Water Mist Fire Suppression Systems for Building and Industrial Applications: Issues and Challenges

Abstract

:1. Introduction

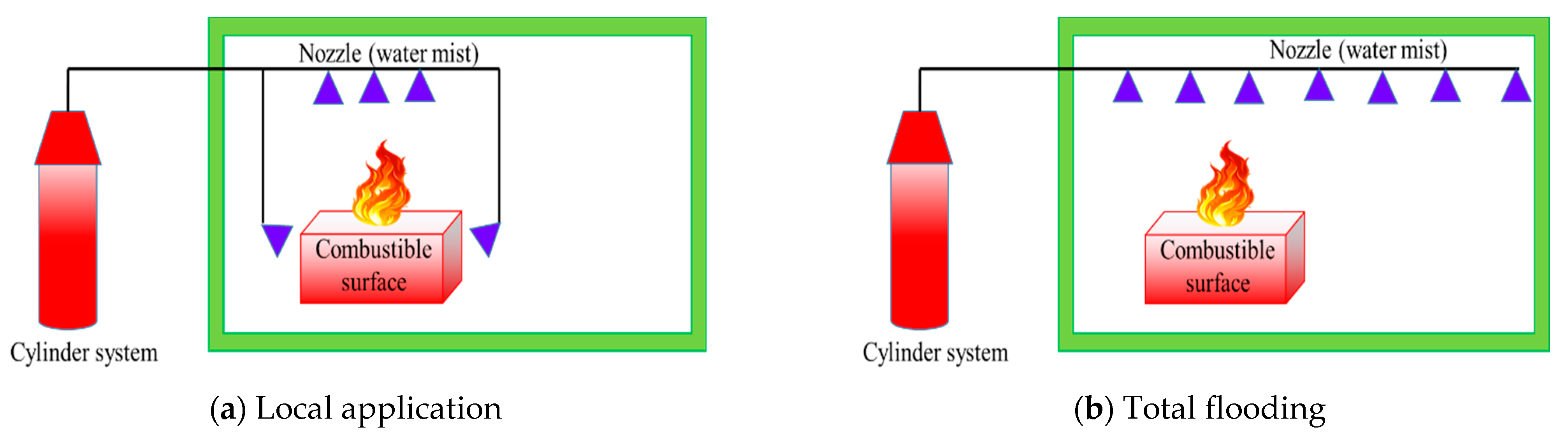

2. Water Mist Fire Systems

2.1. Methods of Generating Water Mist

2.1.1. Impingement Nozzles

2.1.2. Pressure Jet Nozzle

2.1.3. Twin-fluid Nozzle

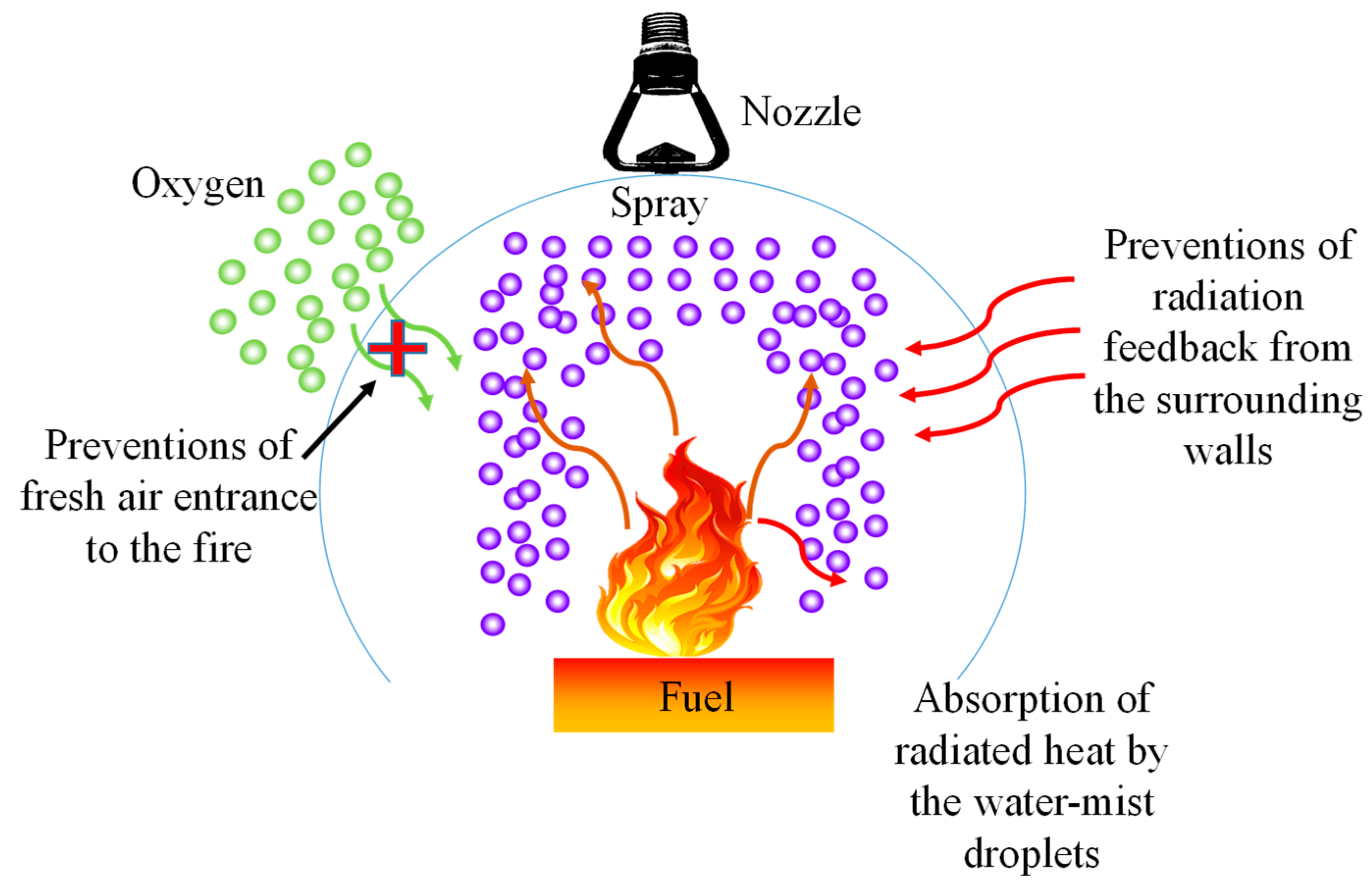

2.2. Fire Control and Suppression Mechanisms

2.2.1. Heat Extractions

2.2.2. Oxygen Displacement

2.2.3. Radiation Attenuation

3. Applications of Water Mist Systems

3.1. Machinery Spaces

3.2. Power Generation Turbines

3.3. Electrical Equipment

3.4. Transportation

3.5. Road and Rail Tunnels

3.6. Nuclear Power Generation

3.7. Explosion Hazard Mitigation

3.8. Cooking Areas

3.9. Commercial Buildings

3.10. Residential Buildings

4. Research and Development on Water Mist Systems

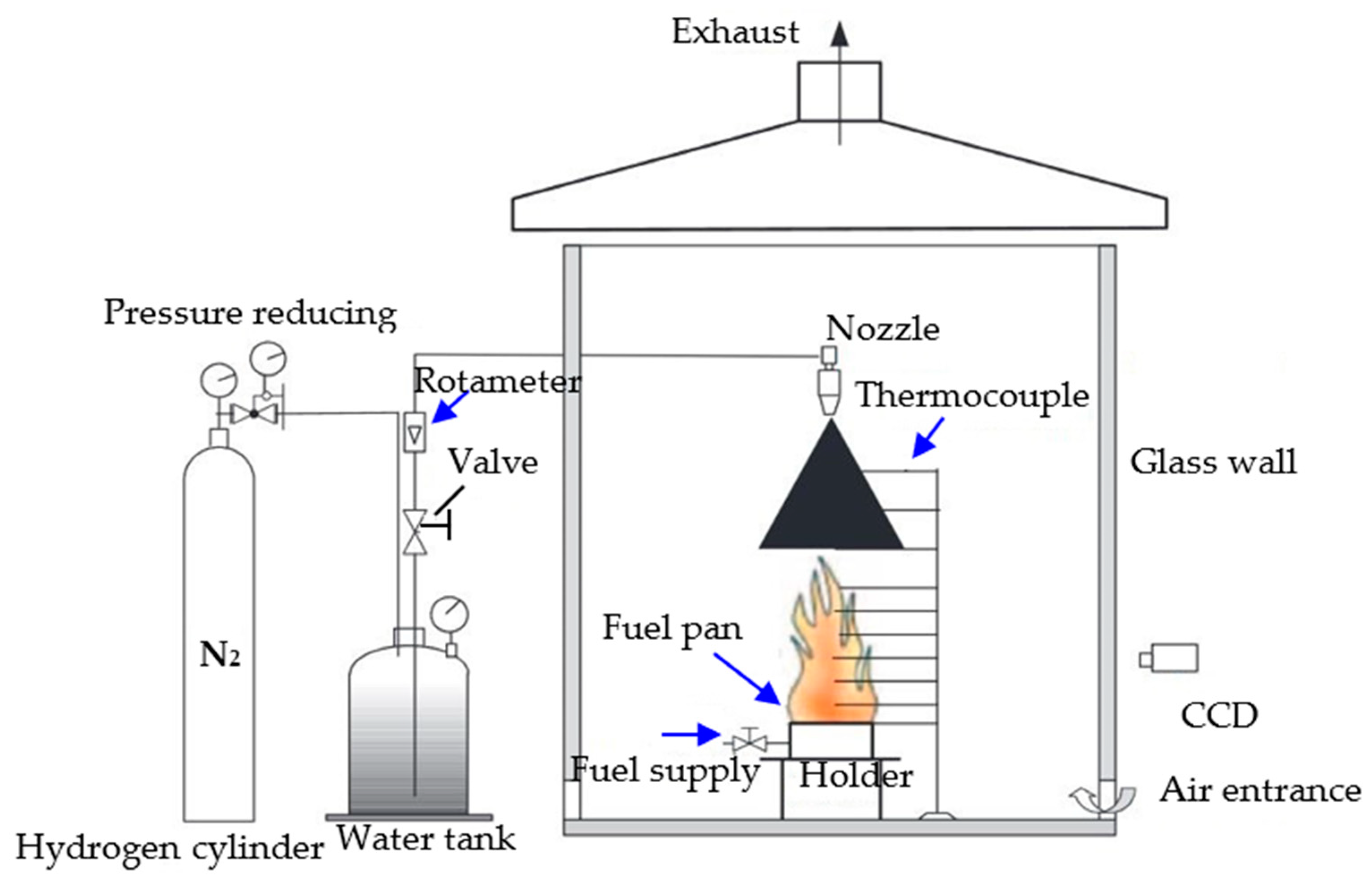

4.1. Spray Characteristics

4.1.1. Effect of Different Water Mist Additives

4.1.2. Effect of Different Operating Pressure

4.1.3. Effect of Different Water Droplet Sizes

4.1.4. Effect of Different Flow Rates

4.1.5. Effect of Different Nozzle K-Factors

4.1.6. Effect of Different Spray Momentum

4.1.7. Effect of Different Spray Angles

4.2. Fire Compartments

4.2.1. Effect of Different Ceiling Heights

4.2.2. Effect of Different Enclosure Volumes and Ventilation

4.2.3. Effect of Different Dynamic Mixing Situations

4.2.4. Effect of External Environment and wind conditions

4.3. Current Products for Water Mist Systems

4.3.1. Low-Pressure and Intermate-Pressure Systems

Tyco AquaMist ULF

VID FireKill APS Atrium System

4.3.2. High-Pressure Systems

Tyco AquaMist FOG

Marioff HI-FOG

Danfoss SEM-SAFE System

5. Design Codes for Water Mist Systems

5.1. American Standards

5.2. Australian Standards

5.3. British Standards

5.4. European Standard

5.5. Test protocols

6. Challenges and Issues

6.1. Operation and Maintenance

6.2. Design and Standardisation

6.3. Application Challenges

6.4. Economic Challenges

7. Conclusions and Recommendations

- (a)

- Further research can be conducted to develop corrosion-resistant materials and other methods of reducing the potential to block small orifice nozzles.

