Abstract

The purpose of this study is to systematically analyze the impact of Industry 4.0 technologies on workforce employability and skills in the South Asian region. The study investigates the driving success factors, challenges, and needed skills by analyzing 48 peer-reviewed articles. The authors searched keywords on the Web of Science database for articles published between 2013 and 2022. The review was conducted using the preferred reporting items for systematic reviews and meta-analyses (PRISMA 2020) and pareto principles. The analysis identifies nine critical success factors, such as artificial intelligence, digital skills, and big data analytics, that contribute to Industry 4.0’s productivity and efficiency. It also identifies six types of challenges, such as training and development, financial constraints, and regulatory issues that must be addressed to grab maximum potential. In addition, the research categorizes five different skills, including the technical, digital, and social skills that are essential for the evolving labor market. The proposed “Industry 4.0 SEI Framework” provides stakeholders with a comprehensive view of the dynamics of Industry 4.0, thereby facilitating policy and industry strategies.

1. Introduction

The Fourth Industrial Revolution (Industry 4.0 or I4.0) has gained increasing attention both in the academic and non-academic domains. Industry 4.0 was a term coined in 2011 in Germany. Since then, the academic literature describing and analyzing I4.0 technologies has grown considerably (Cannavacciuolo et al. 2023; Rad et al. 2022; Pereira et al. 2018). While so-called Industry 3.0 introduced computers, Industry 4.0 is characterized by advancements in computing technology including expanded digitalization in logistics, cognitive and connected machines in various industrial processes, and data analytics (Rahman et al. 2022). Leong et al. (2020) refer to I4.0 as having nine technological pillars: the Internet of Things, cloud computing, robots and autonomous systems, big data analytics, augmented reality, cybersecurity, simulation, system integration, and additive manufacturing. This new technological frontier is transforming the way businesses create value, how individuals perform their work, and the manner in which people connect and communicate with each other. I4.0 has significantly transformed job roles and the skill profiles required of workers (Ghislieri et al. 2018). These technologies are the cornerstones of changing industrial processes to substantially enhance productivity.

However, the rapid shift in robotization and digitalization are also a growing concern. Particularly in South Asian countries (e.g., Bangladesh, India, Pakistan, Nepal, Bhutan, Sri Lanka, Maldives, and Afghanistan), unemployment resulting from replacing jobs with robots is feared. Yet, employers and employees can adopt to technological changes in a timely way for the better of the future labor market (Bajaj et al. 2018). Researchers from engineering to management have increasingly concentrated their academic research on enabling Industry 4.0 technologies (Weerasekara et al. 2022; Perez Perales et al. 2018). Several studies particularly focused on the success factors and benefits of Industry 4.0 technologies while bypassing their downsides (Kadir et al. 2019; Bolbot et al. 2022; Echchakoui and Barka 2020). Studies are lacking that examine the effects of Industry 4.0 technologies on employment and skills. To address these gaps, the current study integrates the driving potential success factors, challenges, and skills gaps with a regional focus in South Asia. By answering the following research questions, the current study aims to identify the required skills and competencies to be ready for the future of work challenges and to benefit from the I4.0 technologies in South Asian countries.

- RQ1: What are the key driving factors contributing to the success of I4.0 technology implementation in South Asia?

- RQ2: What challenges exist regarding the adoption of I4.0 technologies in the region, and how do they impact the labor market and workforce skills?

- RQ3: What are the key skill requirements and gaps resulting from the integration of I4.0 technologies?

Our systematic review significantly contributes to the understanding of Industry 4.0 technology adoption in South Asian countries. However, the findings also reveal a notable gap in scientific research contribution from four countries, i.e., Bhutan, Sri Lanka, Afghanistan, and the Maldives, which needs to be addressed. The study identifies key driving factors, ranging from artificial intelligence to digital skills, shedding light on what fuels technological progress in the region. Additionally, the research pinpoints the challenges and obstacles faced, including workforce shortages and infrastructure limitations, which is crucial for formulating effective strategies. Moreover, by categorizing the required skills into distinct types, such as technical and communication skills, it provides actionable insights into the skill gap and the need for reskilling efforts. Finally, the proposed “Industry 4.0 SEI Framework” offers a conceptual understanding of the dynamics of I4.0 and its impact, which makes this research a valuable resource for policymakers and industry leaders in South Asia. The study consists of 48 articles from the Web of Science database, and the authors used the Microsoft Excel application for analyzing and visualizing the data. The objectives of the research have driven the remaining part of the study. Following the introduction, Section 2 introduces the background and literature, by presenting a historical overview of industrialization and the conceptualization of Industry 4.0, while paying close attention to I4.0 in South Asia. Section 3 describes the methodology, data collection and sources, inclusion and exclusion criteria, and data analysis. Section 4 shows the results and discusses the main findings. Section 5 provides the conclusion, implications, limitations, and avenues for future research.

2. Literature Reviews

2.1. Concept of Industry 4.0

Since the industrial trade fair Hannover Messe, Germany in 2011, the term “Industrie 4.0” has ignited a vision of a new industrial revolution and has been inspiring a lively, ongoing debate about the future of work (Dregger et al. 2016). The Fourth Industrial Revolution refers to the transformation of technology in the 21st century. It is creating a radical shift for employees, organizations, and society as a whole, given the impact of included and emerging technologies such as artificial intelligence and Internet of Things (Ross and Maynard 2021; Kowalikova et al. 2020). Savytska and Salabai (2021) consider I4.0 a trend within the Fourth Industrial Revolution. They found that businesses could benefit from new opportunities, expand operations, and increase efficiencies by integrating digital processes. Industry 4.0 covers a wide range of topics, such as production methods, productivity, data management, consumer relationships, and competitiveness. (Piccarozzi et al. 2018). According to Culot et al. (2020), I4.0 has evolved significantly, leading to similar concepts often referred to as “smart manufacturing”, “digital transformation”, and “fourth industrial revolution”. However, Erboz (2017) identified that the development of highly automated industries through human–machine interaction is one of the main aspects of Industry 4.0. Freund and Al-Majeed (2021) highlighted the effect of Industry 4.0 on both the micro and macro levels, including the financial, political, and socio-cultural spheres.

2.2. Historical Overview of the Industrial Revolution

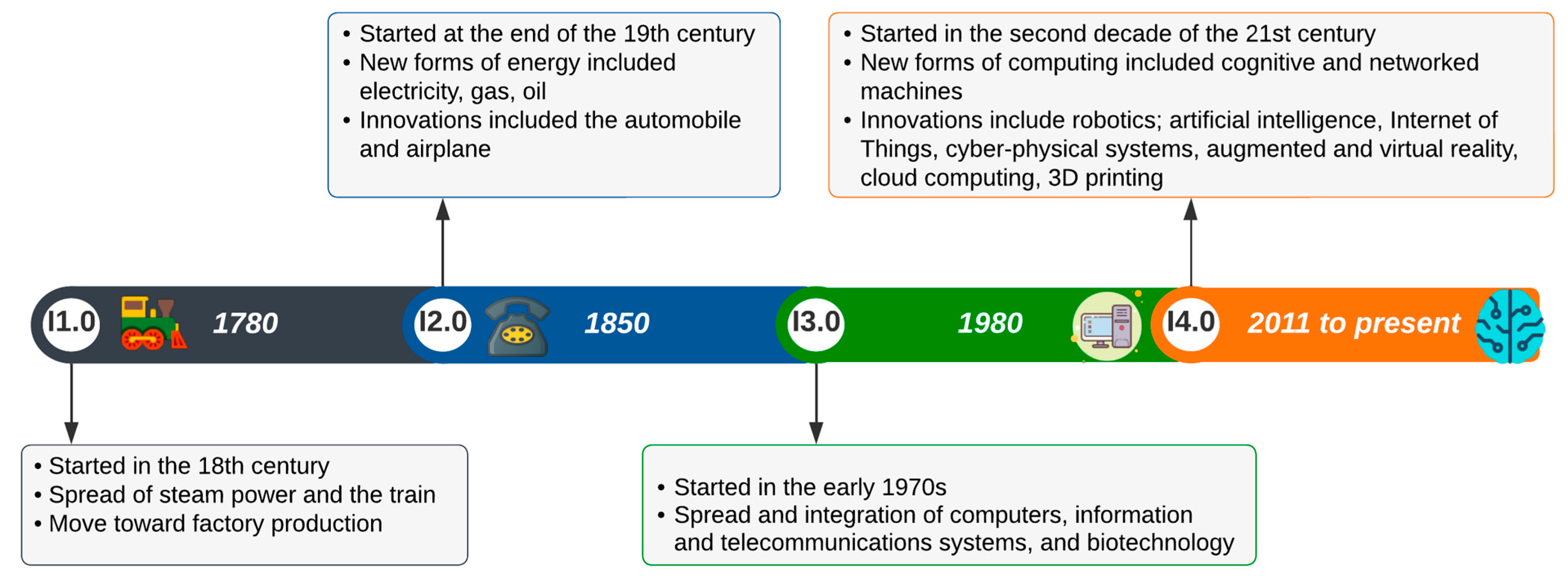

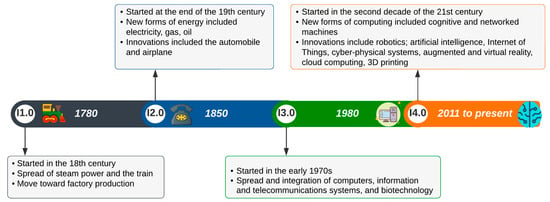

Technological trends have a historical perspective. Figure 1 utilizes two sources to illustrate the history of industrial revolutions. The first industrial revolution, which started at the end of the 18th century, shifted production from labor-intensive to more capital-intensive production. The biggest changes came in the form of mechanization. The invention of steam-powered machines combined with the division of labor changed production technology from piece-to-piece production to mass production. The second industrial revolution started at the end of the 19th century, and by the middle of the 19th century, there were technological advancements helped the emergence of new sources of energy. This era saw the spread of electrification across the world, and radical transformation in transportation including the development of the automobile and the airplane. The third wave of industrialization started in the early 1970s with the development of the computer. This third industrial revolution led directly into the fourth because of how those computing technologies advanced. By the beginning of the 21st century, huge developments in communication and information technologies and software-based production technologies enabled the development of smart systems. Davies (2015) reported that the Europe Union was at the beginning of a new industrial revolution—Industry 4.0—in 2015. Member states began sponsoring national initiatives, such as “Industrie 4.0” in Germany, “the Factory of the Future” in France and Italy, and the Catapult centers in the United Kingdom. In the few short years since then, Industry 4.0 has spread everywhere and changed the production paradigm through a shift from work previously done by humans to work that is now automated (Klingenberg et al. 2022). Today, managers cannot ignore the technological revolution in the field of robotics, artificial intelligence, the Internet of Things, cyber-physical systems, augmented reality, virtual reality, biotechnology, nanotechnology, autonomous vehicles, cloud computing, and 3D printing (Sharma et al. 2021).

Figure 1.

Timeline of the Industrial Revolutions based on: (Kagermann et al. 2013; Vaidya et al. 2018).

