Mixed Position and Twist Space Synthesis of 3R Chains

Abstract

:1. Introduction

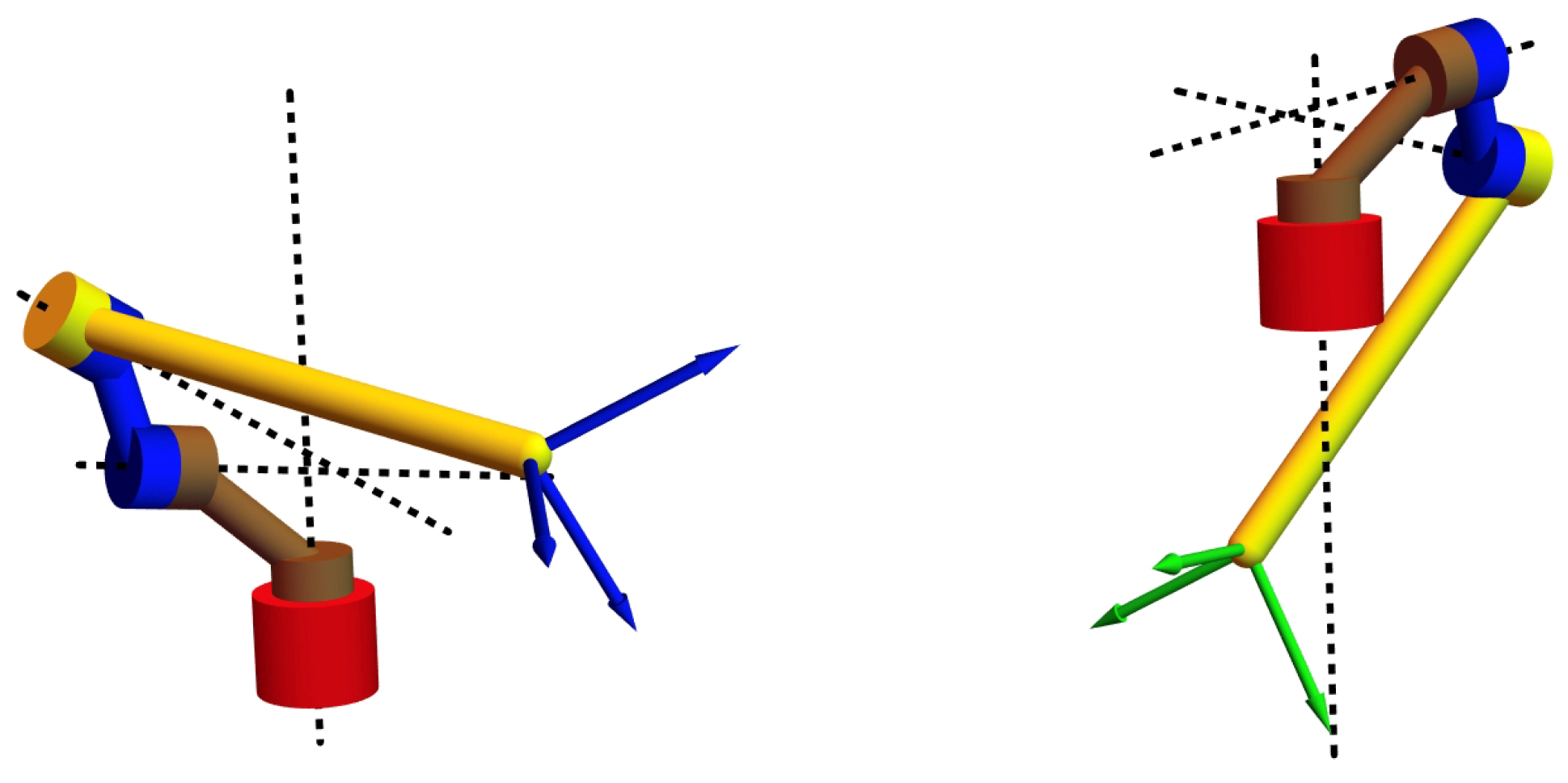

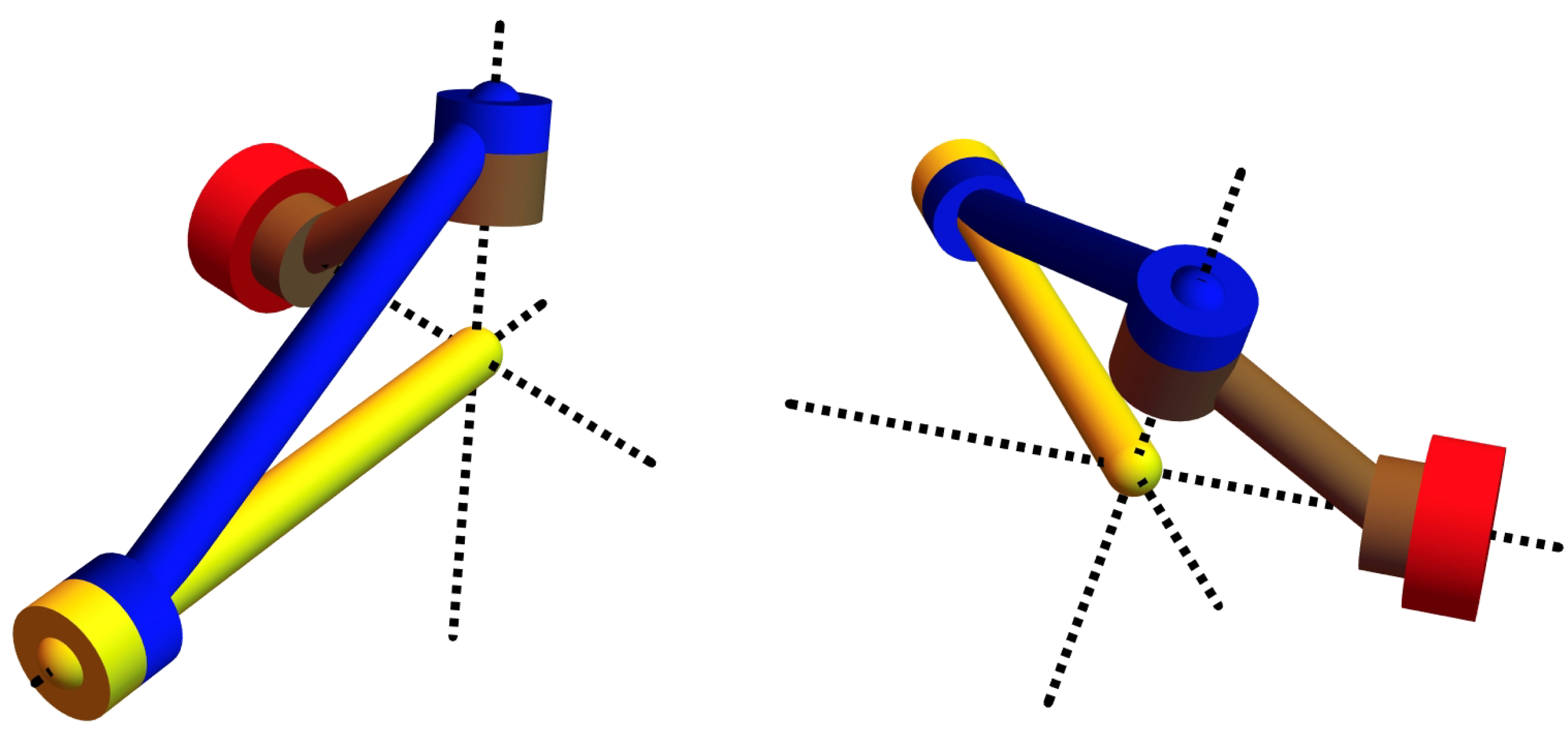

2. The 3R Serial Chain

2.1. Forward and Inverse Kinematics of the 3R Chain

