Numerical Analysis of the Water Entry Process of the Cabin Structure of the Trans-Domain Morphing Aircraft Considering Structural Deformation

Abstract

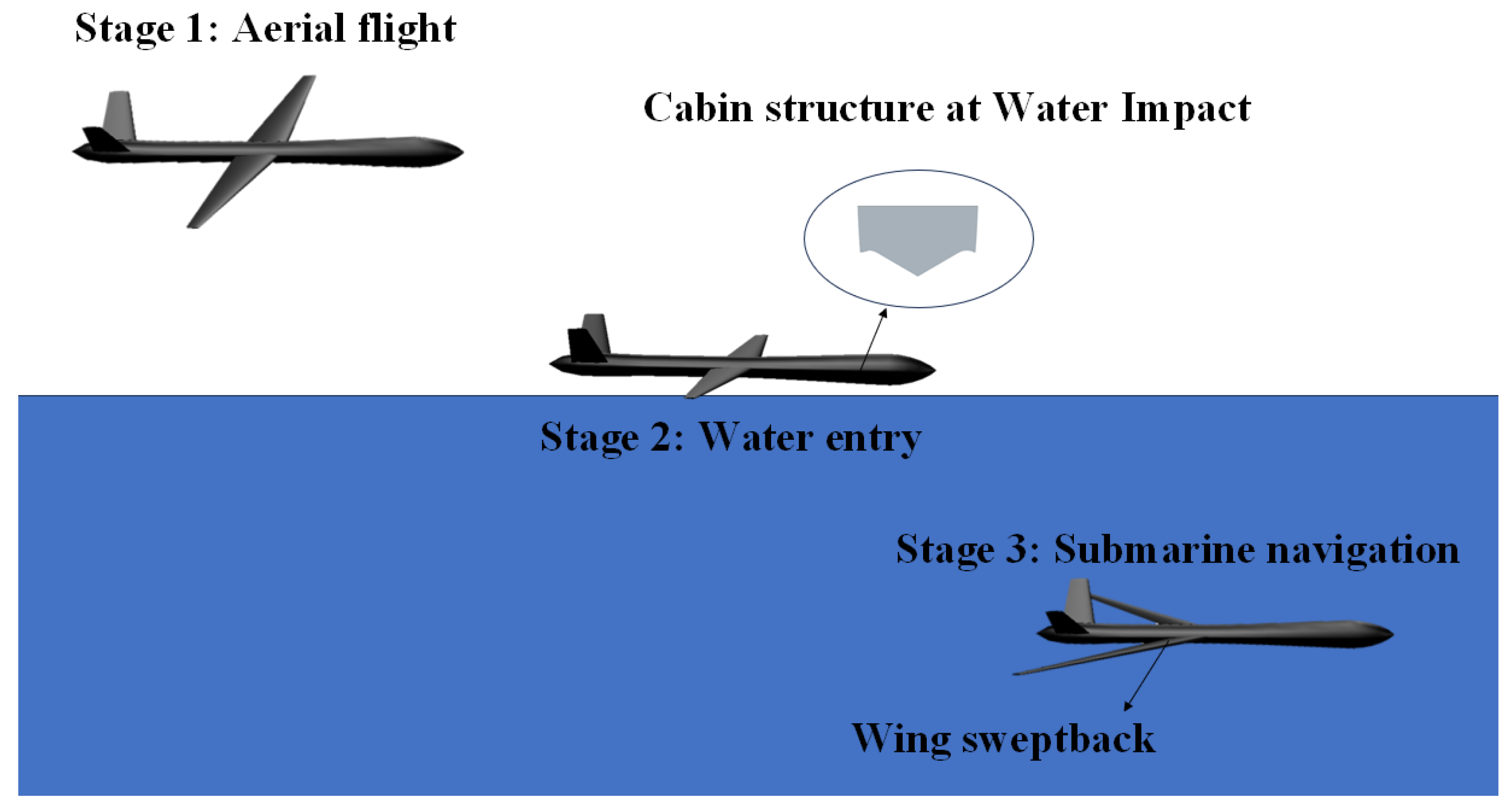

1. Introduction

2. Model Definition

2.1. Problem Description

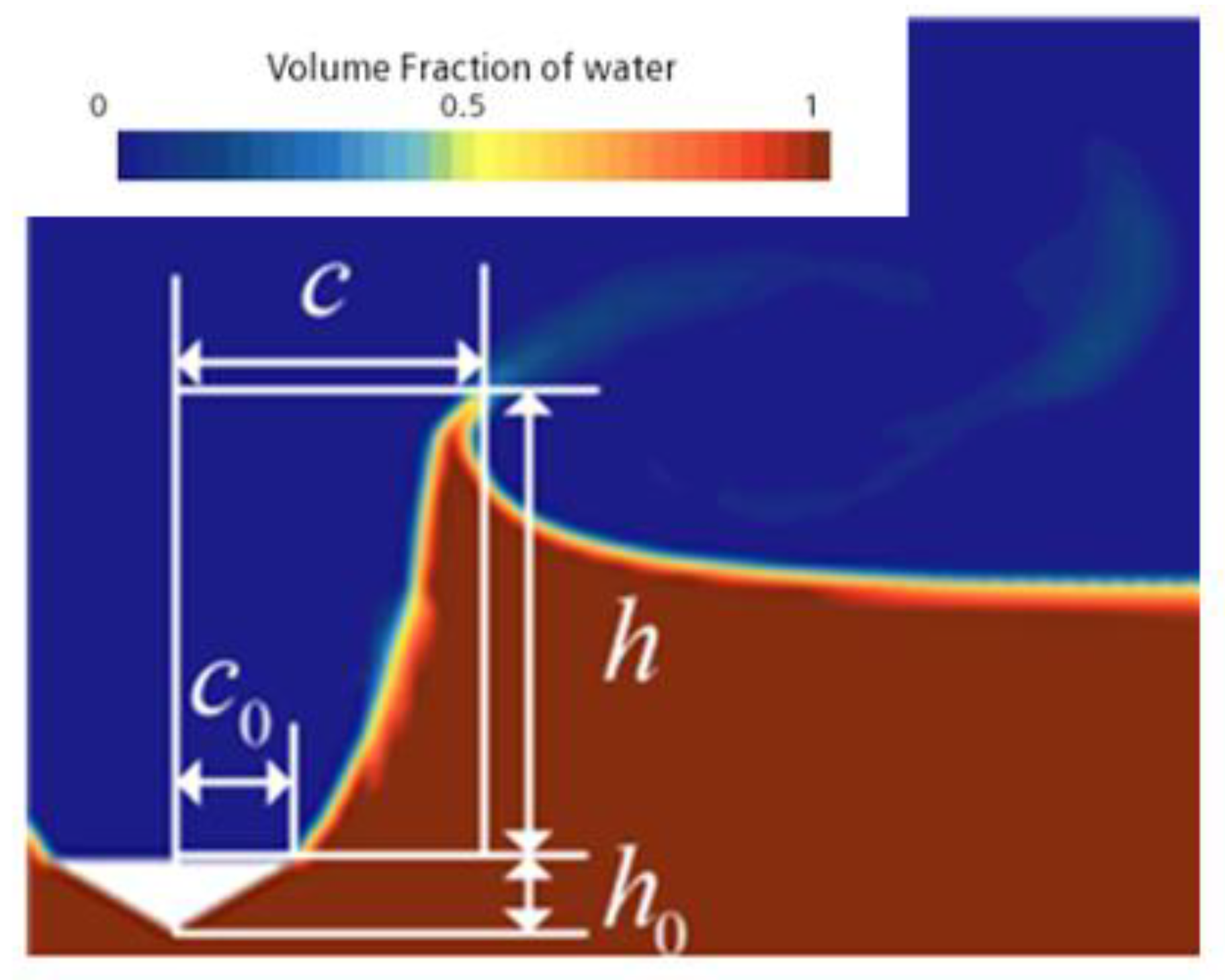

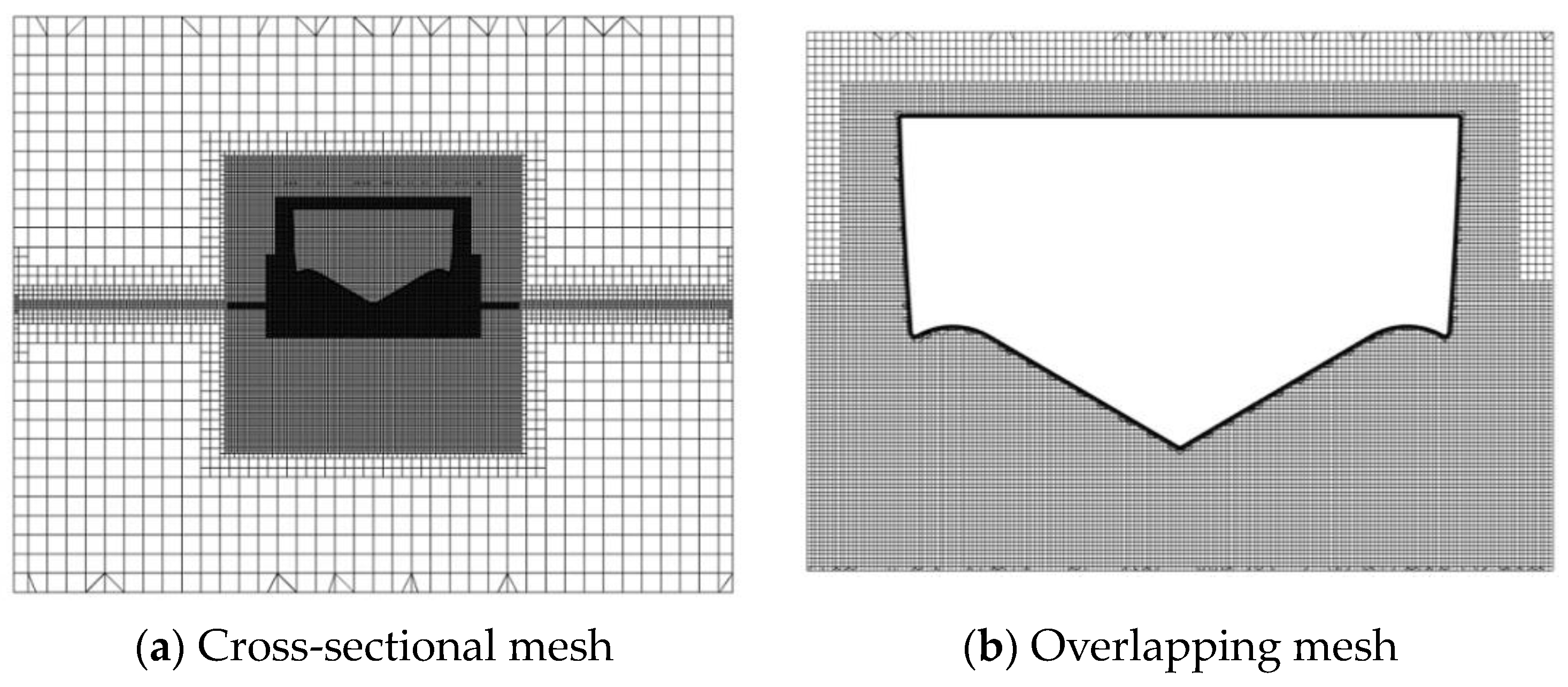

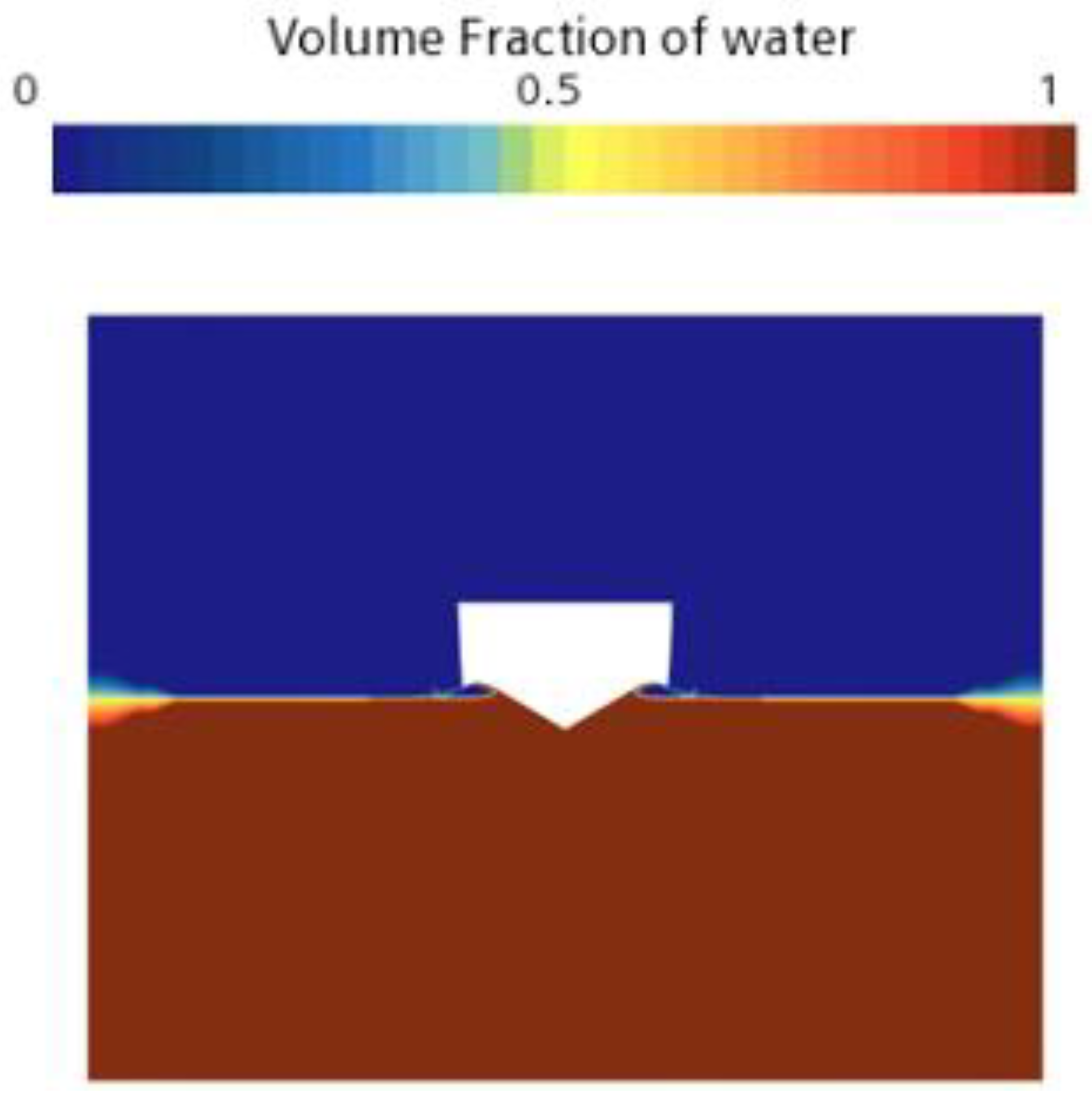

2.2. CFD Model

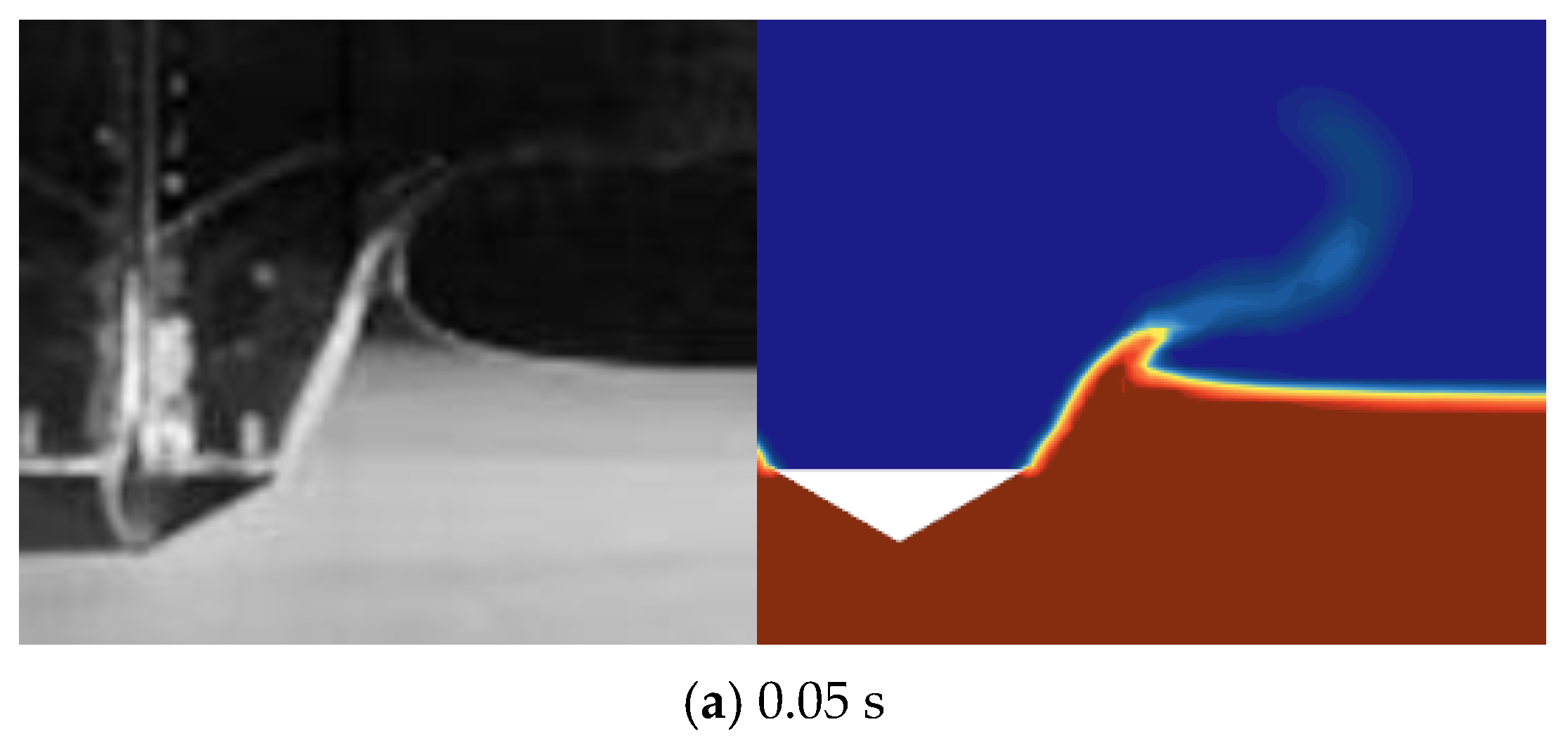

2.3. Method Verification

3. Water Entry Process of Rigid Cabin Structure

3.1. Model Setup

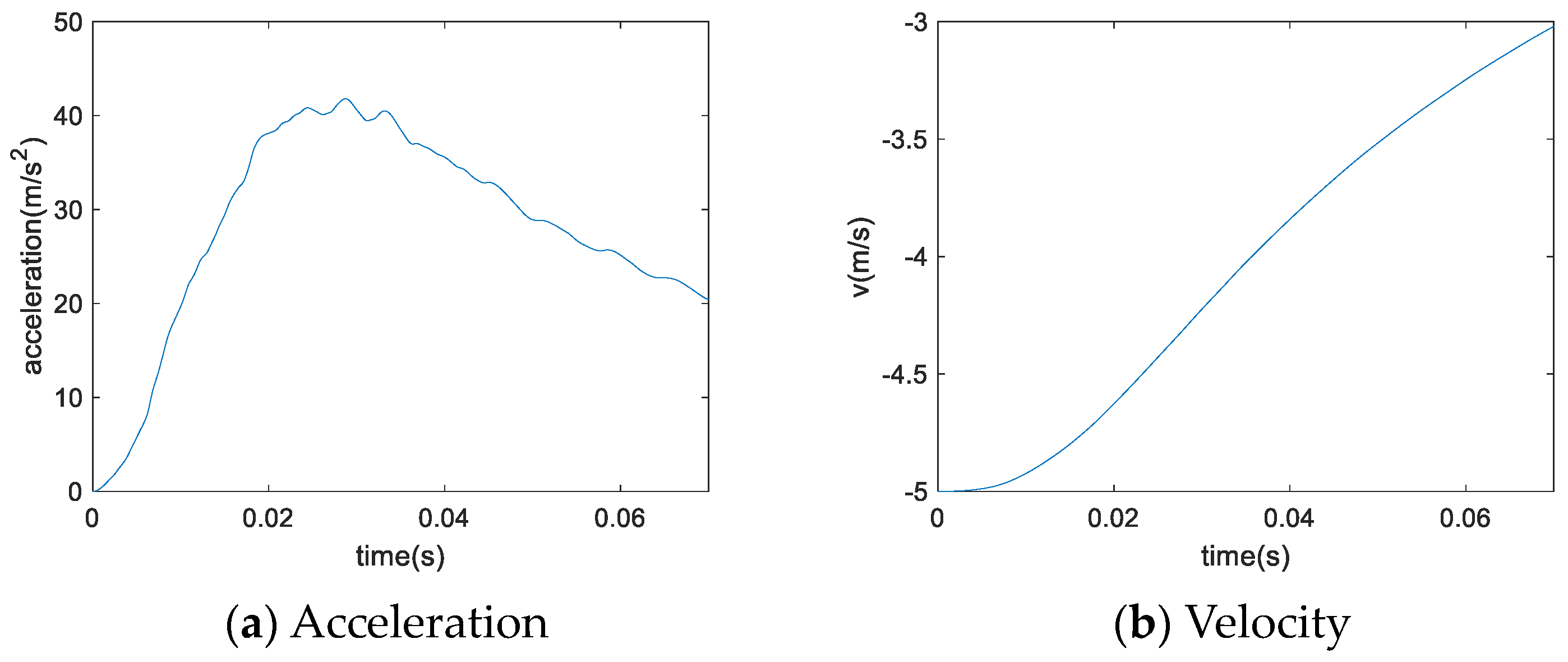

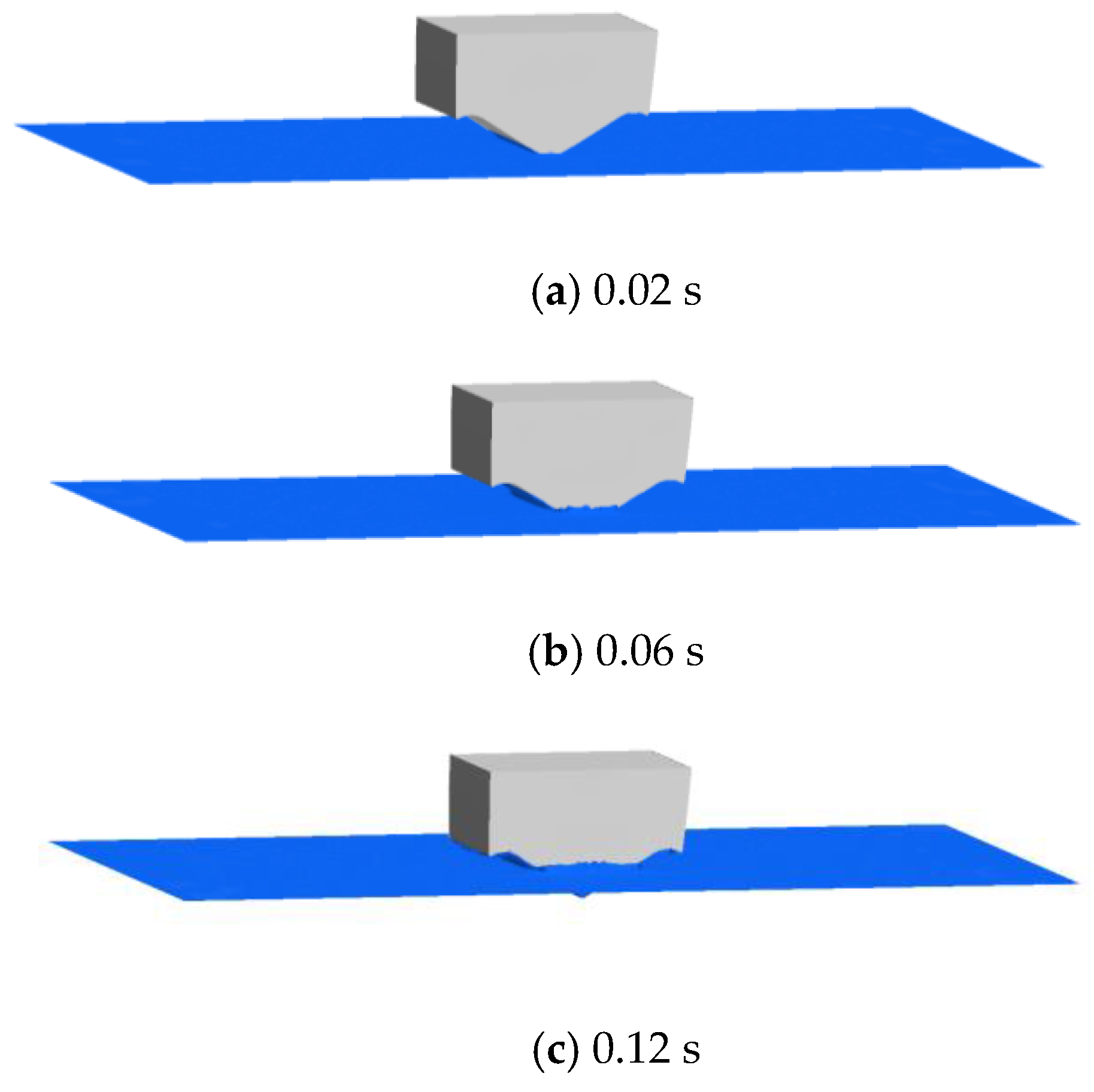

3.2. Numerical Results of Rigid Cabin Structures

