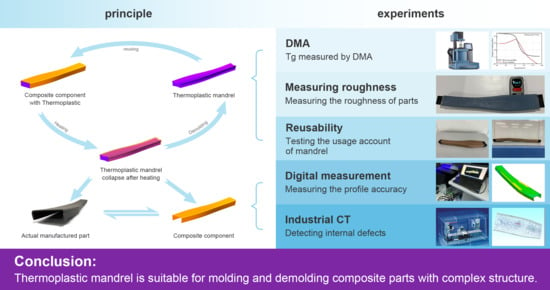

Thermoplastic Mandrel for Manufacturing Composite Components with Complex Structure

Abstract

:1. Introduction

2. Material and Sample Manufacturing

2.1. Materials

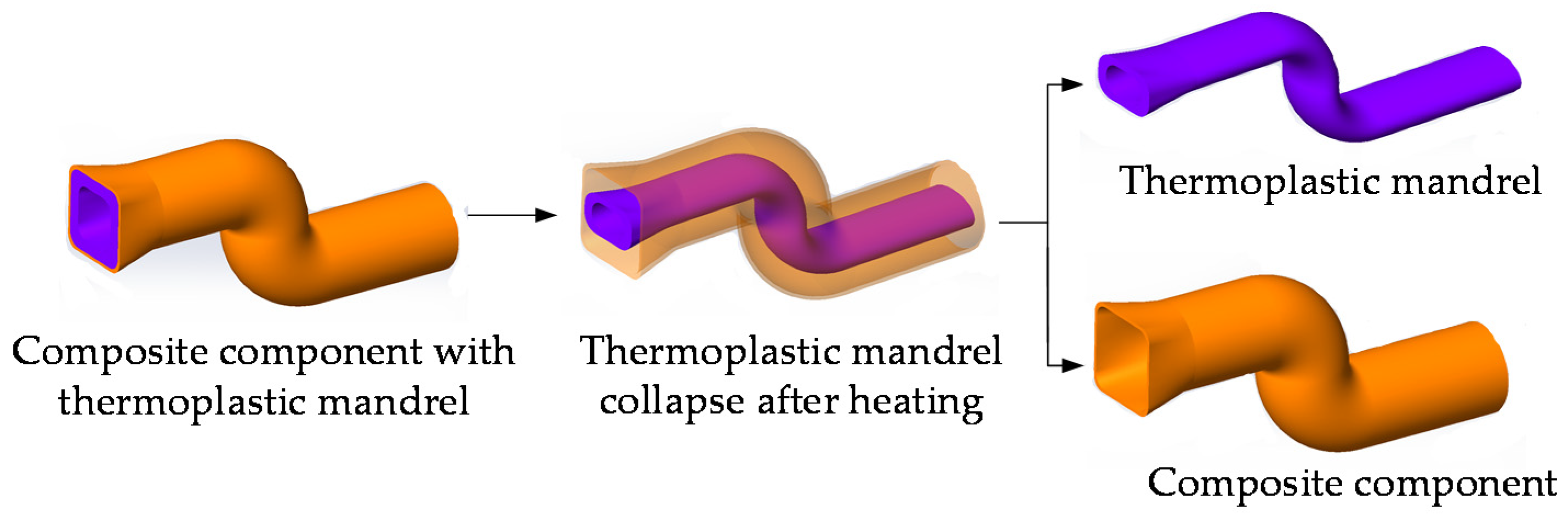

2.2. Thermoplastic Mandrel Manufacturing

2.3. Manufacturing of Composite Parts

3. Experiments and Tests

3.1. Mandrel Performance Test

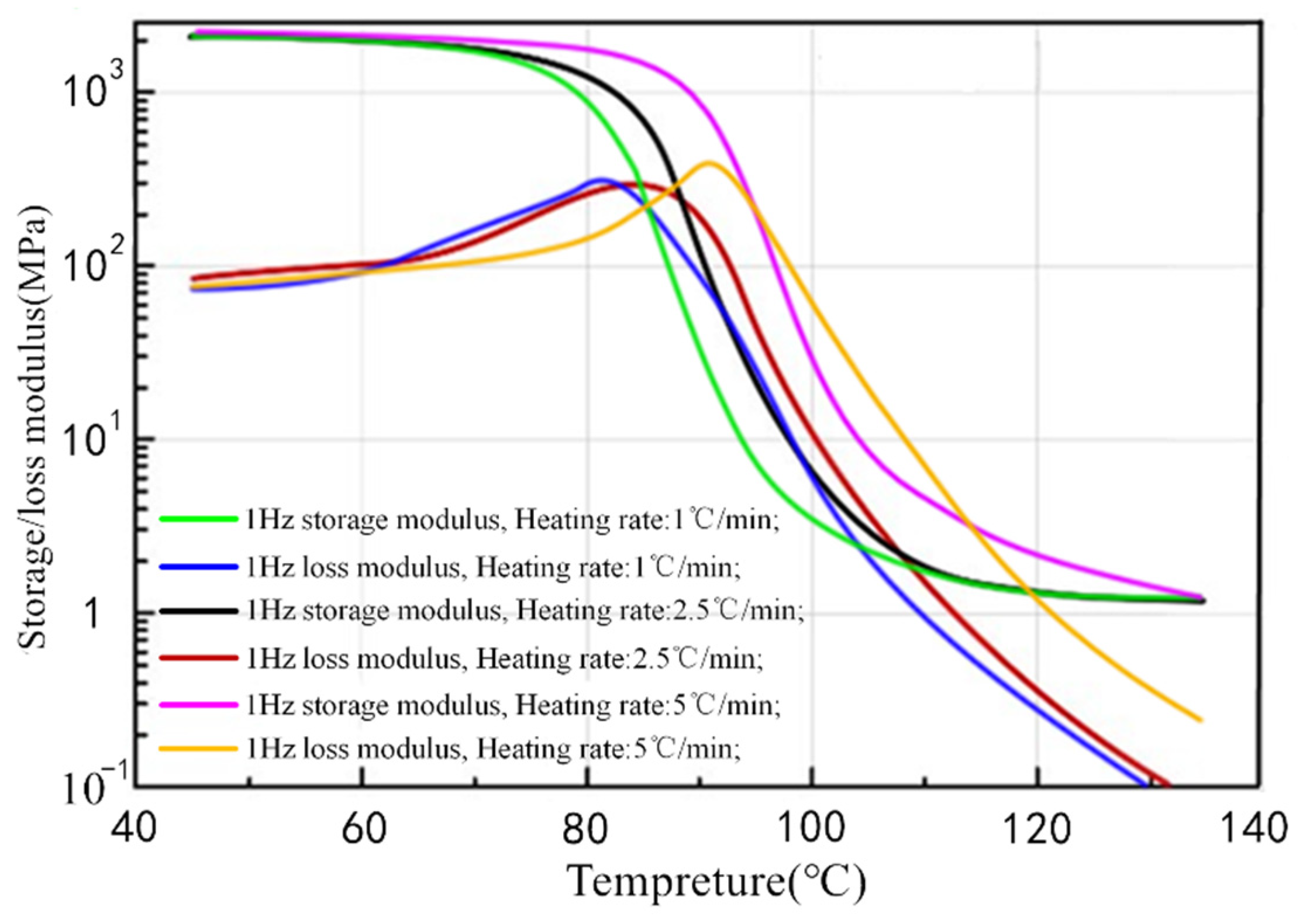

3.1.1. Glass Transition Temperature

