1. Introduction

Sample return is an important tool for recognizing the formation and evolution of extraterrestrial bodies and their resource endowment status. The Soviet Union, the United States, China and Japan have retrieved physical samples from the Moon and asteroids to deepen human knowledge of the Moon, asteroids, and the solar system through physical and chemical analysis of the returns [

1,

2,

3]. Compared with lunar surface samples, profile samples with strati-graphic information have more important scientific value and can provide direct evidence for the formation and evolutionary history of lunar regolith. The lunar flexible-tube coring method is a highly feasible method for lunar regolith coring because of its good retention of lamina information and high coring rate.

The Soviet Luna-16 probe was the world’s first unmanned automatic sampling probe to complete the collection of lunar regolith samples and return to the ground [

4,

5], whose pendulum-type lunar regolith collection device was mounted on the pendulum-type robot arm on the side of the probe. Luna-16 only used the weight of the sampling device to provide drilling pressure during the drilling process, resulting in a low drilling pressure and shallow drilling depth [

6,

7]. The Luna-24 detector had a slide-type drilling and sampling device, and the flexible tube was turned inward into the inner cavity of the rigid-core tube synchronously by the winding mechanism during the drilling process to complete the final encapsulation of the lunar regolith samples. This design of sample collection mechanism improved the coring rate of deep lunar regolith and maintained the original stratigraphic information of lunar regolith samples to the maximum extent [

8,

9,

10]. The United States completed six manned lunar missions. In six missions, astronauts used hollow thin-walled tubes to press in and take cores [

11,

12]. China’s Chang’e V probe has used a surface sampling manipulator and a drilling sampling device to obtain surface and profile samples of the moon, respectively. After being sealed, the sample is carried back to the earth by a returner, enriching the variety of lunar regolith samples owned by humans [

13,

14,

15,

16].

