Challenges and Solutions for High-Speed Aviation Piston Pumps: A Review

Abstract

:1. Introduction

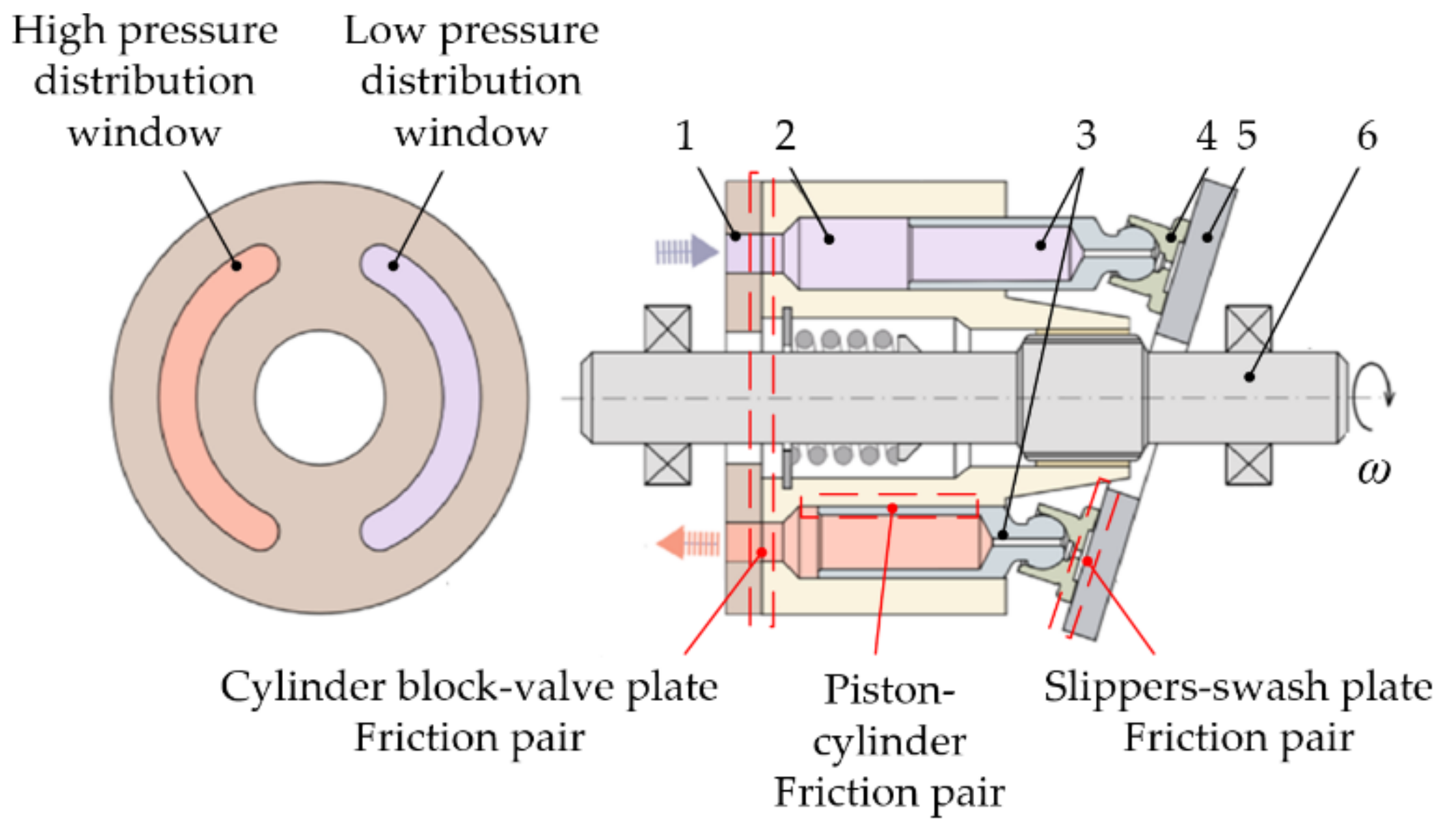

2. Friction Pairs

2.1. Overview

2.2. Research Progress

3. Cavitation

3.1. Overview

3.2. Research Progress

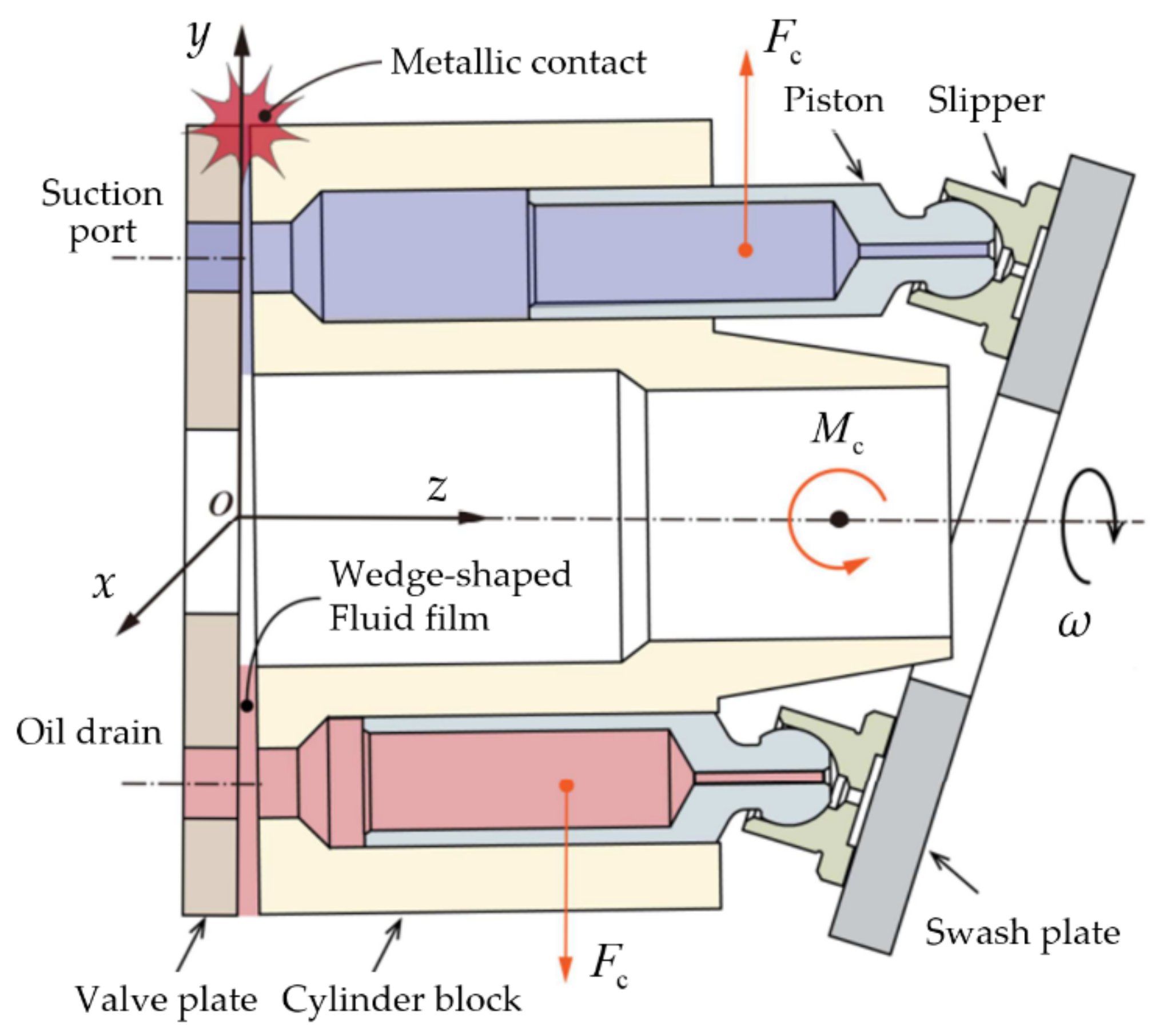

4. Cylinder Overturning

4.1. Overview

4.2. Research Progress

5. Flow and Pressure Pulsation

5.1. Overview

5.2. Research Progress

6. Noise

6.1. Overview

6.2. Research Progress

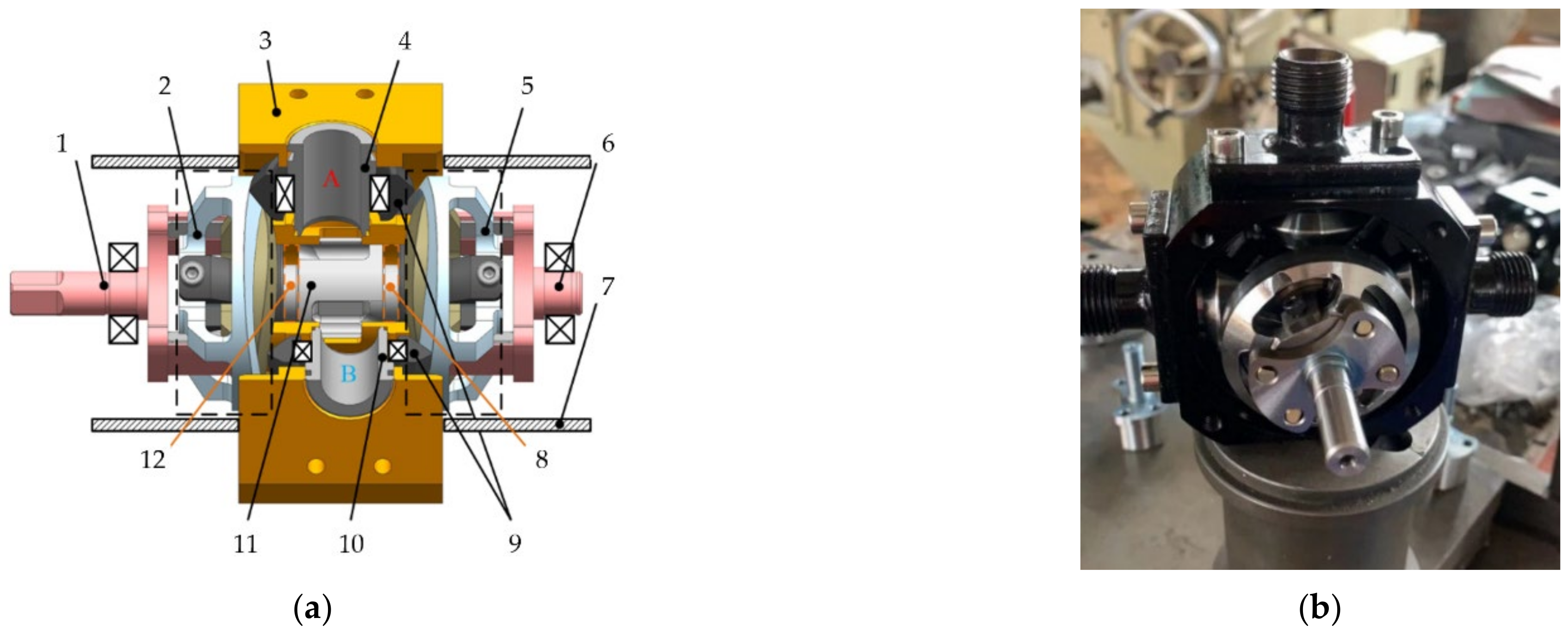

7. Two-Dimensional Piston Pump

- (1)

- Easy to achieve high speeds. For the 2D piston pump, there is no flow distribution friction pair and piston–cylinder friction pair. In the roller–shift fork coupling, a rolling bearing is used between the roller and its shaft to form a rolling friction pair in order to replace sliding friction pair. The coefficient of rolling friction is smaller than the coefficient of sliding friction. It is known that the existing axial piston pump basically adopts static pressure support, but the static pressure support needs additional devices. Furthermore, the oil film thickness of hydrostatic support is difficult to control. Therefore, 2D piston pump based on rolling friction pair entirely breaks through the restriction of the traditional sliding friction pair on the pump performance. Additionally, an axisymmetric structure is adopted in the design of the 2D piston pump, where the piston is always in a state of radial force balance during the rotation and axial reciprocating movement. Thus, it is naturally easier to achieve a high operating speed [142].

- (2)

- High efficiency. The efficiency (including volumetric and mechanical efficiency) of a high-pressure 2D piston fuel pump using a low-viscosity medium is as high as 90% at a speed of 4000 rpm [143].

- (3)

- Easier to achieve high pressure. Due to the small leakage and high volumetric efficiency, it is easier to achieve high output pressure. Experiments have shown that the maximum pressure of the pump can reach about 42 MPa [144].