- (b)

- More research on the performance of water mist suppression at various nozzle heights, fire compartment configurations, and various fuel types and fire scenarios can be conducted.

- (c)

- A theoretical basis can be developed for the design process that can be applied to a wide range of hazards and can be used for a prescriptive design and installation standard.

- (d)

- New test protocols should be developed and tested for water mist in light-hazard occupancies and residential building spaces as an alternative to fire sprinklers.

- (e)

- Environmental benefits associated with water mist can be investigated for an alternative to gaseous suppression systems across the life cycle of products.

- (f)

- Research should be conducted to look at the potential water mist may have in assisting in fire protection in new and emerging fire hazards that the industry is trying to adapt to, such as bushfire protection, combustible cladding, electric battery storage facilities, electric cars, automated warehouse facilities, switchboards, datacentres, and compact residential buildings.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature:

| µm | Micrometre or micron | Critical radiation intensity required for piloted ignition | |

| O2 | Oxygen | Heat vaporisation of water | |

| K | Kelvin | Pressure inlet at nozzle | |

| Flame extinguishing temperature | Q | Nozzle flow rate | |

| Theoretical flame temperature | k | Discharge coefficient K-factor | |

| Surface temperature of fuel | Spray momentum | ||

| Mass fraction of oxygen | Mass of liquid-phase water | ||

| Mass fraction of fuel vapour | Mass of vapour-phase water | ||

| r | Stoichiometric ratio | Mass of air entrained by mist | |

| Heat removed per unit area | Velocity vector of water mist | ||

| Convective heat transfer per unit area | °C | Degree Celsius | |

| Heat required to produce a unit mass of vapour | kg | Kilograms | |

| Burning rate per unit area | kJ | Kilojoules | |

| Heat transfer to the fuel surface | H2O | Dihydrogen monoxide | |

| Heat lost from the surface | C2H2 | Acetylene | |

| Minimum water flow rate | CH2 | Methylene | |

| Fuel surface area | CO | Carbon monoxide | |

| Emissivity of the radiator | m | Meter | |

| Stefan–Boltzmann constant | CO2 | Carbon dioxide | |

| View factor of the fuel load | |||

| Mean absolute temperature of radiation source | |||

| Mean absolute temperature of the surface | |||

| Abbreviations: | |||

| ULF | Ultra-low flow | ||

| FM | Factory Mutual | ||

| HRR | Heat release rate | ||

| NFPA | National Fire Protection Association | ||

| AS | Australian Standard | ||

| FDS | Fire Dynamics Simulator | ||

| LOC | Limiting oxygen concentration | ||

| PMMA | Polymethyl methacrylate | ||

| Lpm | Litres per minute | ||

| MC | Multi-component | ||

References

- Cui, Y.; Liu, J. Research progress of water mist fire extinguishing technology and its application in battery fires. Process Saf. Environ. Prot. 2021, 149, 559–574. [Google Scholar] [CrossRef]

- Adiga, K.; Hatcher, R.F., Jr.; Sheinson, R.S.; Williams, F.W.; Ayers, S. A computational and experimental study of ultra fine water mist as a total flooding agent. Fire Saf. J. 2007, 42, 150–160. [Google Scholar] [CrossRef]

- Mahmud, H. Simulation of the Suppression of Fires Using Water Mists. Ph.D. Thesis, Victoria University, Melbourne, VIC, Australia, 2016. [Google Scholar]

- Yazir, D. Application of IF-TOPSIS method on fixed fire fighting systems for cargo hold fires on the dry/bulk cargo ships. Ocean Eng. 2022, 260, 111891. [Google Scholar] [CrossRef]

- Ko, Y.J.; Elsagan, N.; Gibbs, E. Water Mist Systems for Protection of Mass Timber Structures—Phase 2 Residential Fire Suppression Tests; National Research Council Canada: Ottawa, ON, Canada, 2020. [Google Scholar]

- Liu, Z.; Kim, A.K. A review of water mist fire suppression systems—Fundamental studies. J. Fire Prot. Eng. 1999, 10, 32–50. [Google Scholar]

- Liu, J.; Liao, G.; Li, P.; Fan, W.; Lu, Q. Progress in research and application of water mist fire suppression technology. Chin. Sci. Bull. 2003, 48, 718–725. [Google Scholar] [CrossRef]

- NFPA 750; Standard on Water Mist Fire Protection Systems. 2022.

- Mawhinney, J.R.; Back, G.G. Water mist fire suppression systems. In SFPE Handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2016; pp. 1587–1645. [Google Scholar]

- Chang, W.Y.; Fu, P.K.; Chen, C.H.; Shu, Y.L. Performance evaluation of a water mist system in semiconductor wet bench fires. Process Saf. Environ. Prot. 2008, 86, 213–218. [Google Scholar] [CrossRef]

- Nmira, F.; Consalvi, J.L.; Kaiss, A.; Fernandez-Pello, A.; Porterie, B. A numerical study of water mist mitigation of tunnel fires. Fire Saf. J. 2009, 44, 198–211. [Google Scholar] [CrossRef]

- Bill, R., Jr.; Hansen, R.L.; Richards, K. Fine-spray (water mist) protection of shipboard engine rooms. Fire Saf. J. 1997, 29, 317–336. [Google Scholar] [CrossRef]

- Lee, J. Numerical analysis on the rapid fire suppression using a water mist nozzle in a fire compartment with a door opening. Nucl. Eng. Technol. 2019, 51, 410–423. [Google Scholar] [CrossRef]

- Log, T.; Cannon-Brookes, P. Water mist for fire protection of historic buildings and museums. Mus. Manag. Curatorship 1995, 14, 283–298. [Google Scholar]

