Experimental Study on the Propulsion Performance of Laser Ablation Induced Pulsed Plasma

Abstract

:1. Introduction

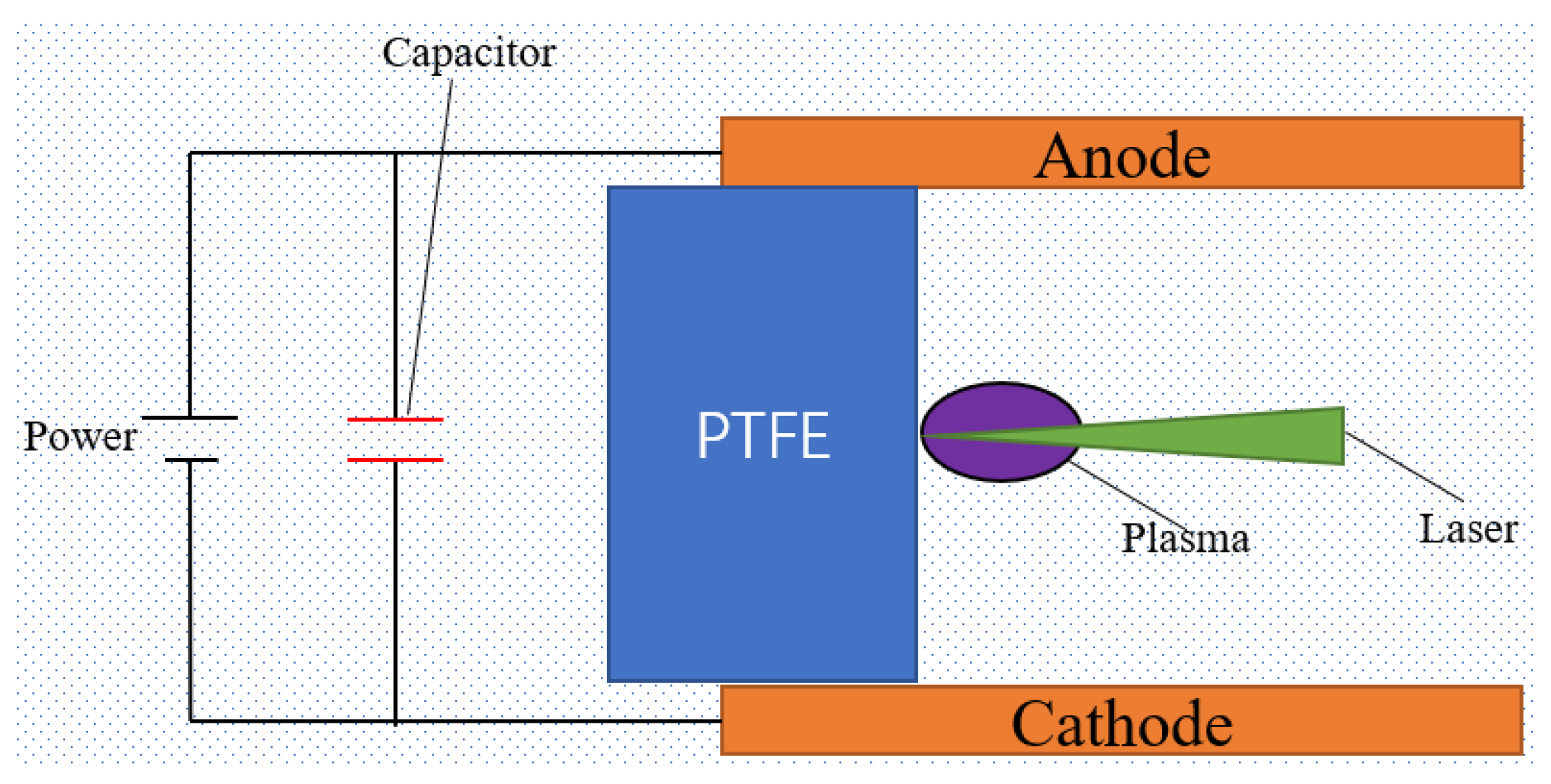

2. Materials and Methods

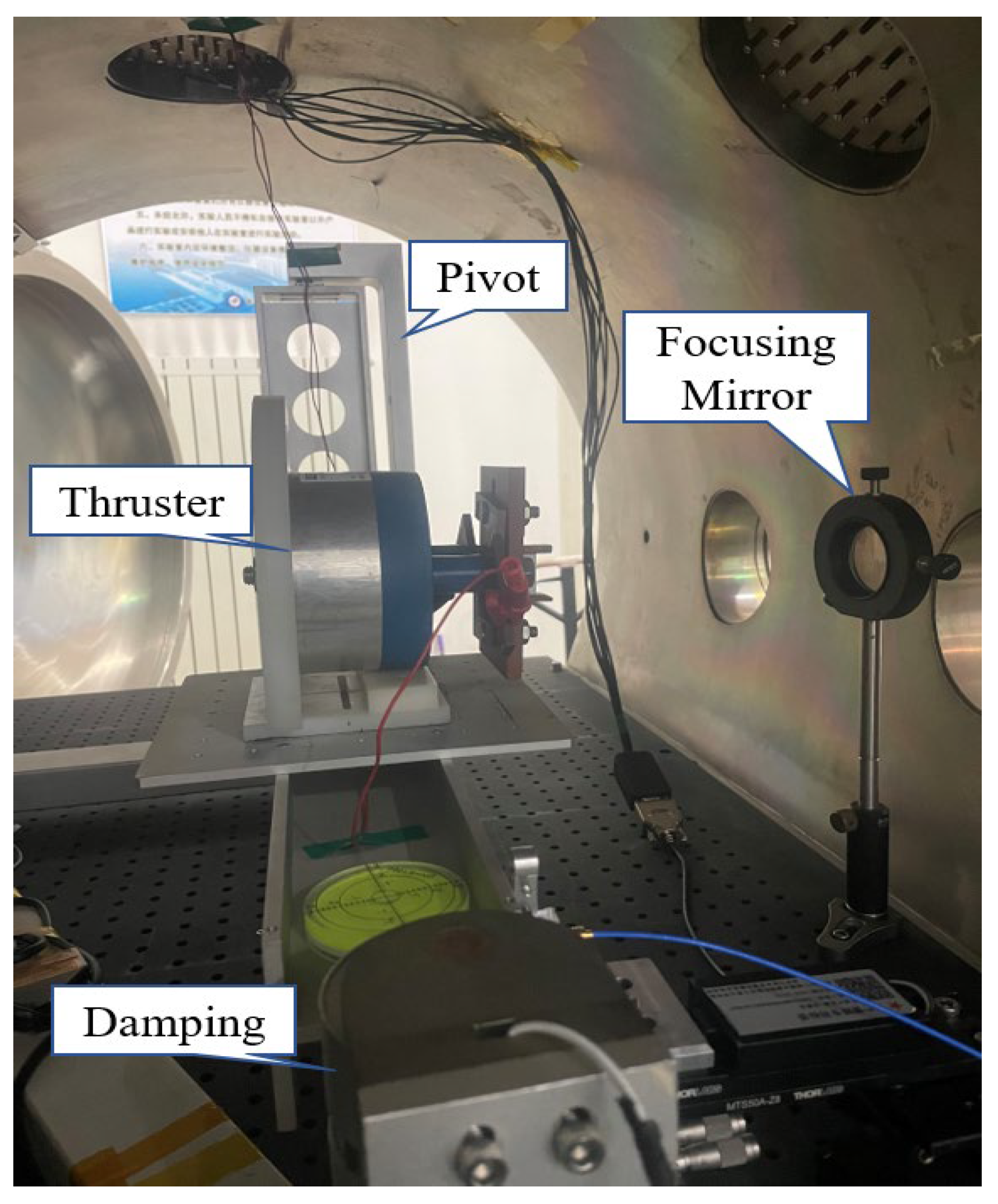

