Concept Design and Load Capacity Analysis of a Novel Serial-Parallel Robot for the Automatic Charging of Electric Vehicles

Abstract

1. Introduction

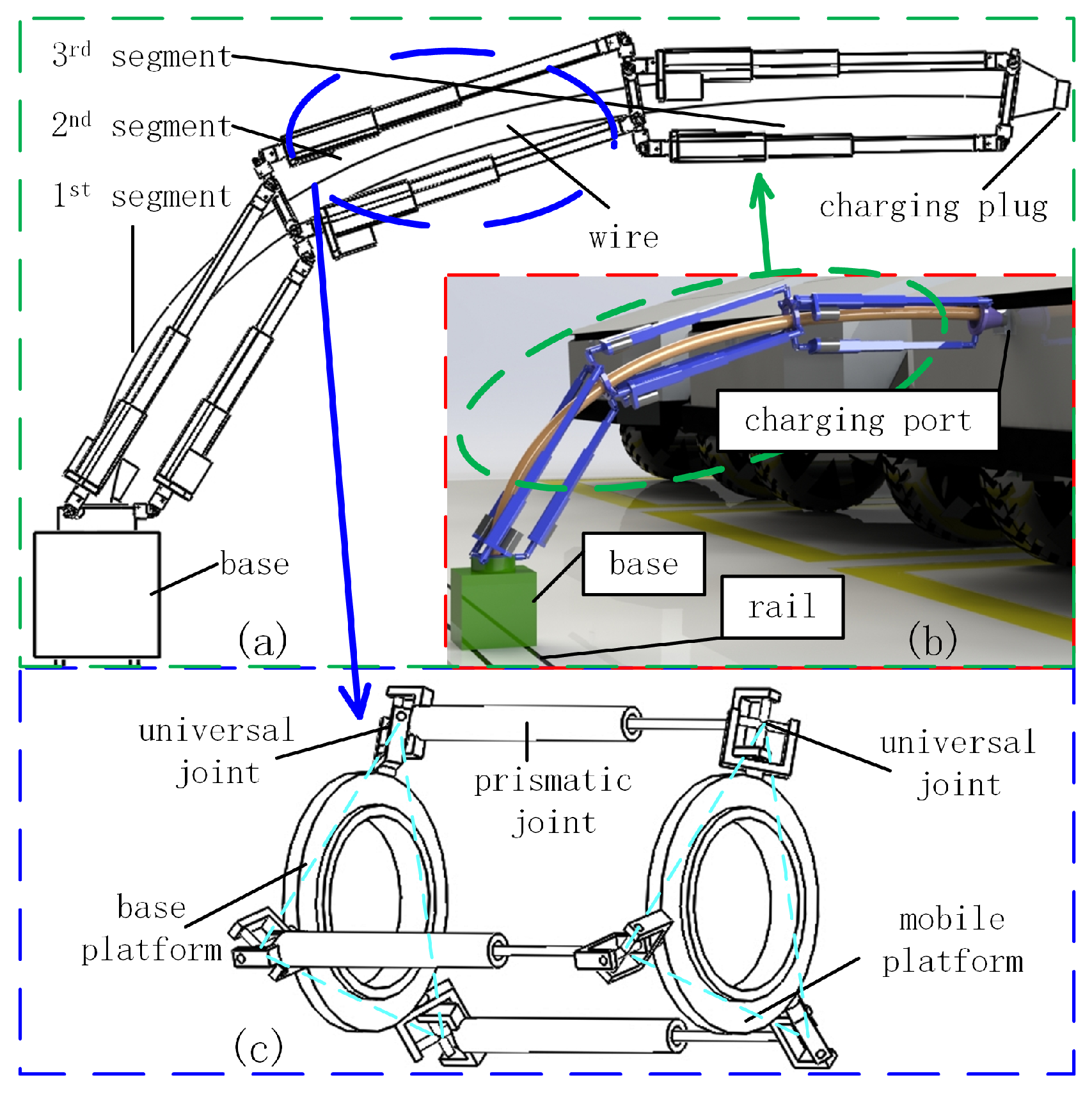

2. Concept Design and Kinematic Model of the EV Charging Robot

2.1. Concept Design

2.2. Kinematic Modeling

- represents the global frame of the robot. Generally, the origin of the global frame is at the center of the upper surface of the base; z-axis is defined perpendicular to the plane of the upper surface of the base; the x-y-plane coincides with the upper surface.

- represents the local frame of the base platform . The origin of the frame is at the center of the platform ; x-axis is parallel with the vector pointing from to ; z-axis is perpendicular to the platform; y-axis is determined by the right-hand rule. It should be noted that the local frame of the base platform of the 3UPU coincides with the global frame of the robot.