2.3. South Asia and Industry 4.0

South Asia is comprised of India, Pakistan, Bangladesh, Sri Lanka, Nepal, Bhutan, the Maldives, and Afghanistan. With its large population, emerging markets, government support, innovative culture, global supply chain presence, and digital infrastructure development, it is indeed an important region for the adoption of I4.0 technologies (Katekar and Deshmukh 2021; Rajamanickam 2016). According to the International Monetary Fund (2023), South Asian countries had a GDP of $4.65 trillion U.S. dollars, around 5% of the world economy, in 2023. Among these, India contributes the highest GDP of $3.73 trillion with Bangladesh at $446.35 billion U.S. dollars. Nepal, Bhutan, and Sri Lanka were among the countries with the lowest GDP in the Asia-Pacific region. In South Asia, the main economic activities include the services, industrial, and manufacturing sectors. Despite having tremendous economic potential, previous studies by Imrana et al. (2021) and Bishwakarma and Hu (2022) found gaps in human capital and innovation including the skills and training of the region’s current workforces.

As these countries continue to modernize their industries, I4.0 is poised to play a pivotal role in shaping their economic future and addressing critical social challenges. Studies, such as those by Su et al. (2017) and Schöning (2018), show productive outcomes in accelerating production, enhancing processes, and creating new opportunities by integrating I4.0 technologies. But there are significant challenges that need to be overcome. For example, in Bangladesh, the lack of awareness, insufficient capital, infrastructure limitations, shortage of skilled workers, and weak government policies are hindrances to the implementation of I4.0 (Bhuiyan et al. 2020; Suha and Sanam 2022). They emphasize the need for an information and communications (ICT) policy that focuses on integrating ICTs with smart industrialization. Hossain et al. (2023) found technical knowledge in the manufacturing industry is a key barrier to adopt the I4.0 in Bangladesh. In Pakistan, studies by Ali and Xie (2021) and Imran et al. (2018) found managerial challenges in adopting I4.0 technologies, including the need for competitive management, infrastructure, and economic stability in the textile industry and service sector. In India, the manufacturing and service sectors need more productivity and efficiency to manage these digital transformations (Jha 2021; Smolka and Papulova 2023). Researchers Kanji and Agrawal (2020) and Mezina et al. (2022) found I4.0 may increase social inequality while creating a heightened need for highly qualified personnel. The authors argue that appropriate policies and partnerships need to be implemented to ensure inclusive development in developing countries, especially in India, Bangladesh, and Pakistan.

I4.0 has significant implications on the future of work and skills required. The changes in the value chain and increased competitiveness among firms and consumers can impact global labor markets (Anuşlu and Frat 2019; Mohiuddin et al. 2022). According to Asian Development Bank (2021), 4IR technologies like the IOT, artificial intelligence, cloud computing, and cognitive computing could profoundly influence jobs and skills.

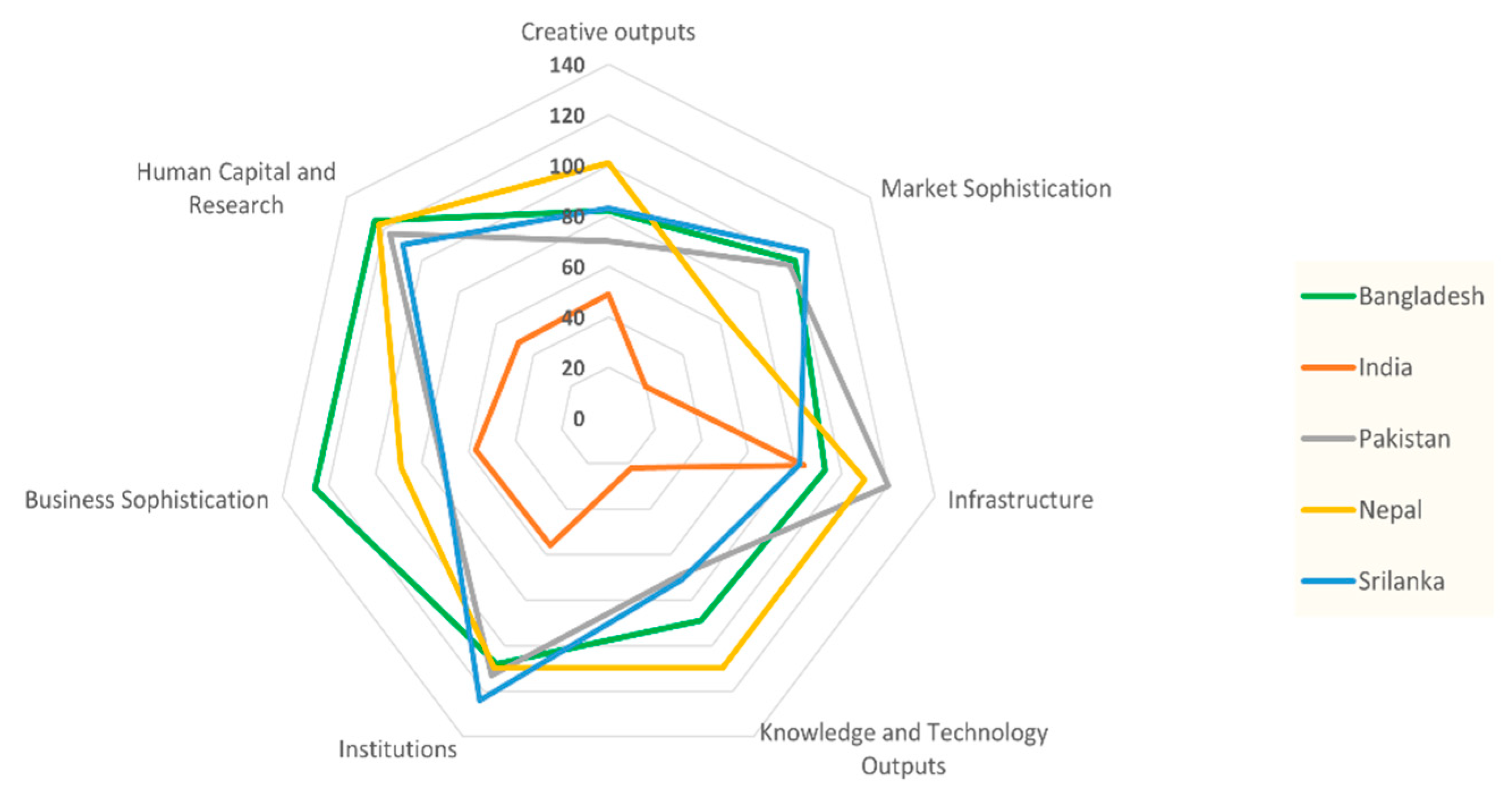

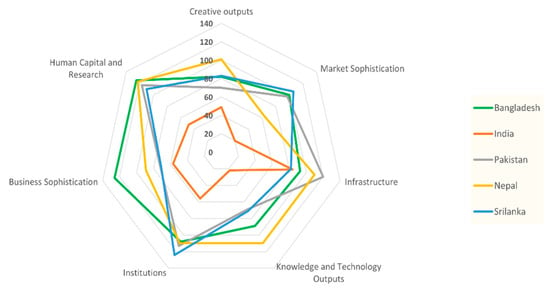

Labor markets in developing and developed countries are likely to undergo major transformations in the coming years and decades. By 2030, the region is expected to create more jobs than it displaces (Balliester and Elsheikhi 2018). Yet, the Global Innovation Index (GII) of 2023 shows that South Asian countries are not yet ready for I4.0 technology adoption. The index provides a comprehensive assessment of the innovation ecosystem across 132 economies in the world. The analysis shows (Figure 2) that India leads among lower middle-income countries in the world and ranks overall 40th in the world. Among other South Asian countries, Bangladesh, Nepal, Pakistan, and Sri Lanka exhibit poor ranking in creative outputs, impeding their ability to generate new ideas and innovations, and infrastructure readiness, which are critical factors for I4.0 success. These countries, along with India, face challenges in other key areas such as market sophistication, knowledge and technology outputs, and institutions. Moreover, many displaced workers may struggle to transition smoothly to new roles. South Asian countries need to prepare their workforce for the impending labor market changes with substantial and timely investments in skills development, especially within the key sectors of the automotive industry, textiles, and tourism.

Figure 2.

Global innovation index on seven pillars. Source: Brás (2023).

These findings motivated us to undertake this research with the aim of developing strategies to prepare the workforce. Improving capacity in line with GII measurable areas should be a priority for South Asian nations to bolster their global competitiveness and embrace the transformative potential of I4.0 technologies. Considering these gaps, the current research strives to systematically extract the driving forces, challenges, and future skills required for the adoption of I4.0 technologies in the South Asian region. We also highlight the need for comprehensive strategies to foster innovation ecosystems, enhance business sophistication, and for investment in education.

