Fault Current Limiting Characteristics of a Small-Scale Bridge Type SFCL with Single HTSC Element Using Flux-Coupling

Abstract

:1. Introduction

2. Structure and Operating Principle

2.1. Sturcture and Principle

2.2. Equivalent Circuit

3. Experimental Results

3.1. Preparation of Experiment

3.2. Experimental Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| SFCL | the superconducting fault current limiter |

| HTSC | the high temperature superconducting |

| N1 | the primary winding |

| N2 | the secondary winding |

| L1 | the inductance of the primary winding |

| L2 | the inductance of the secondary winding |

| Iop-sub | the fault current limiting operating current in the case of a subtractive winding |

| Iop-add | the fault current limiting operating current in the case of an additive winding |

| Ic | the critical current |

| Ein | the AC power supply voltage |

| Xline | the line reactance |

| Rline | the line resistance |

| Rload | the load resistance |

| ib | the current of the bridge type SFCL |

| i1 | the current of the primary winding |

| i2 | the current of the secondary winding |

| Iin | the line current |

| V1 | the voltages induced by the primary winding |

| V2 | the voltages induced by the secondary winding |

| VSC | the voltages induced by the HTSC element |

| RSC | the resistances of HTSC element |

| ϕ1 | the magnetic flux of the primary winding |

| ϕ2 | the magnetic flux of the secondary winding |

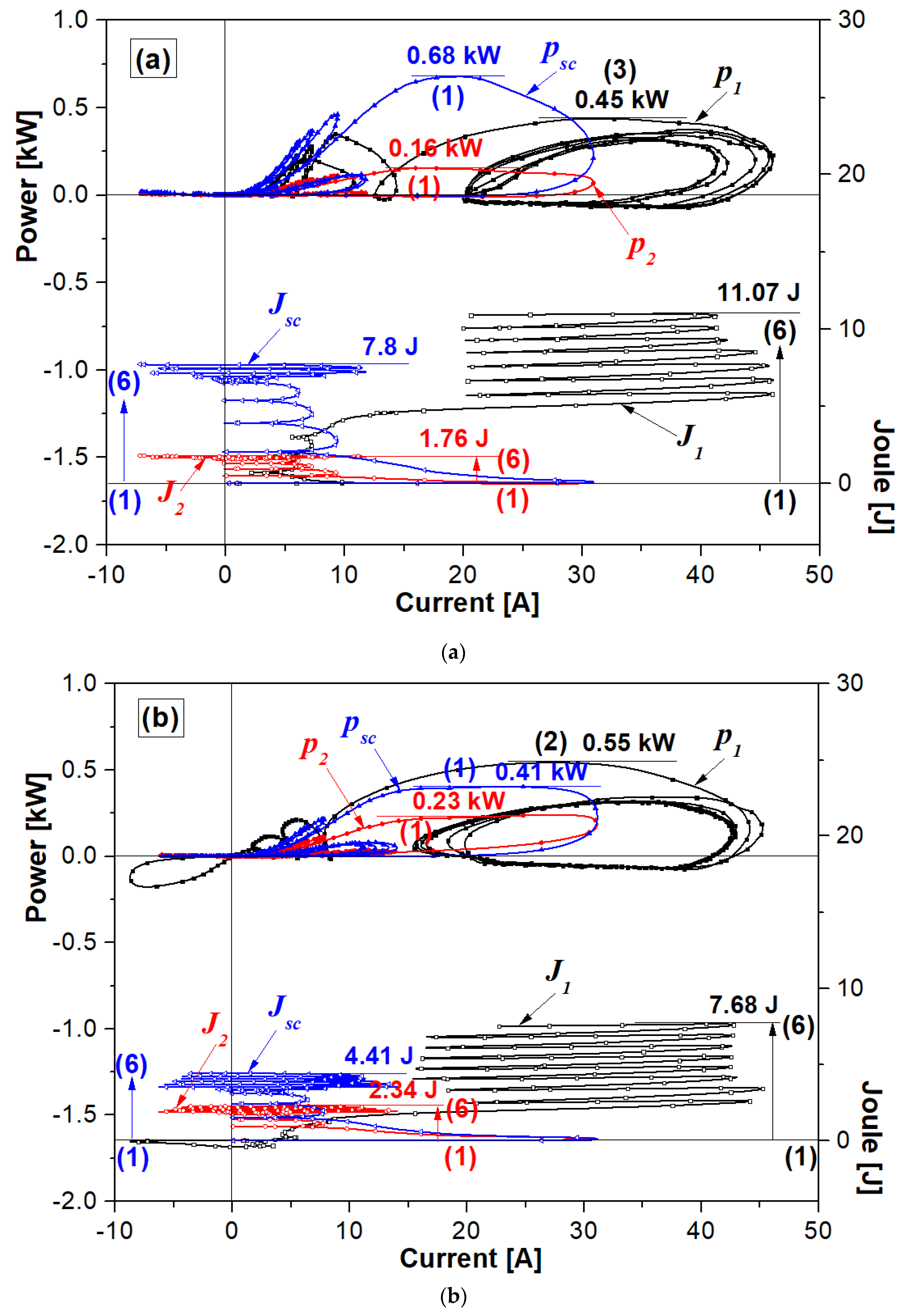

| pSC | the power of HTSC element |

| p1 | the power of the primary winding |

| p2 | the power of the secondary winding |

| JSC | the joule energy of HTSC element |

| J1 | the joule energy of the primary winding |

| J2 | the joule energy of the secondary winding |

References

- Hassenzahl, W.V.; Hazelton, D.W.; Johnson, B.K.; Komarek, P.; Noe, M.; Reis, C.T. Electric power applications of superconductivity. Proc. IEEE 2004, 92, 1655–1674. [Google Scholar] [CrossRef]

- Yuan, X.; Tekletsadik, K.; Kovalsky, L.; Bock, J.; Breuer, F.; Elschner, S. Proof-of-concept prototype test results of a superconducting fault current limiter for transmission-level applications. IEEE Trans. Appl. Supercond. 2015, 15, 1982–1985. [Google Scholar] [CrossRef]

- Lee, H.Y.; Asif, M.; Park, K.H.; Lee, B.W. Feasible application study of several types of superconducting fault current limiters in HVDC grids. IEEE Trans. Appl. Supercond. 2018, 28, 1–5. [Google Scholar] [CrossRef]

- Ko, S.C.; Lim, S.H. Analysis on magnetizing characteristics due to peak fault current limiting operation of a modified flux-lock-type SFCL with two magnetic paths. IEEE Trans. Appl. Supercond. 2016, 26, 1–5. [Google Scholar] [CrossRef]