- Sturm, P.; Pucher, K.; Rodler, J.; Mühlenbruch, G.; Krezschmar, P. Test of Water Mist Equipment to increase Escape Chances in Cases of Fire in Tunnels. In Proceedings of the International Water Mist Association Conference, Vienna, Austria, 4–6 April 2001. [Google Scholar]

- Lee, J. Numerical analysis of how ventilation conditions impact compartment fire suppression by water mist. Ann. Nucl. Energy 2020, 136, 107021. [Google Scholar] [CrossRef]

- Cao, X.Y.; Bi, M.S.; Ren, J.S.; Chen, B. Experimental research on explosion suppression affected by ultrafine water mist containing different additives. J. Hazard. Mater. 2019, 368, 613–620. [Google Scholar] [CrossRef] [PubMed]

- Cong, B.; Liao, G. Experimental studies on water mist suppression of liquid fires with and without additives. J. Fire Sci. 2009, 27, 101–123. [Google Scholar] [CrossRef]

- Ferng, Y.M.; Liu, C.H. Numerically investigating fire suppression mechanisms for the water mist with various droplet sizes through FDS code. Nucl. Eng. Des. 2011, 241, 3142–3148. [Google Scholar] [CrossRef]

- Yinshui, L.; Zhuo, J.; Dan, W.; Xiaohui, L. Experimental research on the water mist fire suppression performance in an enclosed space by changing the characteristics of nozzles. Exp. Therm. Fluid Sci. 2014, 52, 174–181. [Google Scholar] [CrossRef]

- TycoAquaMist. Tyco Fire Protection Products. Available online: https://tycoaquamist.com/uploads/media/AquaMist_Machinery_Space_EMEA_0317_LoRes.pdf (accessed on 3 January 2023).

- Drysdale, D. An Introduction to Fire Dynamics; John Wiley & Sons: New York, NY, USA, 2011. [Google Scholar]

- Yang, D.; Converse, M.C.; Mahvi, D.M.; Webster, J.G. Expanding the bioheat equation to include tissue internal water evaporation during heating. IEEE Trans. Biomed. Eng. 2007, 54, 1382–1388. [Google Scholar] [CrossRef]

- Drysdale, D. Ignition of liquids. In SFPE Handbook of Fire Protection Engineerings; Springer: New York, NY, USA, 2016; pp. 554–580. [Google Scholar]

- Hurley, M.J.; Gottuk, D.T.; Hall, J.R., Jr.; Harada, K.; Kuligowski, E.D.; Puchovsky, M.; Watts, J.M., Jr.; Wieczorek, C.J. SFPE Handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2015. [Google Scholar]

- Majdalani, A.H.; Carvel, R. Effectiveness of the Gas Cooling Technique in Larger Compartment Fires; Final Report; 2016. [Google Scholar]

- Xin, Y.; Khan, M.M. Flammability of combustible materials in reduced oxygen environment. Fire Saf. J. 2007, 42, 536–547. [Google Scholar] [CrossRef]

- Mawhinney, J. Water mist fire suppression systems for marine applications: A case study. In The TRIS and ITRD Database; Institute of Marine Engineers IMAS 94: Hong Kong, 1994. [Google Scholar]

- Liu, H.; Wang, C.; Cordeiro, I.M.D.C.; Yuen, A.C.Y.; Chen, Q.; Chan, Q.N.; Kook, S.; Yeoh, G.H. Critical assessment on operating water droplet sizes for fire sprinkler and water mist systems. J. Build. Eng. 2020, 28, 100999. [Google Scholar] [CrossRef]

- Kashiwagi, T.; Ohlemiller, T.J. A study of oxygen effects on nonflaming transient gasification of PMMA and PE during thermal irradiation. In Symposium (International) on Combustion; Elsevier: Amsterdam, The Netherlands, 1982; pp. 815–823. [Google Scholar]

- Balner, D.; Barcova, K. Attenuation of thermal radiation through water mist. Process Saf. Prog. 2018, 37, 18–24. [Google Scholar] [CrossRef]

- Choi, B.-I.; Han, Y.-S.; Oh, C.-B.; Kim, M.-B.; Kim, C. The assessment of fire suppression capability of water-mist system for machinery engine room. Fire Sci. Eng. 2007, 21, 111–117. [Google Scholar]

- Liu, Z.; Kim, A.; Su, J. Improvement of efficacy of water mist in fire suppression by cycling discharges. In Proceedings of the Second International Conference on Fire Research and Engineering, Gaithersburg, MD, USA, 10–15 August 1997; pp. 3–8. [Google Scholar]

- Liu, Z.; Kim, A.; Su, J. The effect of air convection on the performance of water mist fire suppression systems. Asme-Publ.-Htd 1998, 357, 227–236. [Google Scholar]

- Yudong, F.; Jianghong, L.; Guangxuan, L.; Qiang, X.; Xiaomeng, Z. Experimental studies on electrical breakdown field strength of electrode with water mist containing MC additives. Chin. Sci. Bull. 2005, 50, 2783–2788. [Google Scholar] [CrossRef]

- Lu, J.; Chen, B.-H.; Fang, Z.; Hu, J.; Wang, B.; Wu, C.; Huang, S. Electrical safety of suppressing wildfires near high-voltage transmission lines using water mist. J. Fire Sci. 2018, 36, 295–314. [Google Scholar] [CrossRef]

- Hills, A.T.; Simpson, T.; Smith, D.P. Water mist fire protection systems for telecommunication switch gear and other electronic facilities. In Proceedings of the Water Mist Fire Suppression Workshop, Gaithersburg, MD, USA, 1–2 March 1993; pp. 123–144. [Google Scholar]

- Liu, Z.; Kim, A.K. A review of water mist fire suppression technology: Part II—Application studies. J. Fire Prot. Eng. 2001, 11, 16–42. [Google Scholar] [CrossRef]

- Zhou, Y.; Bu, R.; Gong, J.; Zhang, X.; Fan, C.; Wang, X. Assessment of a clean and efficient fire-extinguishing technique: Continuous and cycling discharge water mist system. J. Clean. Prod. 2018, 182, 682–693. [Google Scholar] [CrossRef]

