Multi-Row Turbomachinery Aerodynamic Design Optimization by an Efficient and Accurate Discrete Adjoint Solver

Abstract

1. Introduction

2. Numerical Schemes and Boundary Conditions

2.1. Numerical Schemes

2.2. Boundary Conditions

3. Adjoint Principle

4. Automatic Differentiation

4.1. Forward and Backward Modes

4.2. Problem Description and Analysis

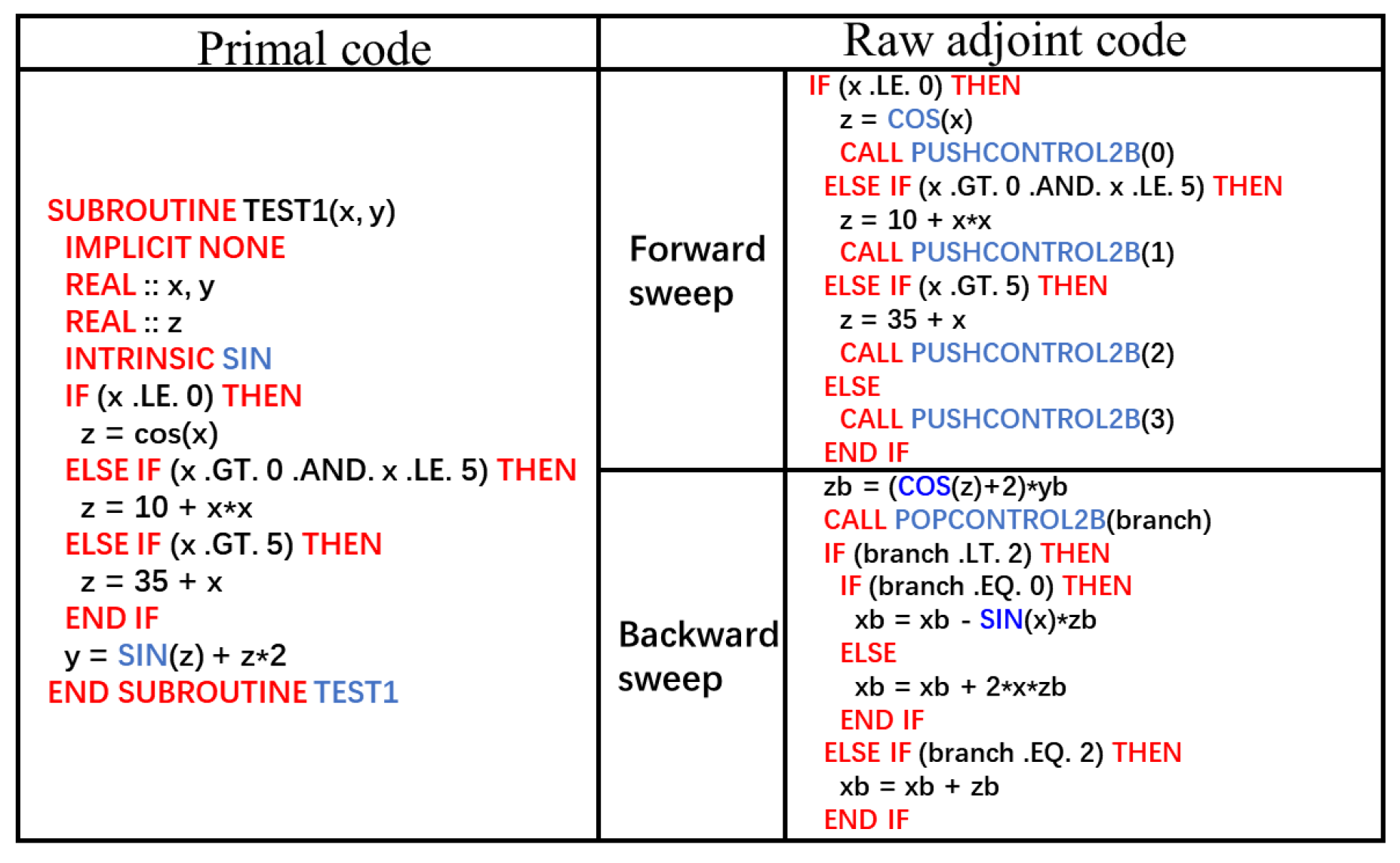

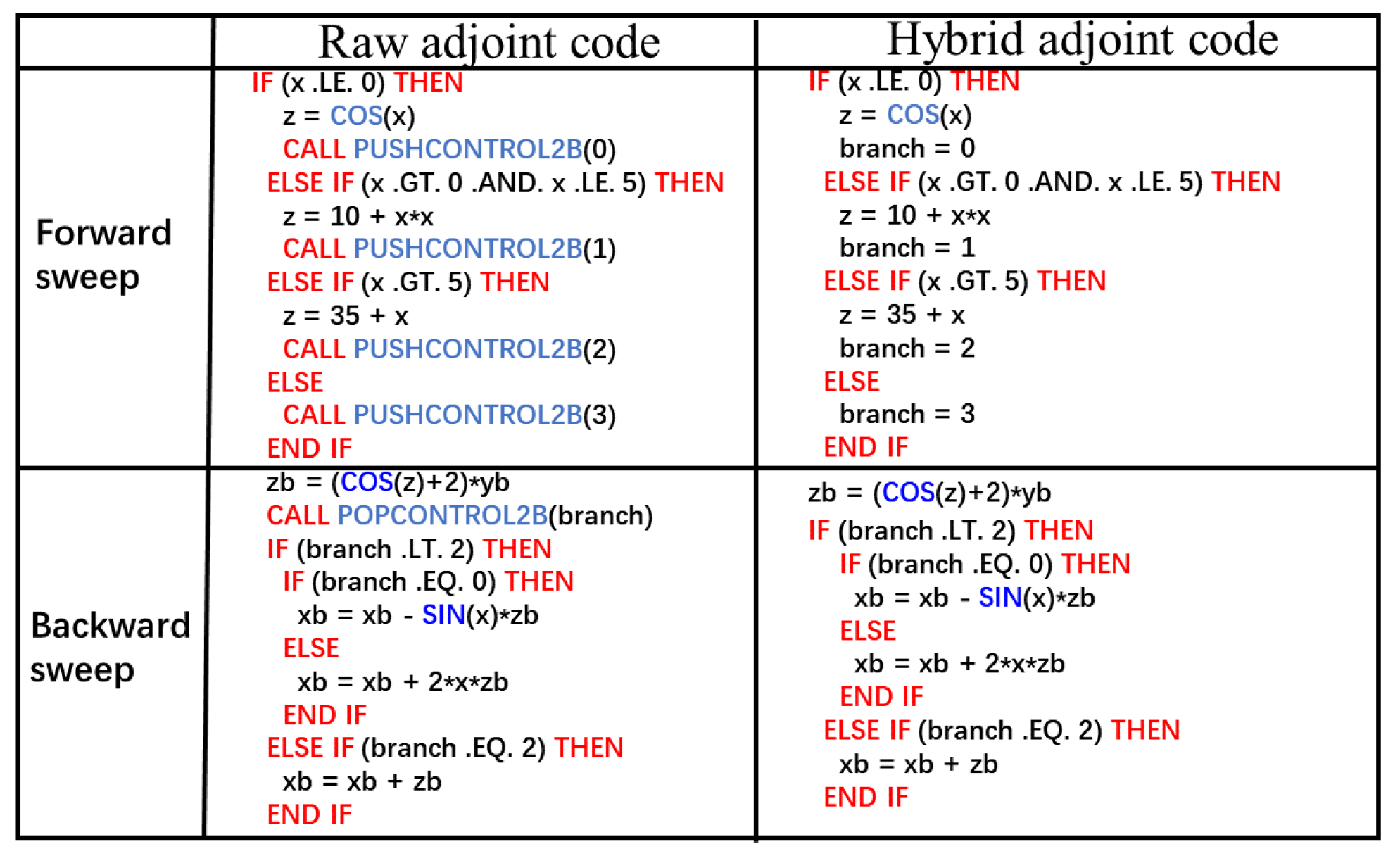

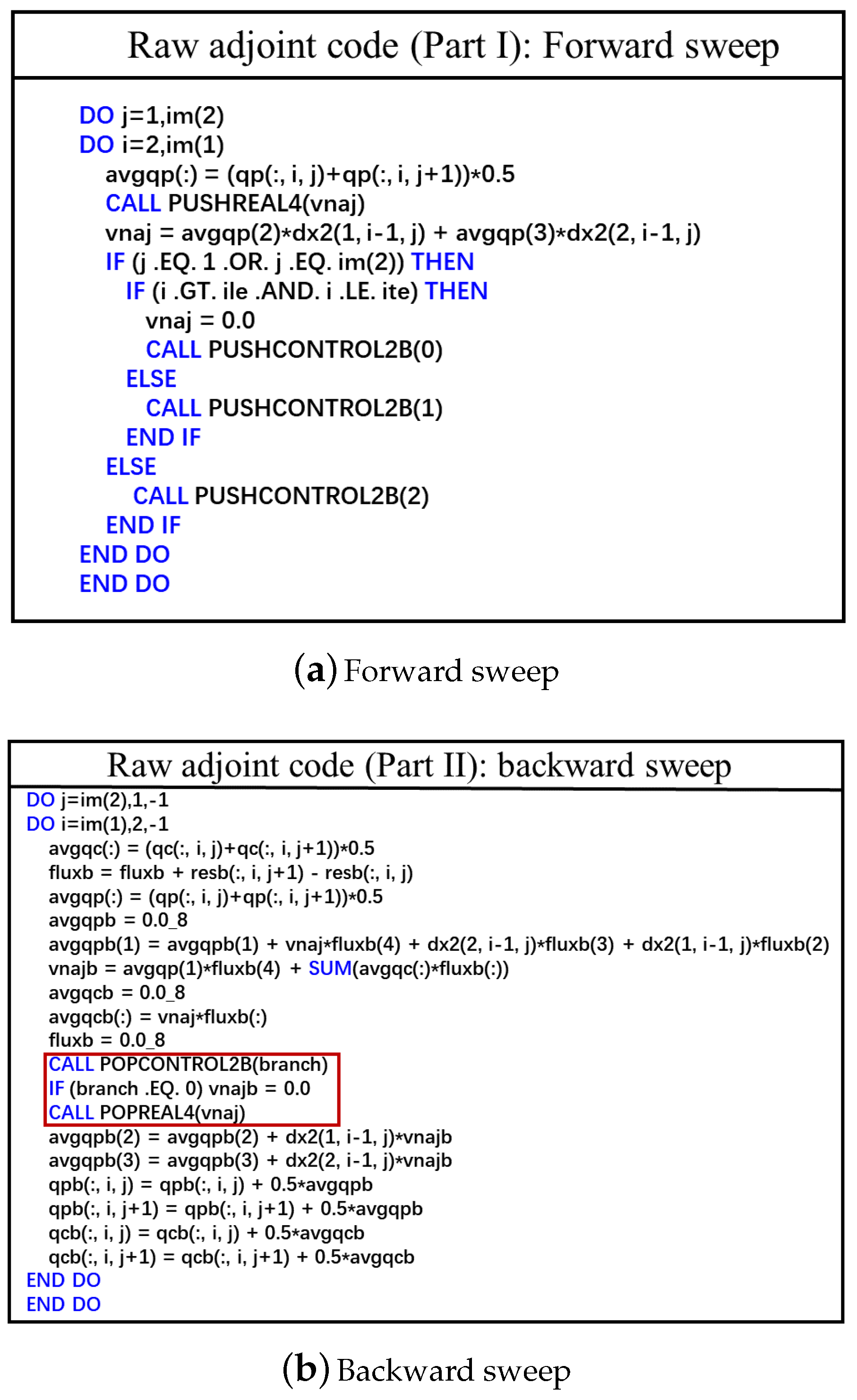

4.2.1. Conditional Branches

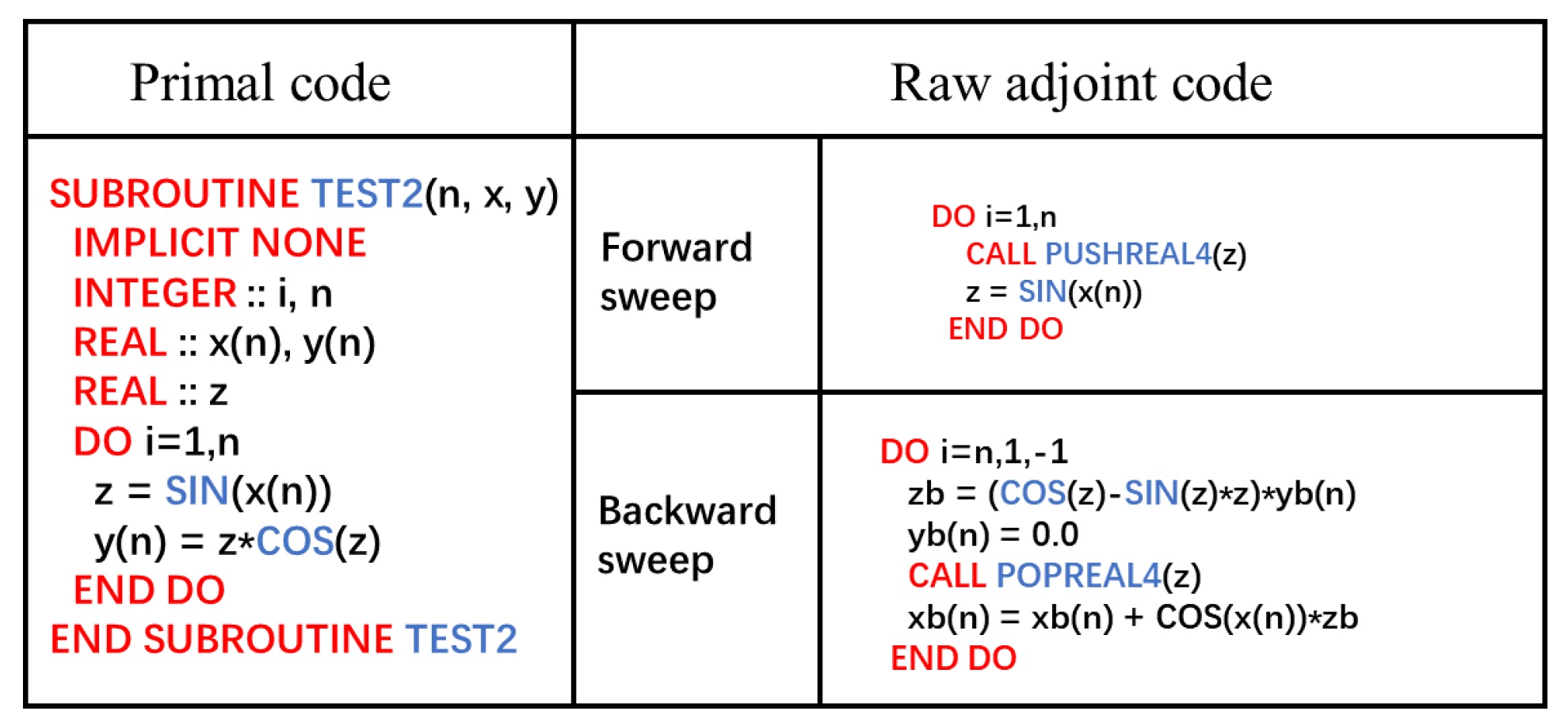

4.2.2. Reals/Integrals

5. Hybrid Automatic and Manual Differentiation

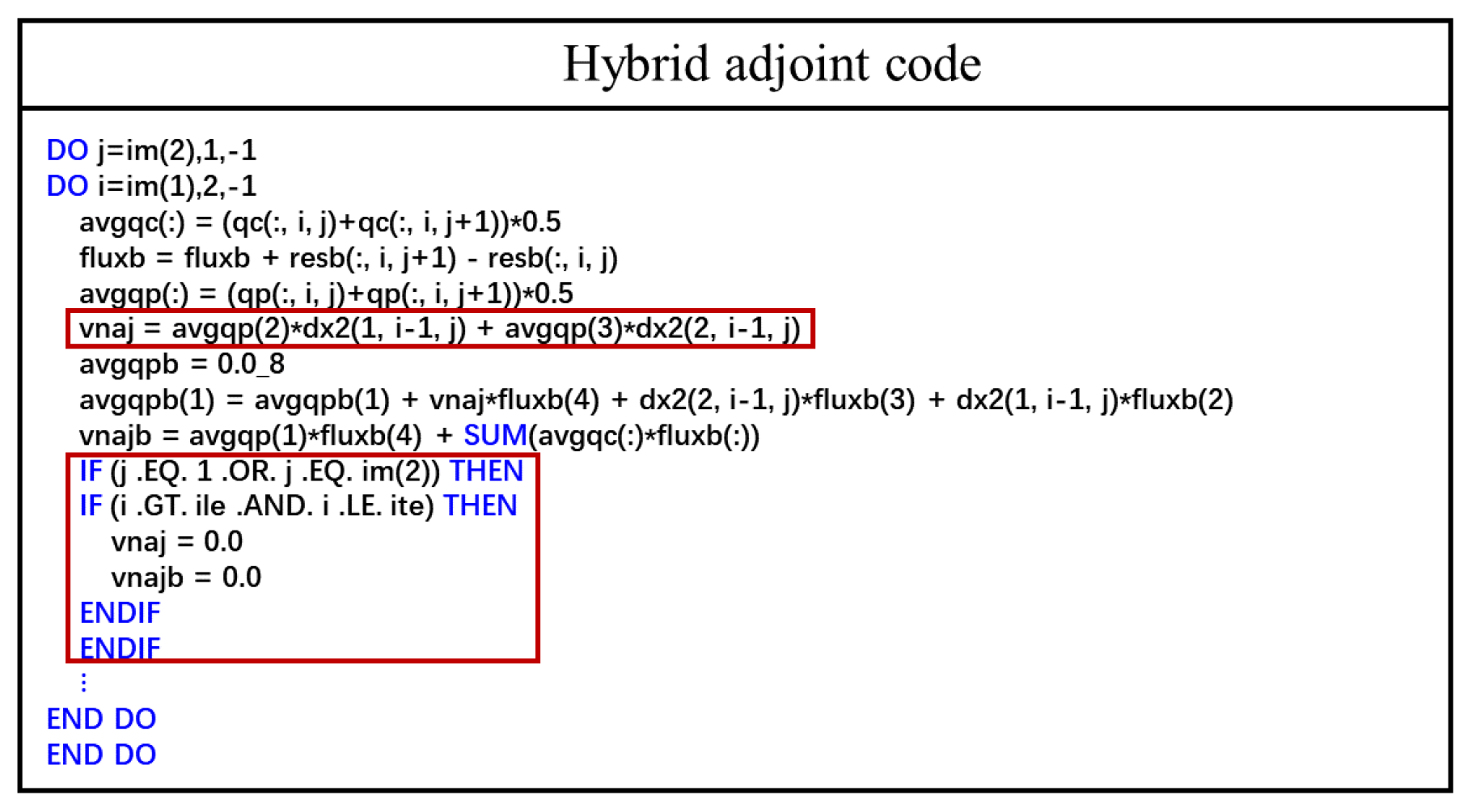

5.1. Strategy One: Directly Evaluate Conditional Branches

5.2. Strategy Two: Directly Evaluate Intermediate Variables

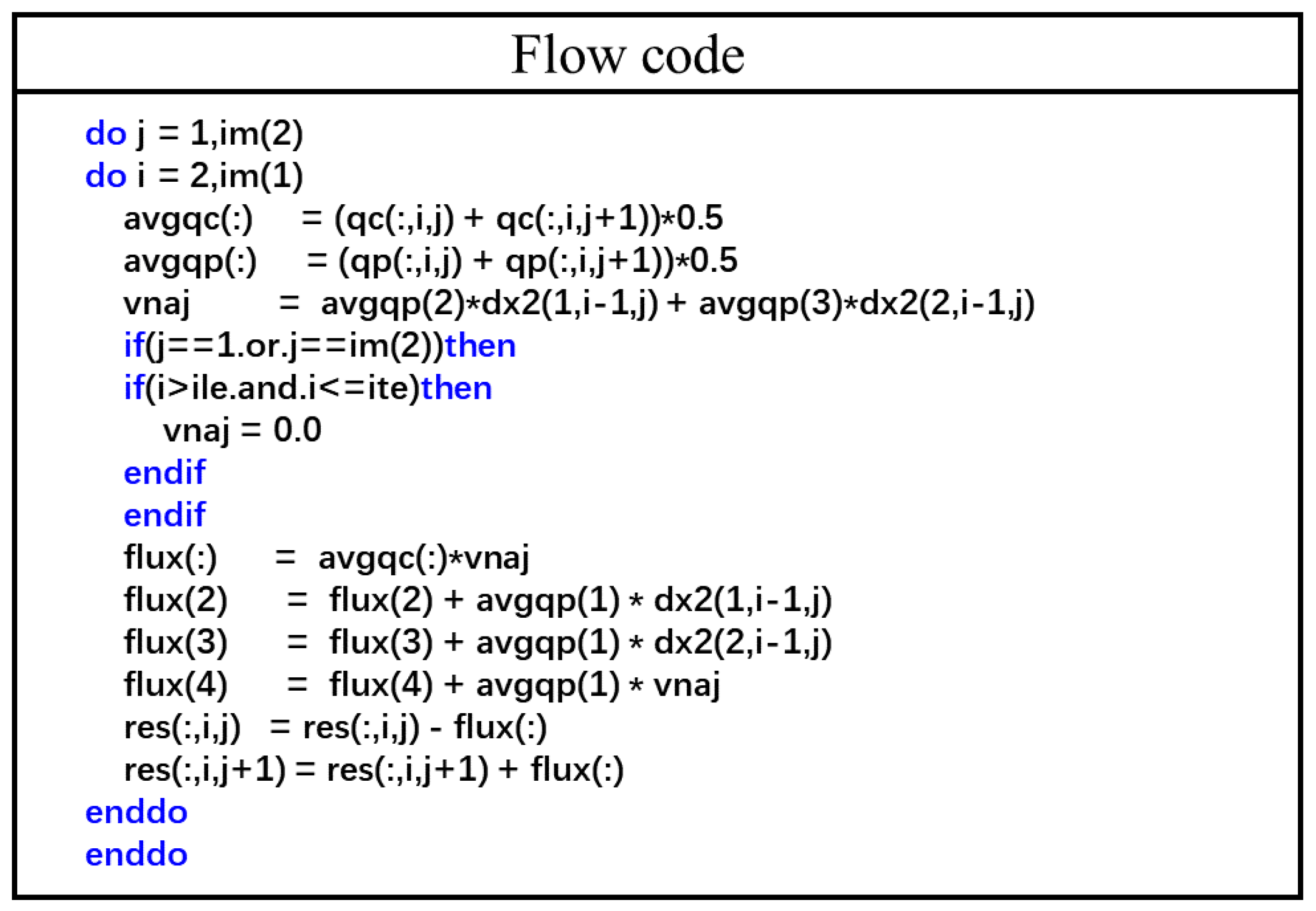

5.3. Strategy for Real-Life Adjoint Codes

6. Rotor-Stator/Stator-Rotor Interface Treatment

6.1. Mixing Plane Method

- (1)

- Average flux in the circumferential direction. It can be expressed in the following symbolic formIn Equation (11), the superscript j represents the upstream or downstream of a rotor-stator/stator-rotor interface. When j equals 1, it represents the upstream of the interface, otherwise, it represents the downstream of the interface. The subscript 0 represents the value before flux interpolation. X is the grid coordinate vector, and is the function related to flux averaging.

- (2)

- Interpolate flux in the radial direction. This step is a must as the grid distribution in the radial direction across an interface is often different as shown in Figure 8b. The interpolation operation is represented symbolically as followswhere represents the function related to flux interpolation and subscript 1 represents the interpolated flux.

- (3)

- Update solution based upon the one-dimensional non-reflective boundary condition. This operation is represented as followsIn the above equation, the superscript ∗ represents the updated solution, and represents the function related to the solution update.

6.2. Discrete Adjoint Mixing Plane Method

- (1)

- Differentiate the subroutines related to solution update.whereIn the above equations, and are initialized by 0.

- (2)

- Differentiate the subroutines related to flux interpolation.where

- (3)

- Differentiate the subroutines related to flux averaging.whereIn the above equations, the subscript a represents the backward mode of the AD.