3. Methodology

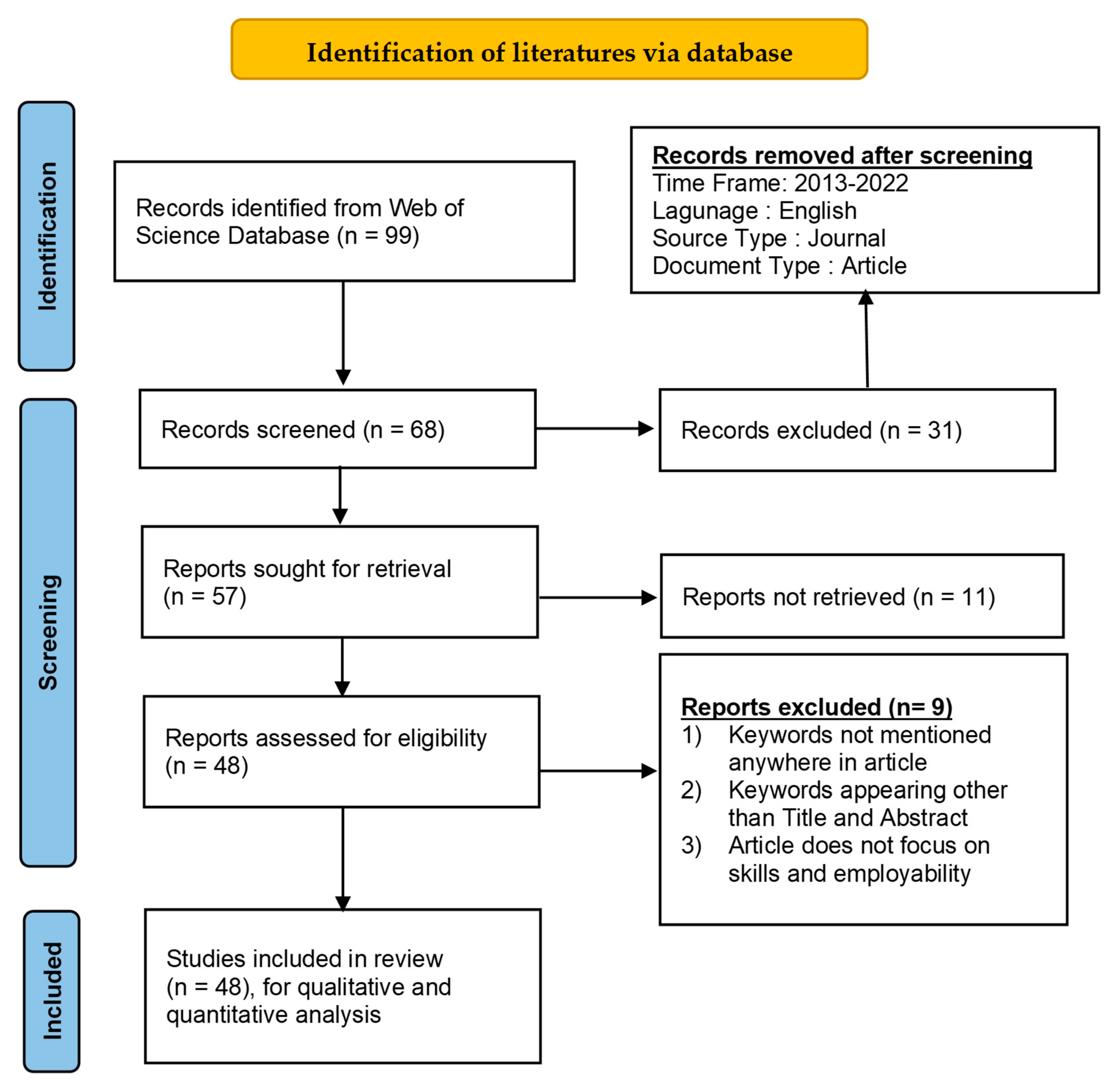

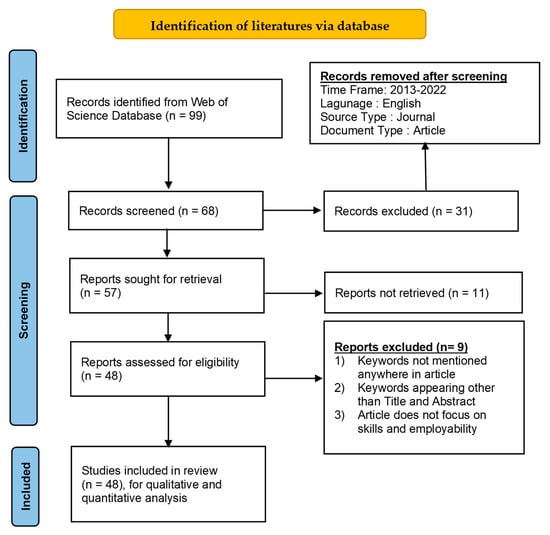

The current study was conducted using the preferred reporting items for systematic review and meta-analyses (PRIZMA). PRISMA offers detailed guidance for different information sources and methods not covered in other guidelines. It includes instructions for reporting study registry searches, web searches, multi-database searches, and updates. This helps authors report their searches for more transparent reporting (Rethlefsen et al. 2021). Systematic review is essential for helping researchers and practitioners stay up to date with a large and rapidly growing body of evidence. According to Pollock and Berge (2018), systematic reviews answer predefined research questions using explicit, reproducible methods to identify, critically appraise, and combine the results of primary research studies. Such a review is a comprehensive summary of all the important research on a specific question. The method finds, selects, and evaluates the high-quality evidence related to the research questions. It also gathers all the relevant evidence based on certain criteria set beforehand. Moreover, systematic review works to reduce bias by following a clear and thorough process (Harris et al. 2014). The PRISMA 2020 statement offers revised guidelines for systematic reviews, ensuring clarity and accuracy. It includes a 27-item checklist for transparent, evidence-based reporting (Page et al. 2021). Our research follows the latest PRISMA flow chart with three steps: identification, screening, and inclusion. While there are other literature review techniques (Moher et al. 2009), the authors chose PRISMA for its wide usage and systematic, user-friendly approach. Figure 3 illustrates the information flow based on PRISMA 2020, with detailed steps discussed in the following sections.

Figure 3.

PRISMA flowchart illustrates the systematic reference selection process adapted from Page et al. (2021).

3.1. Identification

In the first step, a search strategy was developed to identify the relevant literature using the Web of Science database. Compared to functionality, record quality, and coverage in other databases such as Google Scholar and Scopus, Web of Science provides more quality records. It has widespread use and a range of applications, along with reliable sources in various research fields (Birkle et al. 2020; Phethean et al. 2016). In light of incorporating the Scopus database, it was found that the results were not sufficiently specific to the keywords used. This meant that the number of articles directly relevant to the study was insufficient for conducting a systematic review (Gusenbauer and Haddaway 2020).

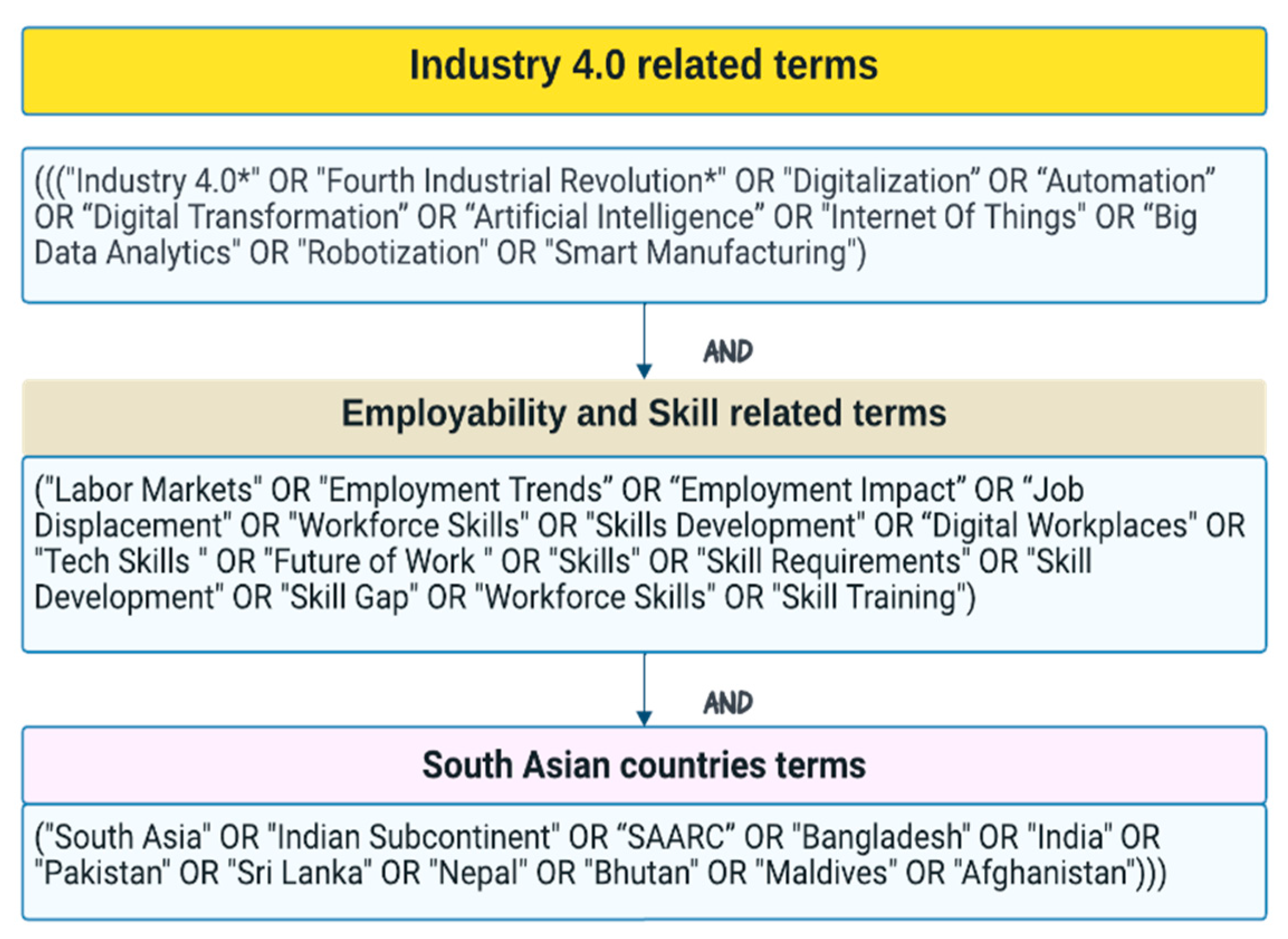

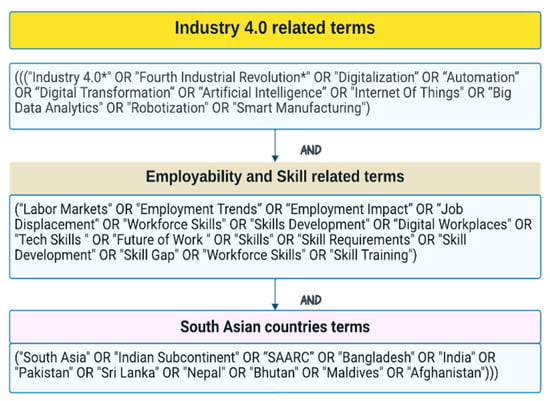

A combined search string (Figure 4) was constructed using the topic field (TS) in the advanced search option of the Web of Science database. The ‘TS’ field in WoS encompasses titles, abstracts, author keywords, and Keywords Plus. Three sets of keywords were employed using Boolean operators to ensure highly relevant search results. The Boolean ‘AND’ operator combined the concepts of Industry 4.0, employability, skills in labor markets, and the geographical focus of South Asia. ‘OR’, on the other hand, was used to broaden the search, including various synonyms and related terms (Pranckutė 2021). The first set of keywords encompassed terms related to Industry 4.0 and its associated technologies. These terms represent the integration of digital technologies in industrial settings (Schwab 2017). Keywords such as ‘Digitalization’, ‘Automation’, and ‘Artificial Intelligence’ were selected to embody the technological pillars of Industry 4.0 (Ghobakhloo 2020). Additionally, ‘Internet of Things’ and ‘Big Data Analytics’ were included to reflect the data-driven aspects of modern industries (Wortmann and Flüchter 2015). The second set of keywords was centered around employability and labor market skills. This set aimed to explore the evolving job roles and skill requirements brought about by technological advancements (Acemoglu and Restrepo 2020). For example, terms such as ‘Employment Trends’ and ‘Job Displacement’ were chosen to highlight the dynamic nature of the labor market in response to technological shifts. Additionally, ‘Skills Development’ and ‘Skill Gap’ were included to emphasize the changing requirements of the workforce. The third set of keywords focused on South Asian countries. As Industry 4.0 is an emerging topic with multifaceted effects in the South Asian region, particularly on labor markets and employability. This geographical focus aims to capture the diverse range of developing economies in the region, each presenting unique challenges and opportunities in the context of Industry 4.0 (Mukherjee and Satija 2020). Our broad search strategy identified a total of 99 articles after searching for each combination of keywords in the title, abstract, or keywords shown in the Figure 3 in identification process. All the documents include the used terms and were focused on South Asian regions in different industry sectors, e.g., manufacturing, mining, education, nursing, health. Only peer-reviewed articles were included using the combined set of keywords.

Figure 4.

Database search terms using Web of Science advanced search criteria.