- Arvidson, M. Large-scale water spray and water mist fire suppression system tests for the protection of Ro–Ro cargo decks on ships. Fire Technol. 2014, 50, 589–610. [Google Scholar] [CrossRef]

- Marker, T.R.; Sarkos, C.P.; Hill, R.G. Water Spray System Development and Evaluation for Enhanced Postcrash Fire Survivability and In-Flight Protection in Cargo Compartments. In Federal Aviation Administration, Aircraft Fire Safety; 1997; Volume 1997, pp. 1–3. [Google Scholar]

- Sarkos, C.P. Development of improved fire safety standards adopted by the Federal Aviation Administration. In Agard, Aircraft Fire Safety 14 (See N 90-17581 10-03); 1989. [Google Scholar]

- Mawhinney, J.R. Approval Testing of a Hi-Fog Water Mist System for Protection of the A86 Passenger Vehicle Highway Tunnel; Marioff Corporation Oy: Bern, Switzerland, 2005. [Google Scholar]

- Ha, G.; Shin, W.G.; Lee, J. Numerical analysis to determine fire suppression time for multiple water mist nozzles in a large fire test compartment. Nucl. Eng. Technol. 2021, 53, 1157–1166. [Google Scholar] [CrossRef]

- Liu, Z.; Carpenter, D.; Kim, A.K. Characteristics of large cooking oil pool fires and their extinguishment by water mist. J. Loss Prev. Process Ind. 2006, 19, 516–526. [Google Scholar] [CrossRef] [Green Version]

- Qin, J.; Yao, B.; Chow, W.K. Experimental study of suppressing cooking oil fire with water mist using a cone calorimeter. Int. J. Hosp. Manag. 2004, 23, 545–556. [Google Scholar] [CrossRef]

- Systems S-SFS. SEM-SAFE by Danfoss High-Pressure Water Mist Fire Fighting System. 2022. Available online: https://www.danfoss.com/en/about-danfoss/our-businesses/fire-safety/ (accessed on 3 January 2023).

- Xu, J.; Duan, Q.; Zhang, L.; Liu, Y.; Sun, J.; Wang, Q. The enhanced cooling effect of water mist with additives on inhibiting lithium ion battery thermal runaway. J. Loss Prev. Process Ind. 2022, 77, 104784. [Google Scholar] [CrossRef]

- Jenft, A.; Collin, A.; Boulet, P.; Pianet, G.; Breton, A.; Muller, A. Experimental and numerical study of pool fire suppression using water mist. Fire Saf. J. 2014, 67, 1–12. [Google Scholar] [CrossRef]

- British Standards BS 8458:2015: Fixed Fire Protection Systems—Residential and Domestic Water Mist Systems—Code of Practice for Design and Installation. NBS Database: 2015.

- Milke, J.; Gerschefski, C. Overview of Water Research for Library Applications. In Proceedings of the International Conference on Fire Research and Engineering, Orlando, FL, USA, 10–15 September 1995; p. 133. [Google Scholar]

- Wang, Z.; Wang, X.; Huang, Y.; Tao, C.; Zhang, H. Experimental study on fire smoke control using water mist curtain in channel. J. Hazard. Mater. 2018, 342, 231–241. [Google Scholar] [CrossRef] [PubMed]

- Budnick, E. USFA Residential Water Mist Test Program (Initial Feasibility); National Institute of Standards and Technology: Gaithersburg, MD, USA, 1996. [Google Scholar]

- Arvidson, M. An evaluation of residential sprinklers and water mist nozzles in a residential area fire scenario, Research Institutions of Sweden. RISE Rep. 2017, 4, 2017. [Google Scholar]

- British Standards BS 8489-7 2016: Fixed Fire Protection Systems—Industrial and Commercial Watermist Systems-Part: Fire performance tests and requirements for watermist systems for the protection of low hazard occupancies, British Standards Institution.

- Huang, X.; Wang, X.; Liao, G. Characterization of an effervescent atomization water mist nozzle and its fire suppression tests. Proc. Combust. Inst. 2011, 33, 2573–2579. [Google Scholar] [CrossRef]

- Liu, Z.; Kim, A.K.; Su, J.Z. Examination of the extinguishment performance of a water mist system using continuous and cycling discharges. Fire Technol. 1999, 35, 336–361. [Google Scholar] [CrossRef]

- Qin, J.; Weng, W. Preliminary study of water mist suppressing ghee flame in historical building in the northwest China. J. Cult. Herit. 2006, 7, 329–333. [Google Scholar] [CrossRef]

- Xiaomeng, Z.; Biao, Z.; Xiang, J. Study of fire-extinguishing performance of portable water-mist fire extinguisher in historical buildings. J. Cult. Herit. 2010, 11, 392–397. [Google Scholar] [CrossRef]

- Prasad, K.; Patnaik, G.; Kailasanath, K. A numerical study of water-mist suppression of large scale compartment fires. Fire Saf. J. 2002, 37, 569–589. [Google Scholar] [CrossRef]

- Mahmud, H.I.; Moinuddin, K.A.; Thorpe, G.R. Experimental and numerical study of high-pressure water-mist nozzle sprays. Fire Saf. J. 2016, 81, 109–117. [Google Scholar] [CrossRef]

- Jeong, C.S.; Lee, C.Y. Experimental investigation on spray characteristics of twin-fluid nozzle for water mist and its heptane pool fire extinguishing performance. Process Saf. Environ. Prot. 2021, 148, 724–736. [Google Scholar] [CrossRef]

- Zhang, P.; Tang, X.; Tian, X.; Liu, C.; Zhong, M. Experimental study on the interaction between fire and water mist in long and narrow spaces. Appl. Therm. Eng. 2016, 94, 706–714. [Google Scholar] [CrossRef]

- Zalosh, R. Water Mist for Deflagration Control. In Water Mist for Deflagration Control; National Fire Protection Association: Quincy, MA, USA, 1994. [Google Scholar]

- Shrigondekar, H.; Chowdhury, A.; Prabhu, S. Characterization of a simplex water mist nozzle and its performance in extinguishing liquid pool fire. Exp. Therm. Fluid Sci. 2018, 93, 441–455. [Google Scholar] [CrossRef]