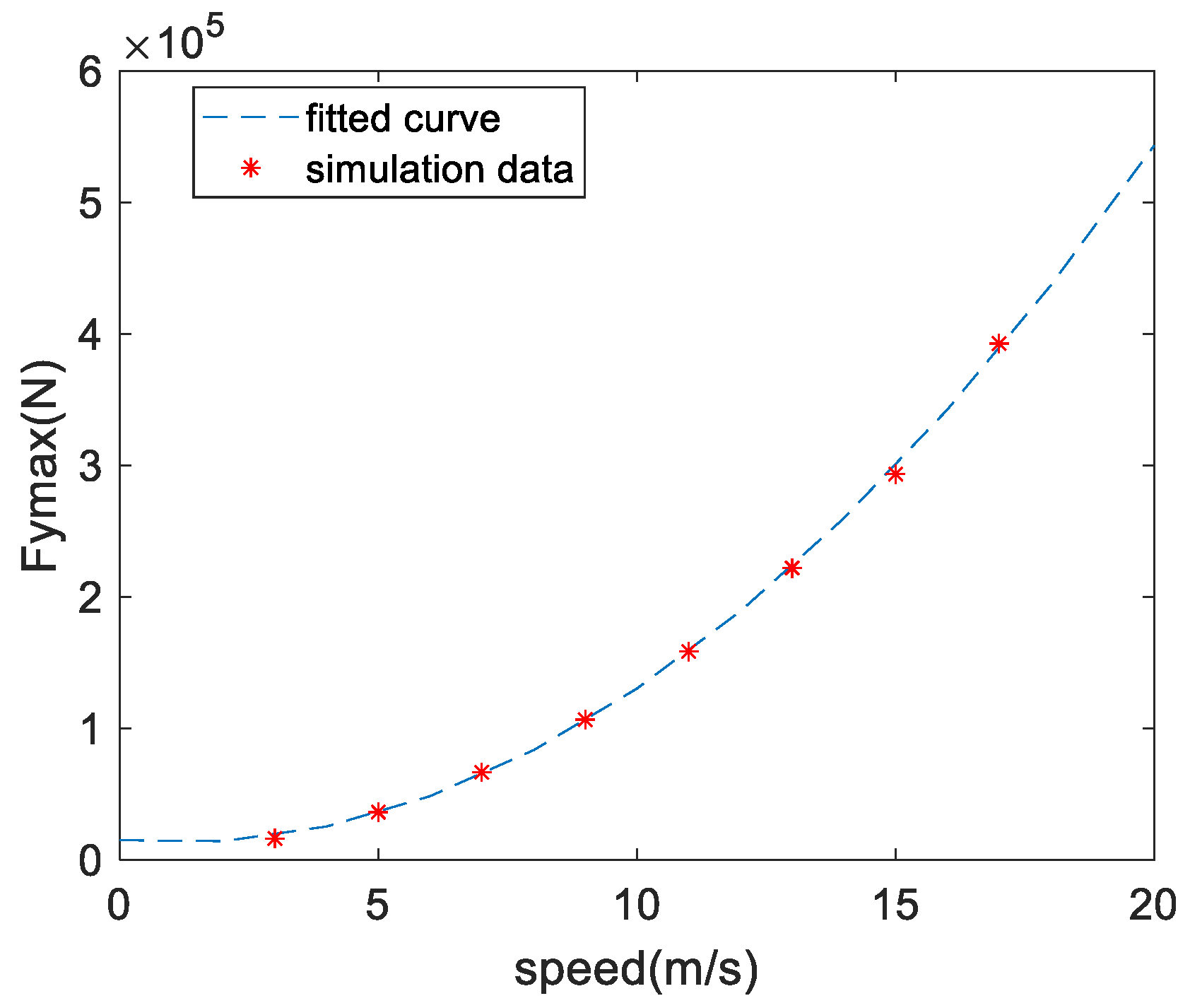

3.3. Empirical Formula

4. Water Entry Process Considering Structural Deformation

4.1. Setup of the Fluid–Structure Interaction

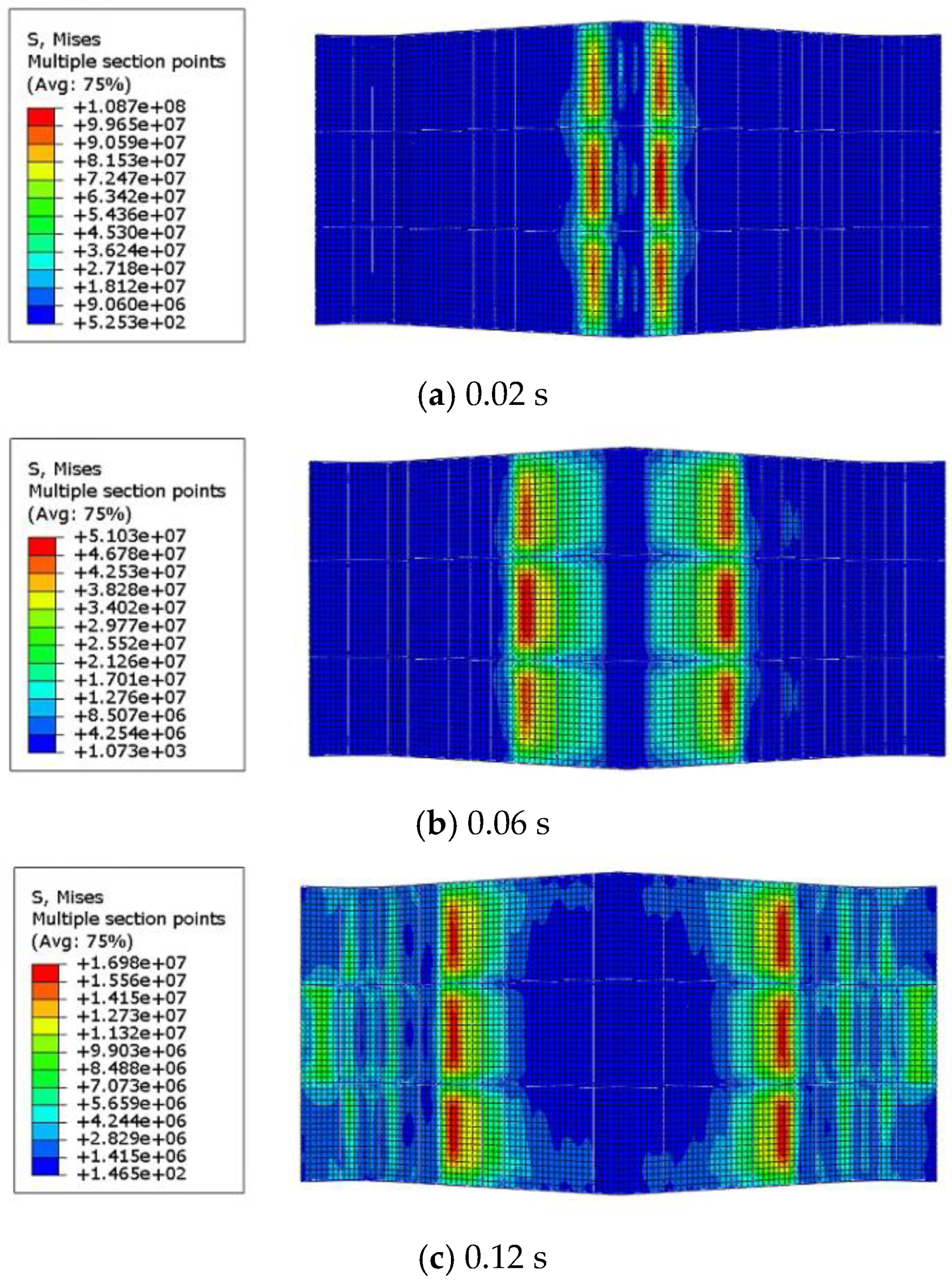

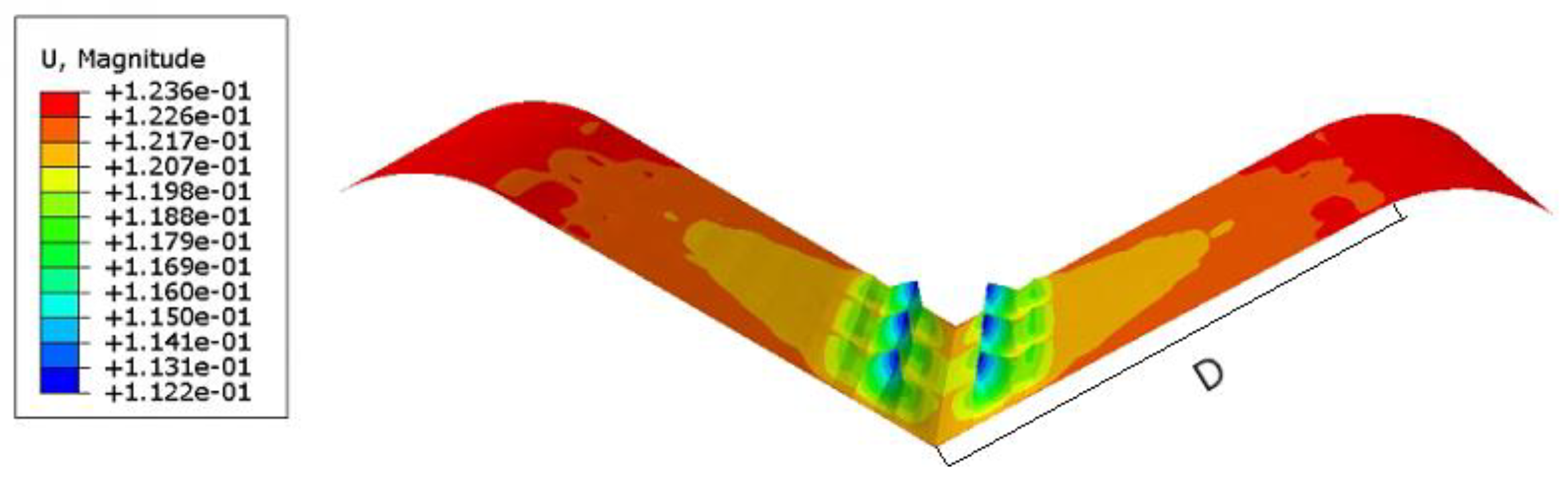

4.2. Analysis of Calculation Results

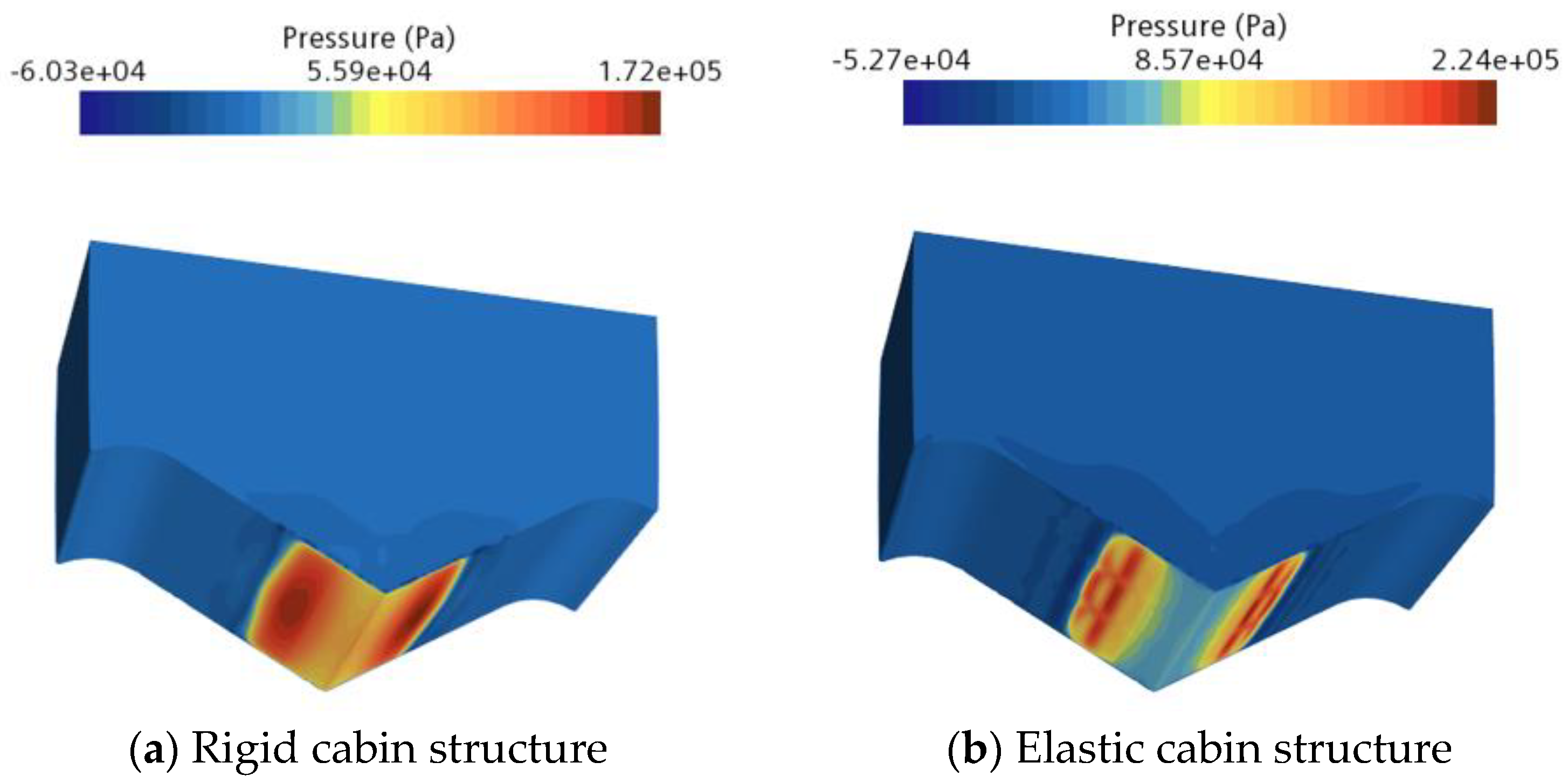

4.3. Effects of the Structural Deformation

- (a)

- At low speeds, the structural deformation is small () and the errors between the elastic and rigid cabin structure water entry analyses are kept below 5%. Conducting rigid cabin structure water entry analysis effectively reduces calculation costs while maintaining accuracy.