- represents the local frame of the mobile platform . The origin point and axis definitions are similar to frame .

- represents the local frame of the chain of the unit. The origin of the frame coincides with point ; z-axis is parallel with z-axis of frame ; y-axis coincides with the bisector of angle ; x-axis is determined by the right-hand rule.

3. Static Model and Validation of the EV Charging Robot

3.1. Static Model

3.2. Simulation Validation

4. Load Capacity Analyses and Optimizations

4.1. Analysis in Term of the Manipulator Configuration

|

|

4.2. Analysis in Term of the Unit Length

|

4.3. Analysis in Term of the Unit Diameter

|

4.4. Analysis in Term of the Unit Actuating Force

|

4.5. Multi-Variable Optimization

|

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| DOF | degrees of freedom |

| UPU | a chain consists of a universal joint on each side of a prismatic joint |

Nomenclature

| n | the number of 3UPU the robot consists |

| i | the sequence number of 3UPU unit |

| k | the sequence number of UPU chain |

| the global frame of the robot | |

| the local frame of the base platform of the 3UPU | |

| the local frame of the mobile platform of the 3UPU | |

| the local frame of the chain of the 3UPU | |

| the rotation angle between and | |

| the homogeneous transformation matrix from to | |

| the distance between and | |

| the coordinate of expressed in | |

| attached point of the chain with the base platform in the 3UPU | |

| attached point of the chain with the mobile platform in the 3UPU | |

| the length of the edge of the triangle on the opposite side of the point | |

| the diameter of the 3UPU | |

| the angle between the axises of the revolute joints attached to the platform and the plane of the platform | |

| the angle of | |

| the length of the chain of the 3UPU | |

| the position of the end-effector | |

| the orientation of the end-effector | |

| the instantaneous velocity of the mobile platform of the 3UPU expressed in | |

| the angular velocity of the mobile platform of the 3UPU expressed in | |

| the Jacobian matrix of the 3UPU | |

| the unit vector from to | |

| the vector from to | |

| the unit vector along the axis of the revolute joint attached to the prismatic joint | |

| the intersection point of the axises of the revolute joints attached to the platforms on the chain | |

| the force of the joint | |

| the displacement of the joint | |

| the force of the mobile platform | |

| the displacement of the mobile platform | |

| the Jacobian matrix from the end-effector to the mobile platform of the 3UPU | |

| the active force of the prismatic of the 3UPU | |

| the constrained force of the prismatic of the 3UPU | |

| the force of the end effector expressed in | |

| the torque of the end effector expressed in |

References

- Taylor-Haw, C.K.; Haw, B.; Simmons, G.C. Electric Vehicle Charging Station. US Patent 8,487,584, 16 July 2013. [Google Scholar]

- Liu, Z.; Wen, F.; Ledwich, G. Optimal planning of electric-vehicle charging stations in distribution systems. IEEE Trans. Power Deliv. 2012, 28, 102–110. [Google Scholar] [CrossRef]

- Yamashita, T.; Jodo, K. Charger for an Automobile. US Patent 29/411,436, 15 January 2013. [Google Scholar]

- Wu, D.; Aliprantis, D.C.; Gkritza, K. Electric energy and power consumption by light-duty plug-in electric vehicles. IEEE Trans. Power Syst. 2010, 26, 738–746. [Google Scholar] [CrossRef]

- Walzel, B.; Sturm, C.; Fabian, J.; Hirz, M. Automated robot-based charging system for electric vehicles. In 16. Internationales Stuttgarter Symposium; Springer: Wiesbaden, Germany, 2016; pp. 937–949. [Google Scholar]

- Long, Y.; Wei, C.; Cao, C.; Hu, X.; Zhu, B.; Long, F. Design of high-power fully automatic charging device. In Proceedings of the 2019 IEEE Sustainable Power and Energy Conference (iSPEC), Beijing, China, 21–23 November 2019; pp. 2738–2742. [Google Scholar]

- Kong, P.-Y. Autonomous robot-like mobile chargers for electric vehicles at public parking facilities. IEEE Trans. Smart Grid 2019, 10, 5952–5963. [Google Scholar] [CrossRef]

- Lv, X.; Chen, G.; Hu, H.; Lou, Y. A robotic charging scheme for electric vehicles based on monocular vision and force perception. In Proceedings of the 2019 IEEE International Conference on Robotics and Biomimetics (ROBIO), Dali, China, 6–8 December 2019; pp. 2958–2963. [Google Scholar]

- Briot, S.; Bonev, I.A. Are parallel robots more accurate than serial robots? Trans. Can. Soc. Mech. Eng. 2007, 31, 445–455. [Google Scholar] [CrossRef]

