Accurate Method for Estimating Wall-Friction Based on Analytical Wall-Law Model

Abstract

:1. Introduction

2. Development of Methodology for Determining WSS

2.1. Comments on the Existing WSS Estimations Based on the Traditional Wall-Law

- the viscous sublayer

- the logarithmic sublayer

- the buffer layer, interval between the viscous and logarithmic sublayers, , where and are defined as and , respectively, with representing the local friction velocity, and these definitions are essentially consistent with the traditional law-of-the-wall.

2.2. Recent Development of the More Advanced Analytical Wall-Law Model

- 1.

- for inner layer in with in the base function,

- 2.

- for buffer layer in with in the base function,

- 3.

- for semi-log layer in with the same form in the conventional wall-law,

- 4.

- for wake layer in with in the base function,

- 1.

- for inner and buffer layer in with being set in the base function:

- 2.

- for full-log linear layer , namely the sublayer with linear form under the full-log coordinates:

- 3.

- for wake transition layer in with being chosen in the base function:

- 4.

- for wake layer in with being given in the base function:

2.3. Application of the Analytical Wall-Law Model to WSS Determination

3. Verification of the Approach Using DNS and Experimental Data

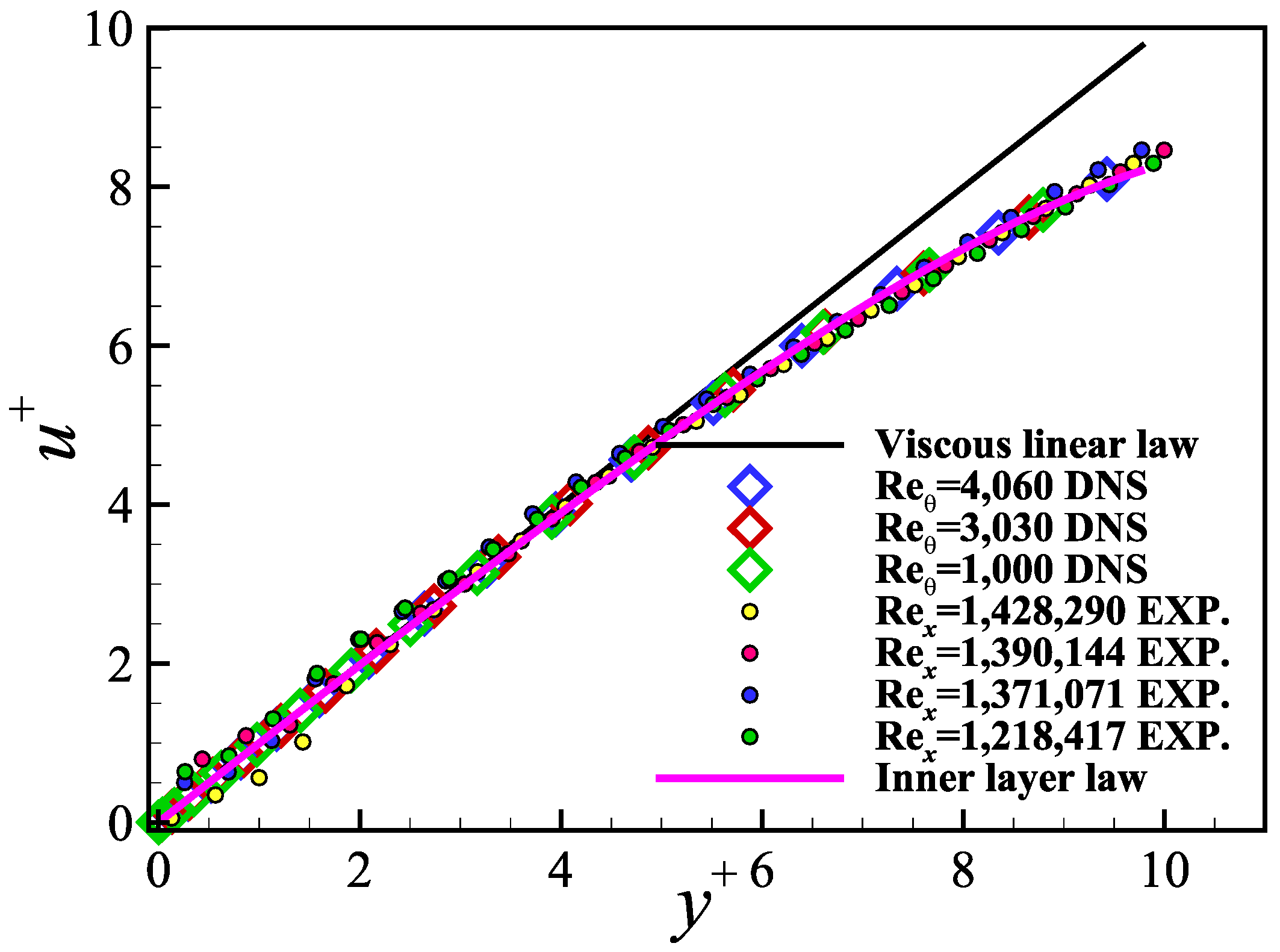

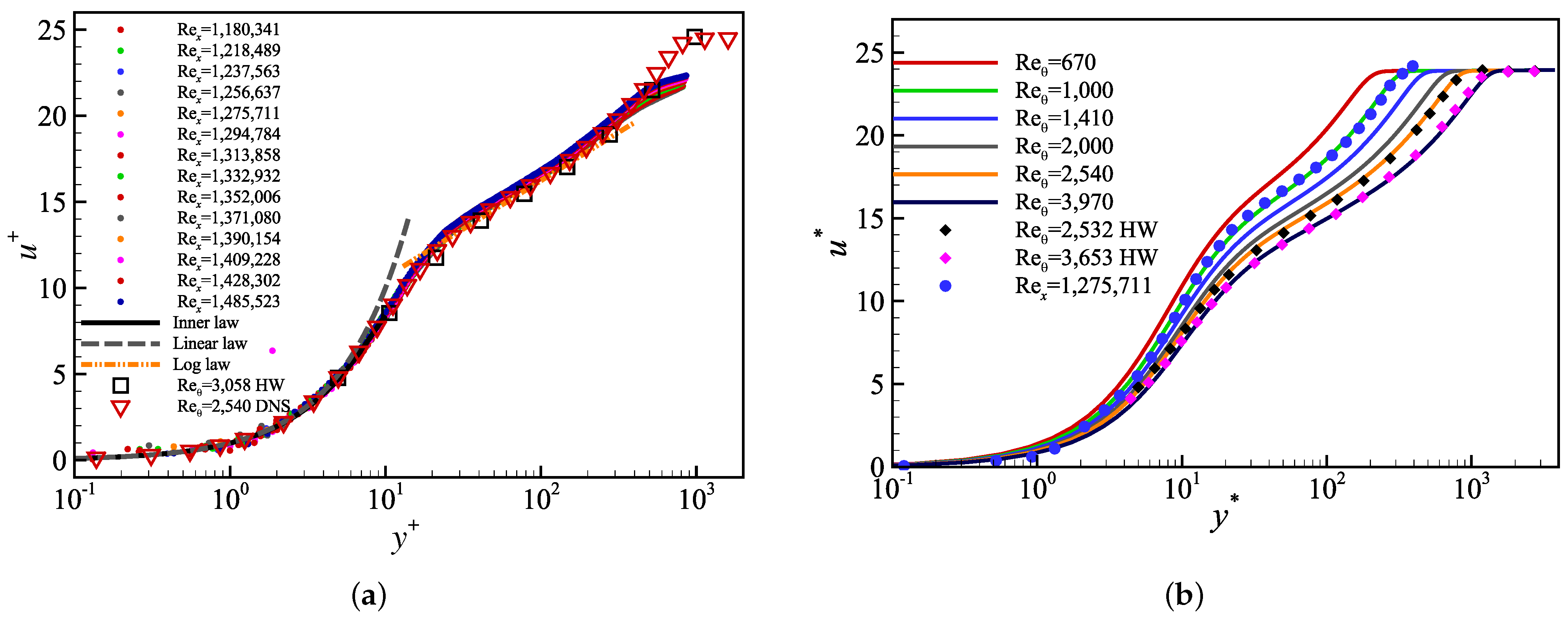

3.1. Validation of the Effectiveness of the Inner Layer Law

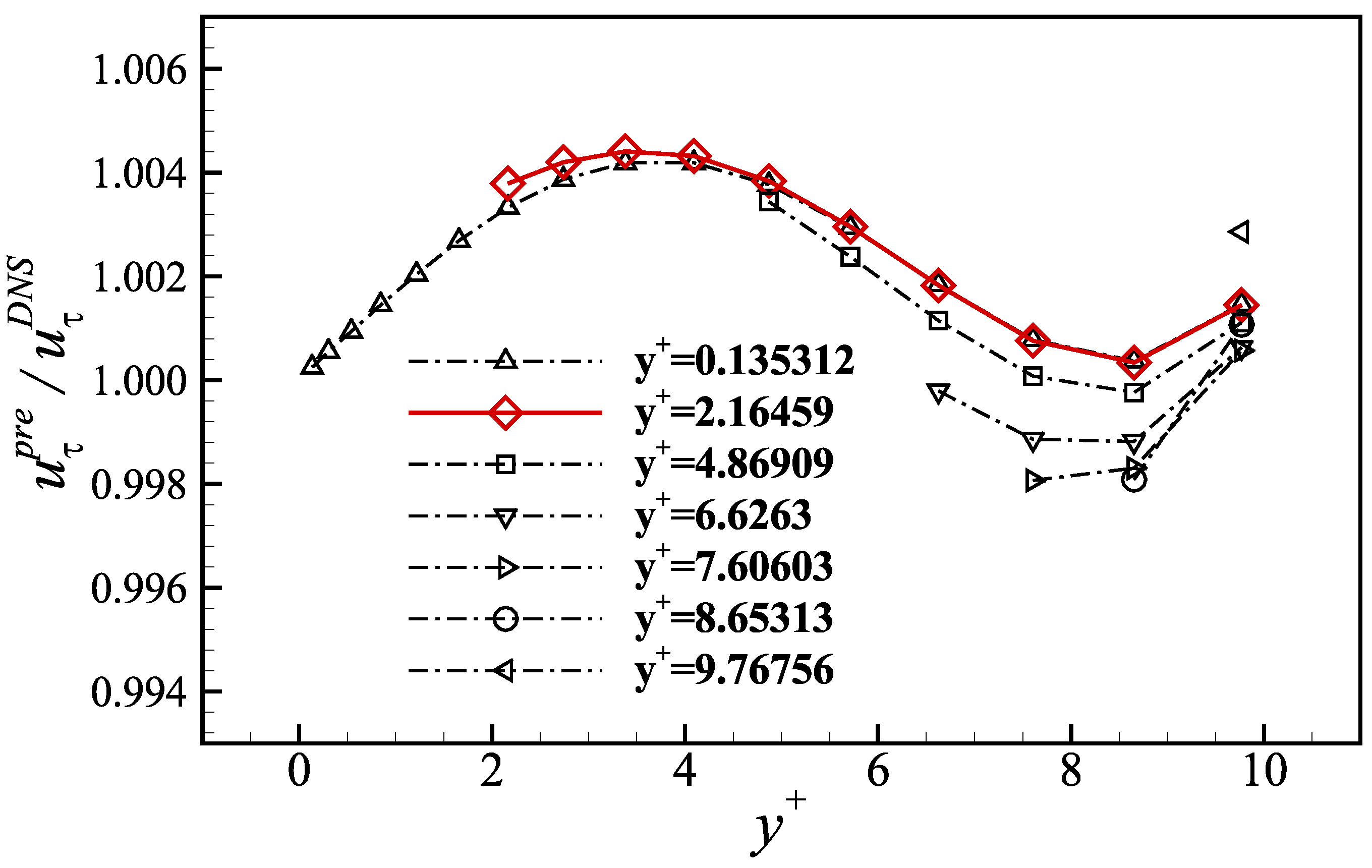

3.2. Prediction Accuracy of the Proposed Method for Estimating WSS

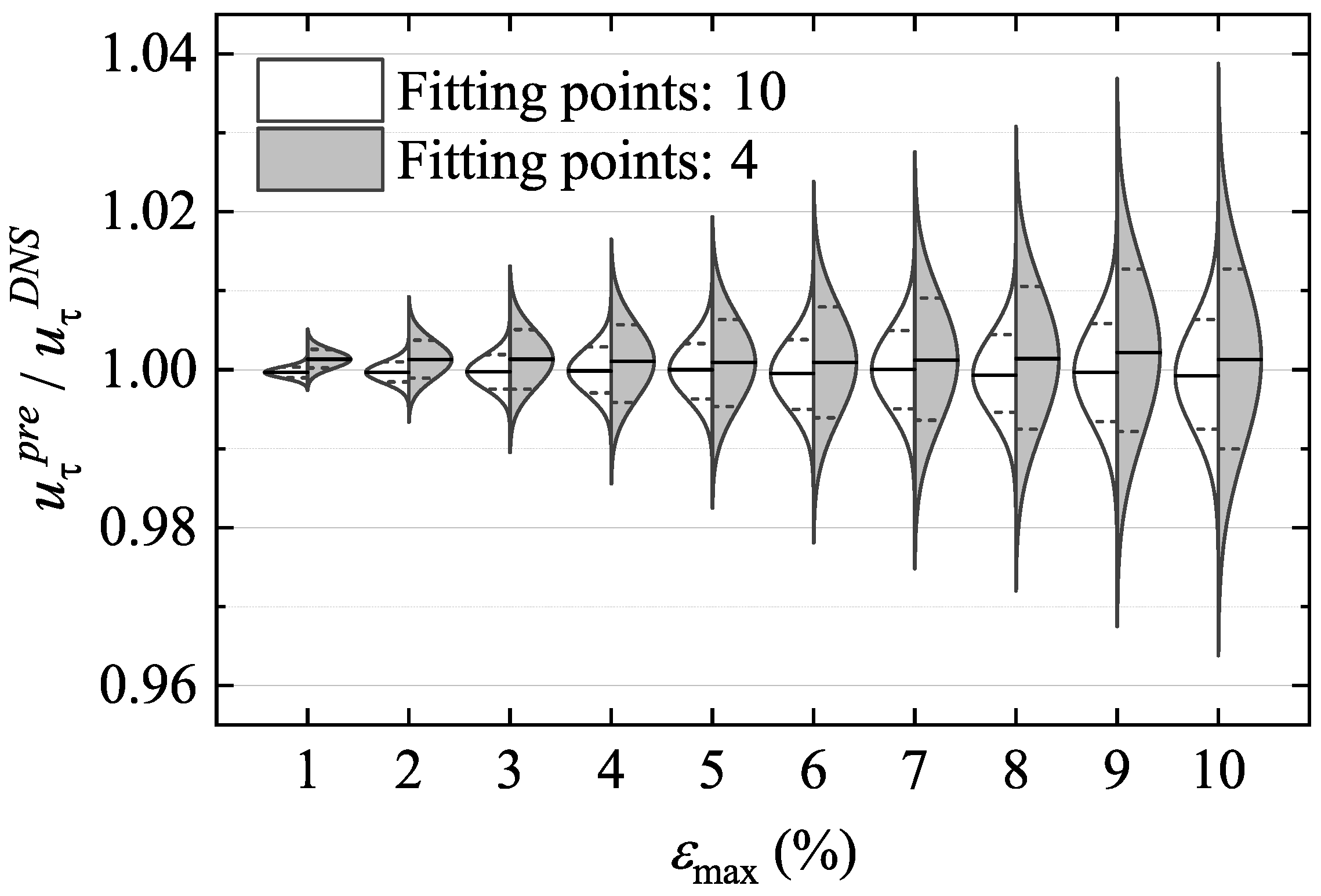

3.3. Evaluating the Proposed Method under Systematic and Random Errors

4. Applying the WSS Estimation Approach to a TBL Experiment

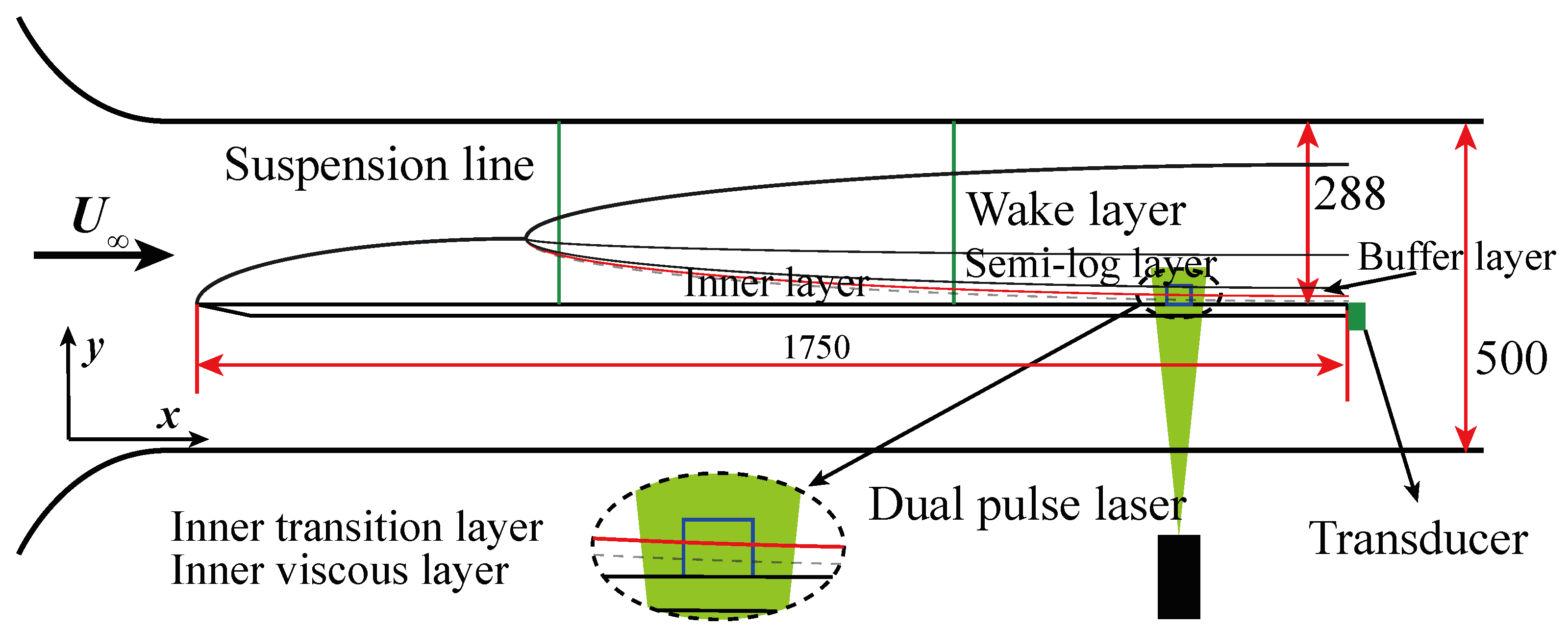

4.1. Experimental Setup

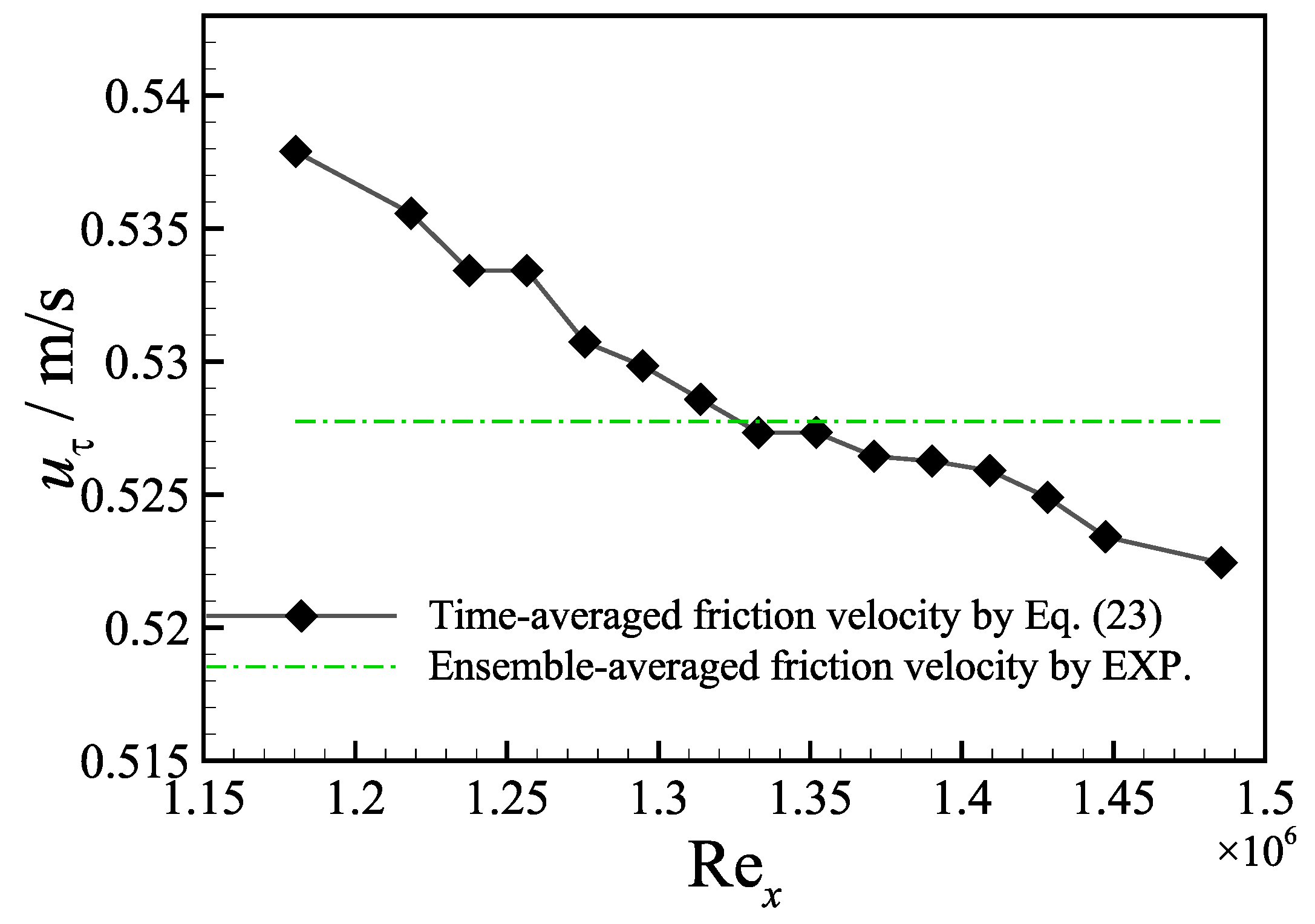

4.2. Results and Analysis

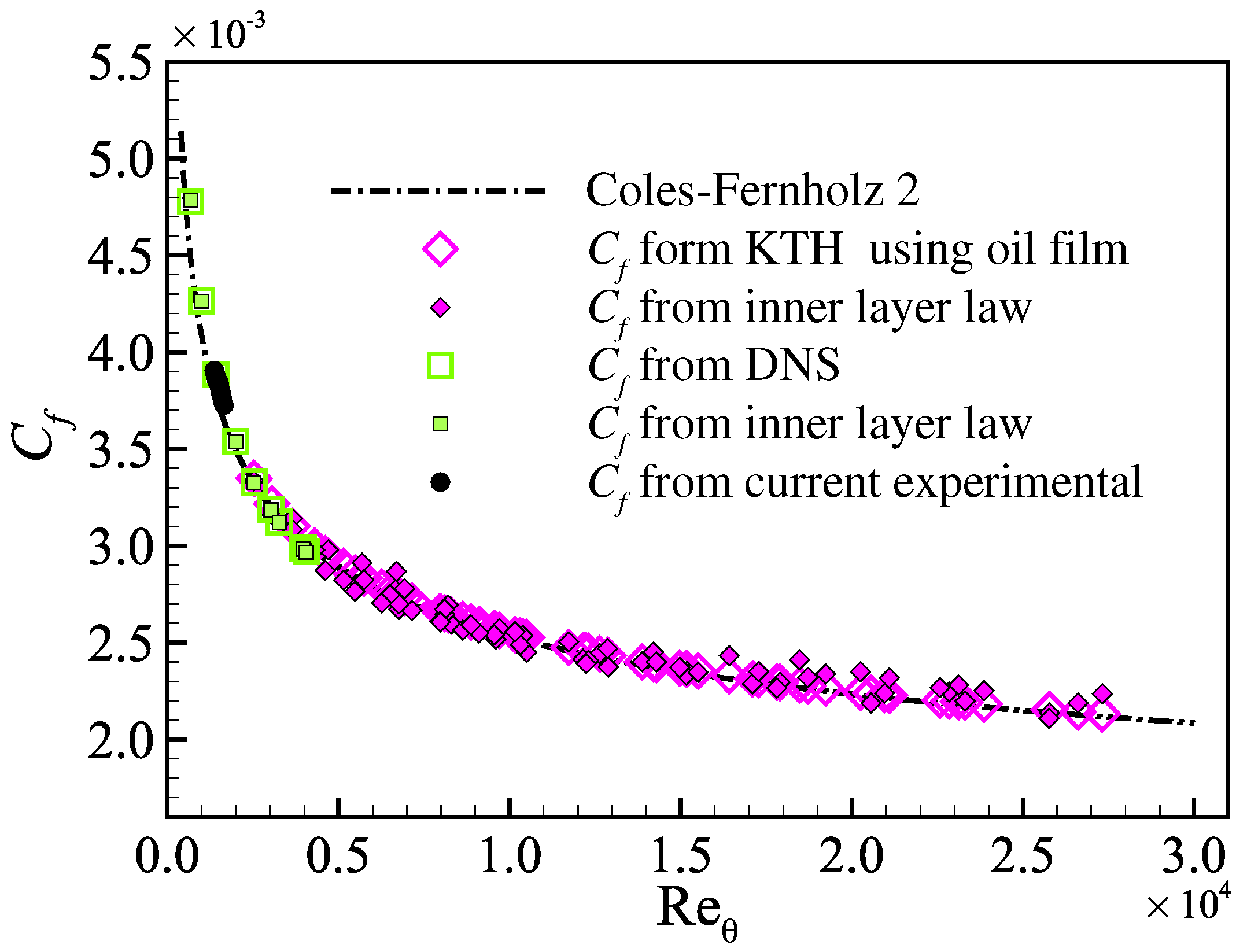

5. Applying the WSS Estimation Approach to Higher Re TBL

6. Conclusions

- 1.

