Watch the Next Step: A Comprehensive Survey of Stair-Climbing Vehicles

Abstract

:1. Introduction

2. Categorization of Stair-Climbing Vehicles

- (1)

- Track-based mechanisms have the largest ground contact surface and are very stable due to a lower center of gravity. To facilitate the stair-climbing process, tracks can be equipped with teeth. Track-based mechanisms enable robots to climb up or down the stairs at a constant speed in a stable manner due to the interlocking effect between the track’s outer teeth and the steps’ sharp corner. There are no problems regarding the different length of rise, run, tread and noising of the stair steps’ shape. The track-based mechanisms are widely adopted.

- (2)

- Wheel cluster-based mechanisms: A wheel cluster is a component with multiple wheels uniformly distributed in the same plane around a common center. While using a stair-climbing mechanism, the wheels rotate around the central axis of the wheel cluster and propel the robot up or down the stairs. Often, wheel cluster-based mechanism robots are not able to overcome all type of stair, so a range of available step lengths are given. Wheel cluster-based robots are characterized by speed fluctuation during the ascending and descending motion.

- (3)

- Articulated mechanism-based systems: This type of stair-climbing robots uses an articulated mechanism in combination with wheels to accomplish the stair-climbing task.

- (4)

- Hybrid and leg-based mechanisms: This type of stair-climbing mechanism originates from the imitation of humans’ and animals’ stair-climbing techniques, using legs and feet to walk on various steps. Theoretically they can adapt to all type of stairs provided that the control system is sufficiently developed.

- (5)

- Wheel-based mechanisms: Two or more wheels are used to perform the stair-climbing task. They can be suspended respect to the robot’s frame, using mechanical suspension, or not. Wheeled robots can reach high speeds with low power consumption.

3. Payload Robots

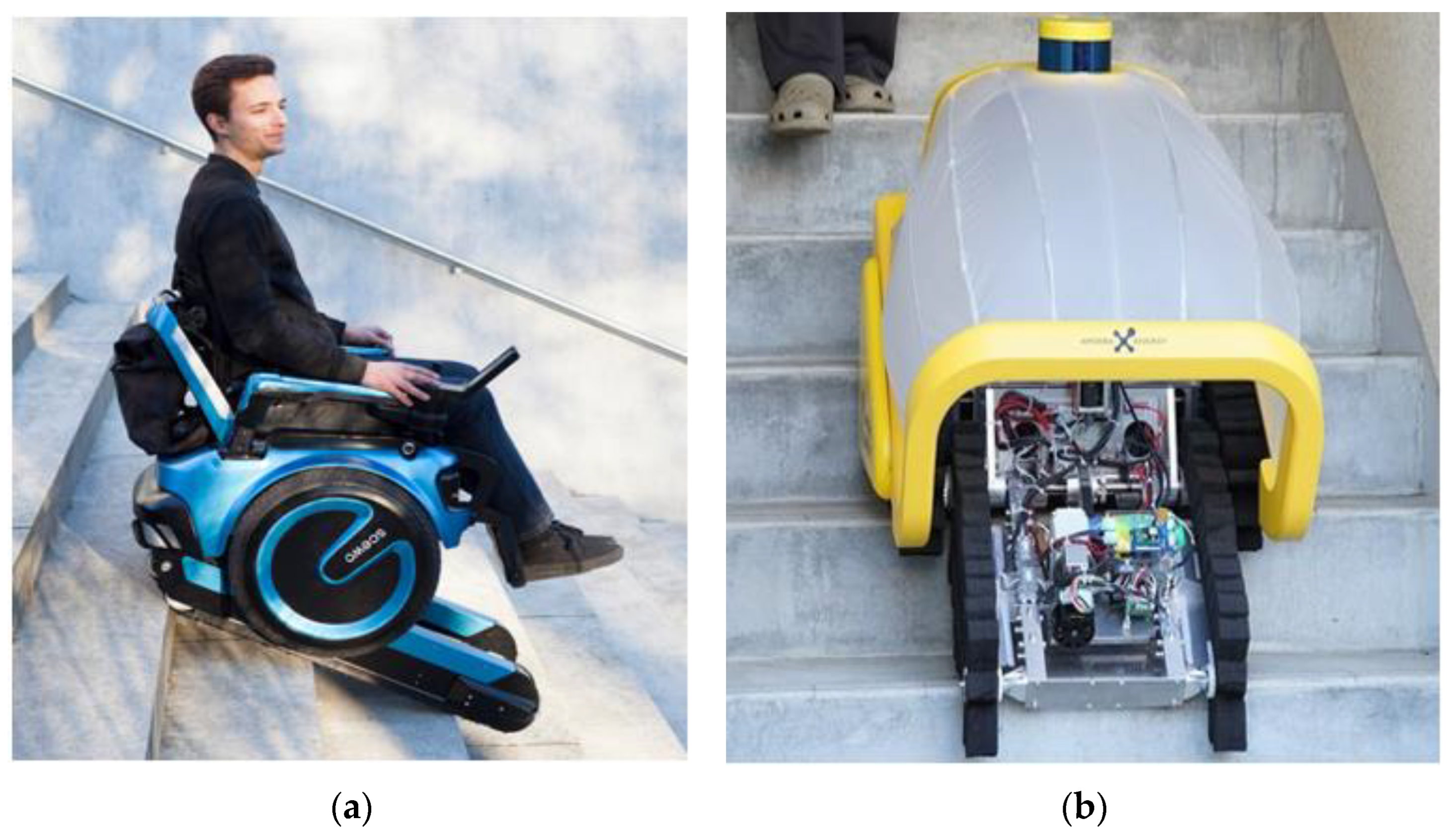

3.1. Wheelchair Type Robots

3.2. Carrier Type Robots

3.3. No Payload Robots

4. Analysis and Comparison

4.1. Performance Metrics

4.2. Comparison Charts

4.3. Complexity and Cost Issues

5. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Name | Type | Category | PC [%] | Payload/Robot |

|---|---|---|---|---|

| Scewo Bro Errore. [25] | WT | Track | 74.07% | 120 kg/162 kg |

| WT Wheelchair [27,28] | WT | Track | 57.69% | 75 kg/130 kg |

| TopChair-S [26] | WT | Track | 73.33% | 110 kg/150 kg |

| Tao [29] | WT | Track | 150% | 75 kg/50 kg |

| B-Free Ranger [30] | WT | Track | 82.19% | 120 kg/146 kg |

| Caterwil GTS5 Lux [33] | WT | Track | 87.71% | 100 kg/114 kg |

| All-Terrain Wheelchair [34] | WT | Track | 50% | 80 kg/160 kg |

| iBOT 4000 [35,36] | WT | Wheel cluster | 123.63% | 136 kg/110 kg |

| Wheelchair.q [37,38] | WT | Wheel cluster | 88.77% | 87 kg/98 kg |

| Zero Carrier [41,42] | WT | Hybrid and Leg | 173.91% | 80 kg/46 kg |

| Lee [47] | WT | Hybrid and Leg | 85.71% | 60 kg/70 kg |

| WL-16 II [45,46] | WT | Hybrid and Leg | 96.77% | 60 kg/62 kg |

| RT-Mover PType WA [48,49,50] | WT | Articulated Mechanism | 76.08% | 70 kg/92 kg |