2.1. Experimental Apparatus

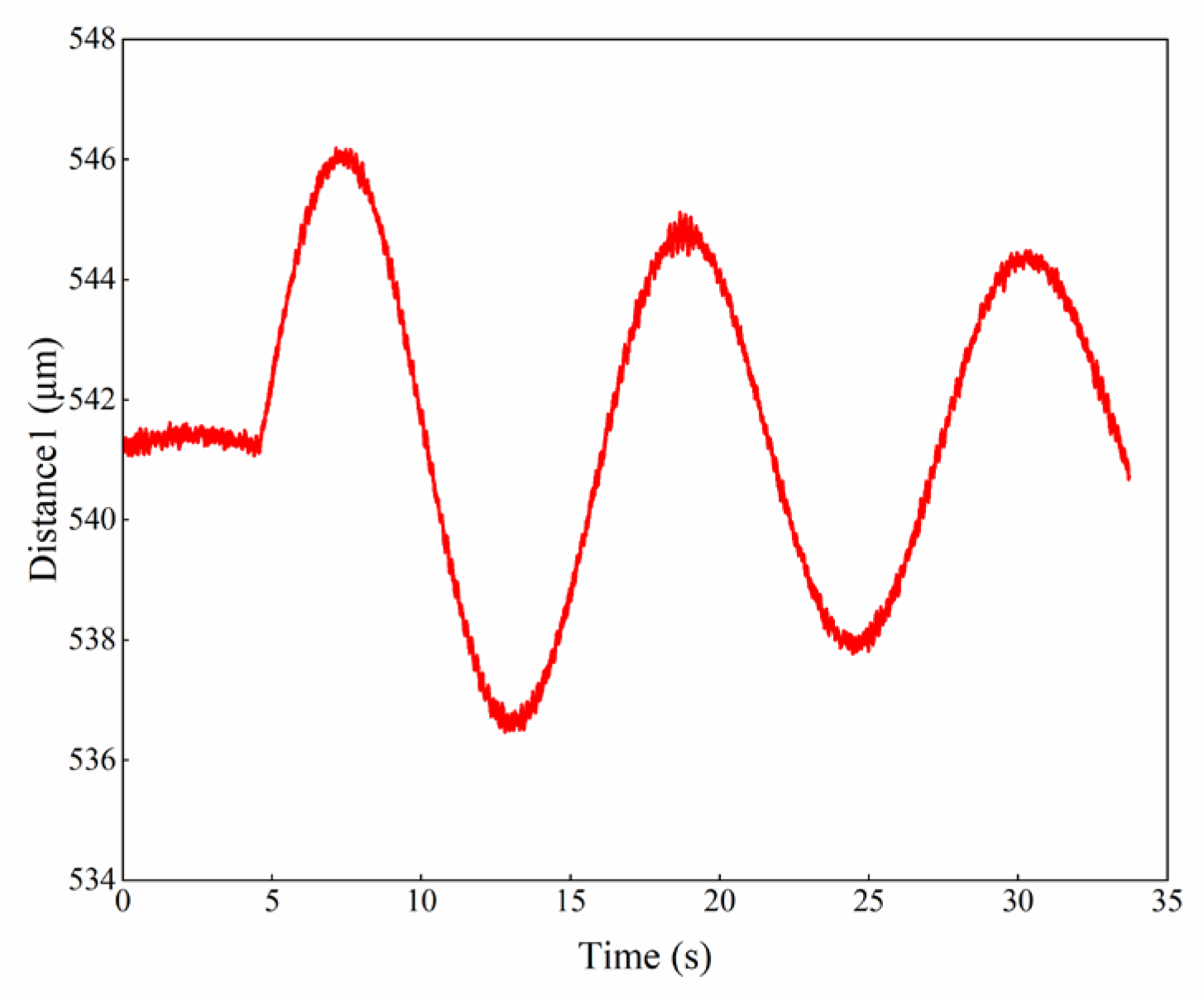

2.2. Measuring Device

2.3. Propulsion Performance Parameter

2.4. Experimental Method

3. Results

3.1. Discharge Characteristic Study

