Effects of Different Materials and Structures on Mechanical Properties of Hail Used in Aviation Testing

Abstract

:1. Introduction

2. Preparation and Testing of Hail Samples

2.1. Preparation of Hail Samples

2.1.1. Materials for Hail Samples

2.1.2. Method for Preparing Hail Samples

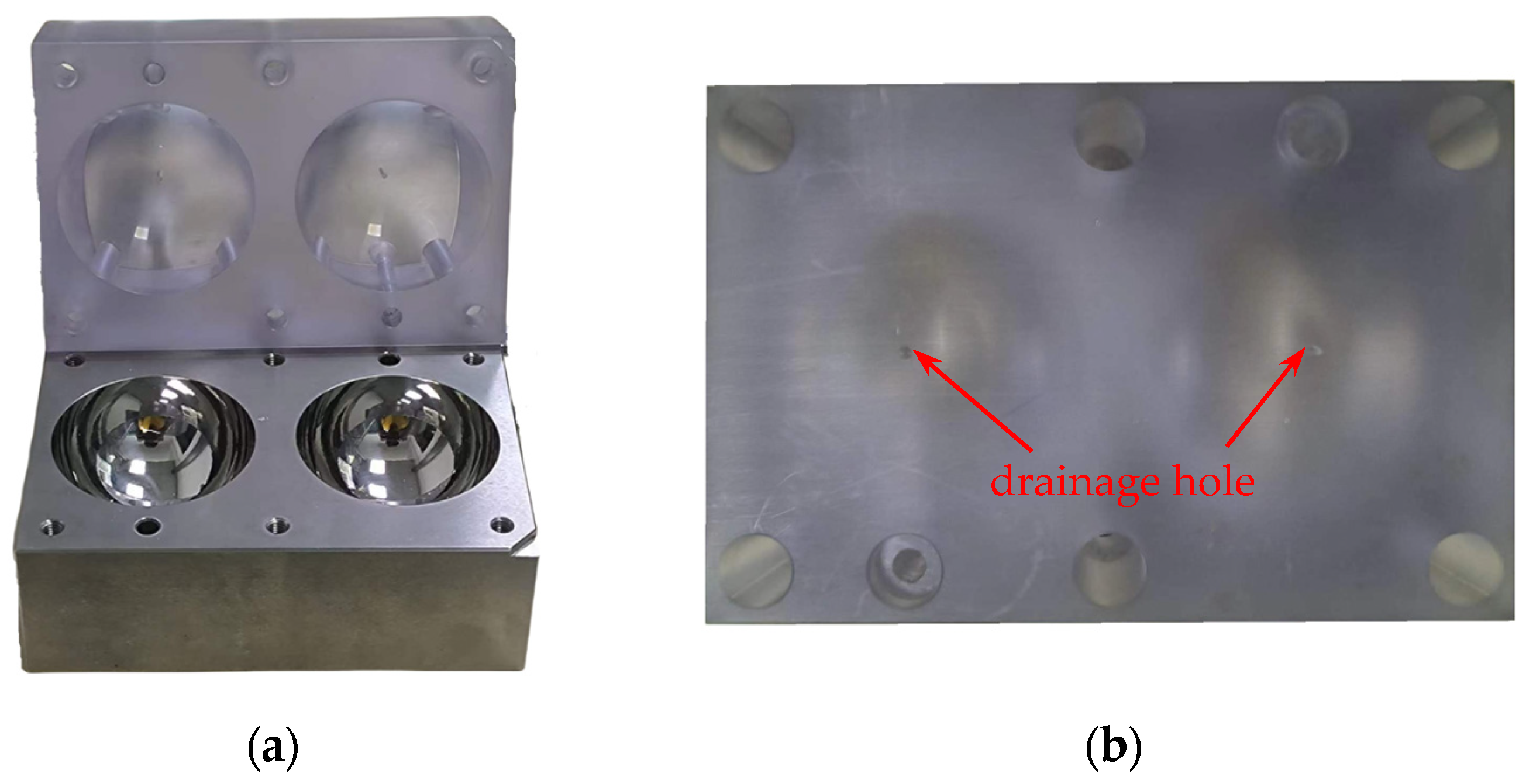

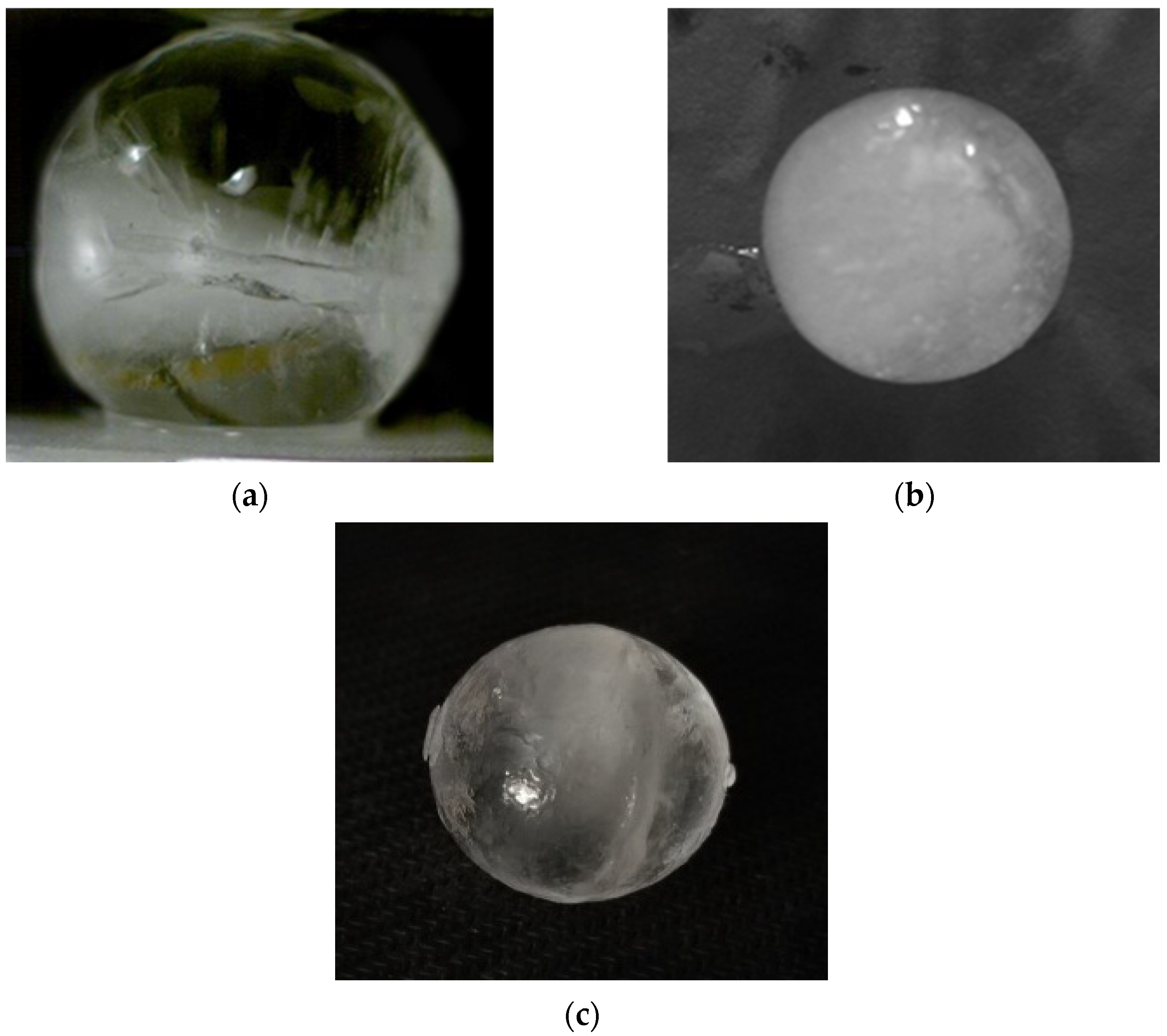

2.1.3. Preparation Process of Hail Samples

2.2. Testing of Hail Samples

2.2.1. Density Testing of Hail Samples

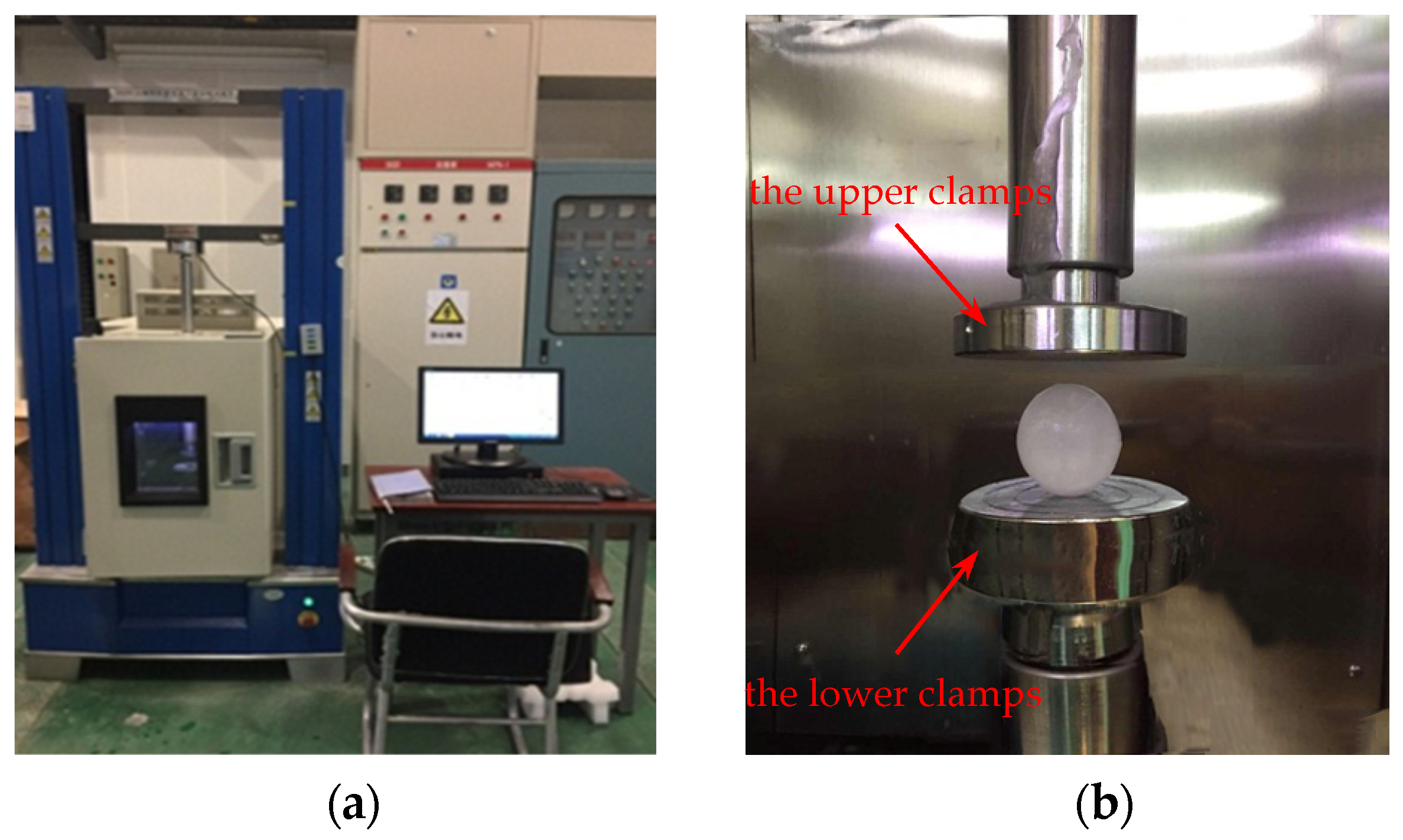

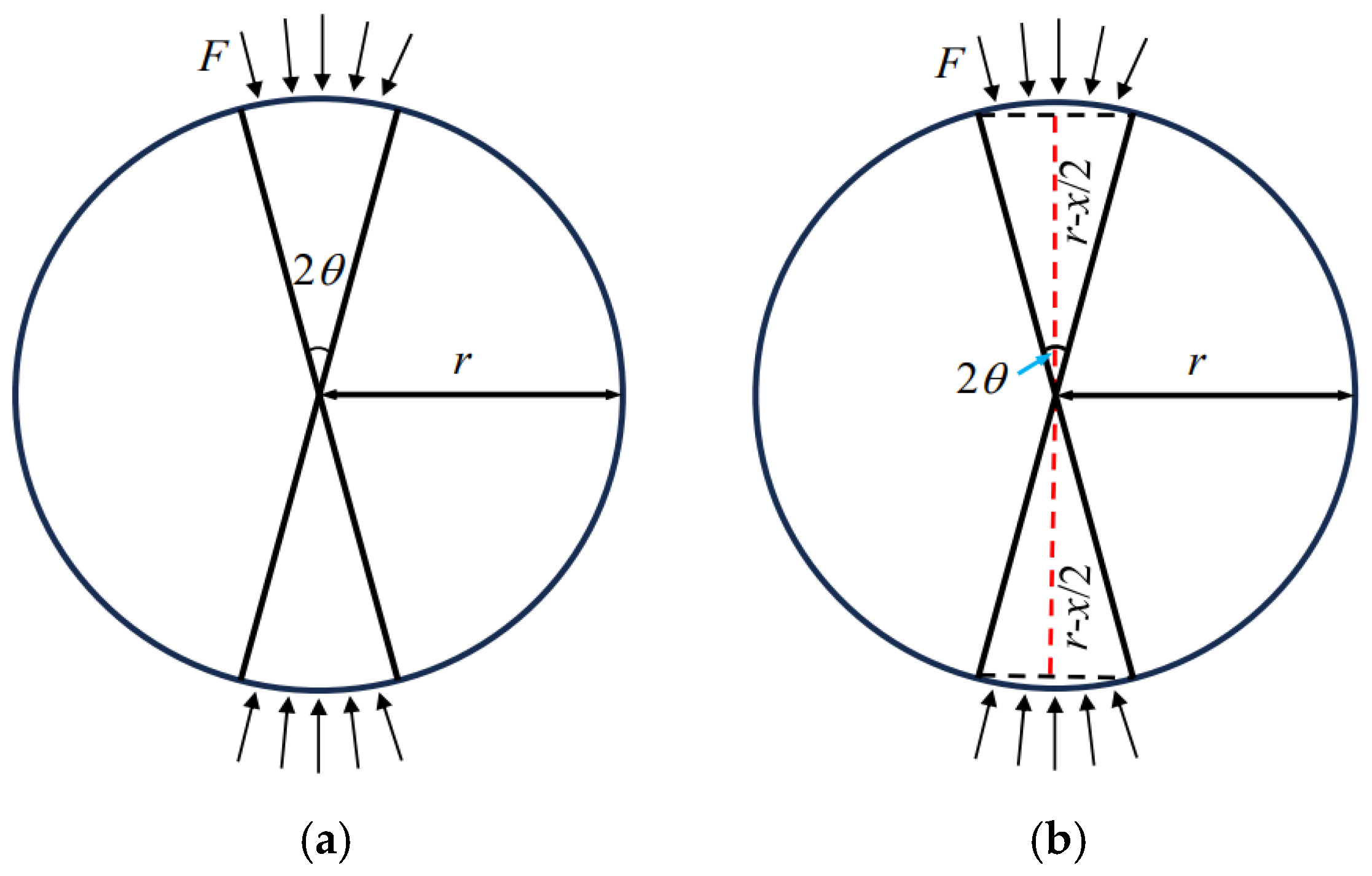

