Biofuel–Electric Hybrid Aircraft Application—A Way to Reduce Carbon Emissions in Aviation

Abstract

:1. Introduction

2. Classification of New-Energy Aircraft

3. Status of Electric Aircraft

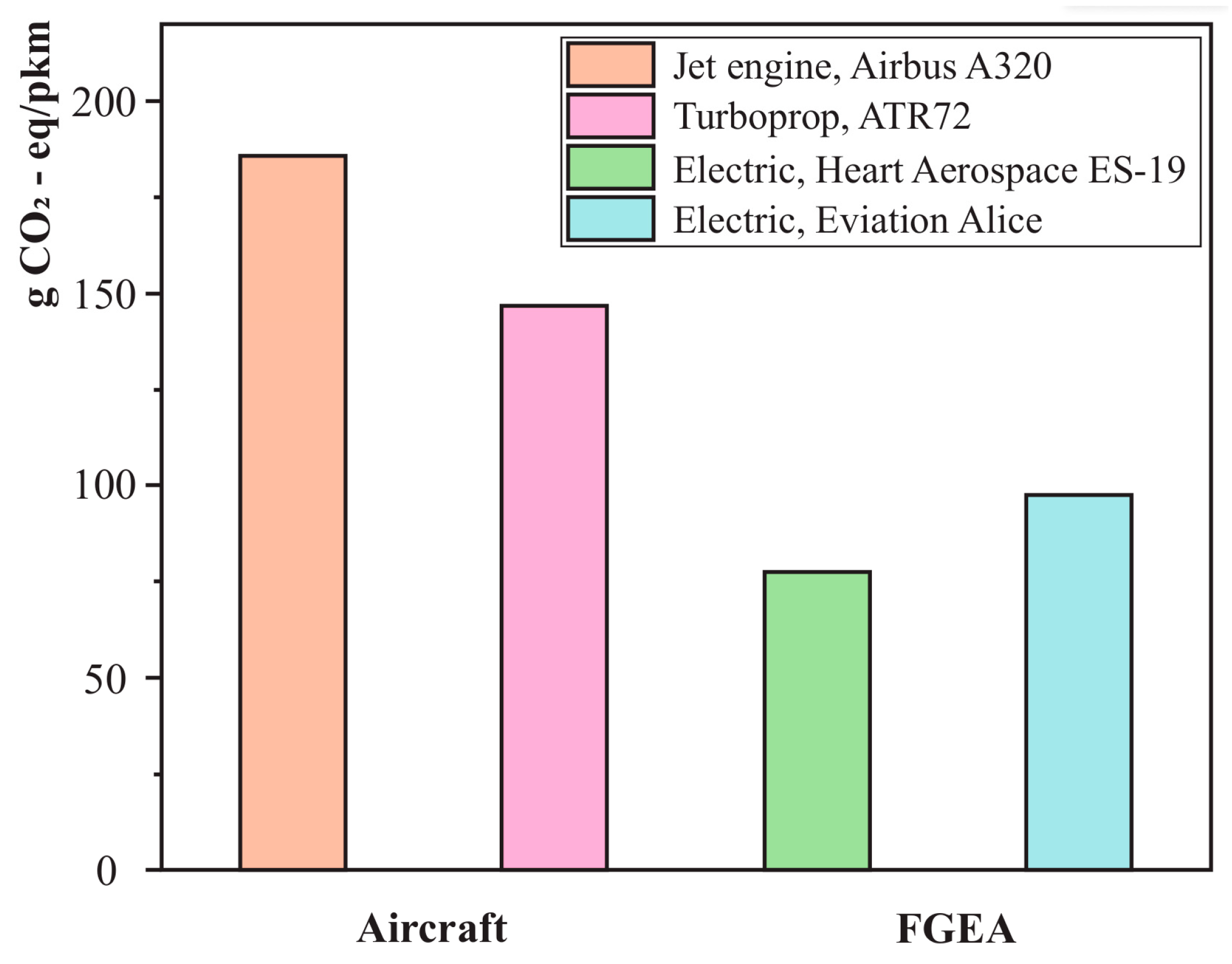

3.1. Carbon Reduction in Electric Aircraft

3.2. Limitations of Purely Electric Aircraft

4. Application of Hybrid Power

4.1. Hybrid Drones

4.2. Hybrid Airliner

5. Biofuel Emission Reductions

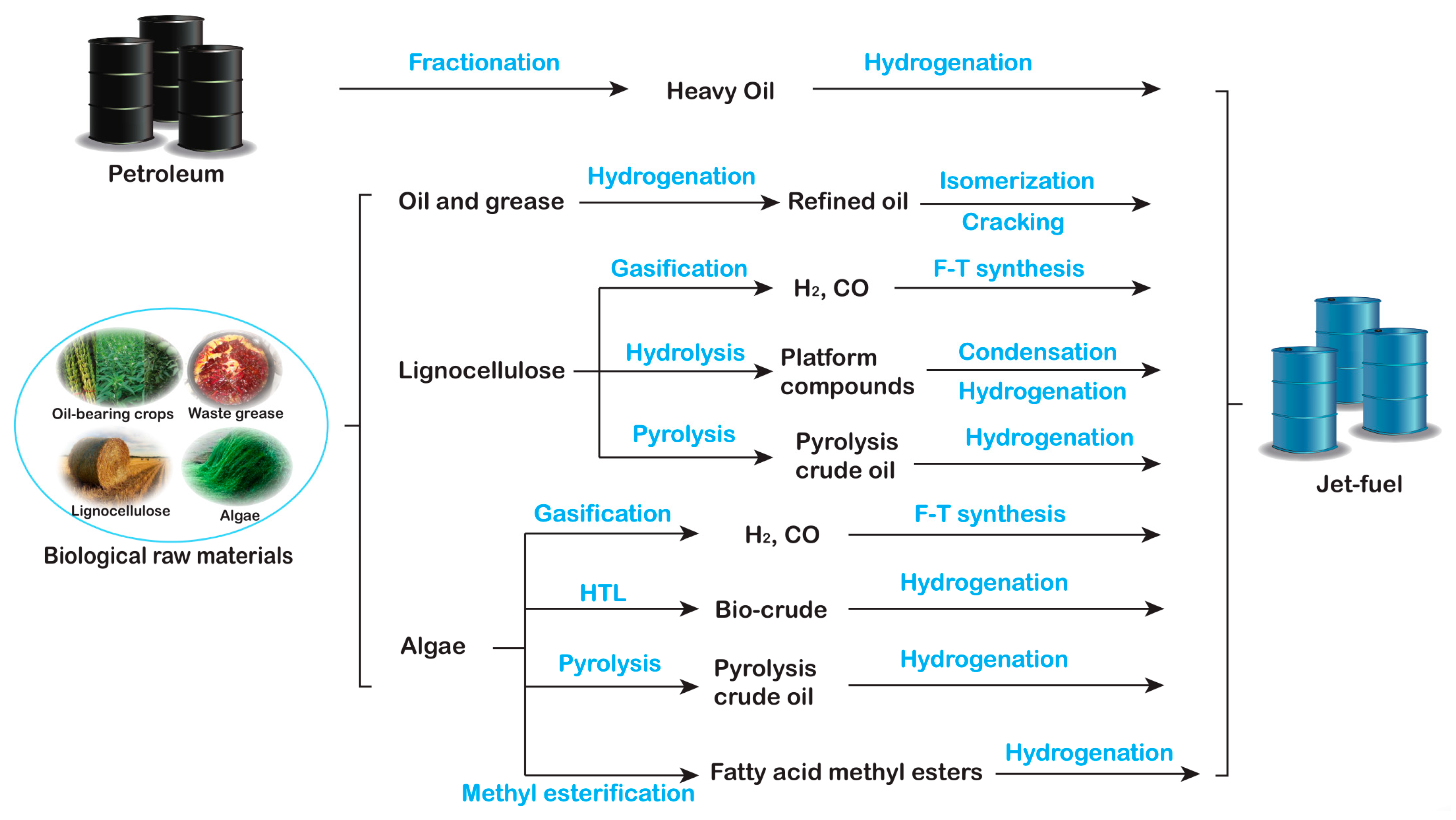

5.1. Preparation Process