- Lim, S.H.; Ko, S.C.; Han, T.H. Analysis on current limiting characteristics of a transformer type SFCL with two triggering current levels. Phys. C Supercond. Appl. 2013, 484, 253–257. [Google Scholar] [CrossRef]

- Abramovitz, A. Survey of solid state fault current limiters. IEEE Trans. Power Electron. 2011, 27, 2770–2782. [Google Scholar] [CrossRef]

- Boenig, H.; Paice, D. Fault current limiter using a superconducting coil. IEEE Trans. Magn. 1983, 19, 1051–1053. [Google Scholar] [CrossRef]

- Bock, J.; Hobl, A.; Schramm, J.; Krämer, S.; Jänke, C. Resistive superconducting fault current limiters are becoming a mature technology. IEEE Trans. Appl. Supercond. 2015, 25, 2880–2887. [Google Scholar] [CrossRef]

- You, H.; Jin, J. Characteristic analysis of a fully controlled bridge type superconducting fault current limiter. IEEE Trans. Appl. Supercond. 2016, 26, 1–6. [Google Scholar] [CrossRef]

- Hekmati, A. Proposed design for a tunable inductive shield-type SFCL. IEEE Trans. Appl. Supercond. 2014, 24, 1–7. [Google Scholar] [CrossRef]

- Li, B.; Jing, F.; Li, B.; Chen, X.; Jia, J. Study of the application of active saturated iron-core superconducting fault current limiters in the VSC-HVDC system. IEEE Trans. Appl. Supercond. 2018, 28, 1–6. [Google Scholar]

- Kumar, P.; Shaw, P. Comparison of superconducting fault current limiter topologies based on power electronic devices. In Proceedings of the 2016 7th India International Conference on Power Electronics, Patiala, India, 17–19 November 2016; pp. 1–5. [Google Scholar]

- Ghanbari, T.; Farjah, E.; Tashakor, N. Thyristor based bridge-type fault current limiter for fault current limiting capability enhancement. IET Gener. Transm. Distrib. 2016, 10, 2202–2215. [Google Scholar] [CrossRef]

- Jiang, L.; Jin, J.X.; Chen, X.Y. Fully controlled hybrid bridge type superconducting fault current limiter. IEEE Trans. Appl. Supercond. 2014, 24, 1–5. [Google Scholar]

- Baimel, D.; Tapuchi, S.; Baimel, N. New control strategies for IGBT based bridge type SFCL. In Proceedings of the 2018 IEEE 18th International Power Electronics and Motion Control Conference (PEMC), Budapest, Hungary, 26–30 August 2018; pp. 401–405. [Google Scholar]

- Radmanesh, H.; Fathi, H.; Gharehpetian, G.B. Series transformer based solid-state fault current limiter. IEEE Trans. Smart Grid 2015, 6, 1983–1991. [Google Scholar] [CrossRef]

- Arathi, T.O.; Reji, P. IGBT based bridge type fault current limiter. In Proceedings of the 2018 International CET Conference on Control, Communication, and Computing (IC4), Thiruvananthapuram, India, 5–7 July 2018; pp. 89–94. [Google Scholar]