2.2.2. Mechanical Properties Testing of Hail Samples

3. Results and Analysis

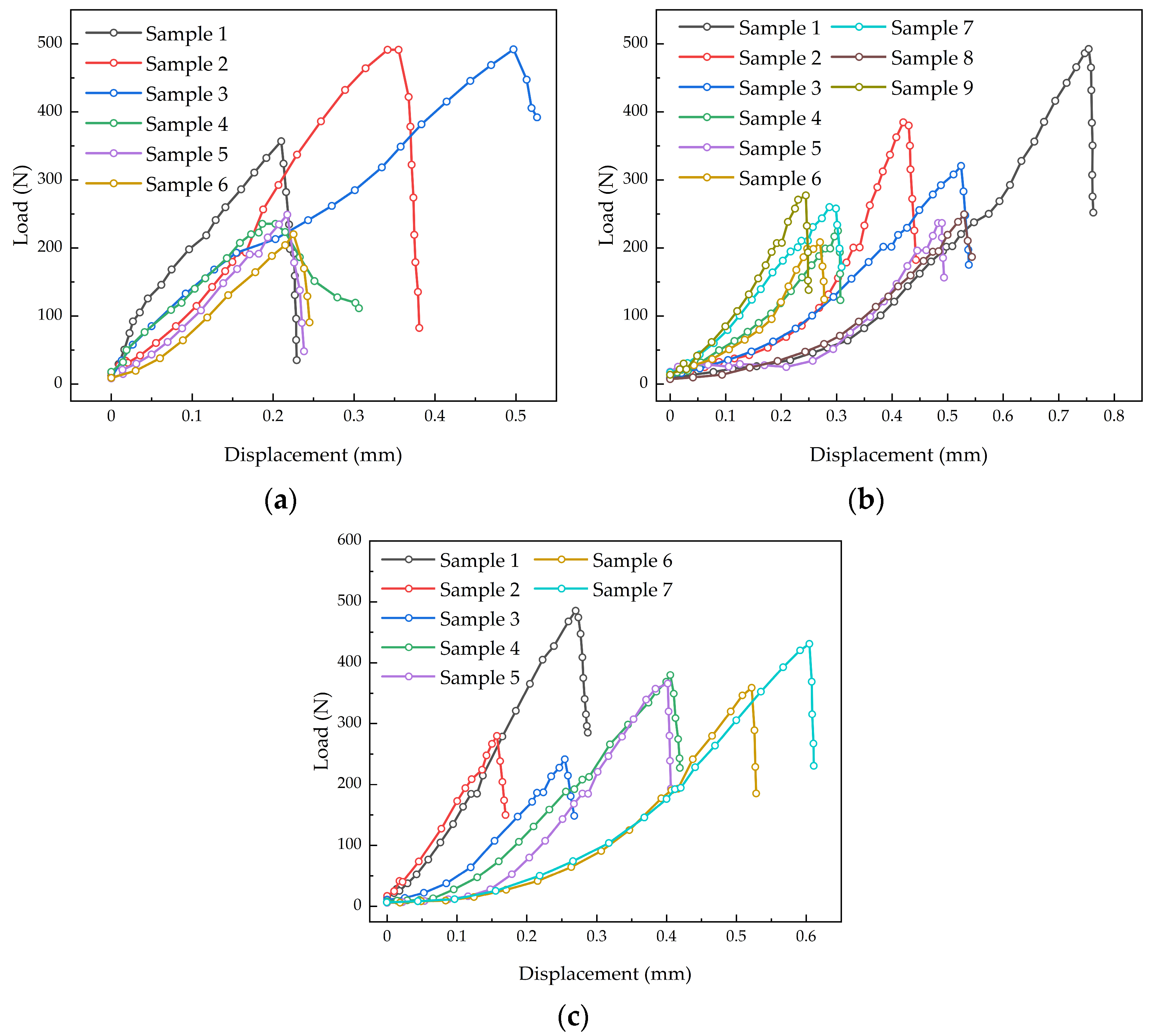

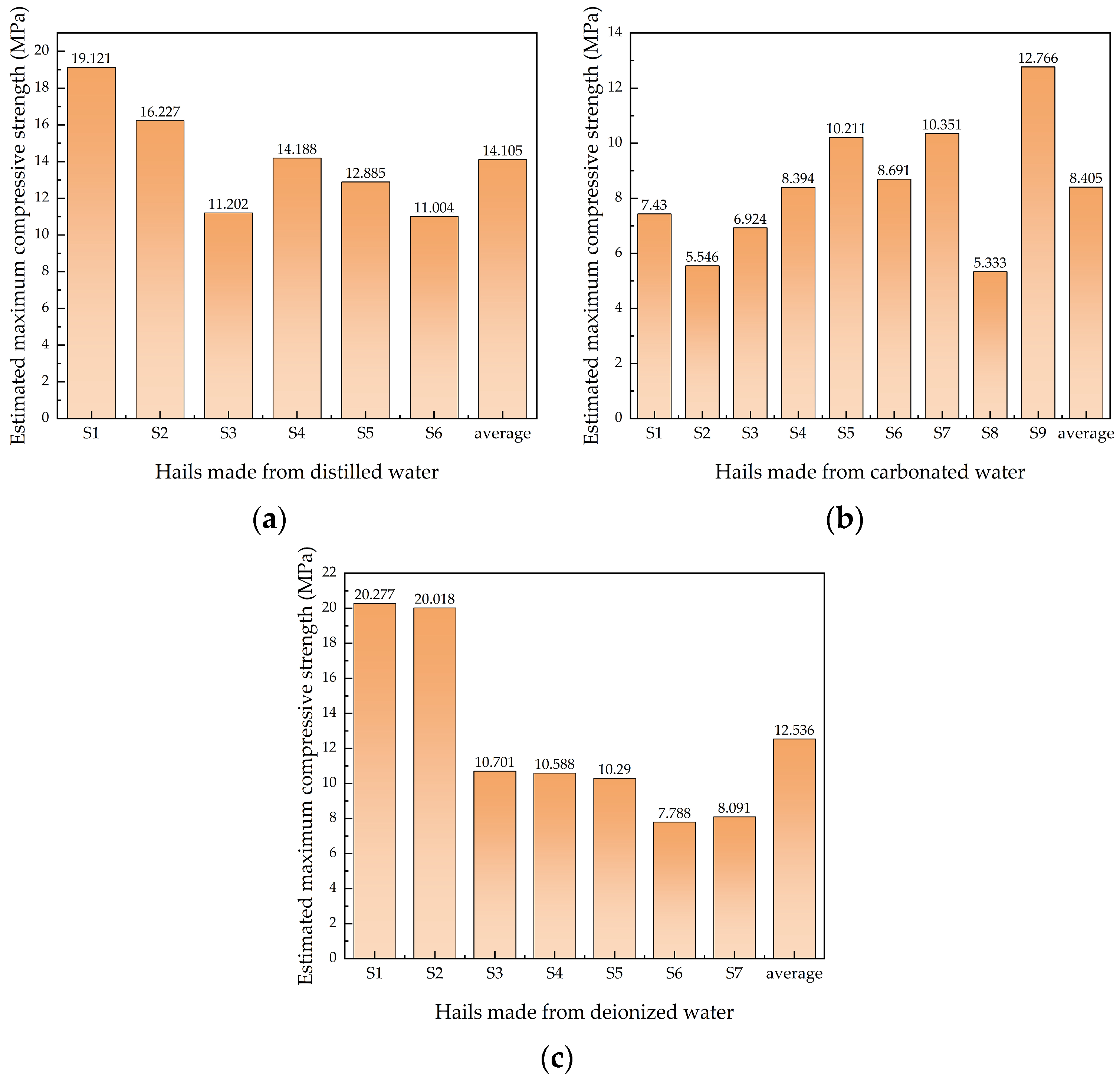

3.1. Impact of Hail Materials on the Density and Mechanical Properties of Artificial Hail

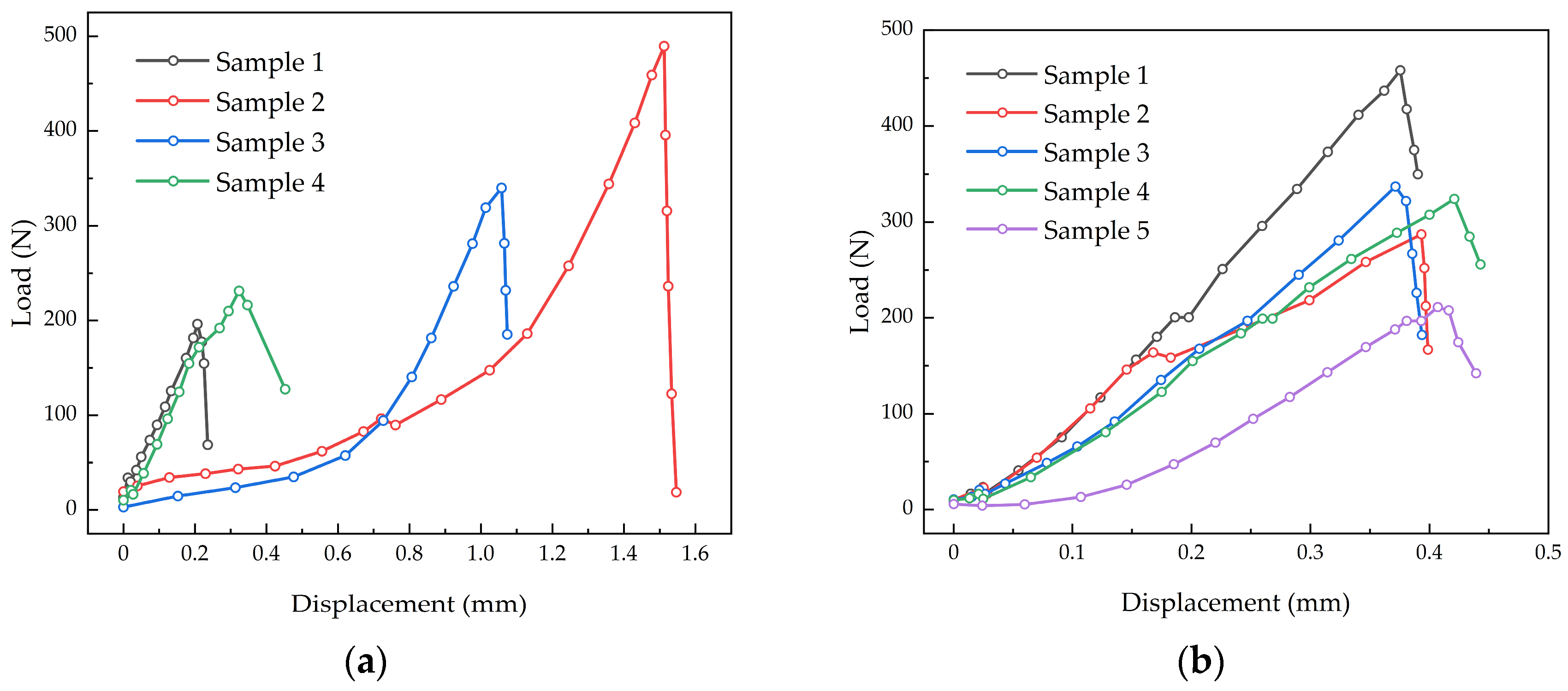

3.2. Impact of Hail Structure on the Density and Mechanical Properties of Artificial Hail

4. Conclusions

- (1)

- Both carbonated water hail and deionized water hail can partly reduce the density of artificial hail. The average density and estimated compressive strength