- (b)

- At high speeds, results from the rigid cabin structure water entry analysis exceed those from the elastic analysis and errors will increase as speed rises.

5. Conclusions

- The water entry velocity of the cabin structure positively correlates with the intensity of the water entry impact. Under similar model mass conditions, higher velocities result in larger impact response parameters, such as peak acceleration and maximum stress. Increased model mass makes it difficult to change the motion state due to inertia, resulting in decreased peak acceleration under identical velocity conditions.

- An empirical formula is derived to predict vertical impact loads when the structural deformation is not considered. Additionally, a dimensionless parameter is introduced to quantitatively assess the relationship between maximum structural deformation and characteristic geometry parameters. The critical value of the dimensionless parameter can be determined based on acceptable error thresholds. The empirical formula, which includes the difference due to the structural deformation is proposed. This helps reduce computational costs while ensuring robustness.

- Structural deformation helps to disperse the impact load. In the rigid structure, the surface pressure distribution is more uniform. In the elastic structure, the pressure is concentrated on the surface that is in contact with the water, where deformation is small.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Montano, F.; Dimino, I.; Milazzo, A. A Preliminary Evaluation of Morphing Horizontal Tail Design for UAVs. Aerospace 2024, 11, 266. [Google Scholar] [CrossRef]

- Wang, H.; Huang, Z.; Guo, Z. Numerical study on the influence of floating ice on the water-exit hydrodynamic characteristics of a trans-media vehicle. J. Phys. Conf. Ser. 2023, 2478, 112008. [Google Scholar] [CrossRef]