3.2. Screening

After identifying the relevant documents from the database, the screening process was defined and performed. The search span was set from 2013 to 2022 and all the documents before 2011 were removed. The term Industry 4.0 became popular after 2011, and the authors wanted to do a literature review on the more recent data since the term came into widespread use. The research fields for this research study were selected and narrowed down to business, accounting and management, economics, and finance. Only the documents that were full articles were selected. The search criteria were restricted to peer-reviewed articles excluding conference proceedings, books, and books chapters. Furthermore, the study included articles published until 2022 to consider the full calendar year. The language of research papers was set to English. A total of 31 documents were excluded at the screening stage, and 57 research papers were moved to the next stage for eligibility and final inclusion.

3.3. Inclusion

In this step, all the extracted papers were reviewed to assess the quality. The abstract of each paper was read and checked to ensure the relevance of the papers was consistent with the research questions. A total of 11 papers were excluded due to lack of relevance, and a further nine papers were removed based on three criteria: (1) keywords not mentioned anywhere in article, (2) keywords appearing other than title and abstract, and (3) the article not focusing on skills and employability. Finally, a total of 48 articles were selected to perform the literature review.

3.4. Data Analysis

The research was conducted based on the analysis of each article’s relevant metadata, which included details such as the publication year, journal source, and the reported driving factors, challenges, and skills required for the future of jobs. Using Microsoft Excel, a data summary sheet of 48 articles was created to systematically record these factors (Table 1). The study focused on relevant articles published between 2013 and 2022, as there were no relevant scientific papers found from the previous years. In addition, a Pareto analysis was used to determine the most influential success factors and challenges driving the adoption of Industry 4.0 technologies. After calculating the frequencies, the study converted these figures into cumulative percentages. All of these factors were systematically categorized and then ranked in accordance with the needs of the research. The Pareto analysis is a quality control tool that arranges data classifications in descending order, with the most frequent at the top (Karuppusami and Gandhinathan 2006; Wuni 2022). The Pareto principle, also known as the 80/20 rule, states that roughly 80% of the effects result from 20% of the causes. In our context, the technique, as done by Bajaj et al. (2018), was appropriate because it allowed for the ranking of cumulative frequencies, which totaled 100. The rationale behind using this principle was to streamline our focus on the most significant factors impacting the labor markets under the influence of Industry 4.0. Previous studies also used this principle in economic studies to extract various factors and assess their individual impact (Hill et al. 2018; Tushar et al. 2023). However, to facilitate this analysis, the authors used Pareto charts, such as clustered column and line charts to identify the most influential factors on the adoption of Industry 4.0 technologies.

Table 1.

Summary of 48 articles on the impact of Industry 4.0 technologies on employment and skills in the South Asian region.

4. Results and Discussion

The initial analysis is based on descriptive information, for example, the trend of annual scientific publications, the country-wide distribution of studies, and the top journals published in the field of I4.0 technologies on employability and skills. Following the descriptive analysis, the authors present the main findings and discussion based on the research questions posed in the introduction section.

4.1. Descriptive Analysis of Systematic Review

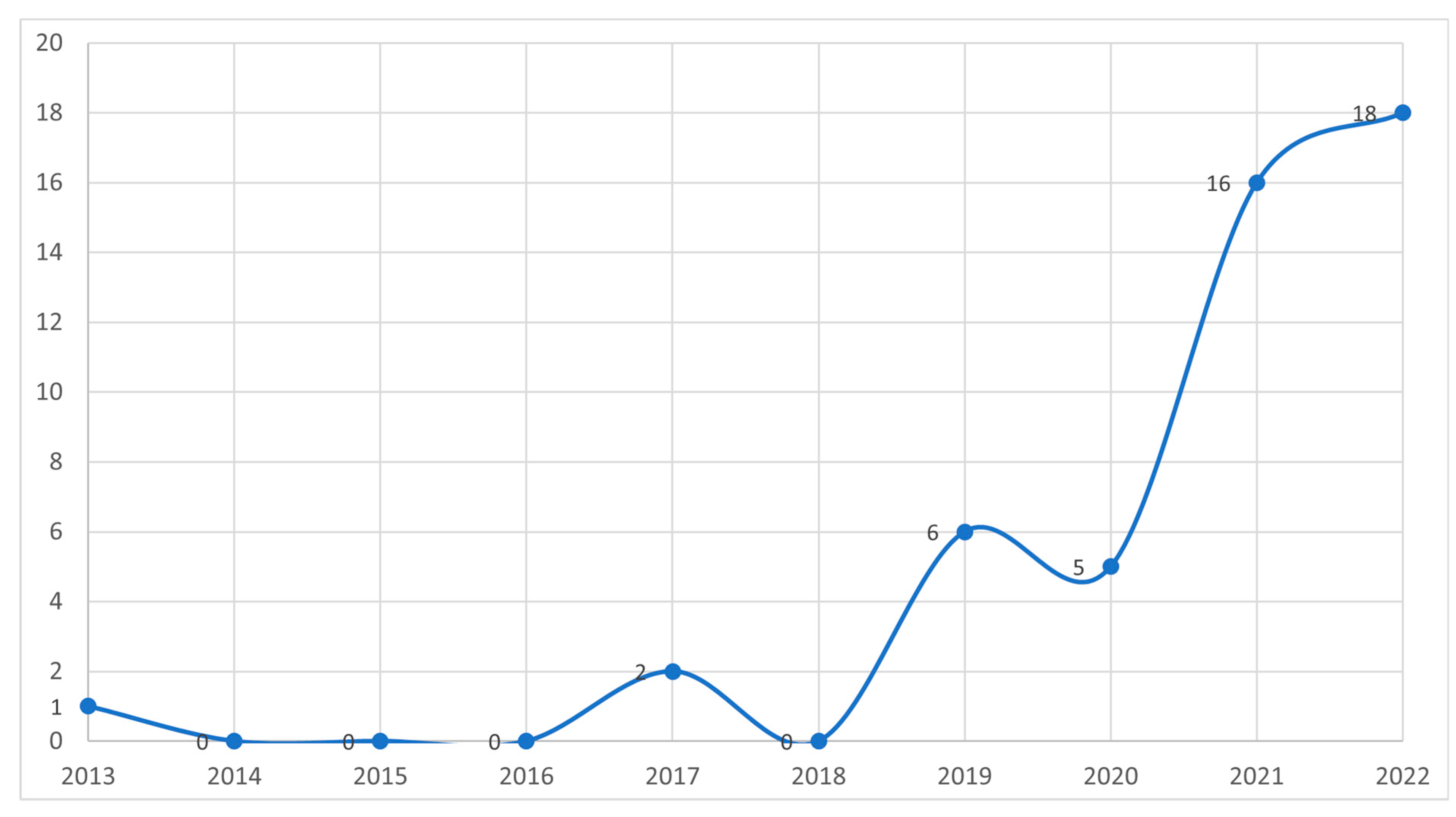

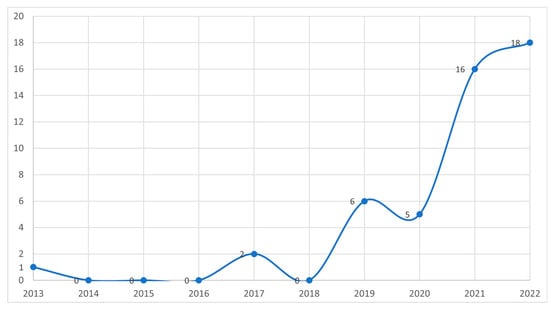

The current study considers 48 eligible papers, published between 2013 and 2022. Figure 5 indicates that before 2016, there was minimal research activity, with no more than one article published in 2013. This represents 0% growth in the topic and indicates a low level of interest since the term gained popularity after 2011 (Zhou et al. 2015). In recent years (2019–2022), the most significant growth in research articles occurred, with 11.25 articles published on average each year in four countries (Bangladesh, India, Pakistan, and Nepal). These represent substantial surges and signify a mature and rapidly expanding area of research. There were no studies published by corresponding authors or carried out within the country in Sri Lanka, Bhutan, or Afghanistan.

Figure 5.

Annual distribution of included studies.