of carbonated water hail are significantly lower than the other two types of hail. It is able to reflect the mechanical properties of natural hailstones.

- (2)

- The average density of hail with carbonated water cores and distilled water shells, as well as hail with distilled water cores and carbonated water shells, both meet the requirements of airworthiness certification testing. Hail with distilled water cores and carbonated water shells exhibit lower mechanical properties, with an average estimated maximum compressive strength of only 6.538 MPa, which is closest to the mechanical properties of natural hail.

- (3)

- This paper provides a new perspective and method for the preparation of hail for airworthiness testing. Furthermore, the paper also finds artificial hail that is closer to natural hail in terms of density and mechanical properties. Future investigations may reveal that this hail has the potential to compensate for the deficiencies of conventional hail in airworthiness certification testing. This could aid regulatory authorities in obtaining more precise airworthiness certification test data and revising airworthiness certification standards with increased detail.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| F | the applied load on the brittle sphere | θ | the angle related to the contact area |

| r | the radius of the brittle sphere | σc | the estimated maximum compressive strength of the brittle sphere |

| x | the total displacement of the loading device | v | the volume of the hail sample |

| m | the mass of the hail sample | S | hail samples for testing |

| ρ | the density of the hail sample | the average density of hail samples | |

| ε | strain rate | V | the loading rate of the machine |

| D | the diameter of the hail sample |

References

- Civil Aviation Administration of China. Decision of the Civil Aviation Administration of China on Amending the Airworthiness Standard for Aircraft Engines. Available online: https://xxgk.mot.gov.cn/2020/gz/202112/t20211227_3633414.html (accessed on 1 April 2024).

- Federal Aviation Administration. Part 33-Airworthiness Standards: Aircraft Engines. Available online: https://www.ecfr.gov/current/title-14/chapter-I/subchapter-C/part-33 (accessed on 1 April 2024).