| Morales [51] | WT | Articulated Mechanism | 90% | 90 kg/100 kg |

| Lawn [52] | WT | Articulated Mechanism | 50% | 80 kg/160 kg |

| TBW-I [53] | WT | Articulated Mechanism | 38.96% | 60 kg/154 kg |

| HELIOS-V [54] | WT | Articulated Mechanism | 100% | 50 kg/50 kg |

| Chen [55] | WT | Articulated Mechanism | 100% | 80 kg/80 kg |

| Yoneda [59] | CT | Track | 92.30% | 60 kg/65 kg |

| TAQT Carrier [60] | CT | Track | 25.80% | 80 kg/310 kg |

| HELIOS-VI [61] | CT | Track | 141.17% | 120 kg/85 kg |

| Haulerbot [62] | CT | Track | 89.04% | 130 kg/146 kg |

| iRobt 710 Kobra [63] | CT | Track | 40.96% | 68 kg/166 kg |

| Deshmukh [68] | CT | Wheel cluster | 125% | 10 kg/8 kg |

| Name | Type | Category | NS [s−1] | Speed/Length |

|---|---|---|---|---|

| Scewo Bro [25] | WT | Track | 0.18 s−1 | 21 cm/s/113.5 cm |

| WT Wheelchair [27,28] | WT | Track | 0.07 s−1 | 10 cm/s/131 cm |

| TopChair-S [26] | WT | Track | 0.16 s−1 | 19 cm/s/115 cm |

| Tao [29] | WT | Track | 0.08 s−1 | 7.3 cm/s/90 cm |

| B-Free Ranger [30] | WT | Track | 0.074 s−1 | 8.3 cm/s/112 cm |

| Caterwil GTS5 Lux [33] | WT | Track | 0.21 s−1 | 22 cm/s/102 cm |

| All-Terrain Wheelchair [34] | WT | Track | 0.19 s−1 | 30 cm/156 cm |

| iBOT 4000 [35,36] | WT | Wheel cluster | 0.12 s−1 | 10 cm/s/81.3 cm |

| Wheelchair.q [37,38] | WT | Wheel cluster | 0.14 s−1 | 10 cm/s/70.9 cm |

| Zero Carrier [41,42] | WT | Hybrid and Leg | 0.01 s−1 | 1 cm/s/60 cm |

| Lee [47] | WT | Hybrid and Leg | 0.02 s−1 | 2 cm/s/85.5 cm |

| WL-16 II [45,46] | WT | Hybrid and Leg | 0.07 s−1 | 5 cm/s/70 cm |

| RT-Mover PType WA [48,49,50] | WT | Articulated Mechanism | 0.02 s−1 | 2.2 cm/s/110 cm |

| Morales [51] | WT | Articulated Mechanism | 0.007 s−1 | 1 cm/s/145 cm |

| Lawn [52] | WT | Articulated Mechanism | 0.006 s−1 | 1 cm/s/170 cm |

| TBW-I [53] | WT | Articulated Mechanism | 0.005 s−1 | 0.5 cm/s/108 cm |

| Chen [55] | WT | Articulated Mechanism | 0.02 s−1 | 2 cm/s/82 cm |

| Yoneda [59] | CT | Track | 0.09 s−1 | 10.2 cm/s/118 cm |

| TAQT Carrier [60] | CT | Track | 0.10 s−1 | 14 cm/s/130 cm |

| HELIOS-VI [61] | CT | Track | 0.06 s−1 | 7 cm/s/105.5 cm |

| Haulerbot [62] | CT | Track | 0.072 s−1 | 8.3 cm/s/115 cm |

| iRobt 710 Kobra [63] | CT | Track | 0.15 s−1 | 14 cm/s/91.4 cm |

| Deshmukh [68] | CT | Wheel cluster | 0.08 s−1 | 6.28 cm/s/78 cm |

| Name | Type | Category | NWC[s−1] |

|---|---|---|---|

| Scewo Bro [25] | WT | Track | 13.33 s−1 |

| WT Wheelchair [27,28] | WT | Track | 4.40 s−1 |

| TopChair-S [26] | WT | Track | 11.73 s−1 |

| Tao [29] | WT | Track | 12.14 s−1 |

| B-Free Ranger [30] | WT | Track | 6.08 s−1 |

| Caterwil GTS5 Lux [33] | WT | Track | 18.85 s−1 |

| All-Terrain Wheelchair [34] | WT | Track | 9.61 s−1 |

| iBOT 4000 [35,36] | WT | Wheel cluster | 14.83 s−1 |

| Wheelchair.q [37,38] | WT | Wheel cluster | 12.43 s−1 |

| Zero Carrier [41,42] | WT | Hybrid and Leg | 1.74 s−1 |

| Lee [47] | WT | Hybrid and Leg | 1.71 s−1 |

| WL-16 II [45,46] | WT | Hybrid and Leg | 6.77 s−1 |

| RT-Mover PType WA [48,49,50] | WT | Articulated Mechanism | 1.52 s−1 |

| Morales [51] | WT | Articulated Mechanism | 0.62 s−1 |

| Lawn [52] | WT | Articulated Mechanism | 0.3 s−1 |

| TBW-I [53] | WT | Articulated Mechanism | 0.195 s−1 |

| Chen [55] | WT | Articulated Mechanism | 2 s−1 |

| Yoneda [59] | CT | Track | 8.30 s−1 |

| TAQT Carrier [60] | CT | Track | 2.58 s−1 |

| HELIOS-VI [61] | CT | Track | 8.47 s−1 |

| Haulerbot [62] | CT | Track | 6.41 s−1 |

| iRobt 710 Kobra [63] | CT | Track | 6.27 s−1 |

| Deshmukh [68] | CT | Wheel cluster | 10.06 s−1 |

| Name | Type | Category | Step Height [cm] | Stairs Slope [°] |

|---|---|---|---|---|

| Scewo Bro [25] | WT | Track | 20 cm | 36° |

| WT Wheelchair [27,28] | WT | Track | 15 cm | 25° |

| TopChair-S [26] | WT | Track | 20 cm | 35° |

| Tao [29] | WT | Track | 18 cm | 35° |

| B-Free Ranger [30] | WT | Track | 20 cm | 35° |

| Caterwil GTS5 Lux [33] | WT | Track | 20 cm | 40° |

| All-Terrain Wheelchair [34] | WT | Track | 17 cm | 31° |

| iBOT 4000 [35,36] | WT | Wheel cluster | 20 cm | 39° |

| Wheelchair.q [37,38] | WT | Wheel cluster | 24 cm | 40° |

| Castillo [39] | WT | Wheel cluster | 18 cm | 37° |

| Zero Carrier [41,42] | WT | Hybrid and Leg | 18 cm | 27° |

| Lee [47] | WT | Hybrid and Leg | 25.5 cm | 45° |

| WL-16 II [45,46] | WT | Hybrid and Leg | 15 cm | 27° |

| RT-Mover PType WA [48,49,50] | WT | Articulated Mechanism | 17 cm | 35° |

| Morales [51] | WT | Articulated Mechanism | 24 cm | 40° |

| Lawn [52] | WT | Articulated Mechanism | 20 cm | 35° |

| TBW-I [53] | WT | Articulated Mechanism | 20 cm | 20° |

| HELIOS-V [54] | WT | Articulated Mechanism | 16 cm | 28° |

| Chen [55] | WT | Articulated Mechanism | 20 cm | 37.5° |

| Yoneda [59] | CT | Track | 16 cm | 30° |

| Haulerbot [62] | CT | Track | 20 cm | 38° |

| iRobt 710 Kobra [63] | CT | Track | 21.2 cm | 45° |

| Deshmukh [68] | CT | Wheel cluster | 16 cm | 40° |

| Wen [69] | CT | Hybrid and Leg | 20 cm | 35.5° |

| Name | Type | Category | TA [kg/W] | Power [W] | Payload [kg] |

|---|---|---|---|---|---|

| TopChair-S [25] | WT | Track | 0.137 | 800 W | 110 kg |

| Tao [29] | WT | Track | 0.075 | 1000 W | 75 kg |

| B-Free Ranger [30] | WT | Track | 0.08 | 1500 W | 120 kg |

| All-Terrain Wheelchair [34] | WT | Track | 0.087 | 920 W | 80 kg |

| iBOT 4000 [35,36] | WT | Wheel cluster | 0.075 | 1800 W | 136 kg |

| Wheelchair.q [37,38] | WT | Wheel cluster | 0.174 | 500 W | 87 kg |

| Castillo [39] | WT | Wheel cluster | 0.041 | 1430 W | 60 kg |

| Zero Carrier [41,42] | WT | Hybrid and Leg | 0.074 | 1080 W | 80 kg |

| Lee [47] | WT | Hybrid and Leg | 0.06 | 1200 W | 60 kg |

| WL-16 II [45,46] | WT | Hybrid and Leg | 0.033 | 1800 W | 60 kg |

| RT-Mover PType WA [48,49,50] | WT | Articulated Mechanism | 0.041 | 1700 W | 70 kg |

