Solid γ-Cyclodextrin Inclusion Compound with Gingerols, a Multi-Component Guest: Preparation, Properties and Application in Yogurt

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Equipment

2.3. Extraction of Gingerols from Fresh Ginger

2.4. Preparation of γ-CD·Gingerols

2.5. Biochemical Assays

2.5.1. ABTS•+ Discoloration Assay

2.5.2. β-Carotene Bleaching Assay

2.5.3. Chemical NO Scavenging Assay

2.5.4. Soybean 5-Lipoxigenase (5-LOX) Assay

2.6. Formulation of Yogurts Fortified with Gingerols and γ-Cyclodextrin·Gingerols

2.7. Analysis of Fortified Yogurts

2.7.1. Colour Measurement

2.7.2. Yogurt Antioxidant Capacity

2.7.3. Yogurt pH Over Time

3. Results and Discussion

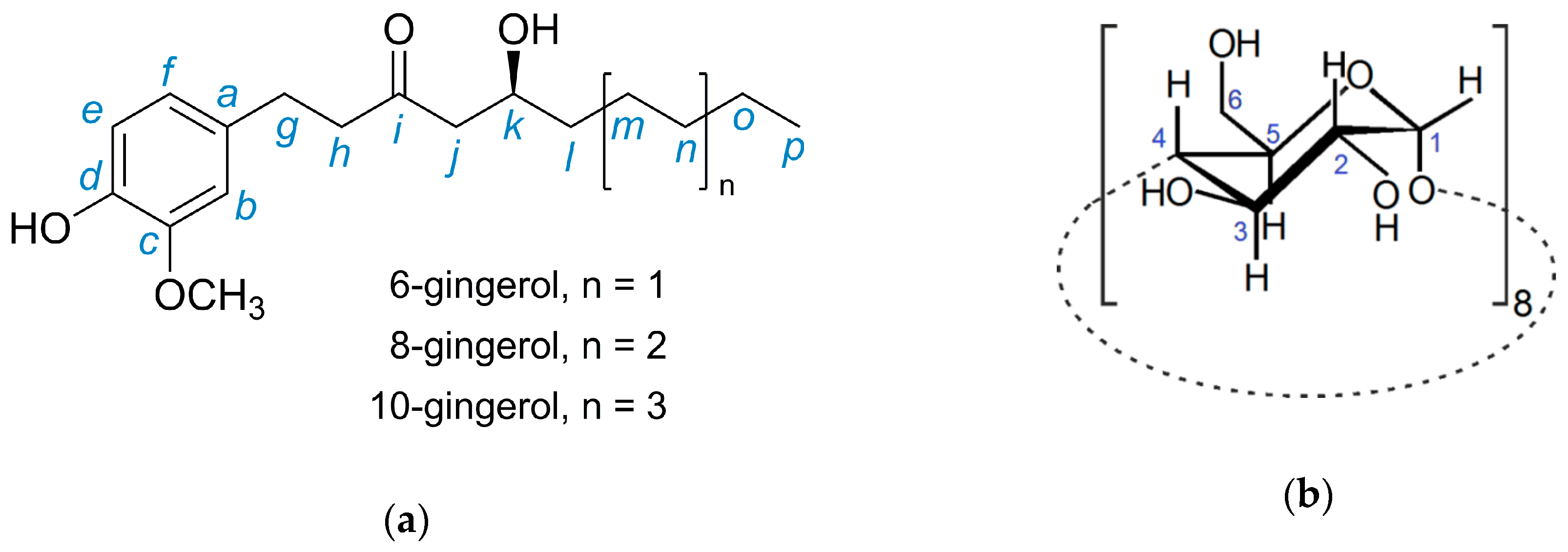

3.1. Isolation of Gingerols

3.2. Preparation and Characterisation of γ-CD·Gingerols

3.2.1. 13C-NMR

3.2.2. Powder X-Ray Diffraction

3.2.3. Differential Scanning Calorimetry (DSC)

3.3. Antioxidant and Anti-Inflammatory Studies

3.4. Application of γ-CD·Gingerols in Yogurt

3.4.1. Colourimetry of the Fortified Yogurt

3.4.2. Antioxidant Properties of Fortified Yogurt

3.4.3. Stability of Yogurt pH Under Storage

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- US Department of Health & Human Services, Code of Federal Regulations—Title 21 Part 182: Substances Generally Recognized As Safe. Volume 3, Revised as of April 1 2017. Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=182.20 (accessed on 19 February 2020).