- (4)

- High power-to-weight ratio. The 2D piston pump has two working chambers. The piston sucks and discharges oil twice per revolution, amounting to four times in total, which is four times the efficiency of an “arbitrary” single piston pump. Figure 14 shows the comparison between the 2D piston pump with a traditional axial piston pump used in a launch vehicle with the same displacement, where the mass of the former is less than one-twentieth of the latter.

8. Conclusions

- (1)

- This study reviewed the problems and challenges encountered by aviation piston pumps under high-speed operating conditions and introduced the current research status in detail, along with potential solutions. These challenges include friction loss of sliding friction pairs, cavitation, cylinder tilt, flow pulsation, pressure pulsation, and noise problems. The proposed solutions can be divided into structure innovation, shape improvement, and contact surface optimization. The purpose is to reduce and eliminate the impact of these problems on the efficiency and performance of the aviation piston pump in order to further improve its power-to-weight ratio. Some approaches have been successfully used in the aviation field, such as pulsation attenuators and spherical valve plates.

- (2)

- Axial piston pumps are the mainstream power sources in today’s aviation hydraulics due to their high volumetric efficiency, mechanical efficiency, and power-to-weight ratio. Due to their mature technology and deep research foundation, they will continue to dominate aviation pumps in the foreseeable future. However, the inherent sliding friction pair is the main bottleneck restricting the further improvement of the speed and power-to-weight ratio. Therefore, pump structural innovation is an essential research direction for piston pump technology.

- (3)

- The 2D piston pump has potential outstanding characteristics of high speed, pressure, efficiency, and power-to-weight ratio. In order to solve the issues of cavitation, cylinder tilt, flow pulsation, and noise, novel structures of 2D piston pump including double-unit type, force balance type, and stacked roll type have also been proposed and studied. As an ideal solution for high-speed pumps, the 2D piston pump has a good application prospect in aviation hydraulic systems.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ouyang, X.P. Hyundai Aircraft Hydraulic Technology; Zhejiang University Press: Hangzhou, China, 2016. [Google Scholar]

- Li, J. Fundamental Theory and Application of Thermal Analysis for Hydraulic Piston Pumps; Shanghai Science and Technology Press: Shanghai, China, 2016. [Google Scholar]

- Chao, Q.; Zhang, J.H.; Wang, Q.N.; Xu, B.; Chen, Y. Experimental verification of slipper spinning motion in axial piston pumps. In Proceedings of the ASME/BATH 2017 Symposium on Fluid Power and Motion Control, Sarasota, FL, USA, 16–19 October 2017. [Google Scholar]

- Zhang, J.H.; Chao, Q.; Wang, Q.N.; Xu, B.; Li, Y.; Chen, Y. Experimental investigations of the slipper spin in an axial piston pump. Measurement 2017, 102, 112–120. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, J.H.; Yang, H.Y. Investigation on structural optimization of anti-overturning slipper of axial piston pump. Sci. China Technol. Sci. 2012, 55, 3010–3018. [Google Scholar] [CrossRef]

- Xu, B.; Li, Y.B.; Zhang, B.; Zhang, J.H. Numerical simulation of overturning phenomenon of axial piston pump slipper pair. J. Mech. Eng. 2010, 46, 161–168. [Google Scholar] [CrossRef]

- Xu, L. Study on the Lubrication Characterisics of the Valve Plate Bearing in Hydraulic Axial Piston Pump. Ph.D. Thesis, Beijing Institute of Technology, Beijing, China, 2016. [Google Scholar]

- Jiang, J.H.; Yang, K.; Shen, T.; Yang, G.W.; Jiao, L.; Yang, A.R. Flow ripple property of double row axial piston pump. Chin. Hydraul. Pneum. 2017, 9, 28–32. [Google Scholar]

- Wang, Z.Q.; Hu, S.; Ji, H.; Wang, Z.; Liang, W. Study on the characteristics of oil film load capacity for axial piston pump. Aust. J. Mech. Eng. 2018, 18, S140–S150. [Google Scholar] [CrossRef]

- Hooke, C.J.; Li, K.Y. The lubrication of slippers in axial piston pumps and motors—The effect of tilting couples. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1989, 203, 343–350. [Google Scholar] [CrossRef]

- Hooke, C.J. The effects of centrifugal load and ball friction on the lubrication of slippers in axial piston pumps. Fluid Power Symp. 1989, 202, 85–102. [Google Scholar]

- Koc, E.; Hooke, C.J.; Li, K.Y. Slipper balance in axial piston pumps and motors. J. Tribol. 1992, 114, 766–772. [Google Scholar] [CrossRef]

- Harris, R.M.; Edge, K.A.; Tilley, D.G. Predicting the behavior of slipper pads in swashplate-type axial piston pumps. J. Dyn. Syst. Meas. Control 1996, 118, 41–47. [Google Scholar] [CrossRef]

- Schenk, A.; Ivantysynova, M. A transient thermoelastohydrodynamic lubrication model for the slipper/swashplate in axial piston machines. J. Tribol. 2015, 137, 031701. [Google Scholar] [CrossRef]

- Schenk, A. Predicting Lubrication Performance between the Slipper and Swashplate in Axial Piston Hydraulic Machines. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2014. [Google Scholar]

- Zecchi, M.; Ivantysynova, M. A novel fluid structure interaction model for the cylinder block/valve plate interface of axial piston machines. In Proceedings of the 52nd National Conference on Fluid Power, Las Vegas, NV, USA, 23-25 March 2011. [Google Scholar]

- Zecchi, M.; Ivantysynova, M. Cylinder block/valve plate interface—A novel approach to predict thermal surface loads. In Proceedings of the Eighth International Fluid Power Conference, Dresden, Germany, 26–28 March 2012. [Google Scholar]

- Zecchi, M. A Novel Fluid Structure Interaction and Thermal Model to Predict the Cylinder Block/Valve Plate Interface Performance in Swash Plate Type Axial Piston Machines. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2013. [Google Scholar]

- Schenk, A.; Zecchi, M.; Ivantysynova, M. Accurate prediction of axial piston machine’s performance through a thermo-elasto-hydrodynamic simulation model. In Proceedings of the ASME/BATH 2013 Symposium on Fluid Power and Motion Control, Sarasota, FL, USA, 6–9 October 2013. [Google Scholar]

- Chacon, R.; Ivantysynova, M. An investigation of the impact of the elastic deformation of the end case/housing on axial piston machines cylinder block/valve plate lubricating interface. In Proceedings of the 10th International Fluid Power Conference, Dresden, Germany, 8–10 March 2016. [Google Scholar]

