3.2.1. Fuel Cell

The FC as a system includes the cell stack as well as a variety of auxiliary systems, including balance of plant and thermal management systems in often complex arrangements. The objective of the FC modelling in this paper is an appropriately simplified representation of aspects relevant for the hybrid power system concept. This includes the water production rate obtainable from the FC, but also the mapping of the FC system efficiency ηFCS (cf. Equation (10)). Moreover, for the estimation of the overall system mass, the thermal household requires suitable consideration.

The FC system efficiency

ηFCS describes the ratio of net electric power delivered by the FC system

PFCS,el to the system power supply via fuel flow, i.e., the product of fuel mass flow required for the cell redox reaction and its heating value

:

where

PFCS,el equals the stack electric power output

PStack,el, reduced by all electric power demands

PAux of the FC auxiliary systems including balance of plant and thermal management. It should be noted that, given the considered FC operating conditions in the present study, the lower heating value LHV is used for all FC efficiency evaluations.

Now, with

(cf. Equation (2)) rewritten as:

ηFCS can be expressed in a factorized form:

with an efficiency factor

capturing all auxiliary electric power demands within the FC system being defined as:

Typical customers of PAux,el amongst the FC auxiliary systems mainly focus on the reactant supply units, i.e., pumps and compressors, and electric controllers. It should be noted that the residual effective excess power of the FC power train (cf. Equation (12)) is conservatively neglected when evaluating acc. to Equation (13).

While for the present study, fuel supply pressure is assumed to be provided through an active regulation of the LH

2 fuel tank delivery pressure, the FC inlet air supply requires active pressurization. This is realized by a turbo compressor. For low temperature FCs without sufficient thermo-kinetic power at the exit of a FC stack, the inlet air compressor requires an electric drive. The correspondingly required power for the compression of inlet air mass flow

to the stack operating pressure is calculated as follows:

where

and

are the representative isobaric specific heat and isentropic exponents for the air compression process. The compressor inlet total pressure

results from the freestream total pressure with an inlet pressure ratio of 99% assumed for the study. The compressor outlet total pressure

corresponds to the FC operating pressure. The efficiency

includes the isentropic efficiency of the turbo compressor, the mechanical efficiency of its shaft and bearing system and its electric drive unit. It should be noted that in the case of high temperature and/or high pressure FCs, the stack outflow is typically expanded through a turbine in order to drive the inlet air compressor, thereby reducing

to zero.

In order to obtain the value of

PAux,el, and thus

, the power requirements of all customers need to be added together. Beside

, this also includes the power required in order to drive the liquid water pump within the product water treatment process (see

Section 3.2.2). The electric power demand for the FC electric controller and auxiliary pumps and blowers within the balance of plant is assumed to be 3% of

PStack, el.

The water mass flow

produced by an FC can be expressed as a function of

PStack,el,

ηStack, the heating value per mol of fuel

FHVmol and the product water’s molar Mass

:

A parametric study of Equation (23) for a hydrogen FC is presented in

Figure 3 below. As can be seen, the expectable water mass flows for typical stack efficiencies range from approximately 0.10 kg/s to 0.18 kg/s per MW of stack electric power.

All FC stacks considered in the study are assumed to be technically operated at an excess supply of reactants. While the excess air is simply passed through the stack, the unused fuel is assumed to be recirculated to the stack inlet without leakage.

While for the efficiency formulation above only the net mass flow rate of fuel that is effectively participating in the cell redox reaction was relevant, the thermal balance requires a more careful consideration of the actual mass flow rate of the reactants. In order to simplify the modelling of this, the stack is embedded in an auxiliary control volume that internalizes the recycling of unused fuel as well as any potentially required preheating of the fuel prior to entering the stack. A schematic representation of the stack and the auxiliary control volume referred to as “FC module” is presented in

Figure 4.

