Simulation-Based Comparison of Novel Automated Construction Systems

Abstract

1. Introduction and State of the Art

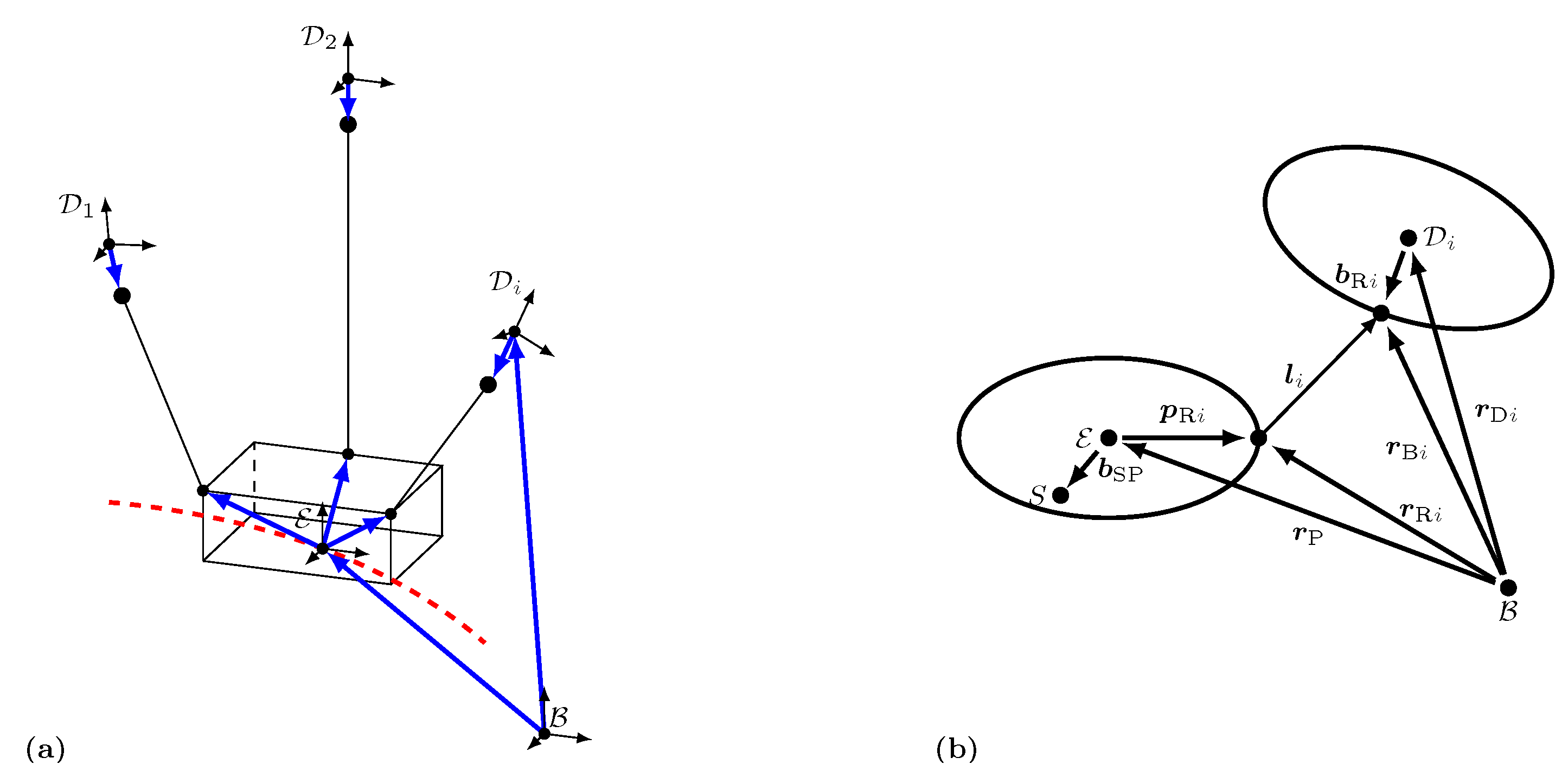

2. Methodological Approach

2.1. Setup of the Software Framework

2.2. Parametrization of Trajectories

- At start: Position is given, the velocity and all higher order time derivatives are set to zero, i.e., no optimization parameters.