- The PIV technique, combined with the high spatial resolution post-processing method SPEC, was applied in the current study to measure the near-wall velocity profile in a ZPGFP TBL and about 24 velocity points were captured in the TBL inner-layer region as defined by Wang [5]. These measurements, along with the current DNS data [37], solidly validated the effectiveness of the inner-layer law formulation in accurately describing both the velocity profile and its derivative in the layer.

- 2.

- A novel non-intrusive method was then developed and proposed for an accurate estimation of WSS based on the near-wall mean velocity measurement and the newly derived analytical wall-law. The WSS prediction accuracy based on the current approach is almost an order of magnitude higher than the existing methods if the velocity can be precisely determined in inner layer. In contrast to the linear wall-slope method, the current approach demonstrated its evident advantage in term of reducing the near-wall velocity measuring difficulty and relieving the high demand for the measuring precision of an experimental instrument. Additionally, the method is relatively insensitive to the absolute wall position. Comparing to the polynomial prediction method for WSS, the current approach exhibits a much better accuracy in the region of with an error consistently less than . Furthermore, the application scope of the current method is clearly defined by the IDF function, which was well validated in the current experiment. Compared to WSS prediction methods based on the semi-log law, the accuracy of the current method is not affected by the upper and lower bounds of the data interval. The superiorities of the current method over the existing approaches are achieved by the fact that the new TBL wall-law relations are formulated with the minimum number of control parameters possessing their clear physical meanings, such as the damping strength and damping distance , and therefore are capable of guaranteeing the continuities of not only the velocity profiles but also the profile’s derivatives even at the transition points of TBL sublayers.

- 3.

- The robustness and reliability of the method was verified by the existing DNS data subjected to random and systematic errors, which proved that the current approach is insensitive