- Ginger, Production Quantity (Tons)—For All Countries. Available online: http://www.factfish.com/statistic/ginger%2C%20production%20quantity (accessed on 19 December 2019).

- Braga, S.S. Ginger: Panacea or Consumer’s Hype? Appl. Sci. 2019, 9, 1570. [Google Scholar] [CrossRef]

- Al-Yahya, M.A.; Rafatullah, S.; Mossa, J.S.; Ageel, A.M.; Parmar, N.S.; Tariq, M. Gastroprotective Activity of Ginger Zingiber Officinale Rosc., in Albino Rats. Am. J. Chin. Med. 1989, 17, 51–56. [Google Scholar] [CrossRef] [PubMed]

- Gaus, K.; Huang, Y.; Israel, D.A.; Penland, S.L.; Adeniyi, B.A.; Mahady, G. Standardized ginger (Zingiber officinale) extract reduces bacterial load and suppresses acute and chronic inflammation in Mongolian gerbils infected with cagA Helicobacter pylori. Pharmaceut. Biol. 2009, 47, 92–98. [Google Scholar] [CrossRef] [PubMed]

- Nanjundaiah, S.M.; Annaiah, H.N.M.; Dharmesh, S.M. Gastroprotective Effect of Ginger Rhizome (Zingiber officinale) Extract: Role of Gallic Acid and Cinnamic Acid in H+, K+-ATPase/H. pylori Inhibition and Anti-Oxidative Mechanism. Evid. Based Complement. Alternat. Med. 2011, 2011, 249487. [Google Scholar] [CrossRef]

- Shanmugam, K.R.; Ramakrishna, C.H.; Mallikarjuna, K.; Reddy, K.S. Protective effect of ginger against alcohol-induced renal damage and antioxidant enzymes in male albino rats. Ind. J. Experim. Biol. 2010, 48, 143–149. [Google Scholar]

- Yamahara, J.; Mochizuki, M.; Rong, H.Q.; Matsuda, H.; Fujimura, H. The anti-ulcer effect in rats of ginger constituents. J. Ethnopharmacol. 1988, 23, 299–304. [Google Scholar]

- Khushtar, M.; Kumar, V.; Javed, K.; Bhandari, U. Protective effect of ginger oil on aspirin and pylorus ligation-induced gastric ulcer model in rats. Ind. J. Pharm Sci. 2009, 71, 554–558. [Google Scholar]

- Bailey-Shaw, Y.A.; Williams, L.A.; Junor, G.A.; Green, C.E.; Hibbert, S.L.; Salmon, C.N.; Smith, A.M. Changes in the contents of oleoresin and pungent bioactive principles of Jamaican ginger (Zingiber officinale Roscoe.) during maturation. J. Agric. Food Chem. 2008, 56, 5564–5571. [Google Scholar] [CrossRef]

- Kiran, C.R.; Chakka, A.K.; Amma, K.P.; Menon, A.N.; Kumar, M.M.; Venugopalan, V.V. Influence of cultivar and maturity at harvest on the essential oil composition, oleoresin and [6]-gingerol contents in fresh ginger from northeast India. J. Agric. Food Chem. 2013, 61, 4145–4154. [Google Scholar] [CrossRef]

- Masuda, Y.; Kikuzaki, H.; Hisamoto, M.; Nakatani, N. Antioxidant properties of gingerol-related compounds from ginger. BioFactors 2004, 21, 293–296. [Google Scholar] [CrossRef]

- Aeschbach, R.; Löliger, J.; Scott, B.C.; Murcia, A.; Butler, J.; Halliwell, B.; Aruoma, O.I. Antioxidant actions of thymol, carvacrol, 6-gingerol, zingerone and hydroxytyrosol. Food Chem. Toxicol. 1994, 32, 31–36. [Google Scholar] [CrossRef]

- Ippoushi, K.; Azuma, K.; Ito, H.; Horie, H.; Higashio, H. [6]-Gingerol inhibits nitric oxide synthesis in activated J774.1 mouse macrophages and prevents peroxynitrite-induced oxidation and nitration reactions. Life Sci. 2003, 73, 3427–3437. [Google Scholar] [CrossRef] [PubMed]

