A Simple Method for Identifying the Natural Frequency of a Micro Satellite with a Primary Structure Made of Aluminum Alloy

Abstract

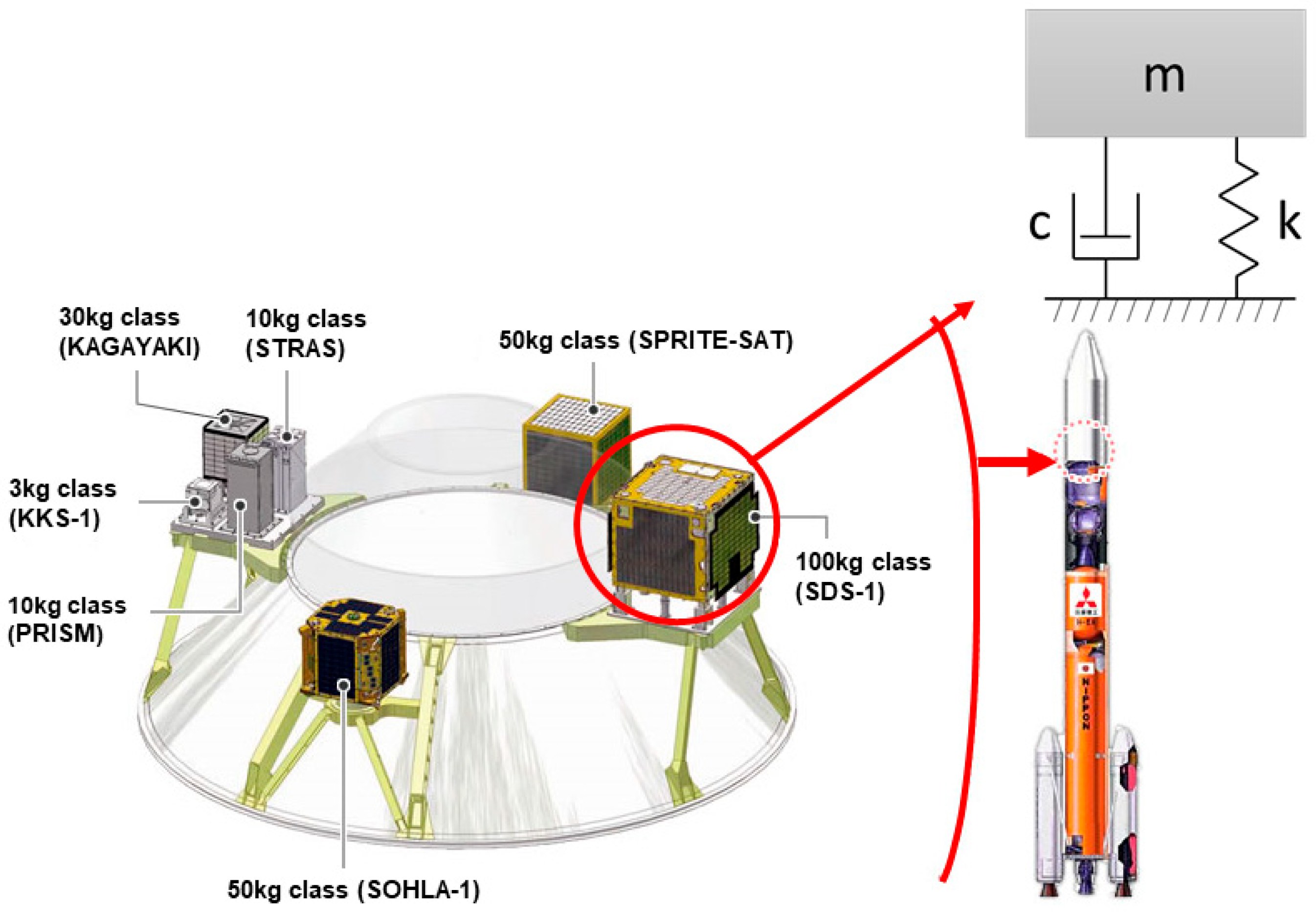

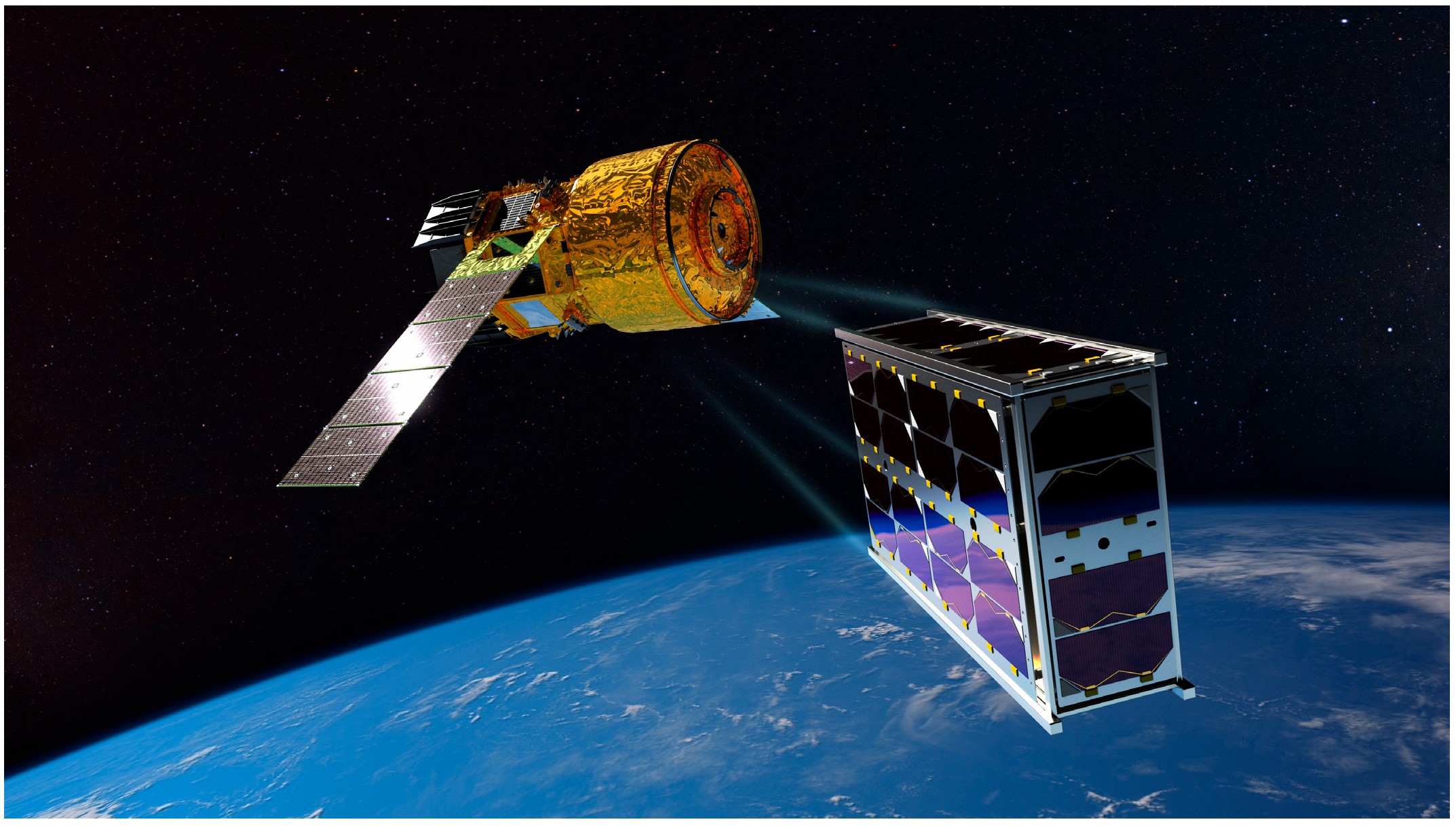

:1. Introduction

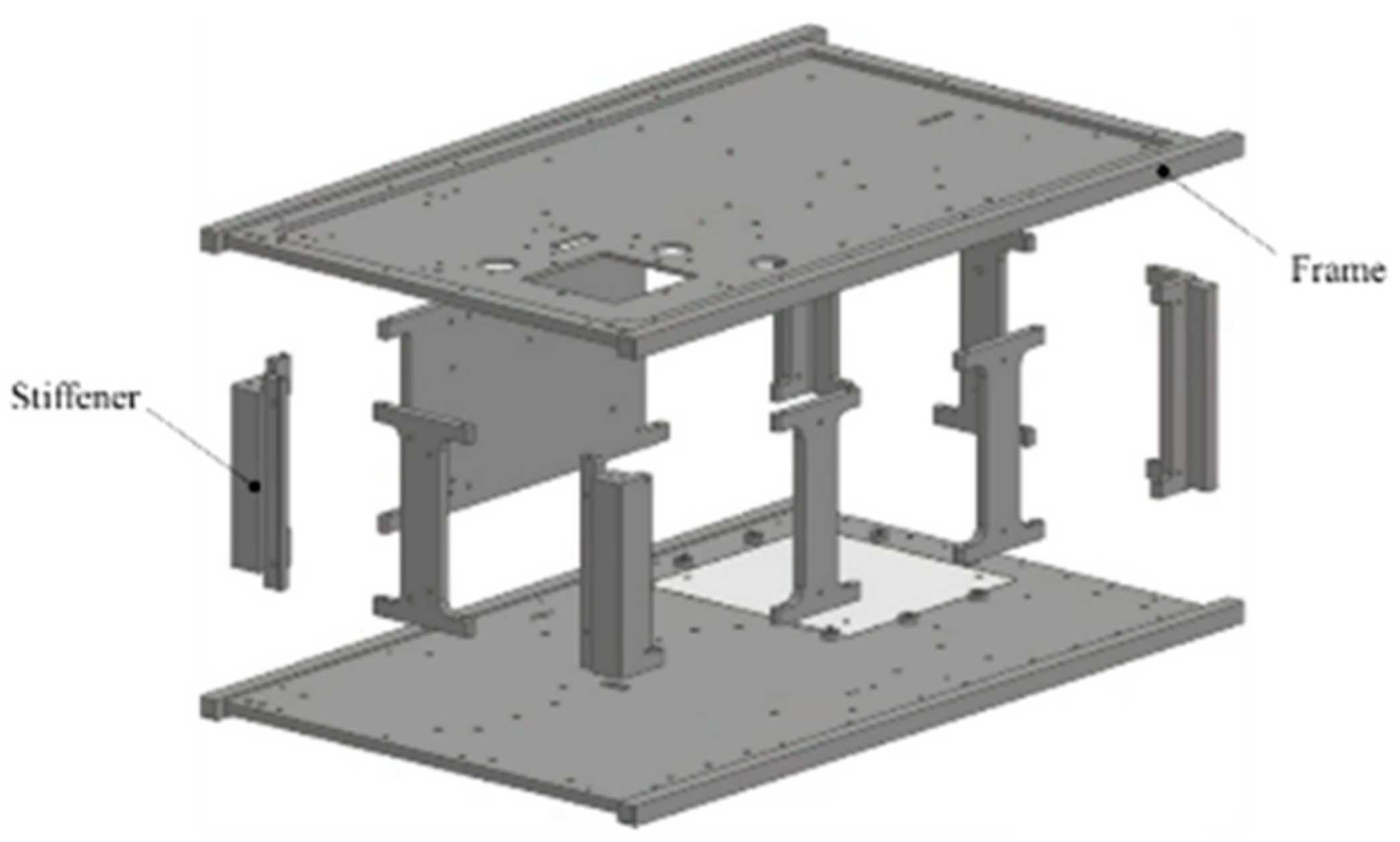

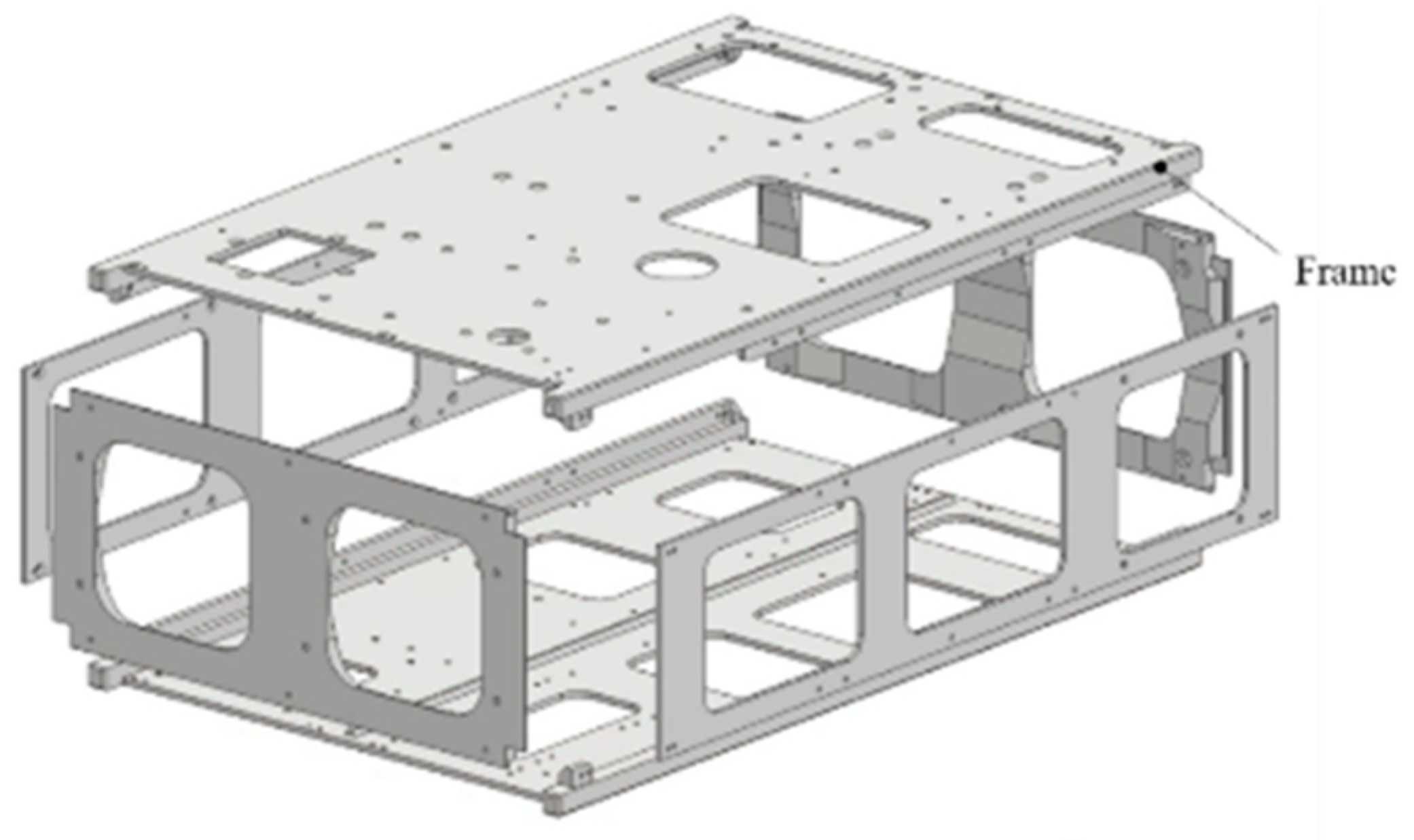

2. A Simple Method for Identifying the Minimum Natural Frequency for Micro Satellites

3. Experimental Verification of the Validity of a Simple Identification Method for the Minimum Natural Frequency

4. Vibration Test Results and Discussions

4.1. Natural Frequencies of Micro Satellites in Longitudinal Direction

4.2. Natural Frequencies of Micro Satellites in Lateral Direction

5. Conclusions