- Liu, T.; Mu, Z.; Wang, H.; Xu, W.; Li, Y. A cable-driven redundant spatial manipulator with improved stiffness and load capacity. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 6628–6633. [Google Scholar]

- Tang, L.; Wang, J.; Zheng, Y.; Gu, G.; Zhu, L.; Zhu, X. Design of a cable-driven hyper-redundant robot with experimental validation. Int. J. Adv. Robot. Syst. 2017, 14, 1729881417734458. [Google Scholar] [CrossRef]

- Mu, Z.; Yuan, H.; Xu, W.; Hu, Z.; Liu, T.; Liang, B. Simultaneous Planning Method Considering Both Overall Configuration and End Pose for Hyper-Redundant Manipulators. IEEE Access 2019, 7, 136842–136854. [Google Scholar] [CrossRef]

- Xu, W.; Liu, T.; Li, Y. Kinematics, dynamics, and control of a cable-driven hyper-redundant manipulator. IEEE/ASME Trans. Mechatron. 2018, 23, 1693–1704. [Google Scholar] [CrossRef]

- Yuan, H.; Li, Z. Workspace analysis of cable-driven continuum manipulators based on static model. Robot. Comput.-Integr. Manuf. 2018, 49, 240–252. [Google Scholar] [CrossRef]

- Yuan, H.; Zhou, L.; Xu, W. A comprehensive static model of cable-driven multi-section continuum robots considering friction effect. Mech. Mach. Theory 2019, 135, 130–149. [Google Scholar] [CrossRef]

- Yuan, H.; Chiu, P.W.Y.; Li, Z. Shape-Reconstruction-Based Force Sensing Method for Continuum Surgical Robots With Large Deformation. IEEE Robot. Autom. Lett. 2017, 2, 1972–1979. [Google Scholar] [CrossRef]

- Hu, B.; Yu, J.; Lu, Y.; Sui, C.; Han, J. Statics and stiffness model of serial-parallel manipulator formed by k parallel manipulators connected in series. J. Mech. Robot. 2012, 4, 021012. [Google Scholar] [CrossRef]

- He, J.; Zheng, H.; Gao, F.; Zhang, H. Dynamics and control of a 7-dof hybrid manipulator for capturing a non-cooperative target in space. Mech. Mach. Theory 2019, 140, 83–103. [Google Scholar] [CrossRef]

- Ibrahim, O.; Khalil, W. Inverse and direct dynamic models of hybrid robots. Mech. Mach. Theory 2010, 45, 627–640. [Google Scholar] [CrossRef]

- Rahmani, A.; Ghanbari, A.; Pedrammehr, S. Kinematic analysis for hybrid 2-(6-upu) manipulator using wavelet neural network. In Advanced Materials Research; Trans Tech Publ: Stafa-Zurich, Switzerland, 2014; Volumn 1016, pp. 726–730. [Google Scholar]

- Staicu, S. Dynamics modelling of a stewart-based hybrid parallel robot. Adv. Robot. 2015, 29, 929–938. [Google Scholar] [CrossRef]

- Merlet, J.-P. Parallel Robots; Springer Science & Business Media: Berlin, Germany, 2006. [Google Scholar]

- Yuan, H.; Courteille, E.; Deblaise, D. Static and dynamic stiffness analyses of cable-driven parallel robots with non-negligible cable mass and elasticity. Mech. Mach. Theory 2015, 85, 64–81. [Google Scholar] [CrossRef]

- Yuan, H.; Courteille, E.; Gouttefarde, M.; Hervé, P.E. Vibration analysis of cable-driven parallel robots based on the dynamic stiffness matrix method. J. Sound Vib. 2017, 394, 527–544. [Google Scholar] [CrossRef]

- Zi, B.; Wang, N.; Qian, S.; Bao, K. Design, stiffness analysis and experimental study of a cable-driven parallel 3d printer. Mech. Mach. Theory 2019, 132, 207–222. [Google Scholar] [CrossRef]

- Romdhane, L. Design and analysis of a hybrid serial-parallel manipulator. Mech. Mach. Theory 1999, 34, 1037–1055. [Google Scholar] [CrossRef]

- Castelli, G.; Ottaviano, E.; Ceccarelli, M. A fairly general algorithm to evaluate workspace characteristics of serial and parallel manipulators. Mech. Based Des. Struct. Mach. 2008, 36, 14–33. [Google Scholar] [CrossRef]

- Zhao, C.; Guo, H.; Liu, R.; Deng, Z.; Li, B.; Tian, J. Actuation distribution and workspace analysis of a novel 3 (3rrls) metamorphic serial-parallel manipulator for grasping space non-cooperative targets. Mech. Mach. Theory 2019, 139, 424–442. [Google Scholar] [CrossRef]