- Jeong, C.H.; Bode, A.M.; Pugliese, A.; Cho, Y.Y.; Kim, H.G.; Shim, J.H.; Jeon, Y.J.; Li, H.; Jiang, H.; Dong, Z. [6]-Gingerol Suppresses Colon Cancer Growth by Targeting Leukotriene A4 Hydrolase. Cancer Res. 2009, 69, 5588–5591. [Google Scholar] [CrossRef] [PubMed]

- Pournaderi, P.S.; Yaghmaei, P.; Khodaei, H.; Noormohammadi, Z.; Hejazi, S.H. The effects of 6-Gingerol on reproductive improvement, liver functioning and Cyclooxygenase-2 gene expression in estradiol valerate-induced polycystic ovary syndrome in Wistar rats. Biochem. Biophys. Res. Comm. 2017, 484, 461–466. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, D.; Bishayee, K.; Ghosh, S.; Biswas, R.; Mandal, S.K.; Khuda-Bukhsh, A.R. [6]-Gingerol induces caspase 3 dependent apoptosis and autophagy in cancer cells: Drug–DNA interaction and expression of certain signal genes in HeLa cells. Eur. J. Pharmacol. 2012, 694, 20–29. [Google Scholar] [CrossRef]

- Mukkavilli, R.; Yang, C.; Tanwar, R.S.; Ghareeb, A.; Luthra, L.; Aneja, R. Absorption, Metabolic Stability, and Pharmacokinetics of Ginger Phytochemicals. Molecules 2017, 22, 553. [Google Scholar] [CrossRef] [PubMed]

- Noorl, E.; Harmi, L.; Maddu, A.; Yusron, M. Fabrication of Nanogingerol by Combining Phase Inversion Composition and Temperature. Res. J. Pharm. Biol. Chem. Sci. 2015, 6, 38–47. [Google Scholar]

- Xu, Y.; Wang, Q.-L.; Feng, Y.-S.; Firempong, C.K.; Zhu, Y.; Omari-Siaw, E.; Zheng, Y.; Pu, Z.; Xu, X.; Yu, J. Enhanced oral bioavailability of [6]-Gingerol-SMEDDS: Preparation, in vitro and in vivo evaluation. J. Funct. Foods 2016, 27, 703–710. [Google Scholar] [CrossRef]

- World Health Organization, Safety evaluation of certain food additives (γ-cyclodextrin). 53rd meeting of the Joint FAO/WHO Expert Committee on Food Additives (JECFA). WHO Food Addit. Ser. 2000, 44, 969.

- Stella, V.J.; He, Q.R. Cyclodextrins. Toxicol. Pathol. 2008, 36, 30–42. [Google Scholar] [CrossRef]

- Ezawa, T.; Inoue, Y.; Tunvichien, S.; Suzuki, R.; Kanamoto, I. Changes in the physicochemical properties of piperine/beta-cyclodextrin due to the formation of inclusion complexes. Int. J. Med. Chem. 2016, 2016, 8723139. [Google Scholar] [CrossRef] [PubMed]

- Ezawa, T.; Inoue, Y.; Murata, I.; Takao, K.; Sugita, Y.; Kanamoto, I. Characterization of the Dissolution Behavior of Piperine/Cyclodextrins Inclusion Complexes. AAPS Pharm. Sci. Tech. 2018, 19, 923–933. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Sun, X.; Ren, K.; Zhang, X.; Zhang, Z.; Gong, T. Enhanced aqueous solubility and bioavailability of capsaicin by the preparation of an inclusion complex. Arzneimittelforschung 2010, 60, 571–574. [Google Scholar] [CrossRef]

- Ohta, Y.; Takatani, K.; Kawakishi, S. Kinetic and thermodynamic analyses of the cyclodextrin-allyl isothiocyanate inclusion complex in an aqueous solution. Biosci. Biotechol. Biochem. 2000, 64, 190–193. [Google Scholar] [CrossRef] [PubMed]

- Sicard-Roselli, C.; Perly, B.; Le Bas, G. The respective benefits of X-ray crystallography and NMR for the structural determination of the inclusion complex between butylisothiocyanate and alpha-cyclodextrin. J. Incl. Phenom. Macro. 2001, 39, 333–337. [Google Scholar] [CrossRef]