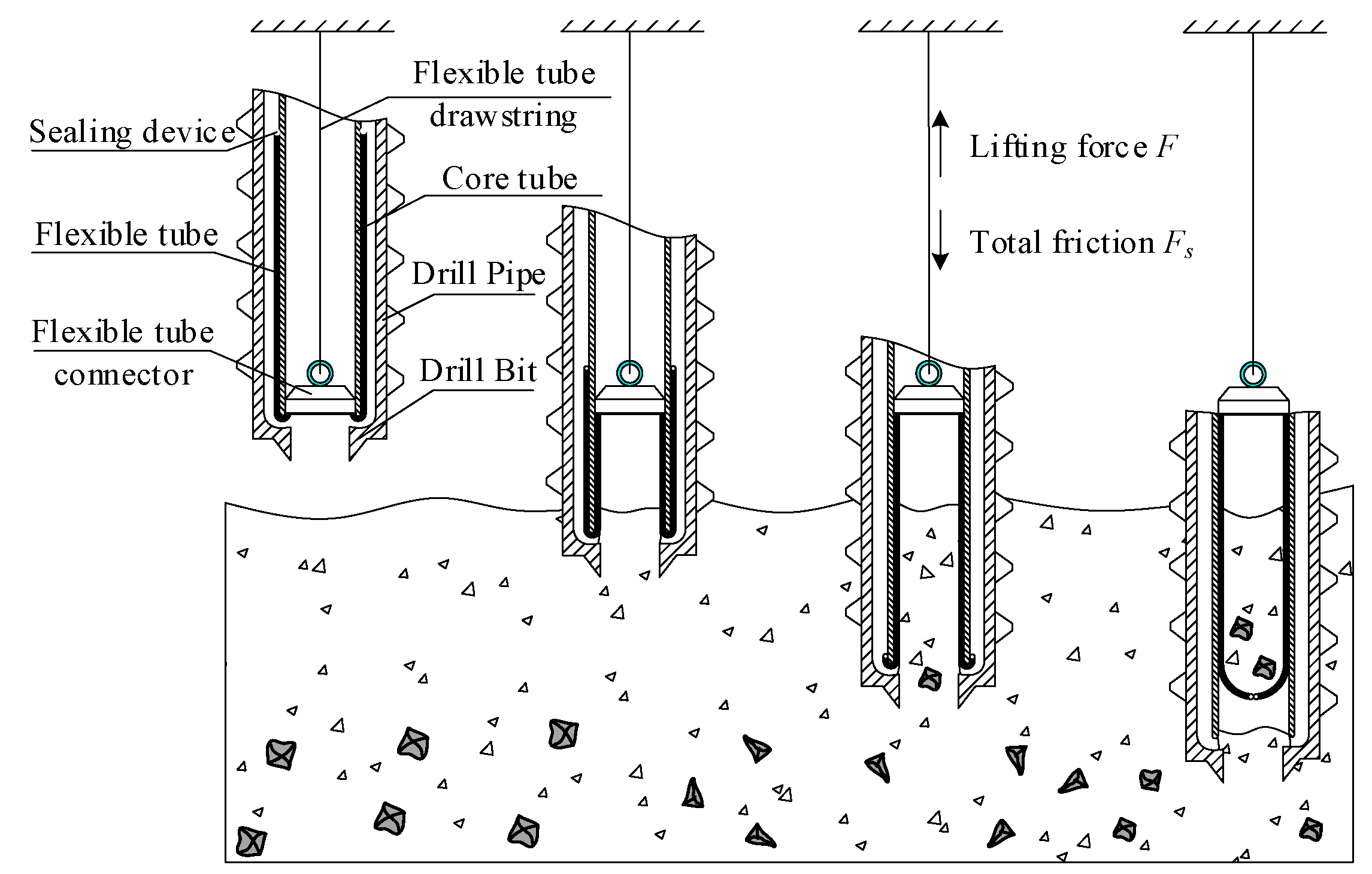

In order to provide theoretical and technical support for the development and optimization of the lunar regolith profile coring assembly, this paper presents a theoretical study of the mechanical properties of the flexible-tube coring assembly. Based on theoretical mechanics and material mechanics, a mechanical model of flexible-tube coring was established, and the correctness of the model was verified by using a drilling and mining test platform. The mechanical model not only describes the change trend of coring force during the coring process, but also has important engineering guidance significance for the development of flexible tube parameters. Based on the mechanical model, the crawling mechanism of the flexible tube during deep moon regolith coring is analyzed. Finally, the judgment conditions of the crawling phenomenon of the flexible tube are proposed.

3. Modeling the Mechanics

3.1. External Wall Force Analysis

In the practical application, the flexible tube is stored on the outer wall of the core tube by means of pleated storage. The core taking process can be divided into two stages. In the first stage, the soft bag in the folded part is flattened continuously, and it mainly rubs against the outer wall of the core tube. In the second stage, the soft bag is completely flattened and gradually turned over to the inside of the core tube under the pull of rope force. The friction between the tube and outer wall consists of the sliding friction and the static friction .

The coring of the flexible tube is shown in

Figure 2. The parameters are shown in

Table 1.

The flexible tube’s characteristic parameters can be expressed as follows: the total length of the flexible tube in its natural state is L, the length of the flexible tube in the folded state at the initial moment is , the length of the flexible tube in the flattened state is , the circumferential modulus of elasticity of the flexible tube is , the coefficient of sliding friction between the flexible tube and the core tube is , and the coefficient of static friction between the flexible tube, and the core tube is . The speed of drilling into the footprint is a constant value , and the speed of the flexible tube from the folded state to the flattened state is a constant value . The length of the flexible tube located on the inner wall of the core tube is . The time required is . The speed of partial disappearance of the folds is . The length of the flattened state at any given moment is .

To explore the spreading state of the sliding friction

, the micro-element of the flexible tube needs to be force analysis. The longitudinal section of the micro-element is subject to circumferential tension

as shown in

Figure 3.