| Morales [51] | WT | Articulated Mechanism | 0.119 | 840 W | 100 kg |

| TBW-I [53] | WT | Articulated Mechanism | 0.066 | 900 W | 60 kg |

| HELIOS-V [54] | WT | Articulated Mechanism | 0.062 | 800 W | 50 kg |

| Chen [55] | WT | Articulated Mechanism | 0.025 | 3200 W | 80 kg |

| TAQT Carrier [60] | CT | Track | 0.044 | 1800 W | 80 kg |

| HELIOS-VI [61] | CT | Track | 0.193 | 622 W | 120 kg |

| Haulerbot [62] | CT | Track | 0.086 | 1500 W | 130 kg |

| Deshmukh [68] | CT | Wheel cluster | 0.069 | 144 W | 10 kg |

| Name | Type | Category | MC | CC |

|---|---|---|---|---|

| Scewo Bro [25] | WT | Track | Medium-low | Medium-low |

| WT Wheelchair [27,28] | WT | Track | Medium-high | Medium-high |

| TopChair-S [26] | WT | Track | Medium-low | Medium-low |

| Tao [29] | WT | Track | Medium-low | Medium-low |

| B-Free Ranger [30] | WT | Track | Medium-high | Medium-high |

| ZED Evolution [31] | WT | Track | Medium-high | Medium-high |

| Caterwil GTS5 Lux [32] | WT | Track | Medium-low | Medium-high |

| Fortissimo [33] | WT | Track | Medium-low | Medium-high |

| Hkust [33] | WT | Track | Low | Medium-low |

| All-Terrain Wheelchair [34] | WT | Track | Medium-high | Medium-high |

| iBOT 4000 [35,36] | WT | Wheel cluster | Medium-low | Medium-high |

| Wheelchair.q [37,38] | WT | Wheel cluster | Medium-low | Medium-high |

| Castillo [39] | WT | Wheel cluster | Low | Low |

| Wang [40] | WT | Hybrid and Leg | Medium-low | Medium-high |

| Zero Carrier [41,42] | WT | Hybrid and Leg | Medium-high | High |

| Lee [47] | WT | Hybrid and Leg | High | High |

| JWCR-1 [43,44] | WT | Hybrid and Leg | Very-high | Very -high |

| WL-16 II [45,46] | WT | Hybrid and Leg | Very -high | Very -high |

| RT-Mover PType WA [48,49,50] | WT | Articulated Mechanism | High | High |

| Morales [51] | WT | Articulated Mechanism | High | High |

| Lawn [52] | WT | Articulated Mechanism | High | High |

| TBW-I [53] | WT | Articulated Mechanism | High | High |

| HELIOS-V [54] | WT | Articulated Mechanism | Medium-high | Medium-high |

| Chen [55] | WT | Articulated Mechanism | High | High |

| RPWheel [56] | WT | Articulated Mechanism | Medium-high | Medium-high |

| Zhang [57,58] | CT | Track | Medium-low | Medium-high |

| Dongsheng [67] | CT | Track | Medium-low | Medium-high |

| Htoo [65] | CT | Track | Low | Low |

| Amoeba Go-1 [22] | CT | Track | Medium-low | Medium-high |

| Yoneda [59] | CT | Track | Low | Low |

| Riuqin [66] | CT | Track | Low | Low |

| TAQT Carrier [60] | CT | Track | Medium-low | Medium-high |

| HELIOS-VI [61] | CT | Track | Medium-low | Medium-low |

| Haulerbot [62] | CT | Track | Medium-high | Medium-high |

| iRobt 710 Kobra [63] | CT | Track | Medium-low | Medium-high |

| Deshmukh [68] | CT | Wheel cluster | Low | Low |

| Wen [69] | CT | Hybrid and Leg | Medium-high | High |

| Shihua [72] | CT | Hybrid and Leg | Medium-low | Medium-high |

| PEOPLER-II [70,71] | CT | Hybrid and Leg | High | Most-high |

| Yeping [73] | CT | Hybrid and Leg | Very-high | Very-high |

| Yinhui [74] | CT | Articulated Mechanism | Medium-high | Medium-high |

| Name | Type | Category | Cost |

|---|---|---|---|

| Scewo Bro [25] | WT | Track | Medium |

| WT Wheelchair [27,28] | WT | Track | Medium |

| TopChair-S [26] | WT | Track | Medium-low |

| Tao [29] | WT | Track | Medium-low |

| B-Free Ranger [30] | WT | Track | Medium |

| ZED Evolution [31] | WT | Track | Medium |

| Caterwil GTS5 Lux [32] | WT | Track | Medium-low |

| Fortissimo [33] | WT | Track | Medium |

| Hkust [33] | WT | Track | Medium-low |

| All-Terrain Wheelchair [34] | WT | Track | Medium |

| iBOT 4000 [35,36] | WT | Wheel cluster | Medium-low |

| Wheelchair.q [37,38] | WT | Wheel cluster | Medium-low |

| Castillo [39] | WT | Wheel cluster | Medium-low |

| Wang [40] | WT | Hybrid and Leg | Medium |

| Zero Carrier [41,42] | WT | Hybrid and Leg | High |

| Lee [47] | WT | Hybrid and Leg | Medium-high |

| JWCR-1 [43,44] | WT | Hybrid and Leg | High |

| WL-16 II [45,46] | WT | Hybrid and Leg | High |

| RT-Mover PType WA [48,49,50] | WT | Articulated Mechanism | Medium-high |

| Morales [51] | WT | Articulated Mechanism | Medium-high |

| Lawn [52] | WT | Articulated Mechanism | Medium-high |

| TBW-I [53] | WT | Articulated Mechanism | Medium-high |

| HELIOS-V [54] | WT | Articulated Mechanism | Medium |

| Chen [55] | WT | Articulated Mechanism | Medium-high |

| RPWheel [56] | WT | Articulated Mechanism | Medium |

| Zhang [57,58] | CT | Track | Medium |

| Dongsheng [67] | CT | Track | Medium |

| Htoo [65] | CT | Track | Medium-low |

| Amoeba Go-1 [22] | CT | Track | Medium |

| Yoneda [59] | CT | Track | Medium-low |

| Riuqin [66] | CT | Track | Medium-low |

| TAQT Carrier [60] | CT | Track | Medium |

| HELIOS-VI [61] | CT | Track | Medium-low |

| Haulerbot [62] | CT | Track | Medium |

| iRobt 710 Kobra [63] | CT | Track | Medium |

| Deshmukh [68] | CT | Wheel cluster | Low |

| Wen [69] | CT | Hybrid and Leg | Medium-high |

| Shihua [72] | CT | Hybrid and Leg | Medium-low |

| PEOPLER-II [70,71] | CT | Hybrid and Leg | High |

| Yeping [73] | CT | Hybrid and Leg | High |

| Yinhui [74] | CT | Articulated Mechanism | Medium |

References

- Green, J.; Clounie, J.; Galarza, R.; Anderson, S.; Campell-Smith, J.; Voicu, R.C. Optimization of an Intelligent Wheelchair: LiDAR and Camera Vision for Obstacle Avoidance. In Proceedings of the 22nd International Conference on Control, Automation and Systems, Busan, Republic of Korea, 27–30 November 2022; pp. 313–318. [Google Scholar]

- Kaye, H.S.; Kang, T.; LaPlante, M. Mobility Device Use in the United States; Disability Statistics Report 14; U.S. Department of Education, National Institute on Disability and Rehabilitation Research: Washington, DC, USA, 2000; Volume 14.