- He, J.; Li, B.; Li, Y. Analysis of the fault current limiting requirement and design of the bridge-type FCL in the multi-terminal DC grid. IET Gener. Transm. Distrib. 2017, 11, 968–976. [Google Scholar] [CrossRef]

- Rashid, G.; Ali, M.H. A modified bridge-type fault current limiter for fault ride-through capacity enhancement of fixed speed wind generator. IEEE Trans. Appl. Supercond. 2014, 29, 527–528. [Google Scholar]

- Abdolkarimzadeh, M.; Heris, M.N.; Abapour, M.; Sabahi, M. A bridge-type fault current limiter for energy management of AC/DC microgrids. IEEE Trans. Appl. Supercond. 2017, 32, 9043–9050. [Google Scholar] [CrossRef]

- Imparato, S.; Morandi, A.; Martini, L.; Bocchi, M.; Grasso, G.; Fabbri, M.; Negrini, F.; Ribani, P.L. Experimental evaluation of AC losses of a DC restive SFCL prototype. IEEE Trans. Appl. Supercond. 2010, 20, 1199–1202. [Google Scholar] [CrossRef]

- Morandi, A.; Brisigotti, S.; Grasso, G.; Marabotto, R. Conduction cooling and fast recovery in MgB2-based DC resistive SFCL. IEEE Trans. Appl. Supercond. 2013, 23, 5604409. [Google Scholar] [CrossRef]

- Wanmin, F.; Wu, B. A novel topology of bridge-type superconducting fault current limiter. In Proceedings of the 2009 Canadian Conference on Electrical and Computer Engineering, St. John’s, NL, Canadian, 3–6 May 2009; Volume 21, pp. 2201–2204. [Google Scholar]

- Hu, Y.; Xun, J. Analysis of a IGBTs-based bridge type superconducting fault current limiter. In Proceedings of the 2015 IEEE International Conference on Applied Superconductivity and Electromagnetic Devices (ASEMD), Shanghai, China, 20–23 November 2015; pp. 21–22. [Google Scholar]

- Sadi, M.A.H.; Ali, M.H. A fuzzy logic controlled bridge type fault current limiter for transient stability augmentation of multi-machine power system. IEEE Trans. Power Syst. 2016, 31, 602–611. [Google Scholar] [CrossRef]

- Lim, S.H.; Cho, Y.S.; Choi, H.S.; Han, B.S. Improvement of current limiting capability of HTSC elements in hybrid type SFCL. IEEE Trans. Appl. Supercond. 2007, 17, 1807–1810. [Google Scholar] [CrossRef]

- Lim, S.H.; Kim, J.C. Quench and recovery characteristics of series-connected resistive type SFCLs with magnetically coupled shunt-reactors. IEEE Trans. Appl. Supercond. 2008, 18, 729–732. [Google Scholar]

- Lim, S.H.; Choi, H.S. Quench characteristics of HTSC elements in series-connected flux-lock type SFCLs through magnetic flux-linkage. Phys. C Supercond. Appl. 2006, 445–448, 1073–1077. [Google Scholar] [CrossRef]

| Windings (Turn Number, Self Inductance) | Value | Unit |

|---|---|---|

| Primary Winding (N1, L1) Secondary Winding (N2, L2) | 45, 20.293 15, 1.295 | Turns, mH Turns, mH |

| Iron Core (Laminated Si) | Size | Unit |

| Outer horizontal length Outer vertical length Inner horizontal length Inner vertical length Thickness | 250 235 155 137 132 | mm mm mm mm mm |

| HTSC Element (RSC) | Value | Unit |

| Material Critical Current (IC) Critical Temperature (Tc) Total Meander Line Length Line Width Thin Film Thickness Gold Layer Thickness | YBCO 18.15 87 420 2 0.3 0.2 | Thin Film A K mm mm μm μm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, T.-H.; Ko, S.-C.; Lim, S.-H. Fault Current Limiting Characteristics of a Small-Scale Bridge Type SFCL with Single HTSC Element Using Flux-Coupling. Electronics 2020, 9, 569. https://doi.org/10.3390/electronics9040569

Han T-H, Ko S-C, Lim S-H. Fault Current Limiting Characteristics of a Small-Scale Bridge Type SFCL with Single HTSC Element Using Flux-Coupling. Electronics. 2020; 9(4):569. https://doi.org/10.3390/electronics9040569

Chicago/Turabian StyleHan, Tae-Hee, Seok-Cheol Ko, and Sung-Hun Lim. 2020. "Fault Current Limiting Characteristics of a Small-Scale Bridge Type SFCL with Single HTSC Element Using Flux-Coupling" Electronics 9, no. 4: 569. https://doi.org/10.3390/electronics9040569

APA StyleHan, T.-H., Ko, S.-C., & Lim, S.-H. (2020). Fault Current Limiting Characteristics of a Small-Scale Bridge Type SFCL with Single HTSC Element Using Flux-Coupling. Electronics, 9(4), 569. https://doi.org/10.3390/electronics9040569