The perimeter and strain of the flexible tube recovered to the flattened state can be found as

Hooke’s law [

22] shows that stress and strain are proportional when the material is subjected to stresses that do not exceed its proportional limits [

23].

and

, where

is the thickness of the flexible tube and

is the height of the micro-element.

The pressure of flexible tube on the core tube can be obtained as

By integrating the above equation, the pressure on the outer wall of the core tube can be expressed as follows.

Thus, the sliding friction in unfolded state can be calculated as follows.

In order to obtain the static friction in the pleated state, the equivalent diameter

of the flexible tube in the fold should be determined first. Only the front part of the folded flexible tube has a movement trend, so the fold rate

is introduced to represent the proportion of the part with a movement trend.

The inner wall diameter of the core tube in the formula is

. The analysis of static friction between flexible tube and core tube in the folded state is similar to the analysis of the sliding friction, and the expression of

can be obtained by the same reason.

Therefore, the friction between the flexible tube and the outer wall of the core tube is

.

3.2. Inward Turning Force Analysis

The flexible tube’s turning process is divided into two parts: Flexible tube turning on the outside of the core tube and flexible tube turning on the inside of the core tube. In

Figure 4,

is the force between the outside flexible tube and the spreading state, and

is the force between the inside flexible tube and the inside of the core tube.

The force analysis of radial and circumferential elements is shown in

Figure 5.

T is the tangential tension force on the micro-element,

is the circumferential tension force on the micro-element,

is the friction force on the micro-element,

is the radial tightening force on the micro-element,

is the radial angle of the taken micro-element,

is the circumferential angle of the taken micro-element,

r is the radius of the corner of the core tube end, and the area of the taken micro-element is

. Building the force balance model yields

Since the radial and circumferential angles of the given flexible tube’s micro-element tend to zero, the above equation is simplified to obtain

Given the force analysis of the flexible tube at the start and end of the inversion process, the above boundary condition can be obtained as

By solving analytically for

, we can obtain

Applying the same method as above,

can be calculated as

In the formula, the friction force of the flexible tube during varus is .