- National Center for Health Statistics. Percentage of any difficulty walking or climbing steps for adults aged 18 and over, United States, 2019–2020. In National Health Interview Survey; NCHS: Hyattsville, MD, USA, 2022. [Google Scholar]

- Di Priamo, C. L’inclusione Scolastica: Accessibilità, Qualità Dell’offerta e Caratteristiche Degli Alunni con Sostegno; Report Istituto Nazionale di Statistica Istat (Italian); ISTAT: Rome, Italy, 2020. [Google Scholar]

- Bruzzone, L.; Quaglia, G. Locomotion systems for ground mobile robots in unstructured environments. Mech. Sci. 2012, 2, 49–62. [Google Scholar] [CrossRef]

- Reina, G.; Foglia, M. On the mobility of all-terrain rovers. Ind. Robot. 2013, 40, 121–131. [Google Scholar] [CrossRef]

- Alamdari, A.; Krovi, V.N. Design of articulated leg–wheel subsystem by kinetostatic optimization. Mech. Mach. Theory 2016, 100, 222–234. [Google Scholar] [CrossRef]

- Gong, Z.; Xie, F.; Liu, X.; Shentu, S. Obstacle-crossing strategy and formation parameters optimization of a multi-tracked-mobile-robot system with a parallel manipulator. Mech. Mach. Theory 2020, 152, 103919. [Google Scholar] [CrossRef]

- Li, H.; Qi, C.; Mao, L.; Zhao, Y.; Chen, X.; Gao, F. Staircase-climbing capability-based dimension design of a hexapod robot. Mech. Mach. Theory 2021, 164, 104400. [Google Scholar] [CrossRef]

- Li, H.; Qi, C.; Gao, F.; Chen, X.; Zhao, Y.; Chen, Z. Mechanism design and workspace analysis of a hexapod robot. Mech. Mach. Theory 2022, 174, 104917. [Google Scholar] [CrossRef]

- Jiang, H.; Xu, G.; Zeng, W.; Gao, F. Design and kinematic modeling of a passively-actively transformable mobile robot. Mech. Mach. Theory 2019, 142, 103591. [Google Scholar] [CrossRef]

- Wei, C.; Wu, J.; Sun, J.; Sun, H.; Yao, Y.; Ruan, Q. Reconfigurable design of a passive locomotion closed-chain multi-legged platform for terrain adaptability. Mech. Mach. Theory 2022, 174, 104936. [Google Scholar] [CrossRef]

- Ni, L.; Wu, L.; Zhang, H. Parameters uncertainty analysis of posture control of a four-wheel-legged robot with series slow active suspension system. Mech. Mach. Theory 2022, 175, 104966. [Google Scholar] [CrossRef]

- Zhang, F.; Yu, Y.; Wang, Q.; Zeng, X.; Niu, H. A terrain-adaptive robot prototype designed for bumpy-surface exploration. Mech. Mach. Theory 2019, 141, 213–225. [Google Scholar] [CrossRef]

- Robert, B. Climbing robots: Recent research and emerging applications. Ind. Robot. 2019, 46, 721–727. [Google Scholar]

- Shin, J.; Son, D.; Kim, Y.; Seo, T. Design exploration and comparative analysis of tail shape of tri-wheel-based stair-climbing robotic platform. Sci. Rep. 2022, 12, 19488. [Google Scholar] [CrossRef] [PubMed]

- Sundaram, S.A.; Wang, H.; Ding, D.; Cooper, R.A. Step-Climbing Power Wheelchairs: A Literature Review. Top. Spinal Cord Inj. Rehabil. 2017, 23, 98–109. [Google Scholar] [CrossRef]

- Grigore, L.S.; Oncioiu, I.; Priescu, I.; Joi, D. Development and Evaluation of the Traction Characteristics of a Crawler EOD Robot. Appl. Sci. 2021, 11, 3757. [Google Scholar] [CrossRef]

- Bruzzone, L.; Nodehi, S.E.; Fanghella, P. Tracked Locomotion Systems for Ground Mobile Robots: A Review. Machines 2022, 10, 648. [Google Scholar] [CrossRef]

- Li, T.; Li, Q. A systematic review on load carriage assistive devices: Mechanism design and performance evaluation. Mech. Mach. Theory 2023, 180, 105142. [Google Scholar] [CrossRef]

- Chatterjee, P.; Lahiri, N.; Bhattacharjee, A.; Chakraborty, A. Automated Hybrid Stair Climber for Physically Challenged People. In Proceedings of the 5th International Conference on Electronics, Materials Engineering & Nano-Technology (IEMENTech), Kolkata, India, 24–26 September 2021; pp. 1–4. [Google Scholar]

- JST (Japan Science and Technology Agency). News, Stories that Change the World: AMOEBA ENERGY (Amoeba-Inspired Technologies to Change the Mobility); JST: Tokyo, Japan, 2020; Volume 3. [Google Scholar]

- Tao, W.; Xu, J.; Liu, T. Electric-powered wheelchair with stair-climbing ability. Int. J. Adv. Robot. Syst. 2017, 14, 1729881417721436. [Google Scholar] [CrossRef]

- Riener, R. The Cybathlon promotes the development of assistive technology for people with physical disabilities. J. Neuroeng. Rehabil. 2016, 13, 49. [Google Scholar] [CrossRef]

- Klöppel, M.; Römer, F.; Wittmann, M.; Hatam, B.; Herrmann, T.; Sim, L.L.; Lim, J.S.D.; Lu, Y.; Medovy, V.; Merkle, L.; et al. Scube—Concept and Implementation of a Self-balancing, Autonomous Mobility Device for Personal Transport. World Electr. Veh. 2018, 9, 48. [Google Scholar] [CrossRef]

- Lee, J.; Jeong, W.; Han, J.; Kim, T.; Oh, S. Barrier-Free Wheelchair with a Mechanical Transmission. Appl. Sci. 2021, 11, 5280. [Google Scholar] [CrossRef]

- Wang, J.; Wang, T.; Yao, C.; Li, X.; Wu, C. Active Tension Control for WT Wheelchair Robot by Using a Novel Control Law for Holonomic or Nonholonomic Systems. In Mathematical Problems in Engineering; Hindawi Publishing Corporation: London, UK, 2013. [Google Scholar]

- Yu, S.; Wang, T. Original design of a wheelchair robot equipped with variable geometry single tracked mechanisms. Int. J. Robot. Autom. 2015, 30, 87–97. [Google Scholar] [CrossRef]

- Tao, W.; Jia, Y.; Liu, T.; Yi, J.; Wang, H.; Inoue, Y. A novel wheel-track hybrid electric powered wheelchair for stairs climbing. J. Adv. Mech. Des. Syst. Manuf. 2016, 10, JAMDSM0060. [Google Scholar] [CrossRef]