7. Results

7.1. NASA Stage 35

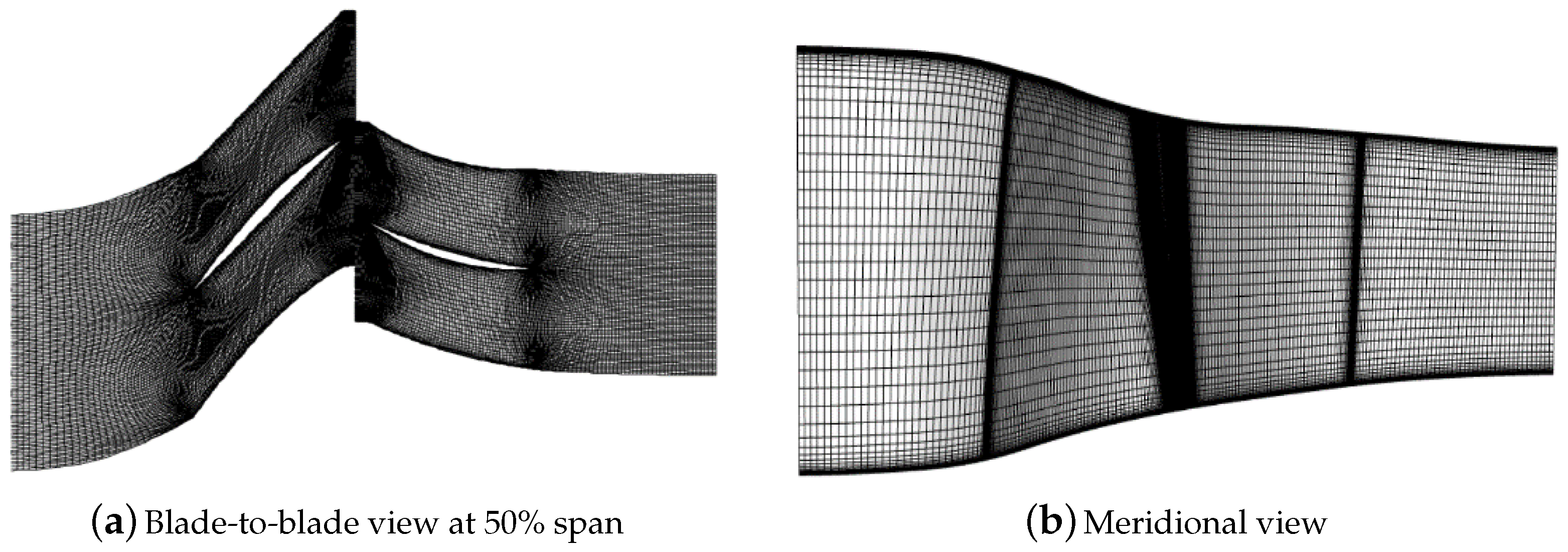

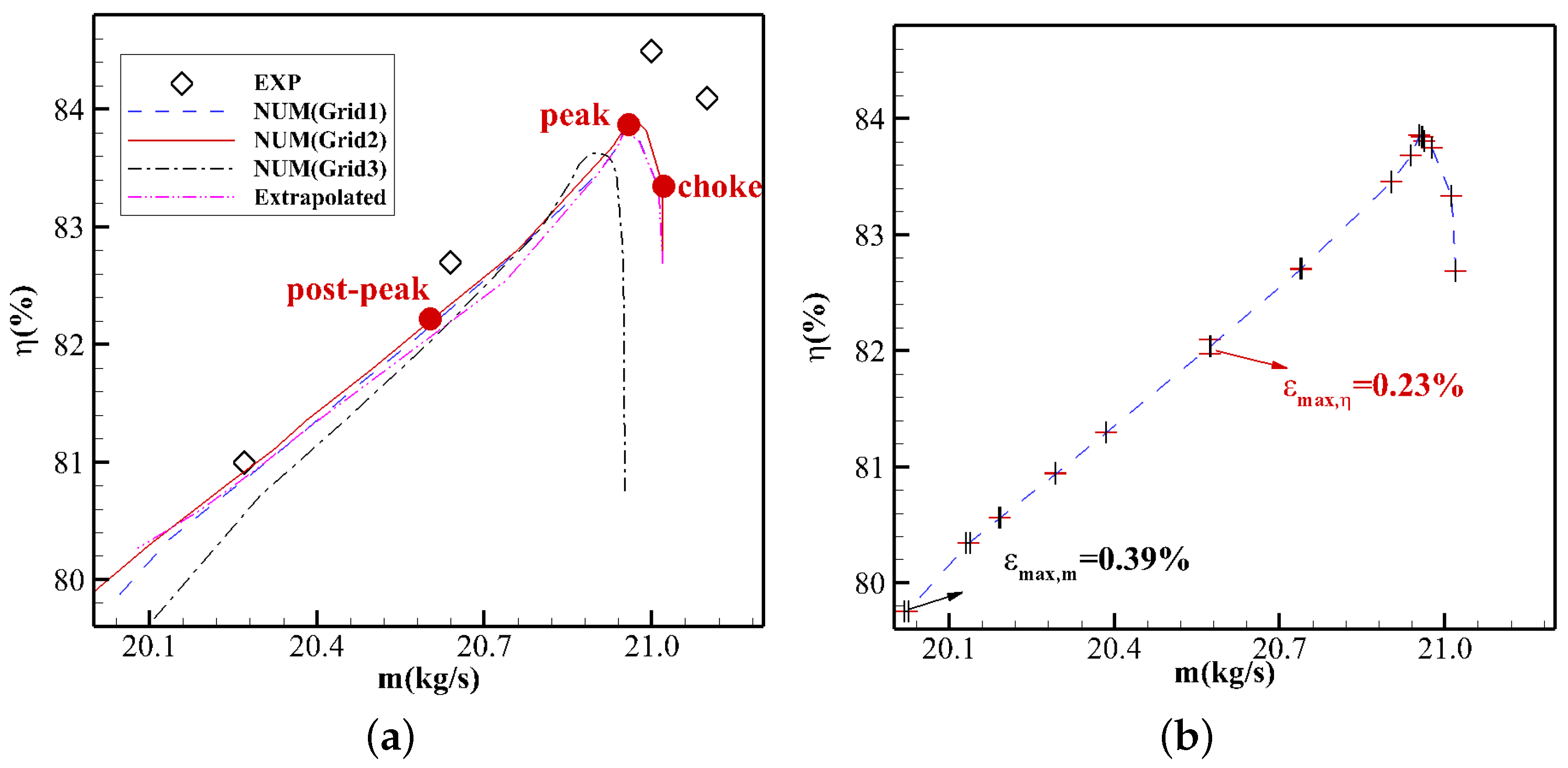

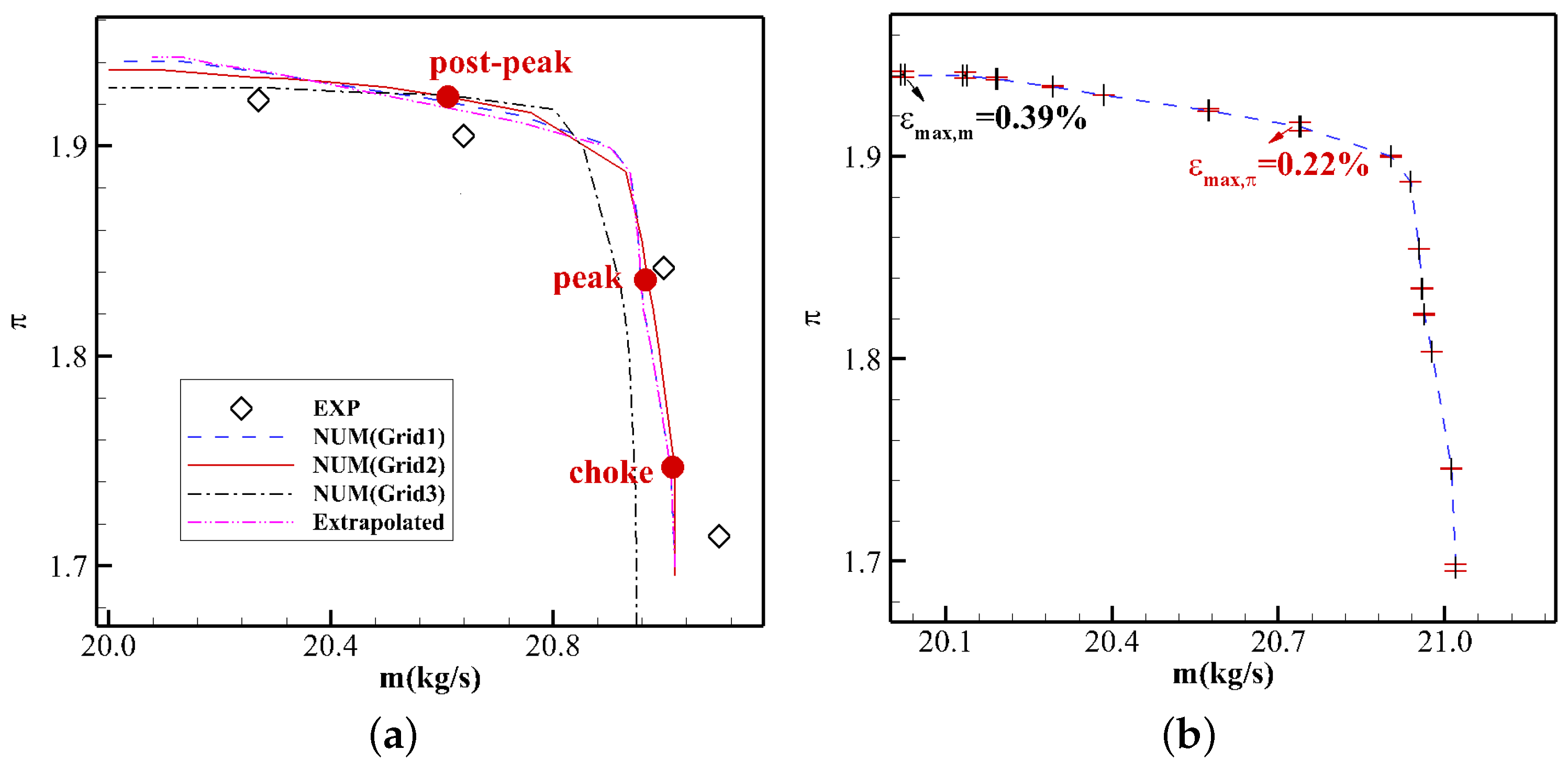

7.1.1. Grid Independence Study

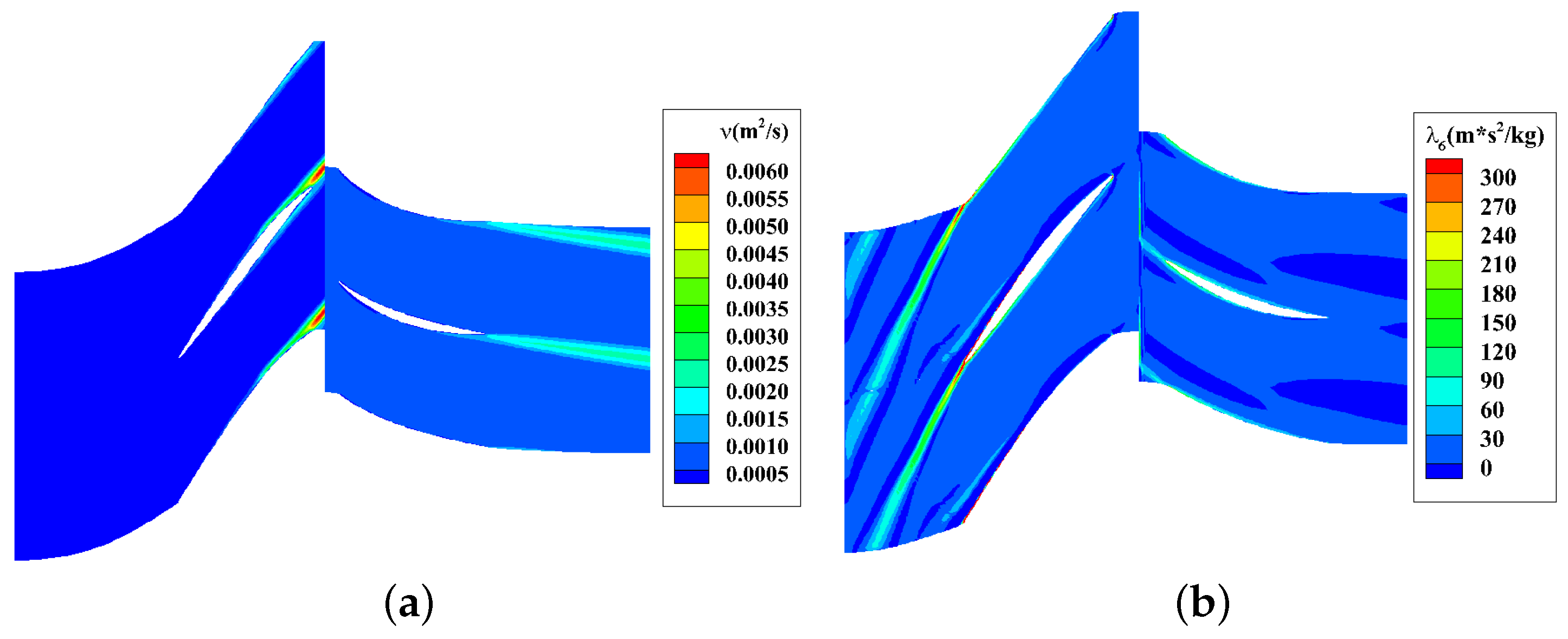

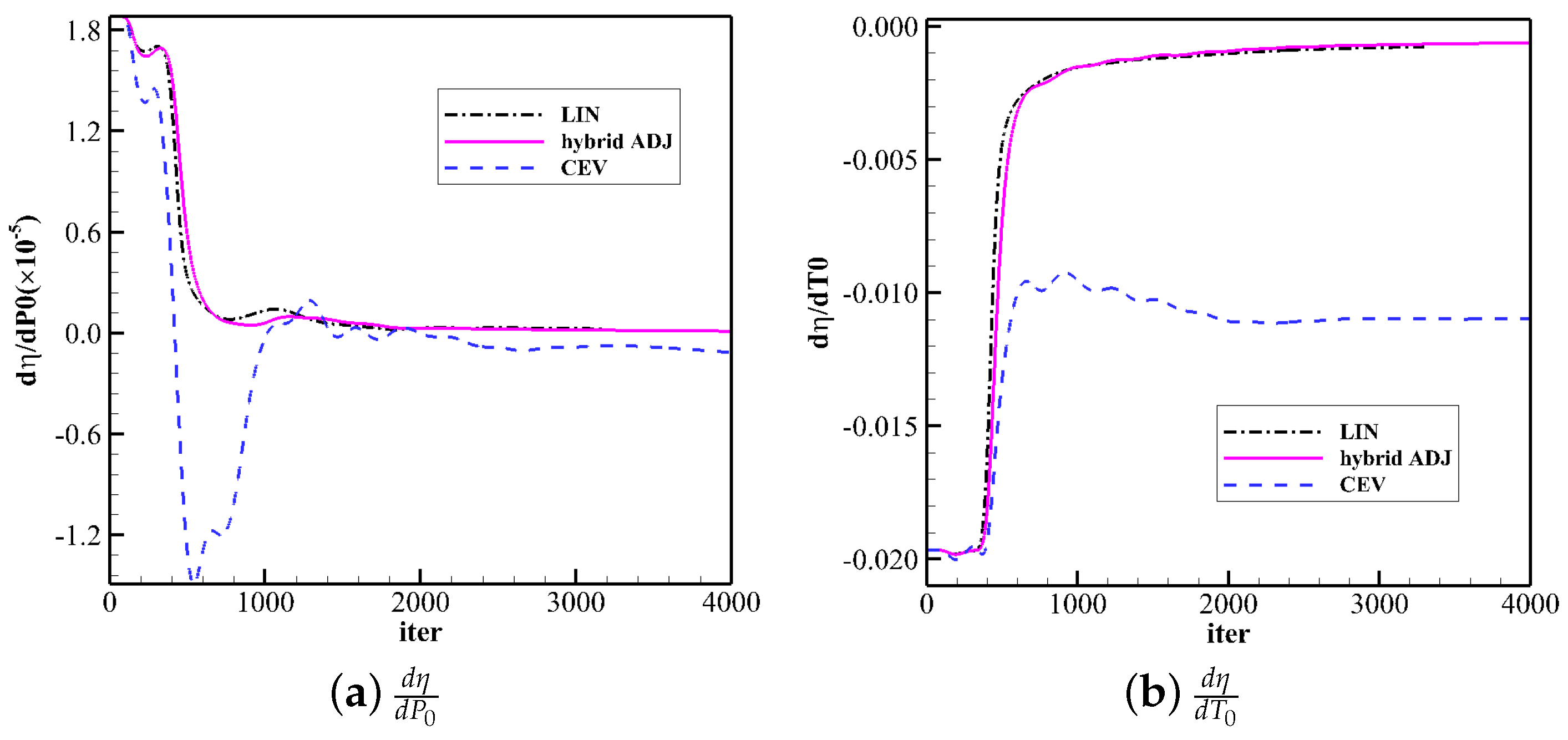