The thermal balance of the FC module in

Figure 4 is given by the heat production rate due to the redox reaction in stack

, the net enthalpy flow across the FC due to its reactants net mass inflows, i.e., fuel and air supply, and its product mass outflow

and the residual waste heat to be removed from the cell

. The stack internal heat source term can be calculated from the stack efficiency:

The heat transfer terms result from the mass flows entering and exiting the control volume of the FC module:

As discussed above,

represents the enthalpy of the gross stack inlet air flow, while

refers to the enthalpy of the net fuel inflow. For a stationary equilibrium stack operating temperature, the following balance must be reached:

while the FC heat production rate

is always positive, the sign and absolute value of

depend on the inflow temperatures of the reactants, the stack operating temperature and the effective operating stoichiometry, i.e., the excess air supply ratio.

In a case where

is negative and its value exceeds

this would mean residual waste heat to be removed from the FC becomes negative, i.e., the cell needs to be heated in order to maintain its operating temperature. While this may be less relevant for low temperature FCs, this may often be the case for highly efficient high-temperature FCs. High temperature cell operation also increases the demand for a preheating of the reactants prior to entering the stack in order to reduce local thermal stresses. While preheating of the pre-compressed inlet air is often not applicable, fuel preheating is often required. In practice, both requirements are tackled by utilising the heat contained in the stack’s product exit mass flow to preheat the fuel inlet mass flow [

18,

60].

In order to emulate this for the present study, heat is transferred from the stack product mass flow to the fuel inflow via an FC internal HEX until equals , in cases where would otherwise be <0. As a result in these cases, the temperature of the product mass flow leaving the FC is reduced relative to the stack operating temperature. The total pressure of the product outflow is assumed to be sufficiently close to the stack operating pressure.

The hydrogen fuel is preheated from the fuel supply temperature at the FC entry. Prior to entering the control volume of the FC, the hydrogen fuel mass flow from the LH2 storage in the fuel tank is assumed to have absorbed a certain amount of heat due to its function as a cryogenic heat sink, e.g., used for the electric power train components as well as non-perfect thermal insulation of the fuel transmission system. A fuel supply temperature to the FC of 200 K is assumed for the present study.