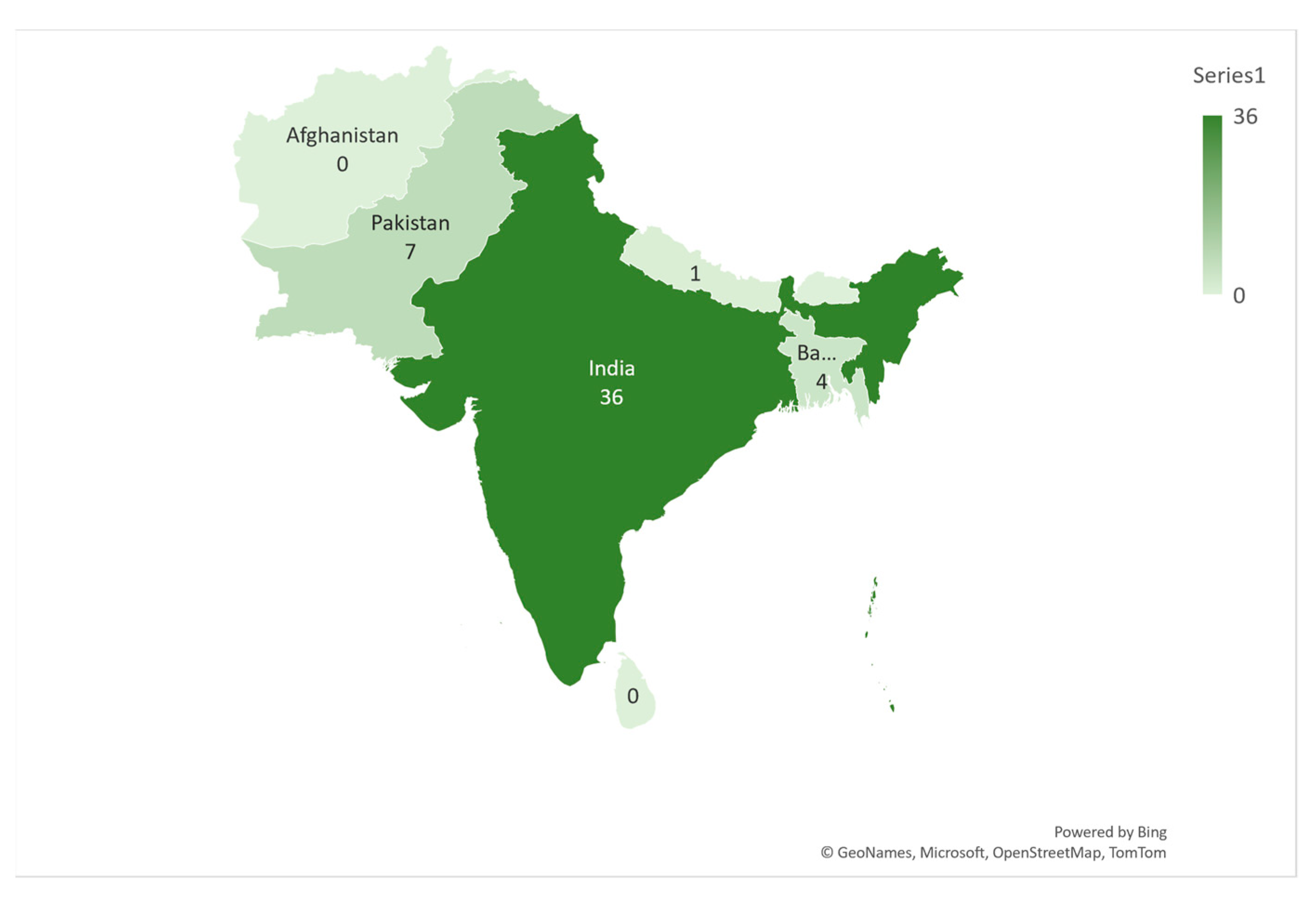

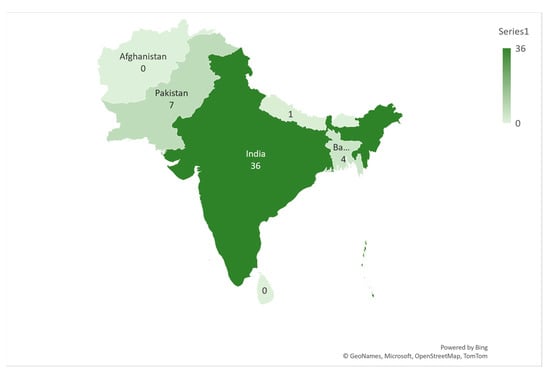

Figure 6 represents the contribution of scientific articles from four South Asian countries to the discourse on I4.0 technologies and their impact on employment and skills. It shows that India emerges as a prominent contributor, accounting for 75% of the total number of articles. India, being a major global player in technology and outsourcing, plays a crucial role in making a strong research contribution. Pakistan and Bangladesh also exhibit significant research activity, contributing 15% and 8% of the studies, respectively. On the other hand, Nepal’s contribution, at 2%, is relatively low, suggesting that research on this subject is in the early stages of development in the country. It’s essential for Nepal, Bhutan, Sri Lanka, and Afghanistan to increase its engagement in this area as I4.0 technologies are increasingly shaping the global employment and labor market.

Figure 6.

Distribution of articles published by South Asian Countries.

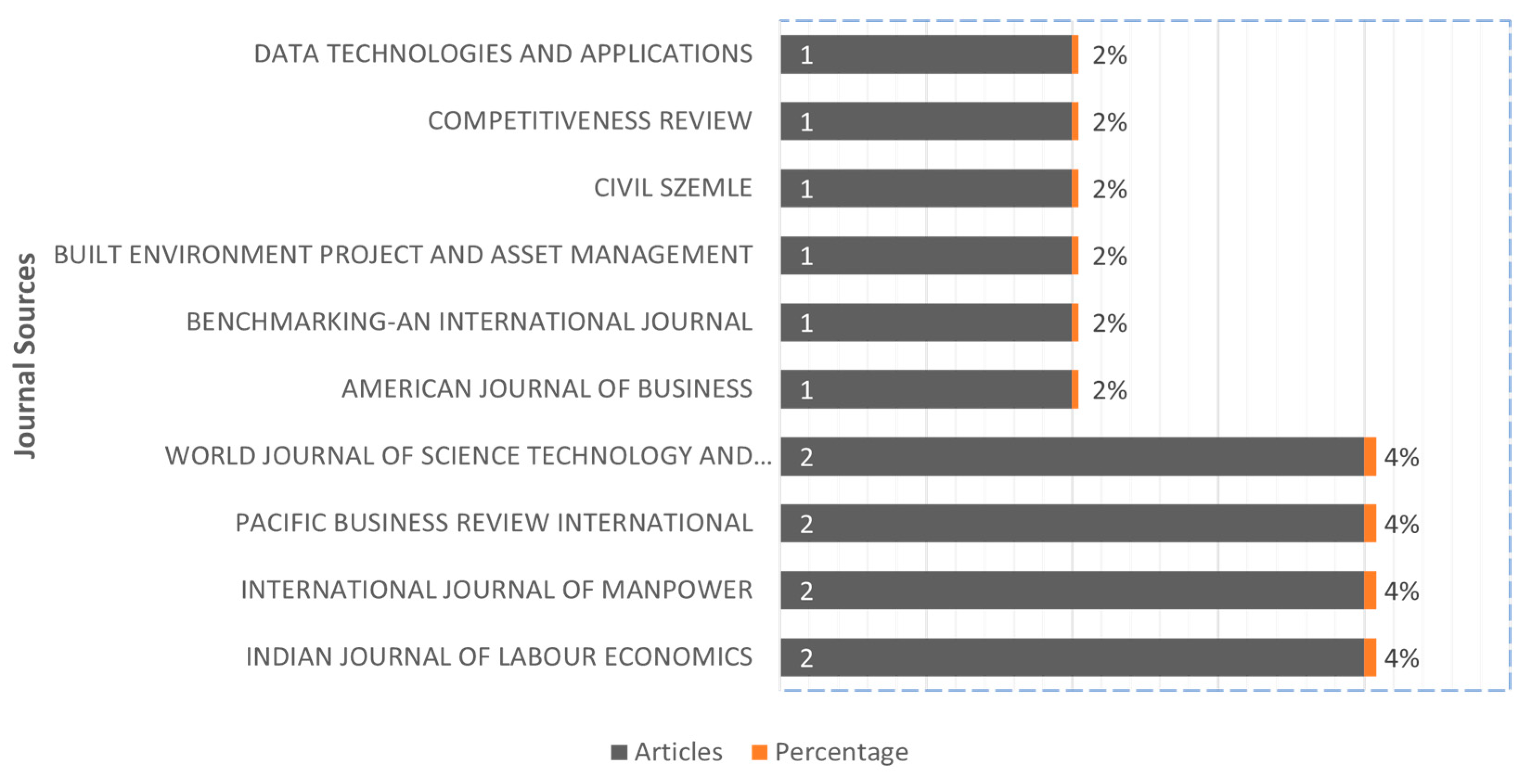

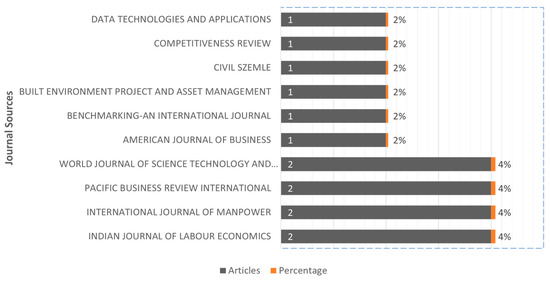

The authors also identified the top 10 journals (Figure 7) that published papers on I4.0 effects on employability and skills. Among them, the Indian Journal of Labor Economics from Springer and the International Journal of Manpower from Emerald are the top journals in this area.

Figure 7.

Top 10 journal distribution.

4.2. Findings and Discussion

- RQ1: What are the key driving factors contributing to the success of Industry 4.0 technology implementation in South Asia?

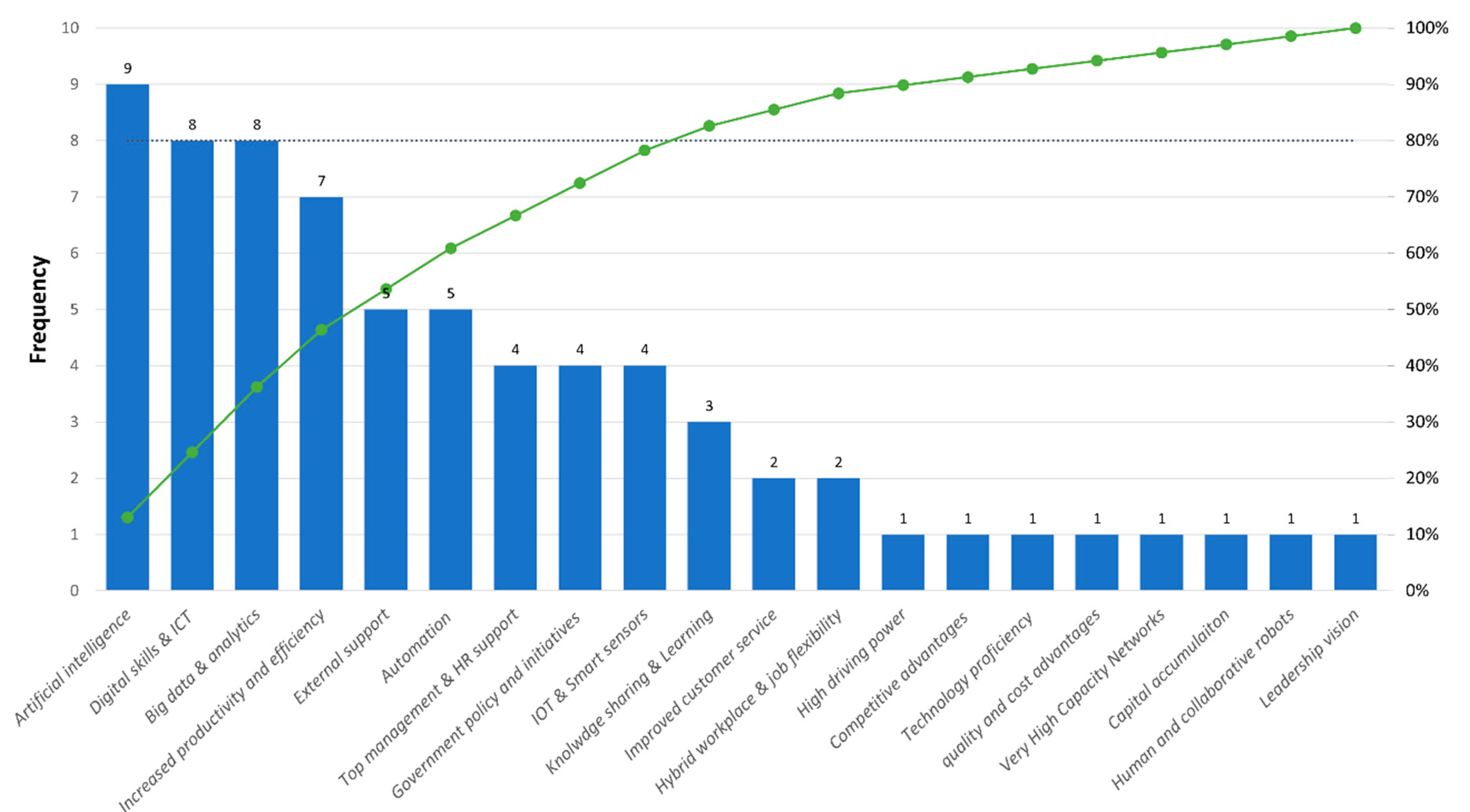

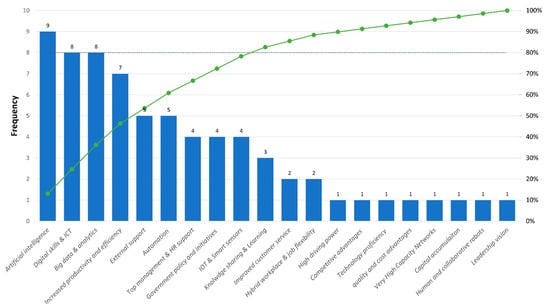

Identifying the influential driving factors of Industry 4.0 technologies is the primary objective of this study. Based on the findings, the authors extracted 20 factors from the 48 included articles. A Pareto chart was used to highlight the most important driving factors in descending order, from the highest frequency of occurrences to the lowest frequency of occurrences. (see Figure 8).