- Ivantysynova, M.; Lasaar, R. An investigation into micro-and macrogeometric design of piston/cylinder assembly of swash plate machines. Int. J. Fluid Power 2004, 5, 23–36. [Google Scholar] [CrossRef]

- Pelosi, M.; Ivantysynova, M. A geometric multigrid solver for the piston–cylinder interface of axial piston machines. Tribol. Trans. 2012, 55, 163–174. [Google Scholar] [CrossRef]

- Pelosi, M.; Ivantysynova, M. A new fluid structure interaction model for the slipper-swashplate interface. In Proceedings of the 5th FPNI-PhD Symposium on Fluid Power, Krakow, Poland, 1–5 July 2008. [Google Scholar]

- Schenk, A.; Ivantysynova, M. An investigation of the impact of elastohydrodynamic deformation on power loss in the slipper swashplate interface. In Proceedings of the 8th JFPS International Symposium on Fluid Power, Okiniwa, Japan, 25–28 October 2011. [Google Scholar]

- Manring, N.D. Slipper tipping within an axial-piston swash-plate type hydrostatic pump. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Fluid Power Systems and Technology, Anaheim, CA, USA, 15–18 November 1998. [Google Scholar]

- Manring, N.D. Predicting the required slipper hold-down force within an axial-piston swash-plate type hydrostatic pump. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, New York, NY, USA, 11–16 November 2001. [Google Scholar]

- Manring, N.D.; Mehta, V.S.; Nelson, B.E.; Graf, K.E.; Kuehn, J.L. Scaling the speed limitations for axial-piston swash-plate type hydrostatic machines. J. Dyn. Syst. Meas. Control 2014, 136, 031004. [Google Scholar] [CrossRef]

- Murrenhoff, H.; Scharf, S. Wear and friction of ZRCG-coated pistons of axial piston pumps. Int. J. Fluid Power 2006, 7, 13–20. [Google Scholar] [CrossRef]

- Li, Y.B.; Xu, B. Axial piston pump slipper pads dynamic characteristics of wedge oil film. Chin. Hydraul. Pneum. 2010, 9, 87–91. [Google Scholar]

- Chao, Q.; Zhang, J.H.; Xu, B. Test rigs and experimental studies of the slipper bearing in axial piston pumps: A review. Measurement 2019, 132, 135–149. [Google Scholar] [CrossRef]

- Hu, X.; Wang, S.P.; Han, L. Modeling and simulation on pressure distribution of plane port pair in axial piston pump. Hydraul. Pneum. Seals 2012, 32, 68–71. [Google Scholar]

- Zhang, C.; Huang, S.K.; Du, J. A new dynamic seven-stage model for thickness prediction of the film between valve plate and cylinder block in axial piston pumps. Adv. Mech. Eng. 2016, 8, 1687814016671446. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Wang, S.; Tomovic, M. Performance degradation analysis of aviation hydraulic piston pump based on mixed wear theory. Tribol. Ind. 2017, 39, 248–254. [Google Scholar] [CrossRef]

- Xu, B.; Chao, Q.; Zhang, J.H.; Li, Y. Slipper optimization model based on equilibrium coefficient. J. Zhejiang Univ. 2015, 49, 1009–1014. [Google Scholar]

- Tang, H.S.; Yan, Y.B.; Li, J. Heat transfer characteristics of axial piston pump slipper pair. J. Beijing Univ. Aeronaut. Astronaut. 2016, 42, 489–496. [Google Scholar]

- Fu, J.F.; Li, H.C.; Zeng, X.Q. Numerical simulation of hybrid lubrication characteristics of slipper pair of aviation fuel piston pump. J. Beijing Univ. Aeronaut. Astronaut. 2018, 44, 939–950. [Google Scholar]

- Kim, J.K.; Kim, H.E.; Lee, Y.B. Measurment of fluid film thickness on the valve plate in oil hydraulic axial piston pumps (Part II: Spherical design effects). J. Mech. Sci. Technol. 2005, 19, 655–663. [Google Scholar] [CrossRef]

- Kakoullis, Y.P. Slipper Lubrication in Axial Piston Pumps. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 1979. [Google Scholar]

- Liu, H.L.; Kim, H.E.; Lee, Y.B. Lubrication characteristics of the water hydraulic sliding shoe pairs. J. Mech. Eng. 2006, 42, 36–39. [Google Scholar] [CrossRef]

- Beale, J. An Investigation of the Slipper/Swashplate Interface of Swashplate-Type Axial Piston Machines. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2017. [Google Scholar]

- Rizzo, G.; Massarotti, G.P.; Bonanno, A. Axial piston pumps slippers with nanocoated surfaces to reduce friction. Int. J. Fluid Power 2015, 16, 1–10. [Google Scholar] [CrossRef]

- Rizzo, G.; Rizzo, G.; Massarotti, G.P. Energy efficiency improvement by the application of nano-structured coatings on axial piston pump slippers. In Proceedings of the Tenth International Fluid Power Conference, Dresden, Germany, 8–10 March 2016. [Google Scholar]

- Schuhler, G.; Jourani, A.; Bouvier, S. Efficacy of coatings and thermochemical treatments to improve wear resistance of axial piston pumps. Tribol. Int. 2018, 126, 376–385. [Google Scholar] [CrossRef]

- Vatheuer, N.; Murrenhoff, H.; Bräckelmann, U. Mechanical losses in the piston-bushing contact of axial piston units. JFPS Int. J. Fluid Power Syst. 2014, 8, 24–29. [Google Scholar] [CrossRef] [Green Version]

- Van Bebber, D.; Murrenhoff, H. Improving the wear resistance of hydraulic machines using PVD-coating technology. Oþ P Olhydraul. Pneum. 2002, 46, 1–35. [Google Scholar]

- Fatemi, A.; Wohlers, A.; Murrenhoff, H. Simulation of elastohydrodynamic contact between piston and cylinder in axial piston pumps. In Proceedings of the 6th International Fluid Power Conference, 31 March–2 April 2008. [Google Scholar]

- Deng, H.S.; Qi, S.; Yu, H.W. Numerical analysis for textured port plate of axial piston pump. Trans. Chin. Soc. Agric. Mach. 2011, 42, 203–207. [Google Scholar]

