Multi-Layered Perceptual Model for Haptic Perception of Compliance

Abstract

1. Introduction

1.1. Factors and Cues of Compliance Perception

1.2. Computational Models for Compliance

2. Method, Experiments, and Data Collection

2.1. Method and Concept

2.2. Experiments and Data Collection

3. Analysis and Discussion

3.1. Perceptual Dimensionality of Compliance

3.2. Factors of Interaction Features

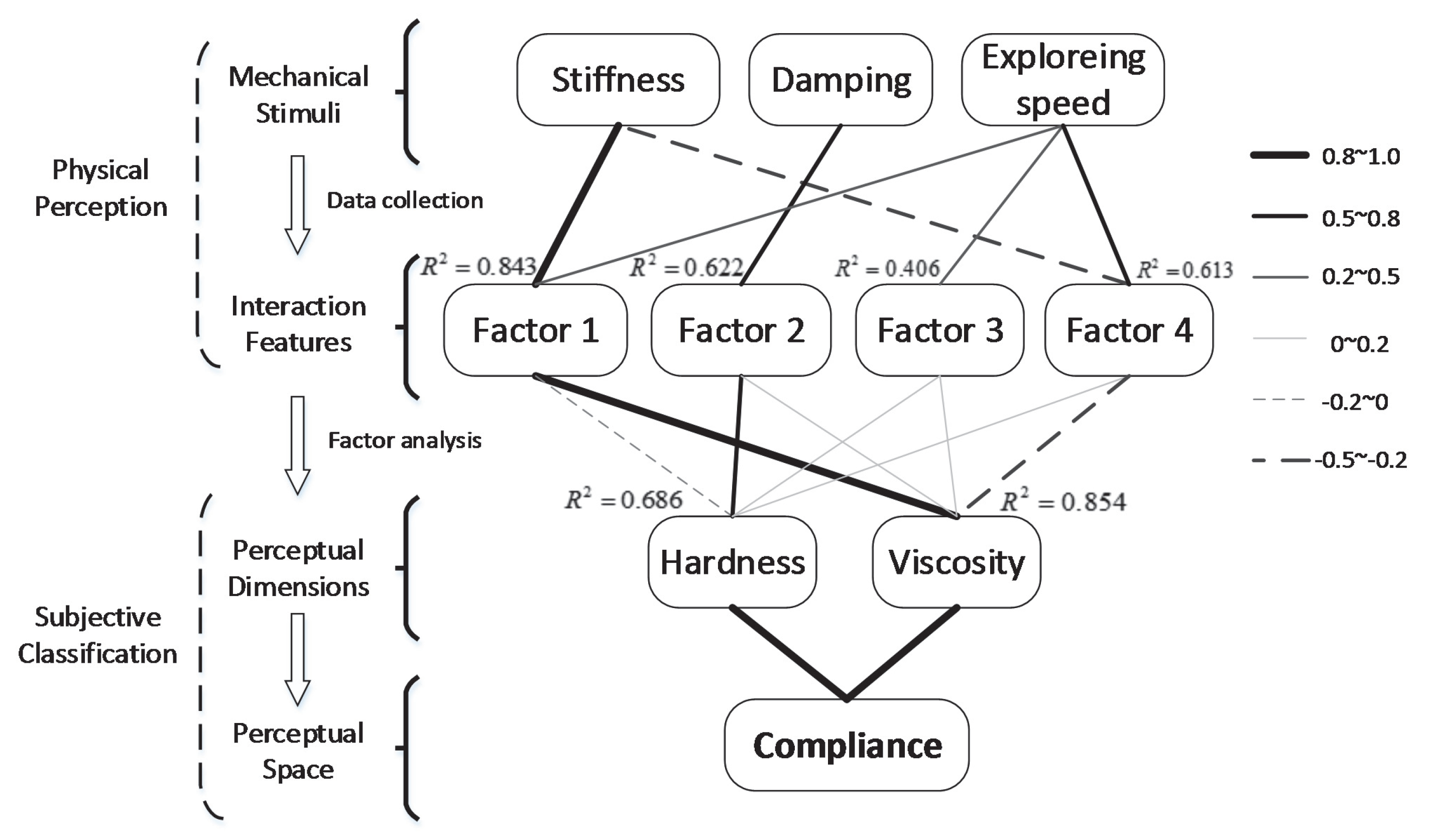

3.3. Multi-Layered Perceptual Model Based on Regression Analysis

4. Verification Experiment

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bergmann Tiest, W.M. Tactual perception of material properties. Vis. Res. 2010, 50, 2775–2782. [Google Scholar] [CrossRef] [PubMed]

