A Non-Contact AI-Based Approach to Multi-Failure Detection in Avionic Systems

Abstract

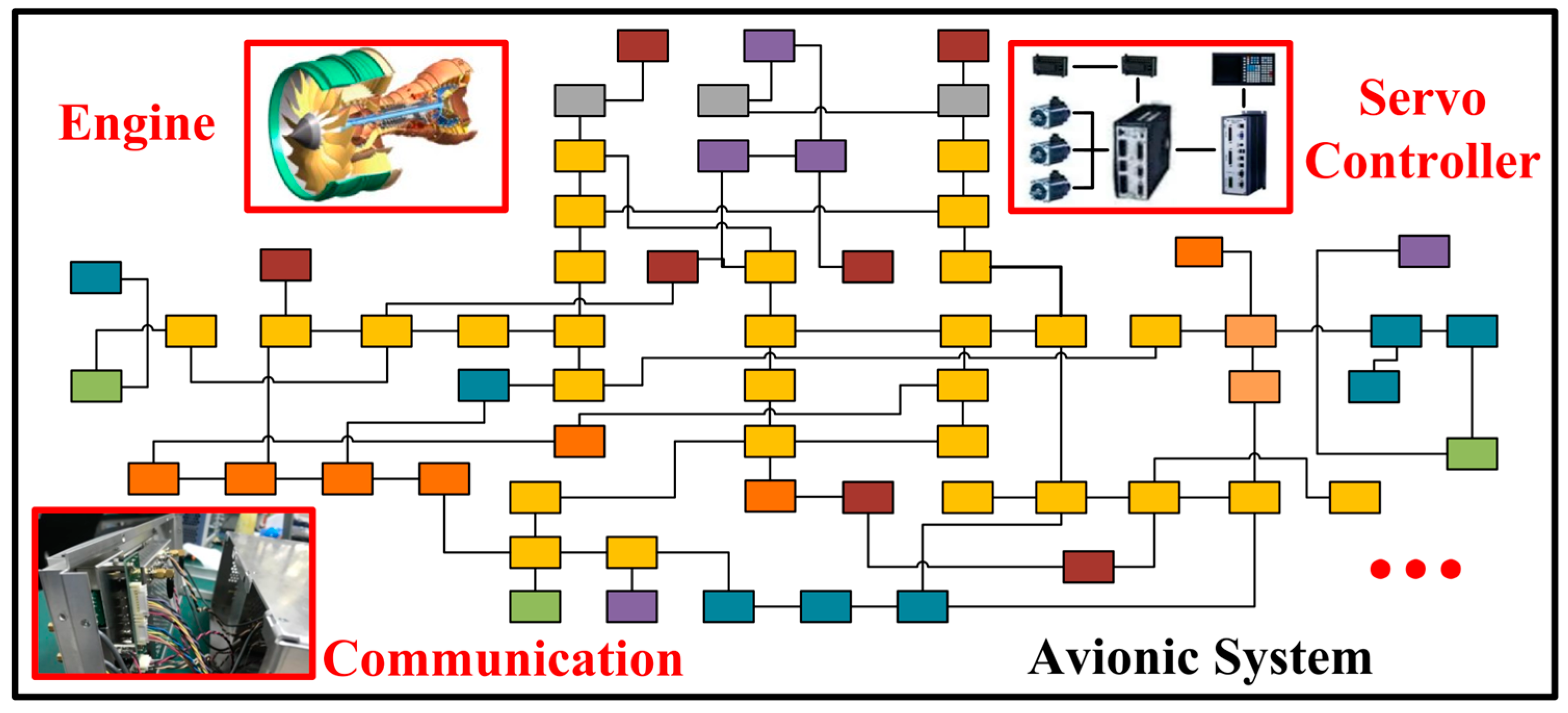

:1. Introduction

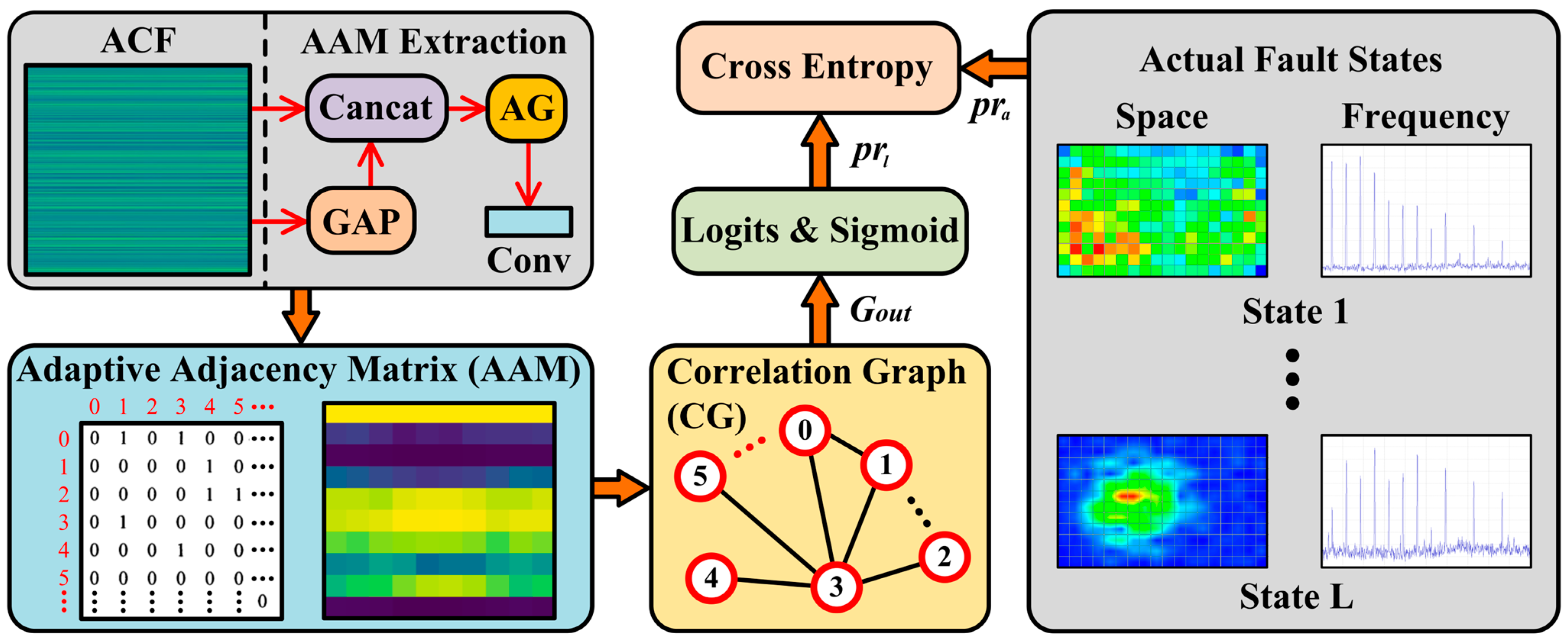

2. Scalar Magnetic Field Feature Extraction Method

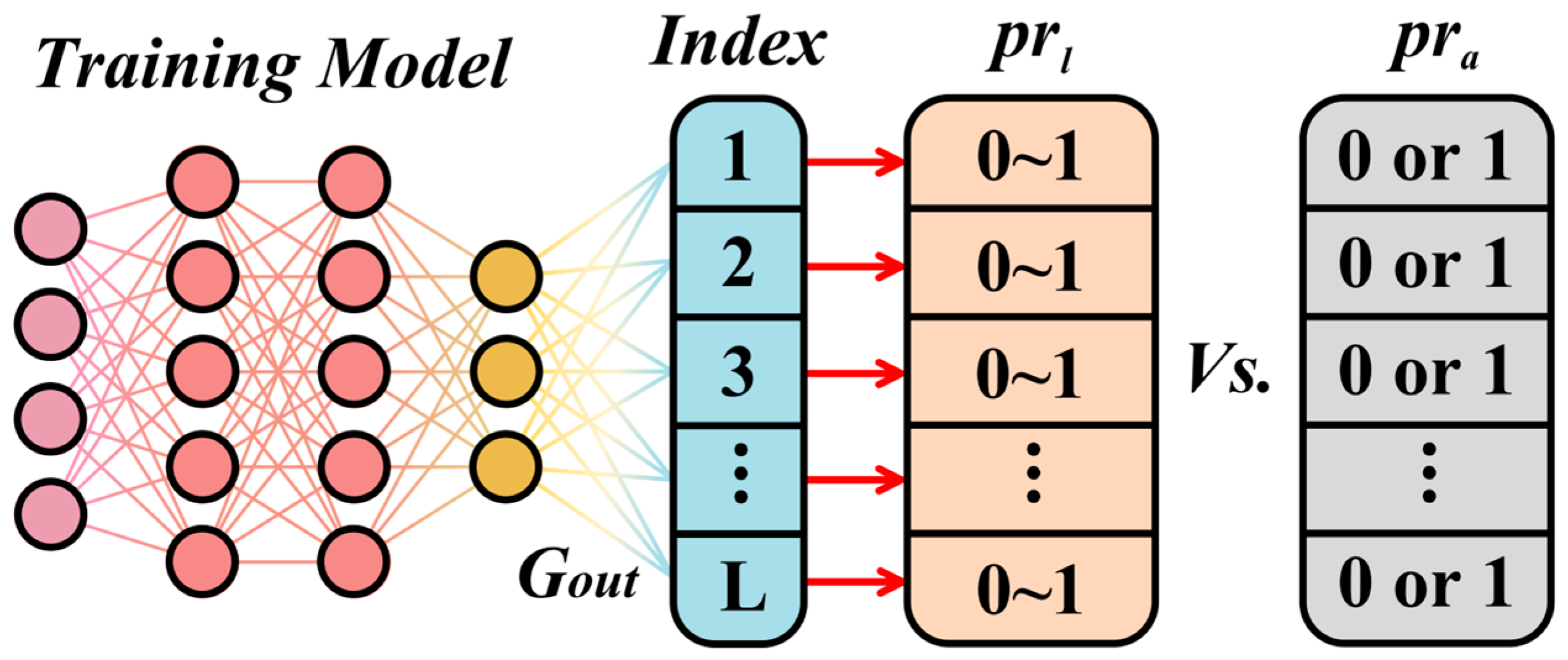

3. Multi-Failure Diagnosis Network Structure

4. Actual Experimental Verification

4.1. Experimental Design

4.2. Test Platform Construction

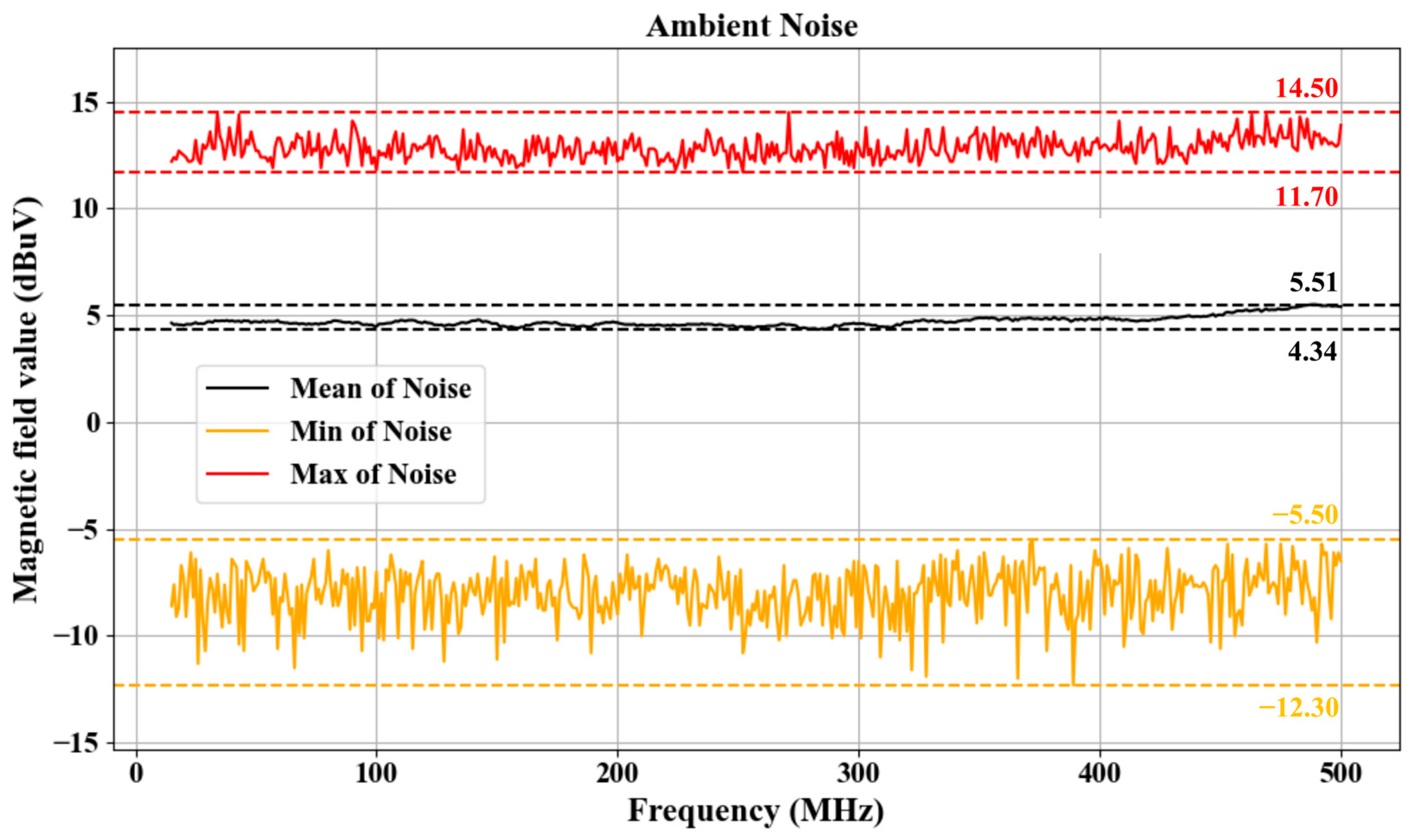

4.3. Experimental Environment Assessment

4.4. Algorithm Setting and Experimental Data Analysis

5. Discussion

5.1. Discussion on the Main Experimental Results of SRA

5.2. Comparison of SRA and Mainstream Diagnostic Methods