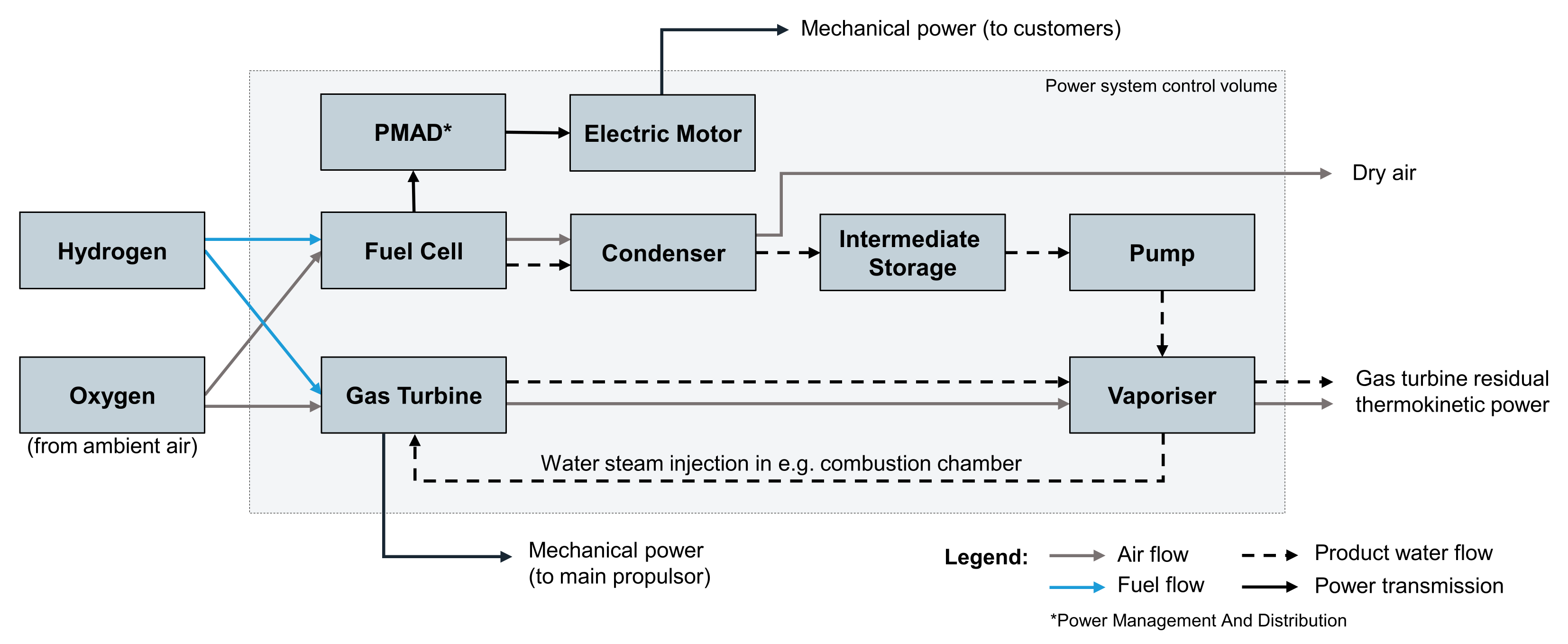

3.2.2. Water Treatment Process

In order to allow for an efficient injection of the FC product water as superheated steam in the GT combustion chamber, the water first needs to be extracted from the FC product outflow, then pressurized in liquid form and re-vaporized. The basic thermodynamic implications of such a water treatment process are illustrated in

Figure 5 based on a temperature entropy diagram for water. The water treatment process examples illustrated in the figure refer to the water released by a typical PEMFC and a typical SOFC, respectively.

An SOFC releases its product water at the anode (cf.

Figure 2) while all other considered FC types release the water at the cathode, together with the excess mass flow from the cells’ oxidant supply. With the hydrogen fuel recirculated inside the FC, this means a pure water condenser for SOFCs. For all other FC types, the condenser sees a mixture of the FC product water mass flow and the residual air fraction of FC oxidant supply. Consequently, the partial pressure of the PEMFC’s product water in

Figure 5 is significantly lower than that of the SOFC, resulting in a larger removal of heat required for the condensation process. At the same time, the condensation process of the PEMFC product water takes place at a lower temperature. The precooling of the FC product mass flow before condensation starts obviously requires more effort for the SOFC example due to the higher release temperature at the FC system exit.

For all studies presented in this paper, a liquid recovery of ≥90% of the FC product water can be assumed. The corresponding heat exchanger design modelling is discussed in

Section 3.2.4. The liquefied fraction of the FC product water is subsequently pressurized by a water pump to a pressure level suitably above the total pressure in the GT combustion chamber and is then piped to the gas turbine core exhaust locations where the high-pressure water is reheated, vaporized and superheated using the residual GT exhaust heat. The power input required for the water pressurization is expressed as follows:

where

is the liquid water mass flow through the pump and

refers to the corresponding fluid density. The pump system efficiency

ηPump includes the hydraulic efficiency of the pump as well as the involved mechanical, electric drive and power system efficiencies. A typical pump-delivered pressure level

pout would be 80 bar. The water inlet pressure level to the pump system,

Pin, is defined by the FC operating pressure reduced by all pressure losses along the water treatment process between the FC stack and the pump inlet. Assuming

Pin of 1.5 bar and

ηPump to be 0.5, the resultant water mass flow specific power input to the water pump system yields 15.7 kW/(kg/s). Extracted from the FC system this equals less than 0.2% of its electric power output. This low pumping power requirement is also reflected the water T-s diagram (cf.

Figure 5) where the condenser outlet conditions (in case of full water recovery) are in immediate proximity of the vaporizer inlet conditions.

The mass of the water pump is calculated from a reference pump given in [

61] using water mass flow-based proportional mass scaling. The mass of the required water piping system is derived in analogy to the aircraft fuel system. As a reference point, fuel system mass and throughput characteristics similar to an Airbus A320 aircraft are assumed. Piping system mass is then estimated via mass flow scaling using the liquid water throughput. An optional water tank acting as an intermediate reservoir of liquid water for increased operational flexibility of the overall system is not yet considered in the modelling.

