1. Introduction

Applying the advanced developments in power electronics, microprocessors and digital signal processors (DSP), permanent magnet synchronous motors (PMSMs) have been extensively used in industrial automatic control applications, from washing machines to electric vehicles, due to their efficient performance characteristics, high power transmission efficiency, large torque-to-weight ratio, and long service life. Among various PMSM drive control techniques, field-oriented control (FOC) has been the most essential and efficient scheme, in which the rotor’s position and speed data are required. As a sensor-based solution, these data are managed by a typical sensor, such as a resolver, encoder, or Hall sensor, installed on the motor’s shaft. However, this makes the PMSM drive control system more expensive and larger in size. In some cases, the sensors are environment-sensitive, reducing control reliability and adaptiveness. To solve these shortcomings, various back-EMF-based (back electromotive force based) sensorless control techniques are designed and applied, such as the extended Kalman filter (EKF) approaches [

1,

2,

3] or the sliding mode observer (SMO) approaches [

4,

5,

6,

7]. The EKF involves a lot of recursive computations because it consists of prediction and innovation. Meanwhile, the SMO is robust against disturbance, has a high accuracy estimation potential, and is easy to be implemented. Generally, the conventional SMO solutions are impacted by chattering problems and noise effects because of using the on-off function and traditional arctangent calculation, so that the novel SMO and PLL combinations are widely applied to enhance the estimator’s robustness and accuracy [

6,

8,

9,

10]. Due to the back EMF value being small at the standstill or the low-speed region, the startup strategies are implemented to speed up the motor to the specific speed threshold at which the back-EMF is large enough to be estimated precisely. A simple

I-f startup strategy was presented [

11] and applied [

1,

5]. It involves the closed-loop current control to ensure the motor starts successfully under different external load situations without initial rotor position estimation and machine parameters estimation.

A proper motor drive control system requires a wide adjustable speed range, adaption to load disturbances and parameter variations, high instantaneous torque response, and lower torque ripple during the operating condition. It is essential to improve the motor control algorithm to obtain optimal performance. Therefore, various controllers have been proposed, such as the ANFIS controller [

12], the neural network controller [

13], the hybrid fuzzy-PID (Proportional-Integral-Derivative) controller [

14], and the backstepping controller [

4]. Among these algorithms, the radial basis function neural network (RBFNN)-based self-tuning PID controller is considered to enhance the speed control quality of the PMSMs drive control system. This intelligent controller not only inherits the typical PID controller’s structural simplicity but also is optimized by online adjusting the operating parameters based on the advantages of a neural network such as the ability to identify nonlinear system dynamics, the ability to learn, generalize, and adapt.

In the realization of the motor control system, the DSP of Texas Instruments provides a flexible solution, improving system reliability and efficiency. The DSP integrates highly optimized peripheral circuits, memory, and a single-chip CPU structure. It exhibits powerful processing and high performance for complex real-time control systems. In particular, with MATLAB’s Embedded Coder Support Package utilities, it is resourceful to build up the motor control algorithm in Simulink. The DSP application development time is significantly shortened. Accordingly, in this paper, an RBFNN-based self-tuning PID speed controller is implemented to improve the performance of the DSP-based sensorless PMSM drive control system with an estimator based on the novel SMO in combination with a PLL (the novel SMO-PLL). The MATLAB-based implemented control algorithm is not only executed in simulation but also applied to the real-time experiment system. The I-f startup mode, tracking response, and speed regulation are investigated to evaluate the control system performance. The proposed control algorithm is verified on an experimental platform with a PMSM, inverter, control circuit, a Texas Instruments DSP F28379D, and the dynamic load.

This paper is organized into the following sections.

Section 2 describes the sensorless PMSM drive control system with the mathematical model, the estimator based on the novel SMO-PLL, and the

I-f startup strategy.

Section 3 introduces the self-tuning PID controller based on an RBFNN.