- Yu, H.Z. The ceiling height limits for water mist protection of two solid combustible fire hazards in open environment. Fire Technol. 2021, 57, 163–187. [Google Scholar] [CrossRef]

- Chow, W.K.; Yao, B. The potential application of water mist systems for fire protection in atria. ASHRAE Trans. 2001, 107, 171. [Google Scholar]

- Moore, T.A.; Weitz, C.; McCormick, S.; Clauson, M. Laboratory Optimization and Mediumscale Screening of Iodide Salts and Water Mixtures. In Proceedings of Halon Option Technical Working Conference, Albuquerque, NM, USA, 7–9 May 1996; pp. 477–498. [Google Scholar]

- DeSipio, P. Evaluation of Fine Water Mist for Aircraft Dry Bay Fire Suppression. 1996. p. 27. Available online: https://www.nist.gov/system/files/documents/el/fire_research/R0301051.pdf (accessed on 10 July 2022).

- Finnerty, A.E. Water-Based Fire-Extinguishing Agents. 1995. p. 461. Available online: https://www.nist.gov/system/files/documents/el/fire_research/R0000244.pdf (accessed on 15 August 2022).

- Yu, H.-Z.; Kasiski, R.; Daelhousen, M. Characterization of twin-fluid (water mist and inert gas) fire extinguishing systems by testing and modeling. Fire Technol. 2015, 51, 923–950. [Google Scholar] [CrossRef]

- Pei, B.; Li, J.; Wang, Y.; Wen, X.; Yu, M.; Jing, G. Synergistic inhibition effect on methane/air explosions by N2-twin-fluid water mist containing sodium chloride additive. Fuel 2019, 253, 361–368. [Google Scholar] [CrossRef]

- Nam, S. Numerical simulation of the penetration capability of sprinkler sprays. Fire Saf. J. 1999, 32, 307–329. [Google Scholar] [CrossRef]

- Yu, H.-Z.; Zhou, X.; Carpenter, J. Physical scaling of water mist fire extinguishment in industrial machinery enclosures. Fire Saf. J. 2017, 91, 596–605. [Google Scholar] [CrossRef]

- Pepi, J.S. Advances in the technology of intermediate pressure water mist systems for the protection of flammable liquid hazards. In Proceedings of the Halon Options Technical Working Conference, Albuquerque, NM, USA, 12–14 May 1998. [Google Scholar]

- Tanner, G.; Knasiak, K.F. Spray characterization of typical fire suppression nozzles. In Proceedings of the Third International Water Mist Conference, Madrid, Spain, 22–24 September 2003. [Google Scholar]

- Santangelo, P.E.; Tartarini, P. Fire control and suppression by water-mist systems. Open Thermodyn. J. 2010, 4, 167–184. [Google Scholar] [CrossRef]

- Pokorný, M.; Eliáš, M.; Kregl, F. Fire Protection of Steel Structures by Low Pressure Water Mist in Large-Scale Fire Test. In Conference Series: Earth Environmental Science; IOP Publishing: Bristol, UK, 2019; p. 012028. [Google Scholar]

- Sikanen, T.; Vaari, J.; Hostikka, S. Large scale simulation of high pressure water mist systems. WIT Trans. Eng. Sci. 2013, 79, 77–88. [Google Scholar]

- Vaari, J. A transient one-zone computer model for total flooding water mist fire suppression in ventilated enclosures. Fire Saf. J. 2002, 37, 229–257. [Google Scholar] [CrossRef]

- Kim, S.C.; Ryou, H.S. An experimental and numerical study on fire suppression using a water mist in an enclosure. Build. Environ. 2003, 38, 1309–1316. [Google Scholar] [CrossRef]

- Lui, Z.; Kim, A. A Review of water mist fire suppression technology. Part II—Fundamental Studies. J. Fire Prot. Eng. 2001, 10, 16–42. [Google Scholar]

- Hansen, R.; Back, G. Fine Water Mist–Fire Control Using Local Application. In Proceedings of the 1997 International CFC and Halon Alternative Conference, Washington, DC, USA; 1997. [Google Scholar]

- He, Y.; Kwok, K.; Douglas, G.; Razali, I. Numerical Investigation of Bushfire-Wind Interactions and its Impacts on Building Structure. Fire Saf. Sci. 2011, 11, 1449–1462. [Google Scholar] [CrossRef]

- Australian Standard AS5414-2012: Bushfire Water Spray Systems. SAI Global. Accessed 6 November 2020.

- Green, A. Sprinkler Systems for Protection of Buildings from Wildfire. Ph.D. Thesis, Wollongong University, Hong Kong, 2019. [Google Scholar]

- Yang, P.; Liu, T.; Qin, X. Experimental and numerical study on water mist suppression system on room fire. Build. Environ. 2010, 45, 2309–2316. [Google Scholar] [CrossRef]

- Vaari, J.; Hostikka, S.; Sikanen, T.; Paajanen, A. Numerical simulations on the performance of water-based fire suppression systems. VTT Technol. 2012, 54, 150. [Google Scholar]

- FireKill. Atrium Fire Protection System Model APS VID FireKill. Available online: https://vidfirekill.dk/solutions/solutions/] (accessed on 15 June 2022).

- Maioff Hi-FOG Water Mist System. Available online: https://www.suppression.com/uploads/pdf/suppression-kidde-hifog/accumulator-units/mau/ls01551.pdf (accessed on 15 June 2022).

- AquaMist. AquaMist Mist Control Center (MCC) Pump Skin Unit, DATASHEET TFP2270.1 OCTOBER 2021. Available online: https://tycoaquamist.com/uploads/media/TFP2270.1_10_2021_v2_.pdf (accessed on 15 August 2022).

- Fire, L. Installation, Maintenance and User Manual for Water Mist Cylinder Bank Systems; 2009. [Google Scholar]

- Luciano Nigro. Performance Based Fire Protection With Water Mist. Available online: https://iwma.net/fileadmin/user_upload/Seminar_Dubai_2013/Marioff_Nigro_Dubai_2013.pdf (accessed on 15 August 2022).