5.2. Combustion Process

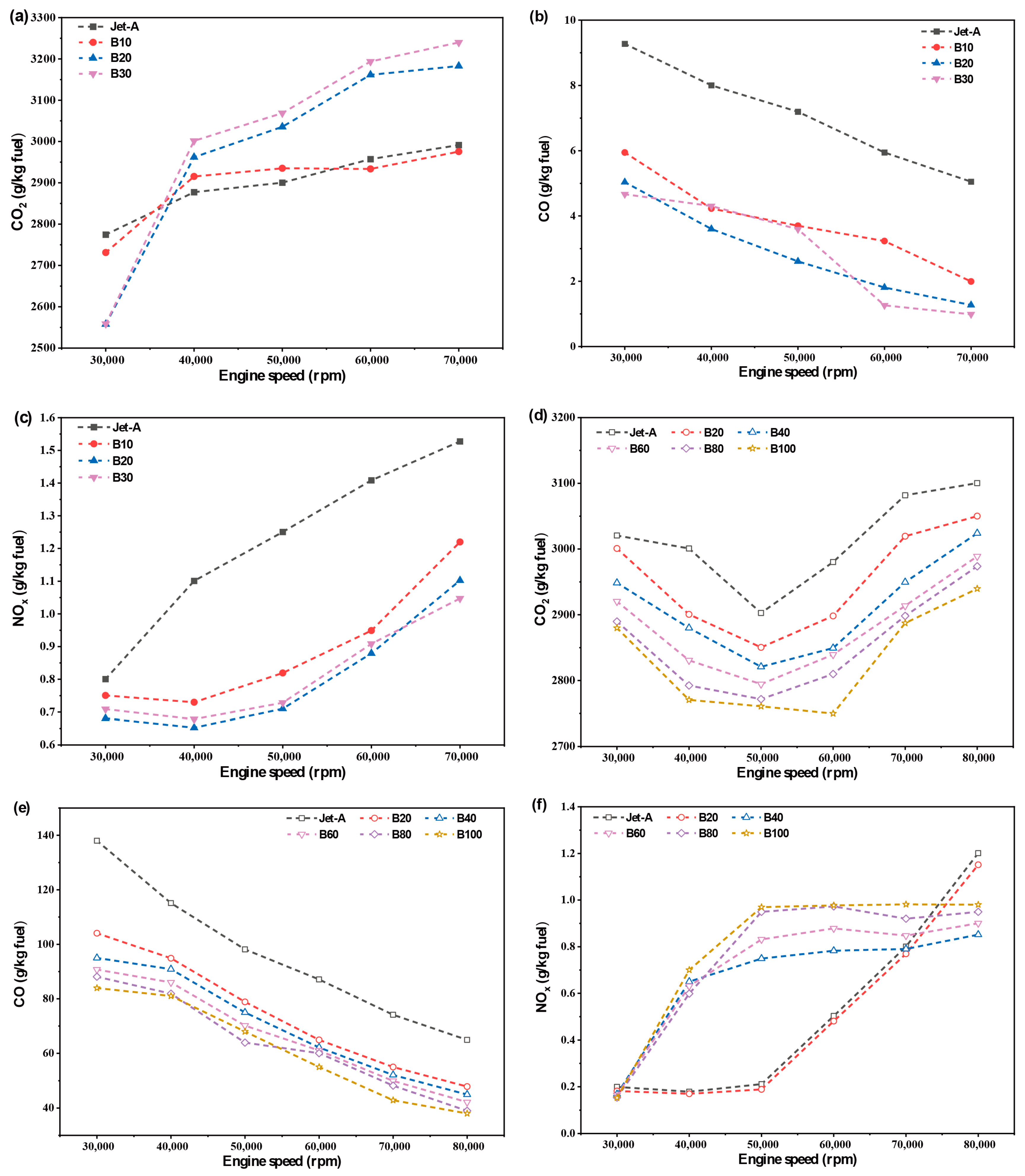

5.2.1. Gaseous Emissions

5.2.2. Particulate Matter (PM) Emissions

6. Concept of Biofuel–Electric Hybrid Aircraft

7. Microturbine Engine Power Systems

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Undavalli, V.; Gbadamosi Olatunde, O.B.; Boylu, R.; Wei, C.; Haeker, J.; Hamilton, J.; Khandelwal, B. Recent advancements in sustainable aviation fuels. Prog. Aerosp. Sci. 2023, 136, 100876. [Google Scholar] [CrossRef]