Section 4 presents the implementation of the control algorithm in MATLAB Simulink. In

Section 5, the control system performance is inspected in the digital simulation to evaluate the correctness and the effectiveness of the control algorithm. In

Section 6, the proposed algorithm is verified on the experimental platform. Finally, the conclusion is given in

Section 7.

4. Implementation of a Sensorless Speed Control Algorithm in MATLAB Simulink

Among the motor control system realization approaches, the DSP-executed hardware solution requires transforming the system description equation from the continuous-time domain to the discrete-time domain. The sliding mode observer is represented by the discrete-time equation as:

where

Ts is the sampling time.

The motor control system expression is standardized in the per-unit system, so the current observer is rewritten as:

with:

and

where Um and Im are the base phase voltage and current, F and G are the feedback and gain factors of the SMO block system, respectively.

Additionally, the back EMF’s low pass filter is also represented by the discrete equation, as:

where

.

Generally, a DSP-based control system is programmed in C/C++ languages, which requires some coding and debugging skills. However, in the case of using the Texas Instruments’ DSP controller, the algorithm is not only being implemented directly by Code Composer Studio (CCS) software but is also enhanced by utilizing MATLAB and CCS software. The algorithm is firstly designed in MATLAB Simulink, then compiled the block system into C/C++ languages by Embedded Coder. Successively, the code is imported into CCS to execute, debug, and monitor the real-time system. Moreover, with enhanced functions of the Embedded Coder Support Package for Texas Instruments in MATLAB, it is very convenient to develop a motor control algorithm with Simulink. This shortens the DSP application development time significantly.

For developing the FOC algorithm, the Digital Control Motor (DCM) blocks are provided with the pre-built functions of not only the Clarke, Park, and Inverse Park transformations, but also for SVPWM, and current PI controllers. The FOC block is not shown in this paper with these functions, because it is already described in MATLAB manuals. Moreover, the TI IQmath library is supported for highly optimized and high precision mathematical functions of cosine, sine, magnitude, etc. Therefore, the sensorless PMSM control algorithm is easily developed in MATLAB Simulink for both simulation and experiment.

Figure 5 presents the detailed block diagram of the novel SMO, the sigmoid function, the low pass filter, and the PLL in Simulink.

According to the design technique in the literature [

15,

17], the discrete PID controller algorithm in (26)–(28), (39)–(41) and an RBFNN identification algorithm in (29)–(37) are implemented as two function blocks, integrated in the closed velocity control loop (

Figure 6).

5. The Simulation Results

The platform of a motor speed control system was built on the PMSM’s parameters, shown in

Table 1. The control algorithm is verified in both the simulation and experiment under three cases. The first case is the

I-f startup mode and switching to the sensorless FOC algorithm. The second one is the tracking response for checking the transient specification and the steady-state error. The last one is the speed regulation for evaluating the system stability regarding external disturbances. All the instances are operated with the dynamic load system, which includes an electrical circuit and a generator, coupled to the PMSM. The electrical circuit consists of a rectifier, a capacitor, and resistors, which are connected in parallel.