- Chacon, R.; Ivantysynova, M. An investigation of the impact of micro surface on the cylinder block/valve plate interface performance. In Proceedings of the 8th FPNI Ph.D Symposium on Fluid Power, Lappeenranta, Finland, 11–13 June 2014. [Google Scholar]

- Chacon, R. Cylinder Block/Valve Plate Interface Performance Investigation through the Introduction of Micro-Surface Shaping. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2014. [Google Scholar]

- Mehta, V.S.; Manring, N.D. Piston pump noise attenuation through modification of piston travel trajectory. In Proceedings of the ASME 2010 International Mechanical Engineering Congress and Exposition, Vancouver, BC, Canada, 12–18 November 2010. [Google Scholar]

- Totten, G.E.; Sun, Y.H.; Bidhop, R.J., Jr. Hydraulic system cavitation: A review. SAE Trans. 1998, 107, 368–380. [Google Scholar]

- Kunkis, M.; Weber, J. Experimental and numerical assessment of an axial piston pump’s speed limit. In Proceedings of the BATH/ASME 2016 Symposium on Fluid Power and Motion Control, Bath, UK, 7–9 September 2016. [Google Scholar]

- Gullapalli, S.; Michael, P.; Kensler, J. An investigation of hydraulic fluid composition and aeration in an axial piston pump. In Proceedings of the ASME/BATH 2017 Symposium on Fluid Power and Motion Control, Sarasota, FL, USA, 16–19 October 2017. [Google Scholar]

- Schleihs, C.; Viennet, E.; Deeken, M. 3D-CFD simulation of an axial piston displacement unit. In Proceedings of the Ninth International Fluid Power Conference, Aachen, Germany, 24–26 March 2014. [Google Scholar]

- Kunimoto, E.; Ogawara, T. Cavitation detection in the oil hydraulic equipments. Proc. JFPS Int. Symp. Fluid Power. Jpn. Fluid Power Syst. Soc. 1996, 3, 461–466. [Google Scholar] [CrossRef] [Green Version]

- Bishop, R.J.; Totten, G.E. Effect of pump inlet conditions on hydraulic pump cavitation: A review. ASTM Spec. Tech. 2001, 339, 318–322. [Google Scholar]

- Hibi, A.; Ibuki, T.; Ichikawa, T. Suction performance of axial piston pump: 1st Report, Analysis and Fundamental Experiments. Bull. JSME 1977, 20, 79–84. [Google Scholar] [CrossRef]

- Ibuki, T.; Hibi, A.; Ichikawa, T. Suction performance of axial piston pump: 2nd report, experimental results. Bull. JSME 1977, 20, 827–833. [Google Scholar] [CrossRef] [Green Version]

- Kollek, W.; Kudźma, Z.; Stosiak, M. Possibilities of diagnosing cavitation in hydraulic systems. Arch. Civ. Mech. Eng. 2007, 7, 61–73. [Google Scholar] [CrossRef]

- Kosodo, H.; Nara, M.; Kakehida, S. Experimental research about pressure-flow characteristics of V-notch. Proc. JFPS Int. Symp. Fluid Power. Jpn. Fluid Power Syst. Soc. 1996, 3, 73–78. [Google Scholar] [CrossRef]

- Yamaguchi, A.; Takabe, T. Cavitation in an axial piston pump. Bull. JSME 1983, 26, 72–78. [Google Scholar] [CrossRef] [Green Version]

- Shi, Y.X.; Lin, T.R.; Meng, G.Y. A study on the suppression of cavitation flow inside an axial piston pump. In Proceedings of the 2016 Prognostics and System Health Management Conference, Chengdu, China, 19–21 October 2016. [Google Scholar]

- Tsukiji, T.; Nakayama, K.; Saito, K. Study on the cavitating flow in an oil hydraulic pump. In Proceedings of the 2011 International Conference on Fluid Power and Mechatronics, Beijing, China, 17–20 August 2011. [Google Scholar]

- Chao, Q.; Zhang, J.H.; Xu, B. A review of high-speed electro-hydrostatic actuator pumps in aerospace applications: Challenges and solutions. J. Mech. Des. 2019, 141, 050801. [Google Scholar] [CrossRef] [Green Version]

- Chao, Q.; Zhang, J.H.; Xu, B. Centrifugal effects on cavitation in the cylinder chambers for high-speed axial piston pumps. Meccanica 2019, 54, 815–829. [Google Scholar] [CrossRef]

- Totten, G.E.; Bishop, R. The hydraulic pump inlet condition: Impact on hydraulic pump cavitation. SAE Tech. Pap. 1999, 1, 1877. [Google Scholar]

- Yin, F.L.; Nie, S.L.; Xiao, S.H. Numerical and experimental study of cavitation performance in sea water hydraulic axial piston pump. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2016, 230, 716–735. [Google Scholar] [CrossRef]

- Ouyang, X.P.; Wang, T.Z.; Fang, X. Research status of the high speed aircraft piston pump. Chin. Hydraul. Pneum. 2018, 2, 1–8. [Google Scholar]

- Zhang, Z.S. Research on the Dynamic Characteristics of the High Speed Piston Pump. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2015. [Google Scholar]

- Yang, C.; Du, L.L.; Qing, H. The design of pressurized tank test bench for a certain airplane hydraulic system. Chin. Hydraul. Pneum. 2012, 2, 103–105. [Google Scholar]

- Mohn, D.I.G.; Nafz, I.T. Swash plate pumps–the key to the future. In Proceedings of the 10th International Fluid Power Conference, Dresden, Germany, 8–10 March 2016. [Google Scholar]

- Kosodo, H. Development of micro pump and micro-HST for hydraulics. JFPS Int. J. Fluid Power Syst. 2012, 5, 6–10. [Google Scholar] [CrossRef]

- Zecchi, M.; Ivantysynova, M. Spherical valve plate design in axial piston machines—A novel thermoelasto-hydrodynamic model to predict the lubricating interface performance. In Proceedings of the Eighth International Conference on Fluid Power Transmission and Control, Hangzhou, China, 9–11 April 2013. [Google Scholar]

- Bügener, N.; Klecker, J.; Weber, J. Analysis and improvement of the suction performance of axial piston pumps in swash plate design. Int. J. Fluid Power 2014, 15, 153–167. [Google Scholar] [CrossRef]

- Bügener, N.; Helduser, S. Analysis of the suction performance of axial piston pumps by means of computational fluid dynamics (CFD). In Proceedings of the Seventh International Fluid Power Conference, Aachen, Germany, 22–24 March 2010. [Google Scholar]