Figure 8.

Driving success factors of Industry 4.0 technology.

According to the Pareto principle of 80/20, the vital view items occupy a substantial majority (80%) of cumulative occurrences, which indicates the nine most important factors in the South Asian region: artificial intelligence, digital skills, ICT, big data analytics, productivity and efficiency, external support, automation, top management and human resources, government policy and support, IOT, and smart sensors. The remaining factors—high driving power, competitive advantages, technology proficiency, quality and cost advantages, very high-capacity networks, capital accumulation, human and collaborative robots, and leadership vision—have a lower impact but are critical for success in the workplace. Our findings emphasize that artificial intelligence, digital skills in ICT, big data analytics, productivity, and efficiency are the top driving factors, with a cumulative percentage of 46% in research in India, Bangladesh, Pakistan, Nepal, and Sri Lanka. Overall, artificial intelligence plays a substantial role in the region in the context of Industry 4.0, especially in the manufacturing and services sectors, in improving operational efficiency and productivity since they reflect the central goals of different industries. AI has the ability to process data, make predictions, and automate tasks to digitally transform industries. Previous studies (Kagermann et al. 2011; Rodriguez et al. 2015) also suggest that artificial intelligence and autonomous robots can communicate with one another to boost productivity and product quality. Additionally, they are capable of handling unforeseen issues and more difficult tasks. According to Holm and Lorenz (2022), AI, digital skills, and big data analytics have connections with jobs in terms of enhancing and supplementing skills requiring the adoption of high-performance work practices, external support, and HR support. This study also found adverse effects on jobs and disparities in the labor market in Denmark.

Over the past few years, the availability of big data, cloud computing, and machine learning has made artificial intelligence extremely powerful. It is likely to reshape the work of many industries by changing the content and design of jobs. By facilitating human—machine collaboration and assisting employees in physical tasks, these enablers can play a significant role in increasing efficiency and productivity (Lane and Saint-Martin 2021). Despite creating economies of scale, researchers also found potential threats of job losses resulting from human–machine collaboration, reskilling, and upskilling (digital skills, decision-making, and cognitive skills) in the present workforce (Jaiswal et al. 2022; Tschang and Almirall 2021). In contrast, Srivastava (2018) concluded that there is a possibility of job losses during the next 10–20 years, estimated to be 47% in the US, 35% in the UK, 49% in Japan, 40% in Australia, and 54% in the European Union. Ultimately, no country can isolate itself from the side effects of I4.0 technologies in the future. Among South Asian nations, India can have significant impacts on healthcare, agriculture, education, and the manufacturing sectors. Developed countries can expect annual economic growth rate to double by 2030. As a result, Industry 4.0 technologies bring with it a spectrum of opportunities as well as challenges such as data quality, privacy, and a lack of a skilled workforce, which are the major concerns for emerging economies (Sharma et al. 2022). In Bangladesh, artificial intelligence, IoT, big data, and blockchain have become very popular due to automation and control technology in the manufacturing and service sectors (Babu 2021). In the research of Iqbal et al. (2021), Bangladesh has been positively and negatively affected by artificial intelligence. Since the digital economy of Bangladesh is emerging, existing jobs are replaced with new opportunities. Such technology allows machines to detect, understand, act, and learn either on their own or to augment human activities (Ehsan 2021). However, India, Pakistan, Bangladesh, Nepal, and Sri Lanka may continue to face technological and economic barriers in the coming years. The current study suggests that far-reaching initiatives from the top management, a focus of government decision- makers on technical and vocational education, and more training are critical. Proper I4.0 technology adoption, industry ecosystem, and infrastructure can drive significant growth in the labor market. The study also suggests grabbing the high potential benefits shown in the Pareto chart, for example, high driving power, competitive advantages, technology proficiency, quality and cost advantages, very high-capacity networks, capital accumulation, and human and collaborative robots that may come from disruptive technologies (Bhuiyan et al. 2020). Overall, the impact of these technologies can be useful for industries to boost their efficiency and productivity (Pathak and Sharma 2022).

- RQ2: What challenges exist regarding the adoption of I4.0 technologies in the region, and how do they impact the labor market and workforce skills?

Regarding the second research question stated in the introduction, this review further explored the challenges and obstacles of I4.0 technologies on employment and skills. The authors identified 33 challenges and categorized them into six types (Table 2) on the basis of the frequency of occurrence. The categories are (1) training and development, (2) skills and workforces, (3) financial, (4) regulatory, (5) technology, and (6) social and psychological challenges. Previous research also found myriad challenges and impacts on the labor market regarding the adoption and implementation of Industry 4.0 technologies in that region. For instance, Raj et al. (2020) highlighted the absence of digital strategy and resource scarcity as significant barriers in both developed and developing economies. In Nepal, the lack of critical infrastructure, shortage of skilled manpower, capital constraints, and policy implementation are the main challenges in industries (Devkota et al. 2022). Rehman et al. (2021) underscored challenges such as workforce availability, infrastructure limitations, management-related concerns, data management, knowledge-driven processes, security, capital constraints, workforce readiness, and education that hinder the process of adopting smart technologies. All these challenges impact the I4.0 ecosystem in developing economies, fueled by automation and digital technologies.

Table 2.

Challenges of Industry 4.0 Technology Adoption in South Asia.

Overall, the findings demonstrated the distribution of barriers in which financial challenges (18%) played a decisive role, affecting technological, regulatory, and organizational workforces (Sayem et al. 2022). Particularly, the skill and workforce challenges (21%), such as lack of specialized workforce, training, and skills require a new set of skills and knowledge for the industries. Training and development challenges (28%) are the most significant barrier to I4.0 in Bangladesh, India, Pakistan, Nepal, and Sri Lanka. There is a need for robust technical and vocational training to equip employees and workers for emerging jobs and the gig economy (Spoettl and Tūtlys 2020). Necessary infrastructure for digital learning, training, and the need for skilled human resources also present significant challenges for the future of work (Rodrigues et al. 2017). Thus, the government and employers should focus on life-long learning by reskilling and upskilling the workforce to be ready for the future job market (Li 2022). I4.0 also demands reformation of the education sector by initiating digital learning, accessing remote learning, and building modern infrastructure. Education has a big role in the transformation of society and the development of human resources (Manda and Ben Dhaou 2019). Besides, organizations must focus on flexible and cross-domain communication for global talent (Oesterreich and Teuteberg 2016). The analysis concludes that the financial, institutional, social, psychological, technological, workplace, and government regulatory challenges pose significant threats to the pace of adoption and implementation of Industry 4.0 technologies in developing countries (Wu and Kao 2022).

- RQ3: What are the key skill requirements and gaps resulting from the integration of I4.0 technologies?

Our third research question focuses on skill requirements and gaps arising from the integration of I4.0 technologies. The changing skill demand for the industry is just the newest case of a fairly old debate. Digitalization, new sets of skills, and diverse knowledge constitute new challenges for today’s industries. By 2030, there will likely be a competence gap in the youth of today, which raises the possibility of robotic replacement of humans (Alhloul and Kiss 2022; Saniuk et al. 2021). To delve into this question comprehensively, the authors categorized all the summarized skills into five types (Table 3). They are: (1) technical and information technology skills, (2) communication and interpersonal skills; (3) digital skills; (4) entrepreneurship and leadership skills; and (5) problem-solving and relationship skills. Our findings aim to assess the impact of these skills to overcome the challenges and drive the benefits to different industries, e.g., manufacturing firms, software firms in India, apparel and service industries in Bangladesh, education sectors in Pakistan, and Nepal. Most South Asian countries have gaps in these skill sets, which require timely actions to produce a skilled workforce.

Table 3.

Skill requirements and gaps in South Asian countries.

However, in our analysis, the authors found technical skills (26%) consisting of information technology, specialized manufacturing skills, data analytical skills, data management skills, communication and interpersonal skills, and problem-solving skills to be highly demanded and influential in Bangladesh, India, and Pakistan, Nepal, and Sri Lanka. The dominant skills are new and a significant contribution to our study. The current study shows skill gaps in these areas and suggests reskilling and upskilling with the collaboration of industry, academia, and government initiatives. Moreover, several previous studies also corroborate our research findings regarding the assessment of required skills. For instance, Woschank et al. (2020) compared skill requirements in Central European and Southeast Asian industries, uncovering significant disparities. Maisiri et al. (2019) concentrated on engineering profession skills, underscoring the imperative for capability development to align with I4.0 needs. In Malaysia, Indonesia, and Brunei, the critical skills and career readiness of tertiary students lack awareness about I4.0′s skill prerequisites (Adnan et al. 2021). As a result, Bongomin et al. (2020) suggest disruptive technologies such as the Internet of Things, big data, and artificial intelligence be integrated to the education sector and stress the importance of their implementation. In order to overcome the challenges and boost the economy, Thailand took initiatives to implement the I4.0 concept—the “Thailand 4.0” policy. Such policies are considered the main tool for integrating innovation, knowledge, technology, and creativity for economic and social development (Puriwat and Tripopsakul 2020).

