Sensitivity Analysis of the Johnson-Cook Model for Ti-6Al-4V in Aeroengine Applications

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Mesh Convergence for Blade-Out Containment Simulation

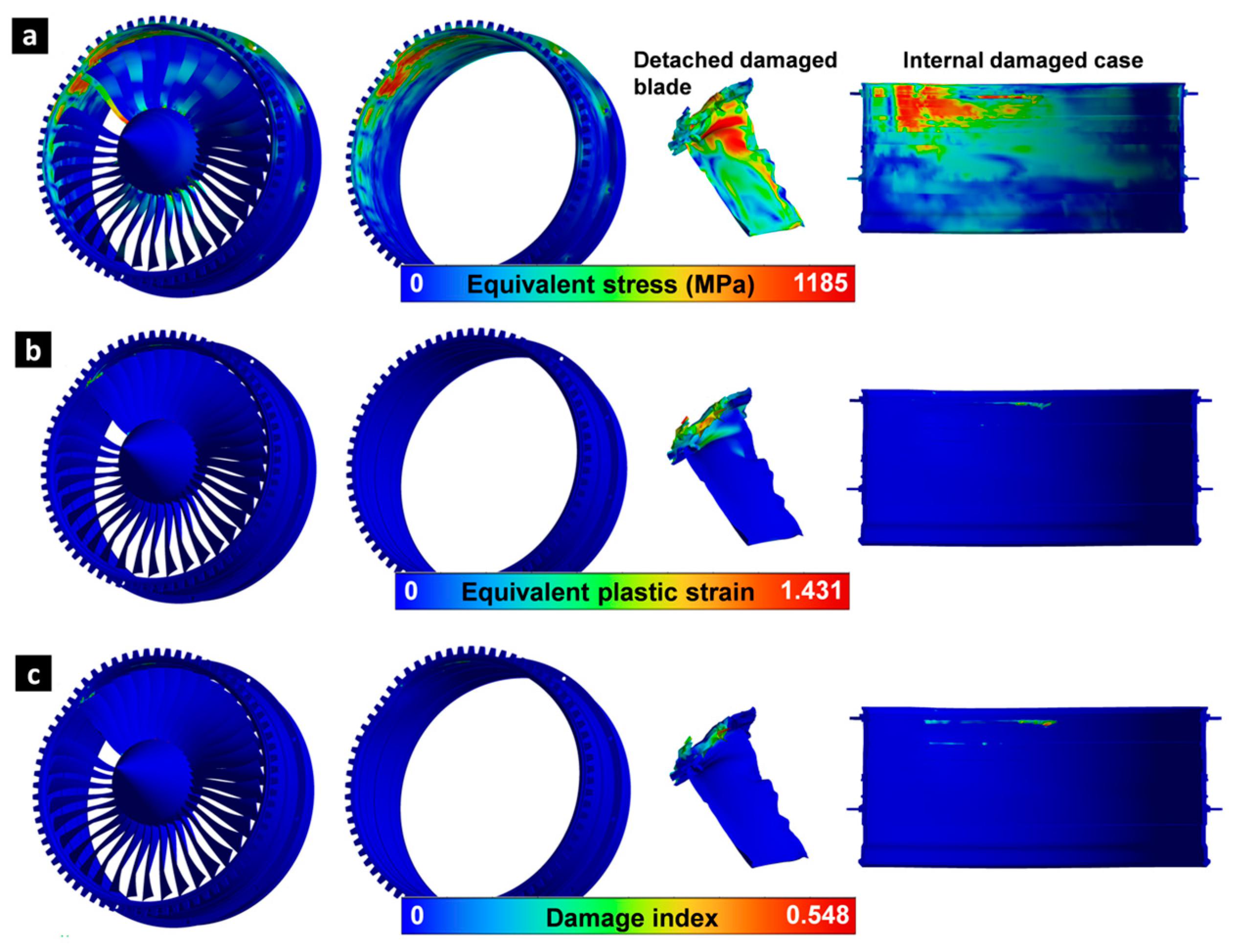

3.2. Aeroengine Blade-Out Containment Simulation Results Using the J-C Control Model

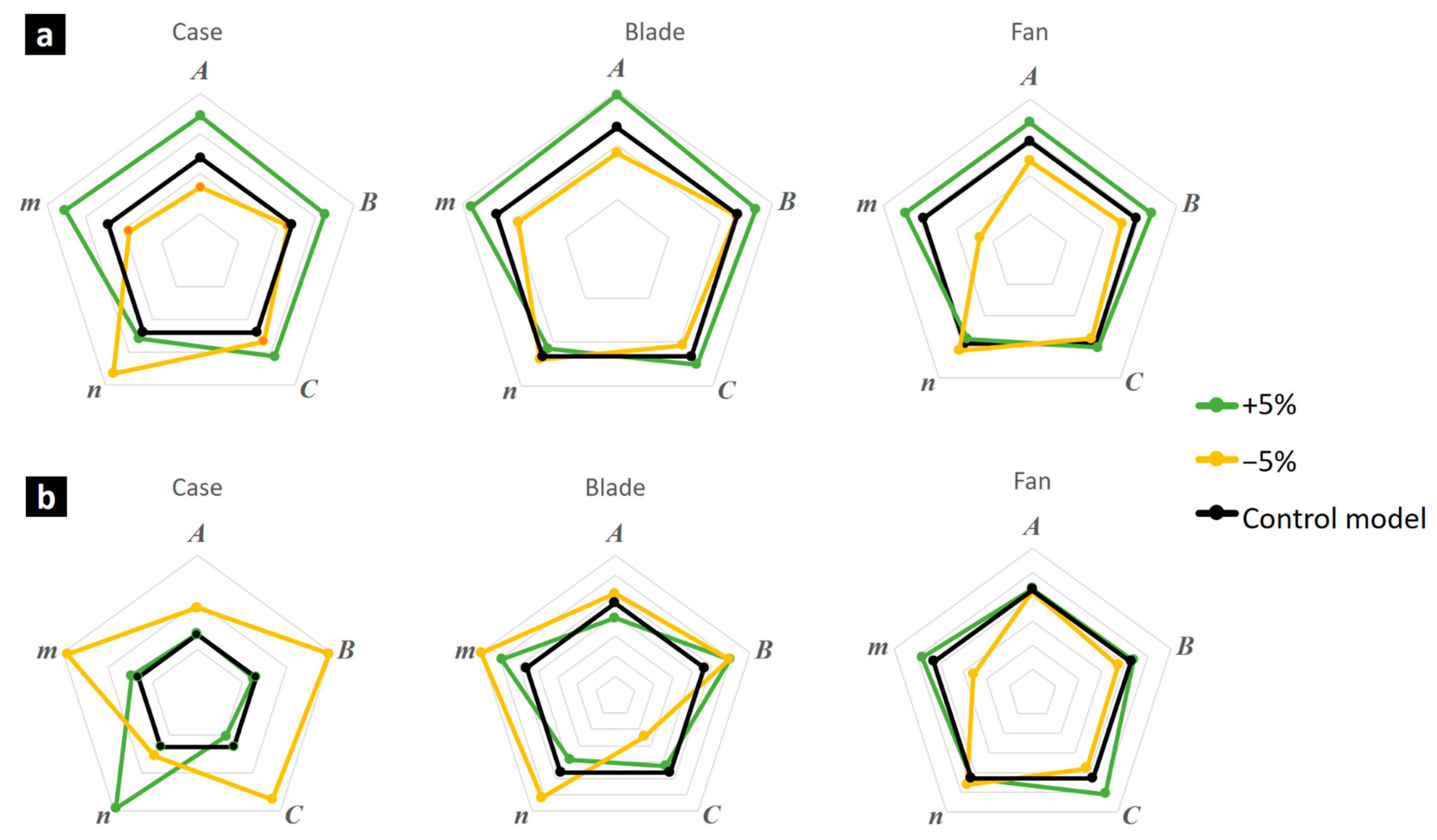

3.3. Influence of J-C Parameter Variation on Plasticity in a Aeroengine Blade-Out Scenario

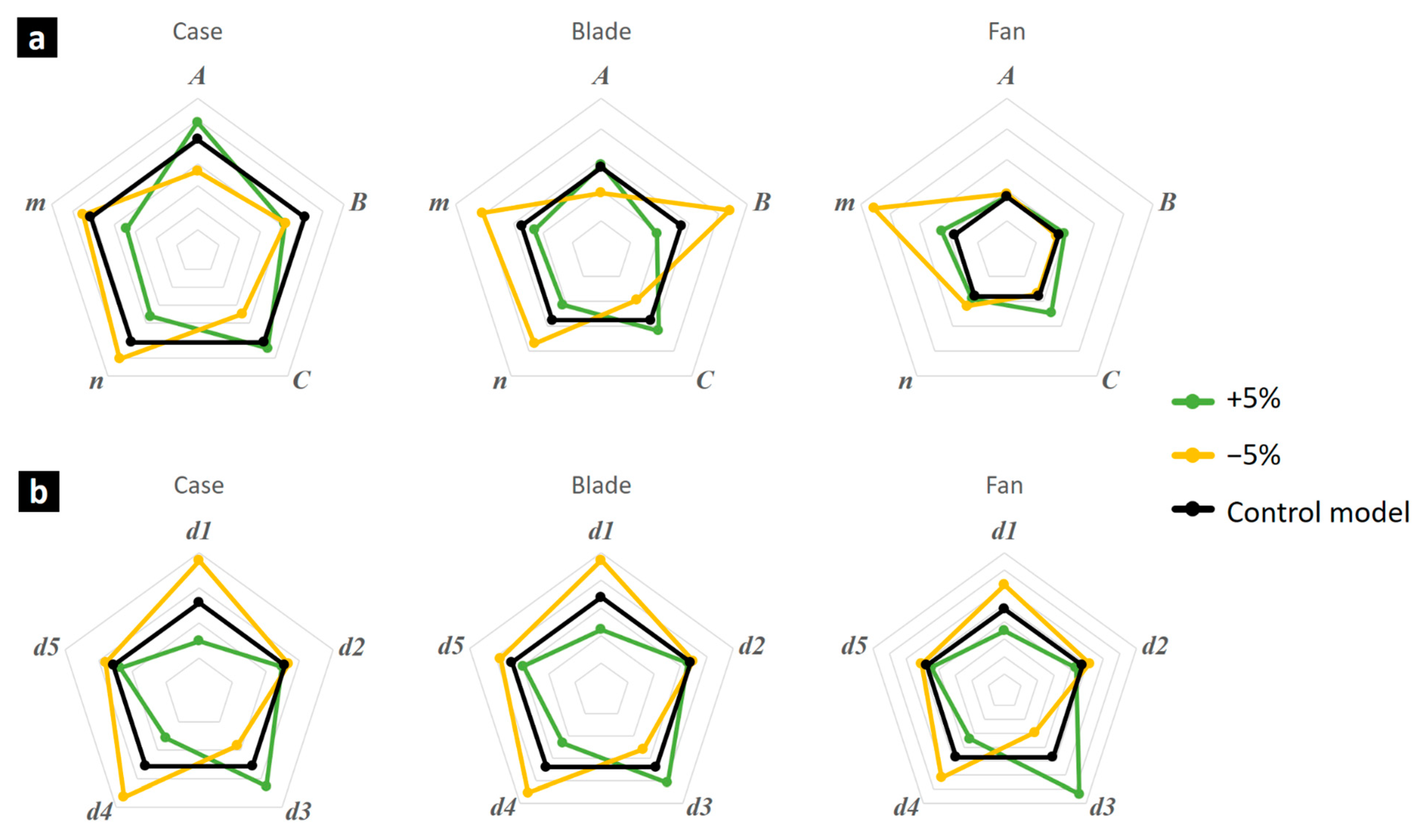

3.4. Influence of J-C Parameter Variation on Damage Evolution of Aeroengine Blade-Out

4. Conclusions

- Nonlinear behavior during blade detachment, characterized by rapid stress and deformation propagation, localized casing deformation due to the high-energy blade impact, and the maximum equivalent plastic strain of 143% in the detached blade, 142% in the casing, and 73% in the fan.