- At first and second knot: Position, velocity and acceleration are parameters, subject to numerical optimization, i.e., three parameters in total, per DOF and knot. In the case of six DOFs, this leads to 18 parameters per knot. Jerk and higher order time derivatives are set to zero.

- At goal: Position is given, the velocity and all higher order time derivatives are set to zero, i.e., no optimization parameters.

2.3. Definition of the Optimization Parameters

- Trajectory time: The robot motion should be as fast as possible. This can be achieved by defining . Since the time has no upper boundary, it follows .

- Maximum end effector position, velocity and acceleration: For each time step in which the boundaries of the position, velocity or acceleration of the end effector are exceeded, the associated penalty term , or is charged. The boundaries of the position are derived from the robot’s frame, the ones of the velocity and acceleration depend on the motor specifications but can also be limited for safety reasons. A limitation in task space is intuitive.

- Actuator forces: In the case of the cable robot, the costs include the cable forces as a major criterion. The physical boundaries and of the cable forces should not be exceeded to avoid cable breaks and cable slackness, respectively [47]. Therefore, the penalty term is added whenever a cable force violates the boundaries. In the case of the cable robot, the necessary cable forces are generated by the torque of the winch motors. As the winches have masses, they introduce their own dynamics and boundaries. Hence, the additional cost value as well as the penalty term are defined. Note that, for simplicity, the motor torque limits are considered constant. The modeling of complex motor effects, such as field weakening, iron losses or temperature dependencies is part of future work. In the case of the drone system, the forces are generated by propellers. This leads to the cost function and the penalty term .

- Power and energy consumption: An electrical power source has technically defined limitations. To protect the source from overload, the total power demand needs to be limited. This is taken into account by the penalty term . A cost value might be used, e.g., to consider thermal load. Within this work such effects are neglected, i.e., . The energy consumption is one out of many factors which influence the economic efficiency of a robotic system. Hence, this parameter can also be considered by a cost function . Since there is often no physical boundary, it usually follows .

- Self-collision of the robots: For both robotic systems, the self-collision of cables are investigated. Whenever a cable collision is detected, the penalty term is assigned to the costs. In the case of the drone system, the self-collisions of drones are considered as well and, if necessary, are taken into account by the penalty term .

- Collisions of the robot with its environment: This includes collisions between objects in the workspace and

- -

- the end effector or payload (ObEE),

- -

- the drones (ObD) and

- -

- the cables (CaOb).

Note that collisions between cables and the end effector (CaEE) can be treated as CaOb collisions.

3. Modeling and Cost Functions

3.1. Modeling of the Platform Dynamics

3.2. Modeling of the Drone Dynamics

3.3. Modeling of the Cable Robot’s Winch Dynamics, Power and Energy Consumption

3.4. Modeling of Collisions

- a collision can be excluded, if and that

- a collision has happened within the chosen time step, if .

4. Discussion of the Optimization Results

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Abbreviations

| BIM | Building Information Modeling |

| CDPR | Cable-Driven Parallel Robot |

| AABB | Axis-Aligned Bounding Box |

| OBB | Oriented Bounding Box |

| DOF | Degree-Of-Freedom |

| EU | European Union |

References

- Borrmann, A.; König, M.; Koch, C.; Beetz, J. Building Information Modeling; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2015. [Google Scholar]

- Templin, T.; Popielarczyk, D. (Eds.) Proceedings of the Creative Construction e-Conference 2020; Budapest University of Technology and Economics: Budapest, Hungary, 2020. [Google Scholar]