- The W6U-type micro satellites used in this study are the Ten-Koh 2(TK2)’FM and the Ten-Koh D(TKD)’s EM, both of which have monocoque aluminum alloy structures. The W6U-type dummy satellite made entirely of aluminum alloy was also used. Five micro satellites with a mass of approximately 50 kg were also used in this study.

- In this study, the minimum natural frequency identification method for micro satellites in the launch direction (the longitudinal direction) and its orthogonal direction (the lateral direction) were clearly made using Equations (4) and (10). The n value in Equation (10) is a coefficient for identifying the natural frequency.

- When the method proposed in this study is used, the calculated values agree with the vibration-tested values within approximately 10%. In particular, in the case of W6U-type satellites, the two agree within a range of approximately 2% in the longitudinal direction and approximately 5% in the lateral direction. In the early stage of a satellite structure design when a FEM cannot be created, the proposed method will work effectively as the method of determining the minimum natural frequency.

- In this study, 2, 3, 8, and 11 were used as the n values in Equation (10). These n values were thought to be related to the load acting on a fixedly supported cantilever beam, but the details are unknown. This is an important research issue that needs to be solved in the future.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- JERG-2-320A; Structural Design Standard. Japan Aerospace Exploration Agency: Tokyo, Japan, 2011. (In Japanese)

- JERG-4-011A; User’s Manual of H-IIA Rocket. Japan Aerospace Exploration Agency: Tokyo, Japan, 2015. (In Japanese)