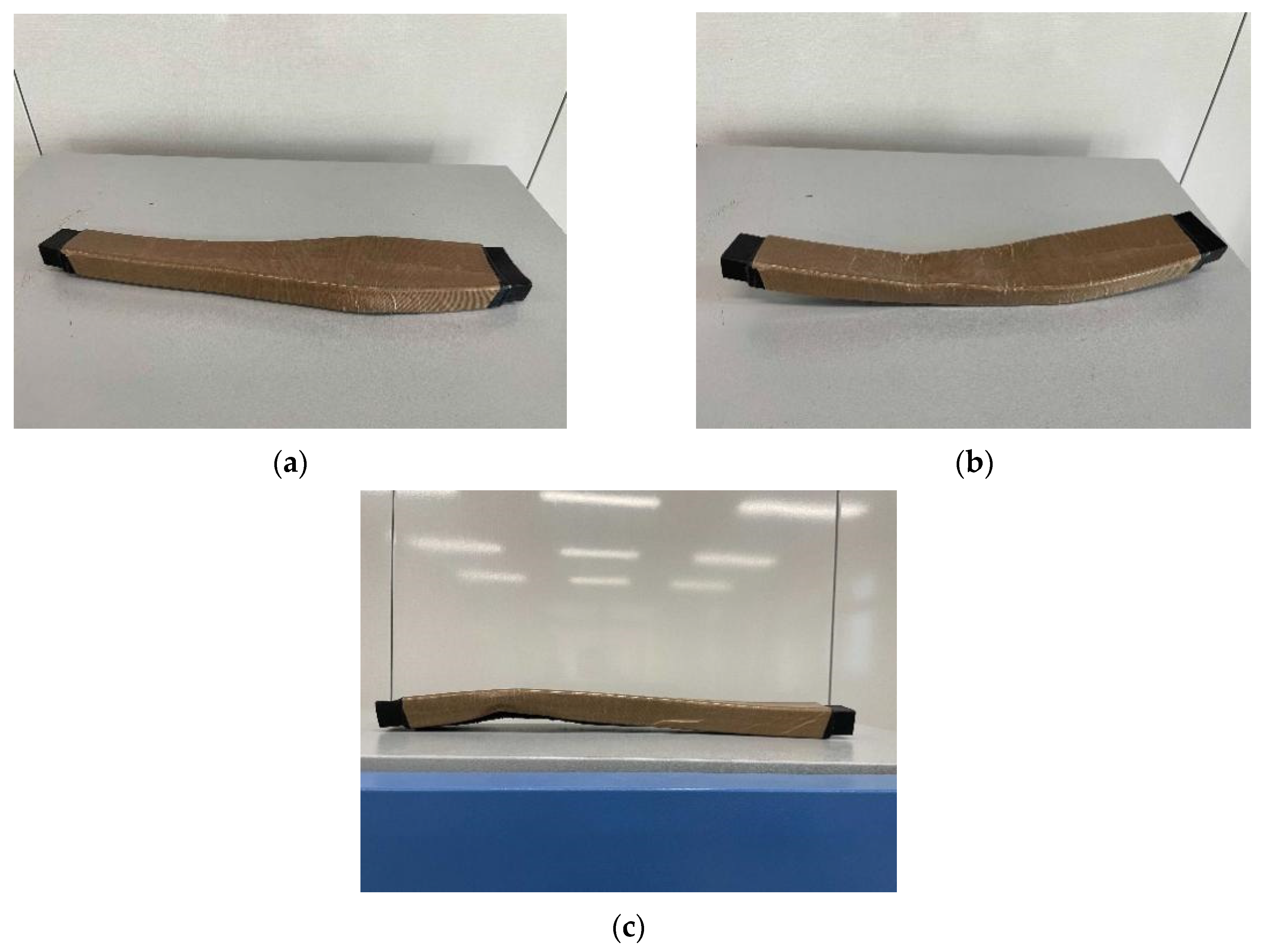

3.1.2. Surface Roughness

3.1.3. Reusability

3.2. Performance Test of Composite Parts

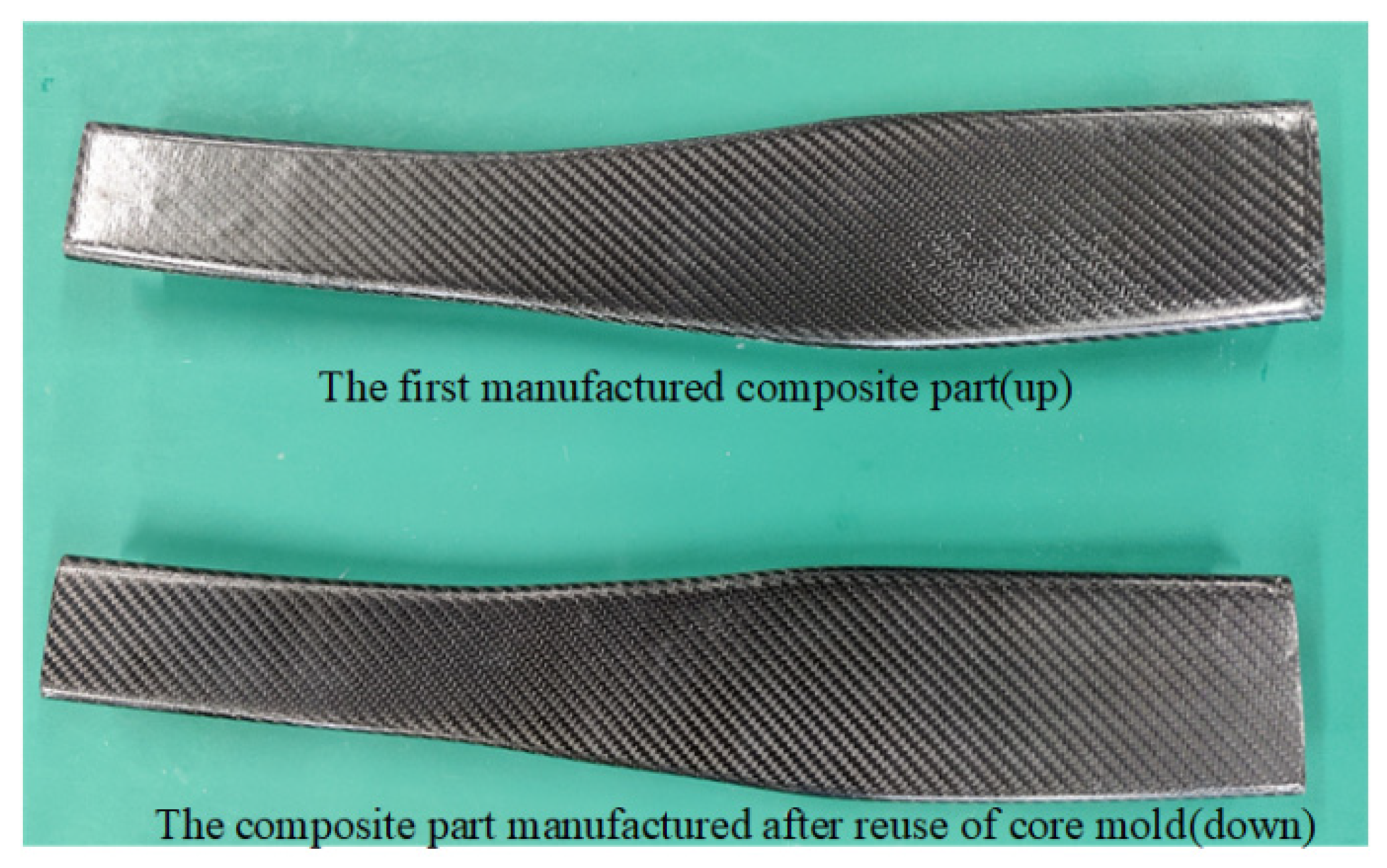

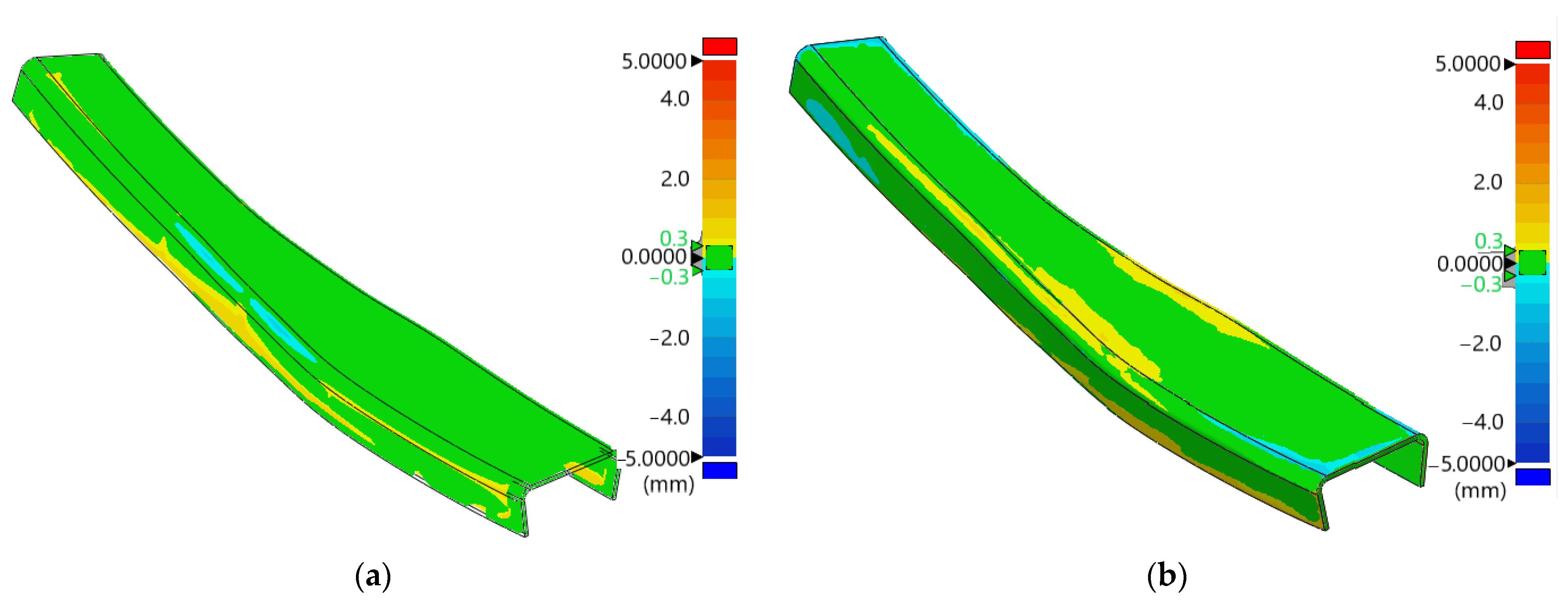

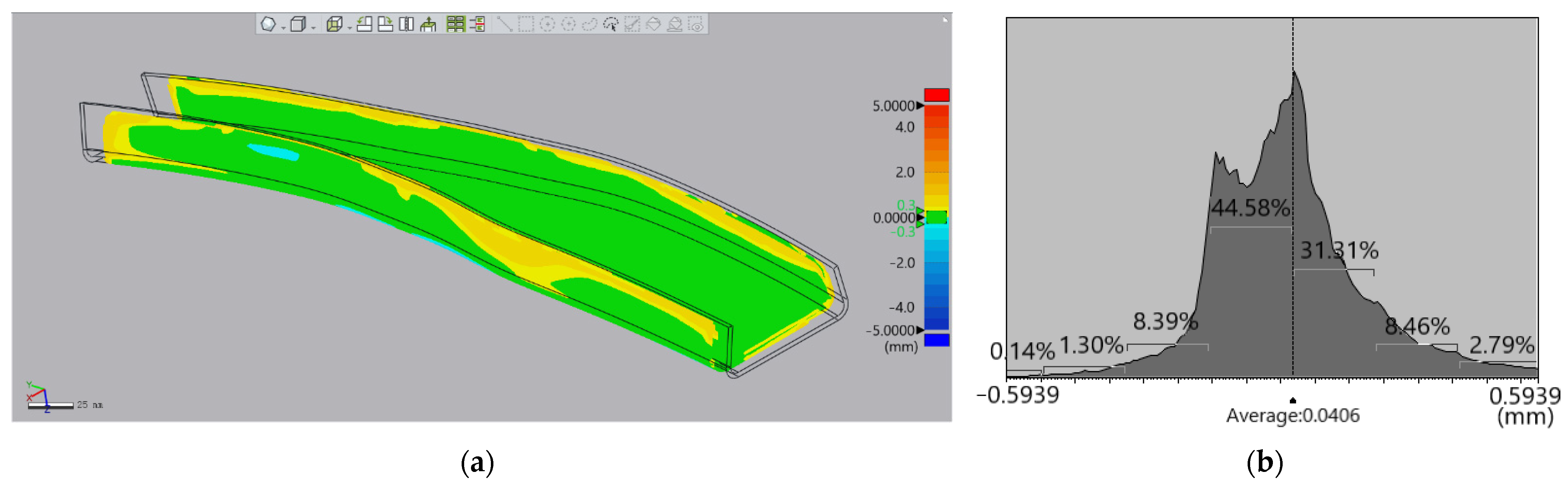

3.2.1. Profile Accuracy

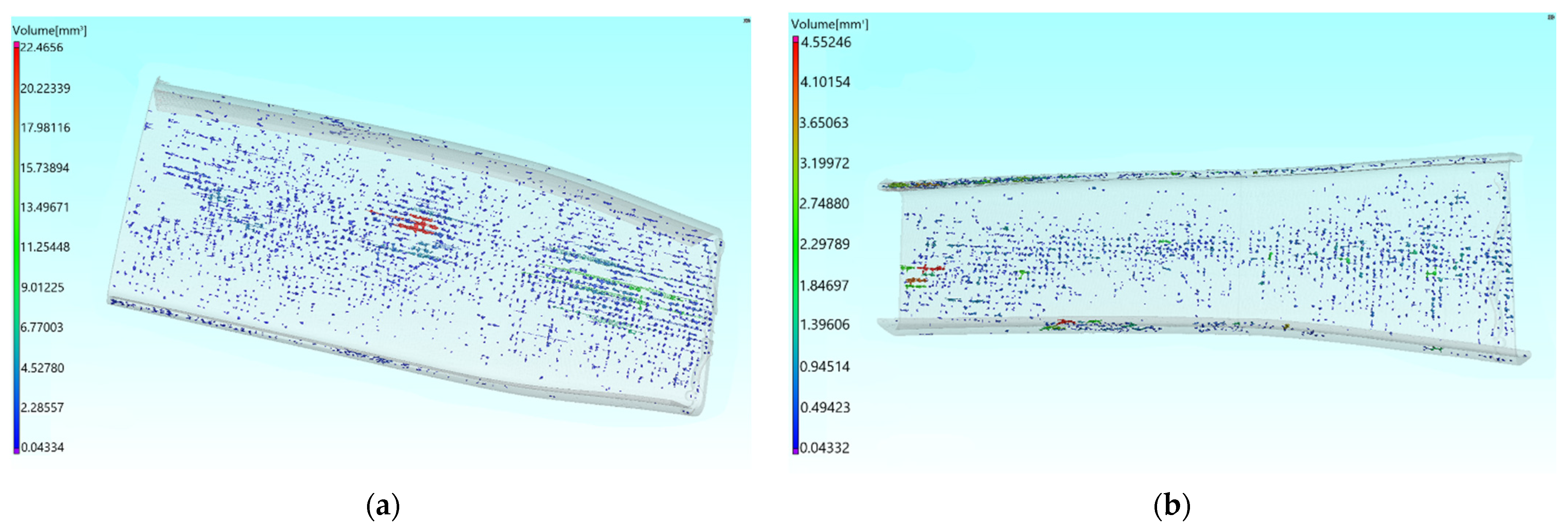

3.2.2. Internal Porosity

4. Conclusions

- The thermoplastic mandrel made in this paper had suitable glass transition temperature, good