- Vähä, P.; Heikkilä, T.; Kilpeläinen, P.; Järviluoma, M.; Gambao, E. Extending automation of building construction—Survey on potential sensor technologies and robotic applications. Autom. Constr. 2013, 36, 168–178. [Google Scholar] [CrossRef]

- Brehm, E. Robots for masonry construction—Status quo and thoughts for the German market. Mauerwerk 2019, 23, 87–94. [Google Scholar] [CrossRef]

- Bruckmann, T.; Mattern, H.; Spengler, A.; Reichert, C.; Malkwitz, A.; König, M. Automated Construction of Masonry Buildings using Cable-Driven Parallel Robots. In Proceedings of the 33rd International Symposium on Automation and Robotics in Construction (ISARC 2016), Auburn, AL, USA, 18–21 July 2016. [Google Scholar] [CrossRef]

- Wu, Y.; Cheng, H.; Fingrut, A.; Crolla, K.; Yam, Y.; Lau, D. CU-brick cable-driven robot for automated construction of complex brick structures: From simulation to hardware realisation. In Proceedings of the 2018 IEEE International Conference on Simulation, Modeling, and Programming for Autonomous Robots (SIMPAR), Brisbane, Australia, 16–19 May 2018; pp. 166–173. [Google Scholar] [CrossRef]

- Bruckmann, T.; Spengler, A.J.; Karl, C.K.; Reichert, C.; König, M. Process Analysis of Cable-Driven Parallel Robots for Automated Construction. In Mechatronics for Cultural Heritage and Civil Engineering. Intelligent Systems, Control and Automation: Science and Engineering; Springer: Cham, Switzerland, 2018; pp. 63–83. [Google Scholar] [CrossRef]

- Heidel, R.; Lemmen, P.; Boumann, R.; Bruckmann, T. Auslegung und Inbetriebnahme eines Seilroboters zum automatisierten Mauern von Gebäudewänden. In Proceedings of the Fachtagung: VDI Mechatronik, Darmstadt, Germany, 23–24 March 2022; pp. 126–132. [Google Scholar] [CrossRef]

- Roske, T.; Eden, W.; Schäfers, M.; Lemmen, P.; Heidel, R.; Boumann, R.; Spengler, A.J.; Bruckmann, T.; Lipowsky, J.; Palzer, U. Automated Construction of Calcium Silicate Masonry by Cable Robots. AAC Worldw. 2021, 3, 34–40. [Google Scholar]

- Bosscher, P.; Williams, R.L.; Bryson, L.; Castro-Lacouture, D. Cable-Suspended Robotic Contour Crafting System. Autom. Constr. 2007, 17, 45–55. [Google Scholar] [CrossRef]

- Izard, J.B.; Dubor, A.; Hervé, P.E.; Cabay, E.; Culla, D.; Rodriguez, M.; Barrado, M. Large-Scale 3D printing with Cable-Driven Parallel Robots. Constr. Robot. 2017, 1, 69–76. [Google Scholar] [CrossRef]

- Izard, J.B.; Dubor, A.; Hervé, P.E.; Cabay, E.; Culla, D.; Rodriguez, M.; Barrado, M. On the Improvements of a Cable-Driven Parallel Robot for Achieving Additive Manufacturing for Construction. In Mechanisms and Machine Science; Springer International Publishing AG: Cham, Switzerland, 2018; Volume 53, pp. 353–363. [Google Scholar] [CrossRef]

- Tenorio Ríos, J.A.; Sotorrío Ortega, G. Possibilities and Requirements for Works and Products on 3D Printing Technology. Digital Construction Week, London, UK. 2019. Available online: http://hdl.handle.net/10261/210926 (accessed on 7 September 2022).