- Deng, F.; Sun, X.; Chi, F.; Ji, R. A Numerical Study on the Water Entry of Cylindrical Trans-Media Vehicles. Aerospace 2022, 9, 805. [Google Scholar] [CrossRef]

- Fabian, A.; Feng, Y.; Swartz, E.; Thurmer, D.; Wang, R. Hybrid Aerial Underwater Vehicle. MIT Lincoln Lab. Available online: https://phoenixfiles.olin.edu/ (accessed on 25 May 2024).

- Liao, B.; Feng, J.; Qi, D.; Li, Y.; Yu, Z. Aerodynamic/hydrodynamic characteristics analysis of a shape-variable transmedia vehicle. Flight Dyn. 2016, 34, 44–47, 57. [Google Scholar]

- Stewart, W.; Weisler, W.; MacLeod, M.; Powers, T.; Defreitas, A.; Gritter, R.; Anderson, M.; Peters, K.; Gopalarathnam, A.; Bryant, M. Design and demonstration of a seabird-inspired fixed-wing hybrid UAV-UUV system. Bioinspiration Biomim. 2018, 13, 056013. [Google Scholar] [CrossRef] [PubMed]

- Weisler, S.; Stewart, F.; Anderson, R.; Peters, K.J.; Gopalarathnam, A.; Bryant, M. Testing and characterization of a fixed wing cross-domain unmanned vehicle operating in aerial and underwater environments. IEEE J. Ocean. Eng. 2017, 43, 969–982. [Google Scholar] [CrossRef]

- Yao, G.; Li, Y.; Zhang, H.; Jiang, Y.; Wang, T.; Sun, F.; Yang, X. Review of hybrid aquatic-aerial vehicle (HAAV): Classifications, current status, applications, challenges and technology perspectives. Prog. Aerosp. Sci. 2023, 139, 100902. [Google Scholar] [CrossRef]