- Di Luca, M. Multisensory Softness; Springer: Berlin, Germany, 2014. [Google Scholar]

- Bergmann Tiest, W.M.; Kappers, A.M. Cues for haptic perception of compliance. IEEE Trans. Haptics 2009, 2, 189–199. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Shao, F.; Barnes, C.; Childs, T.; Henson, B. Exploring relationships between touch perception and surface physical properties. Int. J. Des. 2009, 3, 67–76. [Google Scholar]

- Wu, J.; Li, N.; Liu, W.; Song, G.; Zhang, J. Experimental study on the perception characteristics of haptic texture by multidimensional scaling. IEEE Trans. Haptics 2015, 8, 410–420. [Google Scholar] [CrossRef] [PubMed]

- Bochereau, S.; Sinclair, S.; Hayward, V. Perceptual constancy in the reproduction of virtual tactile textures with surface displays. ACM Trans. Appl. Percept. (TAP) 2018, 15, 10. [Google Scholar] [CrossRef]

- Okamoto, S.; Nagano, H.; Yamada, Y. Psychophysical dimensions of tactile perception of textures. IEEE Trans. Haptics 2013, 6, 81–93. [Google Scholar] [CrossRef]

- Blair, G.W.S.; Coppen, F.M.V. The subjective judgement of the elastic and plastic properties of soft bodies; the" differential thresholds" for viscosities and compression moduli. Proc. R. Soc. Lond. Ser. B-Biol. Sci. 1939, 128, 109–125. [Google Scholar]

- Koçak, U.; Palmerius, K.L.; Forsell, C.; Ynnerman, A.; Cooper, M. Analysis of the JND of Stiffness in Three Modes of Comparison. In Proceedings of the International Workshop on Haptic and Audio Interaction Design, Kusatsu, Japan, 25–26 August 2011; Springer: Berlin, Germany, 2011; pp. 22–31. [Google Scholar]

- Kaim, L.; Drewing, K. Exploratory strategies in haptic softness discrimination are tuned to achieve high levels of task performance. IEEE Trans. Haptics 2011, 4, 242–252. [Google Scholar] [CrossRef]

- Bergmann Tiest, W.M.; Kappers, A.M. Kinaesthetic and cutaneous contributions to the perception of compressibility. In Proceedings of the International Conference on Human Haptic Sensing and Touch Enabled Computer Applications, Madrid, Spain, 10–13 June 2008; Springer: Berlin, Germany, 2008; pp. 255–264. [Google Scholar]

- Srinivasan, M.A.; LaMotte, R.H. Tactual discrimination of softness. J. Neurophysiol. 1995, 73, 88–101. [Google Scholar] [CrossRef]

- Hauser, S.C.; Gerling, G.J. Force-rate cues reduce object deformation necessary to discriminate compliances harder than the skin. IEEE Trans. Haptics 2018, 11, 232–240. [Google Scholar] [CrossRef]

- Lawrence, D.A.; Pao, L.Y.; Dougherty, A.M.; Salada, M.A.; Pavlou, Y. Rate-hardness: A new performance metric for haptic interfaces. IEEE Trans. Robot. Autom. 2000, 16, 357–371. [Google Scholar] [CrossRef]

- Han, G.; Choi, S. Extended rate-hardness: A measure for perceived hardness. In Proceedings of the International Conference on Human Haptic Sensing and Touch Enabled Computer Applications, Amsterdam, The Netherlands, 8–10 July 2010; Springer: Berlin, Germany, 2010; pp. 117–124. [Google Scholar]

- Harper, R.; Stevens, S. Subjective hardness of compliant materials. Q. J. Exp. Psychol. 1964, 16, 204–215. [Google Scholar] [CrossRef]

- Rank, M.; Hirche, S. Dynamic Combination of Movement and Force for Softness Discrimination. In Multisensory Softness; Springer: Berlin, Germany, 2014; pp. 147–165. [Google Scholar]