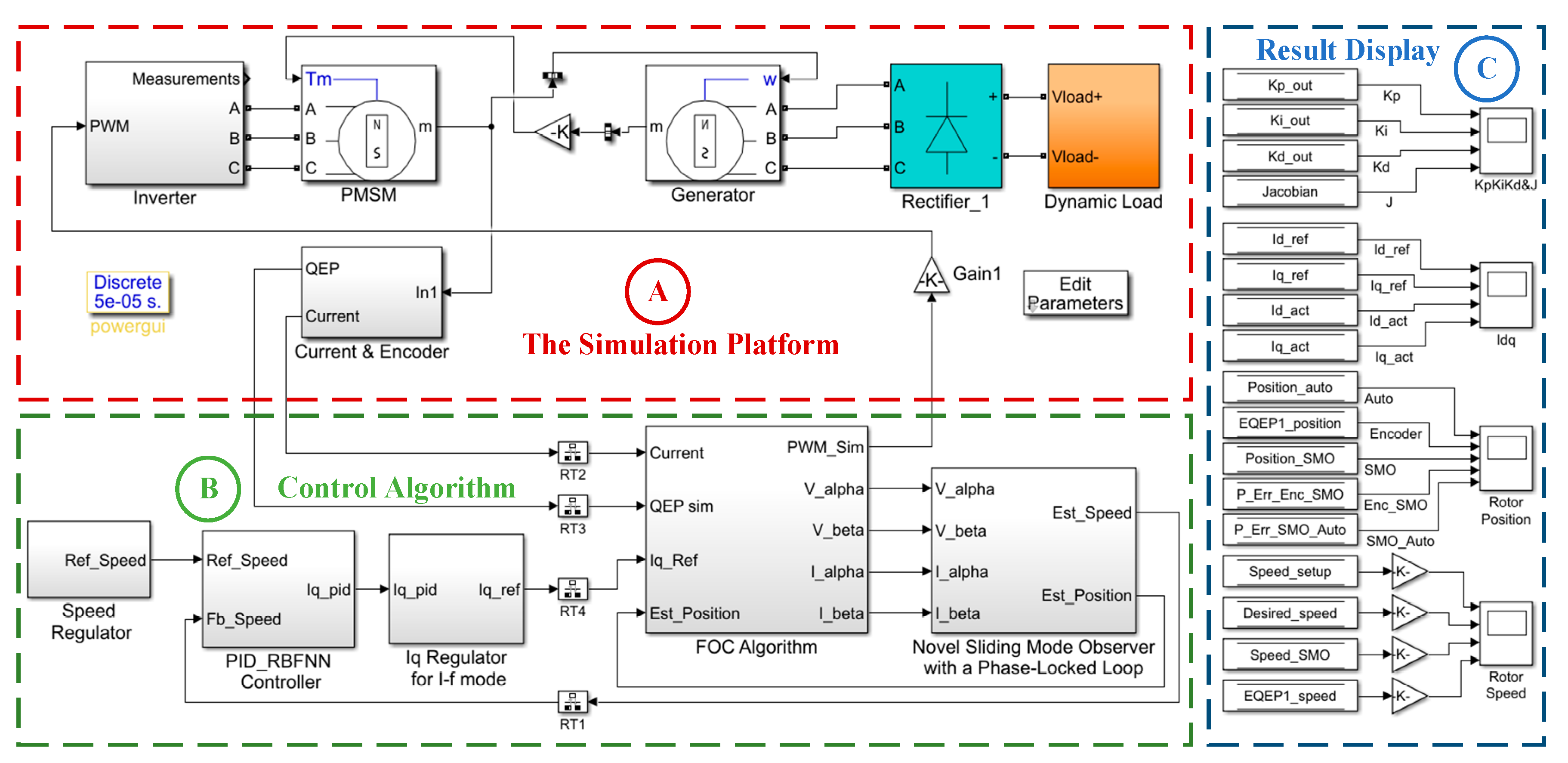

The complete design of the sensorless PMSM drive control system is shown in

Figure 7, which includes three blocks. The first block (A) is built for real-time platform modeling. The discrete times of the PMSM model, the inverter, and the generator are 50 μs. The second block (B) is the motor control algorithm, which is executed in simulation and the real-time experiment. The third block (C) is used to monitor and acquire the simulation data. Within the control algorithm block, five subblocks are executed as the reference speed regulator, the discrete RBFNN-based self-tuning PID controller, the

regulator of

I-f mode, the FOC algorithm, and the novel sliding mode observer with a phase-locked loop, respectively. The sampling time of the velocity loop is 1ms, while the sampling times of the FOC algorithm and the novel SMO-PLL estimator are 50 μs. In the current control loop, two PI controllers are adopted for the currents in