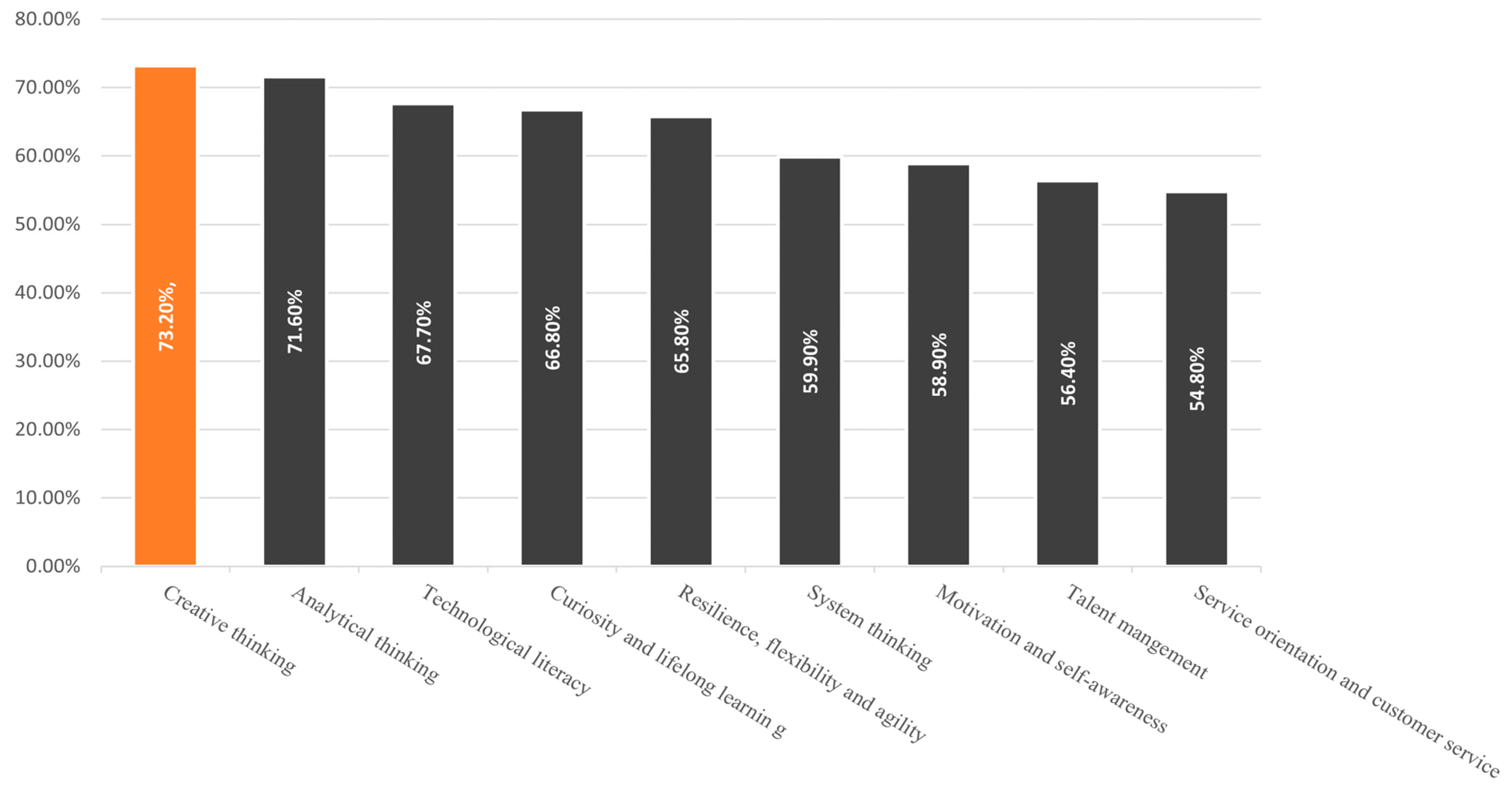

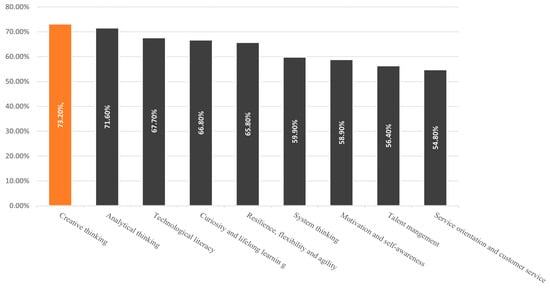

Conversely, the current study aligns with the findings of the World Economic Forum’s report, which indicates that the top skills and skill sets expected to be increasingly in demand from 2023 to 2027 are illustrated in Figure 9. It shows that creative thinking will grow faster in the next five years than demand for analytical thinking. Technology literacy (68.70%) is the third fastest growing category, ahead of curiosity and lifelong learning, resilience, flexibility and agility, and motivation and self-awareness.

Figure 9.

Top 10 skills in demand according to the World Economic Forum. Source: Battista et al. (2023).

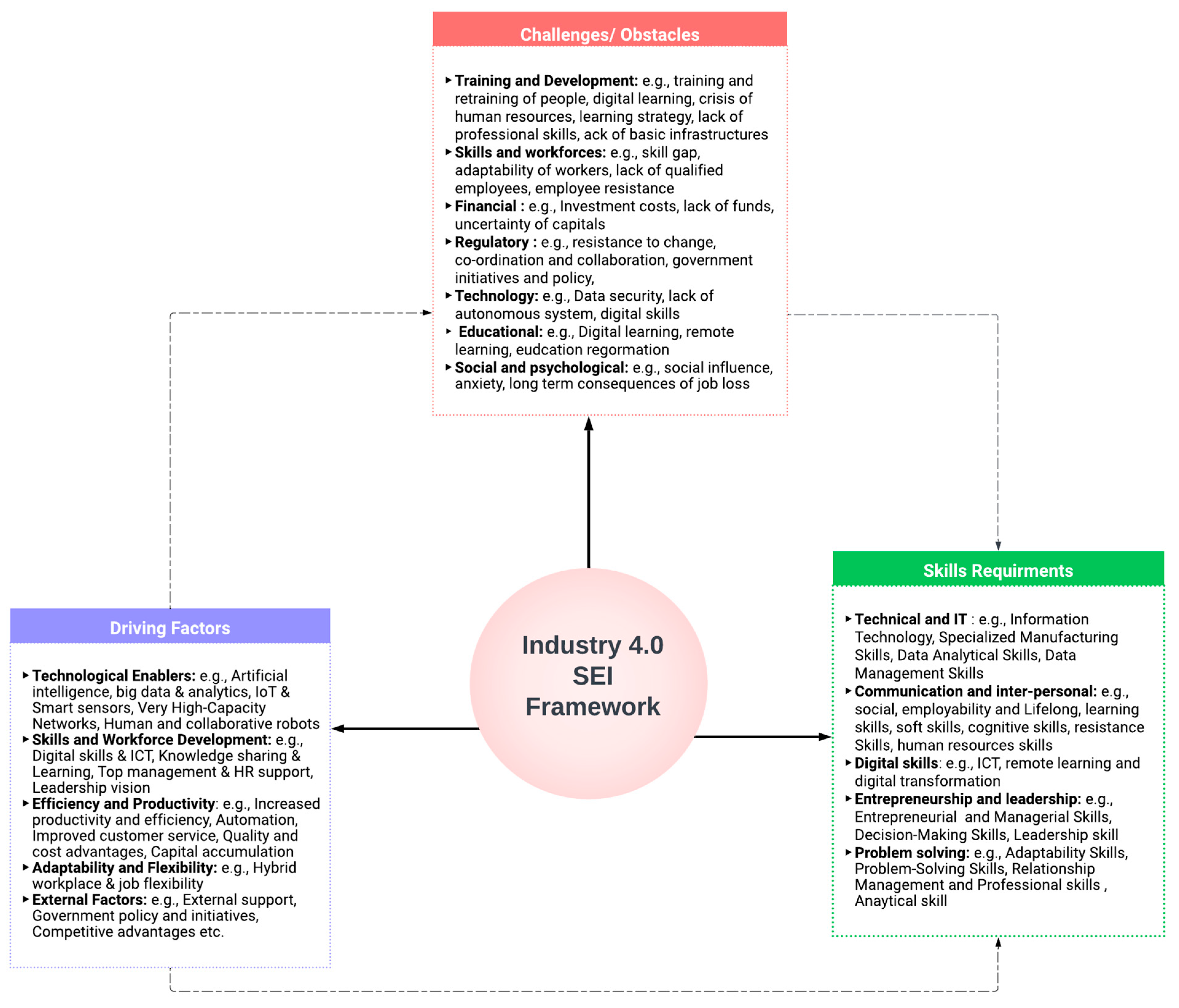

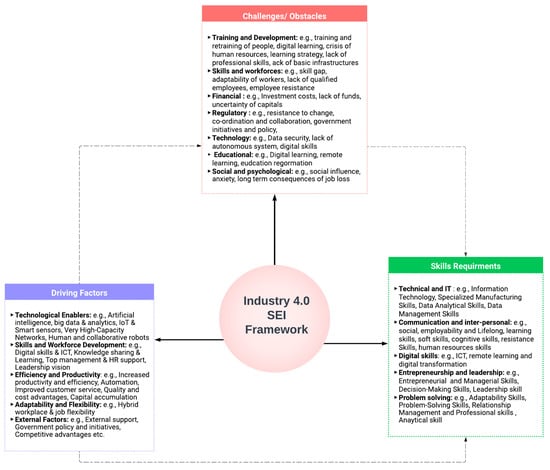

Moreover, the findings suggest strategies for adopting new skills in developing countries, especially in South Asia. Creating a learning environment, industry–academic collaboration, infrastructure development, sharing and transferring of knowledge internally and externally, and reforming education with enhanced training curricula can help in making skilled and efficient workforces (Artifice et al. 2019; Sallati et al. 2019). Based on the analyses and syntheses of the systematic review, the authors propose a framework (Figure 10), “Industry 4.0 SEI Framework”, that depicts the driving factors, challenges, and required skills for the future labor market. Through this framework, the current study also significantly contributes to the existing field of knowledge in the ongoing debate regarding the fourth industrial revolution. Previous studies by Horváth and Szabó (2019) and Vuksanović Herceg et al. (2020) also support our findings. They explored human factors, efficiency factors, and technological factors as the major forces in the pace of digital transformation. However, the driving forces are the key elements and enablers that strengthen the adoption and implementation of Industry 4.0 technologies. For example, technological enablers, skill and workforce development, efficiency and productivity, adaptability and flexibility, and external enablers can transform management functions. The authors also address the challenges that industry might encounter when transitioning to the integration of technologies, such as investment costs, a lack of funds, data security, and a lack of qualified workforce. Therefore, the conceptual framework also suggests specific abilities and skills, which include technical skills, digital skills, cognitive skills, analytical skills, and many more. The authors suggest these skills for the future workforce and individuals who need to effectively operate and manage their operations.

Figure 10.

Industry 4.0 SEI Framework (Source: Authors). Notes: SEI stands for Skills and Employability Framework for Industry 4.0.

4.3. Theoretical and Practical Implications

The current systematic review has a set of potential theoretical and practical implications. In theoretical terms, our study offers insights about the impact of 4IR technology on employment and skills in South Asian countries in several ways using the current body of knowledge. Firstly, the study identifies the key drivers or success factors, including artificial intelligence, digital skills, and big data analytics, which organizations and governments should prioritize for enhanced productivity and efficiency. These driving factors of I4.0 have direct or indirect effects on the labor market, opening a wide range of opportunities, and reducing costs economically (Szabó-Szentgróti et al. 2021). Most of the previous studies conducted research on the integration of human factors and ergonomics, the effects of Industry 4.0 technologies on supply chain management, and digitizing some of the manufacturing, retailing, warehousing, transportation, and industrial procedures of the logistics industry. Overall, these studies explained impact and behavior, with less focus on the critical success factors that can emerge from FIR. The nine most important driving factors can significantly improve the technology readiness and strengthen the digital transformation of manufacturing firms, SMEs, service sectors, and sustainable growth industries (Hizam-Hanafiah et al. 2020; Madhavan et al. 2022). Secondly, the study extracted different challenges of I4.0 technologies that can provide a significant contribution in developing countries to be prepared for the future of work. These findings significantly contribute to the understanding of the complex technological effects and obstacles of I4.0. Thirdly, the authors found skill requirements and gaps in South Asian countries, which can open the eyes of industries, governments, managers, and other practitioners. This finding contributes to preparing a skilled workforce and increasing the employability in that region. Previous studies by Iram Javeed (2023) and Husin et al. (2022) also corroborate the notion that the current labor market needs highly skilled labor because 4IR will create more jobs for people along with replacing existing jobs. Therefore, human capital will undergo major changes due to skill deficiencies, particularly in India, Bangladesh, and Pakistan. Such skills, for example, technical skills, digital skills, creativity, analytical skill, and problem-solving skills, will be required by the labor market and individuals to possess a combination of technical and soft skills to thrive in the future.