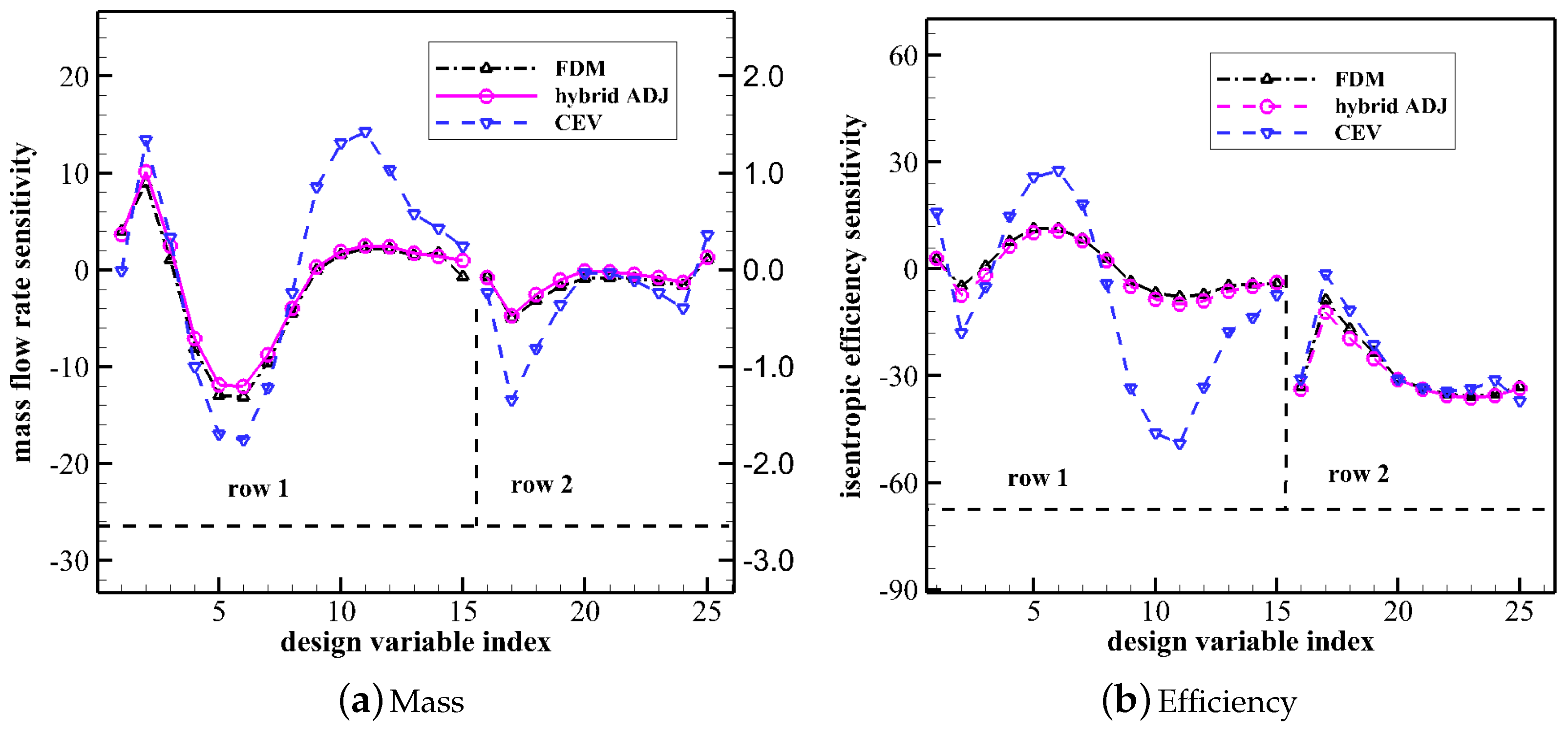

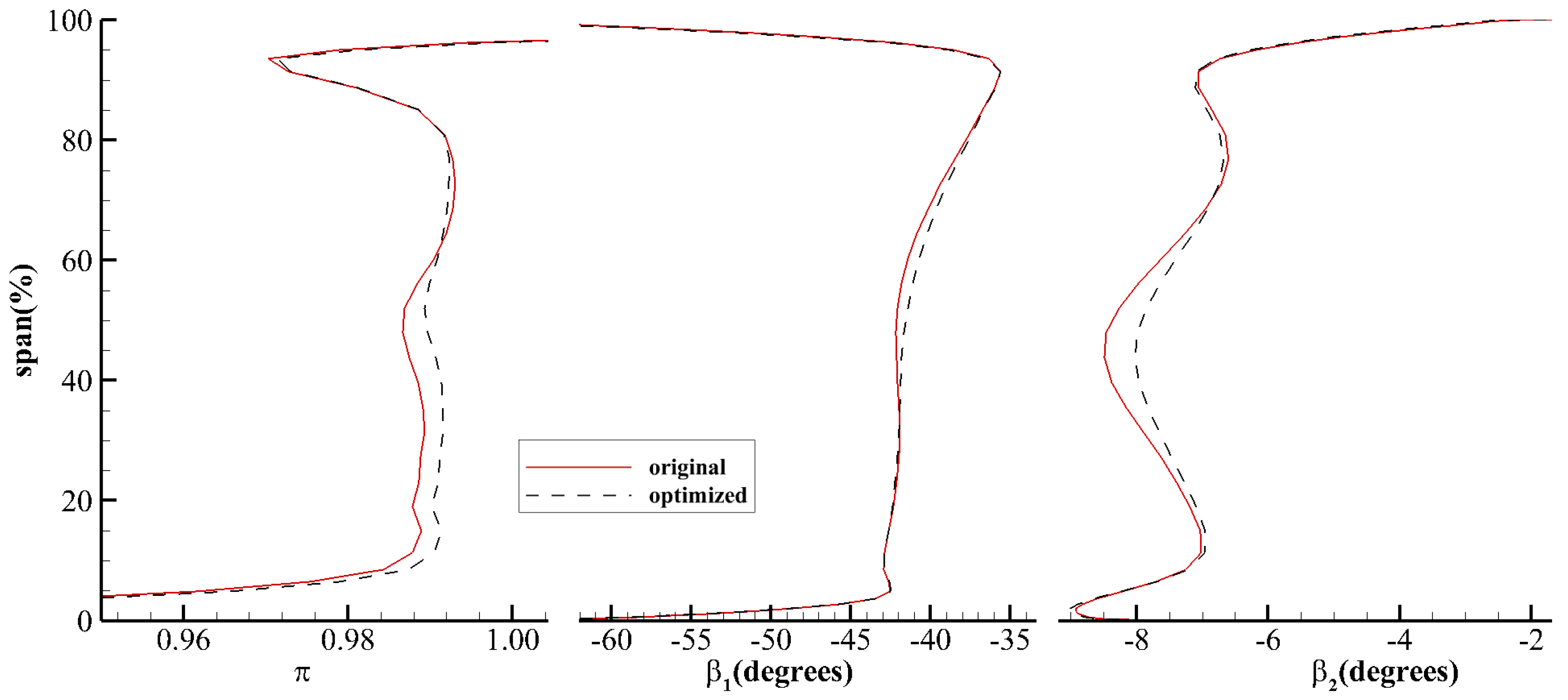

7.1.2. Adjoint Sensitivity Verification

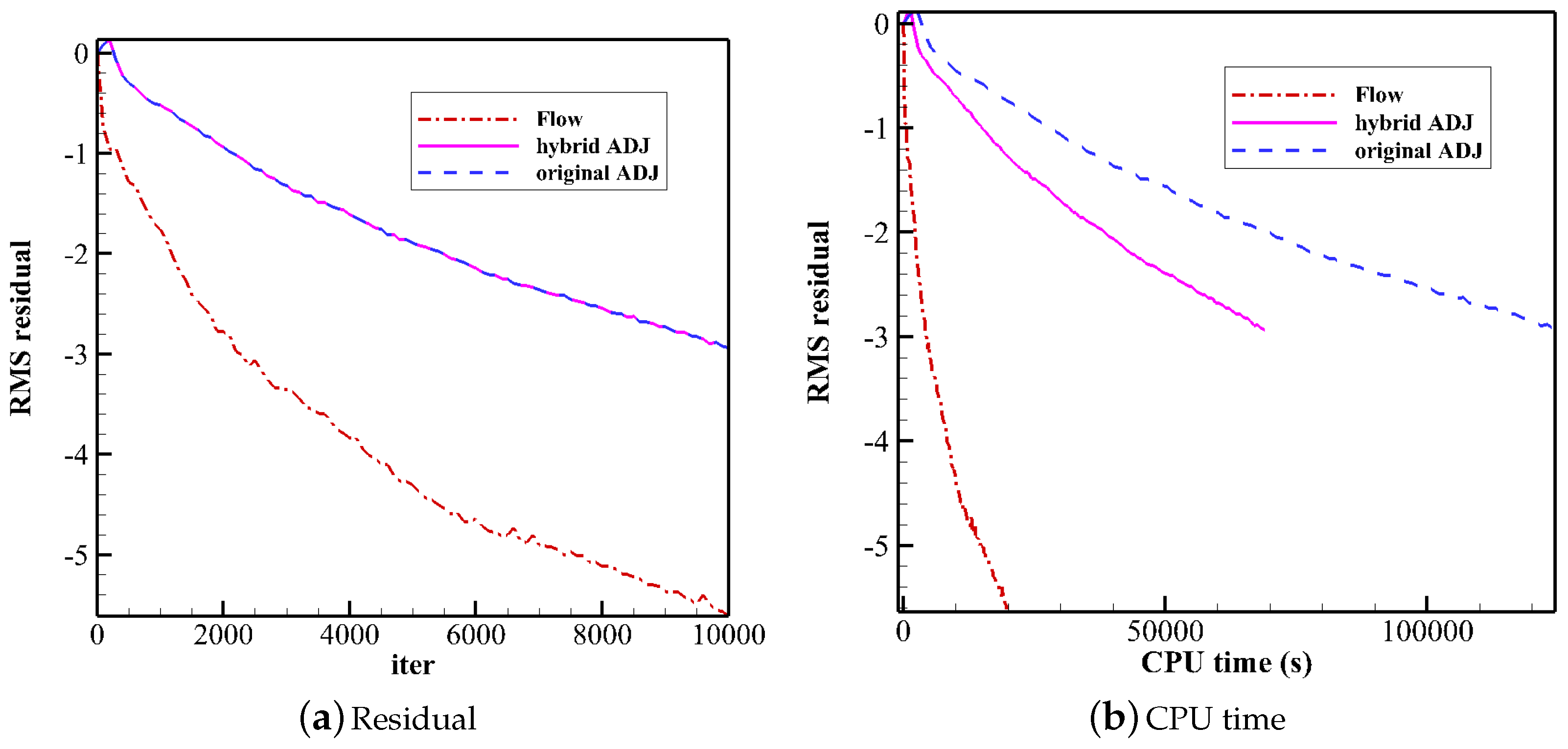

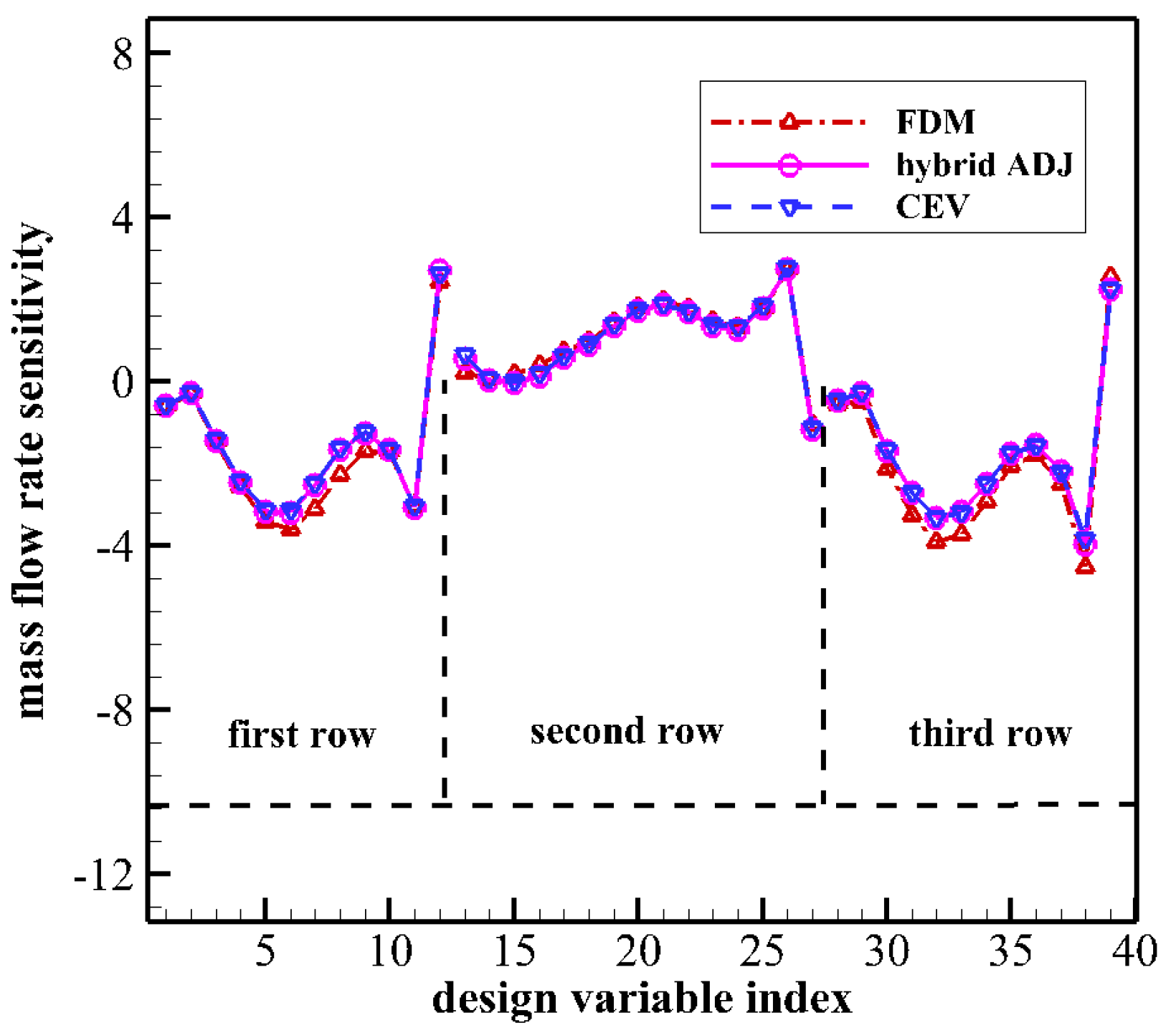

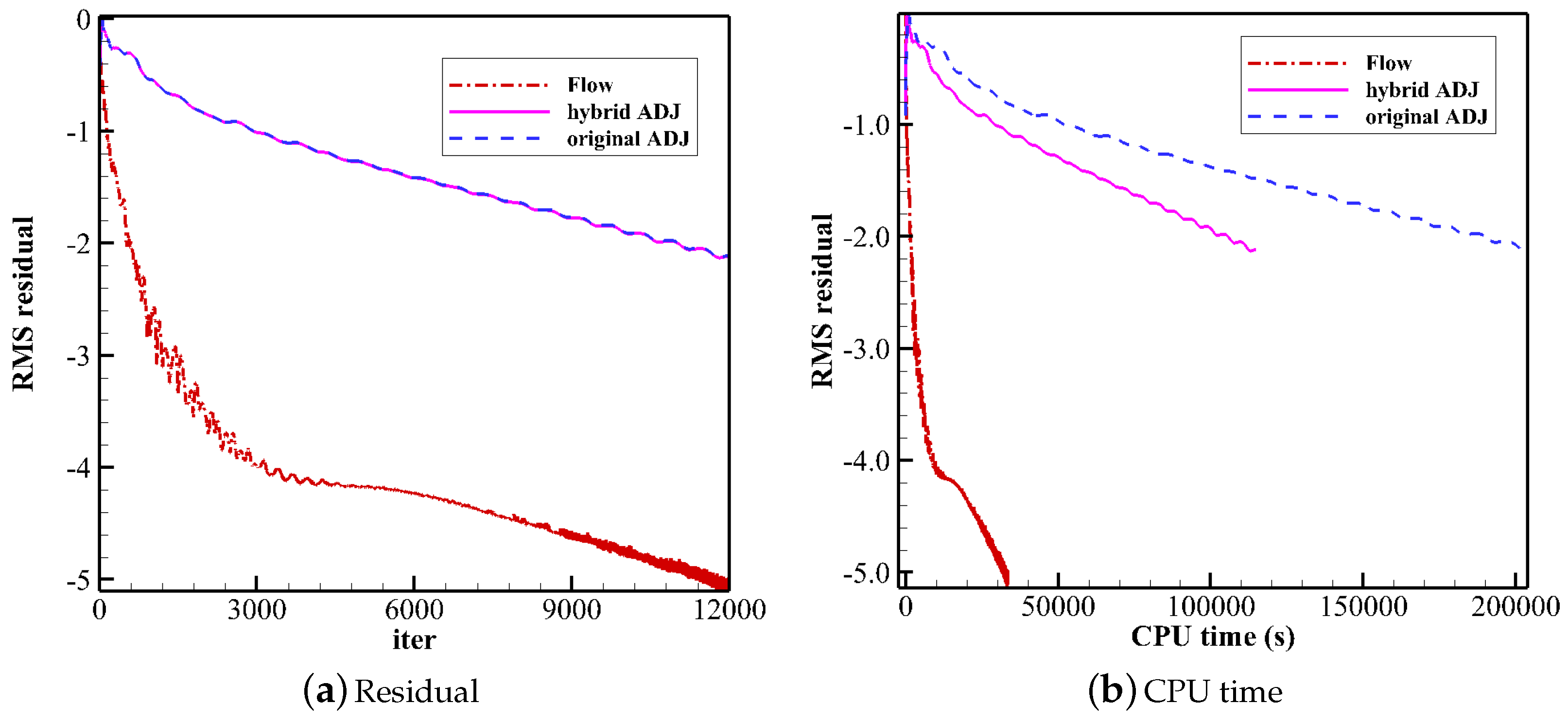

7.1.3. Computational Efficiency

