1. Introduction

The camless valve trains are considered to improve the performance of internal combustion engines in recent research [

1,

2]. The camless variable valve train (VVT) systems eliminate the camshafts and the valves can be driven by electromagnetic actuations [

3,

4], electrohydraulic actuations [

5,

6], or electro-pneumatic actuations [

7]. The electromagnetic VVT (EMVT) is identified as the most flexible VVT employing sensitive electromagnetic linear actuator (EMLA) to draw the valve to open and close. EMVT can control various factors of timing of gas distribution in high efficiency. The valve timing, the opening duration, the lift can be freely adjusted in various working conditions through electronic control to achieve the optimal timing of gas distribution [

8].

One of the main challenges in the research of EMVT is the difficulty to achieve the soft landing of the valve for closing operations. Because of the nonlinear characteristics of electromagnetic force, valves and valve retainers are prone to take the impact with large noise under high velocity [

9]. High seating velocity leads to the sharp rebound of valve, and even affects the valve close in time.

For seating impact suppression, researchers use complex control algorithms to control EMVT. Most studies use feedforward control or feedback control to control the seating velocity [

10,

11]. Peterson K.S [

12] used the extreme search algorithm and the eddy current sensor to measure the impact strength in soft landing research. Eyabi P [

13] constructed an accurate non-linear model and used the synovial control algorithm to control the seating velocity between 0.35 m/s and 0.05 m/s. The disadvantage of synovial control is that it is prone to generate local shake. Hoffmann W [

14] used iterative learning control method to simulate and control EMVT moving, and achieved satisfactory results. After continuous experiments, the valve can track the desired trajectory and the valve seating velocity can be reduced to 0.04 m/s employing iterative learning method. These control methods can achieve better seating performance in the laboratory. However, some control methods require high precision of the model and large amount of calculation, which is not conducive to real-time control, and it is not easy to achieve accurate control of valve motion process [

15]. Liu L [

8] and Zhao J [

16] used advanced modeling methods that allow simple linear controller feedback to reduce the amount of calculation. In reference [

16], a tracking controller with feedback linearization at the end of the valve travel has been presented, and it verifies that this algorithm successfully controls the movement of electromagnetic valves over a wide range of loads.

Adding the buffers to VVTs is another effective solution for the soft landing. The electro-hydraulic VVTs, designed by Lou Z. [

17,

18] have a build-in soft-landing feature including hydraulic valves and snubbers for seating velocity control without complex control strategy. In some hydraulic valves research by Huang Y [

19], double pulse signals of release solenoid valve are designed to eliminate the impacts of electrohydraulic exhaust valve seating. However, in the research of EMVT, Qiu Y [

20] adds a cam-based nonlinear mechanical transformer between the solenoid linear actuator and the valve to solve the landing problem. But the transformer is hard to achieve acceptable power consumption and actuator size. In the research of Zhao J [

21], the valve moves in a linear behavior controlled by a rotating motor to ensure a smooth seating performance. A simulation study by Reinholz B [

22] introduces a novel cogging-torque-assisted motor-driven (CTAMD) valve actuation system to provide low seating velocity. And experimental researches are displayed and compared to the simulated results as well as other EVA systems to validate the conjectured speed and efficiency of the CTAMD system.

It can be seen from the above that the valve seating impact is mainly suppressed by two technologies: control algorithms for EMVT and adding buffers to EMVT. The control algorithms for EMVT need on-line control or continuous iterative learning, which is more difficult and computational. For adding buffers to EMVT system, there is little research active control for buffers. In fact, the working characteristics of buffers are susceptible to environmental disturbances. Without active control of the buffers, the repeatability of the seating process cannot be guaranteed. In order to simplify the seating control algorithm for EMVT, a novel electromagnetic fully variable valve with a magnetorheological buffer is presented in this paper. An active control method of MR buffer is carried out to avoid operating characteristics being disturbed by the environment. In order to achieve the best performance of the valve, the cooperative control method of EMLA and MR buffer must be studied.

Establishing accurate system dynamics model is the basis of system design and control. Modeling considerations vary according to different research purposes. In order to control the seating velocity, Li H [

23] presented the detailed modeling of a novel electro-hydraulic variable valve actuator. The nonlinear mathematical system model is developed component-by-component, considering time delay and time-varying parameters. To analyze the dynamics of different motions, the electromagnetic valve system in research of Di Bernardo M [

24] is a highly non-linear piecewise continuous mechanical oscillator. The mechanical system model based on Newton’s law, finite element electromagnetic force model, Coulomb friction model, and valve impact model is established.

For the dynamic modeling of EMVT, most models are constructed separately according to subsystems, and some non-linear factors are considered preliminarily. Some models have simplified processes, neglecting the coupling relationship between subsystems, which is not conducive to the collaborative control of the EMLA and MR buffer. In this paper, it is necessary to establish the coupling relationship between EMLA, MR buffer, and other subsystems. This precise control-oriented model needs to consider dynamics, electromagnetism, and fluid mechanic to analyze system characteristics. Nonlinearity, hysteresis and other characteristics of the system are analyzed in detail.