- Australian Standard. AS 4587:2020: Water Mist Fire Protection Systems—System Design, Installation, and Commissioning. SAI Global Database, 2020.

- European Standards EN 14972-1:2020: Fixed Fire-Fighting Systems—Water Mist Systems—Part 1: Design, Installation, Inspection and Maintenance. European Standards EN 14972-1:2020; CEN: Oak Brook, IL, USA, 2020.

- British Standards BS 8489-1 2016: Fixed Fire Protection Systems. Industrial and Commercial Water Mist Systems—Code of Practice for Design and Installation.

- Hopkin, C.; Spearpoint, M.; Muhammad, Y.; Makant, W. Estimating the suppression performance of an electronically controlled residential water mist system from BS 8458: 2015 fire test data. Fire 2022, 5, 144. [Google Scholar] [CrossRef]

- Spearpoint, M.; Hopkin, C.; Muhammad, Y.; Makant, W. Replicating the activation time of electronically controlled water mist system nozzles in B-RISK. Fire Saf. J. 2022, 130, 103592. [Google Scholar] [CrossRef]

- Frank, K.; Gravestock, N.; Spearpoint, M.; Fleischmann, C. A review of sprinkler system effectiveness studies. Fire Sci. Rev. 2013, 2, 6. [Google Scholar] [CrossRef]

- Gravestock, N. Effectiveness of Fire Safety Systems for Use in Quantitative Risk Assessments; New Zealand Fire Service Commission: Wellington, New Zealand, 2008. [Google Scholar]

| Material | Extinction (O2) (% vol.) | Material | Extinction (O2) (% vol.) |

|---|---|---|---|

| Liquid Fuel | Solid Fuel | ||

| Unleaded gasoline (dish) | 12.48 | Polyethylene (low density) | 11.39 |

| Methanol (dish) | 11.64 | Polystyrene (high density) | 11.21 |

| Methanol (wick) | 12.33 | PMMA | 10.48 |

| Ethanol (dish) | 12.40 | Red oak | 12.26 |

| Ethanol (wick) | 13.35 | White maple | 14.66 |

| Corn oil (dish) | 12.29 | Corrugated paper (tri-wall) | 12.86 |

| Corrugated paper (single layer) | 12.94 | ||

| Kraft linerboard | 12.33 | ||

| Key Parameter | Findings | Methodology |

|---|---|---|

| Suppression additives |

| E E E |

| Operating Pressure |

| E E E E E E E,E,E E E E |

| Water Droplet Diameter |

| N,E N,E N,E N E/N N E/N,E E |

| Flow Rate |

| E,E,E E,E E,E,E E,E,E E,E E E E E |

| Spray Angle |

| E E,E,E E E |

| Nozzle Height |

| E E E E E,E,E E |

| Compartment Size and Ventilation | E E/N |

| Author/ Manufacturer | Operating pressure (bar) | Flow Rate (lpm) | K-Factor (lpm/bar0.5) | Spray Angle (°) | Droplet Diameter Dv0.9 (µm) | Nozzle Height (m) |

|---|---|---|---|---|---|---|

| Published Research System Parameters | ||||||

| Kim et al. 2003 [81] | 13 | 6 | 1.66 | 70 | 121 | 1.8 |

| Yang et al. 2010 [87] | 100 | 11.9 | 1.19 | 48 | 46 | 2.5 |

| Vaari 2012 [88] | 70 | 6.45 | 0.77 | 30 | 200 | 4 |

| Jenft et al. 2014 [49] | 10.13 | 6.3 | 1.97 | 65 | 112 | 2.45 |

| Yinshui et al. 2014 [20] | 2–12 | 2–5 | - | 60–120 | 80–130 | 2 |

| Lee et al. 2019 [13] | 10 | 22.45 | 7.1 | 76 | 124.6 | 2 |

| Ha et al. 2021 [44] | 10 | 22.8 | 7.25 | 90 | 124.6 | 12.5 |

| Industry-Used System Design Parameters | ||||||

| Aqua Mist ULF [21] | 12.8 | 12.5 | 3.5 | - | 100–200 | 8 |

| VID Fire Kill APS [89] | 10 | 32 | 10.3 | - | <300 | Unlimited |

| Aqua Mist FOG [90] | 100 | 4.4 | 0.44 | - | 50 | 5 |

| Marioff HI-FOG [46] | 40 | 7.3 | 1.15 | 45–68 | 50 | 5 |

| SEM-SAFE [47] | 100 | 39 | 3.9 | - | 10–50 | 5.5 |

| Design Criteria | NFPA 750—2022 [8] | AS 4587—2020 [94] |

|---|---|---|

| Pipework and fittings | Maximum pressure developed by the system at 54 °C or higher temperatures as specified in the manufacturer’s listing. | Shall be rated or selected for at least the maximum system design pressure at 50 °C. |

| Nozzle operating pressure | In accordance with the nozzle’s listing. | In accordance with the nozzle’s listing. |

| Occupancies |

|

|

| Extinguishing criteria | Approved test plan from the authority with jurisdiction. | Extinguishment in half the prescribed discharge duration. |

| Discharge duration | Various for open nozzle systems; 60 min for sealed. | |

| Hangers/ Supports | In accordance with NFPA 13 Standard for the installation of sprinkler systems, and shall be listed. | Hanger shall conform to the requirements of AS 2118.1 automatic fire sprinklers. |

| Nozzle spray angle | The spray angle is set by the listed nozzle used. | The spray angle is set by the listed nozzle used. |

| Flow rate | Selected as appropriate for the hazard. | |

| Maximum height | The minimum and maximum heights shall be in accordance with the manufacturer’s listing. | In accordance with the nozzle’s listing. |

| Maximum coverage per nozzle | Listing. | In total, 18 m2 for sealed nozzle systems unless greater in listing. |

| Maximum spacing of nozzles | In accordance with the nozzle’s listing. | In accordance with the nozzle’s listing. |

| Maximum nozzle spacing from walls | In accordance with the nozzle’s listing. | In accordance with the nozzle’s listing. |

| Activation method | Detection system, automatic, or manual. | Detection system, automatic, or manual. |