- Masiol, M.; Harrison, R.M. Aircraft engine exhaust emissions and other airport-related contributions to ambient air pollution: A review. Atmos. Environ. 2014, 95, 409–455. [Google Scholar] [CrossRef]

- Peace, H.; Maughan, J.; Owen, B.; Raper, D. Identifying the contribution of different airport related sources to local urban air quality. Environ. Model. Softw. 2006, 21, 532–538. [Google Scholar] [CrossRef]

- Beyersdorf, A.J.; Timko, M.T.; Ziemba, L.D.; Bulzan, D.; Corporan, E.; Herndon, S.C.; Howard, R.; Miake-Lye, R.; Thornhill, K.L.; Winstead, E.; et al. Reductions in aircraft particulate emissions due to the use of Fischer–Tropsch fuels. Atmos. Chem. Phys. 2014, 14, 11–23. [Google Scholar] [CrossRef]

- Lee, D.S.; Pitari, G.; Grewe, V.; Gierens, K.; Penner, J.E.; Petzold, A.; Prather, M.J.; Schumann, U.; Bais, A.; Berntsen, T.; et al. Transport impacts on atmosphere and climate: Aviation. Atmos. Environ. 2010, 44, 4678–4734. [Google Scholar] [CrossRef]

- Lee, D.S.; Fahey, D.W.; Forster, P.M.; Newton, P.J.; Wit, R.C.N.; Lim, L.L.; Owen, B.; Sausen, R. Aviation and global climate change in the 21st century. Atmos. Environ. 2009, 43, 3520–3537. [Google Scholar] [CrossRef]

- International Air Transport Association. Fact Sheet Climate Change & CORSIA; IATA: Montreal, QC, Canada, 2017. [Google Scholar]

- Su-ungkavatin, P.; Tiruta-Barna, L.; Hamelin, L. Biofuels, electrofuels, electric or hydrogen? A review of current and emerging sustainable aviation systems. Prog. Energy Combust. Sci. 2023, 96, 101073. [Google Scholar] [CrossRef]

- de Jong, S.; Antonissen, K.; Hoefnagels, R.; Lonza, L.; Wang, M.; Faaij, A.; Junginger, M. Life-cycle analysis of greenhouse gas emissions from renewable jet fuel production. Biotechnol. Biofuels 2017, 10, 64. [Google Scholar] [CrossRef]

- Wise, M.; Muratori, M.; Kyle, P. Biojet fuels and emissions mitigation in aviation: An integrated assessment modeling analysis. Transp. Res. Part D Transp. Environ. 2017, 52, 244–253. [Google Scholar] [CrossRef]

- Hepperle, M. Electric Flight—Potential and Limitations. In Avt-209 Workshop on Energy Efficient Technologies & Concepts Operation; NATO: Washington, DC, USA, 2012. [Google Scholar]

- Zhang, J.; Roumeliotis, I.; Zolotas, A. Sustainable Aviation Electrification: A Comprehensive Review of Electric Propulsion System Architectures, Energy Management, and Control. Sustainability 2022, 14, 5880. [Google Scholar] [CrossRef]

- Gierulski, M.P.; Khandelwal, B. Chapter 11—Electric-powered aircraft. In Aviation Fuels; Khandelwal, B., Ed.; Academic Press: Cambridge, MA, USA, 2021; pp. 271–296. [Google Scholar]

- Reddy, T.B.; Linden, D. Linden’s Handbook of Batteries; McGraw-Hil: New York, NY, USA, 2011. [Google Scholar]

- Sziroczak, D.; Jankovics, I.; Gal, I.; Rohacs, D. Conceptual design of small aircraft with hybrid-electric propulsion systems. Energy 2020, 204, 117937. [Google Scholar] [CrossRef]

- Xie, Y.; Savvarisal, A.; Tsourdos, A.; Zhang, D.; Gu, J. Review of hybrid electric powered aircraft, its conceptual design and energy management methodologies. Chin. J. Aeronaut. 2021, 34, 432–450. [Google Scholar] [CrossRef]

- Lei, T.; Yang, Z.; Lin, Z.; Zhang, X. State of art on energy management strategy for hybrid-powered unmanned aerial vehicle. Chin. J. Aeronaut. 2019, 32, 1488–1503. [Google Scholar] [CrossRef]

- Glassock, R.; Galea, M.; Williams, W.; Glesk, T. Hybrid Electric Aircraft Propulsion Case Study for Skydiving Mission. Aerospace 2017, 4, 45. [Google Scholar] [CrossRef]

- Donateo, T.; Ficarella, A.; Spedicato, L.; Arista, A.; Ferraro, M. A new approach to calculating endurance in electric flight and comparing fuel cells and batteries. Appl. Energy 2017, 187, 807–819. [Google Scholar] [CrossRef]

- Stolaroff, J.K.; Constantine, S.; O’Neill, E.R.; Alia, L.; Mitchell, A.S.; Daniel, C. Energy use and life cycle greenhouse gas emissions of drones for commercial package delivery. Nat. Commun. 2018, 9, 409. [Google Scholar] [CrossRef] [PubMed]

- Venkatasubramanian Viswanathan, A.H.E.Y.; Esther Takeuchi, M.B.J.L. The challenges and opportunities of battery-powered flight. Nature 2022, 601, 519–525. [Google Scholar] [CrossRef] [PubMed]

- Rohacs, J.; Rohacs, D. Energy coefficients for comparison of aircraft supported by different propulsion systems. Energy 2020, 191, 116391. [Google Scholar] [CrossRef]

- Aruvelli, S.V.; Dolgov, O.S. A Method of Increasing the Electric Aircraft Flight Range by Reducing Weight during Flight. Russ. Aeronaut. 2020, 63, 405–412. [Google Scholar] [CrossRef]

- Alan, H.; Epstein, S.M.O. Considerations for Reducing Aviation CO with Aircraft Electric Propulsion. J. Propuls. Power 2019, 3, 572–582. [Google Scholar]

- Ashkan Barzkar, G.S.M.I. Components of Electrical Power Systems in More and All-Electric Aircraft A Review. IEEE Access 2022, 4, 4037–4053. [Google Scholar]

- E-Fan X: A Giant Leap towards Zero-Emission Flight. Available online: https://www.airbus.com/en/innovation/zero-emission/electric-flight/e-fan-x (accessed on 3 April 2023).