- A maximum damage index of 0.55 in the casing, indicating potential damage but below critical failure levels for affecting the structural integrity of the aircraft.

- A strong dependence of damage predictions on specific model parameters, particularly the thermal softening coefficient (m). Variations in m resulted in ±33% changes in casing damage, highlighting its critical role in accurate damage prediction.

- Other influential parameters, in decreasing order of importance, include the strain rate hardening coefficient (C), the strain hardening exponent (n), and yield strength (A). Parameters B, d1, d4, and d3 exhibited moderate to minor influence, while d5 and d2 showed a minimal impact on casing damage.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mosallanejad, M.H.; Abdi, A.; Karpasand, F.; Nassiri, N.; Iuliano, L.; Saboori, A. Additive Manufacturing of Titanium Alloys: Processability, Properties, and Applications. Adv. Eng. Mater. 2023, 25, 2301122. [Google Scholar] [CrossRef]

- del Bosque, A.; Fernández-Arias, P.; Vergara, D. Titanium Additive Manufacturing with Powder Bed Fusion: A Bibliometric Perspective. Appl. Sci. 2024, 14, 10543. [Google Scholar] [CrossRef]

- Fernandes, F.A.O.; Gonçalves, J.J.M.; Pereira, A.B. Evaluation of Laser Lap Weldability between the Titanium Alloy Ti-6Al-4V and Aluminum Alloy 6060-T6. Crystals 2023, 13, 1448. [Google Scholar] [CrossRef]

- Tuninetti, V.; Oñate, A.; Valenzuela, M.; Sepúlveda, H.; Pincheira, G.; Medina, C.; García-Herrera, C.; Duchêne, L.; Habraken, A.M. Characterization Approaches Affect Asymmetric Load Predictions of Hexagonal Close-Packed Alloy. J. Mater. Res. Technol. 2023, 26, 5028–5036. [Google Scholar] [CrossRef]

- Tuninetti, V.; Sepúlveda, H. Computational Mechanics for Turbofan Engine Blade Containment Testing: Fan Case Design and Blade Impact Dynamics by Finite Element Simulations. Aerospace 2024, 11, 333. [Google Scholar] [CrossRef]

- Cui, C.; Hu, B.M.; Zhao, L.; Liu, S. Titanium Alloy Production Technology, Market Prospects and Industry Development. Mater. Des. 2011, 32, 1684–1691. [Google Scholar] [CrossRef]

- Rajendran, R.; Venkateshwarlu, M.; Petley, V.; Verma, S. Strain Hardening Exponents and Strength Coefficients for Aeroengine Isotropic Metallic Materials—A Reverse Engineering Approach. J. Mech. Behav. Mater. 2014, 23, 101–106. [Google Scholar] [CrossRef]

- Miko, T.; Petho, D.; Gergely, G.; Markatos, D.; Gacsi, Z. A Novel Process to Produce Ti Parts from Powder Metallurgy with Advanced Properties for Aeronautical Applications. Aerospace 2023, 10, 332. [Google Scholar] [CrossRef]

- Inagaki, I.; Takechi, T.; Shirai, Y.; Ariyasu, N. Application and Features of Titanium for the Aerospace Industry. Nippon Steel Sumitomo Met. Tech. 2014, 106, 22–27. [Google Scholar]