- Papacharalampopoulos, A.; Bikas, H.; Foteinopoulos, P.; Stavropoulos, P. A Path Planning Optimization Framework for Concrete Based Additive Manufacturing Processes. Procedia Manuf. 2020, 51, 649–654. In Proceedings of the 30th InternationalConference on Flexible Automation and Intelligent Manufacturing (FAIM2021), Athens, Greece, 15–18 June 2021. [Google Scholar] [CrossRef]

- Iturralde, K.; Feucht, M.; Hu, R.; Pan, W.; Schlandt, M.; Linner, T.; Bock, T.; Izard, J.B.; Eskudero, I.; Rodriguez, M.; et al. A Cable Driven Parallel Robot with a Modular End Effector for the Installation of Curtain Wall Modules. In Proceedings of the 37th International Symposium on Automation and Robotics in Construction and Mining (ISARC), Kitakyushu, Japan, 27–28 October 2020; Tateyama, K., Ishii, K., Fumihiro, I., Eds.; The International Association for Automation and Robotics in Construction (IAARC): Tokyo, Japan, 2020; pp. 1472–1479. [Google Scholar] [CrossRef]

- Bright, L.Z.; Handley, M.; Chien, I.; Curi, S.; Brownworth, L.A.; D’hers, S.; Bernier, U.R.; Gurman, P.; Elman, N.M. Analytical models integrated with satellite images for optimized pest management. Precis. Agric. 2016, 17, 628–636. [Google Scholar] [CrossRef]

- Ashour, R.; Taha, T.; Mohamed, F.; Hableel, E.; Kheil, Y.A.; Elsalamouny, M.; Kadadha, M.; Rangan, K.; Dias, J.; Seneviratne, L.; et al. Site inspection drone: A solution for inspecting and regulating construction sites. In Proceedings of the 2016 IEEE 59th International Midwest Symposium on Circuits and Systems (MWSCAS), Abu Dhabi, United Arab Emirates, 16–19 October 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Rizo-Maestre, C.; González-Avilés, Á.; Galiano-Garrigós, A.; Andújar-Montoya, M.D.; Puchol-García, J.A. UAV + BIM: Incorporation of Photogrammetric Techniques in Architectural Projects with Building Information Modeling Versus Classical Work Processes. Remote. Sens. 2020, 12, 2329. [Google Scholar] [CrossRef]

- Suarez Fernandez, R.A.; Dominguez, S.; Campoy, P. L1 adaptive control for Wind gust rejection in quad-rotor UAV wind turbine inspection. In Proceedings of the 2017 International Conference on Unmanned Aircraft Systems (ICUAS), Miami, FL, USA, 13–16 June 2017; pp. 1840–1849. [Google Scholar] [CrossRef]

- Vanderhorst, H.R.; Suresh, S.; Suresh, R. Special Issue. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 416–428. [Google Scholar] [CrossRef]

- Placke, T.; Kloepsch, R.; Dühnen, S.; Winter, M. Lithium ion, lithium metal, and alternative rechargeable battery technologies: The odyssey for high energy density. J. Solid State Electrochem. 2017, 21, 1939–1964. [Google Scholar] [CrossRef]

- Olivares, V.; Cordova, F.; Sepúlveda, J.M.; Derpich, I. Modeling Internal Logistics by Using Drones on the Stage of Assembly of Products. Procedia Comput. Sci. 2015, 55, 1240–1249. [Google Scholar] [CrossRef]

- Apeland, J.; Pavlou, D.; Hemmingsen, T. State-of-Technology and Barriers for Adoption of Fuel Cell Powered Multirotor Drones. In Proceedings of the 2020 International Conference on Unmanned Aircraft Systems (ICUAS), Athens, Greece, 1–4 September 2020; pp. 1359–1367. [Google Scholar] [CrossRef]

- Liang, X.; Fang, Y.; Sun, N.; Lin, H.; Zhao, X. Adaptive Nonlinear Hierarchical Control for a Rotorcraft Transporting a Cable-Suspended Payload. In IEEE Transactions on Systems, Man, and Cybernetics. Systems; IEEE: New, York, NY, USA, 2020; pp. 1–12. [Google Scholar] [CrossRef]

