Ohmic Contact Formation to β-Ga2O3 Nanosheet Transistors with Ar-Containing Plasma Treatment

Abstract

:1. Introduction

2. Experimental Methods

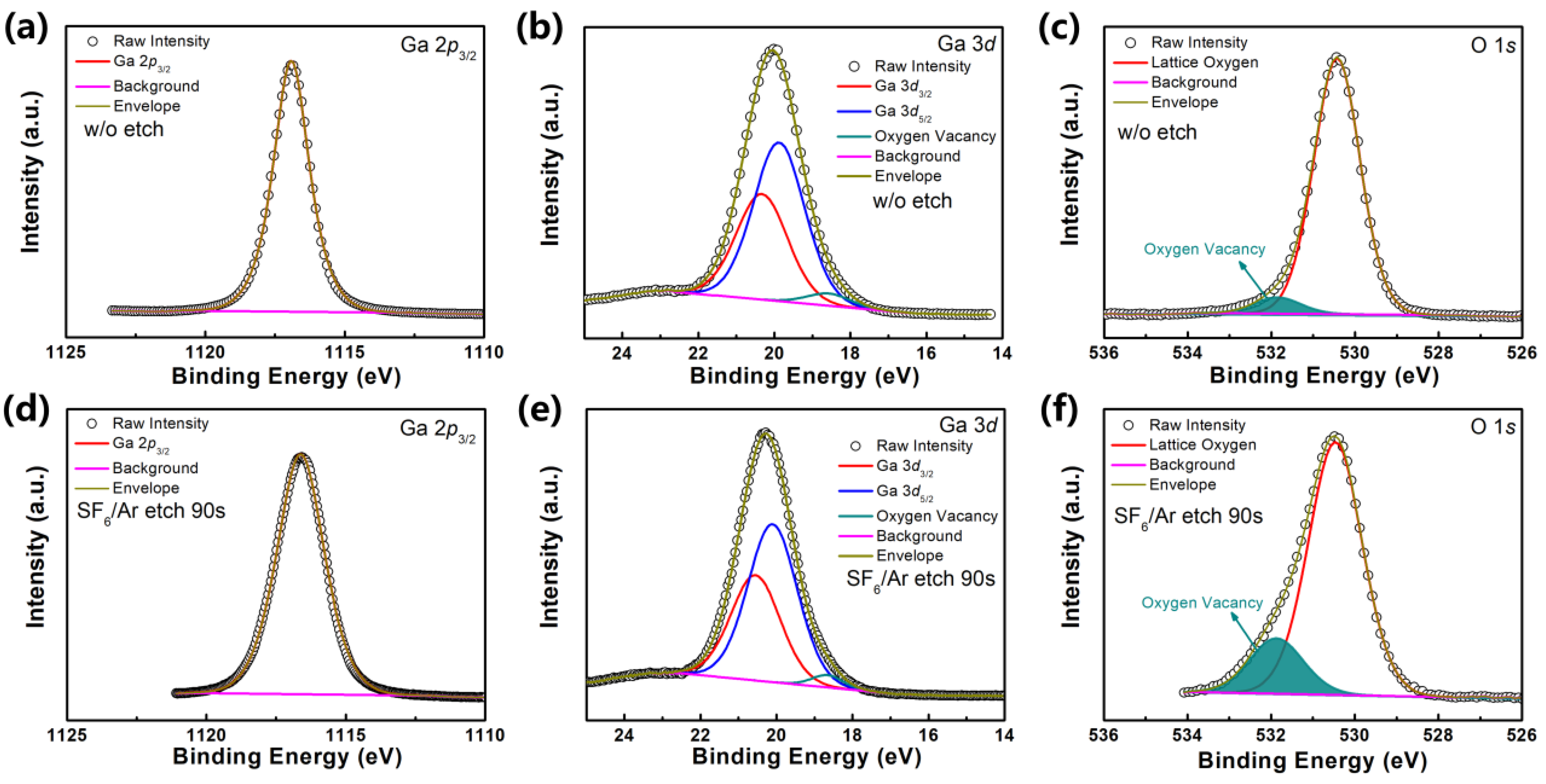

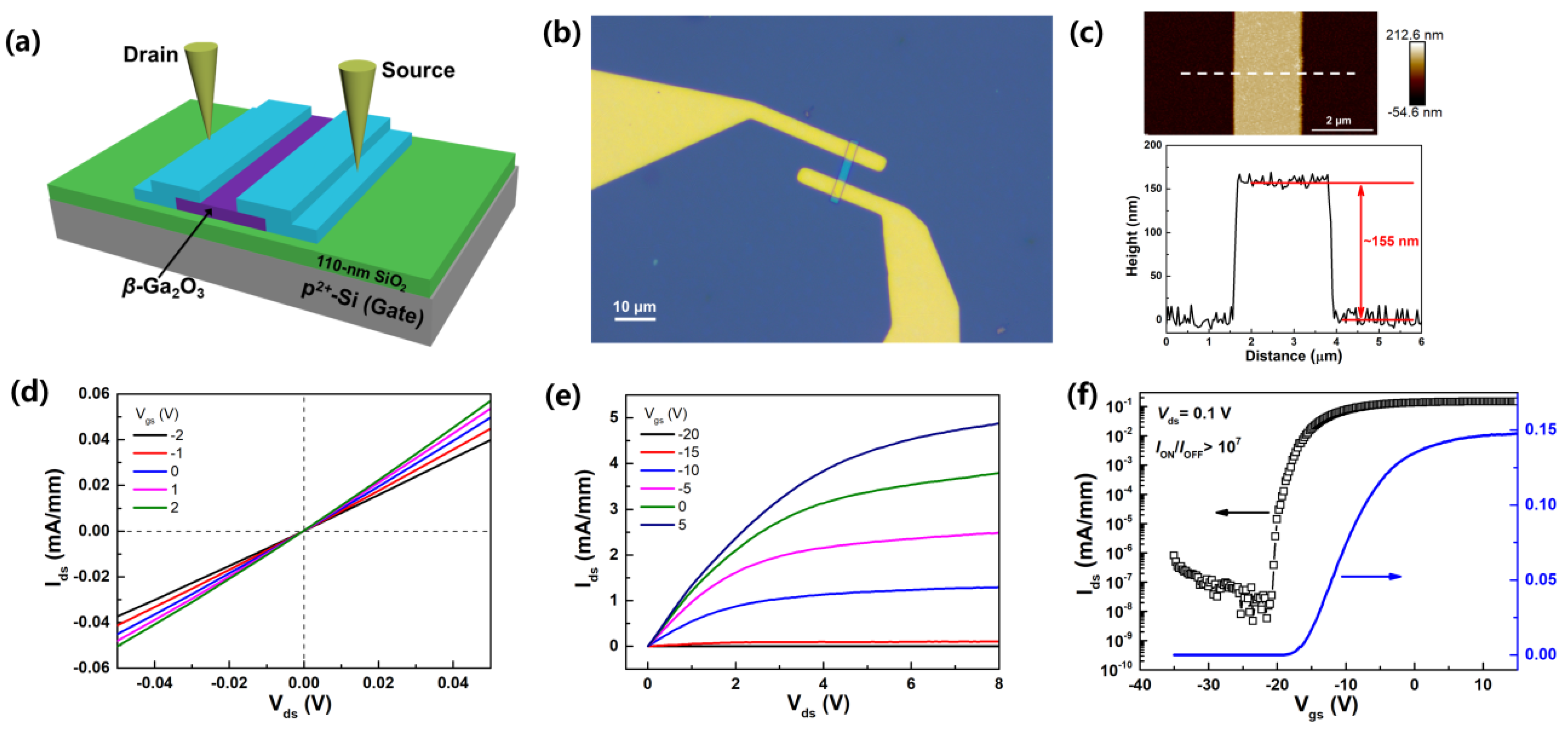

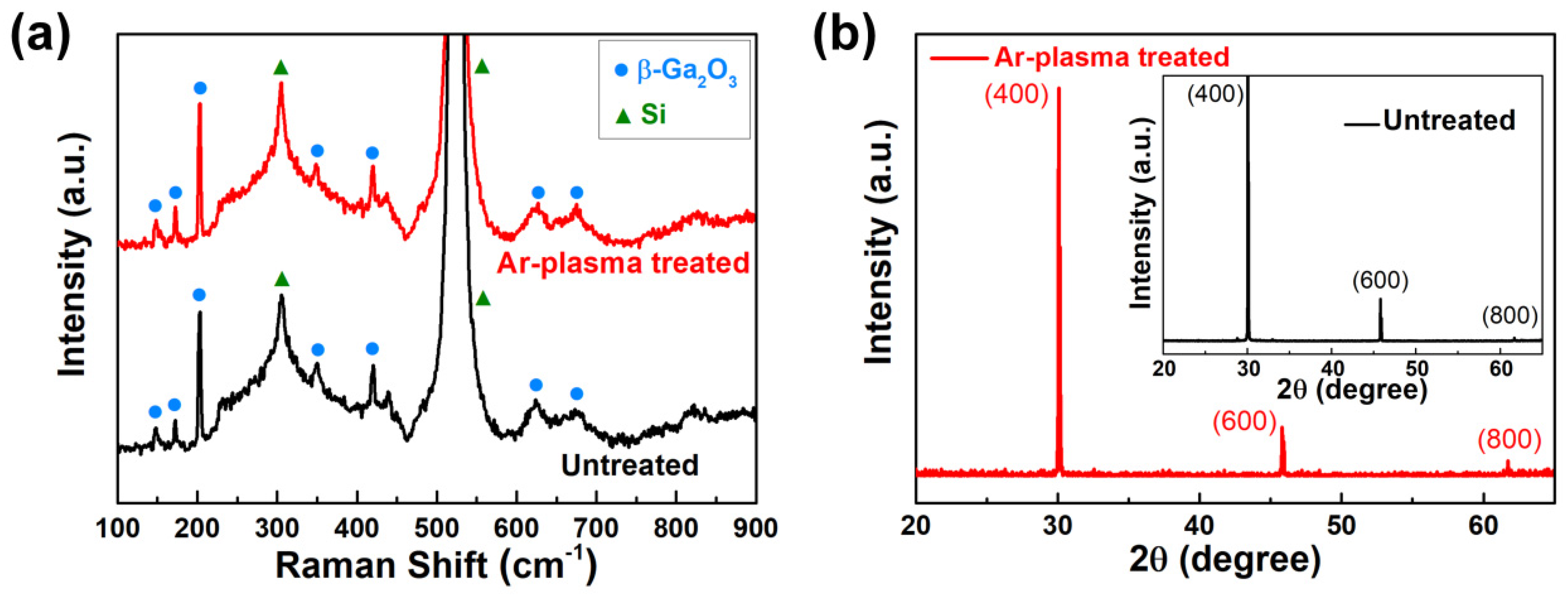

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pearton, S.J.; Yang, J.; Cary IV, P.H.; Ren, F.; Kim, J.; Tadjer, M.J.; Mastro, M.A. A Review of Ga2O3 Materials, Processing, and Devices. Appl. Phys. Rev. 2018, 5, 011301. [Google Scholar] [CrossRef]

- Feng, L.; Li, Y.; Su, X.; Wang, S.; Liu, H.; Wang, J.; Gong, Z.; Ding, W.; Zhang, Y.; Yun, F. Growth and Characterization of Spindle-Like Ga2O3 Nanocrystals by Electrochemical Reaction in Hydrofluoric Solution. Appl. Surf. Sci. 2016, 389, 205–210. [Google Scholar] [CrossRef]