7.1.4. Results of Design Optimizations

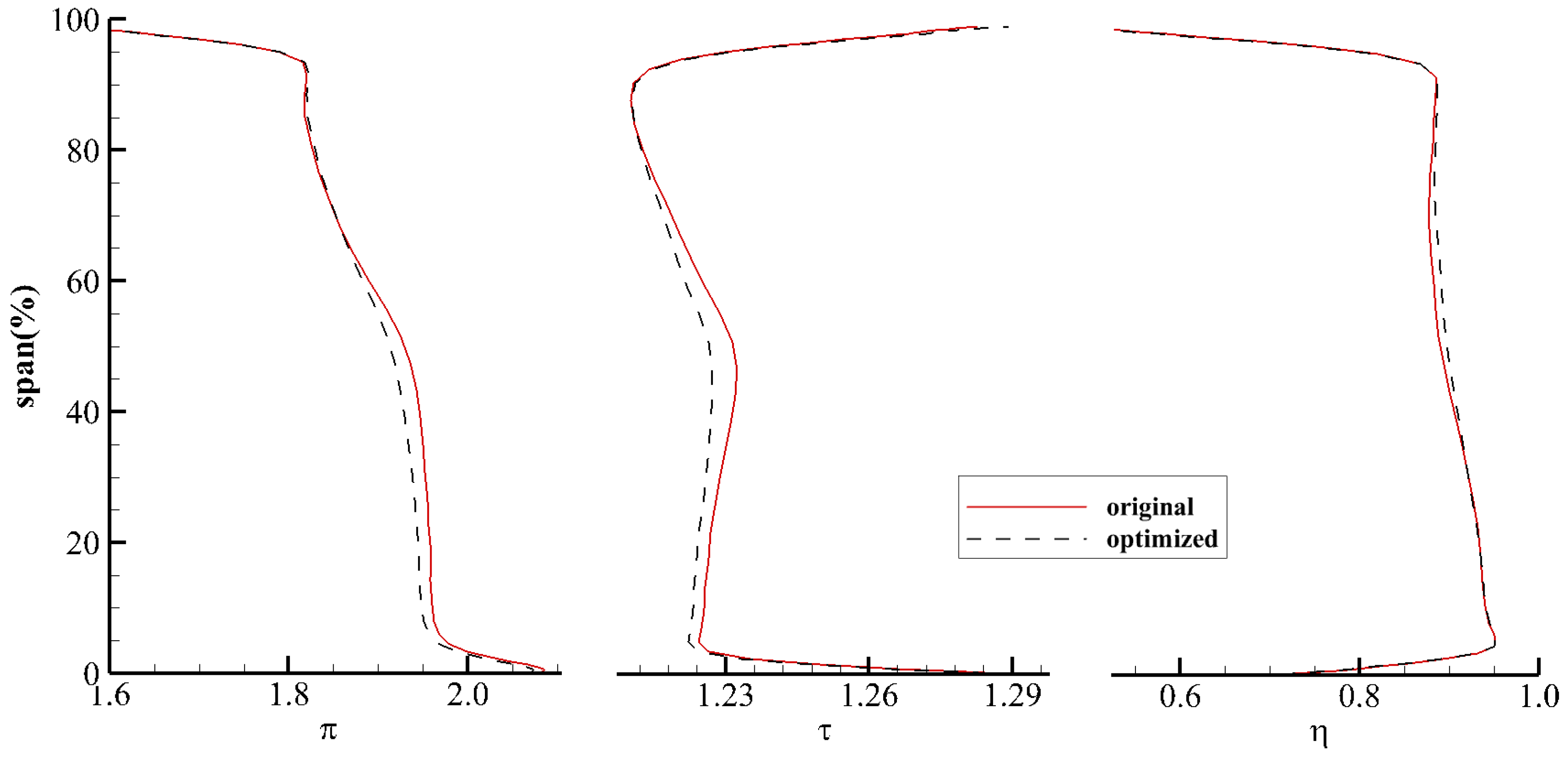

7.2. Aachen Turbine

7.2.1. Adjoint Sensitivity Verification

7.2.2. Computational Efficiency

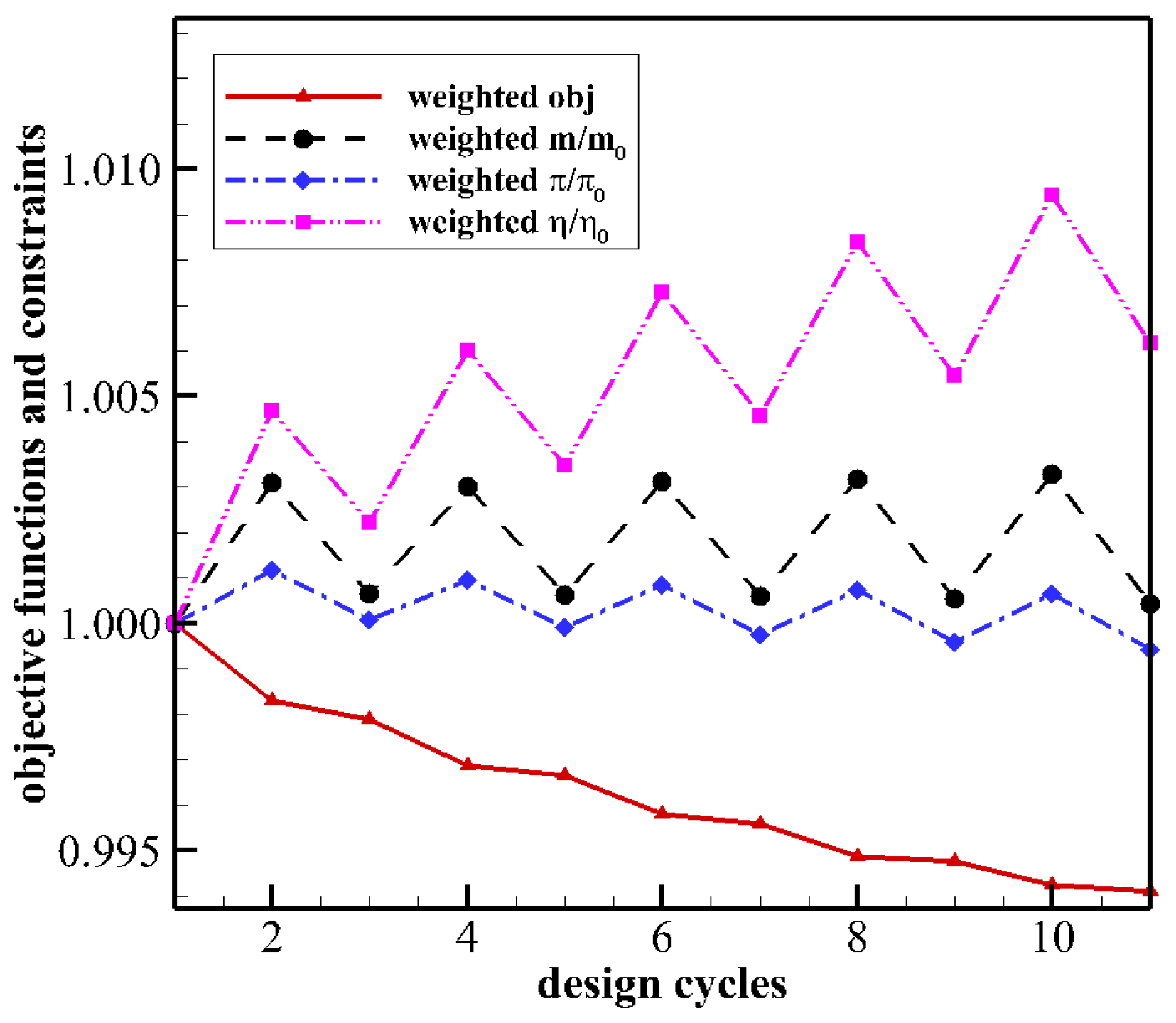

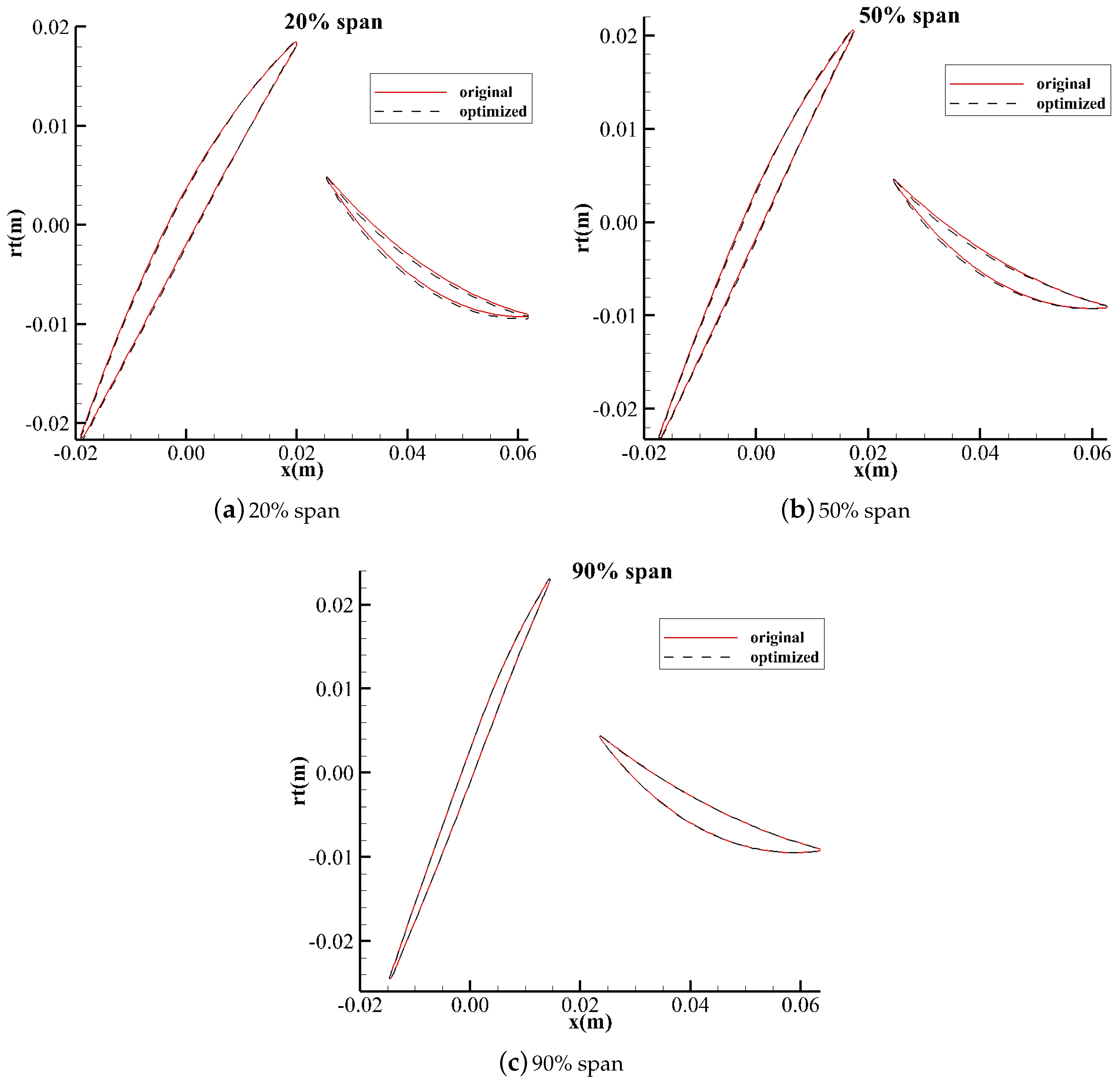