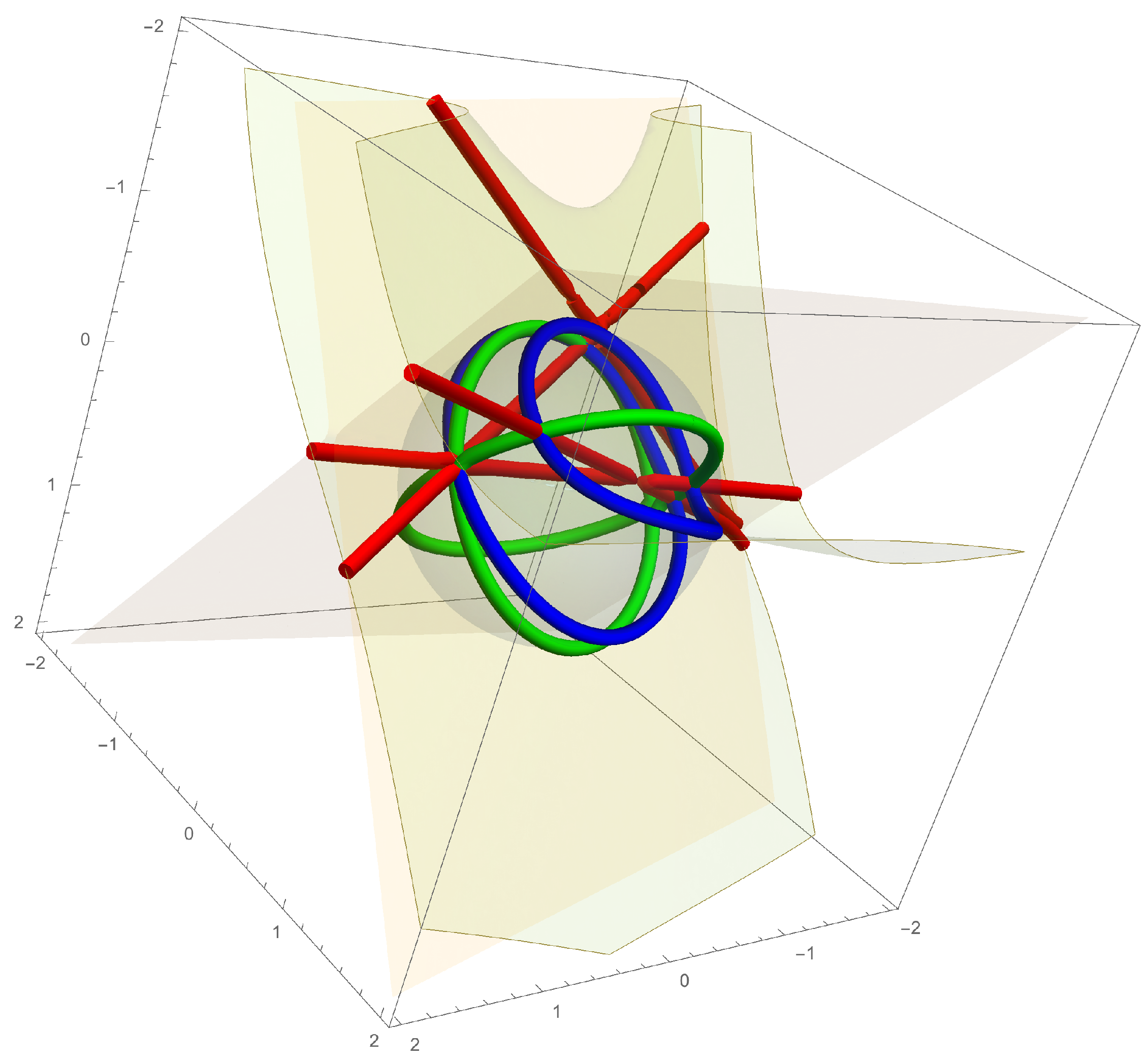

2.2. Space of Potential Twists of the End-Effector

3. Twist Spaces of Dimension 3 for the Serial 3R Chain

3.1. Finite and Infinitesimal Motion

3.2. Kinematic Generators of a Twist System