- Sebastian Nicolay, S.K.Y.L. Conceptual design and optimization of a general aviation aircraft with fuel cells and hydrogen. Int. J. Hydrogen Energy 2021, 64, 32676–32694. [Google Scholar] [CrossRef]

- Kramer, D. Hydrogen-powered aircraft may be getting a lift. Phys. Today 2020, 73, 27–29. [Google Scholar] [CrossRef]

- Ahmad Baroutajia, T.W.M.R. Comprehensive investigation on hydrogen and fuel cell technology in the aviation and aerospace sectors. Renew. Sustain. Energy Rev. 2019, 106, 31–40. [Google Scholar] [CrossRef]

- Jain, S.; Chao, H.; Mane, M.; Crossley, W.A.; DeLaurentis, D.A. Estimating the Reduction in Future Fleet-Level CO2 Emissions from Sustainable Aviation Fuel. Front. Energy Res. 2021, 9. [Google Scholar] [CrossRef]

- ASTM D7566; Standard Specification for Aviation Turbine Fuel Containing Synthesized Hydrocarbons. Neste: Espoo, Finland, 2024.

- Yuhan, J.; Xiasheng, S.; Xiao, Y.; Jiaxi, W. Development Prospect of New Energy Aviation Under Carbon Peaking and Carbon Neutrality Goals. Aeronaut. Sci. Technol. 2022, 33, 1–11. [Google Scholar]

- William, L.; Fredericks, S.S.G.C. Performance Metrics Required of Next-Generation Batteries to Electrify Vertical Takeoff and Landing (VTOL) Aircraft. ACS Energy Lett. 2018, 12, 2989–2994. [Google Scholar]

- Zhenwei, F.; Fengtian, Y.; Song, X.; Weiping, Z. Present Situation and Advice of Electric Aircraft Development in China. Aeronaut. Sci. Technol. 2019, 30, 18–21. [Google Scholar]

- RX1E-S. Available online: https://lgaa.sau.edu.cn/info/1021/1028.htm (accessed on 3 April 2023).

- Alpha Alpha Electro Electric Aircraft Introduction. Available online: https://pipistrel-china.com/?p=459 (accessed on 3 April 2023).

- Introducing the First Electric Vertical Take-Off and Landing Jet. Available online: https://lilium.com/jet (accessed on 3 April 2023).

- Baumeister, S.; Leung, A.; Ryley, T. The emission reduction potentials of First Generation Electric Aircraft (FGEA) in Finland. J. Transp. Geogr. 2020, 85, 102730. [Google Scholar] [CrossRef]

- H55’S Mission Is to Bring Electric Propulsion Solutions to Enable the Aviation Industry to Reach Net Zero C02 BY 2050. Available online: https://www.h55.ch/# (accessed on 3 April 2023).

- First All-Electric Commercial Aircraft Conducts Inaugural Flight. Available online: https://www.aerospace-technology.com/news/first-all-electric-commercial-aircraft-conducts-inaugural-flight/ (accessed on 3 April 2023).

- Dufour Aerospace launches Aero2. Available online: https://helihub.com/2021/11/16/dufour-aerospace-launches-aero2/ (accessed on 3 April 2023).

- Skyworks Aeronautics eGyro. Available online: https://evtol.news/skyworks-global-egyro/ (accessed on 3 April 2023).

- Taxis Take Flight. Available online: https://www.3ds.com/insights/customer-stories/vertical-aerospace (accessed on 3 April 2023).

- Sai-te, W. Feasibility analysis and prospect of electric aircraft application. Energy Conserv. 2020, 39, 57–60. [Google Scholar]

- Moog SureFly. Available online: https://evtol.news/workhorse/ (accessed on 3 April 2023).

- PROSPERITY I Autoflight: Pure Electric Vertical Takeoff and Landing Manned Aircraft. In Chinese. Available online: https://www.autoflight.com/zh/ (accessed on 3 April 2023).

- Exclusive: We Flew the Elektra Trainer. Available online: https://www.e-flight-journal.com/ (accessed on 3 April 2023).

- ZeroAvia Completes World First Hydrogen-Electric Passenger Plane Flight. Available online: https://en.prnasia.com/releases/apac/zeroavia-completes-world-first-hydrogen-electric-passenger-plane-flight-292889.shtml (accessed on 3 April 2023).

- Zero-Emission Aviation. Powered by Hydrogen. Available online: https://www.h2fly.de/ (accessed on 3 April 2023).

- Bringing you Electric Air Travel out to a Thousand Miles. Available online: https://zunum.aero/ (accessed on 3 April 2023).

- Our Electric Propulsion System Powers the Future of Electrified Aircraft. Available online: https://www.ampaire.com/ (accessed on 3 April 2023).

- Boeing 787 Dreamliner. Available online: https://www.boeing.com/commercial/787/ (accessed on 3 April 2023).

- Challenger 350. Available online: https://businessaircraft.bombardier.com/en/aircraft/challenger-350#bba-pdp-section-1 (accessed on 3 April 2023).

- Gulfstream G280. Available online: https://www.gulfstream.com/en/aircraft/gulfstream-g280/ (accessed on 3 April 2023).

- Airbus’ most Popular Aircraft Takes to the Skies with 100% Sustainable Aviation Fuel. Available online: https://www.airbus.com/en/newsroom/stories/2023-03-airbus-most-popular-aircraft-takes-to-the-skies-with-100-sustainable (accessed on 3 April 2023).