- Ji, H.; Wang, Y. Numerical analysis of oil-suction caviation in cylinder chamber of axial piston pump. J. Lanzhou Univ. Technol. 2013, 39, 34–37. [Google Scholar]

- Mandal, N.P.; Saha, R.; Santal, D. Effects of flow inertia modelling and valve-plate geometry on swash-plate axial-piston pump performance. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2012, 226, 451–465. [Google Scholar] [CrossRef]

- Berta, G.; Casoli, P.; Vacca, A. Simulation model of an axial piston pump inclusive of cavitation. In Proceedings of the ASME 2002 International Mechanical Engineering Congress and Exposition, New Orleans, LA, USA, 17–22 November 2002. [Google Scholar]

- Harris, R.; Eage, K.; Tilley, D. Reduction of piston pump cavitation by means of a pre-expansion volume. In Proceedings of the Fifth Bath International Fluid Power Workshop, Bath, UK, 16–19 September 1992. [Google Scholar]

- Pettersson, M.E.; Weddfelt, K.G.; Palmberg, J.S. Methods of reducing ripple from fluid power pumps-a theoretical approach. SAE Tech. Pap. 1991, 100, 158–167. [Google Scholar]

- Liu, X.H.; Yu, L.Y.; Liu, H.L. Cavitation erosion mechanism of port plate of hydraulic axial plunger pump. Chin. J. Mech. Eng. 2008, 44, 203–208. [Google Scholar] [CrossRef]

- Chao, Q.; Zhang, J.H.; Xu, B.; Huang, H.P.; Zhai, J. Effects of inclined cylinder ports on gaseous cavitation of high-speed electro-hydrostatic actuator pumps: A numerical study. Eng. Appl. Comput. Fluid Mech. 2019, 13, 245–253. [Google Scholar] [CrossRef] [Green Version]

- Chao, Q. Research on Some Key Technologies of High-Speed Rotation for Axial Piston Pumps used in EHAs. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2019. [Google Scholar]

- Manring, N.D. Tipping the cylinder block of an axial-piston swash-plate type hydrostatic machine. J. Dyn. Syst. Meas. Control 2000, 122, 216–221. [Google Scholar] [CrossRef]

- Ivantysyn, R. Computational Design of Swash Plate Type Axial Piston Pumps a Framework for Computational Design. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2011. [Google Scholar]

- Wegner, S.; Gels, S.; Jang, D.S. Experimental investigation of the cylinder block movement in an axial piston machine. In Proceedings of the ASME/BATH 2015 Symposium on Fluid Power and Motion Control, Chicago, IL, USA, 12–14 October 2015. [Google Scholar]

- Wegner, D.I.S.; Löschner, F.; Gels, I.S. Validation of the physical effect implementation in a simulation model for the cylinder block/valve plate contact supported by experimental investigations. In Proceedings of the 10th International Fluid Power Conference, Dresden, Germany, 8–10 March 2016. [Google Scholar]

- Wieczorek, U.; Ivantysynova, M. Computer aided optimization of bearing and sealing gaps in hydrostatic machines—The simulation tool CASPAR. Int. J. Fluid Power 2002, 3, 7–20. [Google Scholar] [CrossRef]

- Hooke, C.; Foster, K.; Madera, G. A note on the effect of shaft and casing stiffness on the port plate lubrication film of a particular slipper-pad axial piston pump. In Proceedings of the Fourth International Fluid Power Symposium, Sheffield, UK, 21–28 February 1975. [Google Scholar]

- Wang, Z.; Hu, S.; Ji, H. Analysis of lubricating characteristics of valve plate pair of a piston pump. Tribol. Int. 2018, 126, 49–64. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Yang, J.; Zhang, H.Y. Flow filed character analysis of piston pump valve plate. Hydraul. Pneum. Seals 2016, 36, 41–44. [Google Scholar]

- Achten, P.; Eggenkamp, S. Barrel tipping in axial piston pumps and motors. In Proceedings of the 15th Scandinavian International Conference on Fluid Power, Linköping, Sweden, 7–9 June 2017. [Google Scholar]

- Zhang, J.H.; Chao, Q.; Xu, B. Analysis of the cylinder block tilting inertia moment and its effect on the performance of high-speed electro-hydrostatic actuator pumps of aircraft. Chin. J. Aeronaut. 2018, 31, 169–177. [Google Scholar] [CrossRef]

- Xu, B.; Chao, Q.; Zhang, J.H. Effects of the dimensional and geometrical errors on the cylinder block tilt of a high-speed EHA pump. Meccanica 2017, 52, 2449–2469. [Google Scholar] [CrossRef]

- Zhang, J.H.; Chao, Q.; Xu, B. Effect of piston-slipper assembly mass difference on the cylinder block tilt in a high-speed electro-hydrostatic actuator pump of aircraft. Int. J. Precis. Eng. Manuf. 2017, 18, 995–1003. [Google Scholar] [CrossRef]

- Ivantysyn, J.; Ivantysynova, M. Hydrostatic Pumps and Motors: Principles, Design, Performance, Modelling, Analysis, Control and Testing; Tech Books International: New Delhi, Inda, 2003. [Google Scholar]

- Chao, Q.; Zhang, J.H.; Xu, B. Spline design for the cylinder block within a high-speed electro-hydrostatic actuator pump of aircraft. Meccanica 2018, 53, 395–411. [Google Scholar] [CrossRef]

- Ivantysynova, M.; Baker, J. Power loss in the lubricating gap between cylinder block and valve plate of swash plate type axial piston machines. Int. J. Fluid Power 2009, 10, 29–43. [Google Scholar] [CrossRef]

- Shin, J.H.; Kim, K.W. Effect of surface non-flatness on the lubrication characteristics in the valve part of a swash-plate type axial piston pump. Meccanica 2014, 49, 1275–1295. [Google Scholar] [CrossRef]

- Murrenhoff, H.; Eneke, C.; Gels, S. Efficiency improvement of fluid power components focusing on tribological systems. In Proceedings of the Seventh International Fluid Power Conference, Aachen, Germany, 22–24 March 2010. [Google Scholar]

- Qi, S.; Deng, H.S.; Zhang, E.Y. Experiental research on friction characteristics of testured axial piston pump port plate. Chin. Hydraul. Pneum. 2011, 9, 105–107. [Google Scholar]

