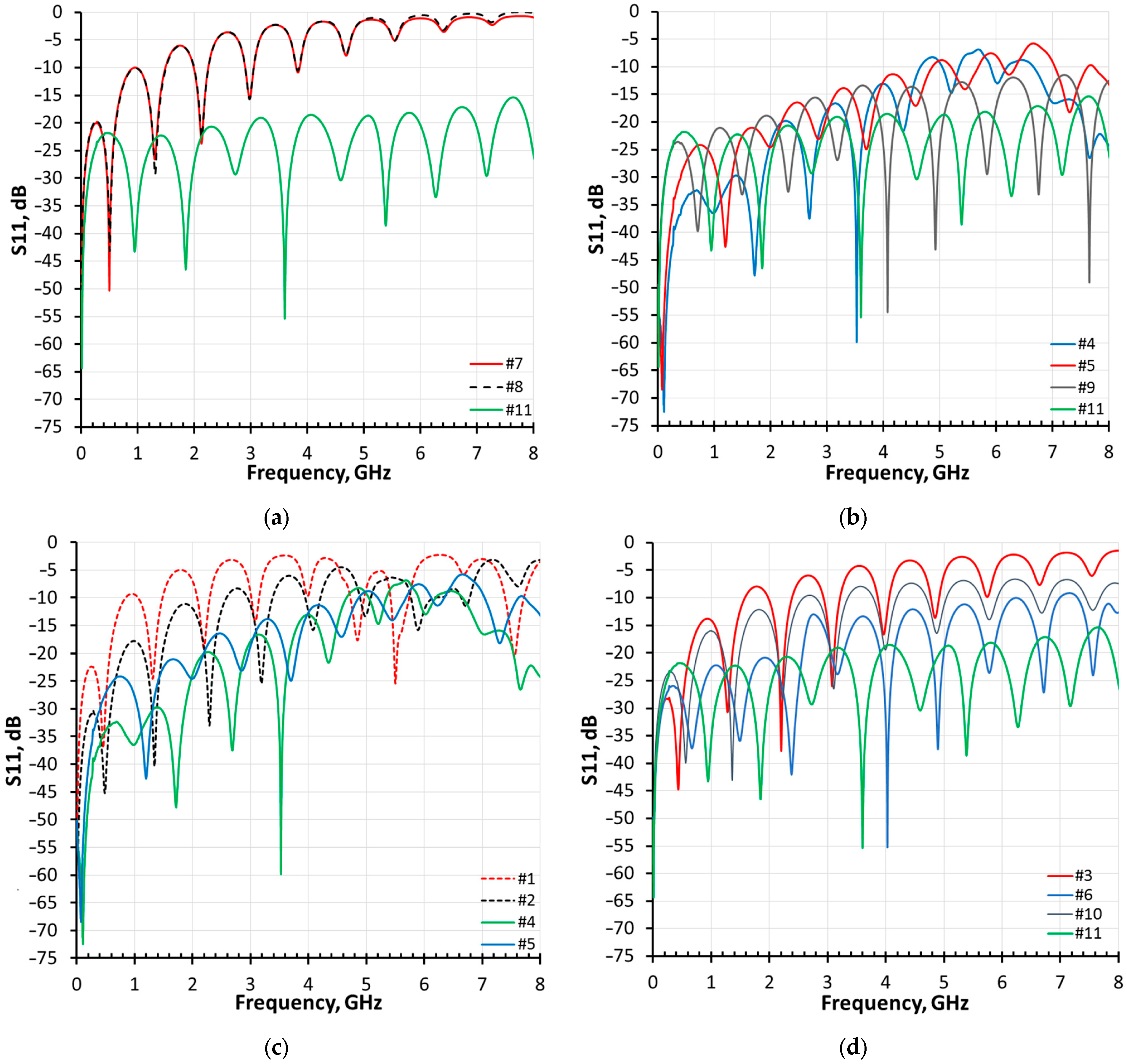

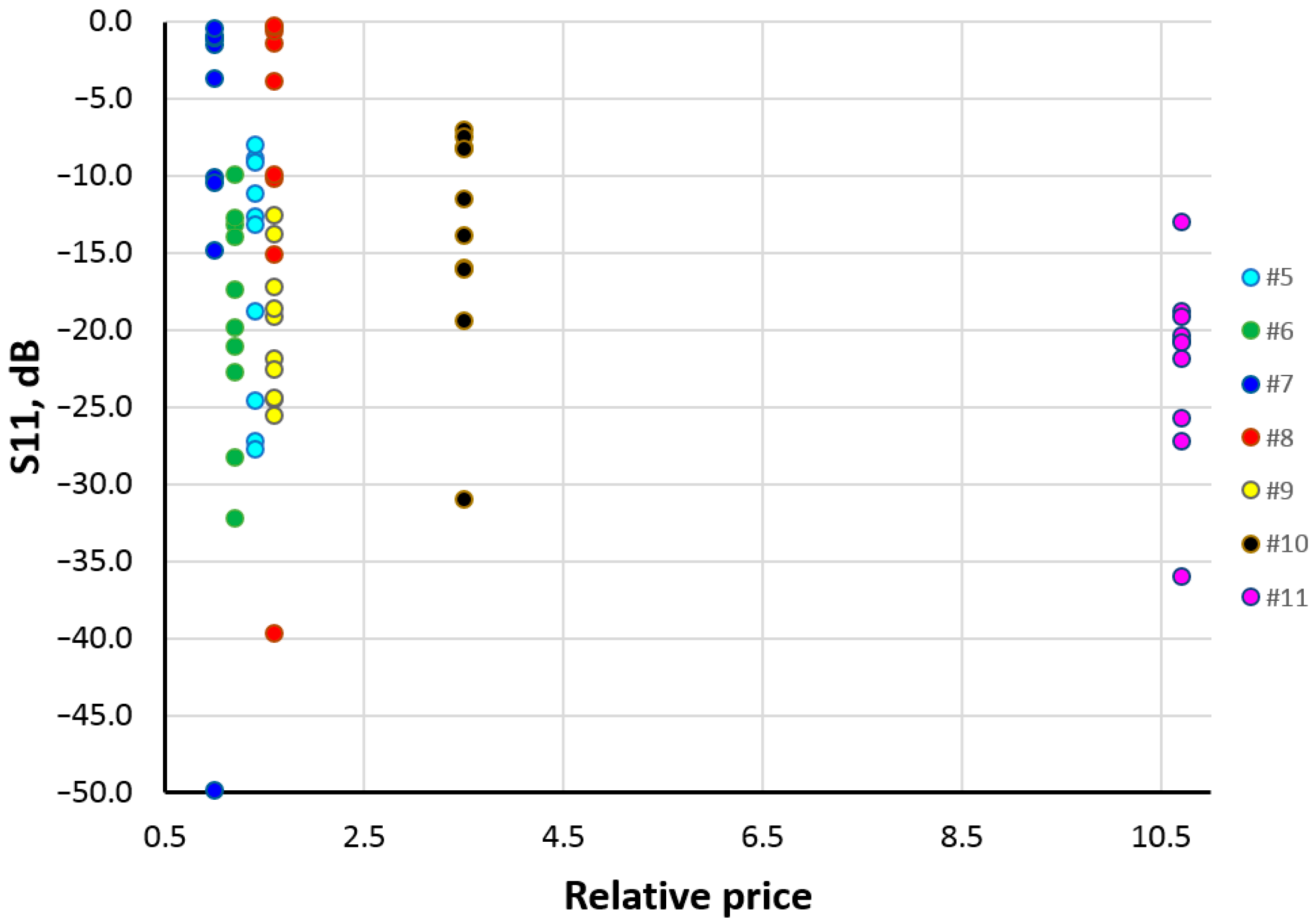

3.1. Measurement Result Analysis

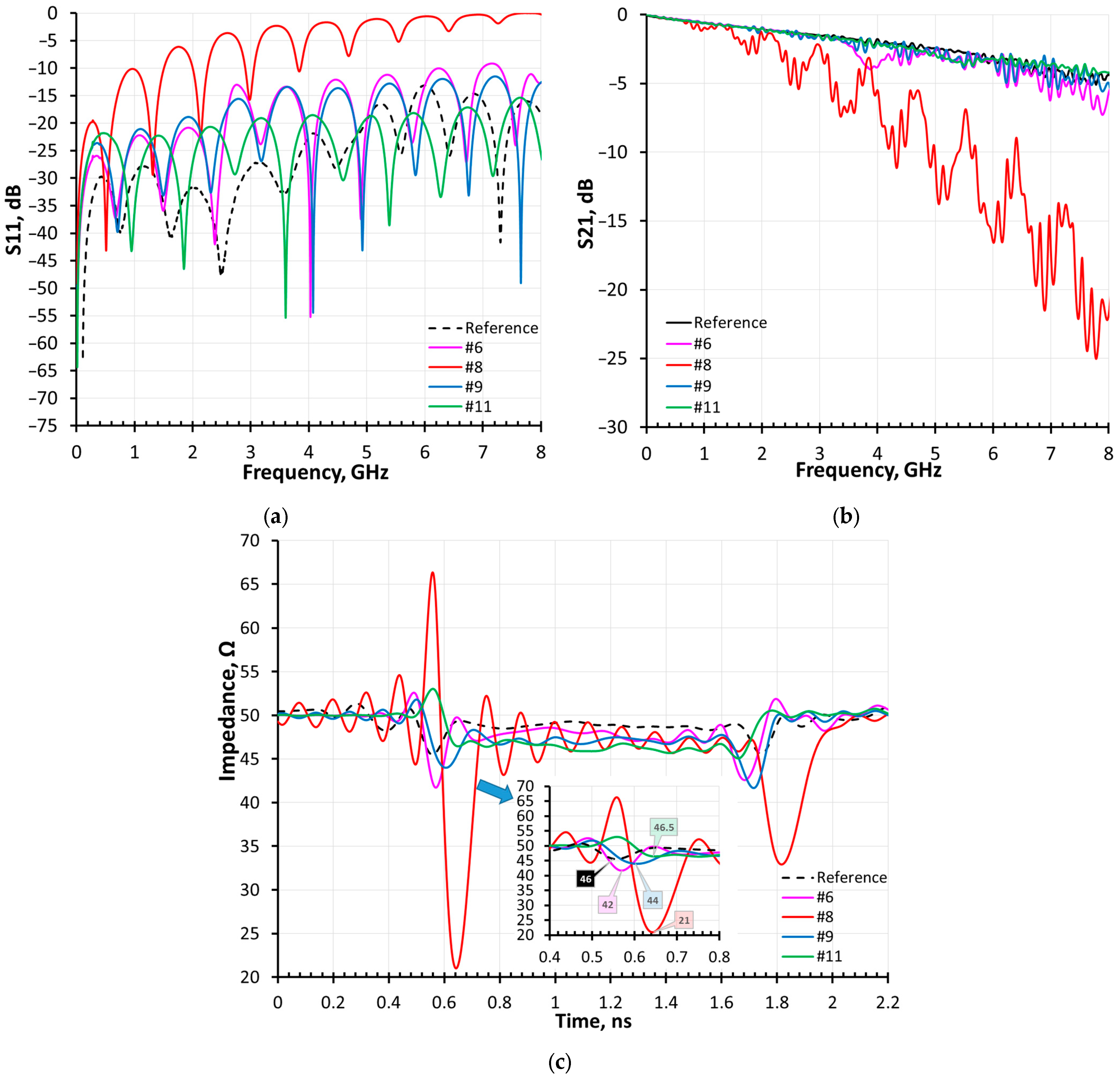

3.2. Linking Measurement Results with Connector Mechanics

3.3. Most Prominent SMA Connector Types

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Chettri, L.; Bera, R. A Comprehensive Survey on Internet of Things (IoT) Toward 5G wireless systems. IEEE Internet Things J. 2020, 7, 16–32. [Google Scholar] [CrossRef]

- Biswas, S.; Sanyal, A.; Božanić, D.; Puška, A.; Marinković, D. Critical Success Factors for 5G Technology Adaptation in Supply chains. Sustainability 2023, 15, 5539. [Google Scholar] [CrossRef]