- Di Luca, M.; Ernst, M.O. Computational aspects of softness perception. In Multisensory Softness; Springer: Berlin, German, 2014; pp. 85–106. [Google Scholar]

- Arbib, M. The Handbook of Brain Theory and Neural Networks; MIT Press: Cambridge, MA, USA, 1995. [Google Scholar]

- Chen, X.; Barnes, C.; Childs, T.; Henson, B.; Shao, F. Materials’ tactile testing and characterisation for consumer products’ affective packaging design. Mater. Des. 2009, 30, 4299–4310. [Google Scholar] [CrossRef]

- Kringelbach, M.L. The human orbitofrontal cortex: Linking reward to hedonic experience. Nat. Rev. Neurosci. 2005, 6, 691. [Google Scholar] [CrossRef]

- Shirado, H.; Maeno, T. Modeling of human texture perception for tactile displays and sensors. In Proceedings of the First Joint Eurohaptics Conference and Symposium on Haptic Interfaces for Virtual Environment and Teleoperator Systems, World Haptics Conference, Pisa, Italy, 18–20 March 2005; pp. 629–630. [Google Scholar]

- Klöcker, A.; Oddo, C.M.; Camboni, D.; Penta, M.; Thonnard, J.L. Physical factors influencing pleasant touch during passive fingertip stimulation. PLoS ONE 2014, 9, e101361. [Google Scholar] [CrossRef]

- Okamoto, S.; Nagano, H.; Kidoma, K.; Yamada, Y. Specification of individuality in causal relationships among texture-related attributes, emotions, and preferences. Int. J. Affect. Eng. 2015, 15, 11–19. [Google Scholar] [CrossRef]

- Hashim, I.H.M.; Kumamoto, S.; Takemura, K.; Maeno, T.; Okuda, S.; Mori, Y. Tactile evaluation feedback system for multi-layered structure inspired by human tactile perception mechanism. Sensors 2017, 17, 2601. [Google Scholar] [CrossRef]

- Karadogan, E.; Williams, R.L.; Howell, J.N.; Conatser, R.R., Jr. A stiffness discrimination experiment including analysis of palpation forces and velocities. Simul. Healthc. 2010, 5, 279–288. [Google Scholar] [CrossRef]

- Nagurka, M.; Marklin, R. Measurement of stiffness and damping characteristics of computer keyboard keys. J. Dyn. Syst. Meas. Control 2005, 127, 283–288. [Google Scholar] [CrossRef]

- Ernst, M.O.; Banks, M.S. Humans integrate visual and haptic information in a statistically optimal fashion. Nature 2002, 415, 429. [Google Scholar] [CrossRef]

- Rosenberg, L.B.; Adelstein, B.D. Perceptual decomposition of virtual haptic surfaces. In Proceedings of the 1993 IEEE Research Properties in Virtual Reality Symposium, San Jose, CA, USA, 25–26 October 1993; pp. 46–53. [Google Scholar]

- Sakamoto, M.; Watanabe, J. Exploring tactile perceptual dimensions using materials associated with sensory vocabulary. Front. Psychol. 2017, 8, 569. [Google Scholar] [CrossRef] [PubMed]

- Lederman, S.J.; Klatzky, R.L. Hand movements: A window into haptic object recognition. Cogn. Psychol. 1987, 19, 342–368. [Google Scholar] [CrossRef]

- Klatzky, R.L.; Lederman, S.J.; Reed, C. Haptic integration of object properties: Texture, hardness, and planar contour. J. Exp. Psychol. Hum. Percept. Perform. 1989, 15, 45. [Google Scholar] [CrossRef] [PubMed]

- Klatzky, R.L.; Lederman, S.J. ZL The Haptic Glance: A Route to Rapid Object Identification and Manipulation. In Attention and Performance XVII: Cognitive Regulation of Performance: Interaction of Theory and Application; MIT Press: Cambridge, MA, USA, 1999; p. 165. [Google Scholar]