surface roughness, and the ability to be reused. According to the experiments of the thermoplastic mandrel, the glass transition temperature of the mandrel was between 80 °C and 90 °C, the surfaces roughness of the mandrel was below Ra 0.5 μm, and the mandrel can be reused more than 20 times, because of the parts manufactured by the mandrel still maintaining high accuracy after the mandrel was reused for 20 times.

- The thermoplastic mandrel can effectively solve the demolding problem and the composite parts manufactured by the mandrel have low profile error and internal porosity. According to the experiments of composite parts, composite parts with complex structure could be manufactured by the mandrel successfully. The average error of the molded part is about 0.04 mm and the average porosity of the upper and lower halves is 0.72% and 0.61%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmed, S.; Thostenson, E.T.; Schumacher, T.; Doshi, S.M.; McConnell, J.R. Integration of carbon nanotube sensing skins and carbon fiber composites for monitoring and structural repair of fatigue cracked metal structures. Compos. Struct. 2018, 203, 182–192. [Google Scholar] [CrossRef]

- Reis, V.; Opelt, C.; Cândido, G.; Rezende, M.; Donadon, M. Effect of fiber orientation on the compressive response of plain weave carbon fiber/epoxy composites submitted to high strain rates. Compos. Struct. 2018, 203, 952–959. [Google Scholar] [CrossRef]

- Radue, M.; Odegard, G. Multiscale modeling of carbon fiber/carbon nanotube/epoxy hybrid composites: Comparison of epoxy matrices. Compos. Sci. Technol. 2018, 166, 20–26. [Google Scholar] [CrossRef]

- Chung, K.-C.; Shu, M.-H.; Wang, Y.-C.; Huang, J.-C.; Lau, E.M. 3D printing technologies applied to the manufacturing of aircraft components. Mod. Phys. Lett. B 2020, 34, 2040018. [Google Scholar] [CrossRef]