- Okuyama, K.I.; Hibino, S.; Matsuoka, M.; Bendoukha, S.A.; Lidtke, A. A Modification of an Estimation Method of the Natural Frequency of a Cubic Form Micro Satellite. Int. J. Res. Granthaalayah 2018, 7, 121–131. [Google Scholar] [CrossRef]

- Wijker, J.J. Spacecraft Structures, 2008th ed.; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Sarafin, T.P.; Larson, W.J. Spacecraft Structures and Mechanisms: From Concept to Launch, 1995th ed.; Springer: Berlin/Heidelberg, Germany, 1995. [Google Scholar]

- Farley, R. Spacecraft Configuration Structural Design-Preliminary Design Methods, Satellite Design Course Material (ENAE691); Department of Aerospace Engineering, University of Maryland, NASA/GSFC: College Park, MD, USA, 2003. [Google Scholar]

- Calvi, A. Spacecraft Loads Analysis-An Overview, Satellite Engineering Class Material; Aerospace and Mechanical Engineering; University of Liege, ESA/ESTEC: Liège, Belgium, 2011. [Google Scholar]

- Ito, N.; Sasaki, H. Development Status of New Space Station Transfer Vehicle (HTV-X), Council for Science and Technology, Research Planning and Evaluation Subcommittee, Space Development and Utilization Subcommittee; Ministry of Education, Culture, Sports, Science and Technology: Tokyo, Japan, 2021. (In Japanese) [Google Scholar]

- Okuyama, K.-I. Rafael Armando RODRIGUEZ LEON, Isai FAJARDO TAPIA and Ten-Koh 2 Team, Completion of the Development of Ten-Koh 2 Spacecraft. In Proceedings of the 33th International Symposium on Space Technology and Science, Kurume, Japan, 3–9 June 2024. [Google Scholar]