- Paleček, J.; Vestenický, M.; Vestenický, P.; Spalek, J. Examination of SMA connector parameters. In Proceedings of the 2012 IEEE 16th International Conference on Intelligent Engineering Systems (INES), Lisbon, Portugal, 13–15 June 2012; pp. 259–263. [Google Scholar]

- Mandic, T.; Magerl, M.; Baric, A. Sequential Buildup of Broadband Equivalent Circuit Model for Low-Cost SMA Connectors. IEEE Trans. Electromagn. Compat. 2019, 61, 242–250. [Google Scholar] [CrossRef]

- Hwang, C.; Ouyang, M.; Fan, J. Bandwidth improvement technique for an edge mount SMA launch structure in multilayer boards. In Proceedings of the 2016 IEEE International Symposium on Electromagnetic Compatibility (EMC), Ottawa, ON, Canada, 25–29 July 2016; pp. 308–311. [Google Scholar]

- Hwang, C.; Ouyang, M.; Fan, J. Return Path Discontinuity Analysis of an Edge Mount SMA Launch Structure in Multilayer Boards. IEEE Trans. Electromagn. Compat. 2018, 60, 453–458. [Google Scholar] [CrossRef]

- Khan, A.A.; Mandal, M.K.; Shaw, R. A compact and wideband SMA connector to empty substrate integrated waveguide (ESIW) transition. In Proceedings of the 2015 IEEE MTT-S International Microwave and RF Conference (IMaRC), Hyderabad, India, 10–12 December 2015; pp. 246–248. [Google Scholar]

- Zha, H.; Lu, D.; Wang, W.; Lin, F. RF modeling and optimization of end-launch SMA to trace transition. In Proceedings of the 2015 IEEE 17th Electronics Packaging and Technology Conference (EPTC), Singapore, 2–4 December 2015; pp. 1–4. [Google Scholar]

- Ben, R.; Hu, S.; Li, X.; Fu, Z. Signal intergrity analysis for SMA via on the PCB. In Proceedings of the 2017 IEEE 9th International Conference on Communication Software and Networks (ICCSN), Guangzhou, China, 6–8 May 2017; pp. 865–869. [Google Scholar]

- Diewald, A.R.; Müller, S.; Olk, A. PCB-side matching networks for coaxial connectors. In Proceedings of the 2017 Antenna Measurement Techniques Association Symposium (AMTA), Atlanta, GA, USA, 15–20 October 2017; pp. 1–5. [Google Scholar]

- Magerl, M.; Mandic, T.; Baric, A. Broadband characterization of SMA connectors by measurements. In Proceedings of the 2014 37th International Convention on Information and Communication Technology, Electronics and Microelectronics (MIPRO), Opatija, Croatia, 26–30 May 2014; pp. 104–109. [Google Scholar]

- MIL-C-39012C, Military Specification: Connectors, Coaxial, Radio Frequency, General Specification for (11 Aug 1982). Available online: http://everyspec.com/MIL-SPECS/MIL-SPECS-MIL-C/MIL-C-39012C_28968/ (accessed on 7 July 2024).

- Amphenol RF “SMA Connectors”. Available online: https://www.amphenolrf.com/rf-connectors/sma-connectors.html (accessed on 7 March 2024).

- Unleashing the Power of SMA Connectors: A Key Component for Seamless Signal Transmission. Available online: https://www.elecrow.com/blog/unleashing-the-power-of-sma-connectors-a-key-component-for-seamless-signal-transmission.html (accessed on 7 March 2024).

- Exploring the Wide Range of Applications for SMA Connectors. Available online: https://www.elecbee.com/en-2532-exploring-the-wide-range-of-applications-for-sma-connectors (accessed on 7 March 2024).