3.3. Feasible Screw Systems for the 3R Serial Chain

3.4. Proofs of Feasibility

3.5. The 3R Chain as a Kinematic Generator of Twists

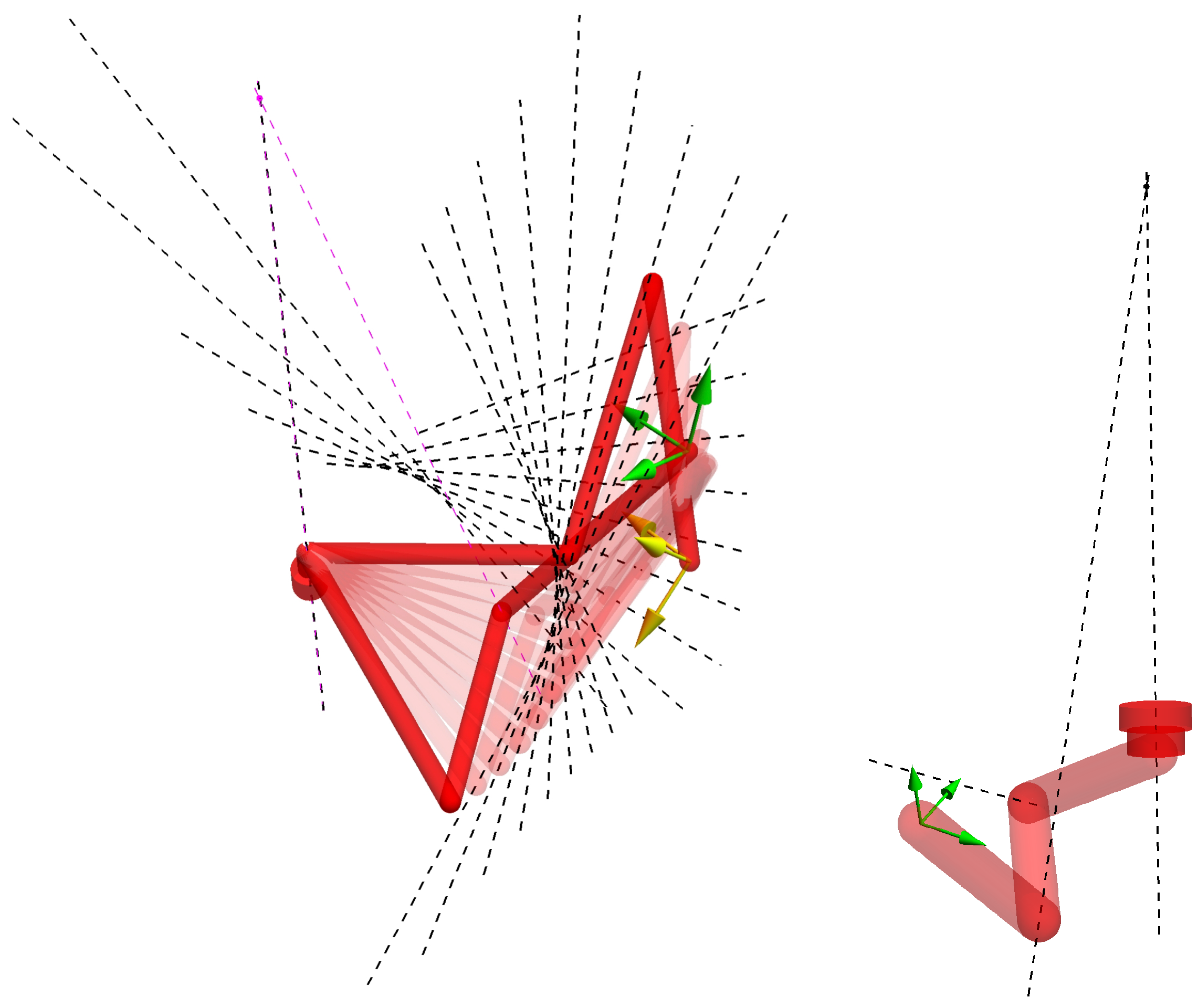

4. Synthesis with a Specified Twist Space

Solving the System of Equations