- Guo, H.; Zhao, C.; Li, B.; Liu, R.; Deng, Z.; Tian, J. A transformation method to generate the workspace of an n (3rrs) serial–parallel manipulator. J. Mech. Des. 2019, 141, 092301. [Google Scholar] [CrossRef]

- Nayak, A.; Caro, S.; Wenger, P. Kinematic analysis of the 3-rps-3-spr series–parallel manipulator. Robotica 2019, 37, 1240–1266. [Google Scholar] [CrossRef]

- Arora, R.; Agarwal, D.; Bera, T.K. Workspace analysis and trajectory tracking of a planar hybrid manipulator with ball screw feed drive. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 378. [Google Scholar] [CrossRef]

- Huang, Z.; Li, Q. General methodology for type synthesis of symmetrical lower-mobility parallel manipulators and several novel manipulators. Int. J. Robot. Res. 2002, 21, 131–145. [Google Scholar] [CrossRef]

- Huang, Z.; Li, S.; Zuo, R. Feasible instantaneous motions and kinematic characteristics of a special 3-dof 3-upu parallel manipulator. Mech. Mach. Theory 2004, 39, 957–970. [Google Scholar] [CrossRef]

- Zheng, X.; Luo, Y.; Deng, Z.; Bin, H. Statics of rotational 3-upu parallel mechanisms based on principle of virtual work. In Proceedings of the 2007 IEEE International Conference on Robotics and Biomimetics (ROBIO), Sanya, China, 15–18 December 2007; pp. 1954–1959. [Google Scholar]

- Di Gregorio, R. Kinematics of the 3-upu wrist. Mech. Mach. Theory 2003, 38, 253–263. [Google Scholar] [CrossRef]

- Di Gregorio, R.; Parenti-Castelli, V. Mobility analysis of the 3-upu parallel mechanism assembled for a pure translational motion. J. Mech. Des. 2002, 124, 259–264. [Google Scholar] [CrossRef]

- Tsai, L.-W.; Joshi, S. Kinematics and optimization of a spatial 3-upu parallel manipulator. J. Mech. Des. 2000, 122, 439–446. [Google Scholar] [CrossRef]

- Zheng, X.; Deng, Z.; Luo, Y.; Bin, H. Static analysis of translational 3-upu parallel mechanism based on principle of virtual work. In Global Design to Gain a Competitive Edge; Springer: London, UK, 2008; pp. 681–690. [Google Scholar]

- Chen, Z.; Zhang, Y.; Huang, K.; Huang, Z. Symmetrical 2r1t parallel mechanism without parasitic motion. J. Mech. Eng. 2016, 52, 9–15. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, X.; Zhang, Y.; Huang, K.; Huang, Z. Dynamics analysis of a symmetrical 2r1t 3-upu parallel mechanism. J. Mech. Eng. 2017, 53, 46–53. [Google Scholar] [CrossRef]

- Joshi, S.A.; Tsai, L.-W. Jacobian analysis of limited-dof parallel manipulators. J. Mech. Des. 2002, 124, 254–258. [Google Scholar] [CrossRef]

| Type of the EV Charging Robots | DOF | Dexterity | Hollow Structure | Load Capacity | Modeling |

|---|---|---|---|---|---|

| Industrial robots in [5] | 6 | Poor | No | Normal | Easy |

| Cable-driven snake robots in [10] | 20 | Excellent | Yes | Poor | Normal |

| The proposed serial-parallel robot | 9 | Good | Yes | Good | Difficult |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| (rad) | (rad) | ||

| (mm) | (mm) | 70–140 | |

| (rad) | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, H.; Wu, Q.; Zhou, L. Concept Design and Load Capacity Analysis of a Novel Serial-Parallel Robot for the Automatic Charging of Electric Vehicles. Electronics 2020, 9, 956. https://doi.org/10.3390/electronics9060956

Yuan H, Wu Q, Zhou L. Concept Design and Load Capacity Analysis of a Novel Serial-Parallel Robot for the Automatic Charging of Electric Vehicles. Electronics. 2020; 9(6):956. https://doi.org/10.3390/electronics9060956

Chicago/Turabian StyleYuan, Han, Qiong Wu, and Lili Zhou. 2020. "Concept Design and Load Capacity Analysis of a Novel Serial-Parallel Robot for the Automatic Charging of Electric Vehicles" Electronics 9, no. 6: 956. https://doi.org/10.3390/electronics9060956

APA StyleYuan, H., Wu, Q., & Zhou, L. (2020). Concept Design and Load Capacity Analysis of a Novel Serial-Parallel Robot for the Automatic Charging of Electric Vehicles. Electronics, 9(6), 956. https://doi.org/10.3390/electronics9060956