- Augugliaro, F.; Lupashin, S.; Hamer, M.; Male, C.; Hehn, M.; Mueller, M.; Willmann, J.S.; Gramazio, F.; Kohler, M.; D’Andrea, R. The Flight Assembled Architecture installation: Cooperative construction with flying machines. IEEE Control Syst. 2014, 34, 46–64. [Google Scholar] [CrossRef]

- Naldi, R.; Gentili, L.; Marconi, L. Modeling and control of the interaction between flying robots and the environment. IFAC Proc. Vol. 2010, 43, 975–980. [Google Scholar] [CrossRef]

- Pounds, P.E.I.; Bersak, D.R.; Dollar, A.M. Grasping from the air: Hovering capture and load stability. In Proceedings of the IEEE International Conference 2011, Shanghai, China, 9–13 May 2011; Volume 2011, pp. 2491–2498. [Google Scholar] [CrossRef]

- Wang, Y.; Cai, H.; Zhang, J.; Li, X. Disturbance Attenuation Predictive Optimal Control for Quad-Rotor Transporting Unknown Varying Payload. IEEE Access 2020, 8, 44671–44686. [Google Scholar] [CrossRef]

- Ryll, M.; Muscio, G.; Pierri, F.; Cataldi, E.; Antonelli, G.; Caccavale, F.; Franchi, A. 6D physical interaction with a fully actuated aerial robot. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; pp. 5190–5195. [Google Scholar] [CrossRef]

- Muscio, G.; Pierri, F.; Trujillo, M.A.; Cataldi, E.; Giglio, G.; Antonelli, G.; Caccavale, F.; Viguria, A.; Chiaverini, S.; Ollero, A. Experiments on coordinated motion of aerial robotic manipulators. In Proceedings of the 2016 IEEE InternationalConference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 1224–1229. [Google Scholar] [CrossRef]

- Tognon, M.; Yuksel, B.; Buondonno, G.; Franchi, A. Dynamic decentralized control for protocentric aerial manipulators. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; pp. 6375–6380. [Google Scholar] [CrossRef]

- Alothman, Y.; Gu, D. Using Constrained Model Predictive Control to Control Two Quadrotors Transporting a Cable-Suspended Payload. In Proceedings of the 2018 13th World Congress on Intelligent Control and Automation (WCICA), Changsha, China, 4–8 July 2018; pp. 228–233. [Google Scholar] [CrossRef]

- Gassner, M.; Cieslewski, T.; Scaramuzza, D. Dynamic collaboration without communication: Vision-based cable-suspended load transport with two quadrotors. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; pp. 5196–5202. [Google Scholar] [CrossRef]

- Heyden, T.; Maier, T.; Woernle, C. Trajectory Tracking Control for a Cable Suspension Manipulator. In Advances in Robot Kinematics: Theory and Applications; Lenarčič, J., Thomas, F., Eds.; Springer: Dordrecht, The Netherlands, 2002; pp. 125–134. [Google Scholar] [CrossRef]

- Michael, N.; Fink, J.; Kumar, V. Cooperative manipulation and transportation with aerial robots. Auton. Robot. 2011, 30, 73–86. [Google Scholar] [CrossRef]

- Manubens, M.; Devaurs, D.; Ros, L.; Cortés, J. Motion Planning for 6-D Manipulation with Aerial Towed-cable Systems. In Proceedings of the Robotics: Science and Systems IX. Robotics: Science and Systems Foundation, Berlin, Germany, 24–28 June 2013. [Google Scholar] [CrossRef]

- Mohammadi, K.; Sirouspour, S.; Grivani, A. Control of Multiple Quad-Copters With a Cable-Suspended Payload Subject to Disturbances. IEEE/ASME Trans. Mechatron. 2020, 25, 1709–1718. [Google Scholar] [CrossRef]