3.2.3. Gas Turbine Engine

For the present study, the GT water injection is assumed to be realized via superheated steam injection into the combustion chamber. The resulting immediate effects on the thermodynamic cycle include an additional turbine mass flow due to injected water/steam and an increased mass flow-specific heat capacity in turbine, as well as a reduced compressor mass flow for a given power demand. A key descriptor for the implications of GT water/steam injection is the water-air-ratio (

WAR), being defined as the ratio of steam mass flow

to compressor delivery mass flow at the combustor inlet

, in the present study:

The increased heat capacity in the turbine section for different levels of temperature and

WAR is displayed in

Figure 6a, while

Figure 6b shows the reduction of core compressor mass flow against increasing steam injection.

As can be seen from the figure above, the specific work potential enhancement due to change of thermodynamic fluid properties is significant, e.g., approximately 25% at WAR = 0.3 for a typical average temperature level in the turbine section. At the same time, the core compressor mass flow reduces at a steep rate of approximately 1.8% per percent WAR increase, if a constant cycle output power is prescribed. This over-proportional compressor mass flow decrease results from the combined effect of the increased specific heat capacity in turbine flow and the added steam mass flow acting in the turbine section only. In this case, the required cycle output power is additionally reduced by the power produced through water supplying FC and the core compressor mass flow is reduced by more than 50% at WAR = 0.1.

Assuming the steam production from the liquefied FC product water mass flow to be performed using heat from the GT exhaust mass flow, the presence of the HEX in the core engine exhaust section will cause a pressure loss as a function of the amount of heat to be exchanged and as a trade-off with HEX size and mass.

In order to appropriately capture these main effects on the GT’s effective core efficiency, a simplified formulation approach is used for the present study. Accordingly, all the primary effects due to the steam injection are combined in the efficiency factor

. The GT effective core efficiency

ηco,eff,GT is obtained when multiplying the steam injection efficiency factor with a baseline efficiency value

:

It should be noted that the baseline efficiency

will strongly depend on GT size effects. In order to also allow for technological sensitivity, the modelling of

is factorised into two parameters, and a technology factor

is used to emulate the

ηco,eff,GT impact of advanced technology status and a true reference efficiency

, which is modelled as a function of

:

For

, a simple data fitting based on BHL-internal models of existing aircraft GT engines of different power classes typical for the year 2000 in service technology is employed in this paper:

Based on its regression input data set, the validity of the correlation ranges from ≈ 1.5 MW up to ≈ 30 MW in cruise. Throughout the studies presented in this paper, a value of 1.2 is chosen for in order to represent an appropriately advanced technology level.

For the

factor, a simple heuristic based on published data and in-house performance synthesis computations was derived. The data basis for the heuristic law is visualized in

Figure 7 below.

Roumeliotis and Mathioudakis [

37] investigated the effects of water injection on GTs more generally, taking varying injection locations and conditions into account. For water steam injection in the combustion chamber, a potential for core efficiency enhancement of approximately 4% per 1%

WAR is stated for low

WAR injection rates and constant turbine inlet temperature operation. In

Figure 7, data points for 2% and 4%

WAR are depicted. Jonsson and Yan [

38] collected data for various GT water/steam injection options. Again, a relevant data point derived from efficiency values provided for steam injection in the combustion chamber is annotated in

Figure 7. Finally, Cheng and Nelson predicted a potential for an efficiency increase of up to 43% at

WAR slightly above 20% while using exhaust gas recuperation for steam generation.

In order to supplement the data obtained from the literature, a number of GT cycle design points were computed for the present study using BHL’s in-house “Aircraft Propulsion System Simulation” (APSS) framework (cf. e.g., [

84,

85,

86]). For these in-house simulated data points (black circles in

Figure 7), steam injection in the combustion chamber of a 2-spool turbofan engine architecture was modelled using constant core turbo component polytropic efficiencies of 90%, a cycle featuring a burner exit temperature T

4 of 1700 K at an Overall Pressure Ratio (OPR) of 40 and a constant turbine cooling air supply of 25% of the high pressure compressor exit mass flow. Secondary customer offtakes including power and bleed air were set to zero. The vaporization and superheating of the recovery FC product water mass flow were modelled via a turbine exit duct-mounted vaporizer assuming a water heating up to LPT exit temperature T

5-50 K (=steam injection temperature in burner). To reflect the increasing heating effort required for the water vaporization and superheating as the water to GT exhaust air flow ratio grows, a linear correlation of core nozzle pressure loss against

WAR was assumed that yields 5% at

WAR = 0.15. For a given ideal nozzle exit velocity ratio according to Gasparovic [

80], this effectively equals an increased back pressure for the cycle, hence reduced turbine expansion capacity. As such, the efficiency implication of the water vaporizer behind the LPT is effectively mapped to the effective core efficiency of the GT.