- Li, Y.; Deng, H.S.; Wang, X.L. Experiment on friction and wear performance of textured port plate pair. J. Aerosp. Power 2014, 29, 1591–1597. [Google Scholar]

- Chen, Y.; Zhang, J.H.; Xu, B. Investigation of Laser Surface Texturing for Integrated PV (Pressure×Velocity)-Value-Decreased Retainer in an EHA Pump; Universitätsbibliothek der RWTH Aachen: Aachen, Germany, 2018. [Google Scholar]

- Zhang, J.H.; Chen, Y.; Xu, B. Effect of surface texture on wear reduction of the tilting cylinder and the valve plate for a high-speed electro-hydrostatic actuator pump. Wear 2018, 414, 68–78. [Google Scholar] [CrossRef]

- Viral, M. Torque Ripple Attenuation for an Axial Piston Swashplate Type Hydrostatic Pump: Noise Considerations. Ph.D. Thesis, University of Missouri, Columbia, MO, USA, 2006. [Google Scholar]

- Darling, J. Piston-Cylinder Dynamics in Oil Hydraulic Axial Piston Pumps. Ph.D. Thesis, University of Bath, Bath, UK, 1985. [Google Scholar]

- Manring, N.D. The discharge flow ripple of an axial-piston swash-plate type hydrostatic pump. J. Dyn. Syst. Meas. Control 2000, 122, 263–268. [Google Scholar] [CrossRef]

- Edge, K.; Darling, J. Cylinder pressure transients in oil hydraulic pumps with sliding plate valves. Proc. Inst. Mech. Eng. Part B Manag. Eng. Manuf. 1986, 200, 45–54. [Google Scholar] [CrossRef]

- Edge, K.A. A theoretical model of axial piston pump flow ripple. In Proceedings of the First Bath International Fluid Power Workshop, Bath, UK, 8 September 1988. [Google Scholar]

- Xu, B.; Hu, M.; Zhang, J.H. Impact of typical steady-state conditions and transient conditions on flow ripple and its test accuracy for axial piston pump. Chin. J. Mech. Eng. 2015, 28, 1012–1022. [Google Scholar] [CrossRef]

- Xu, B.; Lee, K.M.; Song, Y.C. A numerical and experimental investigation of parametric effect on flow ripple. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 2939–2951. [Google Scholar] [CrossRef]

- Edge, K.A.; Freitas, F. Fluid borne pressure ripple in positive displacement pump suction lines. In Proceedings of the Relay Conference, Cambridge, UK, 1 January 1981. [Google Scholar]

- Freitas, F. The Generation and Transmission of Pressure Fluctuations in Pump Suction Lines. Ph.D. Thesis, University of Bath, Bath, UK, 1982. [Google Scholar]

- Edge, K.A.; Wing, T.J. The measurement of the fluid borne pressure ripple characteristics of hydraulic components. Proc. Inst. Mech. Eng. Part B Manag. Eng. Manuf. 1983, 197, 247–254. [Google Scholar] [CrossRef]

- Kim, J.K.; Kim, H.E.; Jung, J.Y. Relation between pressure variations and noise in axial type oil piston pumps. KSME Int. J. 2004, 18, 1019–1025. [Google Scholar] [CrossRef]

- Wang, Z.M.; Tan, S.K. Vibration and pressure fluctuation in a flexible hydraulic power systemon an aircraft. Comput. Fluids 1998, 27, 1–9. [Google Scholar] [CrossRef]

- Ouyang, X.P.; Fang, X.; Yang, H.Y. An investigation into the swash plate vibration and pressure pulsation of piston pumps based on full fluid-structure interactions. J. Zhejiang Univ.-SCIENCE A 2016, 17, 202–214. [Google Scholar] [CrossRef] [Green Version]

- Song, Y.C. Investigation on Test Method and Noise Reduction Structure with Large Operating Conditions for Piston Pump Flow Rate. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2013. [Google Scholar]

- Xu, B.; Zhang, J.H.; Yang, H.Y. Multi-objective drive forward design with damping orifice and groove for axial piston pump. Trans. Chin. Soc. Agric. Mach. 2013, 44, 279–285. [Google Scholar]

- Zhang, J.H. Study on Valve Plate and Flow-Distribution Method for Noise Reduction of Axial Piston Pump. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2013. [Google Scholar]

- Du, R.L.; Chen, Y.L.; Zhou, H. New distributing mechanism for high speed single-piston axial piston pump. J. Zhejiang Univ. 2016, 50, 1902–1910. [Google Scholar]

- Hargreaves, B. Hydraulic systems keep evolving; MRO options expand. Aviation Week Network, 12 May 2017. [Google Scholar]

- Ouyang, X.P.; Li, L.; Fang, X. Research status and prospects of resonant-type hydraulic pulsation attenuators. J. Mech. Eng. 2015, 51, 168–175. [Google Scholar] [CrossRef] [Green Version]

- Gao, F.; Ouyang, X.P.; Yang, H.Y. A novel pulsation attenuator for aircraft piston pump. Mechatronics 2013, 23, 566–572. [Google Scholar] [CrossRef]

- Ericson, L. On Fluid Power Pump and Motor Design: Tools for Noise Reduction. Ph.D. Thesis, Linköping University, Linköping, Sweden, 2012. [Google Scholar]

- Fiebig, W. Location of noise sources in fluid power machines. Int. J. Occup. Saf. Ergon. 2007, 13, 441–450. [Google Scholar] [CrossRef] [Green Version]

- Ye, S.G. Prediction of Vibro-Asoustic Characteristics and Structure Optimization for Noise Reduction of Axial Piston Pumps. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2016. [Google Scholar]

- Johanson, A. Design Principles for Noise Reduction in Hydraulic Piston Pumps: Simulation, Optimisation and Experimental Verification. Ph.D. Thesis, Linköping University, Linköping, Sweden, 2005. [Google Scholar]

- Pettersson, M.; Weddfelt, K.; Palmberg, J.O. Modelling and measurement of cavitation and air release in a fluid power piston pump. In Proceedings of the Third Scandinavian International Conference on Fluid Power, Linköping, Sweden, 25–26 May 1993. [Google Scholar]

- Johansson, A.; Palmberg, J.O. The importance of suction port timing in axial piston pumps. In Proceedings of the 9th International Conference on Fluid Powers, Linköping, Sweden, 1–3 July 1993. [Google Scholar]