- Vijayaraghavan, V.; Castagne, S. Measurement of Surface Characteristics of Ti6Al4V Aerospace Engineering Components in Mass Finishing Process. Meas. J. Int. Meas. Confed. 2018, 115, 279–287. [Google Scholar] [CrossRef]

- Carney, K.S.; Pereira, J.M.; Revilock, D.M.; Matheny, P. Jet Engine Fan Blade Containment Using an Alternate Geometry. Int. J. Impact Eng. 2009, 36, 720–728. [Google Scholar] [CrossRef]

- Sinha, S.K.; Dorbala, S. Dynamic Loads in the Fan Containment Structure of a Turbofan Engine. J. Aerosp. Eng. 2008, 323, 1–14. [Google Scholar] [CrossRef]

- Buzyurkin, A.E.; Gladky, I.L.; Kraus, E.I. Determination of Parameters of the Johnson-Cook Model for the Description of Deformation and Fracture of Titanium Alloys. J. Appl. Mech. Tech. Phys. 2015, 56, 330–336. [Google Scholar] [CrossRef]

- Mangal, S.; Kambhammettu, S.K.S.; Rao, C.L. Oblique Impact Simulation Study of Ti-6Al-4 V Alloy Plates for Analysis of Blade-Off Event in Turbofan Aero-Engine. In Dynamic Behavior of Soft and Hard Materials Volume 1; Velmurugan, R., Balaganesan, G., Kakur, N., Kanny, K., Eds.; Springer Nature: Singapore, 2024; pp. 365–379. [Google Scholar]

- Holenko, K.; Koda, E.; Kernytskyy, I.; Babak, O.; Horbay, O.; Popovych, V.; Chalecki, M.; Leśniewska, A.; Berezovetskyi, S.; Humeniuk, R. Evaluation of Accelerator Pedal Strength under Critical Loads Using the Finite Element Method. Appl. Sci. 2023, 13, 6684. [Google Scholar] [CrossRef]

- Cortis, G.; Nalli, F.; Sasso, M.; Cortese, L.; Mancini, E. Effects of Temperature and Strain Rate on the Ductility of an API X65 Grade Steel. Appl. Sci. 2022, 12, 2444. [Google Scholar] [CrossRef]

- Jiang, X.; Ding, J.; Wang, C.; Shiju, E.; Hong, L.; Yao, W.; Wang, H.; Zhou, C.; Yu, W. Parameter Identification of Johnson–Cook Constitutive Model Based on Genetic Algorithm and Simulation Analysis for 304 Stainless Steel. Sci. Rep. 2024, 14, 21221. [Google Scholar] [CrossRef] [PubMed]

- Khare, S.; Kumar, K.; Choudhary, S.; Singh, P.K.; Verma, R.K.; Mahajan, P. Determination of Johnson–Cook Material Parameters for Armour Plate Using DIC and FEM. Met. Mater. Int. 2021, 27, 4984–4995. [Google Scholar] [CrossRef]

- Osorio-Pinzon, J.C.; Abolghasem, S.; Casas-Rodriguez, J.P. Predicting the Johnson Cook Constitutive Model Constants Using Temperature Rise Distribution in Plane Strain Machining. Int. J. Adv. Manuf. Technol. 2019, 105, 279–294. [Google Scholar] [CrossRef]

- Yin, W.; Liu, Y.; He, X.; Tian, Z. Parametric Analysis and Improvement of the Johnson-Cook Model for a TC4 Titanium Alloy. Metals 2024, 14, 1199. [Google Scholar] [CrossRef]

- Sambo, A.M.; Younas, M.; Njuguna, J. Insights into Machining Techniques for Additively Manufactured Ti6Al4V Alloy: A Comprehensive Review. Appl. Sci. 2024, 14, 10340. [Google Scholar] [CrossRef]