- Šapalas, J. Improvement and Research of Femtosecond Laser Pulse Recurrence Frequency Tuning System. Master’s Thesis, Vilnius Gediminas Technical University (VILNIUS TECH), Vilniaus, Lithuania, 2023; 39p. [Google Scholar]

- Barzdenas, V.; Vasjanov, A. A Method of Optimizing Characteristic Impedance Compensation Using Cut-Outs in High-Density PCB Designs. Sensors 2022, 22, 964. [Google Scholar] [CrossRef] [PubMed]

| No. | SMA Connector Type * (Land Pad Dimensions) | SMA Connector Mounting | Max. Frequency, GHz | Pad Impedance Discontinuity Compensated | Relative Connector Price for 1 pcs. (100 pcs.) |

|---|---|---|---|---|---|

| #1 | Board edge 1 (4.5 × 1.5 mm2 pad) | End launch | 18 | No | 1.6 (1.6) |

| #2 | Board edge 2 (2.3 × 1.5 mm2 pad) | 1.4 (1.4) | |||

| #3 | SMD (⌀2.05 mm pad) | Vertical | 1.2 (1.1) | ||

| #4 | Board edge 1 (4.5 × 1.5 mm2 pad) | End launch | Yes | 1.6 (1.6) | |

| #5 | Board edge 2 (2.3 × 1.5 mm2 pad) | 1.4 (1.4) | |||

| #6 | SMD (⌀2.05 mm pad) | Vertical | 1.2 (1.1) | ||

| #7 | Through-hole (⌀3 mm pad) | Vertical | No | 1.0 (1.0) | |

| #8 | Through-hole (⌀3 mm pad) | Right angle | 1.6 (1.5) | ||

| #9 | Board edge 3 (2 × 0.55 mm2 pad) | End launch | 26.5 | 1.6 (1.6) | |

| #10 | Solderless (⌀0.7 mm pad) | Vertical, compression | 27 | 3.5 (2.6) | |

| #11 | Solderless (0.7 × 0.5 mm2 pad) | End launch, compression | 26.5 | 10.7 (10.8) |

| Parameter | Connector Type | |||

|---|---|---|---|---|

| No. | Reference | #6 | #9 | #11 |

| SMA connector type (land pad dimensions) | - | SMD (⌀2.05 mm pad) | Board edge 3 (2 × 0.55 mm2 pad) | Solderless (0.7 × 0.5 mm2 pad) |

| SMA connector mounting | - | Vertical | End launch | End launch, compression |

| Max. frequency, GHz | - | 18 | 26.5 | |

| Pad impedance discontinuity compensated | - | Yes | No | |

| Relative connector price, buying 1 pcs. (100 pcs.) | - | 1.2 (1.1) | 1.6 (1.6) | 10.7 (10.8) |

| Measured impedance at SMA connector to board Z0, measured ≈ 48 Ω microstrip transition, Ω | 46 (RF probes) | 42 | 44 | 46.5 |

| S11 < −10 dB bandwidth *, GHz | >8 | 7 | >8 | >8 |

| Minimum S11 over measured 8 GHz bandwidth *, dB | −14 | −9 | −12 | −15 |

| S21 = −3 dB bandwidth *, GHz | 6 | 3.6 | 4.5 | 5.1 |

| S21 = −5 dB bandwidth *, GHz | >8 | 6.1 | 6.1 | 7.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasjanov, A.; Barzdenas, V.; Jurgo, M.; Gursnys, D. Unveiling the Sub-10 GHz Performance of SMA Connectors: A Comparative Analysis. Electronics 2024, 13, 2686. https://doi.org/10.3390/electronics13142686

Vasjanov A, Barzdenas V, Jurgo M, Gursnys D. Unveiling the Sub-10 GHz Performance of SMA Connectors: A Comparative Analysis. Electronics. 2024; 13(14):2686. https://doi.org/10.3390/electronics13142686

Chicago/Turabian StyleVasjanov, Aleksandr, Vaidotas Barzdenas, Marijan Jurgo, and Darius Gursnys. 2024. "Unveiling the Sub-10 GHz Performance of SMA Connectors: A Comparative Analysis" Electronics 13, no. 14: 2686. https://doi.org/10.3390/electronics13142686

APA StyleVasjanov, A., Barzdenas, V., Jurgo, M., & Gursnys, D. (2024). Unveiling the Sub-10 GHz Performance of SMA Connectors: A Comparative Analysis. Electronics, 13(14), 2686. https://doi.org/10.3390/electronics13142686