- Nakajima, S.; Sawada, S. Methodology of climbing and descending stairs for four-wheeled vehicles. In Proceedings of the IEEE 23rd International Conference on Intelligent Transportation Systems, Rhodes, Greece, 20–23 September 2020; pp. 1–6. [Google Scholar]

- Meyer, J.T.; Weber, S.; Jäger, L. A survey on the influence of CYBATHLON on the development and acceptance of advanced assistive technologies. J. Neuroeng. Rehabil. 2022, 19, 38. [Google Scholar] [CrossRef] [PubMed]

- Popovic, M.B. Biomechatronics; Elsevier Science: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Martínez, J.A.G.; Cardinale, F. Robotics in Neurosurgery: Principles and Practice, 1st ed.; Springer International Publishing: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Podobnik, J.; Rejc, J.; Slajpah, S.; Munih, M.; Mihelj, M. All-Terrain Wheelchair: Increasing Personal Mobility with a Powered Wheel-Track Hybrid Wheelchair. IEEE Robot. Autom. Mag. 2017, 24, 26–36. [Google Scholar] [CrossRef]

- Uustal, H.; Minkel, J.L. Study of the independence IBOT 3000 mobility system: An innovative power mobility device, during use in community environments. Arch. Phys. Med. Rehabil. 2004, 85, 2002–2010. [Google Scholar] [CrossRef]

- Onozuka, Y.; Tomokuni, N.; Murata, G.; Shino, M. Dynamic Stability Control of Inverted-Pendulum-Type Robotic Wheelchair for Going Up and Down Stairs. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Las Vegas, NV, USA, 24 October 2020–24 January 2021; pp. 4114–4119. [Google Scholar]

- Quaglia, G.; Nisi, M. Design of a self-leveling cam mechanism for a stair climbing wheelchair. Mech. Mach. Theory 2017, 112, 84–104. [Google Scholar] [CrossRef]

- Quaglia, G.; Franco, W.; Oderio, R. Wheelchair. q, a motorized wheelchair with stair climbing ability. Mech. Mach. Theory 2011, 11, 1601–1609. [Google Scholar] [CrossRef]

- Castillo, B.D.; Kuo, Y.; Chou, J. Novel design of a wheelchair with stair climbing capabilities. In Proceedings of the International Conference on Intelligent Informatics and Biomedical Sciences, Okinawa, Japan, 28–30 November 2015; pp. 208–215. [Google Scholar]

- Wang, H.; He, L.; Qi, L. Research on a kind of leg-wheelstair-climbing wheelchair. In Proceedings of the IEEE International Conference on Mechatronics and Automation, Tianjin, China, 3–6 August 2014. [Google Scholar]

- Yuan, J.; Hirose, S. Research on leg-wheel hybrid stair-climbing robot, Zero Carrier. In Proceedings of the IEEE International Conference on Robotics and Biomimetics, Shenyang, China, 22–26 August 2004. [Google Scholar]

- Yuan, J.; Hirose, S. Zero Carrier: A Novel Eight Leg-Wheels Hybrid Stair Climbing Mobile Vehicle. J. Robot. Mechatron. 2005, 17, 44–51. [Google Scholar] [CrossRef]

- Cao, X.; Zhao, Q.; Ma, P. Humanoid Robot 3-D Motion Simulation for Hardware Realization. J. Donghua Univ. 2007, 24, 713–717. [Google Scholar]

- Tang, J.; Zhao, Q.; Huang, J. Application of “human-in-the-loop” control to a biped walking-chair robot. In Proceedings of the 2007 IEEE International Conference on Systems, Man and Cybernetics, Montreal, QC, Canada, 7–10 October 2007. [Google Scholar]

- Sugahara, Y. Towards the Biped Walking Wheelchair. In Proceedings of the First IEEE/RAS-EMBS International Conference on Biomedical Robotics and Biomechatronic, Pisa, Italy, 20–22 February 2006. [Google Scholar]

- Zheng, C.; Zhao, Q.; Ma, P.; Zhang, H.; Gou, Z. Mechanism design of a biped walking-chair robot. Jiqiren/Robot 2006, 28, 297–302. [Google Scholar]

- Lee, C.; Lee, K.; Yoo, J.; Kim, I.; Bang, Y. A compact stair-climbing wheelchair with two 3-DOF legs and a 1-DOF base. Ind. Robot 2016, 43, 181–192. [Google Scholar] [CrossRef]

- Nakajima, S. Stair-climbing gait for a four-wheeled vehicle. Robomech J. 2020, 7, 20. [Google Scholar] [CrossRef]

- Nakajima, S. Evaluation of the mobility performance of a personal mobility vehicle for steps. IEEE Access 2017, 5, 9748–9756. [Google Scholar] [CrossRef]

- Nakajima, S. RT-Mover: A rough terrain mobile robot with a simple leg–wheel hybrid mechanism. Int. J. Robot. Res. 2011, 13, 1609–1626. [Google Scholar] [CrossRef]

- Chocoteco, J.; Morales, R.; Feliu-Batlle, V. Enhancing the Trajectory Generation of a Stair-Climbing Mobility System. Sensors 2017, 17, 2608. [Google Scholar] [CrossRef]

- Lawn, J.M.; Ishimatsu, T. Modeling of a Stair-Climbing Wheelchair Mechanism with High Single-Step Capability. IEEE Trans. Neural Syst. Rehabil. Eng. 2003, 3, 323–332. [Google Scholar] [CrossRef] [PubMed]

- Sugahara, Y.; Yonezawa, N.; Kosuge, K. A novel stair-climbing wheelchair with transformable wheeled four-bar linkages. In Proceedings of the IEEE 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010. [Google Scholar]

- Uchida, Y.; Furuichi, K.; Hirose, S. Fundamental performance of a 6 wheeled off-road vehicle “HELIOS-V”. In Proceedings of the 1999 IEEE International Conference on Robotics and Automation, Detroit, MI, USA, 10–15 May 1999; Volume 3, pp. 2336–2341. [Google Scholar]

- Chen, C.; Pham, H. Design and fabrication of a statically stable stair-climbing robotic wheelchair. Ind. Robot. Int. J. 2009, 6, 562–569. [Google Scholar] [CrossRef]

- RPWheel Project for Cybathlon. Available online: https://sites.google.com/osakac.ac.jp/rpwheel/cybathlon2020?authuser=0 (accessed on 15 April 2023).

- Zhang, H.; Yang, S.; Chen, X.; Lu, X.; Wang, Y. Final Design Review: Stair-Climbing Machine. 2016. Available online: https://docs.google.com/document/d/1W2TeU4i8153FuLejfbfsoq7PUXol_FTQb_bXV0Blf7k/edit (accessed on 15 April 2023).