- Gnadt, A.R.; Speth, R.L.; Sabnis, J.S.; Barrett, S.R.H. Technical and environmental assessment of all-electric 180-passenger commercial aircraft. Prog. Aerosp. Sci. 2019, 105, 1–30. [Google Scholar] [CrossRef]

- Schaefer, A.W.; Evans, A.D.; Reynolds, T.G.; Dray, L. Costs of mitigating CO2 emissions from passenger aircraft. Nat. Clim. Change 2016, 6, 412–417. [Google Scholar] [CrossRef]

- International Energy Statistics, U.S. Energy Information Agency. Available online: https://www.eia.gov/opendata/qb.php?category=2135044&sdid=INTL.63-2-WORL-TBPD.A (accessed on 28 November 2018).

- Brelje, B.J.; Martins, J.R.R.A. Electric, hybrid, and turboelectric fixed-wing aircraft: A review of concepts, models, and design approaches. Prog. Aerosp. Sci. 2019, 104, 1–19. [Google Scholar] [CrossRef]

- Schäfer, A.W.; Barrett, S.R.H.; Doyme, K.; Dray, L.M.; Gnadt, A.R.; Self, R.; O’Sullivan, A.; Synodinos, A.P.; Torija, A.J. Technological, economic and environmental prospects of all-electric aircraft. Nat. Energy 2019, 4, 160–166. [Google Scholar] [CrossRef]

- Misra, A. Summary of 2017 NASA Workshop on Assessment of Advanced Battery Technologies for Aerospace Applications; NASA Glenn Research Center Rept.; NASA: Washington, DC, USA, 2018.

- Thackeray, M.M.; Wolverton, C.; Isaacs, E.D. Electrical energy storage for transportation-approaching the limits of, and going beyond, lithium-ion batteries. Energy Environ. Sci. 2012, 5, 7854–7863. [Google Scholar] [CrossRef]

- Tiede, B.; O’Meara, C.; Jansen, R. Battery Key Performance Projections based on Historical Trends and Chemistries. In Proceedings of the 2022 IEEE/AIAA Transportation Electrification Conference and Electric Aircraft Technologies Symposium (ITEC+EATS 2022), Anaheim, CA, USA, 15–17 June 2022. [Google Scholar]

- Yu, L.; Wu, H.; Zhao, W.; Qian, Y.; Zhu, L.; Lu, X. Experimental study on the application of n-butanol and n-butanol/kerosene blends as fuel for spark ignition aviation piston engine. Fuel 2021, 304, 121362. [Google Scholar] [CrossRef]

- Caceres-Martinez, L.E.; Lopez, J.S.; Dagle, R.A.; Gillespie, R.; Kenttämaa, H.I.; Kilaz, G. Influence of blending cycloalkanes on the energy content, density, and viscosity of Jet-A. Fuel 2024, 358, 129986. [Google Scholar] [CrossRef]

- Prapotnik Brdnik, A.; Kamnik, R.; Marksel, M.; Božičnik, S. Market and Technological Perspectives for the New Generation of Regional Passenger Aircraft. Energies 2019, 12, 1864. [Google Scholar] [CrossRef]

- Abdullah, M.; Faizan, M.; Bhatti, M.Y.; Hasham, H.J. System Design and Analysis ofHand Lunched UAV. In Proceedings of the 14th International Bhurban Conference on Applied Sciences and Technology (IBCAST), Islamabad, Pakistan, 10–14 January 2017; pp. 551–560. [Google Scholar]

- Adamo, F.; Andria, G.; Di Nisio, A.; Carducci, C.G.C.; Lanzolla, A.M.L.; Mattencini, G. Development and Characterization of a Measurement Instrumentation System for UAV Components Testing. In Proceedings of the 2017 IEEE International Workshop on Metrology for AeroSpace (MetroAeroSpace), Padua, Italy, 21–23 June 2017; pp. 355–359. [Google Scholar]

- Gao, X.; Liu, C.; Huang, Y.; Song, Z. Design of an UAV-Oriented Wireless Power Transfer System with Energy-Efficient Receiver. In Proceedings of the IECON 2020 The 46th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 18–21 October 2020; pp. 2025–2030. [Google Scholar]

- Batth, J.R. Classification of Unmanned Aerial vehicles: A Mirror Review. In Proceedings of the 2020 International Conference on Intelligent Engineering and Management (ICIEM), London, UK, 17–19 June 2020; pp. 408–413. [Google Scholar]

- Watts, A.C.; Ambrosia, V.G.; Hinkley, E.A. Unmanned Aircraft Systems in Remote Sensing and Scientific Research: Classification and Considerations of Use. Remote Sens. 2012, 4, 1671–1692. [Google Scholar] [CrossRef]

- Zhang, B.; Song, Z.; Zhao, F.; Liu, C. Overview of Propulsion Systems for Unmanned Aerial Vehicles. Energies 2022, 15, 455. [Google Scholar] [CrossRef]

- Lieh, J.; Spahr, E.; Behbahani, A.; Hoying, J. Design of Hybrid Propulsion Systems for Unmanned Aerial Vehicles. In Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, San Diego, CA, USA, 31 Huly–3 August 2011. [Google Scholar]

- Hung, J.Y.; Gonzalez, L.F. On parallel hybrid-electric propulsion system for unmanned aerial vehicles. Prog. Aerosp. Sci. 2012, 51, 1–17. [Google Scholar] [CrossRef]

- Xiao, C.; Wang, B.; Zhao, D.; Wang, C. Comprehensive investigation on Lithium batteries for electric and hybrid-electric unmanned aerial vehicle applications. Therm. Sci. Eng. Prog. 2023, 38, 101677. [Google Scholar] [CrossRef]

- Pan, Z.F.; An, L.; Wen, C.Y. Recent advances in fuel cells based propulsion systems for unmanned aerial vehicles. Appl. Energy 2019, 240, 473–485. [Google Scholar] [CrossRef]

- Wang, B.; Zhao, D.; Li, W.; Wang, Z.; Huang, Y.; You, Y.; Becker, S. Current technologies and challenges of applying fuel cell hybrid propulsion systems in unmanned aerial vehicles. Prog. Aerosp. Sci. 2020, 116, 100620. [Google Scholar] [CrossRef]

- Pipistrel. Available online: https://www.pipistrel-aircraft.com/ (accessed on 9 July 2024).