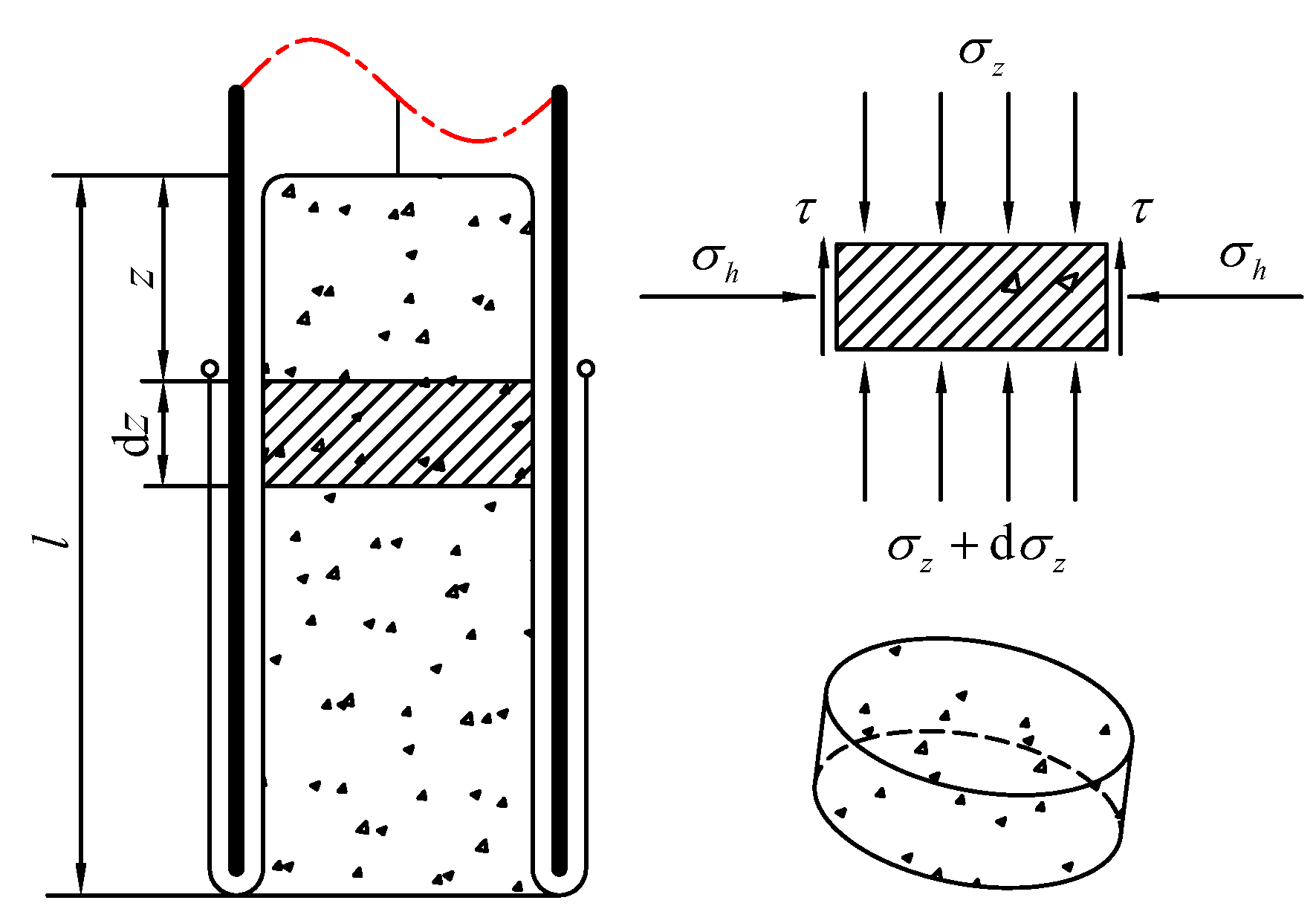

3.3. Internal Cavity Force Analysis

The tube diameter of the flexible tube in the natural state is the same as that after coring. In this case, the flexible tube in the inner cavity is affected by the static friction force of the lunar regolith and the sliding friction force of the core tube.

Since the soil at different depths has various internal friction angles and densities, the lunar regolith located in the core-tube cavity is differentiated, as shown in

Figure 6. The elements of lunar regolith are in static equilibrium. By integrating the friction force, the static friction force

of lunar regolith on the flexible tube can be calculated.

where the height of the lunar regolith in the flexible tube is

, and

is the static friction coefficient between the lunar regolith and the flexible tube.

Flexible-tube-wrapped lunar regolith has a positive pressure on the flexible tube,

, resulting in a positive pressure between the flexible tube and the core tube, so the sliding friction between the two can be calculated using Coulomb’s law of friction.

The axial positive pressure

and lateral compressive stress

on the lunar micro-element inside the core tube can be converted by the lateral pressure coefficient in geomechanics.

where

is the lunar regolith’s lateral pressure coefficient, the relationship of K can be obtained by fitting the empirical equation of Jaky [

24,

25,

26], and the data on the friction angle and porosity ratio of the lunar regolith can be obtained from Lunar Prospector [

27,

28]. The relation between lunar regolith’s lateral pressure coefficient and drilling depth is shown in

Figure 7.

By drawing the chart according to the formula and taking

, the characteristic height of the cored lunar regolith can be obtained.

As the lunar regolith wrapped by the flexible tube is not a semi-infinite body, the axial compressive stress

cannot be calculated by the method of vertical self-weight stress in geomechanics. If lunar regolith particles are regarded as grain particles, the axial compressive stress on lunar regolith particles can be calculated by the “granary effect” model.

where

is the saturation compressive stress.