- Mourikis, A.I.; Trawny, N.; Roumeliotis, S.I.; Helmick, D.M.; Matthies, L. Autonomous Stair Climbing for Tracked Vehicles. Int. J. Robot. Res. 2007, 7, 737–758. [Google Scholar] [CrossRef]

- Yoneda, K.; Ota, Y.; Hirose, S. Development of a Hi-Grip Stair Climbing Crawler with Hysteresis Compliant Blocks. In Proceedings of the 4th International Conference on Climbing and Walking Robots, Karlsruhe, Germany, September 2001; pp. 569–576. [Google Scholar]

- Hirose, S.; Sensu, T. The TAQT Carrier: A Practical Terrain Adaptive Quadru-track Carrier Robot. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Raleigh, NC, USA, 7–10 July 1992; pp. 2068–2073. [Google Scholar]

- Hirose, S.; Fukushima, E.F.; Damoto, R.; Nakamoto, H. Design of terrain adaptive versatile crawler vehicle HELIOS-VI. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Maui, HI, USA, 29 October–3 November 2001; Volume 3, pp. 1540–1545. [Google Scholar]

- Thamel, S.R.; Munasinghe, R.; Lalitharatne, T. Motion Planning of Novel Stair-Climbing Wheelchair for Elderly and Disabled People. In Proceedings of the Moratuwa Engineering Research Conference, Moratuwa, Sri Lanka, 28–30 July 2020; pp. 590–595. [Google Scholar]

- Rehman, B.U.; Caldwell, D.G.; Semini, C. Centaur robots—A survey. In Human-Centric Robotics: Proceedings of the CLAWAR 2017: 20th International Conference on Climbing and Walking Robots and the Support Technologies for Mobile Machines, Porto, Portugal, 11–13 September 2017; World Scientific: Singapore, 2017; pp. 247–258. [Google Scholar]

- Ugenti, A.; Galati, R.; Mantriota, G.; Reina, G. Analysis of an all-terrain tracked robot with innovative suspension system. Mech. Mach. Theory 2023, 182, 105237. [Google Scholar] [CrossRef]

- Htoo, P.T. Development of a Stair-Climbing Robot; Asian Institute of Technology: Khlong Nueng, Thailand, 2016. [Google Scholar]

- Ruiqin, L.; Kaitong, X.; Shijie, L.; Jianwei, Z. Object Loading Robot Which Can Move as well as Climb Stairs. China Patent CN107640235A, 30 January 2018. [Google Scholar]

- Dongsheng, I.; Congying, L. Multi-Mode Driving Crawler-Type Electric Carrying Device and Method. China Patent CN111547145A, 18 August 2020. [Google Scholar]

- Deshmukh, S.H.; Yadav, D.; Chowalloor, B. Development of stair climbing transporter. In Proceedings of the 13th National Conference on Mechanisms and Machines, Bangalore, India, 12–13 December 2007. [Google Scholar]

- Wen, H.; Yang, H.; Chen, Y.; Zhou, L.; Wu, D. A Robot with Decoupled Mechanical Structure and Adapted State Machine Control for Both Ground and Staircase Situations. Appl. Sci. 2019, 9, 5185. [Google Scholar] [CrossRef]

- Okada, T.; Botelho, W.T.; Shimizu, T. Motion Analysis with Experimental Verification of the Hybrid Robot PEOPLER-II for Reversible Switch between Walk- and Roll-on Demand. Int. J. Robot. Res. 2010, 29, 1199–1221. [Google Scholar] [CrossRef]

- Okada, T.; Mahmoud, A.; Botelho, W.T.; Shimizu, T. Trajectory Estimation of a Skid-Steering Mobile Robot Propelled by Independently Driven Wheels. Robotica 2012, 30, 123–132. [Google Scholar] [CrossRef]

- Shihua, J. Multi-Road-Condition Vertical Movement Transporting Device and Transporting Method. China Patent CN106394721A, 15 February 2017. [Google Scholar]

- Yeping, L.; Yong, X. A Multistep Attitude Conveying Robot for Takeaway Food Delivery. China Patent CN208278190U, 25 December 2018. [Google Scholar]

- Yinhui, Z.; Yuyan, L.; Sen, W.; Zifen, H. Climb Stair Robot. China Patent CN207579987U, 6 July 2018. [Google Scholar]

- Lee, W.; Kang, S.; Kim, M.; Park, M. ROBHAZ-DT3: Teleoperated mobile platform with passively adaptive double-track for hazardous environment applications. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Sendai, Japan, 28 September–2 October 2004. [Google Scholar]

- Ben-Tzvi, P.; Ito, S.; Goldenberg, A.A. Autonomous Stair Climbing with Reconfigurable Tracked Mobile Robot. In Proceedings of the 2007 International Workshop on Robotic and Sensors Environments, Ottawa, ON, Canada, 12–13 October 2007; pp. 1–6. [Google Scholar]

- Vu, Q.; Kim, B.; Song, J. Autonomous stair climbing algorithm for a small four-tracked robot. In Proceedings of the 2008 International Conference on Control, Automation and Systems, Seoul, Republic of Korea, 14–17 October 2008; pp. 2356–2360. [Google Scholar]

- Moosavian, A.; Semsarilar, H.; Kalantari, A. Design and Manufacturing of a Mobile Rescue Robot. In Proceedings of the 2006 IEEE/RSJ International Conference on Intelligent Robots and Systems, Beijing, China, 9–13 October 2006; pp. 3982–3987. [Google Scholar]

- Michaud, F.; Létourneau, D.; Arsenault, M.; Bergeron, Y.; Cadrin, R.; Gagnon, F.; Legault, M.; Millette, M.; Paré, J.; Tremblay, M.; et al. AZIMUT, a leg-track-wheel robot. In Proceedings of the 2003 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2003), Las Vegas, NV, USA, 27–31 October 2003. [Google Scholar]

- Mohammad, I.; Emir, I.; Ibraahiim, J.; Juniza, M.D.S.; Mastura, S. Mechanical design and development of Tri-Star wheel system for stair climbing robot. In Proceedings of the Aceh Development International Conference, Kuala Lumpur, Malaysia, 26–28 March 2012. [Google Scholar]

- Smith, L.M.; Quinn, R.D.; Johnson, K.A.; Tuck, W.R. The Tri-Wheel: A novel wheel-leg mobility concept. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems, Hamburg, Germany, 28 September–3 October 2015; pp. 4146–4152. [Google Scholar]

- Eich, M.; Grimminger, F.; Bosse, S.; Spenneberg, D.; Kirchner, F. Asguard: A Hybrid-Wheel Security and SAR-Robot Using Bio-Inspired Locomotion for Rough Terrain. Proc. ROBIO 2007, 20082008, 774–779. [Google Scholar]

- Eich, A.M.; Grimminger, F.; Kirchner, F. A Versatile Stair-Climbing Robot for Search and Rescue Applications. In Proceedings of the IEEE International Workshop on Safety, Security and Rescue Robotics, Sendai, Japan, 21–24 October 2008; pp. 35–40. [Google Scholar]

- Krys, V.; Bobovský, Z.; Kot, T.; Marek, J. Synthesis of action variable for motor controllers of a mobile system with special wheels for movement on stairs. Perspect. Sci. 2016, 7, 329–332. [Google Scholar] [CrossRef]

- Mostyn, V.; Krys, V.; Kot, T.; Bobovsky, Z.; Novak, P. The synthesis of a segmented stair-climbing wheel. Int. J. Adv. Robot. Syst. 2018, 15, 1729881417749470. [Google Scholar] [CrossRef]

- Herbert, S.D.; Drenner, A.; Papanikolopoulos, N. Loper: A quadruped-hybrid stair climbing robot. In Proceedings of the 2008 IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008; pp. 799–804. [Google Scholar]

- Choe, J.; Kwon, U.; Nah, M.C.; Kim, H. Design Analysis of TuskBot: Universal Stair Climbing 4-Wheel Indoor Robot. In Proceedings of the International Conference on Intelligent Robots and Systems, Vancouver, BC, Canada, 24–28 September 2017. [Google Scholar]

- Kim, D.; Hong, H.; Kim, H.S.; Kim, J. Optimal design and kinetic analysis of a stair-climbing mobile robot with rocker-bogie mechanism. Mech. Mach. Theory 2012, 50, 90–108. [Google Scholar] [CrossRef]