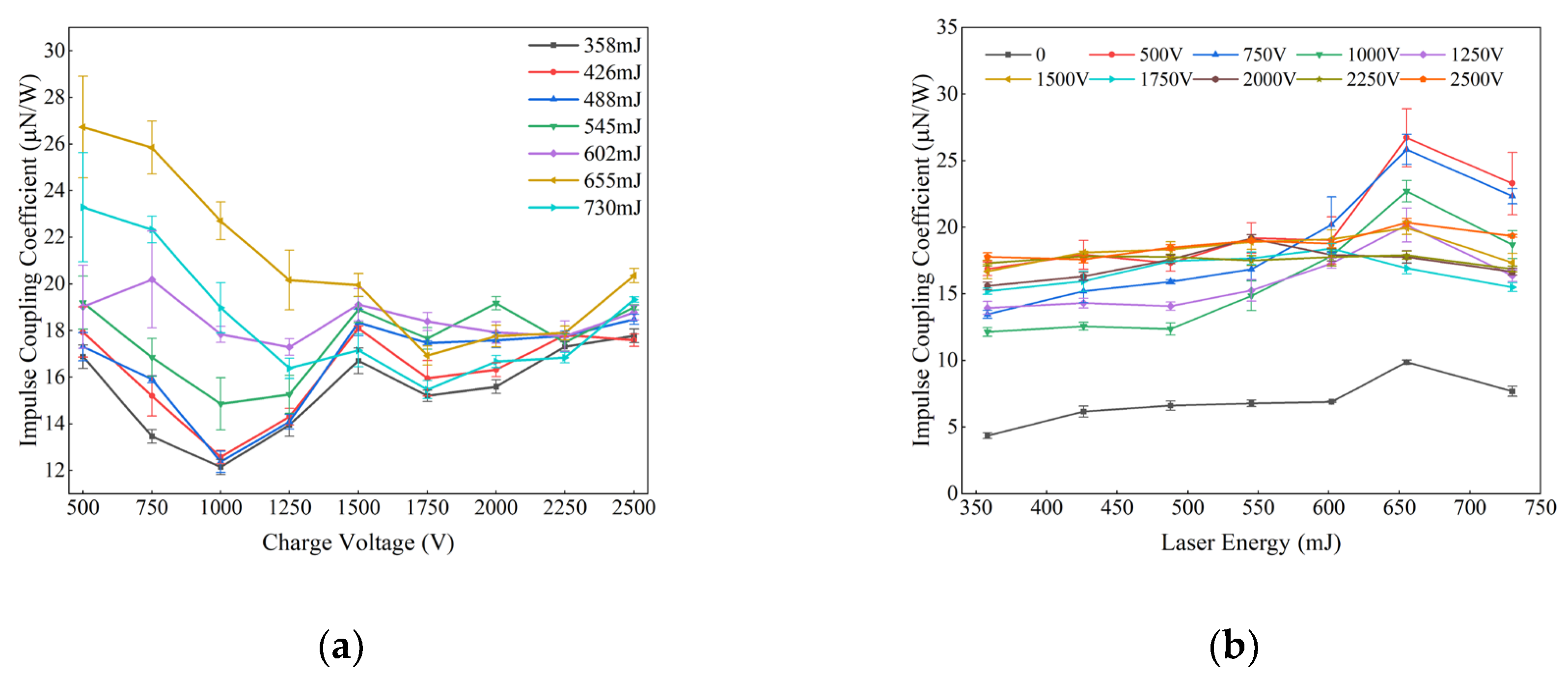

3.2. Propulsion Performance Study

4. Conclusions

- (1)

- The study of discharge characteristics indicates that increasing the charging voltage leads to larger peak discharge currents and longer discharge durations. The laser energy has minimal effects on the discharge characteristics, and the laser only acts as a source to generate the initial plasma.