- Li, X.H.; Jin, Z.Y.; Wang, J. Complexation of allyl isothiocyanate by alpha- and beta-cyclodextrin and its controlled release characteristics. Food Chem. 2007, 103, 461–466. [Google Scholar] [CrossRef]

- Neoh, T.L.; Yamamoto, C.; Ikefuji, S.; Furuta, T.; Yoshii, H. Heat stability of allyl isothiocyanate and phenyl isothiocyanate complexed with randomly methylated beta-cyclodextrin. Food Chem. 2012, 131, 1123–1131. [Google Scholar] [CrossRef]

- Yuan, H.-N.; Yao, S.-J.; Shen, L.-Q.; Mao, J.-W. Preparation and characterization of inclusion complexes of β-cyclodextrin-BITC and β-cyclodextrin-PEITC. Ind. Eng. Chem. Res. 2009, 48, 5070–5078. [Google Scholar] [CrossRef]

- Trend Monitor. Yogurt Spotlight: Moosa Orange & Ginger. Available online: https://trndmonitor.com/yogurt-spotlight-noosa-orange-ginger/ (accessed on 15 January 2020).

- Felfoul, I.; Borchani, M.; Samet-Bali, O.; Attia, H.; Ayadi, M.A. Effect of ginger (Zingiber officinalis) addition on fermented bovine milk: Rheological properties, sensory attributes and antioxidant potential. J. New. Sci. Agric. Biotechnol. 2017, 44, 2400–2409. [Google Scholar]

- Arslan, D.; Sert, D.; Ayar, A.; Özkan, M.M. Shelf life determination of Yayik butter fortified with spice extracts. Int. J. Dairy Technol. 2009, 62, 189–194. [Google Scholar] [CrossRef]

- Yang, G.H.; Guan, J.J.; Wang, J.S.; Yin, H.C.; Qiao, F.D.; Jia, F. Physicochemical and sensory characterization of ginger-juice yogurt during fermentation. Food Sci. Biotech. 2012, 21, 1541–1548. [Google Scholar] [CrossRef]

- Rial, R.C. Avaliação da Ação de Extrato de Gengibre em Biodíesel de Soja: Comparação com Antioxidantes Comerciais. Master’s Thesis, Federal University of Mato Grosso do Sul, Campo Grande, Brazil, 2014. [Google Scholar]

- Wasli, H.; Jelali, H.; Silva, A.M.S.; Ksouri, R.; Cardoso, S.M. Variation of polyphenolic composition, antioxidants and physiological characteristics of dill (Anethum graveolens L.) as affected by bicarbonate-induced iron deficiency conditions. Ind. Crops Prod. 2018, 126, 466–476. [Google Scholar] [CrossRef]

- Afonso, A.F.; Pereira, O.R.; Neto, R.T.; Silva, A.M.S.; Cardoso, S.M. Health-promoting effects of Thymus herba-barona, Thymus pseudolanuginosus, and Thymus caespititius decoctions. Int. J. Mol. Sci. 2017, 18, 1879. [Google Scholar] [CrossRef] [PubMed]

- Catarino, M.D.; Silva, A.M.S.; Cruz, M.T.; Cardoso, S.M. Antioxidant and anti-inflammatory activities of Geranium robertianum L. decoctions. Food Funct. 2017, 8, 3355–3365. [Google Scholar] [CrossRef]

- Gan, Z.; Liang, Z.; Chen, X.; Wen, X.; Wang, Y.; Li, M. Separation and preparation of 6-gingerol from molecular distillation residue of Yunnan ginger rhizomes by high-speed counter-current chromatography and the antioxidant activity of ginger oils in vitro. J. Chromatogr. B 2016, 1011, 99–107. [Google Scholar] [CrossRef]

- Kubra, I.R.; Ramalakshmi, K.; Rao, L.J.M. Antioxidant Enriched Fractions from Zingiber officinale Roscoe. J. Chem. 2011, 8, 721–726. [Google Scholar]