- Tuninetti, V.; Sepúlveda, H.; Beecher, C.; Rojas-Ulloa, C.; Oñate, A.; Medina, C.; Valenzuela, M. A Combined Experimental and Numerical Calibration Approach for Modeling the Performance of Aerospace-Grade Titanium Alloy Products. Aerospace 2024, 11, 285. [Google Scholar] [CrossRef]

- Yin, W.; Liu, Y.; He, X.; Li, H. Effects of Different Materials on Residual Stress Fields of Blade Damaged by Foreign Objects. Materials 2023, 16, 3662. [Google Scholar] [CrossRef]

- Rodríguez Prieto, J.M.; Larsson, S.; Afrasiabi, M. Thermomechanical Simulation of Orthogonal Metal Cutting with PFEM and SPH Using a Temperature-Dependent Friction Coefficient: A Comparative Study. Materials 2023, 16, 3702. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Ji, H.; Zhong, Y.; Han, C.; Tang, X. Mechanical Properties and Fracture Behavior of a TC4 Titanium Alloy Sheet. Materials 2022, 15, 8589. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, L.; Zhang, J.; Liu, L.; Chen, W. Prediction of High-Cycle Fatigue Strength in a Ti-17 Alloy Blade after Foreign Object Damage. Eng. Fract. Mech. 2021, 241, 107385. [Google Scholar] [CrossRef]

- Shi, L.; Wang, T.; Wang, L.; Liu, E. Research on Johnson–Cook Constitutive Model of γ-TiAl Alloy with Improved Parameters. Materials 2023, 16, 6715. [Google Scholar] [CrossRef] [PubMed]

- Johnson, G.R.; Cook, W.H. Fracture Characteristics of Three Metals Subjected to Various Strains, Strain Rates, Temperatures and Pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Tuninetti, V.; Forcael, D.; Valenzuela, M.; Martínez, A.; Ávila, A.; Medina, C.; Pincheira, G.; Salas, A.; Oñate, A.; Duchêne, L. Assessing Feed-Forward Backpropagation Artificial Neural Networks for Strain-Rate-Sensitive Mechanical Modeling. Materials 2024, 17, 317. [Google Scholar] [CrossRef] [PubMed]

- He, Q.; Xuan, H.J.; Liao, L.F.; Hong, W.R.; Wu, R.R. Simulation Methodology Development for Rotating Blade Containment Analysis. J. Zhejiang Univ. Sci. A 2012, 13, 239–259. [Google Scholar] [CrossRef]

- Bai, C.; Xuan, H.; Huang, X.; He, Z.; Hong, W. Containment Ability and Groove Depth Design of U Type Protection Ring. Chin. J. Aeronaut. 2016, 29, 395–402. [Google Scholar] [CrossRef][Green Version]

- Wimperis, H.E. The Future of Flying. Nature 1939, 144, 538–541. [Google Scholar] [CrossRef]

- Choi, Y.; Lee, J. Estimation of Liquid Hydrogen Fuels in Aviation. Aerospace 2022, 9, 564. [Google Scholar] [CrossRef]

- Faure, A.; Schuermans, B.; Wang, G.; Caruso, S.; Zahn, M.; Noiray, N. Acoustic Transfer Matrix of High-Pressure Hydrogen/Air Flames for Aircraft Propulsion. Combust. Flame 2024, 270, 113776. [Google Scholar] [CrossRef]

- Ruffles, P.C. Aero Engines of the Future. Aeronaut. J. 2003, 107, 307–322. [Google Scholar] [CrossRef]

- Pollock, T.M. Alloy Design for Aircraft Engines. Nat. Mater. 2016, 15, 809–815. [Google Scholar] [CrossRef] [PubMed]

- Tirpak, J.A. Next-Gen Fighter Engines. Air Force Mag. 2023, 106, 42–45. [Google Scholar]

- Ye, D.; Xuan, H.J.; Liu, L.L. Research Overview of Full Aero-Engine Dynamic Response Caused by Blade-Off. Appl. Mech. Mater. 2013, 423–426, 1552–1557. [Google Scholar] [CrossRef]