- (2)

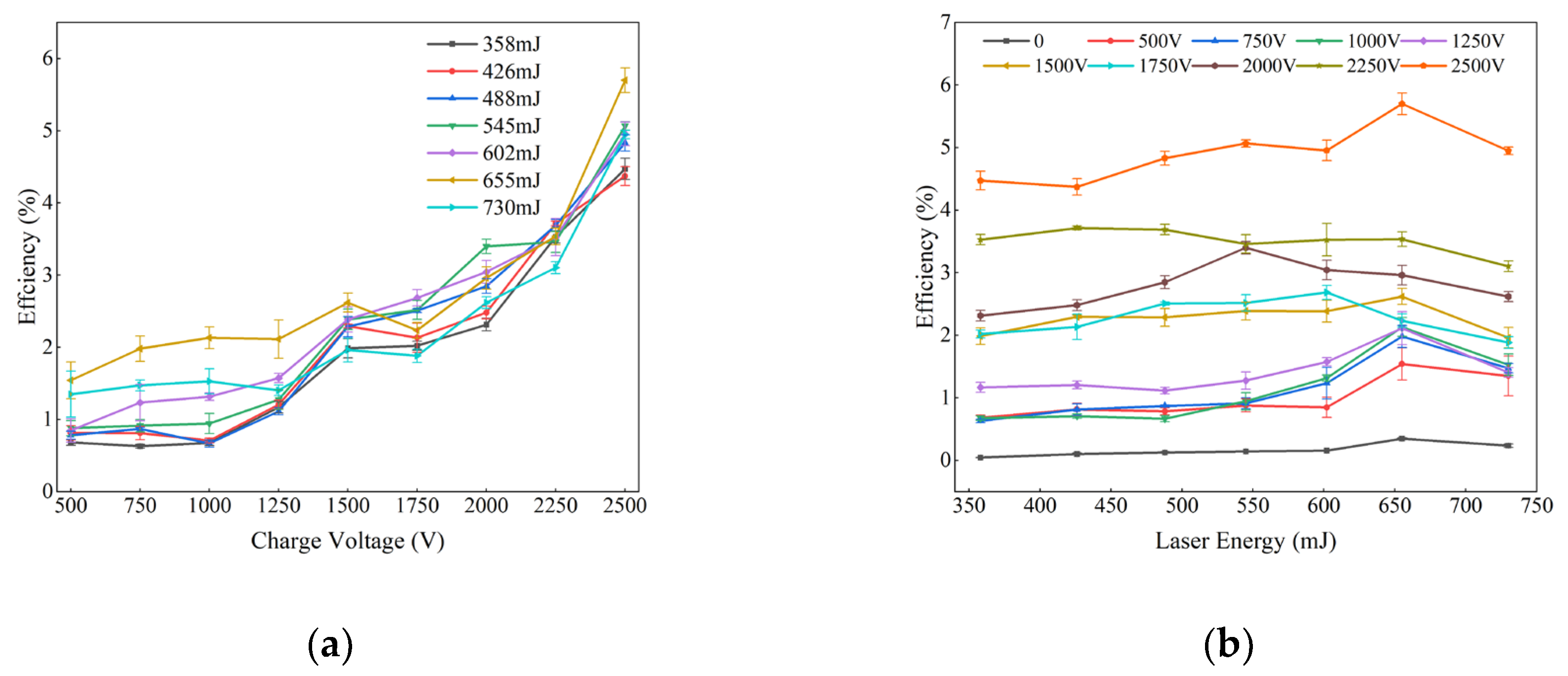

- Through the study of propulsion performance, it is suggested that the size of the electromagnetic field, that is, the charging voltage, significantly improves the propulsion performance of the laser plasma. The higher the voltage, the greater the impulse and specific impulse. When U = 500 V, the maximum impulse is 23.5 μN·s and the maximum specific impulse is 114.1 s. When the charging voltage is increased to U = 2500 V, the maximum impulse is 138.8 μN·s and the maximum specific impulse is 568.9 s, which are increased by 5.9 times and 5 times, respectively.