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Davis, M.E. Technology Innovation Continues to Drive Aerospace Electronic Systems Development. IEEE Aerosp. Electron. Syst. Mag. 2023, 38, 14–20. [Google Scholar] [CrossRef]

- Zheng, Z.X.; Guo, J.; Gill, E. Onboard Mission Allocation for Multi-Satellite System in Limited Communication Environment. Aerosp. Sci. Technol. 2018, 79, 174–186. [Google Scholar] [CrossRef]

- Xu, J. Research on the role of new electronic information technology in the development of modern avionics equipment. In Proceedings of the 2019 International Conference on Cloud Computing and Information Science, 2019 International Conference on Cloud Computing and Information Science, Shenyang, China, 27–29 December 2019. [Google Scholar]

- Saemi, F.; Benedict, M. Brushless DC Motor Sizing Algorithm for Small UAS Conceptual Designers. Aerospace 2024, 11, 649. [Google Scholar] [CrossRef]

- Reid, S.J.; Perez, R.E.; Jansen, P.W. Hybrid electric aircraft design with optimal power management. Aerosp. Sci. Technol. 2024, 154, 109479. [Google Scholar] [CrossRef]

- Cardone, L.M.; Petrone, G.; Rosa, S.D.; Franco, F.; Greco, C.S. Review of the Recent Developments About the Hybrid Propelled Aircraft. Aerotec. Missili. Spaz. 2024, 103, 17–37. [Google Scholar] [CrossRef]

- Zhang, Q.Y.; Norman, P.; Burt, G. Design Rules to Establish a Credible More-Electric Engine Baseline Power Architecture Concept. IET Electr. Syst. Transp. 2023, 13, e12076. [Google Scholar] [CrossRef]

- Wang, H.L.; Deng, J.Q.; Zhang, L.Y.; Bao, Q.L.; Mao, Y. Enhanced disturbance observer-based hybrid cascade active disturbance rejection control design for high-precise tracking system in application to aerospace satellite. Aerosp. Sci. Technol. 2024, 146, 108939. [Google Scholar] [CrossRef]

- Levchenko, I.; Xu, S.; Teel, G.; Mariotti, D.; Walker, M.L.R.; Keidar, M. Recent progress and perspectives of space electric propulsion systems based on smart nanomaterials. Nat. Commun. 2018, 9, 879. [Google Scholar] [CrossRef]

- Fkirin, M.A.; Khira, M.A.-E. Enhanced Antenna Positioning Control System Using Adapted DC Servo Motor and Fuzzy-PI Controller. IEEE Access 2023, 11, 102661–102668. [Google Scholar] [CrossRef]