- Chen, J.X.; Ta, J.J.; Ma, H.P.; Zhang, H.; Feng, J.J.; Liu, W.J.; Xia, C.; Lu, H.L.; Zhang, D.W. Band Alignment of AlN/β-Ga2O3 Heterojunction Interface Measured by X-ray Photoelectron Spectroscopy. Appl. Phys. Lett. 2018, 112, 261602. [Google Scholar] [CrossRef]

- Lee, Y.; Johnson, N.R.; George, S.M. Thermal Atomic Layer Etching of Gallium Oxide Using Sequential Exposures of HF and Various Metal Precursors. Chem. Mater. 2020, 32, 5937–5948. [Google Scholar] [CrossRef]

- Lv, Y.; Zhou, X.; Long, S.; Song, X.; Wang, Y.; Liang, S.; He, Z.; Han, T.; Tan, X.; Feng, Z.; et al. Source-Field-Plated β-Ga2O3 MOSFET with Record Power Figure of Merit of 50.4 MW/cm2. IEEE Electron Device Lett. 2019, 40, 83. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Liu, Y.; Guo, D.; Li, S.; Yan, Z.; Tan, C.K.; Li, W.; Li, P.; Tang, W. A High-Performance Ultraviolet Solar-Blind Photodetector Based on a β-Ga2O3 Schottky Photodiode. J. Mater. Chem. C 2019, 7, 13920–13929. [Google Scholar] [CrossRef]

- O’Donoghue, R.; Rechmann, J.; Aghaee, M.; Rogalla, D.; Becker, H.W.; Creatore, M.; Wieck, A.D.; Devi, A. Low Temperature Growth of Gallium Oxide Thin Films via Plasma Enhanced Atomic Layer Deposition. Dalton Trans. 2017, 46, 16551–16561. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.X.; Li, X.X.; Ta, J.J.; Cui, H.Y.; Huang, W.; Ji, Z.G.; Sai, Q.L.; Xia, C.T.; Lu, H.L.; Zhang, D.W. Fabrication of a Nb-Doped β-Ga2O3 Nanobelt Field-Effect Transistor and Its Low-Temperature Behavior. ACS Appl. Mater. Interfaces 2020, 12, 8437–8445. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Oh, S.; Mastro, M.A.; Kim, J. Exfoliated β-Ga2O3 Nano-Belt Field-Effect Transistors for Air-Stable High Power and High Temperature Electronics. Phys. Chem. Chem. Phys. 2016, 18, 15760. [Google Scholar] [CrossRef] [PubMed]

- Baliga, B.J. Power Semiconductor Device Figure of Merit for High-Frequency Applications. IEEE Electron Device Lett. 1989, 10, 455–457. [Google Scholar] [CrossRef]

- Chen, J.X.; Liu, B.Y.; Gu, Y.; Chen, R.; Li, B.; Zhou, C. Influence of Ultralow Temperature on Quasi-2-D β-Ga2O3 Field-Effect Transistors. IEEE Trans. Electron Devices 2024, 71, 4233–4239. [Google Scholar] [CrossRef]

- Kim, J.; Mastro, M.A.; Tadjer, M.J.; Kim, J. Quasi-Two-Dimensional h-BN/β-Ga2O3 Heterostructure Metal-Insulator-Semiconductor Field-Effect Transistor. ACS Appl. Mater. Interfaces 2017, 9, 21322–21327. [Google Scholar] [CrossRef] [PubMed]

- Galazka, Z.; Irmscher, K.; Uecker, R.; Bertram, R.; Pietsch, M.; Kwasniewski, A.; Naumann, M.; Schulz, T.; Schewski, R.; Klimm, D.; et al. On the Bulk β-Ga2O3 Single Crystals Grown by the Czochralski Method. J. Cryst. Growth 2014, 404, 184–191. [Google Scholar] [CrossRef]