- Abedi, M.M.; Nedoushan, R.J.; Sheikhzadeh, M.; Yu, W.-R. The crashworthiness performance of thin-walled ultralight braided lattice composite columns: Experimental and finite element study. Compos. Part B Eng. 2020, 202, 108413. [Google Scholar] [CrossRef]

- Guo, K.; Wen, L.; Xiao, J.; Lei, M.; Wang, S.; Zhang, C.; Hou, X. Design of winding pattern of filament-wound composite pressure vessel with unequal openings based on non-geodesics. J. Eng. Fibers Fabr. 2020, 15, 15. [Google Scholar] [CrossRef]

- Zu, L.; Xu, H.; Jia, X.; Zhang, Q.; Wang, H.; Zhang, B. Winding path design based on mandrel profile updates of composite pressure vessels. Compos. Struct. 2019, 235, 111766. [Google Scholar] [CrossRef]

- Wang, R.; Jiao, W.; Liu, W.; Yang, F. A new method for predicting dome thickness of composite pressure vessels. J. Reinf. Plast. Compos. 2010, 29, 3345–3352. [Google Scholar] [CrossRef]

- Brodsjo, A.; Dekker, J. An Automated and Digital Approach to Manufacture Complex, One-off Composite Structures. Sampe J. 2020, 56, 34–42. [Google Scholar]

- Fal, M.; Abutunis, A.; Chandrashekhara, K.; Dhaliwal, G.S. Investigation of laminate debonding in horizontal axis water turbine composite blades. J. Renew. Sustain. Energy 2020, 12, 044501. [Google Scholar] [CrossRef]

- Ni, X.; Liao, C.; Li, Y.; Zhang, Z.; Sun, M.; Chai, H.; Wu, H.; Jiang, S. Experimental study of multi-stable morphing structures actuated by pneumatic actuation. Int. J. Adv. Manuf. Technol. 2020, 108, 1203–1216. [Google Scholar] [CrossRef]

- Engelhardt, R.; Irmanputra, R.; Brath, K.; Aufenanger, N.; Drechsler, K. Thermoset Prepreg Compaction during Automated Fiber Placement and Vacuum Debulking. Procedia CIRP 2019, 85, 153–158. [Google Scholar] [CrossRef]

- Forcellese, A.; Simoncini, M.; Vita, A.; Di Pompeo, V. 3D printing and testing of composite isogrid structures. Int. J. Adv. Manuf. Technol. 2020, 109, 1881–1893. [Google Scholar] [CrossRef]

- Hao, W.; Liu, Y.; Zhou, H.; Chen, H.; Fang, D. Preparation and characterization of 3D printed continuous carbon fiber reinforced thermosetting composites. Polym. Test. 2018, 65, 29–34. [Google Scholar] [CrossRef]

- Lombardi, J.L.; Vaidyanathan, K.; Artz, G.; Gillespie, J.; Yarlagadda, S. A water soluble mandrel material for fabricating complex polymer composite components. In Proceedings of the SAMPE 2001, Long Beach, CA, USA, 6–10 May 2001; Volume 46, pp. 1316–1319. [Google Scholar]

- Vaidyanathan, R.K.; Campbell, J.; Artz, G.; Yarlagadda, S.; Gillespie, J.W., Jr.; Dunaj, D.; Guest, B.; Nesmith, K.L. Water soluble tooling materials for complex polymer composite components and honeycombs. SAMPE J. 2003, 39, 22–33. [Google Scholar]

- Mohammadi, M.; Sadeghi, A. The compressive behavior of a composite cylindrical pyramidal lattice structure manufactured with a new production methodology. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2020, 234, 222–231. [Google Scholar] [CrossRef]

- Xie, P.; Zhu, S.; Shao, Y.; Peng, W.; Zhan, L.; Li, S. Simulation and experimental analysis of autoclave co-curing CFRP hat-stiffened panels with silicone airbag mandrels. Iran. Polym. J. 2019, 28, 505–514. [Google Scholar] [CrossRef]

- Li, S.; Zhan, L.; Chang, T. Numerical simulation and experimental studies of mandrel effect on flow-compaction behavior of CFRP hat-shaped structure during curing process. Arch. Civ. Mech. Eng. 2018, 18, 1386–1400. [Google Scholar] [CrossRef]