- Ren, J.; Ji, X.; Han, L.; Li, J.; Song, S.; Wu, Y. Direct Closed-Loop Control Structure for the Three-Axis Satcom-on-the-Move Antenna. Aerospace 2024, 11, 659. [Google Scholar] [CrossRef]

- Heltzel, S.; Cauwe, M.; Bennett, J.; Rohr, T. Advanced PCB technologies for space and their assessment using up-to-date standards. CEAS Space J. 2023, 15, 89–100. [Google Scholar] [CrossRef]

- Duzellier, S. Radiation effects on electronic devices in space. Aerosp. Sci. Technol. 2005, 9, 93–99. [Google Scholar] [CrossRef]

- Ji, M.M.; Zhi, S.B.; Shi, J.B.; Wu, Q.; Huang, Z.Q.; Xie, P.F. Research on High Reliable Aerospace Secondary Power Supply Based on Resonant Reset Forward Converter. In Proceedings of the 3rd International Conference on Electrical Engineering and Control Technologies, Macau, Macao, 16–18 December 2021; pp. 8–13. [Google Scholar]

- Aliparast, P. Design and implementation of a high efficiency RF power amplifier for S-band telemetry subsystems. Int. J. Electron. Commun. 2016, 70, 1311–1320. [Google Scholar] [CrossRef]

- Chang, D.; Yang, B.; Lv, W.; Huang, J. Research on the Aerospace Mechatronic Servo System’s Digital Production Line Construction. In Proceedings of the 2021 4th World Conference on Mechanical Engineering and Intelligent Manufacturing (WCMEIM), Shanghai, China, 12–14 November 2021; pp. 311–315. [Google Scholar]

- Marcy, H.T. Parallel circuits in servomechanisms. Electr. Eng. 1946, 65, 1128. [Google Scholar] [CrossRef]

- Qian, J.Y.; Liu, M.; Xia, F.; Bai, Y.F.; Ou, D.X.; Kang, J.S. A Multimode Fusion-Based Aviation Communication System. Aerospace 2024, 11, 719. [Google Scholar] [CrossRef]

- Wileman, A.J.; Aslam, S.; Perinpanayagam, S. A road map for reliable power electronics for more electric aircraft. Prog. Aerosp. Sci. 2021, 127, 100739. [Google Scholar] [CrossRef]

- Yamaoka, A.; Hone, T.M.; Yamaguchi, K. 70% Efficient Dual-Input Doherty-Outphasing Power Amplifier for Large PAPR Signals. In Proceedings of the 2019 IEEE MTT-S International Microwave Symposium (IMS), Shanghai, China, 2–7 June 2021; pp. 311–315. [Google Scholar]

- Xie, D.; Lin, C.X.; Deng, Q.L.; Lin, H.J.; Cai, C.S.; Basler, T. Simple Vector Calculation and Constraint-Based Failure-Tolerant Control for a Single-Phase CHBMC. IEEE Trans. Power Electron. 2024, 1–14. [Google Scholar] [CrossRef]

- Jlassi, I.; Cardoso, A.J.M. A Single Method for Multiple IGBT, Current, and Speed Sensor Failures Diagnosis in Regenerative PMSM Drives. IEEE Trans. Emerg. Sel. Top. Power Electron. 2020, 8, 2583–2599. [Google Scholar] [CrossRef]

- Gou, B.; Xu, Y.; Xia, Y.; Deng, Q.; Ge, X. An Online Data-Driven Method for Simultaneous Diagnosis of IGBT and Current Sensor Failure of Three-Phase PWM Inverter in Induction Motor Drives. IEEE Trans. Power Electron. 2020, 35, 13281–13294. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Cloutier, S.G. End-to-end deep learning framework for printed circuit board manufacturing defect classification. Sci. Rep. 2022, 12, 12559. [Google Scholar] [CrossRef]

- Park, J.-H.; Kim, Y.-S.; Seo, H.; Cho, Y.-J. Analysis of Training Deep Learning Models for PCB Defect Detection. Sensors 2023, 23, 2766. [Google Scholar] [CrossRef]

- Wagh, C.R.; Baru, V.B. Detection of Failurey Region on Printed Circuit Board with IR Thermography. Int. J. Sci. Eng. Res. 2013, 4, 1–4. [Google Scholar]