The heuristic correlation for

derived from the data collected in

Figure 7 yields:

As can be seen in

Figure 7, the correlation is supported by reference data up to

WAR values of approximately 20%. As a first indication for the correlation’s confidence level, the logarithmic upper and linear lower bounds of the reference data basis are indicated as dashed lines in the figure.

The impact of steam injection in the GT combustion chamber on cruise NO

x emissions is estimated based on the experimental results for ultra-wet hydrogen combustion published by Göke et al. in their

Figure 8 [

42]. Therefore, quadratic data fittings for the NO

x concentrations measured in the combustion products under water-to-air ratios between 0% and 30% were produced at relevant combustion temperature levels. For a given

WAR, an average NO

x concentration can be calculated from the set of data fittings. Absolute GT NO

x emissions obtained as the product of NO

x concentration and actual fuel flow can then be related to the NO

x emissions at

WAR = 0 in order to evaluate the NO

x reduction potentials. Assuming zero NO

x emissions from the FC system, GT-produced NO

x represents the total NO

x emissions of the propulsion system.

3.2.4. Heat Exchangers

While for the efficiency of the FC module internal HEX used for the preheating of fuel (cf.

Section 3.2.1), a prescribed value of 90% is assumed, the HEXs involved in the water treatment process require a more detailed consideration: The first one along the process is a HEX (condenser) required for water recovery from the FC product mass flow. It should be noted that the composition and thermal conditions of the relevant part of the FC outflow strongly depend on the FC type (cf.

Section 3.2.2).

The condenser is modelled to be operated with freestream air as a coolant. The freestream mass flow rate is tailored to ensure a sufficient pinch point temperature difference between hot and cold HEX sides of 40 K at design point conditions (FL350, M0.78, ISA+10). The HEX performance calculation is therefore divided into two steps:

temperature reduction down to saturation conditions; and,

subsequent further cooling for latent heat transfer during phase change.

A second HEX (vaporizer) uses the GT exhaust gas mass flow for the vaporization and superheating of the pressurized water. The heat transfer of this HEX is segmented in three parts:

For sufficient thermodynamic conservatism in the studies presented in

Section 4, steam superheating was limited to T

5 − 50 K. Both HEXs are modelled as counter flow HEXs with assumptions on pressure losses as summarized in

Table 1.

HEX efficiency

for the condenser and vaporizer components is defined by the ratio of realized temperature difference between inlet to outlet and the theoretically maximum temperature difference between HEX hot side and cold side inlet:

HEX mass estimation is based on a semi-empirical method for air-air HEX acc. to Grieb [

59]. Therefore, data for mass flow-specific matrix weights of exhaust recuperators versus HEX efficiency

provided in [

59] were fitted and scaled by a constant factor representing GT exhaust recuperator HEX installation weight effects

, yielding the following correlation:

where

is the representative air mass flow through the HEX matrix. Taking into account the specific matrix weight data used for the regression, the validity of Equation (34) ranges from

≈ 0.6 up to

≈ 0.9. For all HEX weight estimates in the present paper, a value of 1.6 is assumed for

(cf. also [

59]).

In order to emulate the sizing of the multi-fluid, multi-phase HEXs involved in the water treatment process, the correlation in Equation (35) is applied using an equivalent air mass flow derived from the actually required heat capacity flows in the condenser and vaporiser HEXs. The respective equivalent air mass flows are tailored to facilitate the same amounts of heat transfer at the same temperature differences as the real multi-fluid, phase-changing condensers and vaporizers.