- Frosina, E.; Caputo, C.; Marinaro, G.; Senatore, A.; Pascarella, C.; Di Lorenzo, G. Modelling of a Hybrid-Electric Light Aircraft. Energy Procedia 2017, 126, 1155–1162. [Google Scholar] [CrossRef]

- Pornet, C.; Isikveren, A.T. Conceptual design of hybrid-electric transport aircraft. Prog. Aerosp. Sci. 2015, 79, 114–135. [Google Scholar] [CrossRef]

- Finger, D.F.; Braun, C.; Bil, C. Comparative Assessment of Parallel-Hybrid-Electric Propulsion Systems for Four Different Aircraft. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; Volume 57, pp. 843–853. [Google Scholar]

- Friedrich, C.; Robertson, P.A. Hybrid-Electric Propulsion for Aircraft. J. Aircr. 2015, 52, 176–189. [Google Scholar] [CrossRef]

- Ribeiro, J.; Afonso, F.; Ribeiro, I.; Ferreira, B.; Policarpo, H.; Pecas, P.; Lau, F. Environmental assessment of hybrid-electric propulsion in conceptual aircraft design. J. Clean. Prod. 2020, 247, 119477. [Google Scholar] [CrossRef]

- Hoelzen, J.; Liu, Y.; Bensmann, B.; Winnefeld, C.; Elham, A.; Friedrichs, J.; Hanke-Rauschenbach, R. Conceptual Design of Operation Strategies for Hybrid Electric Aircraft. Energies 2018, 11, 217. [Google Scholar] [CrossRef]

- Bhagwan, R.; Habisreuther, P.; Zarzalis, N.; Turrini, F. An Experimental Comparison of the Emissions Characteristics of Standard Jet A-1 and Synthetic Fuels. Flow Turbul. Combust. 2014, 92, 865–884. [Google Scholar] [CrossRef]

- Wang, Z.; Feser, J.S.; Lei, T.; Gupta, A.K. Performance and emissions of camelina oil derived jet fuel blends under distributed combustion condition. Fuel 2020, 271, 117685. [Google Scholar] [CrossRef]

- Khan, M.A.H.; Bonifacio, S.; Clowes, J.; Foulds, A.; Holland, R.; Matthews, J.C.; Percival, C.J.; Shallcross, D.E. Investigation of Biofuel as a Potential Renewable Energy Source. Atmosphere 2021, 12, 1289. [Google Scholar] [CrossRef]

- Zhang, Q.; Xiao, J.; Hao, J.; Wu, Q.; Song, G. Energy and exergy analyses of bio-jet fuel production from full components in lignocellulosic biomass via aqueous-phase conversion. Appl. Therm. Eng. 2021, 201, 117723. [Google Scholar] [CrossRef]

- Kandaramath Hari, T.; Yaakob, Z.; Binitha, N.N. Aviation biofuel from renewable resources: Routes, opportunities and challenges. Renew. Sustain. Energy Rev. 2015, 42, 1234–1244. [Google Scholar] [CrossRef]

- Guo, F.; Zhao, J.; Lusi, A.; Yang, X. Life cycle assessment of microalgae-based aviation fuel: Influence of lipid content with specific productivity and nitrogen nutrient effects. Bioresour. Technol. 2016, 221, 350–357. [Google Scholar] [CrossRef] [PubMed]

- Xiu, S.; Shahbazi, A. Bio-oil production and upgrading research: A review. Renew. Sustain. Energy Rev. 2012, 16, 4406–4414. [Google Scholar] [CrossRef]

- Seber, G.; Malina, R.; Pearlson, M.N.; Olcay, H.; Hileman, J.I.; Barrett, S.R.H. Environmental and economic assessment of producing hydroprocessed jet and diesel fuel from waste oils and tallow. Biomass Bioenergy 2014, 67, 108–118. [Google Scholar] [CrossRef]

- Chheda, J.N.; Dumesic, J.A. An overview of dehydration, aldol-condensation and hydrogenation processes for production of liquid alkanes from biomass-derived carbohydrates. Catal. Today 2007, 123, 59–70. [Google Scholar] [CrossRef]

- Li, C.; Zhao, X.; Wang, A.; Huber, G.W.; Zhang, T. Catalytic Transformation of Lignin for the Production of Chemicals and Fuels. Chem. Rev. 2015, 115, 11559–11624. [Google Scholar] [CrossRef]

- Tucki, K.; Orynycz, O.; Wasiak, A.; Świć, A.; Mruk, R.; Botwińska, K. Estimation of Carbon Dioxide Emissions from a Diesel Engine Powered by Lignocellulose Derived Fuel for Better Management of Fuel Production. Energies 2020, 13, 561. [Google Scholar] [CrossRef]

- Tang, S.; Shi, Z.; Tang, X.; Yang, X. Hydrotreatment of biocrudes derived from hydrothermal liquefaction and lipid extraction of the high-lipidScenedesmus. Green Chem. 2019, 21, 3413–3423. [Google Scholar] [CrossRef]

- Altmann, B.A.; Rosenau, S. Spirulina as Animal Feed: Opportunities and Challenges. Foods 2022, 11, 965. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Guo, F.; Xue, S.; Wang, X. Carbon distribution of algae-based alternative aviation fuel obtained by different pathways. Renew. Sustain. Energy Rev. 2016, 54, 1129–1147. [Google Scholar] [CrossRef]

- Sun, M.; Gan, Z.; Yang, Y. A Comparison Study of Soot Precursor and Aggregate Property Between Algae-Based Aviation Biofuel and Aviation Kerosene RP-3 in Laminar Flame. J. Energy Resour. Technol. Trans. Asme 2021, 143, 112304. [Google Scholar] [CrossRef]

- Shi, Z.; Zhao, B.; Tang, S.; Yang, X. Hydrotreating lipids for aviation biofuels derived from extraction of wet and dry algae. J. Clean. Prod. 2018, 204, 906–915. [Google Scholar] [CrossRef]