The mechanical model of the coring process can be obtained by analyzing the forces on different parts of the flexible tube.

3.4. Flexible Tube Mechanics Model

Comprehensive analysis of the forces on different parts of the flexible tube requires the mathematical expression of the mechanical model of the flexible tube in the process of coring:

The value of each parameter of the mechanical model for flexible-tube coring is shown in

Table 2.

Simulation results are shown in

Figure 8. The ordinate

represents the coring force. In the initial drilling process, the flexible tube gradually turns inside out, and the friction force of the inner wall of the core pipe acts on the flexible tube, making the core force increase in a quadratic function. When a certain drilling depth is reached, the internal stress of lunar regolith reaches a stable value, and the friction force between the flexible tube and outer wall of the core pipe occupies a dominant position. The coring force has a linear relationship with the length of the flexible tube. When the fold of the flexible tube disappeared, the compressive stress of the lunar regolith reached the maximum value, which made the friction on outer wall of the core tube reach the maximum value; therefore, the core force reached the maximum value. Subsequently, the length of the flexible tube on the outer wall of the core tube gradually shrank, and the coring force decreased.

4. Flexible Tube Crawl Analysis

As the flexible tube is made of fibrous material with a certain degree of elasticity, and there is friction between its surface and core tube wall, there may be a “crawling” phenomenon, also known as stick–slip behavior, when the speed is slow [

28,

29,

30]. Therefore, theoretical analysis and physical modeling were conducted for the possible crawling problem.

Due to the thin wall thickness of the core tube, the friction force of the flexible tube at the rounded corner of the end of the core tube can be ignored. The friction force on the flexible tube during the movement can be divided into the friction force between the flexible tube and the outer wall of the core tube , and the friction force between the flexible tube and the inner wall of the core tube . When is transferred to the inner wall by the rounded corner, the friction force will increase linearly, so the overall friction force on the flexible tube is .

In order to simplify the system, it is assumed that the mass

of the flexible tube does not change during crawling, and the vertical movement caused by surface roughness and surface corrugations of the core tube is ignored. The physical model of flexible tube crawling is shown in

Figure 9.

The rope stiffness is

k and the damping coefficient is

c. The mathematical model of the crawling motion of the flexible tube can be established by the physical model.

is the mass of the flexible tube in the flattened state, and it flips into internal state after the th crawling movement. is the rope stretch at the beginning of the ith crawling movement, and is the displacement of the flexible tube during the ith crawling movement.

From the flexible tube mechanics model, it can be seen that the speed of the folded-state flexible tube returning to the flattened state is

. The length of the flexible tube in the flattened state at moment

t is

. The length of the flexible tube needed to complete the inward turning is

, and the mass ratio of the two is

. Therefore, the mass of the flexible tube in the flattened state at any moment is

, and the mass of the flexible tube to complete the inward turning is

. The length–mass coefficient of the flexible tube is

. The pressure coefficient between the outer wall flexible tube and the outer wall of the core tube is

. The pressure coefficient between the inner flexible tube and the inner wall of the core tube is

. Then, the friction force

between the outer wall of the flexible tube and the outer wall of the core tube, and the friction force

between the inner wall of the flexible tube and the inner wall of the core tube to give are

Therefore, the friction force on the flexible tube is

The mathematical model of the flexible tube’s crawling motion can be simplified as

where

is the

ith crawl beginning when the amount of stretching of the pull rope,

, is the constant, and the driving speed of the upper end of the pull rope,

, is the instantaneous friction from when the flexible tube began to move. It can be seen that when the flexible tube is about to move, the force in its critical state is balanced, so

.

Let the input signal be

. The following equation is obtained by the Rasch transform.

where the undamped natural frequency is

, the motion damping factor is

, and the equivalent damping of the system is

.