d-q axis. Those PI controllers’ parameters are set as

KPd = 0.25,

KId = 0.025,

KPq = 0.25,

KIq = 0.025. In the speed control loop, it is implemented by a self-tuning PID controller based on an RBFNN. The neuron parameters of those compositional five hidden nodes are initially set, as node centers (

c1 = −0.01,

c2 = −0.005,

c3 = 0.0,

c4 = 0.005,

c5 = 0.01), node widths (

b1 =

b2 =

b3 =

b4 =

b5 = 0.005), connective weights (

w1 =

w2 =

w3 =

w4 =

w5 = 0.000625). The learning rate is 0.475, and the momentum factor is 0.95. Additionally, the discrete PID’s initial parameters are designed as

KPs = 0.725,

KIs = 0.0105,

KDs = 0.483. These initial values are tuned during the operating time. The dynamic load system is set up with an initial resistance load of 100 Ω and a capacitor of 470 μF.

Figure 8 shows the motor’s speed responses while speeding up the rotor speed from 0 to 2000 rpm. The reference speed is changed in a period of 1s with a sequence of 200 → 400 → 700 → 1000 → 700 → 1000 → 1400 → 1700 → 2000 rpm.

Figure 8a refers that the novel SMO-PLL estimated rotor speed is closely tracked to the reference speed, and overlaps the actual rotor speed, calculated by the encoder.

Figure 8b presents the current response in the

d-q axis. The current

iq is varied and regarded to the reference speed. When the rotor speed is increased, the external load becomes higher. Therefore, the more torque is required in the motor, and the current

iq is regulated to be larger. The current

id almost is equal to zero and has some small pulses when changing the speed.

Figure 8c–f illustrates the electrical positions of the rotor, separately calculated by the novel SMO-PLL estimator and the encoder, with the estimated errors at the speeds of 700, 1000, 1400, and 2000 rpm. There are 7, 10, 14 and 20 position cycles in a period of 0.15s, respectively. Correspondingly, the rotation frequencies are 46.67, 66.67, 93.33, and 133.33 Hz. These values are suitable for the mentioned rotor speed. The estimated and actual positions are approximated to each other; thus, the estimated error is equal to zero. The PID gains are updated during the operating time. At = 3.5 s (as

ωr = 700 rpm), the PID gains are tuned to

KPs = 0.7424,

KIs = 0.0107, and

KDs = 0.4806. At = 4.5 s (as ω

r = 1000 rpm), the PID gains are tuned to

KPs = 0.7694,

KIs = 0.0110, and

KDs = 0.4768. At t = 7.5 s (as

ωr = 1400 rpm), the PID gains are tuned to

KPs = 0.8549,

KIs = 0.0117, and

KDs = 0.4648. Lastly, the rotor speed reaches 2000 rpm and the PID gains are also tuned to

KPs = 1.0288,

KIs = 0.0131, and

KDs = 0.4400 at t = 9.5 s.

Figure 9 demonstrates the detailed speed response for the startup motor mode and switching to the sensorless control mode at the speed of 200 rpm. The ramp-up speed ratio is set at 500 rpm/s. As mentioned in step 1 of the

I-f strategy, the rotor speed is increased, following the ramp function, with the initial reference current

of 0.63 A. The actual rotor speed reaches 200 rpm in 0.415 s. At t = 0.441 s, the actual rotor speed reaches the maximum of 207.6 rpm, so the maximum error is +7.6 rpm. In step 2 of the

I-f strategy, from t = 0.5 s, the reference current

decreases down to 0.183 A, with a current down ratio of 0.42 A/s. The actual rotor speed is kept close to 200 rpm. At t = 1.585 s, the actual rotor speed is reduced to a minimum of 191.3 rpm, so the minimum error is −9.7 rpm. At t = 1.682 s, the switching operation occurs, when the deviation of the estimated position and the auto-generated position is 3.6 degrees. Three rotor position curves are almost overlapped together. The current

iq has a small ripple, while the small pulse (about 0.05 A) appears in the current

id. Therefore, the switching transient is smooth. Then, the motor begins to operate in the sensorless control mode.