- Yu, P.; Zhang, D.; Ma, Y.; Hong, J. Dynamic Modeling and Vibration Characteristics Analysis of the Aero-Engine Dual-Rotor System with Fan Blade Out. Mech. Syst. Signal Process. 2018, 106, 158–175. [Google Scholar] [CrossRef]

- He, Q.; Xie, Z.; Xuan, H.; Liu, L.; Hong, W. Multi-Blade Effects on Aero-Engine Blade Containment. Aerosp. Sci. Technol. 2016, 49, 101–111. [Google Scholar] [CrossRef]

- He, Q.; Xie, Z.; Xuan, H.; Hong, W. Ballistic Testing and Theoretical Analysis for Perforation Mechanism of the Fan Casing and Fragmentation of the Released Blade. Int. J. Impact Eng. 2016, 91, 80–93. [Google Scholar] [CrossRef]

- Roy, P.A.; Meguid, S.A. Containment of Blade Shedding in Gas Turbine Engines: Part II—Experimental and Numerical Investigations. Int. J. Mech. Mater. Des. 2021, 17, 13–24. [Google Scholar] [CrossRef]

- Cendón, D.A.; Erice, B.; Gálvez, F.; Sánchez-Gálvez, V. Numerical Simulation of Tangling in Jet Engine Turbines. Int. J. Turbo Jet Engines 2012, 29, 269–282. [Google Scholar] [CrossRef][Green Version]

- Saltelli, A.; Tarantola, S.; Campolongo, F.; Ratto, M. Sensitivity Analysis in Practice: A Guide to Assessing Scientific Models. In Sensitivity Analysis in Practice: A Guide to Assessing Scientific Models; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2002; ISBN 9780470870952. [Google Scholar]

- Torii, A.J.; Novotny, A.A. A Priori Error Estimates for Local Reliability-Based Sensitivity Analysis with Monte Carlo Simulation. Reliab. Eng. Syst. Saf. 2021, 213, 107749. [Google Scholar] [CrossRef]

- Jardin, R.T.; Tuninetti, V.; Tchuindjang, J.T.; Hashemi, N.; Carrus, R.; Mertens, A.; Duchêne, L.; Tran, H.S.; Habraken, A.M. Sensitivity Analysis in the Modelling of a High Speed Steel Thin-Wall Produced by Directed Energy Deposition. Metals 2020, 10, 1554. [Google Scholar] [CrossRef]

- Teixeira, R.; O’Connor, A.; Nogal, M. Probabilistic Sensitivity Analysis of Offshore Wind Turbines Using a Transformed Kullback-Leibler Divergence. Struct. Saf. 2019, 81, 101860. [Google Scholar] [CrossRef]

- Gallo, C.; Duchêne, L.; Quy Duc Pham, T.; Jardin, R.; Tuninetti, V.; Habraken, A.-M. Impact of Boundary Parameters Accuracy on Modeling of Directed Energy Deposition Thermal Field. Metals 2024, 14, 173. [Google Scholar] [CrossRef]

- Razavi, S.; Jakeman, A.; Saltelli, A.; Prieur, C.; Iooss, B.; Borgonovo, E.; Plischke, E.; Lo Piano, S.; Iwanaga, T.; Becker, W.; et al. The Future of Sensitivity Analysis: An Essential Discipline for Systems Modeling and Policy Support. Environ. Model. Softw. 2021, 137, 104954. [Google Scholar] [CrossRef]

- Tuninetti, V.; Habraken, A.M. Impact of Anisotropy and Viscosity to Model the Mechanical Behavior of Ti-6Al-4V Alloy. Mater. Sci. Eng. A 2014, 605, 39–50. [Google Scholar] [CrossRef]