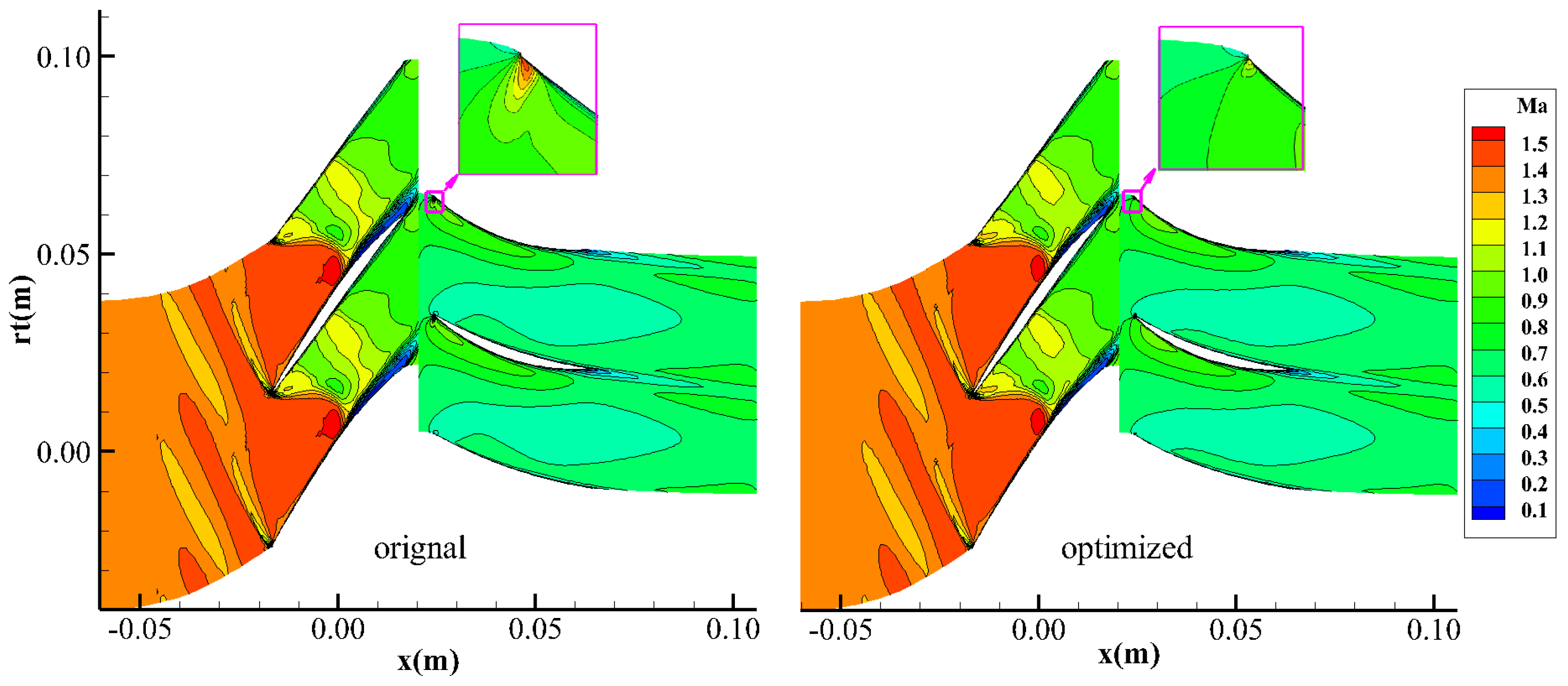

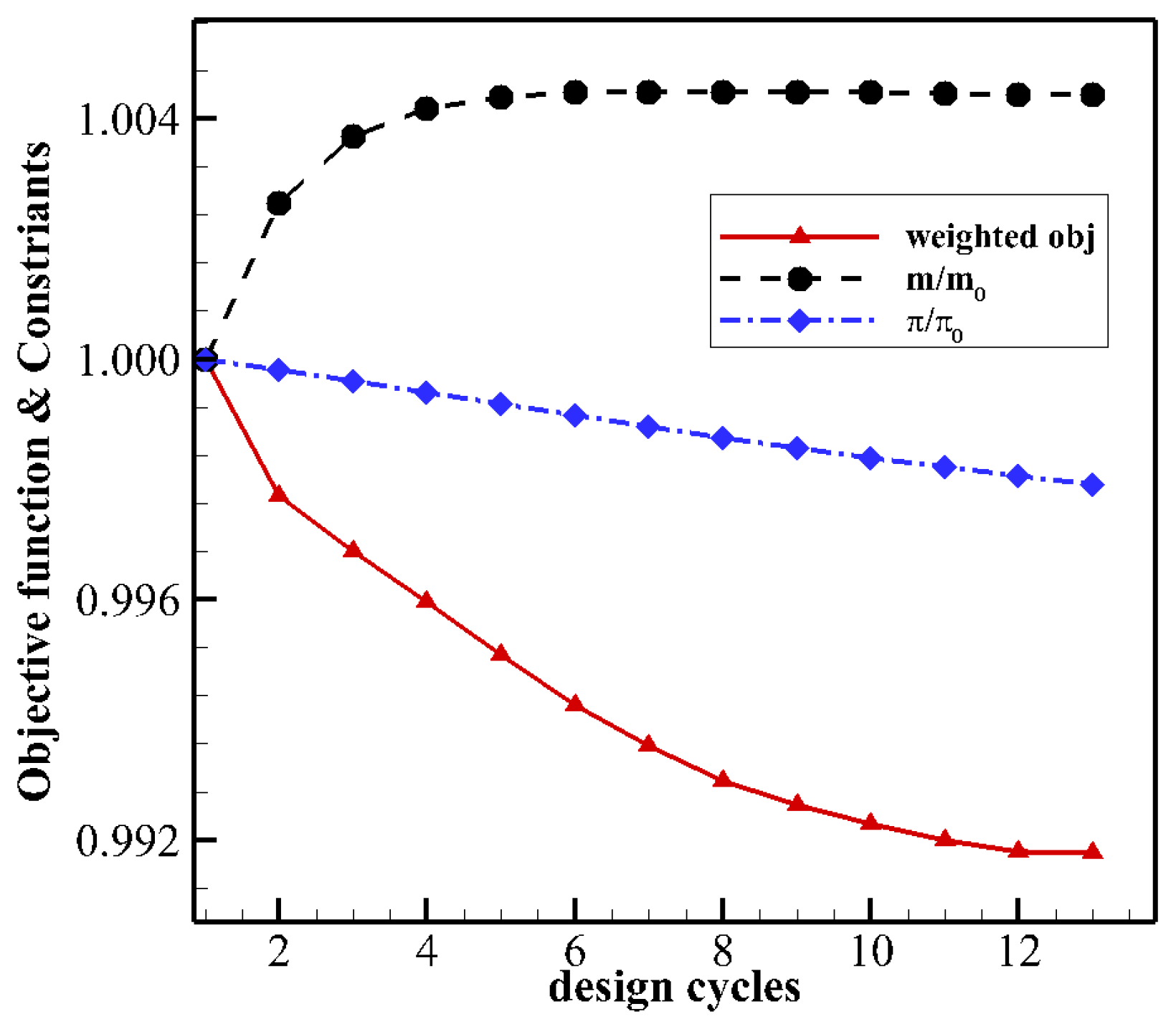

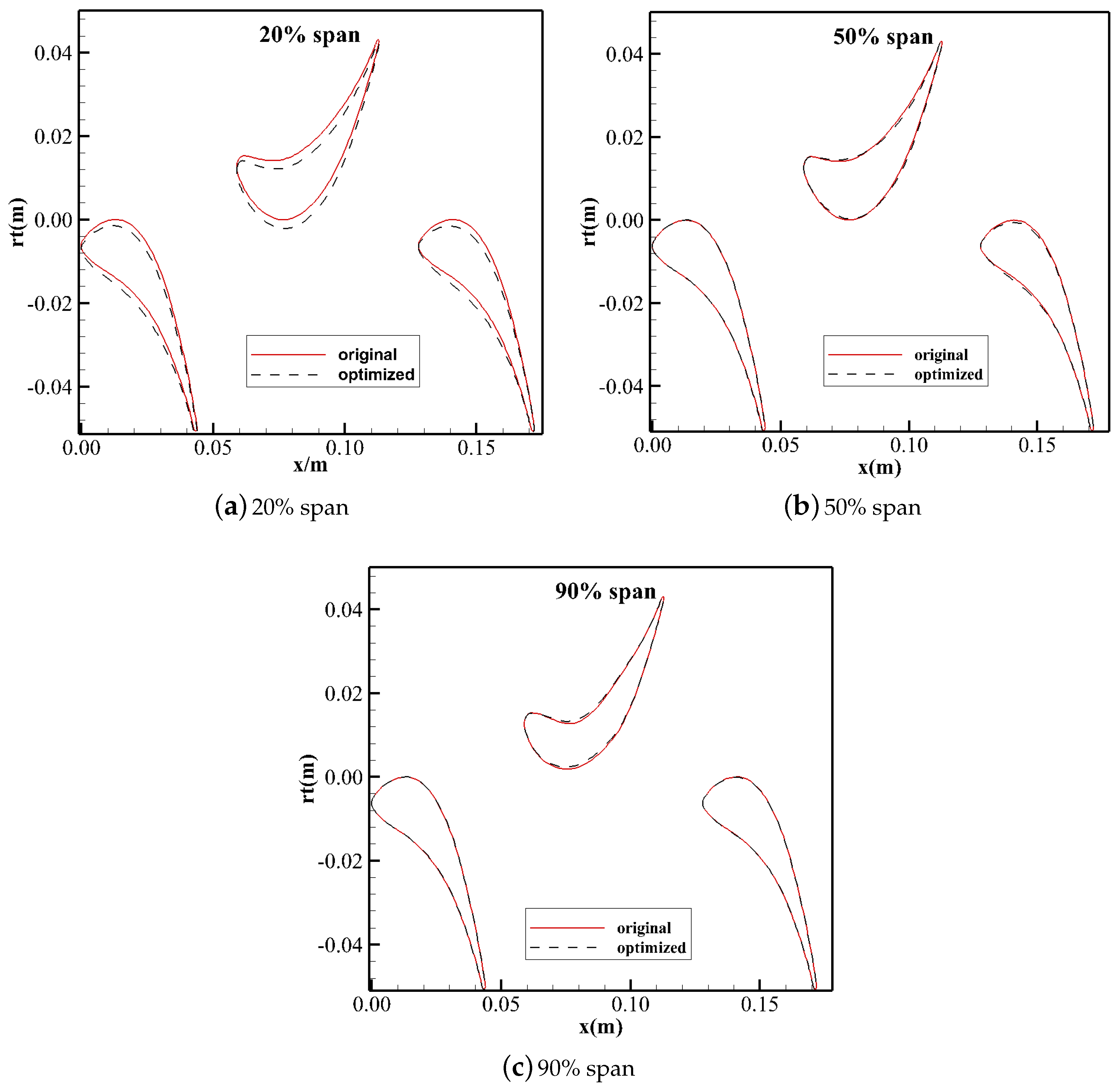

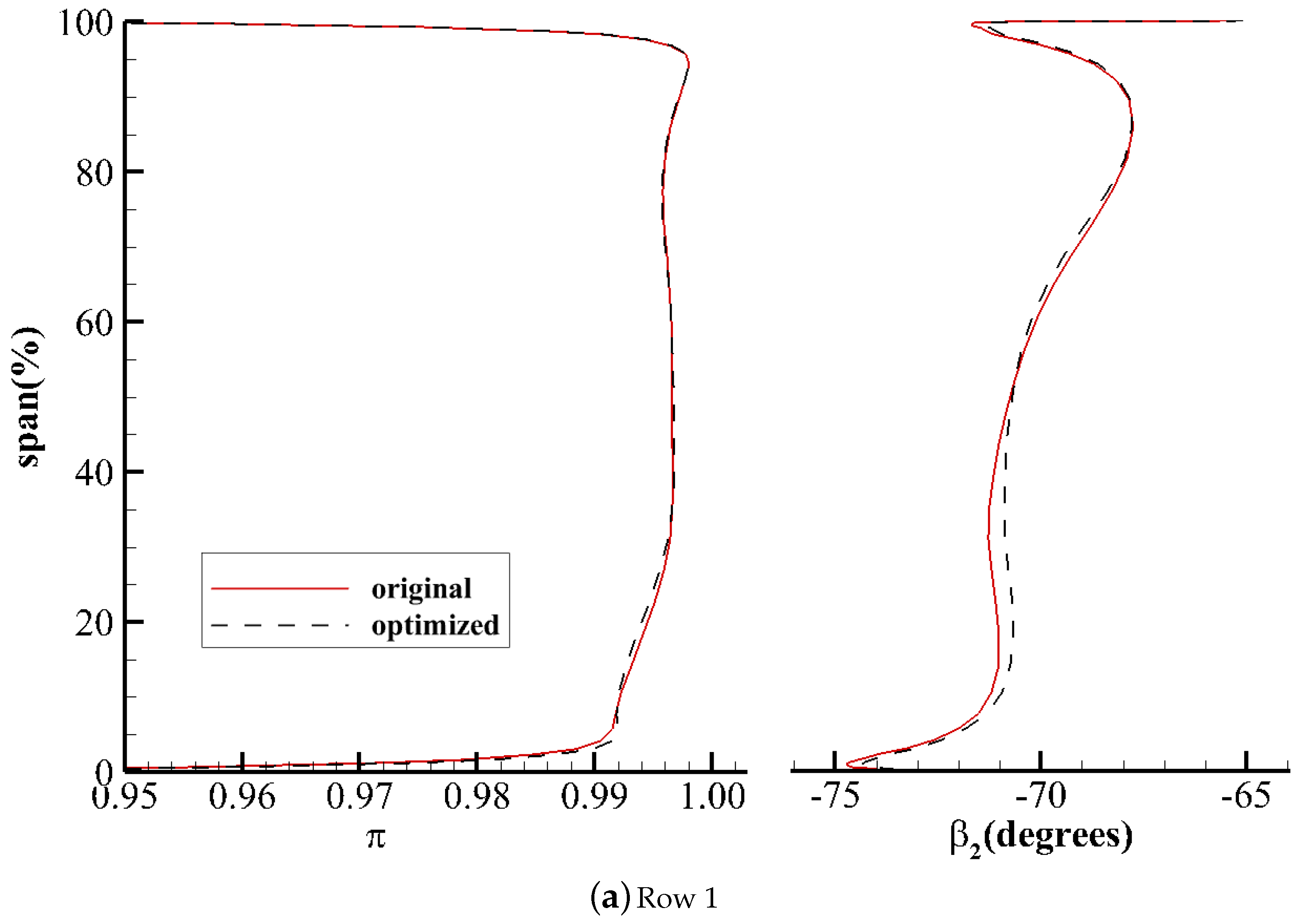

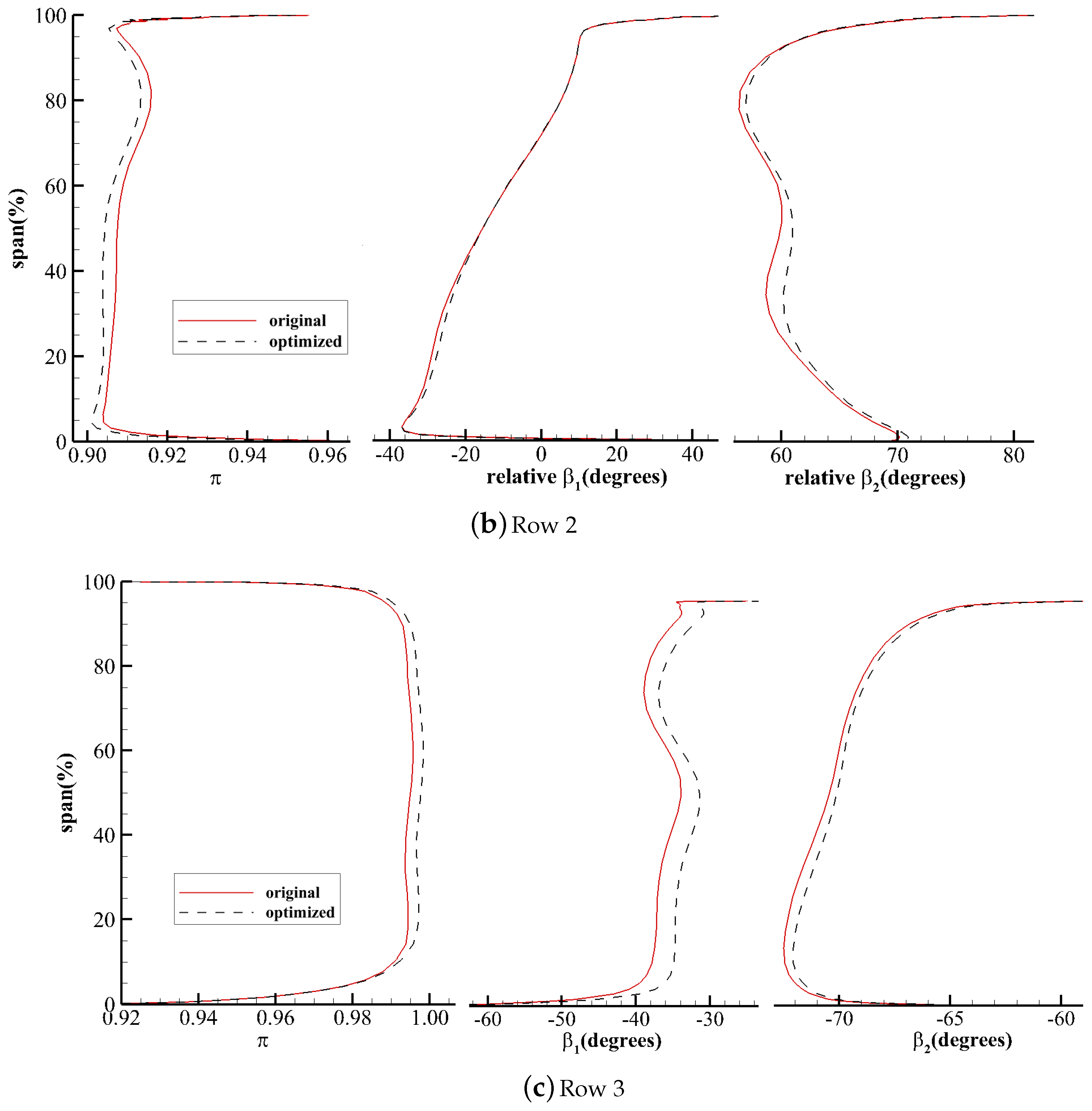

7.2.3. Results of Design Optimizations

8. Conclusions

- (1)

- The hybrid ADJ almost has the same sensitivity convergence histories as those from the linearized solver and higher sensitivity accuracy than the CEV. The maximum relative difference of sensitivities between the FDM and the hybrid ADJ is no more than for the cases studied in the paper.