- European Aviation Safety Agency. Certification Specifications for Engines: CS-E Amendment-4. Available online: https://www.easa.europa.eu/en/document-library/certification-specifications/cs-e-amendment-4 (accessed on 1 April 2024).

- Haynes, F.D. Effect of Temperature on the Strength of Snow-Ice; CRREL Report 78-27; Engineering Research and Development Center Hanover New Hampshire Cold Regions Research and Engineering Lab: Hanover, NH, USA, 1978. [Google Scholar]

- Ju, D.W. Experiments and Simulations of Ice Mechanics Property and Impacting Behavior. Master’s Thesis, Harbin Engineering University, Harbin, China, 2020. [Google Scholar]

- Ge, X.; Zhang, L.F.; Liu, Z.X. Effect of freezing temperature on mechanical properties of hail in airworthiness test. J. Aeros. Power. 2020, 35, 1744–1751. [Google Scholar]

- Liu, Y.W.; Zhang, L.F.; Ge, X.; Liu, Z.X. Influence of storage parameters on the mechanical properties of hail for airworthiness. J. Aeros. Power, 2023, in press.

- Song, Z.H. The Dynamic Response of Stringer-Stiffened Curved Composite Panels under the Hail Ice Impact. Ph.D. Thesis, Jinan University, Guangzhou, China, 2015. [Google Scholar]

- Feng, X.W.; Feng, G.P.; Fang, H. Experimental study of ice failure characteristics at different strain rates. Chin. J. Appl. Mech. 2016, 33, 223–228. [Google Scholar]

- Xu, M.; Chen, Y.; Wang, A.Z. Experiment on Nonlinear Mechanics of Artificial Hail Based on ASTM F320-2010. Sci. Technol. Eng. 2016, 16, 290–294. [Google Scholar]

- Zhang, Y.K.; Li, Y.L.; Tang, Z.B.; Jin, K.H.; Yang, H. Mechanical Behavior and Failure Mechanism of Ice at Cryogenic Temperatures under Uniaxial Compression. Chin. J. Soli. Mech. 2018, 39, 530–538. [Google Scholar]

- Tabassum, S. Study of Mechanical Properties of Cellulose Reinforced Ice. Master’s Thesis, Aalto University, Espoo, Finland, 2017. [Google Scholar]

- Timco, G.W.; Weeks, W.F. A Review of the Engineering Properties of Sea Ice. Cold Reg. Sci. Technol. 2010, 60, 107–129. [Google Scholar] [CrossRef]

- Jordan, I.; Taylor, R.; Derradji, A.A. Scaling of Flexural and Compressive Ice Failure. In Proceedings of the ASME 2012 31st International Conference on Ocean, Offshore and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 July 2012. [Google Scholar]

- Marchenko, A.; Karulina, M.; Karulin, E. Flexural Strength of Ice Reconstructed from Field Tests with Cantilever Beams and Laboratory Tests with Beams and Disks. In Proceedings of the International Conference on Port and Ocean Engineering Under Arctic Conditions, Busan, Republic of Korea, 11–16 June 2017. [Google Scholar]

- Aly, M. Analysis of Scale Effects in Ice Flexural Strength. Master’s Thesis, Memorial University of Newfoundland, St. John’s, NL, Canada, 2018. [Google Scholar]

- Tang, E.L.; Liu, C.; Chang, M.Z.; Han, Y.F.; Chen, C. Influence of freezing temperature and cotton content of ice on dynamic mechanical properties and energy dissipation. Eur. Phys. J. Plus 2022, 137, 123. [Google Scholar] [CrossRef]

- Wang, J.Z.; Liu, X.C. Effect of cotton fibers reinforced hail on impact dynamic behavior of composite panels. Acta Mater. Comp. Sini. 2018, 35, 3298–3303. [Google Scholar]

- Zhang, L.F.; Ge, X.; Liu, Z.X. Experimental study on mechanical properties of artificial hail. Acta Aeronaut. Astronaut. Sin. 2021, 42, 174–184. [Google Scholar]

- Li, S.K.; Feng, X.W.; Xie, R.Z.; Zhang, F.J.; Hu, W.J.; Xu, W.F.; Huang, X.C. Dynamic mechanical behavior of pure water ice and impurity ice at high strain rate. Exp. Shock. Wav. 2019, 39, 76–83. [Google Scholar]

- Uz, M.E.; Kop, M.D.; Yildirim, E.M. Analysis of Out-of-Plane Hail Impact Resistance of Steel Roof Panels. Exp. Technol. 2022, 46, 509–527. [Google Scholar] [CrossRef]

- Kim, H.; Kedward, K. Modeling Hail Ice and Predicting Impact Damage Initiation in Composite Structures. J. AIAA 2000, 38, 7. [Google Scholar] [CrossRef]

- Kim, H.; Welch, D.; Kedward, K. Experimental investigation of high velocity ice impacts on woven carbon/epoxy composite panels. Appl. Sci. Manuf. 2003, 34, 25–41. [Google Scholar] [CrossRef]