- Huang, W.B.; Wei, P. A PCB Dataset for Defects Detection and Classification. arXiv 2019, arXiv:1901.08204. [Google Scholar] [CrossRef]

- Lei, L.; Li, H.-X.; Yang, H.-D. Multi-scale Convolution-Based Probabilistic Classification for Detecting Bare PCB Defects. IEEE Trans. Instrum. Meas. 2023, 72, 1–8. [Google Scholar] [CrossRef]

- Stoynova, A.; Bonev, B.; Brayanov, N. Thermographic Approach for Reliability Estimation of PCB. In Proceedings of the 2018 41st International Spring Seminar on Electronics Technology (ISSE), Zlatibor, Serbia, 16–20 May 2018; pp. 1–7. [Google Scholar]

- He, W.; He, Y.G.; Li, B. Generative Adversarial Networks with Comprehensive Wavelet Feature for Failure Diagnosis of Analog Circuits. IEEE Trans. Instrum. Meas. 2020, 69, 6640–6650. [Google Scholar] [CrossRef]

- Chen, W.; Chinga, R.A.; Yoshida, S.; Lin, J.; Chen, C.; Lo, W. A 25.6 W 13.56 MHz wireless power transfer system with a 94% efficiency GaN Class-E power amplifier. In Proceedings of the 2012 IEEE/MTT-S International Microwave Symposium Digest, Montreal, QC, Canada, 17–22 June 2012; pp. 1–3. [Google Scholar]

- Marpaung, D.; Yao, J.P.; Capmany, J. Integrated microwave photonics. Nat. Photon 2019, 13, 80–90. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Hori, M.; Noji, H.; Fukuda, G.; Kawasaki, S. The S-band GaN-based high power amplifier and rectenna for space energy transfer applications. In Proceedings of the 2012 IEEE MTT-S International Microwave Workshop Series on Innovative Wireless Power Transmission: Technologies Systems and Applications, Kyoto, Japan, 10–11 May 2012; pp. 271–274. [Google Scholar]

- Li, B.; Lei, M.Z.; Chen, M.; Zhang, L.Y. Electromagnetic Analysis of High-Frequency Digital Signal Processors. SpringerPlus 2016, 5, 1–14. [Google Scholar] [CrossRef]

- Wright, R.G. Spectroscopic electromagnetic analysis approach to non-contact circuit board test and diagnosis. In Proceedings of the 2015 IEEE AUTOTESTCON, National Harbor, MD, USA, 2–5 November 2015; pp. 173–180. [Google Scholar]

- Yu, S.W.; Cheng, J.Q.; Li, Z.C.; Liu, W.W.; Cheng, H.; Tian, J.G.; Chen, S.Q. Electromagnetic wave manipulation based on few-layer metasurfaces and polyatomic metasurfaces. ChemPhysMater 2022, 1, 6–16. [Google Scholar] [CrossRef]

- Spence, H.F. Printed circuit board diagnosis using artificial neural networks and circuit magnetic fields. IEEE Aerosp. Electron. Syst. Mag. 1994, 9, 20–24. [Google Scholar] [CrossRef]

- Yao, Z.; Pan, H. Failure diagnosis using magnetic image of PCB. In Proceedings of the 2012 UKACC International Conference on Control, Cardiff, UK, 3–5 September 2012; pp. 702–707. [Google Scholar]

- Jabbar, A.; Ramzan, R.; Siddiqui, O.; Amin, M.; Tahir, F.A. Wave discrimination at C-band frequencies in microstrip structures inspired by electromagnetically induced transparency. Sci. Rep. 2021, 11, 2983. [Google Scholar] [CrossRef]

- Jia, H.C.; Wan, F.Y.; Cheng, X.; Mordachev, V.; Chen, X.H.; Murad, N.M.; Ravelo, B. Electric near-field scanning for electronic PCB electromagnetic radiation measurement. Measurement 2024, 228, 114355. [Google Scholar] [CrossRef]

- Alaoui, N.E.B.; Boyer, A.; Tounsi, P.; Viard, A. New defect detection approach using near electromagnetic field probing of high density PCBAs. Microelectron. Reliab. 2018, 88–90, 288–293. [Google Scholar] [CrossRef]

- EMSCAN. EMxpert EHX User Manual. 2024. Available online: https://www.emcfastpass.com/test-equipment/wp-content/uploads/2016/10/EMxpert_EHX_User_Manual_v5.0.6.1-10.15.pdf (accessed on 12 October 2024).