5. Design for Lower-Dimensional Twist Spaces

6. Design for Fully Specified Twist Space

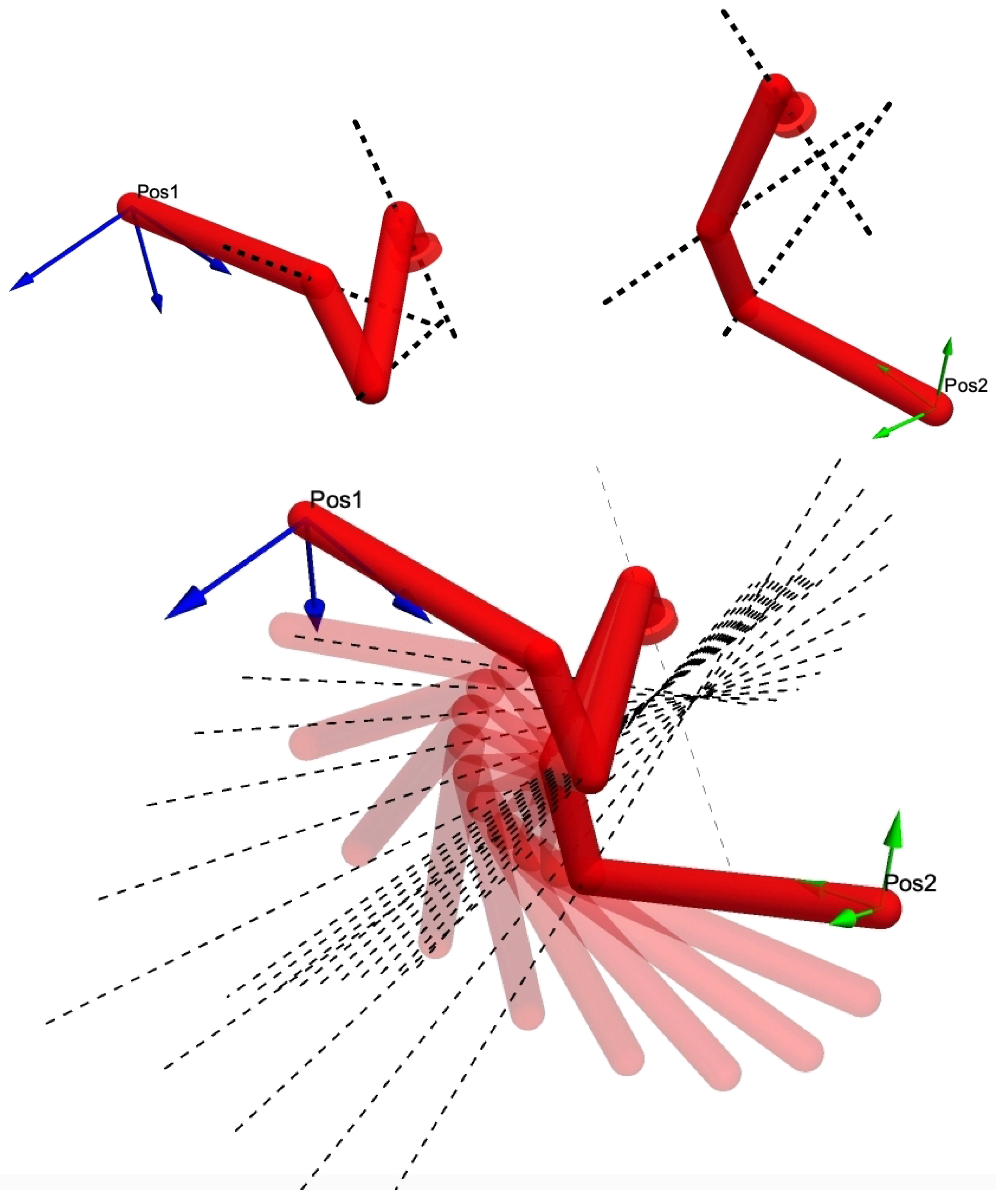

6.1. Example 2: Arbitrary Finite Motion and General Twist System

6.2. Example 3: Invariant Twist System–Motion within a Subgroup of SE(3)

7. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sandor, G.; Freudenstein, F. Higher-order plane motion theories in kinematic synthesis. J. Eng. Ind. 1967, 89, 223–230. [Google Scholar] [CrossRef]