- Ding, H.; Visser, F.; Jiang, Y. Demonstration and validation of a 3D CFD simulation tool predicting pump performance and cavitation for industrial applications. J. Fluids Eng. 2011, 133, 011101. [Google Scholar] [CrossRef]

- Edge, K.; Darling, J. The pumping dynamics of swash plate piston pumps. J. Dyn. Syst. Meas. Control 1989, 111, 307–312. [Google Scholar] [CrossRef]

- Ivantysynova, M.; Seenirag, G.K.; Huang, C. Comparison of different valve plate designs focusing on oscillating forces and flow pulsation. In Proceedings of the Ninth Scandinavian International Conference on Fluid Power, Linköping, Sweden, 1–3 June 2005. [Google Scholar]

- Pettersson, M. Design of Fluid Power Piston Pumps: With Special Reference to Noise reduction; Division of Fluid Power Technology, Department of Mechanical Engineering, Linköping University: Linköping, Sweden, 1995. [Google Scholar]

- Manring, N.D. Valve-plate design for an axial piston pump operating at low displacements. J. Mech. Des. 2003, 125, 200–205. [Google Scholar] [CrossRef]

- Lin, C.; Wei, Y.Q.; Zhao, X.L.; Manring, N.D. Design and analysis of new type of piston pump. J. Southwest Jiaotong Univ. 2018, 53, 602–609. [Google Scholar]

- Zhang, Z.T.; Cao, S.P.; Luo, X.H. Design and research on the new type water hydraulic Axis piston pump. J. Press. Vessel. Technol. 2016, 138, 031203. [Google Scholar]

- Ericson, L.; Forssell, J. A novel axial piston pump/motor principle with floating pistons. In Proceedings of the BATH/ASME 2018 Symposium on Fluid Power and Motion Control, Bath, UK, 12–14 September 2018. [Google Scholar]

- Altare, G.; Vacca, A.; Richter, C. A novel pump design for an efficient and compact Electro-Hydraulic Actuator IEEE aerospace conference. In Proceedings of the 2014 IEEE Aerospace Conference, Big Sky, MT, USA, 1–8 March 2014. [Google Scholar]

- Wang, H.J.; Shi, G.L. Study of a novel axial piston pump with adjustable tilting piston. In Proceedings of the 2019 IEEE 8th International Conference on Fluid Power and Mechatronics, Wuhan, China, 10–13 April 2019. [Google Scholar]

- Xing, T.; Xu, Y.Z.; Ruan, J. Two-dimensional piston pump: Principle, design, and testing for aviation fuel pumps. Chin. J. Aeronaut. 2020, 33, 1349–1360. [Google Scholar] [CrossRef]

- Ruan, J.; Li, J.Y.; Jin, D.C. Research and feasibility verification of two-dimensional(2D) piston pump. J. Zhejiang Univ. Technol. 2017, 45, 264–269. [Google Scholar]

- Jin, D.C. Research on Design Method and Experimental Verification of Two-Dimensional Piston Pump. Ph.D. Thesis, Zhejiang University of Technology, Hangzhou, China, 2019. [Google Scholar]

- Jin, D.C.; Ruan, J. Design and research of two-dimensional fuel pump. Acta Aeronaut. Astronaut. Sin. 2019, 40, 318–327. [Google Scholar]

- Qian, J.Y.; Shentu, S.N.; Ruan, J. Volumetric efficiency analysis of two-dimensional piston aviation fuel pump. Acta Aeronaut. Astronaut. Sin. 2020, 41, 271–283. [Google Scholar]

- Shentu, S.N.; Ruan, J.; Qian, J.Y. Optimization analysis of flow characteristic and distribution window of 2D pump. Trans. Chin. Soc. Agric. Mach. 2019, 50, 403–410. [Google Scholar]

- Jin, D.C.; Ruan, J.; Li, S. Modelling and validation of a roller-cam rail mechanism used in a 2D piston pump. J. Zhejiang Univ.-Sci. A 2019, 20, 201–217. [Google Scholar] [CrossRef]

- Ruan, J.; Jin, D.C.; Shentu, S.N. Research and feasibility verification of two-dimensional(2D) tandem pump. Chin. Hydraul. Pneum. 2017, 11, 1–5. [Google Scholar]

- Li, J.Y.; Jin, D.C.; Tong, C.W. Design and an error compensation of end cam for two dimensional(2D) axial piston pump. Hydraul. Pneum. Seals 2017, 37, 18–22. [Google Scholar]

- Shentu, S.N.; Ruan, J.; Qian, J.Y. Study of flow ripple characteristics in an innovative two-dimensional fuel piston pump. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 1–15. [Google Scholar] [CrossRef]

- Huang, Y.; Ding, C.; Wang, H.Y. Numerical and experimental study on the churning losses of 2D high-speed piston pumps. Eng. Appl. Comput. Fluid Mech. 2020, 14, 764–777. [Google Scholar] [CrossRef]

- Ruan, J.; Wang, H.Y.; Wu, S. Heavy-Duty Force-Balanced Two-Dimensional Piston Unit Pump. China Patent CN111502952A, 7 October 2020. [Google Scholar]

- Huang, Y.; Ruan, J.; Zhang, C.C. Research on the mechanical efficiency of high-speed 2D piston pumps. Processes 2020, 8, 853. [Google Scholar] [CrossRef]

- Huang, Y.; Ruan, J.; Chen, Y. Research on the volumetric efficiency of 2D piston pumps with a balanced force. Energies 2020, 13, 4796. [Google Scholar] [CrossRef]

- Ruan, J.; Zhu, K.; Li, S. Stacked Rolling Heavy-Duty Two-Dimensional Piston Pump. China Patent CN212454718U, 2 February 2021. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Zhu, C.; Meng, B.; Li, S. Challenges and Solutions for High-Speed Aviation Piston Pumps: A Review. Aerospace 2021, 8, 392. https://doi.org/10.3390/aerospace8120392

Zhang C, Zhu C, Meng B, Li S. Challenges and Solutions for High-Speed Aviation Piston Pumps: A Review. Aerospace. 2021; 8(12):392. https://doi.org/10.3390/aerospace8120392

Chicago/Turabian StyleZhang, Chenchen, Chenhang Zhu, Bin Meng, and Sheng Li. 2021. "Challenges and Solutions for High-Speed Aviation Piston Pumps: A Review" Aerospace 8, no. 12: 392. https://doi.org/10.3390/aerospace8120392