- (3)

- Laser energy improves the propulsion performance of plasma in the process of electromagnetic field acceleration. However, in general, the laser energy exerts no obvious effect on the propulsion performance compared to the charging voltage. Under the same charging voltage, impulse and specific impulse first increase and then decrease with the rise in laser energy, reaching the maximum advantage when the laser energy is 655 mJ.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Da-Ren, Y.; Lei, Q.; Wen-Jia, J.; Hui, L. Development and Prospect of Electric Propulsion Technology in China. J. Propuls. Technol. 2020, 41, 1. [Google Scholar]

- Sheng, T.; Jian-Jun, W.U.; Yu, Z.; Yu-Qiang, C.; Jian, L.I.; Yang, O.U. Research Progress of Laser-supported Space Micropropulsion Technology. J. Propuls. Technol. 2018, 39, 2415–2428. [Google Scholar]

- Levchenko, I.; Xu, S.; Mazouffre, S.; Lev, D.; Pedrini, D.; Goebel, D.; Garrigues, L.; Taccogna, F.; Bazaka, K. Perspectives, Frontiers, and New Horizons for Plasma-based Space Electric Propulsion. Phys. Plasmas 2020, 27, 020601. [Google Scholar] [CrossRef]

- Rüdenauer, F.G. Field Emission Devices for Space Applications. Surf. Interface Anal. 2007, 39, 116–122. [Google Scholar] [CrossRef]

- Wu, H.; Jiang, Y.; Zhang, Z. Application and Development Trend of Electric Propulsion. J. Propuls. Technol. 2003, 24, 387–394. [Google Scholar]

- Zhang, Y. Current Status and Trend of Electric Propulsion Technology Development and Application. J. Propuls. Technol. 2005, 31, 27–36. [Google Scholar]

- Berkery, J.; Choueiri, E. Laser Discharge Initiation for Gas-Fed Pulsed Plasma Thrusters. In Proceedings of the 37th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Salt Lake City, UT, USA, 8–11 July 2001; p. 3897. [Google Scholar]

- Furukawa, T.; Takizawa, K.; Kuwahara, D.; Shinohara, S. Study on Electromagnetic Plasma Propulsion Using Rotating Magnetic Field Acceleration Scheme. Phys. Plasmas 2017, 24, 043505. [Google Scholar] [CrossRef]

- Horisawa, H.; Kimura, I. Characterization of Novel Laser Particle Accelerators for Space Propulsion. In Proceedings of the 36th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Las Vegas, NV, USA, 24–28 July 2000; p. 3487. [Google Scholar]

- Horisawa, H.; Kimura, I. Fundamental Study on Laser Plasma Accelerator for Propulsion Applications. Vacuum 2002, 65, 389–396. [Google Scholar] [CrossRef]

- Horisawa, H.; Kawakami, M.; Igari, A.; Kimura, I. Discharge Characteristics of Laser-Electric Hybrid Thrusters. In Proceedings of the 37th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Fort Lauderdale, FL, USA, 20–24 June 2004; p. 3937. [Google Scholar]

- Horisawa, H.; Igari, A.; Uchida, Y.; Kino, S.; Kimura, I. Electrostatic Acceleration Mode of Laser-Electric Hybrid Thruster. In Proceedings of the 37th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Tucson, AZ, USA, 10–13 July 2005; p. 3697. [Google Scholar]

- Ayabe, T.; Horisawa, H.; Funaki, I.; Kimura, I. Rectangular Laser-Electromagnetic Hybrid Pulsed Plasma Thruster. In Proceedings of the 30th International Electric Propulsion Conference, Florence, Italy, 17–20 September 2007; p. 58. [Google Scholar]