- KEYSIGHT. N9010B EXA X-Series Signal Analyzer Multi-Touch. Available online: https://www.keysight.com/us/en/assets/7018-05049/data-sheets/5992-1256.pdf (accessed on 12 October 2024).

- Liu, C.X.; Yuan, H.W.; Lv, J.X.; Wang, Z.W.; Li, J.M.; Xu, H.; Zhou, H. A Calculation Method for Reconstructing Radiation State of PCB Using Known Magnetic Field Amplitude Information. IEEE Trans. Instrum. Meas. 2024, 73, 1–13. [Google Scholar] [CrossRef]

- Kingma, D.P.; Ba, J.L. Adam: A Method for Stochastic Optimization; Computer Science: San Diego, CA, USA, 2015. [Google Scholar]

- Chen, T.S.; Xu, M.X.; Hui, X.L.; Wu, H.F.; Lin, L. Learning Semantic-Specific Graph Representation for Multi-Label Image Recognition. In Proceedings of the 2019 IEEE/CVF International Conference on Computer Vision (ICCV), Seoul, Republic of Korea, 27 October–2 November 2019; pp. 522–531. [Google Scholar]

- Wang, X.W.; Zhao, Y.H.; Wang, Z.H.; Hu, N. An ultrafast and robust structural damage identification framework enabled by an optimized extreme learning machine. Mech. Syst. Signal. Process. 2024, 216, 111509. [Google Scholar] [CrossRef]

- Waikat, J.; Jelidi, A.; Lic, S.; Sopidis, G.; Kähler, O.; Maly, A.; Pestana, J.; Fuhrmann, F.; Belavić, F. First Measurement Campaign by a Multi-Sensor Robot for the Lifecycle Monitoring of Transformers. Energies 2024, 17, 1152. [Google Scholar] [CrossRef]

- Jia, Z.; Wang, S.D.; Zhao, K.; Li, Z.F.; Yang, Q.Q.; Liu, Z.B. An efficient diagnostic strategy for intermittent failures in electronic circuit systems by enhancing and locating local features of failures. Meas. Sci. Technol. 2023, 35, 3. [Google Scholar] [CrossRef]