- Kramer, R.S.S. Selective precision synthesis of planar mechanisms satisfying position and velocity constraints. Mech. Mach. Theory 1979, 14, 161–170. [Google Scholar]

- Holte, J.; Chase, T.; Erdman, A. Approximate velocities in mixed exact-approximate position synthesis of mechanisms. AMSE J. Mech. Des. 2001, 123, 388–394. [Google Scholar] [CrossRef]

- Sathyadev, D.; Soni, A. Synthesis of planar mechanisms for coupler tangent-line envelope generation: An alternative to coupler point-path generation. ASME J. Mech. Des. 1988, 110, 122–129. [Google Scholar] [CrossRef]

- Chen, P.; Roth, B. A unified theory for the finitely and infinitesimally separated position problems of kinematic synthesis. ASME J. Eng. Ind. 1969, 91, 203–208. [Google Scholar] [CrossRef]

- Chen, P.; Roth, B. Design equations for finitely and infinitesimally separated position synthesis of binary link and combined link chains. ASME J. Eng. Ind. 1969, 91, 209–219. [Google Scholar] [CrossRef]

- Tsai, L.W.; Roth, B. Design of dyads with helical, cylindrical, spherical, revolute and prismatic joints. Mech. Mach. Theory 1972, 7, 85–102. [Google Scholar] [CrossRef]

- Robson, N.; McCarthy, J. Second order task specifications used in the geometric design of spatial mechanical linkages. Int. J. Mod. Eng. 2010, 11, 5–11. [Google Scholar]

- Robson, N.; Chen, B. Geometric Design with Multiple Realizable Motion Directions in the Vicinity of a Planar Mechanism-Environment Contact. In Proceedings of the ASME 2018 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference IDETC/CIE 2018, Quebec City, QC, Canada, 26–29 August 2018. [Google Scholar]

- Moon, H.; Robson, N.; Langari, R. Approximating elbow constrained hand paths via kinematic synthesis with contact specifications. In Advances in Robot Kinematics; Lenarcic, J., Khatib, O., Eds.; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Robson, N.; Soh, G.S. Kinematic Synthesis of Planar Multi-limb Mechanisms for Multi-directional Interaction with Bodies in the Environment. In Advances in Robot Kinematics 2018; Lenarcic, J., Parenti-Castelli, V., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; pp. 356–363. [Google Scholar]

- Hasanzadeh, N.; Gosh, S.; Robson, N.; Perez-Gracia, A. Velocity-field tasks for in-hand manipulative synthesis. In Advances in Robot Kinematics; Merlet, J., Lenarcic, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Robson, N.; Ghosh, S.; Soh, G.S. Kinematic Synthesis and Design of the Robust Closed Loop Articulated Minimally actuated (CLAM) Hand. Robotica 2019, 38, 1921–1939. [Google Scholar] [CrossRef]

- Tian, C.; Fang, Y.; Ge, Q.J. Structural synthesis of parallel manipulators with coupling sub-chains. Mech. Mach. Theory 2017, 118, 84–99. [Google Scholar] [CrossRef]

- Lee, E.; Mavroidis, C. Solving the geometric design problem of spatial 3r robot manipulators using polynomial homotopy continuation. ASME J. Mech. Des. 2002, 124, 652–661. [Google Scholar] [CrossRef]

- Lee, E.; Mavroidis, C. An elimination procedure for solving the geometric design of spatial 3r manipulators. ASME J. Mech. Des. 2006, 128, 142–146. [Google Scholar] [CrossRef]