- Du, H.; Liu, L.; Leng, J.; Peng, H.-X.; Scarpa, F.; Liu, Y. Shape memory polymer S-shaped mandrel for composite air duct manufacturing. Compos. Struct. 2015, 133, 930–938. [Google Scholar] [CrossRef]

- Du, H.; Liu, L.; Zhang, F.; Leng, J.; Liu, Y. Shape retainability and reusability investigation of bottle-shaped SMP mandrel. Polym. Test. 2018, 69, 325–331. [Google Scholar] [CrossRef]

- Jang, J.H.; Bin Hong, S.; Kim, J.-G.; Goo, N.S.; Lee, H.; Yu, W.-R. Long-term properties of carbon fiber-reinforced shape memory epoxy/polymer composites exposed to vacuum and ultraviolet radiation. Smart Mater. Struct. 2019, 28, 115013. [Google Scholar] [CrossRef]

- Yan, Y.; Zhou, P.; Wang, H.; Mao, Y. Thermal Effect on Poly(methyl methacrylate) (PMMA) Material Removal in the Micromilling Process. Polymers 2020, 12, 2122. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Li, J.; Gao, X.; Deng, B.; Huang, G. Double network epoxies with simultaneous high mechanical property and shape memory performance. J. Polym. Res. 2018, 25, 1–12. [Google Scholar] [CrossRef]

- Zhou, B.; Liu, Y.-J.; Lan, X.; Leng, J.-S.; Yoon, S.-H. A glass transition model for shape memory polymer and its composite. Int. J. Mod. Phys. B 2009, 23, 1248–1253. [Google Scholar] [CrossRef]

- Rasa, K.M.; Aycan, O.O.; Holger, S. Characterization of shape memory polymer estane by means of dynamic mechanical thermal analysis technique. Smart Mater. Res. 2014, 2014, 250258. [Google Scholar]

| Experimental Equipment | Size (mm) | Mode | Control Model | Frequency (Hz) | Heating Rate (°C/min) | Temperature Range (°C) |

|---|---|---|---|---|---|---|

| DMA Q800 (TA Instruments) | 10 × 3.5 × 2.5 | Tensile | Displacement Control | 1 | 1 | 45–140 |

| 2.5 | ||||||

| 5 |

| Heating Rate | The Peak Value of the Loss Modulus | The Peak Value of Derivative of Storage Modulus |

|---|---|---|

| 1 °C/min | 81 | 81.5 |

| 2.5 °C/min | 86 | 86.5 |

| 5 °C/min | 91 | 90 |

| Point | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Surface Roughness Ra (μm) | 0.35 | 0.2 | 0.27 | 0.26 | 0.37 | 0.17 | 0.25 | 0.29 | 0.28 | 0.27 |

| Point | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 |

| Surface Roughness Ra (μm) | 0.33 | 0.19 | 0.23 | 0.21 | 0.31 | 0.19 | 0.22 | 0.17 | 0.24 | 0.33 |

| Test Parameters | Voltage | Electric Current | Detector Pixel | Projection Number | Voxel | Scan Duration |

|---|---|---|---|---|---|---|

| Figure | 100 kV | 500 μA | 127 μm | 1440 | 95 μm | 56 min |

| Test Area | Pore Volume (mm3) | Material Volume (mm3) | Internal Porosity |

|---|---|---|---|

| Upper half of part | 683.0574 | 94,798.1093 | 0.72% |

| Lower half of part | 511.0985 | 82,698.5078 | 0.61% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jing, X.; Chen, S.; An, J.; Zhang, C.; Xie, F. Thermoplastic Mandrel for Manufacturing Composite Components with Complex Structure. Aerospace 2021, 8, 399. https://doi.org/10.3390/aerospace8120399

Jing X, Chen S, An J, Zhang C, Xie F. Thermoplastic Mandrel for Manufacturing Composite Components with Complex Structure. Aerospace. 2021; 8(12):399. https://doi.org/10.3390/aerospace8120399

Chicago/Turabian StyleJing, Xishuang, Siyu Chen, Jiuzhi An, Chengyang Zhang, and Fubao Xie. 2021. "Thermoplastic Mandrel for Manufacturing Composite Components with Complex Structure" Aerospace 8, no. 12: 399. https://doi.org/10.3390/aerospace8120399