- Kuroiwa, F.; Okuyama, K.I.; Nishio, M.; Morita, H.; Szasz, B.A.; Bendoukha, S.A.; Saganti, P.; Holland, D. A Design Method of an Autonomous Control System for a Deep-Space Probe. Trans. JSASS Aeronaut. Space Sci. JSASS Aerosp. Tech Jpn. 2016, 14, Pf_105–Pf_112. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez-Llorente, J.; Lidtke, A.A.; Hatanaka, K.; Kawauchi, R.; Okuyama, K.I. Solar Module Integrated Converters as Power Generator in Small Spacecrafts: Design and Verification Approach. Aerospace 2019, 6, 61. [Google Scholar] [CrossRef]

- Fajardo, I.; Lidtke, A.A.; Bendoukha, S.A.; Gonzalez-Llorente, J.; Rodríguez, R.; Morales, R.; Faizullin, D.; Matsuoka, M.; Urakami, N.; Kawauchi, R.; et al. Design, Implementation, and Operation of a Small Satellite Mission to Explore the Space Weather Effects in Leo. Aerospace 2019, 6, 108. [Google Scholar] [CrossRef]

- ISO 17025; General Requirements for the Competence of Testing and Calibrating Laboratories. International Organization for Standardization: Geneva, Switzerland, 2015.

| Specimen Name | Aluminum Alloy | Length with Rail ×10−3 [m] | Length without Rail ×10−3 [m] | Mass [kg] | Shell Thickness ×10−3 [m] | Cross-Sectional Area ×10−3 [m2] | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Young’s Modulus [GPa] | Density [kg/m3] | L | h | b | L | h | b | Whole Satellite | Structural Subsystem | Alateral | As | ||

| Dummy satellite | 72 | 2750 | 366 | 226 | 100 | 355 | 215 | 100 | 14.1 | 14.1 | 22.9 | 22.6 | 14.4 |

| TK2’FM | 72 | 2750 | 366 | 226 | 100 | 355 | 215 | 100 | 6.83 | 2.25 | 3.65 | 22.6 | 2.30 |

| TKD’EM | 72 | 2750 | 366 | 226 | 100 | 355 | 215 | 100 | 7.89 | 2.25 | 3.65 | 22.6 | 2.30 |

| Specimen Name | Length without Rail ×10−3 [m] | Mass [kg] | Shell Thickness ×10−3 [m] | Cross-Sectional Area ×10−3 [m2] | Young’s Modulus [GPa] | Minimum Longitudinal Natural Frequency [Hz] | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Llongitudinal | h | b | Whole Satellite | Structural Subsystem | t | Alateral | As | Es | Calculated Value | Measured Value | |

| Dummy satellite | 355 | 215 | 100 | 14.1 | 14.1 | 22.9 | 22.6 | 14.4 | 48 | 1880 | 1927 |

| TK2’FM | 355 | 215 | 100 | 6.83 | 2.25 | 3.65 | 22.6 | 2.35 | 7.7 | 430 | 440 |

| TKD’EM | 355 | 215 | 100 | 7.89 | 2.25 | 3.65 | 22.6 | 2.35 | 7.7 | 400 | 409 |

| CubeSat1 | 500 | 500 | 500 | 45.7 | 17.2 | 6.25 | 25.0 | 12.5 | 3.6 | 223 | 209 |

| CubeSat2 | 550 | 500 | 500 | 57.6 | 18.9 | 6.25 | 25.0 | 12.5 | 3.6 | 190 | 186 |

| CubeSat3 | 700 | 500 | 500 | 64.8 | 24.1 | 6.25 | 25.0 | 12.5 | 3.6 | 158 | 144 |

| CubeSat4 | 500 | 500 | 490 | 43.9 | 16.8 | 6.19 | 24.5 | 12.3 | 3.6 | 226 | 207 |