- Von Kármán, T. The impact on seaplane floats during landing. In National Advisory Committee for Aeronautics—Technical Note; NASA: Washington, DC, USA, 1929; p. 321. [Google Scholar]

- Wagner, H. Über Stoß- und Gleitvorgänge an der Oberfläche von Flüssigkeiten. Z. Für Angew. Math. Und Mech. 1932, 12, 193–215. [Google Scholar] [CrossRef]

- Courant, R.; Shiffman, M.; Spencer, D.C. The Force of Impact on a Sphere Striking a Water Surface; Creative Media Partners: London, UK, 1945. [Google Scholar]

- Trilling, L. The Impact of a Body on a Water Surface at an Arbitrary Angle. J. Appl. Phys. 1950, 21, 161–170. [Google Scholar] [CrossRef]

- Steiner, M. Ditching Behavior of Military Airplanes as Affected by Ditching Aids; Technical Report Archive & Image Library; NASA: Washington, DC, USA, 1945. [Google Scholar]

- Fisher, L.J.; Windham, J.O. Water-Landing Characteristics of a 1/10-Scale Model of a Winged Missile (Water Landing Characteristics of Winged Missile Scale Model); NASA: Washington, DC, USA, 1967. [Google Scholar]

- Shibue, T.; Ito, A.; Nakayama, E. Structural Response Analysis of a Cylinder under Water Impact. J. Soc. Nav. Archit. Jpn. 1993, 174, 479–484. [Google Scholar] [CrossRef] [PubMed]

- Arai, M.; Miyauchi, T. Numerical Simulation of the Water Impact on Cylindrical Shells Considering Fluid-structure Interaction. J. Soc. Nav. Archit. Jpn. 1997, 182, 827–835. [Google Scholar] [CrossRef] [PubMed]

- Wittlin, G.; Smith, M.; Sareen, A.; Richards, M. Airframe water impact analysis using a combined MSC/DYTRAN-DRI/KRASH approach. In Annual Forum Proceedings—American Helicopter Society; Vertical Flight Society: Fairfax, VA, USA, 1997; Volume 53, pp. 1138–1150. [Google Scholar]

- Sun, H.; Faltinsen, O.M. The influence of gravity on the performance of planing vessels in calm water. J. Eng. Math. 2007, 58, 91–107. [Google Scholar] [CrossRef]

- Wu, G.X.; Sun, H.; He, Y.S. Numerical simulation and experimental study of water entry of a wedge in free fall motion. J. Fluids Struct. 2004, 19, 277–289. [Google Scholar] [CrossRef]

- Zhao, R.; Faltinsen, O. Water entry of two-dimensional bodies. J. Fluid Mech. 1993, 246, 593–612. [Google Scholar] [CrossRef]

- Pantousa, D.; Mistakidis, E. Interface modeling between CFD and FEM analysis: The dual layer post-processing model. Eng. Comput. 1984, 34, 1166–1190. [Google Scholar] [CrossRef]

- Kang, T.; Tian, Z.; Zhang, Y.; Li, J. Numerical Wave Simulation using Geometrical VOF Method Based on OpenFOAM. Shànghăi Jiāotōng Dàxué Xuébào 2021, 55, 1–10. [Google Scholar]

- Fuhrman, D.R.; Li, Y. Instability of the Realizable k–ε Turbulence Model Beneath Surface Waves. Phys. Fluids 2020, 32, 115108. [Google Scholar] [CrossRef]

- Chen, G.M.; Zheng, X.B.; Wu, X.N.; Zhang, H.X.; Li, Y. Numerical and experimental study of water entry problem of two-dimensional wedge. Ship Sci. Technol. 2021, 43, 53–60. [Google Scholar]

- CD-adapco. 11.04_STAR-CCMP_Tutorial+Guide_ZH, A Siemens Business, Germany. 2016. Available online: https://oss.jishulink.com/upload/202012/a8a4fad57be24f3c8ff81740124ac327.pdf (accessed on 6 June 2024).

- Datta, N.; Siddiqui, M.A. Hydroelastic analysis of axially loaded Timoshenko beams with intermediate end fixities under hydrodynamic slamming loads. Ocean Eng. 2016, 127, 124–134. [Google Scholar] [CrossRef]

- Song, B.W.; Du, X.X.; Meng, R.; Li, J.W.; Shao, C. Numerical simulation of water-entry impact force for air-launched mine. Torpedo Technol. 2008, 3, 6–8, 12. [Google Scholar]

| Time/s | (Simulation) | (Experiment) | Error | (Simulation) | (Experiment) | Error |

|---|---|---|---|---|---|---|

| 0.05 | 0.484 | 0.517 | 6.38% | 0.304 | 0.280 | 8.57% |

| 0.136 | 0.326 | 0.341 | 4.38% | 0.116 | 0.128 | 9.54% |

| Number of Meshes | 2.73 Million | 3.73 Million | 5.12 Million |

|---|---|---|---|

| Vertical peak acceleration | 41.79 m/s2 | 41.94 m/s2 | 41.78 m/s2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; He, Z.; Wang, C.; Hu, Q.; Dong, S.; Shen, X.; Zhang, J.; Wang, T. Numerical Analysis of the Water Entry Process of the Cabin Structure of the Trans-Domain Morphing Aircraft Considering Structural Deformation. Aerospace 2024, 11, 611. https://doi.org/10.3390/aerospace11080611

Zhang Y, He Z, Wang C, Hu Q, Dong S, Shen X, Zhang J, Wang T. Numerical Analysis of the Water Entry Process of the Cabin Structure of the Trans-Domain Morphing Aircraft Considering Structural Deformation. Aerospace. 2024; 11(8):611. https://doi.org/10.3390/aerospace11080611

Chicago/Turabian StyleZhang, Yu, Ziyi He, Chen Wang, Qi Hu, Songwen Dong, Xing Shen, Jun Zhang, and Taoxi Wang. 2024. "Numerical Analysis of the Water Entry Process of the Cabin Structure of the Trans-Domain Morphing Aircraft Considering Structural Deformation" Aerospace 11, no. 8: 611. https://doi.org/10.3390/aerospace11080611

APA StyleZhang, Y., He, Z., Wang, C., Hu, Q., Dong, S., Shen, X., Zhang, J., & Wang, T. (2024). Numerical Analysis of the Water Entry Process of the Cabin Structure of the Trans-Domain Morphing Aircraft Considering Structural Deformation. Aerospace, 11(8), 611. https://doi.org/10.3390/aerospace11080611