- Balaji, V.; Kaliappan, S.; Madhuvanesan, D.M.; Ezhumalai, D.S.; Boopathi, S.; Pravin, P.P.; Mani, S. Combustion analysis of biodiesel-powered propeller engine for least environmental concerns in aviation industry. Aircr. Eng. Aerosp. Technol. 2022, 94, 760–769. [Google Scholar]

- Liang, Z.; Yu, Z.; Liu, H.; Chen, L.; Huang, X. Combustion and emission characteristics of a compression ignition engine burning a wide range of conventional hydrocarbon and alternative fuels. Energy 2022, 250, 123717. [Google Scholar] [CrossRef]

- Corporan, E.; DeWitt, M.J.; Belovich, V.; Pawlik, R.; Lynch, A.C.; Gord, J.R.; Meyer, T.R. Emissions characteristics of a turbine engine and research combustor burning a Fischer− Tropsch jet fuel. Energy Fuels 2007, 21, 2615–2626. [Google Scholar] [CrossRef]

- Boomadevi, P.; Paulson, V.; Samlal, S.; Varatharajan, M.; Sekar, M.; Alsehli, M.; Elfasakhany, A.; Tola, S. Impact of microalgae biofuel on microgas turbine aviation engine: A combustion and emission study. Fuel 2021, 302, 121155. [Google Scholar] [CrossRef]

- Yang, J.; Xin, Z.; He, Q.S.; Corscadden, K.; Niu, H. An overview on performance characteristics of bio-jet fuels. Fuel 2019, 237, 916–936. [Google Scholar] [CrossRef]

- Corporan, E.; Edwards, T.; Shafer, L.; DeWitt, M.J.; Klingshirn, C.; Zabarnick, S.; West, Z.; Striebich, R.; Graham, J.; Klein, J. Chemical, Thermal Stability, Seal Swell, and Emissions Studies of Alternative Jet Fuels. Energy Fuels 2011, 25, 955–966. [Google Scholar] [CrossRef]

- Lobo, P.; Hagen, D.E.; Whitefield, P.D. Comparison of PM Emissions from a Commercial Jet Engine Burning Conventional, Biomass, and Fischer–Tropsch Fuels. Environ. Sci. Technol. 2011, 45, 10744–10749. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Wang, Z.; Yang, X. Emission characteristics of cellulosic jet biofuel blend under laminar and turbulent combustion. Biotechnol. Biofuels Bioprod. 2023, 16, 196. [Google Scholar] [CrossRef] [PubMed]

- Ziyu, L.; Xiaoyi, Y. Engine Performance and Emission Characteristics of Cellulosic Jet Biofuel Blends. China Pet. Process. Petrochem. Technol. 2023, 25, 29. [Google Scholar]

- Calcote, H.F.; Manos, D.M. Effect of Molecular Structure on Incipient Soot Formation. Combust. Flame 1983, 49, 289–304. [Google Scholar] [CrossRef]

- International Coordinating Council of Aerospace Industries Associations (Ed.) Impact of Alternative Fuels on Aircraft Engine Emissions. In Proceedings of the Conference on Aviation and Alternative Fuels, Rio de Janeiro, Brazil, 16–18 November 2009; ICAO Conference on Aviation and Alternative Fuels: Rio de Janeiro, Brazil, 2009; pp. 1–10. [Google Scholar]

- Liu, S.; Zhang, H.; Fan, Q.; Wang, W.; Qi, Y.; Wang, Z. Investigation of combustion and particle number (PN) emissions in a spark induced compression ignition (SICI) engine for ethanol-gasoline blends. Fuel 2022, 316, 123155. [Google Scholar] [CrossRef]

- He, Y.; Wang, C.; Zhou, Q.; Li, J.; Makridis, M.; Williams, H.; Lu, G.; Xu, H. Multiobjective component sizing of a hybrid ethanol-electric vehicle propulsion system. Appl. Energy 2020, 266, 114843. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, S.; Lei, N.; Fan, Q.; Wang, Z. Leveraging the benefits of ethanol-fueled advanced combustion and supervisory control optimization in hybrid biofuel-electric vehicles. Appl. Energy 2022, 326, 120033. [Google Scholar] [CrossRef]

- Cican, G. Experimental Transient Process Analysis of Micro-Turbojet Aviation Engines: Comparing the Effects of Diesel and Kerosene Fuels at Different Ambient Temperatures. Energies 2024, 17, 1366. [Google Scholar] [CrossRef]

- Cican, G.; Crunteanu, D.E.; Mirea, R.; Ceatra, L.C.; Leventiu, C. Biodiesel from Recycled Sunflower and Palm Oil—A Sustainable Fuel for Microturbo-Engines Used in Airside Applications. Sustainability 2023, 15, 2079. [Google Scholar] [CrossRef]

- Badami, M.; Nuccio, P.; Pastrone, D.; Signoretto, A. Performance of a small-scale turbojet engine fed with traditional and alternative fuels. Energy Convers. Manag. 2014, 82, 219–228. [Google Scholar] [CrossRef]

- Chiariello, F.; Allouis, C.; Reale, F.; Massoli, P. Gaseous and particulate emissions of a micro gas turbine fuelled by straight vegetable oil–kerosene blends. Exp. Therm. Fluid Sci. 2014, 56, 16–22. [Google Scholar] [CrossRef]

- Metin, E.Y.; Aygun, H. Energy and power aspects of an experimental target drone engine at non-linear controller loads. Energy 2019, 185, 981–993. [Google Scholar] [CrossRef]