- Shinohara, T.; Horisawa, H.; Baba, M.; Tei, K. High Specific Impulse Mode of Pulsed Laser Electromagnetic Hybrid Accelerator for Space Propulsion Applications. In Proceedings of the AIP Conference, Santa Fe, NM, USA, 18–22 April 2010; Volume 1278, pp. 191–199. [Google Scholar]

- Kobayashi, H.; Horisawa, H.; Funaki, I. A Plasma Behavior Analysis of a Laser-Assisted Pulsed Plasma Thruster. In Proceedings of the 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Atlanta, GA, USA; 2012; p. 4281. [Google Scholar]

- Hosokawa, H.; Yamada, O.; Kobayashi, H.; Horisawa, H. Characterization and Improvement of a Laser-Assisted Pulsed Plasma Thruster. Aerospace 2014, 12, 25–29. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, D.; Wu, J.; He, Z.; Zhang, H. A Novel Laser Ablation Plasma Thruster with Electromagnetic Acceleration. Acta Astronaut. 2016, 127, 438–447. [Google Scholar] [CrossRef]

- Tan, S.; Wang, M.; Wu, J.; Zhang, Y.; Li, J. A Study on the Plasma Plume Expansion Dynamics of Nanosecond Laser Ablating Al/PTFE. Energies 2020, 13, 3321. [Google Scholar] [CrossRef]

- Duan, B.; Zhang, H.; Hua, Z.; Wu, L.; Bao, Z.; Guo, N.; Ye, Y.; Shen, R. Impulse and Electric Charge Characteristics of Chemical Propellant under Pulsed Laser Irradiation. Vacuum 2021, 192, 110419. [Google Scholar] [CrossRef]

- Ou, Y.; Wu, J.; Zhang, Y.; Li, J.; Zhao, Y. Plume Characteristics of Polymeric Material Doped with Different Metal Particles under Pulsed Laser Irradiation. Opt. Laser Technol. 2022, 152, 108132. [Google Scholar] [CrossRef]

- Ou, Y.; Wu, J.; Du, X.; Zhang, H.; He, Z. Experimental Investigation on Characteristics of Pulsed Plasma Thrusters with the Propellant Samples of Modified PTFE filled Si, Al and Al2O3. Vacuum 2019, 165, 163–171. [Google Scholar] [CrossRef]

| System Parameter | Numerical Value |

|---|---|

| Measuring force arm d′ (mm) | 630 |

| Ablation force arm d (mm) | 364 |

| Natural frequency ωn (rad/s) | 0.6107 |

| Damping ratio ζ | 0.1379 |

| Moment of inertia J (kg·m2) | 1.2332 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, H.; Ye, J.; Wen, M.; Cui, H.; Zhao, W. Experimental Study on the Propulsion Performance of Laser Ablation Induced Pulsed Plasma. Aerospace 2024, 11, 1013. https://doi.org/10.3390/aerospace11121013

Song H, Ye J, Wen M, Cui H, Zhao W. Experimental Study on the Propulsion Performance of Laser Ablation Induced Pulsed Plasma. Aerospace. 2024; 11(12):1013. https://doi.org/10.3390/aerospace11121013

Chicago/Turabian StyleSong, Hang, Jifei Ye, Ming Wen, Haichao Cui, and Wentao Zhao. 2024. "Experimental Study on the Propulsion Performance of Laser Ablation Induced Pulsed Plasma" Aerospace 11, no. 12: 1013. https://doi.org/10.3390/aerospace11121013

APA StyleSong, H., Ye, J., Wen, M., Cui, H., & Zhao, W. (2024). Experimental Study on the Propulsion Performance of Laser Ablation Induced Pulsed Plasma. Aerospace, 11(12), 1013. https://doi.org/10.3390/aerospace11121013