- Pais, J.M.; Barroca, M.J.; Marques, M.P.M.; Paz, F.A.A.; Braga, S.S. Solid-state studies and antioxidant properties of the γ-cyclodextrin·fisetin inclusion compound. Beilstein J. Org. Chem. 2017, 13, 2138–2145. [Google Scholar] [CrossRef]

- Heyes, S.J.; Clayden, N.J.; Dobson, C.M. 13C-CP/MAS NMR studies of the cyclomalto-oligosaccharide (cyclodextrin) hydrates. Carbohydr. Res. 1992, 233, 1–14. [Google Scholar] [CrossRef]

- Gidley, M.J.; Bociek, S.M. Carbon-13 CP/MAS NMR studies of amylose inclusion complexes, cyclodextrins, and the amorphous phase of starch granules: Relationships between glycosidic linkage conformation and solid-state carbon-13 chemical shifts. J. Am. Chem. Soc. 1988, 110, 3820–3829. [Google Scholar] [CrossRef]

- Coelho, A. Topas Academic, Version 5.0; Coelho Software: Brisbane, Australia, 2013. [Google Scholar]

- Young, R.A. Introduction to the Rietveld method—The Rietveld Method; Oxford University Press: Oxford, UK, 1993. [Google Scholar]

- Caira, M.R. On the isostructurality of cyclodextrin inclusion complexes and its practical utility. Rev. Roumaine Chim. 2001, 46, 371–386. [Google Scholar]

- Morad, N.A.B.H.; Aziz, M.K.A. High Sensitivity Differential Scanning Calorimeter (HSDSC) Technique for Assaying Ginger Oleoresin. Research vote: 74212. 2006 Malaysia University of Technology, Kuala Lumpur. Available online: http://eprints.utm.my/id/eprint/id/eprint/440/contents (accessed on 21 February 2020).

- 10-Gingerol—Product Info. Available online: https://www.lktlabs.com/product/10-gingerol (accessed on 21 February 2020).

- Lin, J.; Li, X.; Chen, L.; Lu, W.; Chen, X.; Han, L.; Chen, D. Protective Effect Against Hydroxyl Radical-Induced DNA Damage and Antioxidant Mechanism of [6]-Gingerol: A Chemical Study. Bull. Korean Chem. Soc. 2014, 35, 1633–1638. [Google Scholar] [CrossRef]

- Elosta, A.; Slevin, M.; Rahman, K.; Ahmed, N. Aged garlic has more potent antiglycation and antioxidant properties compared to fresh garlic extract in vitro. Sci. Rep. 2017, 3, 39613. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Wu, H.; Du, L.; Zhang, W.; Yang, J. Comparative Antioxidant Properties of Some Gingerols and Shogaols, and the Relationship of Their Contents with the Antioxidant Potencies of Fresh and Dried Ginger (Zingiber Officinale Roscoe). J. Agr. Sci. Tech. 2014, 16, 1063–1072. [Google Scholar]

- Kim, H.W.; Murakami, A.; Abe, M.; Ozawa, Y.; Morimitsu, Y.; Williams, M.V.; Ohigashi, H. Suppressive effects of mioga ginger and ginger constituents on reactive oxygen and nitrogen species generation, and the expression of inducible pro-inflammatory genes in macrophages. Antiox. Redox Signal. 2005, 7, 1621–1629. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.S.; Oh, J.S. Phenylpropanoid esters from Zingiber officinale and their inhibitory effects on the production of nitric oxide. Arch. Pharm. Res. 2012, 35, 315–320. [Google Scholar] [CrossRef]

- Amri, M.; Touil-Boukoffa, C. In vitro anti-hydatic and immunomodulatory effects of ginger and [6]-gingerol. Asian Pac. J. Trop. Med. 2016, 9, 749–756. [Google Scholar] [CrossRef]

| Fraction Number | Volume (mL) | Composition (v/v) |

|---|---|---|

| 1 | 70 | hexane/ethyl acetate 4:1 |

| 2 | 60 | |

| 3 | 20 | |

| 4 | 70 | hexane/ethyl acetate 1:1 |

| Fractions | Total Volume (mL) | Composition (v/v) |

|---|---|---|

| 1–17 | 340 | hexane/ethyl acetate 5:1 |

| 18–27 | 200 | hexane/ethyl acetate 3:2 |

| 28–40 | 260 | hexane/ethyl acetate 1:1 |

| Sample | L | a* | b* | ȳ (L*) | ȳ (a*) | ȳ (b*) |

|---|---|---|---|---|---|---|

| entry 1 | data | data | ||||

| Plain Yogurt | ||||||

| 1 (n = 5) | 88.980 | −1.408 | 3.500 | 87.986 ± 5.003 | −1.317 ± 0.286 | 4.086 ± 1.053 |