- Choi, D.; Kim, J.R.; Cho, S.; Jung, S.; Kim, J. Rocker-Pillar: Design of the rough terrain mobile robot platform with caterpillar tracks and rocker bogie mechanism. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura, Portugal, 7–12 October 2012; pp. 3405–3410. [Google Scholar]

- Lauria, M.; Piguet, Y.; Siegwart, R. Octopus—An Autonomous Wheeled Climbing Robot. In Proceedings of the Fifth International Conference on Climbing and Walking Robots, Paris, France, 25–27 September 2002. [Google Scholar]

- Bruzzone, L.; Baggetta, M.; Nodehi, S.E.; Bilancia, P.; Fanghella, P. Functional Design of a Hybrid Leg-Wheel-Track Ground Mobile Robot. Machines 2021, 9, 10. [Google Scholar] [CrossRef]

- Bruzzone, L.; Fanghella, P. Mantis hybrid leg-wheel robot: Stability analysis and motion law synthesis for step climbing. In Proceedings of the IEEE/ASME 10th International Conference on Mechatronic and Embedded Systems and Applications, Senigallia, Italy, 10–12 September 2014; pp. 1–6. [Google Scholar]

- Mabuchi, T.; Nagasawa, T.; Awa, K. Development of a stair-climbing mobile robot with legs and wheels. Artif. Life Robot. 1998, 2, 184–188. [Google Scholar] [CrossRef]

- Takanishi, A.; Takeya, T.; Kato, H.K.I. A control method for dynamic biped walking under unknown external force. In Proceedings of the IEEE International Workshop on Intelligent Robots and Systems, Towards a New Frontier of Applications, Piscatway, NJ, USA, 3–6 July 1990; Volume 2, pp. 795–801. [Google Scholar]

- Zhang, R.X.; Vadakkepat, P. Motion planning of biped robot climbing stairs. Proc. FIRA Congr. 2003. Available online: http://ai.stanford.edu/~rxzhang/Motion%20Planning%20of%20Biped%20Robot%20Climbing.pdf (accessed on 15 April 2023).

- Gong, Y.; Hartley, R.; Da, X.; Hereid, A.; Harib, O.; Huang, J.; Grizzle, J. Feedback Control of a Cassie Bipedal Robot: Walking, Standing, and Riding a Segway. In Proceedings of the 2019 American Control Conference, Philadelphia, PA, USA, 10–12 July 2019. [Google Scholar]

- Dai, M.; Xiong, X.; Ames, A. Bipedal Walking on Constrained Footholds: Momentum Regulation via Vertical COM Control. In Proceedings of the 2022 International Conference on Robotics and Automation, Philadelphia, PA, USA, 23–27 May 2022; pp. 10435–10441. [Google Scholar]

- Chen, S.; Huang, K.J.; Li, C.; Lin, P. Trajectory planning for stair climbing in the leg-wheel hybrid mobile robot quattroped. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 1229–1234. [Google Scholar]

- Chen, S.; Huang, K.J.; Chen, W.H.; Shen, S.Y.; Li, C.H.; Lin, P. Quattroped: A Leg-Wheel Transformable Robot. IEEE/ASME Trans. Mechatron. 2014, 2, 730–742. [Google Scholar] [CrossRef]

- Liu, C.; Lin, M.; Huang, Y.; Pai, T.; Wang, C. The development of a multi-legged robot using eight-bar linkages as leg mechanisms with switchable modes for walking and stair climbing. In Proceedings of the 3rd International Conference on Control, Automation and Robotics, Nagoya, Japan, 22–24 April 2017; pp. 103–108. [Google Scholar]

- Bledt, G.; Powell, M.J.; Katz, B.; Di Carlo, J.; Wensing, P.M.; Kim, S. MIT Cheetah 3: Design and Control of a Robust, Dynamic Quadruped Robot. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Madrid, Spain, 1–5 October 2018. [Google Scholar]

- Bouman, A. Autonomous Spot: Long-Range Autonomous Exploration of Extreme Environments with Legged Locomotion. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Las Vegas, NV, USA, 24 October 2020–24 January 2021; pp. 2518–2525. [Google Scholar]

- Hutter, M.; Gehring, C.; Jud, D.; Lauber, A.; Bellicoso, C.D.; Tsounis, V.; Hwangbo, J.; Bodie, K.; Fankhauser, P.; Bloesch, M.; et al. ANYmal—A highly mobile and dynamic quadrupedal robot. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Daejeon, Republic of Korea, 9–14 October 2016; pp. 38–44. [Google Scholar]

- Lu, D.; Dong, E.; Liu, C.; Xu, M.; Yang, J. Design and development of a leg-wheel hybrid robot “HyTRo-I”. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 6031–6036. [Google Scholar]

- Labib, O.; El-Safty, S.; Mueller, S.; Haalboom, T.; Strand, M. Towards a Stair Climbing Robot System Based on a Re-configurable Linkage Mechanism. Intell. Auton. Syst. 2018, 15, 278–288. [Google Scholar]

- Moore, E.Z.; Campbell, D.; Grimminger, F.; Buehler, M. Reliable Stair Climbing in Simple Hexapod ‘RHex’. In Proceedings of the 2002 IEEE International Conference on Robotics and Automation, Washington, DC, USA, 11–15 May 2002; Volume 3, pp. 2222–2227. [Google Scholar]

- Klemm, V. Ascento: A two-wheeled jumping robot. In Proceedings of the 2019 International Conference on Robotics and Automation, Montreal, QC, Canada, 20–24 May 2019; pp. 7515–7521. [Google Scholar]

- Binnard, M.B. Design of a Small Pneumatic Walking Robot. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1995. [Google Scholar]

- Dudek, G.; Jenkin, M. Computational Principles of Mobile Robotics; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

| Name | Solution | Features |

|---|---|---|

| Scewo Bro [25] |  | Commercial solution, automatic stair-climbing system, self-balancing software control, high safety |

| TopChair-S [26] |  | Commercial solution, automatic stair-climbing system, self-balancing software control |

| WT Wheelchair [27,28] |  | Prototype solution, manual stair-climbing system, no self-balancing control system |

| Tao [29] |  | Prototype solution, manual stair-climbing system, self-balancing software control |

| B-Free Ranger [30] |  | Commercial solution, automatic stair-climbing system, self-balancing software control |

| ZED evolution [31] |  | Prototype solution, manual stair-climbing system, no self-balancing control system |

| Caterwil GTS5 Lux [32] |  | Commercial solution, automatic stair-climbing system, self-balancing software control, high speed |

| Fortissimo [33] |  | Prototype solution, manual stair-climbing system, no self-balancing control system |

| Hkust [33] |  | Prototype solution, manual control, no self-balancing control system |

| All-Terrain Wheelchair [34]. Adapted with permission ref. [34] 2017 Janez Podobnik |  | Prototype solution, automatic stair-climbing system, self-balancing software control, Chebyshev-based linkage mechanism for lifting and lowering the tracks |

| Name | Solution | Features |

|---|---|---|

| iBOT 4000 [35,36] |  | Commercial solution, automatic stair-climbing system, self-balancing software control, good driving range |

| Wheelchair.q [37,38]. Adapted with permission from ref. [37] 2017 Giuseppe Quaglia, Matteo Nisi |  | Prototype solution, manual control, no self-balancing control system, good performance |

| Castillo [39]. Adapted with permission from ref [39] 2017 Basilio Dobras Castillo |  | Prototype solution, manual control, self-balancing control system, low comfort |

| Name | Solution | Features |

|---|---|---|

| Wang [40]. Adapted with permission from ref [40] 2014 Hongbo Wang |  | Prototype solution, manula stair-climbing system |