| State Numbers | The Considered DPAB Statuses | The Involved Jumper Blocks |

|---|---|---|

| 1 | RF input failure | Cut P5 and Cut P17 |

| 2 | DC power failure | Cut P1 or P3 or P7 or P16 or P19 |

| 3 | Input matching failure of PA1 | Cut P8 and Connect (Con) P15 |

| 4 | Output matching failure of PA1 | Cut P12 and Con P14 |

| 5 | Input matching failure of PA2 | Cut P20 and Con P25 |

| 6 | Output matching failure of PA2 | Cut P23 and Con P24 |

| 7 | Load failure of PA1 | Cut P10 and (Con P4 or Con P11) |

| 8 | Load failure of PA2 | Cut P22 and (Con P18 or Con P21) |

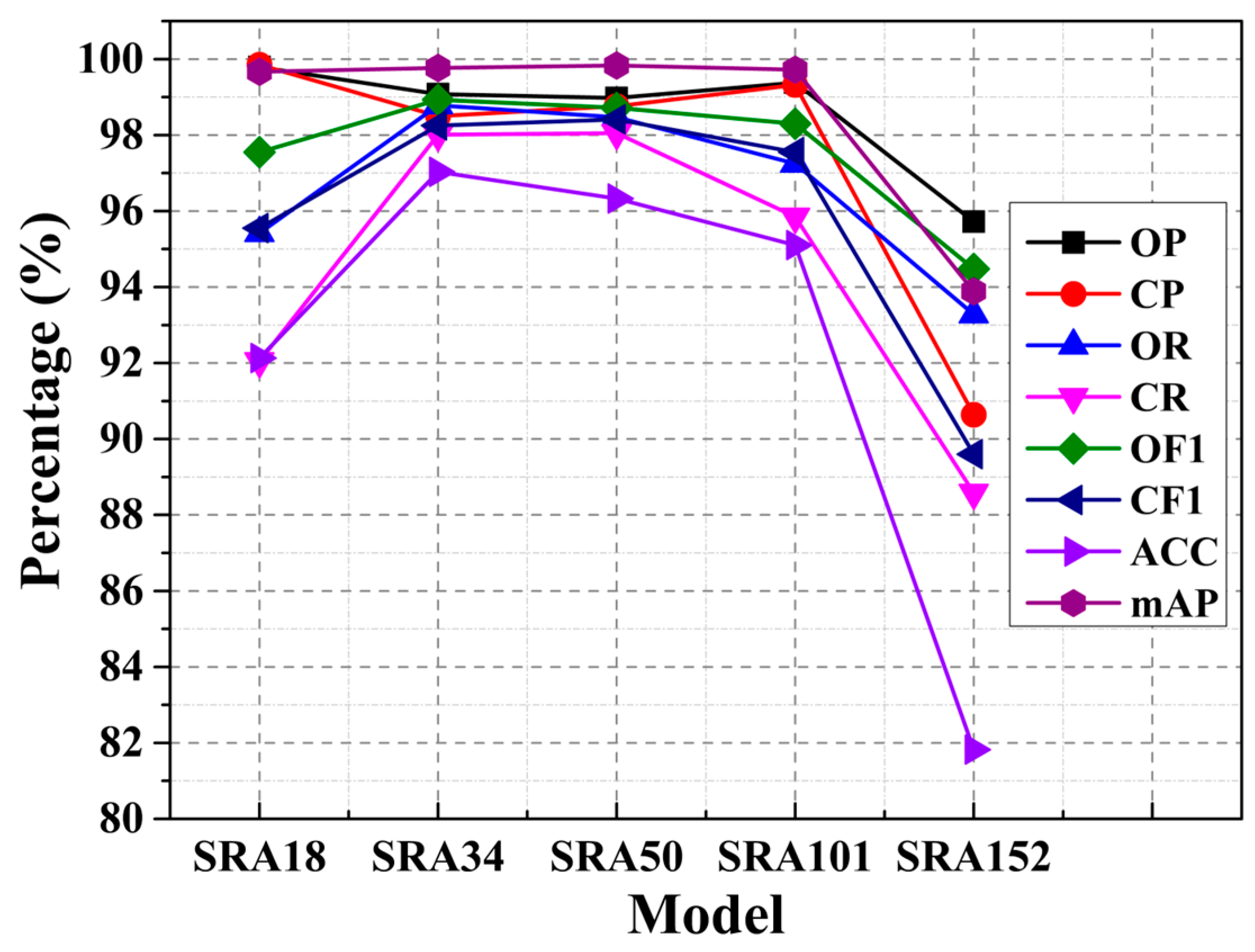

| Model | OP | CP | OR | CR | OF1 | CF1 | ACC | MAP |

|---|---|---|---|---|---|---|---|---|

| SRA18 | 99.79% | 99.85% | 95.42% | 92.05% | 97.55% | 95.55% | 92.13% | 99.67% |

| SRA34 | 99.08% | 98.50% | 98.78% | 98.01% | 98.93% | 98.25% | 97.03% | 99.77% |

| SRA50 | 98.98% | 98.76% | 98.47% | 98.05% | 98.72% | 98.41% | 96.33% | 99.83% |

| SRA101 | 99.38% | 99.32% | 97.25% | 95.85% | 98.30% | 97.55% | 95.10% | 99.72% |

| SRA152 | 95.72% | 90.64% | 93.28% | 88.58% | 94.48% | 89.60% | 81.82% | 93.89% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Ferlauto, M.; Yuan, H. A Non-Contact AI-Based Approach to Multi-Failure Detection in Avionic Systems. Aerospace 2024, 11, 864. https://doi.org/10.3390/aerospace11110864

Liu C, Ferlauto M, Yuan H. A Non-Contact AI-Based Approach to Multi-Failure Detection in Avionic Systems. Aerospace. 2024; 11(11):864. https://doi.org/10.3390/aerospace11110864

Chicago/Turabian StyleLiu, Chengxin, Michele Ferlauto, and Haiwen Yuan. 2024. "A Non-Contact AI-Based Approach to Multi-Failure Detection in Avionic Systems" Aerospace 11, no. 11: 864. https://doi.org/10.3390/aerospace11110864

APA StyleLiu, C., Ferlauto, M., & Yuan, H. (2024). A Non-Contact AI-Based Approach to Multi-Failure Detection in Avionic Systems. Aerospace, 11(11), 864. https://doi.org/10.3390/aerospace11110864