- Lee, E.; Mavroidis, C.; Merlet, J. Five precision point synthesis of spatial rrr manipulators using interval analysis. ASME J. Mech. Des. 2004, 126, 842–850. [Google Scholar] [CrossRef]

- Hauenstein, J.D.; Wampler, C.W.; Pfurner, M. Synthesis of three-revolute spatial chains for body guidance. Mech. Mach. Theory 2017, 110, 61–72. [Google Scholar] [CrossRef]

- Gibson, C.; Hunt, K. Geometry of screw systems–2: Classification of screw systems. Mech. Mach. Theory 1990, 25, 11–27. [Google Scholar] [CrossRef]

- Selig, J.M. Geometric Fundamentals of Robotics Monographs in Computer Science, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Carricato, M.; Zlatanov, D. Persistent Screw Systems. Mech. Mach. Theory 2014, 73, 296–313. [Google Scholar] [CrossRef]

- Carricato, M.; Rico-Martinez, J. Persistent screw systems. In Advances in Robot Kinematics: Motion in Man and Machine; Lenarcic, J., Stanisic, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 185–194. [Google Scholar]

- Carricato, M.; Rico-Martinez, J. Persistent screw systems of Dimension 3. In Proceedings of the 13th World Congress in Mechanism and Machine Science, Guanajuato, Mexico, 19–23 June 2011. [Google Scholar]

- Huynh, P.; Hervé, J.M. Equivalent Kinematic Chains of Three Degree-of-Freedom Tripod Mechanisms with Planar-Spherical Bonds. J. Mech. Des. 2005, 127, 95–102. [Google Scholar] [CrossRef]

- Tsai, M.; Lee, H. On the Special Bases of Two- and Three-Screw Systems. ASME J. Mech. Des. 1993, 115, 540–546. [Google Scholar] [CrossRef]

- Donelan, P.; Gibson, C. On the hierarchy of Screw Systems. Acta Appl. Math. 1993, 32, 267–296. [Google Scholar] [CrossRef]

| Completion Group | Gibson Hunt Type | Normal Form | Invariance | Feasible | |||

|---|---|---|---|---|---|---|---|

| ∞ | ∞ | ∞ | Invariant | NO | |||

| 0 | 0 | 0 | Invariant | YES | |||

| 0 | ∞ | ∞ | Invariant | YES | |||

| h | ∞ | ∞ | Invariant | NO | |||

| 0 | ∞ | ∞ | Variable | NO | |||

| 0 | ∞ | ∞ | Persistent | NO | |||

| h | h | ∞ | Variable | NO | |||

| 0 | 0 | ∞ | Variable | YES | |||

| ∞ | Variable | YES | |||||

| ∞ | Variable | YES | |||||

| h | h | h | Variable | NO | |||

| Variable | YES | ||||||

| Variable | YES | ||||||

| Position | End-Effector Twists |

|---|---|

| Axes | Plücker Coordinates |

|---|---|

| Position | End-Effector Twists |

|---|---|

| Axes | Plücker Coordinates |

|---|---|

| Position | End-Effector Twists |

|---|---|

| Axes | Plücker Coordinates |

|---|---|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassanzadeh, N.; Perez-Gracia, A. Mixed Position and Twist Space Synthesis of 3R Chains. Robotics 2022, 11, 13. https://doi.org/10.3390/robotics11010013

Hassanzadeh N, Perez-Gracia A. Mixed Position and Twist Space Synthesis of 3R Chains. Robotics. 2022; 11(1):13. https://doi.org/10.3390/robotics11010013

Chicago/Turabian StyleHassanzadeh, Neda, and Alba Perez-Gracia. 2022. "Mixed Position and Twist Space Synthesis of 3R Chains" Robotics 11, no. 1: 13. https://doi.org/10.3390/robotics11010013

APA StyleHassanzadeh, N., & Perez-Gracia, A. (2022). Mixed Position and Twist Space Synthesis of 3R Chains. Robotics, 11(1), 13. https://doi.org/10.3390/robotics11010013