- (2)

- The hybrid ADJ has higher computational efficiency than the discrete adjoint solver purely developed by the AD tool. About CPU time and memory consumption can be saved for the single-stage NASA Stage 35, and CPU time and memory consumption can be saved for the 1.5-stage Aachen turbine.

- (3)

- The multi-row turbomachinery aerodynamic design optimizations can be effectively performed by the hybrid ADJ. For the single-stage NASA Stage 35, the isentropic efficiency over the entire operating range of design speed is significantly improved, and the stall margin is increased for the optimized blades. For the 1.5-stage Aachen turbine, the entropy generation rate is decreased after optimization. Moreover, the variations in mass flow rate and total pressure ratio are also acceptable.

Author Contributions

Funding

Conflicts of Interest

References

- Oyama, A.; Liou, M.; Obayashi, S. Transonic Axial-Flow Blade Optimization: Evolutionary Algorithms/Three-Dimensional Navier-Stokes Solver. J. Propuls. Power 2012, 20, 612–619. [Google Scholar] [CrossRef]

- Semlitsch, B.; Huscava, A. Shape Optimization of Turbomachinery Components. In Proceedings of the 8th European Congress on Computational Methods in Applied Sciences and Engineering, Oslo, Norway, 5–9 June 2022. [Google Scholar]

- Yang, S.; Liu, F. Aerodynamic Design of Cascades by Using an Adjoint Equation Method. In Proceedings of the Aerospace Sciences Meeting & Exhibit, Reno, NV, USA, 6–9 January 2003. [Google Scholar]

- Luo, J.; Liu, F. Multi-objective Optimization of a Transonic Compressor Rotor by Using an Adjoint Method. AIAA J. 2014, 53, 797–801. [Google Scholar] [CrossRef]

- Wang, D.; He, L. Adjoint Aerodynamic Design Optimization for Blades in Multistage Turbomachines-Part I: Methodology and Verification. J. Turbomach. 2010, 132, 021011. [Google Scholar] [CrossRef]

- Wang, D.X.; He, L.; Li, Y.S.; Wells, R.G. Adjoint Aerodynamic Design Optimization for Blades in Multistage Turbomachines-Part II: Validation and Application. J. Turbomach. 2010, 132, 021012. [Google Scholar] [CrossRef]

- Vitale, S.; Pini, M.; Colonna, P. Multistage Turbomachinery Design Using the Discrete Adjoint Method within the Open-Source Software SU2. J. Propuls. Power 2020, 36, 465–478. [Google Scholar] [CrossRef]

- Ntanakas, G.; Meyer, M.; Giannakoglou, K. Employing the Time-Domain Unsteady Discrete Adjoint Method for Shape Optimization of Three-Dimensional Multirow Turbomachinery Configurations. J. Turbomach. 2018, 140, 081006. [Google Scholar] [CrossRef]

- Yi, J.; Capone, L. Adjoint-Based Sensitivity Analysis for Unsteady Bladerow Interaction Using Space–Time Gradient Method. J. Turbomach. 2017, 139, 111008. [Google Scholar] [CrossRef]

- Rubino, A.; Vitale, S.; Colonna, P.; Pini, M. Fully-Turbulent Adjoint Method for the Unsteady Shape Optimization of Multi-row Turbomachinery. Aerosp. Sci. Technol. 2020, 13, 106–132. [Google Scholar] [CrossRef]

- Verstraete, T.; Mueller, L. Adjoint-Based Multi-Point and Multi-Objective Optimization of a Turbocharger Radial Turbine. Int. J. Turbomach. Propuls. Power 2019, 4, 10. [Google Scholar]

- He, L.; Wang, D. Concurrent Blade Aerodynamic-Aero-elastic Design Optimization Using Adjoint Method. J. Turbomach. 2010, 133, 011021. [Google Scholar] [CrossRef]

- Jameson, A. Aerodynamic Design via Control Theory. J. Sci. Comput. 1988, 3, 120–143. [Google Scholar] [CrossRef]

- Li, W.; Tian, Y.; Yi, W.; Ji, L.; Shao, W.; Xiao, Y. Study on Adjoint-Based Optimization Method for Multi-stage Turbomachinery. J. Therm. Sci. 2011, 20, 398–405. [Google Scholar] [CrossRef]

- Wather, B.; Nadarajah, S. Constrained Adjoint-Based Aerodynamic Shape Optimization of a Single-Stage Transonic Compressor. J. Turbomach. 2013, 153, 021017. [Google Scholar] [CrossRef]

- Ma, C.; Su, X.; Yuan, X. An Efficient Unsteady Adjoint Optimization System for Multistage Turbomachinery. J. Turbomach. 2017, 139, 011003. [Google Scholar] [CrossRef]

- Huang, H.; Ekici, K. A Discrete Adjoint Harmonic Balance Method for Turbomachinery Shape Optimization. Aerosp. Sci. Technol. 2014, 39, 481–490. [Google Scholar] [CrossRef]

- Xu, S.; Radfor, D.; Meyer, M.; Muller, J. Stabilisation of Discrete Steady Adjoint Solvers. J. Comput. Phys. 2015, 299, 175–195. [Google Scholar] [CrossRef]

- Jameson, A. A Perspective on Computational Algorithms for Aerodynamic Analysis and Design. Prog. Aerosp. Sci. 2001, 37, 197–243. [Google Scholar] [CrossRef]

- Forth, S. An Efficient Overloaded Implementation of Forward Mode Automatic Differentiation in MATLAB. ACM Trans. Math. Softw. 2006, 32, 195–222. [Google Scholar] [CrossRef]

- Hascoet, L.; Pascual, V. The Tapenade Automatic Differentiation Tool: Principle, Model, and Specification. ACM Trans. Math. Softw. Assoc. Comput. Mach. 2013, 39, 00913983f. [Google Scholar] [CrossRef]

- Muller, J.; Cusdin, P. On the Performance of Discrete Adjoint CFD Codes Using Automatic Differentiation. Int. J. Numer. Methods Fluids 2005, 47, 939–945. [Google Scholar] [CrossRef]

- Wu, H.; Xu, S.; Huang, X.; Wang, D. The Development and Verification of A Fully Turbulent Discrete Adjoint Solver Using Algorithmic Differentiation. In Proceedings of the Turbine Technical Conference and Exposition, GT2021-59610, Virtual, 7–11 June 2021. [Google Scholar]

- Giles, M.B.; Duta, M.C.; Muller, J.D.; Pierce, N.A. Algorithm Developments for Discrete Adjoint Methods. AIAA J. 2003, 41, 939–945. [Google Scholar] [CrossRef]

- Mader, C.A.; Martins, J.R.; Alonso, J.J.; Van Der Weide, E. Adjoint: An Approach for the Rapid Development of Discrete Adjoint Solvers. AIAA J. 2003, 46, 863–873. [Google Scholar] [CrossRef]

- Reid, L.; Moore, R.D. Performance of Single-Stage Axial-Flow Transonic Compressor with Rotor and Stator Aspect Ratios of 1.19 and 1.26, Respectively, and with Design Pressure Ratio of 1.82; NASA Technical Report 1338; National Aeronautics and Space Administration, Scientific and Technical Information Office: Hampton, VA, USA, 1978. [Google Scholar]

- Walraevens, R.E.; Gallus, H.E.; Jung, A.R.; Mayer, J.F.; Stetter, H. Experimental and Computational Study of the Unsteady Flow in a 1.5 Stage Axial Turbine with Emphasis on the Secondary Flow in the Second Stator. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Glasgow, UK, 14–18 June 1998. [Google Scholar]

- Wang, D. An Improved Mixing-Plane Method for Analyzing Steady Flow through Multiple-Blade-Row Turbomachines. J. Turbomach. 2014, 136, 63–69. [Google Scholar] [CrossRef]

- Huang, X.; Wu, H.; Wang, D. Implicit Solution of Harmonic Balance Equation System Using the LU-SGS Method and One-Step Jacobi/Gauss-Seidel Iteration. Int. J. Comput. Fluid Dyn. 2018, 32, 218–232. [Google Scholar] [CrossRef]

- Spalart, P.; Allmaras, S. A One-Equation Turbulence Model for Aerodynamic Flows. AIAA J. 1994, 94, 1–22. [Google Scholar]

- Jameson, A.; Schmidt, W.; Turkel, E. Numerical Solution of the Euler Equations by Finite Volume Methods Using Runge-Kutta Time Stepping Schemes. In Proceedings of the AIAA Paper 81-1259, Palo Alto, CA, USA, 23–25 June 1984. [Google Scholar]

- Celils, I.; Ghia, U.; Roache, P.; Freitas, C.; Coleman, H.; Raad, P. Procedure for Estimation and Reporting of Uncertainty Due to Discretization in CFD Applications. J. Fluids Eng. 2008, 130, 078001. [Google Scholar]

- Hicks, R.; Henne, P. Wing Design by Numerical Optimization. J. Aircr. 1977, 15, 407–415. [Google Scholar] [CrossRef]

| Axial | Circumferential | Radial | Total | ||

|---|---|---|---|---|---|

| Row 1 | Grid1 | 133 | 37 | 57 | ∼280 k |

| Grid2 | 149 | 57 | 73 | ∼620 k | |

| Grid3 | 161 | 85 | 89 | ∼1218 k | |

| Row 2 | Grid1 | 145 | 33 | 57 | ∼273 k |

| Grid2 | 161 | 49 | 61 | ∼481 k | |

| Grid3 | 169 | 61 | 81 | ∼835 k |

| Flow | Original ADJ | Hybrid ADJ | |

|---|---|---|---|

| time | 1 | 6.16 | 3.49 (−43%) |

| memory | 1 | 2.52 | 2.29 (−9%) |

| m(kg/s) | ||||

|---|---|---|---|---|

| choke | original | 21.02 | 1.745 | 83.35 |

| optimized | 21.05 (+0.14%) | 1.745 (0%) | 84.00 (+0.65) | |

| peak | original | 20.97 | 1.835 | 83.91 |

| optimized | 21.00 (+0.14%) | 1.835 (0%) | 84.73 (+0.82) | |

| stall | original | 20.60 | 1.924 | 82.19 |

| optimized | 20.55 (−0.24%) | 1.922 (−0.10%) | 82.67 (+0.48) |

| Flow | Original ADJ | Hybrid ADJ | |

|---|---|---|---|

| time | 1 | 6.16 | 3.43 (−44%) |

| memory | 1 | 1.94 | 1.77 (−9.6%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Da, X.; Wang, D.; Huang, X. Multi-Row Turbomachinery Aerodynamic Design Optimization by an Efficient and Accurate Discrete Adjoint Solver. Aerospace 2023, 10, 106. https://doi.org/10.3390/aerospace10020106

Wu H, Da X, Wang D, Huang X. Multi-Row Turbomachinery Aerodynamic Design Optimization by an Efficient and Accurate Discrete Adjoint Solver. Aerospace. 2023; 10(2):106. https://doi.org/10.3390/aerospace10020106

Chicago/Turabian StyleWu, Hangkong, Xuanlong Da, Dingxi Wang, and Xiuquan Huang. 2023. "Multi-Row Turbomachinery Aerodynamic Design Optimization by an Efficient and Accurate Discrete Adjoint Solver" Aerospace 10, no. 2: 106. https://doi.org/10.3390/aerospace10020106

APA StyleWu, H., Da, X., Wang, D., & Huang, X. (2023). Multi-Row Turbomachinery Aerodynamic Design Optimization by an Efficient and Accurate Discrete Adjoint Solver. Aerospace, 10(2), 106. https://doi.org/10.3390/aerospace10020106