to the disturbances in an experimental measurement. The PIV experiment equipped with SPEC was performed for the fully developed ZPGFP (Type-A) TBL at several Reynolds numbers and the collected data were analyzed using the proposed method which presented the accurate predictive capability of both the velocity profile and its derivatives including the WSS. Meanwhile, the SPEC post-processing method demonstrated its suitability for measuring the time-averaged turbulence statistics in a TBL.

- 4.

- When being applied to the higher Reynolds number TBL data from KTH, the current method provided WSS predictions which exhibited a high degree of consistency with the measurements from the oil film interferometry reported in the literature. Even with very sparse data points, including the instance with only a single data point, the method still presents its superior prediction capability, which evidently suggests that the method possesses the potential to deliver a satisfactory WSS measurement for future engineering applications through using significantly less costly experimental instruments. Moreover, if the current method can be further extended to the wall-law relation in the buffer-layer, i.e., Equation (14), the difficulty in predicting WSS is anticipated to be practically overcome through measuring the near-wall velocity profile, which will be expected to significantly benefit a broad range of fluid engineering applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TBL | Turbulent Boundary Layer |

| DNS | Direct Numerical Simulations |

| ZPGFP | Zero-Pressure-Gradient Flat-Plate |

| PIV | Particle Image Velocimetry |

| SPEC | Single-Pixel Ensemble Correlation |

| WSS | Wall Shear Stress |

| MEMS | MicroElectroMechanical System |

| HW | Hot-Wire |

| LSM | Least Squares Method |

| LDV | Laser Doppler Velocimetry |

| CCD | Charge-Coupled Device |

| FOV | Field Of View |

| IW | Interrogation Window |

| SNR | Signal-to-Noise Ratio |

References

- Prandtl, L. Turbulent Flow; Technical Report Memo. 435; NASA: Washington, DC, USA, 1927. Available online: https://ntrs.nasa.gov/citations/19930090799 (accessed on 20 June 2020).