- Aida, H.; Nishiguchi, K.; Takeda, H.; Aota, N.; Sunakawa, K.; Yaguchi, Y. Growth of β-Ga2O3 Single Crystals by the Edge-Defined, Film Fed Growth Method. Jpn. J. Appl. Phys. 2008, 47, 8506–8509. [Google Scholar] [CrossRef]

- Hoshikawa, K.; Ohba, E.; Kobayashi, T.; Yanagisawa, J.; Miyagawa, C.; Nakamura, Y. Growth of β-Ga2O3 Single Crystals Using Vertical Bridgman Method in Ambient Air. J. Cryst. Growth 2016, 447, 36. [Google Scholar] [CrossRef]

- Vo, T.H.; Kim, S.; Kim, H.Y.; Park, J.H.; Jeon, D.W.; Hwang, W.S. Temperature-Dependent Capacitance-Voltage Characteristics of β-Ga2O3 Schottky Barrier Diodes with (001) Epitaxial Grown Layer Using MOCVD. Mater. Sci. Semicond. Process. 2024, 173, 108130. [Google Scholar] [CrossRef]

- Kwon, Y.; Lee, G.; Oh, S.; Kim, J.; Pearton, S.J.; Ren, F. Tuning the Thickness of Exfoliated Quasi-Two-Dimensional β-Ga2O3 Flakes by Plasma Etching. Appl. Phys. Lett. 2017, 110, 131901. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, P.; Wang, Y.; Lin, Z.; Liu, H.; Huang, J.; Huang, Y.; Duan, X. Van der Waals Integrated Devices Based on Nanomembranes of 3D Materials. Nano Lett. 2020, 20, 1410–1416. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Si, M.; Alghamdi, S.; Qiu, G.; Yang, L.; Ye, P.D. High-Performance Depletion/Enhancement Mode β-Ga2O3 on Insulator (GOOI) Field-Effect Transistors with Record Drain Currents of 600/450 mA/mm. IEEE Electron Device Lett. 2017, 38, 103–106. [Google Scholar] [CrossRef]

- Ma, J.; Cho, H.J.; Heo, J.; Kim, S.; Yoo, G. Asymmetric Double-Gate β-Ga2O3 Nanomembrane Field-Effect Transistor for Energy-Efficient Power Devices. Adv. Electron. Mater. 2019, 5, 1800938. [Google Scholar] [CrossRef]

- Tan, P.; Zou, Y.; Zhao, X.; Hou, X.; Zhang, Z.; Ding, M.; Yu, S.; Ma, X.; Xu, G.; Hu, Q.; et al. Hysteresis-Free Ga2O3 Solar-Blind Phototransistor Modulated from Photoconduction to Photogating Effect. Appl. Phys. Lett. 2022, 120, 071106. [Google Scholar] [CrossRef]

- Chen, J.X.; Li, X.X.; Huang, W.; Ji, Z.G.; Wu, S.Z.; Xiao, Z.Q.; Ou, X.; Zhang, D.W.; Lu, H.L. High-Energy X-ray Radiation Effects on the Exfoliated Quasi-Two-Dimensional β-Ga2O3 Nanoflake Field-Effect Transistors. Nanotechnology 2020, 31, 345206. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Liu, Y.; Zhang, A.; Liu, Q.; Shen, C.; Wu, F.; Xu, C.; Chen, M.; Fu, H.; Zhou, C. Quasi-Two-Dimensional β-Ga2O3 Field Effect Transistors with Large Drain Current Density and Low Contact Resistance via Controlled Formation of Interfacial Oxygen Vacancies. Nano Res. 2019, 12, 143–148. [Google Scholar] [CrossRef]