Figure 10 shows the motor’s speed responses while slowing down the rotor speed from 2000 to 400 rpm. The reference speed is sequentially varied as 2000 → 1700 → 1400 → 1200 → 800 → 1000 → 1200 → 1400 → 1000→ 700 → 400 rpm.

Figure 10a shows that the estimated rotor speed is closely tracked by the reference speed and overlaps the actual rotor speed.

Figure 10b presents the current response in the

d-q axis. The current

iq is also varied to the rotor speed. When the rotor speed is decreased, the external load becomes lower. Therefore, the less torque is required to the motor, and the current

iq is regulated to be smaller. Moreover, the self-tuning PID controller’s parameters are also tuned successfully. At t = 12.5 s (as

ωr = 1200 rpm), the PID gains are tuned to

KPs = 0.8490,

KIs = 0.0115,

KDs = 0.4666. At t = 17.5 s (as

ωr = 1000 rpm), the PID gains are tuned to

KPs = 0.6567,

KIs = 0.0094,

KDs = 0.4947. Lastly, the rotor speed decreases to 400 rpm and the PID gains are also tuned to

KPs = 0.6020,

KIs = 0.0087,

KDs = 0.5026 at t = 19.5 s.

Figure 11 presents the system performance when changing the external load. In the beginning, the dynamic load system is operated with a capacitor of 470 μF, and the total resistor of 100 Ω, connected in the electrical circuit. The motor starts up and increases the rotor speed following the sequence of 200 → 500 → 1000 → 1500 → 2000 rpm. The rotor speed reaches 2000 rpm after 5 s. The current

iq is approximately 1.79 A. At t = 6 s, the resistance load is changed from 100 Ω to 50 Ω by turning on some resistors in parallel connection. The external load is enhanced. The rotor speed reduces to the minimum of 1838 rpm, at t = 6.037 s, and stabilizes at 2000 rpm again at t = 6.468 s. The speed reduction is 162 rpm, and the recovery time is 0.431 s. The current

iq is increased to 2.51 A. Additionally, at t = 8 s, the resistance load is returned to the initial value of 100 Ω by turning off the same resistors. The motor speed is increased to the maximum of 2170 rpm at t = 8.041 s and stabilized at 2000 rpm again at t = 8.492 s. The speed increment is 170 rpm, and the recovery time is 0.451 s. The current

iq is decreased to the previous value of 1.79 A because the additional external load is removed. It can be inferred that the motor still operates stably with the sensorless control algorithm by the novel SMO-PLL estimator in the dynamic load condition.

As a summary, the various reference speed changes and the dynamic load condition are investigated in

Figure 8,

Figure 9,

Figure 10 and

Figure 11 to analyze the controller performance. Referring to those results, it is easy to find that the rotor speed almost tracks to the commands very well, in which all the steady-state errors approach zero, and the overshoot or undershoot is also too small. The estimator works successfully because the estimated position approaches the actual position. The estimated error is almost zero. Moreover, the system has a good mode transition and robust performance against disturbance. The simulation results confirm that the proposed estimation and control algorithm for the sensorless PMSM drive system are correct and effective.

6. The Experimental Verification and Results

After finishing the simulation, to verify the algorithm and analyze the system performance, the motor control algorithm is implemented by the platform in

Figure 12. The hardware platform consists of a PMSM coupled to a generator, with an electrical load system, an inverter, a DSP F28379D (as TI-DSP), and a control circuit. The parameters of PMSM are listed in

Table 1. The DSP F28379D is equipped with 200 MHz dual C28xCPUs and dual CLAs, 1 MB Flash, 16-bit/12-bit ADCs, comparators, 12-bit DACs, HRPWMs, eCAPs, eQEPs, CANs, etc. The control circuit is designed to isolate the PWM signal between the inverter and TI-DSP, process the phase current measurement, and protect the overcurrent status. When the overcurrent happens, the PWM control signal generated by TI-DSP will be locked. The electrical load system includes a rectifier, a capacitor of 470 μF-450 V, and power resistors of 100 Ω-100 W.