| CubeSat5 | 520 | 520 | 500 | 60.0 | 18.6 | 6.37 | 26.0 | 13.0 | 3.6 | 195 | 170 |

| Specimen Name | Length without Rail ×10−3 [m] | Mass [kg] | Moment of Inertia of Area ×10−6 [m4] | n Value | Minimum Lateral Natural Frequency [Hz] | ||

|---|---|---|---|---|---|---|---|

| Llongitudinal | Whole Satellite | Structural Subsystem | Ilateral | Calculated Value | Measured Value | ||

| Dummy satellite | 355 | 14.1 | 14.1 | 60.9 | 11 | 1141 | 1195 |

| TK2’FM | 355 | 6.83 | 2.25 | 13.6 | 2 | 230 | 240 |

| TKD’EM | 355 | 7.89 | 2.25 | 13.6 | 2 | 230 | 220 |

| CubeSat1 | 500 | 45.7 | 17.2 | 501 | 3 | 56.5 | 55 |

| CubeSat2 | 550 | 57.6 | 18.9 | 501 | 3 | 46.7 | 47 |

| CubeSat3 | 700 | 64.8 | 24.1 | 501 | 8 | 47.1 | 43 |

| CubeSat4 | 500 | 43.9 | 16.8 | 489 | 3 | 56.4 | 63 |

| CubeSat5 | 520 | 60.0 | 18.6 | 559 | 3 | 54.1 | 53 |

| Specimen Name | Minimum Longitudinal Natural Frequency | Minimum Lateral Natural Frequency | |||||

|---|---|---|---|---|---|---|---|

| Calculated Value [Hz] | Measured Value [Hz] | Errors in Calculated and Measured Values [%] | n Value | Calculated Value [Hz] | Measured Value [Hz] | Errors in Calculated and Measured Values [%] | |

| Dummy satellite | 1880 | 1927 | 2.44 | 11 | 1141 | 1195 | 4.52 |

| TK2’FM | 430 | 440 | 2.27 | 2 | 230 | 240 | 4.17 |

| TKD’EM | 400 | 409 | 2.2 | 2 | 230 | 220 | 4.54 |

| CubeSat1 | 223 | 209 | 6.7 | 3 | 56.5 | 55 | 2.72 |

| CubeSat2 | 190 | 186 | 2.15 | 3 | 46.7 | 47 | 0.64 |

| CubeSat3 | 158 | 144 | 9.72 | 8 | 47.1 | 43 | 9.53 |

| CubeSat4 | 226 | 207 | 9.18 | 3 | 56.4 | 63 | 10.5 |

| CubeSat5 | 195 | 170 | 14.7 | 3 | 54.1 | 53 | 2.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okuyama, K.-i.; Yoshikawa, K.; Oue, C. A Simple Method for Identifying the Natural Frequency of a Micro Satellite with a Primary Structure Made of Aluminum Alloy. Aerospace 2024, 11, 436. https://doi.org/10.3390/aerospace11060436

Okuyama K-i, Yoshikawa K, Oue C. A Simple Method for Identifying the Natural Frequency of a Micro Satellite with a Primary Structure Made of Aluminum Alloy. Aerospace. 2024; 11(6):436. https://doi.org/10.3390/aerospace11060436

Chicago/Turabian StyleOkuyama, Kei-ichi, Keigo Yoshikawa, and Chihiro Oue. 2024. "A Simple Method for Identifying the Natural Frequency of a Micro Satellite with a Primary Structure Made of Aluminum Alloy" Aerospace 11, no. 6: 436. https://doi.org/10.3390/aerospace11060436

APA StyleOkuyama, K.-i., Yoshikawa, K., & Oue, C. (2024). A Simple Method for Identifying the Natural Frequency of a Micro Satellite with a Primary Structure Made of Aluminum Alloy. Aerospace, 11(6), 436. https://doi.org/10.3390/aerospace11060436