- Von Kármán, T. Mechanical Similitude and Turbulence; Technical Report 611; NASA: Washington, DC, USA, 1931; Available online: http://hdl.handle.net/2060/19930094805 (accessed on 20 June 2020).

- Barenblatt, G. The 1999 James Lighthill Memorial Paper: Scaling laws for turbulent wall-bounded shear flows at very large Reynolds numbers. J. Eng. Math. 1999, 36, 361–384. [Google Scholar] [CrossRef]

- De Graaff, D.B.; Eaton, J.K. Reynolds-number scaling of the flat-plate turbulent boundary layer. J. Fluid Mech. 2000, 422, 319–346. [Google Scholar] [CrossRef]

- Wang, D.; Li, H.; Cao, B.C.; Xu, H. Law-of-the-wall analytical formulations for Type-A turbulent boundary layers. J. Hydrodyn. 2020, 32, 296–313. [Google Scholar] [CrossRef]

- Li, H.; Wang, D.; Xu, H. Improved law-of-the-wall model for turbulent boundary layer in engineering. AIAA J. 2020, 58, 3308–3319. [Google Scholar] [CrossRef]

- Wang, D.; Li, H.; Li, Y.; Yu, T.; Xu, H. Direct numerical simulation and in-depth analysis of thermal turbulence in square annular duct. Int. J. Heat Mass Transf. 2019, 144, 118590. [Google Scholar] [CrossRef]

- Cabot, W.; Moin, P. Approximate wall boundary conditions in the large-eddy simulation of high Reynolds number flow. Flow, Turbul. Combust. 2000, 63, 269–291. [Google Scholar] [CrossRef]

- Saeedi, M.; Wang, B.C. Large-eddy simulation of turbulent flow and dispersion over a matrix of wall-mounted cubes. Phys. Fluids 2015, 27, 115104. [Google Scholar] [CrossRef]

- Zarbi, G.; Reynolds, A. Skin friction measurements in turbulent flow by means of Preston tubes. Fluid Dyn. Res. 1991, 7, 151. [Google Scholar] [CrossRef]

- Ruedi, J.D.; Nagib, H.; Österlund, J.; Monkewitz, P. Unsteady wall-shear measurements in turbulent boundary layers using MEMS. Exp. Fluids 2004, 36, 393–398. [Google Scholar] [CrossRef]

- Schober, M.; Obermeier, E.; Pirskawetz, S.; Fernholz, H.H. A MEMS skin-friction sensor for time resolved measurements in separated flows. Exp. Fluids 2004, 36, 593–599. [Google Scholar] [CrossRef]

- Naughton, J.W.; Sheplak, M. Modern developments in shear-stress measurement. Prog. Aerosp. Sci. 2002, 38, 515–570. [Google Scholar] [CrossRef]

- Costantini, M.; Lee, T.; Nonomura, T.; Asai, K.; Klein, C. Feasibility of skin-friction field measurements in a transonic wind tunnel using a global luminescent oil film. Exp. Fluids 2021, 62, 21. [Google Scholar] [CrossRef]

- Pailhas, G.; Barricau, P.; Touvet, Y.; Perret, L. Friction measurement in zero and adverse pressure gradient boundary layer using oil droplet interferometric method. Exp. Fluids 2009, 47, 195–207. [Google Scholar] [CrossRef]

- Kendall, A.; Koochesfahani, M. A method for estimating wall friction in turbulent boundary layers. In Proceedings of the 25th AIAA Aerodynamic Measurement Technology and Ground Testing Conference, San Francisco, CA, USA, 5–8 June 2006; p. 3834. [Google Scholar]

- Mandal, B.; Mazumdar, H.P. The importance of the law of the wall. Int. J. Appl. Mech. Eng. 2015, 20, 857–869. [Google Scholar] [CrossRef]

- Rodríguez-López, E.; Bruce, P.J.; Buxton, O.R. A robust post-processing method to determine skin friction in turbulent boundary layers from the velocity profile. Exp. Fluids 2015, 56, 68. [Google Scholar] [CrossRef]

- Wei, T.; Schmidt, R.; McMurtry, P. Comment on the Clauser chart method for determining the friction velocity. Exp. Fluids 2005, 38, 695–699. [Google Scholar] [CrossRef]

- Marusic, I.; Monty, J.P.; Hultmark, M.; Smits, A.J. On the logarithmic region in wall turbulence. J. Fluid Mech. 2013, 716, R3. [Google Scholar] [CrossRef]

- Nobach, H.; Honkanen, M. Two-dimensional Gaussian regression for sub-pixel displacement estimation in particle image velocimetry or particle position estimation in particle tracking velocimetry. Exp. Fluids 2005, 38, 511–515. [Google Scholar] [CrossRef]

- Esteban, L.B.; Dogan, E.; Rodríguez-López, E.; Ganapathisubramani, B. Skin-friction measurements in a turbulent boundary layer under the influence of free-stream turbulence. Exp. Fluids 2017, 58, 115. [Google Scholar] [CrossRef]

- McEligot, D.M. Measurement of wall shear stress in favorable pressure gradients. In Flow of Real Fluids; Meier, G.E.A., Obermeier, F., Eds.; Springer: Berlin/Heidelberg, Germany, 1985; pp. 292–303. [Google Scholar] [CrossRef]