In the simulation structure in

Figure 7, only the second block (B) is compiled to generate the algorithm code in C/C++ language, which is imported into the CCS software. The CCS software was responsible for connecting, downloading, debugging, and monitoring online the variables during the operation of the system. Moreover, some data in the block (C) are acquired online by MATLAB, based on the SCI function.

The sampling times of the velocity loop, the current loop and the novel SMO-PLL estimator, are still set as the same as the simulation values. The inverter’s switching frequency is set at 15 Khz. The parameters of PI current controller are set as KPd = 0.25, KId = 0.025, KPq = 0.25, and KIq = 0.025. The RBFNN’s initial parameters are setup as the node centers (c1 = -0.0025, c2 = -0.00125, c3 = 0.0, c4 =0.00125, c5 = 0.0025), the node widths (b1 = b2 = b3 = b4= b5 = 0.5), the connective weights (w1 = w2 = w3 = w4 = w5 = 0.0000625). The learning rate is 0.435 and the momentum factor is 0.75. Additionally, the discrete PID’s initial parameters are designed as KPs = 0.735, KIs = 0.00435, and KDs = 0.478. All experimental results are implemented with an initial resistance load of 100Ω-400 W, a capacitor of 470μF-450V in the dynamic load system.

Figure 13 shows the motor’s speed responses while speeding up the rotor speed from 0 to 2000 rpm. The reference speed is changed in a period of 5s with the sequences as 300 → 500 → 700 → 1000 → 800 → 1200 → 1600 → 1800 → 2000 rpm.

Figure 13a refers that the novel SMO-PLL estimated rotor speed is closely tracked to the reference speed, and overlapped the actual rotor speed, measured by the encoder. Although there is the oscillation of the current responses in

Figure 13b, their average value still follows the current command.

Figure 13c–f illustrates the electrical positions of the rotor, separately calculated by the novel SMO-PLL estimator and the encoder, with the estimated errors at the speeds of 500, 1000, 1600, 2000 rpm. There are approximately 5, 10, 16 and 20 position cycles in a period of 0.15s, respectively. Correspondingly, the rotation frequencies are 33.33, 66.67, 106.67, and 133.33 Hz. These values are suitable for the rotor speed. The estimated and actual positions are approximated to each other, so the estimated error approaches zero. The self-tuning PID controller’s parameters are also updated during the operating time. The PID gains are tuned to

KPs = 0.7378,

KIs = 0.0039,

KDs = 0.4751 at t = 12 s (as

ωr = 500 rpm);

KPs = 0.7583,

KIs = 0.0039,

KDs = 0.4692 at t = 22 s (as ω

r = 1000 rpm);

KPs = 0.8408,

KIs = 0.0034,

KDs = 0.4619 at t = 37.5 s (as

ωr = 1600 rpm). Lastly, rotor speed reaches 2000 rpm, and

KPs = 0.8672,

KIs = 0.0034,

KDs = 0.4487 at t = 46 s.

Figure 14 demonstrates the detailed speed response for the startup motor mode and switching to the sensorless control mode at the speed of 300 rpm. The ramp-up speed ratio is set up at 66.67 rpm/s. At t = 0.623 s, the motor starts to speed up. The rotor speed is increased, following the ramp function with the initial reference current

of 0.635 A. The actual rotor speed reaches 295 rpm at t = 5.2 s. Then, the reference current

decreases down to 0.336 A with a current down ratio of 0.085 A/s. The reference speed is kept at 300 rpm, and the actual rotor speed is still close to 300 rpm. At t = 6.403s, the actual rotor speed reaches the maximum of 302.7 rpm. The maximum speed error is +2.7 rpm. At t = 8.832 s, the actual rotor speed drops to a minimum of 286.1 rpm. The minimum speed error is −13.9 rpm. The estimated position leads the auto position by 27.95 degrees at t = 5 s, while the estimated position error is 39.02 degrees. These values are reduced in the current down region. The switching operation occurs at t = 8.782 s when the deviation of estimated position and auto position (

θL) is also equal to 3.6 degrees. The estimated position error is only 0.175 degrees. The ripple of the current

iq is roughly 0.06 A, while the current

id fluctuates around zero within a range of 0.1 A. The motor switches the control mode smoothly. After this, the motor begins to operate in the sensorless control mode.