- Higashi, K.; Okamoto, S.; Yamada, Y.; Nagano, H.; Konyo, M. Hardness perception through tapping: Peak and impulse of the reaction force reflect the subjective hardness. In Proceedings of the International Conference on Human Haptic Sensing and Touch Enabled Computer Applications, Pisa, Italy, 13–16 June 2018; Springer: Berlin, Germany, 2018; pp. 366–375. [Google Scholar]

| Stiffness | Damping | Exploring Speed | |

|---|---|---|---|

| Samples | k (N/mm) | b (Ns/mm) | v (mm/s) |

| 1 | 0.1 | 0.005 | 120 |

| 2 | 0.1 | 0.001 | 80 |

| 3 | 0.1 | 0.001 | 40 |

| 4 | 0.1 | 0.003 | 120 |

| 5 | 0.15 | 0.001 | 80 |

| 6 | 0.15 | 0.003 | 120 |

| 7 | 0.15 | 0.005 | 80 |

| 8 | 0.05 | 0.003 | 80 |

| 9 | 0.15 | 0.003 | 40 |

| 10 | 0.15 | 0.001 | 40 |

| 11 | 0.05 | 0.005 | 80 |

| 12 | 0.1 | 0.005 | 80 |

| 13 | 0.15 | 0.003 | 80 |

| 14 | 0.1 | 0.001 | 120 |

| 15 | 0.05 | 0.001 | 120 |

| 16 | 0.05 | 0.005 | 120 |

| 17 | 0.1 | 0.005 | 40 |

| 18 | 0.05 | 0.001 | 80 |

| 19 | 0.15 | 0.005 | 40 |

| 20 | 0.15 | 0.005 | 120 |

| 21 | 0.05 | 0.005 | 40 |

| 22 | 0.05 | 0.005 | 120 |

| 23 | 0.1 | 0.003 | 40 |

| 24 | 0.15 | 0.001 | 120 |

| 25 | 0.05 | 0.001 | 40 |

| 26 | 0.05 | 0.003 | 40 |

| 27 | 0.1 | 0.003 | 80 |

| Principal Components | ||

|---|---|---|

| Adjective Labels | 1 | 2 |

| Hardness | 0.170 | 0.984 |

| Viscosity | 0.851 | 0.122 |

| Roughness | 0.955 | 0.201 |

| Crispness | 0.892 | 0.409 |

| Cleanness | 0.962 | 0.112 |

| Principal Components | ||||

|---|---|---|---|---|

| Interaction Features | 1 | 2 | 3 | 4 |

| peak force | 0.939 | 0.098 | 0.029 | −0.158 |

| peak force rate (press) | 0.914 | 0.189 | 0.081 | 0.234 |

| peak force rate (release) | 0.854 | 0.282 | −0.047 | 0.201 |

| initial speed | 0.151 | −0.052 | 0.882 | 0.305 |

| release speed | −0.001 | 0.304 | 0.139 | 0.845 |

| extended rate-hardness (press) | 0.138 | 0.571 | −0.688 | 0.367 |

| extended rate-hardness (release) | 0.441 | 0.420 | −0.090 | −0.648 |

| initial force change rate | 0.182 | 0.723 | 0.171 | −0.202 |

| release force change rate | 0.555 | 0.548 | −0.117 | −0.316 |

| rate-hardness | 0.874 | −0.098 | 0.090 | −0.214 |

| measured stiffness | 0.918 | 0.165 | 0.078 | −0.237 |

| measured damping | 0.058 | 0.867 | −0.076 | −0.007 |

| damping force | 0.066 | 0.575 | 0.767 | 0.050 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, Z.; Wu, J.; Ouyang, Q.; He, C.; Cao, Z. Multi-Layered Perceptual Model for Haptic Perception of Compliance. Electronics 2019, 8, 1497. https://doi.org/10.3390/electronics8121497

Shao Z, Wu J, Ouyang Q, He C, Cao Z. Multi-Layered Perceptual Model for Haptic Perception of Compliance. Electronics. 2019; 8(12):1497. https://doi.org/10.3390/electronics8121497

Chicago/Turabian StyleShao, Zhiyu, Juan Wu, Qiangqiang Ouyang, Cong He, and Zhiyong Cao. 2019. "Multi-Layered Perceptual Model for Haptic Perception of Compliance" Electronics 8, no. 12: 1497. https://doi.org/10.3390/electronics8121497

APA StyleShao, Z., Wu, J., Ouyang, Q., He, C., & Cao, Z. (2019). Multi-Layered Perceptual Model for Haptic Perception of Compliance. Electronics, 8(12), 1497. https://doi.org/10.3390/electronics8121497