- Masone, C.; Bulthoff, H.H.; Stegagno, P. Cooperative transportation of a payload using quadrotors: A reconfigurable cable-driven parallel robot. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016; pp. 1623–1630. [Google Scholar] [CrossRef]

- Hashemi, D.; Heidari, H. Trajectory Planning of Quadrotor UAV with Maximum Payload and Minimum Oscillation of Suspended Load Using Optimal Control. J. Intell. Robot. Syst. 2020, 100, 1369–1381. [Google Scholar] [CrossRef]

- Qian, L.; Liu, H.H. Path-Following Control of A Quadrotor UAV With A Cable-Suspended Payload Under Wind Disturbances. IEEE Trans. Ind. Electron. 2020, 67, 2021–2029. [Google Scholar] [CrossRef]

- Guo, M.; Gu, D.; Zha, W.; Zhu, X.; Su, Y. Controlling a Quadrotor Carrying a Cable-Suspended Load to Pass Through a Window. J. Intell. Robot. Syst. 2020, 98, 387–401. [Google Scholar] [CrossRef]

- Foehn, P.; Falanga, D.; Kuppuswamy, N.; Tedrake, R.; Scaramuzza, D. Fast Trajectory Optimization for Agile Quadrotor Maneuvers with a Cable-Suspended Payload. In Proceedings of the Robotics: Science and Systems XIII. Robotics: Science and Systems Foundation, Cambridge, MA, USA, 12–16 July 2017. [Google Scholar] [CrossRef]

- Cruz, P.; Fierro, R. Autonomous lift of a cable-suspended load by an unmanned aerial robot. In Proceedings of the 2014 IEEE Conference on Control Applications (CCA), Juan Les Antibes, France, 8–10 October 2014; pp. 802–807. [Google Scholar] [CrossRef]

- Cruz, P.J.; Oishi, M.; Fierro, R. Lift of a cable-suspended load by a quadrotor: A hybrid system approach. In Proceedings of the 2015 American Control Conference (ACC), Chicago, IL, USA, 1–3 July 2015; pp. 1887–1892. [Google Scholar] [CrossRef]

- The MathWorks, Inc. Global Optimization Toolbox. Available online: https://www.mathworks.com/help/gads/ (accessed on 7 September 2022).

- Benson, H.P. Multi-Objective Optimization: Pareto Optimal Solutions, Properties. In Encyclopedia of Optimization; Floudas, C.A., Pardalos, P.M., Eds.; Springer: Boston, MA, USA, 2009; pp. 2478–2481. [Google Scholar] [CrossRef]

- Mattern, H.; Bruckmann, T.; Spengler, A.J.; König, M. Simulation of Automated Construction using Wire Robots. In Proceedings of the 2016 Winter Simulation Conference; Roeder, T.M., Frazier, P.I., Szechtman, R., Zhou, E., Huschka, T., Chick, S.E., Eds.; IEEE Press: Arlington, VA, USA, 2016; pp. 3302–3313. [Google Scholar] [CrossRef]

- Bruckmann, T.; Boumann, R. Simulation and optimization of automated masonry construction using cable robots. Adv. Eng. Inform. 2021, 50, 101388. [Google Scholar] [CrossRef]

- Pott, A. Cable-Driven Parallel Robots: Theory and Application; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Mahony, R.; Kumar, V.; Corke, P. Multirotor Aerial Vehicles: Modeling, Estimation, and Control of Quadrotor. IEEE Robot. Autom. Mag. 2012, 19, 20–32. [Google Scholar] [CrossRef]

- Herrmann, L.; Bröcker, M. Flatness based control of a ball in tube system. IFAC-Papers OnLine 2015, 48, 790–795. [Google Scholar] [CrossRef]