| Zero Carrier [41,42]. Adapted with permission from ref. [41] 2004 Jianjun Yuan |  | Prototype solution, automatic stair-climbing system, low speed |

| JWCR-1 [43,44]. Adapted with permission from ref. [44] 2007 Jiaoyan Tang |  | Prototype solution, manual control, low safety |

| WL-16 II [45,46]. Adapted with permission from ref. [45] 2006 Y. Sugahara |  | Prototype solution, manual control |

| Name | Solution | Features |

|---|---|---|

| RT-Mover PType WA [48,49,50] |  | Prototype solution, automatic stair-climbing system, self-balancing software control |

| Morales [51] |  | Prototype solution, automatic stair-climbing system, self-balancing software control, low speed |

| Lawn [52]. Adapted with permission from ref. [52] 2003 M.J. Lawn |  | Prototype solution, automatic stair-climbing system, self-balancing software control |

| TBW-I [53]. Adapted with permission from ref. [53] 2010 Yusuke Sugahara |  | Prototype solution, manual control, no self-balancing control system |

| HELIOS-V [54]. Adapted with permission from ref. [54] 1999 Y. Uchida |  | Prototype solution, manual control, no self-balancing control system |

| Chen [55]. Adapted with permission from ref. [55] 2012 Chun-Ta Chen, Hoang-Vuong Pham |  | Prototype solution, manual control, no self-balancing control system, low stability |

| RPWheel [56] |  | Prototype solution, manual control, no self-balancing control system |

| Name | Solution | Features |

|---|---|---|

| Zhang [57,58] |  | Prototype solution, autonomous driving, self-balancing control system, small dimensions |

| Amoeba Go-1 [22] |  | Commercial solution, autonomous driving, self-balancing control system, soft rubber tracks |

| Yoneda [59] |  | Prototype solution, manual control, no self-balancing control system |

| TAQT Carrier [60]. Adapted with permission from ref. [60] 1992 S. Hirose |  | Prototype solution, manual control, self-balancing system |

| HELIOS-VI [61] |  | Prototype solution, manual control, no self-balancing control system |

| Haulerbot [62] |  | Commercial solution, autonomous driving, self-balancing control system, high payload capacity |

| iRobt 710 Kobra [63] |  | Commercial solution, autonomous driving, self-balancing control system |

| Polibot [64] |  | Prototype solution, manual control, no self-balancing control system |

| Name | Solution | Features |

|---|---|---|

| Deshmukh [68] |  | Prototype solution, manual control, no self-balancing control system |

| Name | Solution | Features |

|---|---|---|

| Wen [69] |  | Prototype solution, autonomous driving, automatic stair-climbing system |

| PEOPLER-II [70,71] |  | Prototype solution, autonomous driving, no self-balancing control system |

| Name | Solution | Features |

|---|---|---|

| ROBHAZ-DT3 [75]. Adapted with permission from ref. [75] 2004 Woosub Lee |  | Prototype solution, teleoperated control |

| Variable configuration articulated tracked vehicle [76]. Adapted with permission from ref. [76] 2007 Pinhas Ben-Tzvi |  | Prototype solution, teleoperated control, self-balancing control system |

| MACbot [77] |  | Prototype solution, automatic stair-climbing system |

| Silver [78]. Adapted with permission from ref. [78] 2006 S. Ali A. Moosavian |  | Prototype solution, mobile rescue robot automatic stair-climbing system, teleoperated control, self-balancing control system |

| Azimut [79]. Adapted with permission from ref. [79] 2003 F. Michaud |  | Prototype solution, flat diamond-shape tracks, local perception system |

| Name | Solution | Features |

|---|---|---|

| The Tri-Wheel [80,81]. Adapted with permission from ref. [81] 2015 Lauren M. Smith |  | Prototype solution |

| Asguard [82,83] |  | Prototype solution, mobile rescue robot, motion control software |

| Krys [84,85] |  | Prototype solution, segmented stair-climbing wheels |

| Looper [86]. Adapted with permission from ref. [86] 2008 Sam D. Herbert |  | Prototype solution |

| Name | Solution | Features |

|---|---|---|

| TuskBot [87]. Adapted with permission from ref. [87] 2017 Jonghun Choe |  | Prototype solution, indoor operations, length-adaptable platform |

| Rocker-Bogie [88]. Adapted with permission from ref. [88] 2012 Dongmok Kim, Heeseung Hong, Hwa Soo Kim, Jongwon Kim |  | Prototype solution, automatic stair-climbing system |

| Rocker-Pillar [89]. Adapted with permission from ref. [89] 2012 Dongkyu Choi |  | Prototype solution, automatic stair-climbing system |

| Octopus [90] |  | Prototype solution, automatic stair-climbing system |

| WheTLHLoc [91] |  | Prototype solution, all-terrain mobile robot, automatic stair-climbing system |

| Mantis [92]. Adapted with permission from ref. [92] 2014 Luca Bruzzone |  | Prototype solution, teleoperated control |

| Name | Solution | Features |

|---|---|---|

| WL-12RIII [94] |  | Prototype solution, ZMP (Zero Moment Point) stability control, teleoperated system |

| RoboSapien [95] |  | Prototype solution, ZMP (Zero Moment Point) stability control, teleoperated system |

| Cassie [96,97]. Adapted with permission from White, J.; Swart, D.; Hubicki, C.; Force-based Control of Bipedal Balancing on Dynamic Terrain with the “Tallahassee Cassie” Robotic Platform. 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 2020, pp. 6618–6624, 2020 J. White |  | Prototype solution, autonomous walking |

| Reference | Solution | Features |

|---|---|---|

| Quattroped [98,99]. Adapted from permission from ref. [98] 2011 Shen-Chiang Chen |  | Prototype solution, teleoperated system |

| Liu [100]. Adapted with permission from ref. [100] 2017 Chih-Hsing Liu |  | Prototype solution, teleoperated system, balancing control system |

| Cheetah 3 [101] |  | Prototype solution, autonomous walking without use of cameras |

| Spot [102] |  | Commercial solution, autonomous walking |

| ANYmal [103]. Adapted with permission from ref. [103] 2016 Marco Hutter |  | Prototype solution, autonomous walking |

| HyTRO-I [104]. Adapted with permission from ref. [104] 2013 Dongping Lu |  | Prototype solution, manual control |

| Name | Solution | Features |

|---|---|---|

| RHex [106]. Adapted with permission from ref. [106] 2002 E.Z. Moore |  | Prototype solution, automatic stair-climbing system |

| Name | Solution | Features |

|---|---|---|

| Ascento Pro [107] |  | Commercial solution, autonomous drive, outdoor survelliance service |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pappalettera, A.; Bottiglione, F.; Mantriota, G.; Reina, G. Watch the Next Step: A Comprehensive Survey of Stair-Climbing Vehicles. Robotics 2023, 12, 74. https://doi.org/10.3390/robotics12030074

Pappalettera A, Bottiglione F, Mantriota G, Reina G. Watch the Next Step: A Comprehensive Survey of Stair-Climbing Vehicles. Robotics. 2023; 12(3):74. https://doi.org/10.3390/robotics12030074

Chicago/Turabian StylePappalettera, Antonio, Francesco Bottiglione, Giacomo Mantriota, and Giulio Reina. 2023. "Watch the Next Step: A Comprehensive Survey of Stair-Climbing Vehicles" Robotics 12, no. 3: 74. https://doi.org/10.3390/robotics12030074

APA StylePappalettera, A., Bottiglione, F., Mantriota, G., & Reina, G. (2023). Watch the Next Step: A Comprehensive Survey of Stair-Climbing Vehicles. Robotics, 12(3), 74. https://doi.org/10.3390/robotics12030074