- Wessley, G.J.J.; Chauhan, S. Investigation on scaling of Gas Turbine engines for Drone propulsion. Int. J. Eng. Technol. Manag. Appl. Sci. 2017, 5, 48–53. [Google Scholar]

| Type of Aircraft | Voyage (km) | Seating Capacity (Person) |

|---|---|---|

| Electric aircraft | 0–500 | 0–20 |

| Hydrogen fuel cell aircraft | 300–1500 | 6–80 |

| Hydrogen turbine aircraft | 1000–10,000 | 11–400 |

| SAF aircraft | 600–16,000 | 30–500 |

| Type | Model | Seating Capacity | Max. Cruising Speed (km/h) | Max. Takeoff Weight/kg | Lift Limit/m | Voyage/km | Endurance | Companies | References |

|---|---|---|---|---|---|---|---|---|---|

| Electric aircraft | RX1E | 2 | 110 | 500 | 300 | 1 h | Liaoning General Aviation Academy (LGAA) (Liaoning, China) | [34] | |

| RX1E-A | 2 | 190 | 400 | 2 h | [34] | ||||

| RX1E-S | 2 | 160 | 650 | 100 min | [35] | ||||

| Pipistrel Alpha Electro | 2 | 550 | 1 h | Pipistrel d.o.o. (Slovenia) | [36] | ||||

| Lilium jet | 2 | 250–300 | 300 | Lilium (Germany) | [37] | ||||

| Eviation Alice | 9 | 6350 | 1040 | Eviation (WA, USA) | [38] | ||||

| Heart Aerospace ES-19 | 19 | 400 | Heart Aerospace (Gothenburg, Sweden) | [38] | |||||

| H55 electric aircraft | 2 | 200 | 1 h | H55 S.A. (Switzerland) | [39] | ||||

| Harbour Air ePlane | 6–8 | 160 | Harbour Air (YVR, Canada) | [40] | |||||

| Dufour Aerospace aEro 2 | 4 | 170 | 150 | 100 | 3 h | Dufour Aerospace (Switzerland) | [41] | ||

| Skyworks Global eGyro | 2–4 | 241 | 161 | Skyworks Aeronautics Corp. (IL, USA) | [42] | ||||

| Vertical Aerospace VA-X4 | 4 | 160 | 240 | Dassault Systèmes (Paris, France) | [43] | ||||

| RX4E | 4 | 1200 | 5000 | 300 | 1.5 h | LGAA | [44] | ||

| SureFly | 2 | 113 | 680 | 1200 | 112 | Moog Inc. (NYC, USA) | [45] | ||

| Centro Dragon 4 | 5 | 200 | 1500 | 250 | Autofight (Shanghai, China) | [46] | |||

| Elektra Trainer | 2 | 600 | 300 | 2.5 h | Elektra Solar GmbH (Germany) | [47] | |||

| Hydrogen-powered aircraft | Spirit Sparrow H | 180 | 500 | Commercial Aircraft Corporation of China Ltd. (Shanghai, China) | [34] | ||||

| ZeroAvia HyFlyer | 10–20 | 800 | ZeroAvia, Inc. (England) | [48] | |||||

| HY4 | 4 | 200 | 1500 | 2134 | 1500 | H2FLY (Germany) | [49] | ||

| Hybrid aircraft | Airbus E-Fan X | 100 | 2250 | Airbus (Toulouse, France) | [26] | ||||

| Zunum Aero | 10–50 | 1127 | Zunum Aero (SEA, USA) | [50] | |||||

| Ampaire Electric EEL | 6 | 480 | 2 h | Ampaire (CA, USA) | [51] | ||||

| SAF aircraft (Testing with SAF on conventional aircraft) | Boeing 787 Dreamliner | 248–336 | 1041 | 254,700 | - | 14,010 | - | The Boeing Company (VA, USA) | [52] |

| Bombardier Challenger 350 | 10 | 1017 | 18,416 | 13,716 | 5926 | - | Bombardier Inc. (QC, Canada) | [53] | |

| Gulfstream G280 | 10 | 1041 | 17,962 | 13,716 | 6667 | - | Gulfstream Aerospace Corporation (GA, USA) | [54] | |

| Airbus A321neo | 180–220 | 840 | 97,000 | 12,100 | 7400 | - | Airbus (Toulouse, France) | [55] |

| Chemistry | Theoretical Limit (Wh/kg) | Specific Energy (Wh/kg) | |

|---|---|---|---|

| Battery | LiCoO2/C6 | 568 | 275 |

| Pd-Acid | 171 | 55 | |

| NiMH | 240 | 116 | |

| Li-S | 2654 | 420 | |

| Na-S | 792 | 240 | |

| Fossil fuel | Gasoline | - | 12,012 |

| RP-3 | - | 11,984 | |

| Jet-A | - | 11,917 |

| Biofuel–Electric Hybrid Aircraft vs. Conventional Aircraft/Biofuel Aircraft | Biofuel–Electric Hybrid Aircraft vs. Electric Aircraft | Biofuel–Electric Hybrid Aircraft vs. Hybrid Aircraft | |

|---|---|---|---|

| Advantages | Reduced emissions (vs. conventional aircraft); Enhanced efficiency; flexible power system; Low noise. | Better flight performance like maximum takeoff weight, seating capacity, max. cruising speed, and flight time. | Lower CO2 emissions from a full lifecycle perspective; Lower SO2 and PM emissions. |

| Disadvantages | Common issues; Infrastructure development; Need to change power structure of existing aircraft. | Common issues; More pollutant emissions. | The “drop-in” nature of biofuels needs to be verified. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, S.; Song, Z.; Meng, Z.; Liu, Z. Biofuel–Electric Hybrid Aircraft Application—A Way to Reduce Carbon Emissions in Aviation. Aerospace 2024, 11, 575. https://doi.org/10.3390/aerospace11070575

Dong S, Song Z, Meng Z, Liu Z. Biofuel–Electric Hybrid Aircraft Application—A Way to Reduce Carbon Emissions in Aviation. Aerospace. 2024; 11(7):575. https://doi.org/10.3390/aerospace11070575

Chicago/Turabian StyleDong, Shengfei, Zehua Song, Zheyi Meng, and Ziyu Liu. 2024. "Biofuel–Electric Hybrid Aircraft Application—A Way to Reduce Carbon Emissions in Aviation" Aerospace 11, no. 7: 575. https://doi.org/10.3390/aerospace11070575

APA StyleDong, S., Song, Z., Meng, Z., & Liu, Z. (2024). Biofuel–Electric Hybrid Aircraft Application—A Way to Reduce Carbon Emissions in Aviation. Aerospace, 11(7), 575. https://doi.org/10.3390/aerospace11070575