- Pillay, P.; Krishnan, R. Application characteristics of permanent magnet synchronous and brushless DC motors for servo drives. IEEE Trans. Ind. Appl. 1991, 27, 986–996. [Google Scholar] [CrossRef]

- Bruckmann, T.; Reichert, C.; Ji, H. Energy Consumption Reduction of a Cable-Driven Storage and Retrieval System. In Advances in Robot Kinematics 2018; Lenarčič, J., Parenti-Castelli, V., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 383–391. [Google Scholar] [CrossRef]

- Reichert, C.; Glogowski, P.; Bruckmann, T. Dynamische Rekonfiguration eines seilbasierten Manipulators zur Verbesserung der mechanischen Steifigkeit. In Fachtagung Mechatronik 2015: Dortmund (12–13 March 2015), Proceedings; Bertram, T., Corves, B., Janschek, K., Eds.; Institute of Mechanism Theory, Machine Dynamics and Robotics: Aachen, Germany, 2015; pp. 91–96. [Google Scholar] [CrossRef]

- Ericson, C. Real-Time Collision Detection; The Morgan Kaufmann Series in Interactive 3D Technology; Morgan Kaufmann: San Francisco, CA, USA, 2005; p. iv. [Google Scholar] [CrossRef]

- Ericson, C. Real-Time Collision Detection; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Nguyen, D.Q.; Gouttefarde, M. On the Improvement of Cable Collision Detection Algorithms; Cable-Driven Parallel Robots; Pott, A., Bruckmann, T., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 29–40. [Google Scholar]

- Merlet, J.P. Analysis of the Influence of Wires Interference on the Workspace of Wire Robots. In On Advances in Robot Kinematics; Lenarčič, J., Galletti, C., Eds.; Springer: Dordrecht, The Netherlands, 2004; pp. 211–218. [Google Scholar]

- Merlet, J.P.; Daney, D. Legs interference checking of parallel robots over a given workspace or trajectory. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation, Orlando, FL, USA, 15–19 May 2006; pp. 757–762. [Google Scholar] [CrossRef]

- Perreault, S.; Cardou, P.; Gosselin, C.M.; Otis, M.J.D. Geometric Determination of the Interference-Free Constant-Orientation Workspace of Parallel Cable-Driven Mechanisms. J. Mech. Robot. 2010, 2, 031016. [Google Scholar] [CrossRef]

- Blanchet, L.; Merlet, J.P. Interference detection for cable-driven parallel robots (CDPRs). In Proceedings of the 2014 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Besancon, France, 8–11 July 2014; pp. 1413–1418. [Google Scholar] [CrossRef]

- Rich, H. Kalksandstein: Die Maurerfibel, 8th ed.; Verlag Bau+Technik GmbH: Düsseldorf, Germany, 2014. [Google Scholar]

- Deutsche Institut für Normung, e.V. DIN V 106:2005-10: Calcium Silicate Units with Specific Properties; Beuth-Verlag: Berlin, Germany, 2005. [CrossRef]

- Heyden, T.; Woernle, C. Flatness-Based Trajectory Tracking Control of an Underconstrained Cable Suspension Manipulator. PAMM 2004, 4, 129–130. [Google Scholar] [CrossRef]

- The MathWorks, Inc. Particle Swarm. Available online: https://www.mathworks.com/help/gads/particle-swarm.html (accessed on 7 September 2022).

- Gouttefarde, M.; Lamaury, J.; Reichert, C.; Bruckmann, T. A Versatile Tension Distribution Algorithm for n-DOF Parallel Robots Driven by n+2 Cables. IEEE Trans. Robot. 2015, 31, 1444–1457. [Google Scholar] [CrossRef]

- The MathWorks, Inc. Fmincon. Available online: https://www.mathworks.com/help/optim/ug/fmincon.html (accessed on 7 September 2022).