- Deng, K.; Feng, X.W.; Tan, X.J.; Hu, Y.H. Experimental research on compressive mechanical properties of ice under low strain rates. Mater. Today Commun. 2020, 24, 101029. [Google Scholar] [CrossRef]

- Dai, Y.M.; Xu, Y.; Li, Y.X.; Wang, W.; Yang, W.Y. Research Progress and Prospect of Hail Impact Resistance of Engineering Structures. J. Hunan Univ. (Nat. Sci. Ed.) 2023, 50, 228–236. [Google Scholar]

- Giammanco, I.; Maiden, B.R.; Estes, H.E.; Brown-Giammanco, T.M. Using 3D Laser Scanning Technology to Create Digital Models of Hailstones. Bull. Am. Meteorol. Soc. 2017, 98, 1341–1347. [Google Scholar] [CrossRef]

- Giammanco, I.; Brown, T.M.; Grant, R.G.; Dewey, D.L.; Hodel, J.D.; Stumpf, R.A. Evaluating the Hardness Characteristics of Hail through Compressive Strength Measurements. J. Atmos. Ocean. Technol. 2015, 32, 2100–2113. [Google Scholar] [CrossRef]

- Phelps, M.B.; Fedler, C.; Smith, M.; Giammanco, I.; Spradling, D.J. Evaluating the Compressive Strength of Hail and Its Relationship to Freezer Ice balls. RCI Interface 2019, 37, 24–36. [Google Scholar]

- Christensen, R.M. Yield Functions, Damage States, and Intrinsic Strength. Math. Mech. Solids 2000, 5, 285–300. [Google Scholar] [CrossRef]

- Adrian, R.R.; David, M.W. Point load tests and strength measurements for brittle spheres. Int. J. Rock Mech. Min. Sci. 2009, 46, 272–280. [Google Scholar]

| Sample (S) | Hail Species | m/g | v/cm3 | ρ/g·cm−3 | /g·cm−3 |

|---|---|---|---|---|---|

| 1 | hail samples produced from distilled water | 7.704 | 8.07 | 0.954 | 0.949 |

| 2 | 7.735 | 8.11 | 0.953 | ||

| 3 | 7.505 | 7.90 | 0.950 | ||

| 4 | 7.373 | 7.85 | 0.939 | ||

| 5 | hail samples produced from carbonated water | 6.882 | 8.00 | 0.860 | 0.849 |

| 6 | 6.351 | 7.50 | 0.847 | ||

| 7 | 6.518 | 7.80 | 0.835 | ||

| 8 | 6.810 | 7.90 | 0.861 | ||

| 9 | 6.495 | 7.80 | 0.832 | ||

| 10 | 6.800 | 7.90 | 0.860 | ||

| 11 | hail samples produced from deionized water | 7.227 | 8.10 | 0.892 | 0.897 |

| 12 | 6.247 | 7.10 | 0.880 | ||

| 13 | 7.338 | 8.10 | 0.905 | ||

| 14 | 7.275 | 8.00 | 0.909 |

| Sample (S) | Hail Species | m/g | v/cm3 | ρ/g·cm−3 | /g·cm−3 |

|---|---|---|---|---|---|

| 1 | carbonated water cores and distilled water shells | 7.440 | 8.50 | 0.875 | 0.873 |

| 2 | 7.526 | 8.45 | 0.891 | ||

| 3 | 7.167 | 8.50 | 0.843 | ||

| 4 | 7.305 | 8.30 | 0.880 | ||

| 5 | 7.440 | 8.50 | 0.875 | ||

| 6 | distilled water cores and carbonated water shells | 7.498 | 8.60 | 0.872 | 0.871 |

| 7 | 7.161 | 8.10 | 0.884 | ||

| 8 | 7.304 | 8.30 | 0.880 | ||

| 9 | 7.384 | 8.70 | 0.849 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Zhang, L.; Ge, X.; Liu, Z. Effects of Different Materials and Structures on Mechanical Properties of Hail Used in Aviation Testing. Aerospace 2024, 11, 508. https://doi.org/10.3390/aerospace11070508

Liu Y, Zhang L, Ge X, Liu Z. Effects of Different Materials and Structures on Mechanical Properties of Hail Used in Aviation Testing. Aerospace. 2024; 11(7):508. https://doi.org/10.3390/aerospace11070508

Chicago/Turabian StyleLiu, Yewei, Lifen Zhang, Xin Ge, and Zhenxia Liu. 2024. "Effects of Different Materials and Structures on Mechanical Properties of Hail Used in Aviation Testing" Aerospace 11, no. 7: 508. https://doi.org/10.3390/aerospace11070508

APA StyleLiu, Y., Zhang, L., Ge, X., & Liu, Z. (2024). Effects of Different Materials and Structures on Mechanical Properties of Hail Used in Aviation Testing. Aerospace, 11(7), 508. https://doi.org/10.3390/aerospace11070508