- Kendall, A.; Koochesfahani, M. A method for estimating wall friction in turbulent wall-bounded flows. Exp. Fluids 2008, 44, 773–780. [Google Scholar] [CrossRef]

- Djenidi, L.; Talluru, K.; Antonia, R. A velocity defect chart method for estimating the friction velocity in turbulent boundary layers. Fluid Dyn. Res. 2019, 51, 045502. [Google Scholar] [CrossRef]

- Wang, J.; Pan, C.; Wang, J. Characteristics of fluctuating wall-shear stress in a turbulent boundary layer at low-to-moderate Reynolds number. Phys. Rev. Fluids 2020, 5, 074605. [Google Scholar] [CrossRef]

- Shen, J.; Pan, C.; Wang, J. Accurate measurement of wall skin friction by single-pixel ensemble correlation. Sci. China Physics, Mech. Astron. 2014, 57, 1352–1362. [Google Scholar] [CrossRef]

- Örlü, R.; Fransson, J.H.; Alfredsson, P.H. On near wall measurements of wall bounded flows—The necessity of an accurate determination of the wall position. Prog. Aerosp. Sci. 2010, 46, 353–387. [Google Scholar] [CrossRef]

- Durst, F.; Kikura, H.; Lekakis, I.; Jovanović, J.; Ye, Q. Wall shear stress determination from near-wall mean velocity data in turbulent pipe and channel flows. Exp. Fluids 1996, 20, 417–428. [Google Scholar] [CrossRef]

- Adrian, R.J. Particle-imaging techniques for experimental fluid mechanics. Annu. Rev. Fluid Mech. 1991, 23, 261–304. [Google Scholar] [CrossRef]

- Sugii, Y.; Nishio, S.; Okuno, T.; Okamoto, K. A highly accurate iterative PIV technique using a gradient method. Meas. Sci. Technol. 2000, 11, 1666–1673. [Google Scholar] [CrossRef]

- Van Driest, E.R. On turbulent flow near a wall. J. Aeronaut. Sci. 1956, 23, 1007–1011. [Google Scholar] [CrossRef]

- Cao, B.; Xu, H. Re-understanding the law-of-the-wall for wall-bounded turbulence based on in-depth investigation of DNS data. Acta Mech. Sin. 2018, 34, 793–811. [Google Scholar] [CrossRef]

- Nagib, H.M.; Chauhan, K.A.; Monkewitz, P.A. Approach to an asymptotic state for zero pressure gradient turbulent boundary layers. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2007, 365, 755–770. [Google Scholar] [CrossRef]

- Kähler, C.J.; Scholz, U.; Ortmanns, J. Wall-shear-stress and near-wall turbulence measurements up to single pixel resolution by means of long-distance micro-PIV. Exp. Fluids 2006, 41, 327–341. [Google Scholar] [CrossRef]

- Österlund, J.M.; Johansson, A.V.; Nagib, H.M.; Hites, M.H. Wall shear stress measurements in high Reynolds number boundary layers from two facilities. In Proceedings of the 30th Fluid Dynamics Conference, Norfolk, VA, USA, 28 June –1 July 1999; p. 3814. [Google Scholar]

- Schlatter, P.; Örlü, R. Assessment of direct numerical simulation data of turbulent boundary layers. J. Fluid Mech. 2010, 659, 116–126. [Google Scholar] [CrossRef]

- Österlund, J.M.; Johansson, A.V.; Nagib, H.M.; Hites, M.H. A note on the overlap region in turbulent boundary layers. Phys. Fluids 2000, 12, 1–4. [Google Scholar] [CrossRef]

- Fernholz, H.; Finleyt, P. The incompressible zero-pressure-gradient turbulent boundary layer: An assessment of the data. Prog. Aerosp. Sci. 1996, 32, 245–311. [Google Scholar] [CrossRef]

- Zanoun, E.S.; Nagib, H.; Durst, F. Refined cf relation for turbulent channels and consequences for high-Re experiments. Fluid Dyn. Res. 2009, 41, 021405. [Google Scholar] [CrossRef]

| Stage | |||

|---|---|---|---|

| Initial Load Stage | 109.81 | 0.26 | 0.24 |

| Stable Load Stage | 109.82 | 0.03 | 0.03 |

| 0.108 | 0.131 | 0.0496 | |

| 1.790 | 5.700 | 0.0252 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, L.; Wang, D.; Cao, B.; Xu, H. Accurate Method for Estimating Wall-Friction Based on Analytical Wall-Law Model. Aerospace 2024, 11, 544. https://doi.org/10.3390/aerospace11070544

Zhou L, Wang D, Cao B, Xu H. Accurate Method for Estimating Wall-Friction Based on Analytical Wall-Law Model. Aerospace. 2024; 11(7):544. https://doi.org/10.3390/aerospace11070544

Chicago/Turabian StyleZhou, Lei, Duo Wang, Bochao Cao, and Hongyi Xu. 2024. "Accurate Method for Estimating Wall-Friction Based on Analytical Wall-Law Model" Aerospace 11, no. 7: 544. https://doi.org/10.3390/aerospace11070544