| Trajectory | Function | Payload | Time [s] |

|---|---|---|---|

| 1 | Measuring the dimensions of the masonry unit | no | 32.7 |

| 2 | Slowly move down to the pickup position | no | 9.12 |

| 3 | Pick up the masonry unit | no | 5.54 |

| 4 | Slowly move up half a meter | yes | 4.89 |

| 5 | Move up to transition height | yes | optimized |

| 6 | Transition through workspace to target | yes | optimized |

| 7 | Move down to half a meter above target position | yes | optimized |

| 8 | Measuring the target position | yes | 20.64 |

| 9 | Slowly move down half a meter | yes | 2.62 |

| 10 | Placing down the masonry unit | yes | 11.78 |

| 11 | Slowly move up half a meter | no | 1.31 |

| 12 | Move up to transition height | no | optimized |

| 13 | Transition through workspace | no | optimized |

| 14 | Move down to half a meter above next masonry unit | no | optimized |

| 15 | Wait until the mortar system has finished | no | externally defined |

| Parameter | Value |

|---|---|

| Number and type of drones | quadrocopters |

| Platform mass | |

| Drone mass | |

| Masonry unit mass | – |

| Length of the i-th cable | |

| Vector from the drone’s center of gravity to the attachment point of the cable | |

| Tensor of inertia of the drone | |

| Tensor of inertia of the platform | |

| Thrust coefficient | = 7.243 |

| Drag coefficient | |

| Rotor speed | |

| Vector to the cable attachment points of the platform |

| Cost Function | Cost | Weight | Penalty | Limits |

|---|---|---|---|---|

| Time | 1 | - | - | |

| Propeller speed | 1 | 21,952 | 10,000 | |

| DD | 1 | 1 | ||

| ObEE | 1 | 1 | 1000 | |

| ObD | 1 | 0 | ||

| CaCa | 1 | 0 | ||

| CaOb | 1 | 1 | ||

| Position end effector | 1 | 0 | 1000 | |

| Velocity end effector | 1 | 0 | 1000 | |

| Acceleration end effector | 1 | 0 | 1000 |

| Knot | Position | Velocity | Acceleration |

|---|---|---|---|

| Knot S1 at | |||

| Knot S2 at |

| Costfunction | Cost | Weight | Penalty | Limits |

|---|---|---|---|---|

| Time | 1 | - | - | |

| Cable force | 1 | 0 | 10,000 | |

| Cable velocity limits | 1 | 0 | 1000 | |

| ObEE | 1 | 0 | 1000 | |

| CaCa | 1 | 0 | 1000 | - |

| CaEE | 1 | 0 | 1000 | |

| CaOb | 1 | 0 | 1000 | |

| Position end effector | 1 | 0 | 1000 | |

| Velocity end effector | 1 | 0 | 1000 | |

| Acceleration end effector | 1 | 0 | 1000 | |

| Motor torque | 1 | 0 | 1000 | |

| Power | 1 | 0 | 1000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herrmann, L.; Boumann, R.; Lehmann, M.; Müller, S.; Bruckmann, T. Simulation-Based Comparison of Novel Automated Construction Systems. Robotics 2022, 11, 119. https://doi.org/10.3390/robotics11060119

Herrmann L, Boumann R, Lehmann M, Müller S, Bruckmann T. Simulation-Based Comparison of Novel Automated Construction Systems. Robotics. 2022; 11(6):119. https://doi.org/10.3390/robotics11060119

Chicago/Turabian StyleHerrmann, Lukas, Roland Boumann, Mario Lehmann, Samuel Müller, and Tobias Bruckmann. 2022. "Simulation-Based Comparison of Novel Automated Construction Systems" Robotics 11, no. 6: 119. https://doi.org/10.3390/robotics11060119

APA StyleHerrmann, L., Boumann, R., Lehmann, M., Müller, S., & Bruckmann, T. (2022). Simulation-Based Comparison of Novel Automated Construction Systems. Robotics, 11(6), 119. https://doi.org/10.3390/robotics11060119