| 2 (n = 5) | 92.418 | −1.548 | 5.302 | |||

| 3 (n = 5) | 82.561 | −0.997 | 3.456 | |||

| Gingerols Yogurt | ||||||

| 4 (n = 10) | 90.587 | −1.830 | 6.524 | 89.076 ± 3.020 | −1.874 ± 0.155 | 6.646 ± 0.344 |

| 5 (n = 10) | 91.044 | −2.048 | 7.035 | |||

| 6 (n = 10) | 85.598 | −1.746 | 6.380 | |||

| γ-CD·gingerols Yogurt | ||||||

| 7 (n = 5) | 83.964 | −1.372 | 3.678 | 87.615 ± 5.258 | −1.620 ± 0.310 | 5.968 ± 2.066 |

| 8 (n = 5) | 85.240 | −1.520 | 6.536 | |||

| 9 (n = 5) | 93.642 | −1.968 | 7.692 | |||

| Compound | ABTS•+ EC50 (μM) | β-Carotene EC50 (μM) | NO• Scavenging 1 (%) | 5-LOX EC50 (μM) |

|---|---|---|---|---|

| γ-CD | — | > 100 2 | 11.3 ± 1.5 | > 1000 3 |

| gingerols | 9.13 ± 1.03 | 83 ± 5 | 17.5 ± 3.2 | 695 ± 47 |

| γ-CD·gingerols | 8.80 ± 0.81 | 85 ± 7 | 25.3 ± 1.2 | 629 ± 101 |

| Trolox | 7.99 ± 0.99 | — | — | — |

| Ascorbic acid | 183.3 ± 14.9 | — | 50.3 ± 1.9 | 234 ± 21 |

| BHA | — | 7.0 ± 0.1 | — | — |

| Batch | Week 1 | Week 2 | Week 3 | Week 4 | Week 8 |

|---|---|---|---|---|---|

| Plain Yogurt | 3.71 ± 0.06 | 3.73 ± 0.02 | 3.62 ± 0.04 | 3.59 ± 0.06 | 3.59 ± 0.05 |

| Gingerols Yogurt | 3.72 ± 0.07 | 3.78 ± 0.06 | 3.65 ± 0.06 | 3.60 ± 0.04 | 3.62 ± 0.09 |

| γ-CD·Gingerols Yogurt | 3.65 ± 0.06 | 3.71 ± 0.01 | 3.59 ± 0.04 | 3.56 ± 0.07 | 3.53 ± 0.02 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pais, J.M.; Pereira, B.; Paz, F.A.A.; Cardoso, S.M.; Braga, S.S. Solid γ-Cyclodextrin Inclusion Compound with Gingerols, a Multi-Component Guest: Preparation, Properties and Application in Yogurt. Biomolecules 2020, 10, 344. https://doi.org/10.3390/biom10020344

Pais JM, Pereira B, Paz FAA, Cardoso SM, Braga SS. Solid γ-Cyclodextrin Inclusion Compound with Gingerols, a Multi-Component Guest: Preparation, Properties and Application in Yogurt. Biomolecules. 2020; 10(2):344. https://doi.org/10.3390/biom10020344

Chicago/Turabian StylePais, Joana M., Bruna Pereira, Filipe A. Almeida Paz, Susana M. Cardoso, and Susana S. Braga. 2020. "Solid γ-Cyclodextrin Inclusion Compound with Gingerols, a Multi-Component Guest: Preparation, Properties and Application in Yogurt" Biomolecules 10, no. 2: 344. https://doi.org/10.3390/biom10020344

APA StylePais, J. M., Pereira, B., Paz, F. A. A., Cardoso, S. M., & Braga, S. S. (2020). Solid γ-Cyclodextrin Inclusion Compound with Gingerols, a Multi-Component Guest: Preparation, Properties and Application in Yogurt. Biomolecules, 10(2), 344. https://doi.org/10.3390/biom10020344