- Tuninetti, V.; Flores, P.; Valenzuela, M.; Pincheira, G.; Medina, C.; Duchêne, L.; Habraken, A.M. Experimental Characterization of the Compressive Mechanical Behaviour of Ti6Al4V Alloy at Constant Strain Rates over the Full Elastoplastic Range. Int. J. Mater. Form. 2020, 13, 709–724. [Google Scholar] [CrossRef]

- Sepúlveda, H.; Valle, R.; Pincheira, G.; Prasad, C.S.; Salas, A.; Medina, C.; Tuninetti, V. Dynamic Numerical Prediction of Plasticity and Damage in a Turbofan Blade Containment Test. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023, 237, 2551–2560. [Google Scholar] [CrossRef]

- EASA. Type-Certificate Data Sheet: Trent 1000 Series; EASA: Blankenfelde-Mahlow, Germany, 2024. [Google Scholar]

- Yang, B. Blade Containment Evaluation of Civil Aircraft Engines. Chin. J. Aeronaut. 2013, 26, 9–16. [Google Scholar] [CrossRef]

- FAA (Federal Aviation Administration). 14-Aeronautics and Space, 14 CFR § 33.94—Blade Containment and Rotor Unbalance Tests. Code of Federal Regulations (Annual Edition). 2016. Available online: https://www.govinfo.gov/content/pkg/CFR-2016-title14-vol1/pdf/CFR-2016-title14-vol1-chapI.pdf (accessed on 12 December 2024).

- ANSYS Inc. ANSYS Meshing User’s Guide; ANSYS Inc.: Canonsburg, PA, USA, 2010; Volume 13, pp. 1–342. [Google Scholar]

- Tuninetti, V.; Gómez, Á.; Bustos, F.; Oñate, A.; Hinojosa, J.; Gallo, C.; Habraken, A.; Duchêne, L. Computational Modeling of U-Shaped Seismic Dampers for Structural Damage Mitigation. Appl. Sci. 2024, 14, 10238. [Google Scholar] [CrossRef]

| Plasticity Related Model Constants | Progressive Damage Model Constants | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| A (MPa) | B (MPa) | C | m | n | |||||

| 927.0 | 878.0 | 0.0137 | 0.594 | 0.795 | 0.246 | 186.0 | 15.70 | 0.2582 | 1.206 |

| Component | Stress (MPa) | Plastic Strain | Damage Index |

|---|---|---|---|

| Detached blade | 1176 | 1.431 | 0.548 |

| Case | 1120 | 1.416 | 0.511 |

| Fan | 1185 | 0.728 | 0.179 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beecher, C.; Sepúlveda, H.; Oñate, A.; Habraken, A.M.; Duchêne, L.; Pincheira, G.; Tuninetti, V. Sensitivity Analysis of the Johnson-Cook Model for Ti-6Al-4V in Aeroengine Applications. Aerospace 2025, 12, 3. https://doi.org/10.3390/aerospace12010003

Beecher C, Sepúlveda H, Oñate A, Habraken AM, Duchêne L, Pincheira G, Tuninetti V. Sensitivity Analysis of the Johnson-Cook Model for Ti-6Al-4V in Aeroengine Applications. Aerospace. 2025; 12(1):3. https://doi.org/10.3390/aerospace12010003

Chicago/Turabian StyleBeecher, Carlos, Héctor Sepúlveda, Angelo Oñate, Anne Marie Habraken, Laurent Duchêne, Gonzalo Pincheira, and Víctor Tuninetti. 2025. "Sensitivity Analysis of the Johnson-Cook Model for Ti-6Al-4V in Aeroengine Applications" Aerospace 12, no. 1: 3. https://doi.org/10.3390/aerospace12010003

APA StyleBeecher, C., Sepúlveda, H., Oñate, A., Habraken, A. M., Duchêne, L., Pincheira, G., & Tuninetti, V. (2025). Sensitivity Analysis of the Johnson-Cook Model for Ti-6Al-4V in Aeroengine Applications. Aerospace, 12(1), 3. https://doi.org/10.3390/aerospace12010003