- Yao, Y.; Davis, R.F.; Porter, L.M. Investigation of Different Metals as Ohmic Contacts to β-Ga2O3: Comparison and Analysis of Electrical Behavior, Morphology, and Other Physical Properties. J. Electron. Mater. 2017, 46, 2053–2060. [Google Scholar] [CrossRef]

- Chen, J.X.; Li, X.X.; Ma, H.P.; Huang, W.; Ji, Z.G.; Xia, C.; Lu, H.L.; Zhang, D.W. Investigation of the Mechanism for Ohmic Contact Formation in Ti/Al/Ni/Au Contacts to β-Ga2O3 Nanobelt Field-Effect Transistors. ACS Appl. Mater. Interfaces 2019, 11, 32127–32134. [Google Scholar] [CrossRef] [PubMed]

- Guo, D.Y.; Wu, Z.P.; An, Y.H.; Guo, X.C.; Chu, X.L.; Sun, C.L.; Li, L.H.; Li, P.G.; Tang, W.H. Oxygen Vacancy Tuned Ohmic-Schottky Conversion for Enhanced Performance in β-Ga2O3 Solar-Blind Ultraviolet Photodetectors. Appl. Phys. Lett. 2014, 105, 023507. [Google Scholar] [CrossRef]

- Liu, T.; Feng, Z.; Li, Q.; Yang, J.; Li, C.; Dupuis, M. Role of Oxygen Vacancies on Oxygen Evolution Reaction Activity: β-Ga2O3 as a Case Study. Chem. Mater. 2014, 30, 7714–7726. [Google Scholar] [CrossRef]

- Yamaga, M.; Víllora, E.G.; Shimamura, K.; Ichinose, N.; Honda, M. Donor Structure and Electric Transport Mechanism in β-Ga2O3. Phys. Rev. B 2003, 68, 155207. [Google Scholar] [CrossRef]

- Hajnal, Z.; Miró, J.; Kiss, G.; Réti, F.; Deák, P.; Herndon, R.C.; Kuperberg, J.M. Role of Oxygen Vacancy Defect States in the n-Type Conduction of β-Ga2O3. J. Appl. Phys. 1999, 86, 3792–3796. [Google Scholar] [CrossRef]

- Narayanan, M.; Shah, A.P.; Ghosh, S.; Thamizhavel, A.; Bhattacharya, A. Elucidating the Role of Oxygen Vacancies on the Electrical Conductivity of β-Ga2O3 Single-Crystals. Appl. Phys. Lett. 2023, 123, 172106. [Google Scholar] [CrossRef]

- Higashiwaki, M.; Sasaki, K.; Kuramata, A.; Masui, T.; Yamakoshi, S. Gallium Oxide (Ga2O3) Metal-Semiconductor Field-Effect Transistors on Single-Crystal β-Ga2O3 (010) Substrates. Appl. Phys. Lett. 2012, 100, 013504. [Google Scholar] [CrossRef]

- Liang, H.; Chen, Y.; Xia, X.; Zhang, C.; Shen, R.; Liu, Y.; Luo, Y.; Du, G. A Preliminary Study of SF6 Based Inductively Coupled Plasma Etching Techniques for Beta Gallium Trioxide Thin Film. Mater. Sci. Semicond. Process. 2015, 39, 582–586. [Google Scholar] [CrossRef]

- Bourque, J.L.; Biesinger, M.C.; Baines, K.M. Chemical State Determination of Molecular Gallium Compounds Using XPS. Dalton Trans. 2016, 45, 7678–7696. [Google Scholar] [CrossRef] [PubMed]

- Tao, J.; Lu, H.L.; Gu, Y.; Ma, H.P.; Li, X.; Chen, J.X.; Liu, W.J.; Zhang, H.; Feng, J.J. Investigation of Growth Characteristics, Compositions, and Properties of Atomic Layer Deposited Amorphous Zn-Doped Ga2O3 Films. Appl. Surf. Sci. 2019, 476, 733–740. [Google Scholar] [CrossRef]