| Application methods |

|

|

| System limitations | Light hazards = 4831 m2 Ordinary hazards = 4831 m2 | Sealed nozzle system = 9000 m2 Open nozzle system = as per listing |

| Temperature rating of nozzle | Temperature rating chosen depending on the maximum ambient temperature. Table for guidance is provided. | Heat rating to be 30 °C above highest ambient temperature. |

| Water supply | At least one automatic water supply. | Public water, automatic pumps, or containers (pressure cylinders). |

| Connecting to public water supply | Light hazards—minimum 378 lpm Ordinary Hazards—minimum 946 lpm | NIL |

| Water droplet size | <1000 µm within the nozzle operating range | <1000 µm at minimum operating pressure. |

| Acceptable listing authority (test protocol) | JAS-ANS, CSIRO Actifire, FM, LPCB, SP Technical Research Institute of Sweden, UL, VdS | Organisation that is acceptable to the authority with jurisdiction. |

| Agency | Water Mist Fire Test Protocol |

|---|---|

| International Maritime Organization (IMO) | IMO Res. A800 (19): Revised Guidelines for Approval of Sprinkler Systems Equivalent to that referred to in SOLAS Regulations II-2, Chap. 12 |

| Appendix 1, “Component Manufacturing Standards for Water Mist Nozzles” | |

| Appendix 2, “Fire Test Procedures for Equivalent Sprinkler Systems in Accommodation, Public Space and Service Areas on Passenger Ships”, December 1995 | |

| IMO MSC/Circular 668: Alternative Arrangements for Halon Fire Extinguishing Systems in Machinery Spaces and Pump Rooms | |

| Appendix A: “Component Manufacturing Standards of Equivalent Water-Based Fire Extinguishing Systems”, 1994 | |

| Appendix B: “Interim Test Method for Fire Testing Equivalent Water-Based Fire Extinguishing Systems for Machinery Spaces of Category A and Cargo Pump Rooms”, 1994 | |

| As amended in MSC/Circ. 728: “Amendments to the Test Method for Equivalent Water-Based Fire-Extinguishing Systems for Machinery Spaces of Category A and Cargo Pump-Rooms contained in MSC/Circ. 668, Annex B”, June 1996 | |

| MSC/Circ. 913: “Guidelines for the Approval of Fixed Water-Based Local Application Fire-Fighting Systems for use in Category A Machinery Spaces”, 4 June 1999 | |

| MSC/Circ. 1165, “Revised Guidelines for the Approval of Equivalent Water-Based Fire-Extinguishing Systems for Machinery Spaces and Cargo Pump-Rooms”, 10 June 2005 | |

| FM Global Research Corporation | FM Global, Approval Standard for Water Mist Systems, Class Number 5560, 2009 |

| (a) Appendix A, B, C: Fire Tests for Water Mist Systems for the Protection of Machinery Spaces, Special Hazard Machinery Spaces, Combustion Turbines with Volumes up to, and including, 2825 ft3 (80 m3) (respectively) | |

| (b) Appendices D, E, and F: Fire Tests for Water Mist Systems for the Protection of Machinery Spaces, Special Hazard Machinery Spaces, Combustion Turbines with Volumes up to and including 9175 ft3 (260 m3) (respectively) | |

| (c) Appendix G: Fire Tests for Water Mist Systems for the Protection of Machinery Spaces and Special Hazard Machinery Spaces with Volumes Exceeding 9175 ft3 (260 m3) | |

| (d) Appendix H: Fire Tests for Water Mist Systems for the Protection of Combustion Turbines with Volumes Exceeding 9175 ft3 (260 m3) | |

| (e) Appendix I: Fire Tests for Water Mist Systems for the Protection of Light Hazard Occupancies | |

| (f) Appendix J: Fire Tests for Water Mist Systems for the Protection of Wet Benches and Other Similar Processing Equipment | |

| (g) Appendix K: Fires Tests for Water Mist Systems for the Protection of Local Applications | |

| (h) Appendix L: Fire Tests for Water Mist Systems for the Protection of Industrial Oil Cookers | |

| (i) Appendix M: Fire Tests for Water Mist Systems for the Protection of Computer Room Subfloors | |

| (j) Appendix N: Other Occupancies Which FM Global Has an Interest in Protecting with Water Mist Systems | |

| Underwriters Laboratories Inc. (UL) | ANSI/UL 2167, Proposed First Edition of the Standard for Water Mist Nozzles for Fire Protection Service, June 1998 |

| Machinery Spaces; Passenger Cabin Fire Tests; Passenger Cabins Greater than 12 m2; Public Space Fire Tests; Residential Area Fire Tests; Light Hazard Area Fire Tests; Ordinary Hazard I and II Tests; Nozzle Construction Design, Marking, and Performance Requirements. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farrell, K.; Hassan, M.K.; Hossain, M.D.; Ahmed, B.; Rahnamayiezekavat, P.; Douglas, G.; Saha, S. Water Mist Fire Suppression Systems for Building and Industrial Applications: Issues and Challenges. Fire 2023, 6, 40. https://doi.org/10.3390/fire6020040

Farrell K, Hassan MK, Hossain MD, Ahmed B, Rahnamayiezekavat P, Douglas G, Saha S. Water Mist Fire Suppression Systems for Building and Industrial Applications: Issues and Challenges. Fire. 2023; 6(2):40. https://doi.org/10.3390/fire6020040

Chicago/Turabian StyleFarrell, Kyle, Md Kamrul Hassan, Md Delwar Hossain, Bulbul Ahmed, Payam Rahnamayiezekavat, Grahame Douglas, and Swapan Saha. 2023. "Water Mist Fire Suppression Systems for Building and Industrial Applications: Issues and Challenges" Fire 6, no. 2: 40. https://doi.org/10.3390/fire6020040

APA StyleFarrell, K., Hassan, M. K., Hossain, M. D., Ahmed, B., Rahnamayiezekavat, P., Douglas, G., & Saha, S. (2023). Water Mist Fire Suppression Systems for Building and Industrial Applications: Issues and Challenges. Fire, 6(2), 40. https://doi.org/10.3390/fire6020040