Figure 15 shows the motor’s speed responses while slowing down the rotor speed from 1800 to 300 rpm. The reference speed is sequentially varied as 1800 → 1600 → 1400 → 1000 → 1200 → 800 → 500 → 300→ 500 → 700 → 1000 rpm.

Figure 15a shows that the estimated rotor speed is closely tracked by the reference speed and overlaps the actual rotor speed.

Figure 15b presents the current response in the

d–q axis. The current

iq is also varied according to the rotor speed. When the rotor speed is decreased, the external load becomes lower. Therefore, the less torque is required by the motor, and the current

iq is regulated to be smaller. Moreover, the self-tuning PID controller’s parameters are also tuned effectively. The PID gains are tuned to

KPs = 0.832,

KIs = 0.0039,

KDs = 0.4531 at t = 62 s (as

ωr = 1400 rpm);

KPs = 0.7280,

KIs = 0.0044,

KDs = 0.4580 at t = 77 s (as

ωr = 800 rpm); and

KPs = 0.7046,

KIs = 0.0044,

KDs = 0.4639 at t = 87 s (as

ωr = 300 rpm).

Figure 16 presents the system performance when the external load is varied. In the beginning, the dynamic load is set up with a capacitor of 470 μF-450 V, the total resistor of 100 Ω-400 W. The motor starts up and increases the rotor speed, reaching 2000 rpm. The current

iq fluctuates around 1.56 A. At t = 37.99 s, the total resistance load is changed to 50 Ω-800 W by turning on more resistors. At t = 38.11 s, the actual rotor speed (red line) drops to a minimum of 1797 rpm while the minimum estimated value (blue line) is 1817 rpm. The recovery time is 2.99 s when the motor reaches 1995 rpm again at t = 40.98 s. The average current

iq reaches 2.42 A due to the external load increment. In addition, at t = 45.60 s, the total resistance load is returned to the initial value of 100 Ω-400 W by turning off the same resistor. The actual rotor speed is increased to the maximum of 2171 rpm at t = 45.71 s, while the maximum estimated value is 2157 rpm. The recovery time is 1.06 s when the motor stabilizes at 2000 rpm again at t = 46.66 s. The average current

iq is decreased to 1.57 A because of the external load reduction. Within the speed regulation at 2000rpm, the estimate speed error is about +5 rpm, while this error is larger at the up peak (20 rpm) or the low peak (14 rpm). The maximum control speed steady-state error is ±5 rpm at 2000 rpm. Although the system is affected by the disturbance of the external load, the motor still operates stably and successfully with the sensorless control algorithm based on the novel SMO-PLL estimator.

Finally, similar to the simulation, the experimental results in

Figure 13,

Figure 14,

Figure 15 and

Figure 16 show that the rotor speed almost tracks to the command very well, all the steady-state errors approach zero (within ±5 rpm in tolerance), and the overshoot or undershoot is also too small. The novel SMO-PLL estimator works successfully. The estimated position approaches the actual position. The estimated error is close to zero. Additionally, the real-time system has a good mode transition and robust performance against disturbance. The experimental results again confirm that the proposed estimation and control algorithm of the PMSM system are correct and effective in the real-time system. Furthermore, the DSP application for the PMSM drive control system is built in MATLAB Simulink properly, and is deployed to CCS software to realize the real-time system successfully. This deployment method shortens the application development time.