- Ilhom, S.; Mohammad, A.; Shukla, D.; Grasso, J.; Willis, B.G.; Okyay, A.K.; Biyikli, N. Low-Temperature As-Grown Crystalline β-Ga2O3 Films via Plasma-Enhanced Atomic Layer Deposition. ACS Appl. Mater. Interfaces 2021, 13, 8538–8551. [Google Scholar] [CrossRef]

- Tezani, L.L.; Pessoa, R.S.; Maciel, H.S.; Petraconi, G. Chemistry Studies of SF6/CF4, SF6/O2, and CF4/O2 Gas Phase during Hollow Cathode Reactive Ion Etching Plasma. Vacuum 2014, 106, 64–68. [Google Scholar] [CrossRef]

- Jeong, Y.J.; Yang, J.Y.; Lee, C.H.; Park, R.; Lee, G.; Chung, R.B.K.; Yoo, G. Fluorine-Based Plasma Treatment for Hetero-Epitaxial β-Ga2O3 MOSFETs. Appl. Surf. Sci. 2021, 558, 149936. [Google Scholar] [CrossRef]

- Yang, J.; Fares, C.; Ren, F.; Sharma, R.; Patrick, E.; Law, M.E.; Pearton, S.J.; Kuramata, A. Effects of Fluorine Incorporation into β-Ga2O3. J. Appl. Phys. 2018, 123, 165706. [Google Scholar] [CrossRef]

- Yang, G.; Jang, S.; Ren, F.; Pearton, S.J.; Kim, J. Influence of High-Energy Proton Irradiation on β-Ga2O3 Nanobelt Field-Effect Transistors. ACS Appl. Mater. Interfaces 2017, 9, 40471–40476. [Google Scholar] [CrossRef] [PubMed]

- Chang, H.Y.; Zhu, W.; Akinwande, D. On the Mobility and Contact Resistance Evaluation for Transistors Based on MoS2 or Two-Dimensional Semiconducting Atomic Crystals. Appl. Phys. Lett. 2014, 104, 113504. [Google Scholar] [CrossRef]

- Cao, Q.; Han, S.J.; Tulevski, G.S.; Franklin, A.D.; Haensch, W. Evaluation of Field-Effect Mobility and Contact Resistance of Transistors that Use Solution-Processed Single-Walled Carbon Nanotubes. ACS Nano 2012, 6, 6471–6477. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Pearton, S.J.; Fares, C.; Yang, J.; Ren, F.; Kim, S.; Polyakov, A.Y. Radiation Damage Effects in Ga2O3 Materials and Devices. J. Mater. Chem. C 2019, 7, 10–24. [Google Scholar] [CrossRef]

- Sfuncia, G.; Nicotra, G.; Giannazzo, F.; Pécz, B.; Gueorguiev, G.K.; Georgieva, A.K. 2D Graphitic-Like Gallium Nitride and Other Structural Selectivity in Confinement at the Graphene/SiC Interface. CrystEngComm 2023, 25, 5810–5817. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.-X.; Liu, B.-Y.; Gu, Y.; Li, B. Ohmic Contact Formation to β-Ga2O3 Nanosheet Transistors with Ar-Containing Plasma Treatment. Electronics 2024, 13, 3181. https://doi.org/10.3390/electronics13163181

Chen J-X, Liu B-Y, Gu Y, Li B. Ohmic Contact Formation to β-Ga2O3 Nanosheet Transistors with Ar-Containing Plasma Treatment. Electronics. 2024; 13(16):3181. https://doi.org/10.3390/electronics13163181

Chicago/Turabian StyleChen, Jin-Xin, Bing-Yan Liu, Yang Gu, and Bin Li. 2024. "Ohmic Contact Formation to β-Ga2O3 Nanosheet Transistors with Ar-Containing Plasma Treatment" Electronics 13, no. 16: 3181. https://doi.org/10.3390/electronics13163181