The EMVT with buffer system mainly consists of EMLA, MR buffer, and spring. The EMLA is a typical electromagnetic direct driving structure and generates electromagnetic force to achieve valve movement requirements. MR buffer has promising applications for providing instantaneous and controllable damping to attenuate vibrations in various dynamic systems [

25]. Previously, MR buffers were mainly used in seismic vibration attenuators in heavy machinery [

26]. Recently, The small-scale MR buffer is used in the field of rehabilitation robotics [

27] and the intelligent bionic leg [

28]. The MR buffer can get the damping force by changing the coil current of the buffer to ensure soft-seating for closing operations without complex control methods. With the controllable characteristics of MR buffer damping, the valve movement can be controlled in piecewise variable damping. When the distance from the seating point is large, the MR buffer is in a low-damping state. In fast moving state, the valve can be quickly close to the seating area to achieve rapid response requirement. When the distance from the seating point is less than a set distance, the coil of MR buffer is switched on and current is applied. In seating state, the system damping can be increased and the seating performance can be improved.

The paper is organized as follows.

Section 2 describes the system configuration of the EMVT with MR buffer system. In

Section 3, The nonlinear mathematical models of the whole system is presented component-by-component. In

Section 4, The EMVT with MR buffer model simplification and linearization model at equilibrium point are shown. The correctness and accuracy of the linearized model are verified. In research for precise motion and seating performance, the simulation and experiment results are described and discussed in

Section 5. Finally, conclusions are drawn in

Section 6.

4. Model Linearization and Validation

4.1. Model Linearization

This EMVT with MR buffer system in this paper is an integrated complex system of mechanical, electromagnetism, and liquid coupled multi-object components. The dynamic models of the main parts are correlated and summarized to jointly constitute the model of the whole system. Because of the coil inductances, magnetic flux leakage, eddy current change of EMLA, and the hysteresis characteristics of MR fluid, the model developed in the paper is a nonlinear mathematical model. The nonlinear dynamic model brings difficulties in the design and online implementation of the control algorithm. So the system model needs to be degraded and linearized reasonably to establish a linearized model for modern control theory.

In the differential equation of motion, gas pressure is used to study the impact of gases on valves in various working conditions of engines. At this research stage, we mainly study the valve motion law and seating performance, so can be ignored in this paper. In the Bingham model of damping force, there is which determines the direction of buffer force. For this function, two motion processes (valve opening and closing) can be piecewise processed, to deal with the complexity generated by function.

The EMVT with MR buffer system is a double input and single output system. The state space is expressed as:

where

represents dynamic matrices,

represents dynamic matrices,

represents dynamic matrices,

is state vector,

is input vector, and

is output vector.

Define the states vector as:

Define the input vector as:

Define the output vector as:

Variable formal expression in the EMVT with MR buffer:

After defining the input, output, and state vector, the fraction, and the square in state vector require further linearization. The linearization of the commonly used method for the nonlinear system is Jacobi linearization method. At the equilibrium point of the system, the higher order part of the system can be approximated by Taylor series. The equilibrium point is a special working point. At the equilibrium point of the system, if the input variables are unchanged at this time, the system state variables will keep constant. In other word, the equilibrium point in the system equations reflect that the state variables of the derivative are zero. Jacobi linearization is a local linearization technique, where Taylor series expansion is carried out at the equilibrium point to achieve the first-order linear approximation of the system by ignoring the quadratic and higher order terms.

Using Jacobi linearization, Matrix

A and

B can be obtained from the following equation:

Among them

is the equilibrium point of the system when

.

The ideal moving result is the equilibrium state of the system at the seat point of the valve, where the derivative of displacement, velocity, damper current, and actuator current of the valve are all zero. Since the valve closing point is set to the displacement zero, the ideal state is as follows:

The equilibrium state vector can be obtained as follows:

The equilibrium input vector can be obtained as follows:

The expression of state space after Jacobi linearization is:

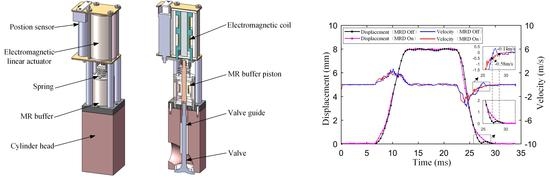

4.2. Experiment Setup

The whole test bench is composed of EMVT with MR buffer system, PC, circuit controller-based DSP (digital signal processor) and power supply shown in

Figure 8. EMVT with MR buffer system is the control objectives, which is used to research valve opening, closing, and seating characteristics. DSP-based circuit controller is used to drive the EMLA and MR buffer, and it can also collect process displacement, current, and other data. The PC is used for data interaction and communication between DSP controller and the computer. The specific model of displacement sensor is 500 LCIT. LCIT is based on patented linear displacement sensor technology. It has all the advantages of current LVDT induction technology, but is much cheaper. The specific parameters are expressed in

Table 7.

4.3. Model Validation and Analysis

The

Figure 9 is the comparison diagram of experiment and linearized model simulation. Open-loop control (multi-stage PWM adjustment) on EMLA is implemented at different stages to drive the valve in the experiment. The driving voltage of EMLA is high in the early stage and low in the later stage. A certain amount of buffer current is applied to the MR buffer in the later process to verify the effect of MR buffer.

The same driving voltages signal is applied to the linearized simulation model, and then the displacement curves of experiment and simulation are compared for model validation. The experimental results are consistent with the displacement curve of the linearized model. The maximum average error of experiment and simulation displacement is 3.1%. It can be seen that the electromagnetic force and buffer force can be well simulated in the linearized model, which is well reflected in the displacement.