6. Discussion

On 2 December 2020, China’s Chang’e V probe completed drilling, lifting, and sample transfer on the moon’s surface in the Storm Ocean Luemke Mountain area. In the process of drilling the core at a depth of one meter, complicated operating conditions, such as drilling load fluctuation, drilling pressure exceeding the limit, and core lifting force exceeding the limit occurred between the coring drill tool and the lunar regolith. These problems were finally solved by self-controlled pre-programming and remote control on the ground. The main functional performance indexes of Chang’e vs. drilling and sampling device are shown in

Table 7. Based on the characteristics of telemetry data, three representative drilling load conditions were identified: drilling load stable, Condition A; drilling load fluctuation, Condition B; and drilling pressure out of limit, Condition C.

Condition A: The drilling pressure and core lifting force showed a slow growth trend, and the drilling depth was 30–320 mm. It can be judged that the diameters of luner regolith particles at this depth were small and uniform; the drilling and core lifting device played an effective role. The comparison between the actual telemetry data and the simulation is shown in

Figure 16. The telemetry data are basically consistent with the simulation curve.

Condition B: The drilling depth of section B was 460–582 mm. The fluctuation of B was caused by small-scale lunar regolith particles in front of the coring tool. The small-scale lunar regolith particles were gradually squeezed from the front of the cutting edge to the side, resulting in fluctuations in drilling force. The comparison between actual telemetry data and simulation is shown in

Figure 17. The telemetry data are basically consistent with the simulation curve.

Condition C: Large critical particles entered the coring channel and formed two-force rod stagnation with the outer sheath, resulting in no sample injection to the flexible tube. The filled lunar regolith samples begin to slide, and the friction state of the cored flexible tube changed from high-filling-rate sliding friction to low-filling-rate sliding friction, which led to the extremely low load state of the cored force. By repeated rotary coring drill shake and dangling vibration after operation, the characteristics of particle vibration to the end of drilling hole, sealing the sample was completed. The drilling pressure and tension curves of Condition C are shown in

Figure 18.

According to the telemetry data of Chang’e V coring sampling, the core lifting force increases slowly in stage A. It can be judged that the profile lunar regolith from this stage is fine-grained and non dense, and the core lifting force is basically consistent with the model simulation. In stage B, the core lifting force fluctuated due to the additional load of small-scale particles in the front section of the bit; the actual data follow the simulation curve. In stage C, large-scale critical particles blocked around 769 mm during drilling, resulting in a sudden drop in core lifting force and entering the sealing stage in advance. The final drilling depth of Chang’e V was about 1m, and the core lifting force of flexible tube increased slowly throughout the whole process. After three drilling stages, the flexible tube fold of coring still did not flatten and directly entered the core lifting and shaping stage, so the core lifting force did not enter the attenuation stage like the model predicted.

7. Conclusions

In this paper, the force magnitude of the flexible tube in deep lunar regolith coring process is divided into three parts, the detailed mechanical analysis is carried out, and the mechanical model of flexible tube cored is established. This mechanical model describes in detail the changing trend of flexible tube coring force, which lays a theoretical foundation for the formulation of pull rope and flexible tube parameters, the selection of flexible tube lifting motor and the analysis of lunar regolith coring rate. Aiming at the problem of flexible tube crawling, the concept of the differential unit was proposed, and the crawling mathematical model was established. The judgment conditions for the existence of flexible tube crawling phenomenon were obtained, which provide a judgment basis for testing whether the parameters such as the pulling rope’s radial and axial elastic modulus can eliminate the crawling phenomenon.

At last, the core telemetry data of Chang’e V were analyzed. It was found that the coring force trend of the flexible tube mechanical model is basically consistent with that of the telemetry coring force, which verified the correctness of the mechanical model. Finally, during the drilling process, the core was forced to stop due to extreme working conditions. The effect of soil particle size distribution with depth should be considered in subsequent studies to improve the core model and lay the foundation for future lunar sampling.