In terms of practical implications, our research can assist managers from a variety of industries, government policymakers, and other practitioners in updating their understanding of the surrounding technologies and the effects of I4.0 on the current labor market. It could also assist aspiring entrepreneurs in better comprehending and adopting new workplace technologies (Piccarozzi et al. 2018). Managers can gain insight into the future of digital transformation and the capabilities of Industry 4.0 concepts by utilizing our proposed Industry 4.0 SEI Framework. The driving factors, challenges, and skill requirements can assist human resource managers in identifying their strengths and weaknesses when it comes to locating the best talent.

5. Conclusions

This systematic review and Pareto analysis on the impact of I4.0 technologies on employability and skills has provided South Asian regions with valuable insights. The paper investigated 48 articles from the Web of Science database that have been peer-reviewed. The findings of the study significantly elucidate the regional I4.0 trends, driving factors, challenges, and required skills. India, followed by Pakistan and Bangladesh, has emerged as a leading contributor of research articles in recent years, as research activity as a whole has increased significantly over the past decade. Artificial intelligence, digital skills, and information technology have been identified as the primary factors driving the adoption of Industry 4.0 technologies, including the need for reskilling and upskilling. Adoption challenges include training and development, financial constraints, regulatory issues, and technological obstacles. In South Asian industries, technical and ICT skills, communication, problem-solving, digital literacy, and leadership skills are essential. The study also suggests a comprehensive strategy to address these challenges, emphasizing industry, academic, and government collaboration. The proposed “Industry 4.0 SEI Framework” provides stakeholders with guidance for understanding the dynamics of Industry 4.0 in South Asia, allowing the region to capitalize on the potential benefits of this technological revolution while mitigating its risks.

6. Limitation and Future Research Agenda

This study has several limitations, primarily stemming from the choice of the database. In our source selection, the authors exclusively used the Web of Science database, and no other databases were taken into account. Additionally, our study employed a search strategy reliant on research strings to determine the documents for analysis, restricting the search to specific keywords. Subsequent research might contemplate employing alternative combinations of terms to yield more comprehensive results.

The analysis in this study is founded on a sample of 48 articles, which might not adequately represent the full spectrum of research in the field. It is important to note that there could be pertinent studies excluded from our sample, particularly since the authors excluded books, book chapters, and conference proceedings. The analysis is confined to articles published up to December 2022, and it is conceivable that research trends and influential papers may have evolved beyond this timeframe, leaving newer developments unaccounted for due to our omission of a complete calendar year. The findings from this study may not be generalizable to all regions and contexts, as the concepts related to I4.0 are continually evolving. Despite these constraints, our research provides a valuable overview of the driving forces, potential challenges, and skill gaps, which lays the groundwork for further exploration and research in the domain of the labor market. More research, preferably empirical research, should look into how Industry 4.0 technologies are used and how they affect the growth of human capital in this digital age. The goal is to create a skilled workforce for the current job market. These insights can serve as valuable resources for both researchers and practitioners, enabling them to inform their work and contribute to the ongoing discourse and advancements in this field.

Author Contributions

Conceptualization, M.F.-F. and M.T.M.; methodology, M.T.M. and M.F.-F.; software, M.T.M. and S.E.-G.; validation, S.E.-G.; formal analysis, M.T.M.; investigation, M.T.M. and; resources, M.T.M. and M.F.-F.; data curation, M.T.M.; writing—original draft preparation, M.T.M.; writing—M.T.M.; editing, A.D. and S.E.-G.; visualization, M.T.M.; supervision, M.F.-F. and A.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Informed Consent Statement

Not applicable.

Data Availability Statement

The corresponding author will provide the datasets used in research upon valid request.

Acknowledgments

We thank the Hungarian University of Agriculture and Life Sciences, Doctoral School of Economic and Regional Sciences for their support to this research. We also thank the editor and the anonymous reviewers for their insightful and constructive comments.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Abuzaid, Mohamed M., Wiam Elshami, Jonathan McConnell, and H. O. Tekin. 2021. An Extensive Survey of Radiographers from the Middle East and India on Artificial Intelligence Integration in Radiology Practice. Health and Technology 11: 1045–50. [Google Scholar] [CrossRef]

- Acemoglu, Daron, and Pascual Restrepo. 2020. Robots and Jobs: Evidence from US Labor Markets. Journal of Political Economy 128: 2188–244. [Google Scholar] [CrossRef]

- Adnan, A. H. M., A. M. Rahmat, N. M. Mohtar, and N. Anuar. 2021. Industry 4.0 Critical Skills and Career Readiness of ASEAN TVET Tertiary Students in Malaysia, Indonesia and Brunei. Journal of Physics: Conference Series 1793: 12004. [Google Scholar] [CrossRef]

- Alam, Shafiqul, and Pavitra Dhamija. 2022. Human Resource Development 4.0 (HRD 4.0) in the Apparel Industry of Bangladesh: A Theoretical Framework and Future Research Directions. International Journal of Manpower 43: 263–85. [Google Scholar] [CrossRef]

- Alhloul, Abdelkarim, and Eva Kiss. 2022. Industry 4.0 as a Challenge for the Skills and Competencies of the Labor Force: A Bibliometric Review and a Survey. Sci 4: 34. [Google Scholar] [CrossRef]

- Ali, Shahbaz, and Yongping Xie. 2021. The Impact of Industry 4.0 on Organizational Performance: The Case of Pakistan’s Retail Industry. European Journal of Management Studies 26: 63–86. [Google Scholar] [CrossRef]

- Andrade, Cristiana Renno D’Oliveira, and Claudio Reis Goncalo. 2021. Digital Transformation by Enabling Strategic Capabilities in the Context of ‘BRICS’. Rege-Revista de Gestao 28: 297–315. [Google Scholar] [CrossRef]

- Anuşlu, Merve Doğruel, and Seniye Ümit Frat. 2019. Clustering Analysis Application on Industry 4.0-Driven Global Indexes. Procedia Computer Science 158: 145–52. [Google Scholar] [CrossRef]

- Artifice, Andreia, Fernando Luis-Ferreira, João Sarraipa, and Ricardo Jardim-Goncalves. 2019. Computational Model for Knowledge Transfer Skills in Industry 4.0 in an Enhanced and Effective Way. Paper presented at ASME 2019 International Mechanical Engineering Congress and Exposition. Volume 2B: Advanced Manufacturing, Salt Lake City, UT, USA, November 11–14. [Google Scholar] [CrossRef]

- Asian Development Bank. 2021. Reaping the Benefits of Industry 4.0 through Skills Development in High-Growth Industries in Southeast Asia. Metro Manila: ADB Publications. [Google Scholar] [CrossRef]

- Babu, Kudrat-E-Khuda. 2021. Artificial Intelligence in Bangladesh, Its Applications in Different Sectors and Relevant Challenges for the Government: An Analysis. International Journal of Public Law and Policy 7: 319–33. [Google Scholar] [CrossRef]

- Bajaj, Shweta, Ruchi Garg, and Monika Sethi. 2018. Total Quality Management: A Critical Literature Review Using Pareto Analysis. International Journal of Productivity and Performance Management 67: 128–54. [Google Scholar] [CrossRef]

- Balliester, Thereza, and Adam Elsheikhi. 2018. The Future of Work: A Literature Review. ILO Research Department Working Paper 29: 1–54. Available online: https://englishbulletin.adapt.it/wp-content/uploads/2018/07/wcms_625866.pdf (accessed on 19 December 2023).

- Battista, Attilio Di, Sam Grayling, and Else Hasselaar. 2023. Future of Jobs Report 2023. Geneva: World Economic Forum. Available online: https://www3.weforum.org/docs/WEF_Future_of_Jobs_2023.pdf (accessed on 19 December 2023).

- Behl, Abhishek, Meena Chavan, Kokli Jain, Isha Sharma, Vijay Edward Pereira, and Justin Zuopeng Zhang. 2022. The Role of Organizational Culture and Voluntariness in the Adoption of Artificial Intelligence for Disaster Relief Operations. International Journal of Manpower 43: 569–86. [Google Scholar] [CrossRef]

- Bhasin, Narinder Kumar, and Anupama Rajesh. 2022. The Role of Emerging Banking Technologies for Risk Management and Mitigation to Reduce Non-Performing Assets and Bank Frauds in the Indian Banking System. International Journal of E-Collaboration 18: 1–25. [Google Scholar] [CrossRef]

- Bhattacharya, Sanjay, Kirankumar S. Momaya, and K. C. Iyer. 2021. Bridging the Gaps for Business Growth among Indian Construction Companies. Built Environment Project and Asset Management 11: 231–50. [Google Scholar] [CrossRef]

- Bhattacharyya, Sujatra, and Arup Mitra. 2020. Fourth Industrial Revolution and India’s ‘Employment Problem’. International Journal of Social Economics 47: 851–66. [Google Scholar] [CrossRef]

- Bhattacharyya, Som Sekhar, and Srikant Nair. 2019. Explicating the Future of Work: Perspectives from India. Journal of Management Development 38: 175–94. [Google Scholar] [CrossRef]

- Bhuiyan, Abul Bashar, Md Jafor Ali, Norhayah Zulkifli, and Mokana Muthu Kumarasamy. 2020. Industry 4.0: Challenges, Opportunities, and Strategic Solutions for Bangladesh. International Journal of Business and Management Future 4: 41–56. [Google Scholar] [CrossRef]

- Birkle, Caroline, David A Pendlebury, Joshua Schnell, and Jonathan Adams. 2020. Web of Science as a Data Source for Research on Scientific and Scholarly Activity. Quantitative Science Studies 1: 363–76. [Google Scholar] [CrossRef]

- Bishwakarma, Jham Kumar, and Zongshan Hu. 2022. Problems and Prospects for the South Asian Association for Regional Cooperation (SAARC). Politics & Policy 50: 154–79. [Google Scholar] [CrossRef]

- Bolbot, Victor, Ketki Kulkarni, Päivi Brunou, Osiris Valdez Banda, and Mashrura Musharraf. 2022. Developments and Research Directions in Maritime Cybersecurity: A Systematic Literature Review and Bibliometric Analysis. International Journal of Critical Infrastructure Protection 39. [Google Scholar] [CrossRef]

- Bongomin, Ocident, Gilbert Gilibrays Ocen, Eric Oyondi Nganyi, Alex Musinguzi, and Timothy Omara. 2020. Exponential Disruptive Technologies and the Required Skills of Industry 4.0. Journal of Engineering 2020: 4280156. [Google Scholar] [CrossRef]

- Brás, Gonçalo Rodrigues. 2023. Pillars of the Global Innovation Index by Income Level of Economies: Longitudinal Data (2011–2022) for Researchers’ Use. Data in Brief 46: 108818. [Google Scholar] [CrossRef]

- Brigitta, C. 2022. The Past and Present of Indian Civil Society. Civil Szemle 19: 81–108. [Google Scholar]

- Cannavacciuolo, Lorella, Giovanna Ferraro, Cristina Ponsiglione, Simonetta Primario, and Ivana Quinto. 2023. Technological Innovation-Enabling Industry 4.0 Paradigm: A Systematic Literature Review. Technovation 124: 102733. [Google Scholar] [CrossRef]

- Chen, Weiru, Wu He, Jiayue Shen, Xin Tian, and Xianping Wang. 2023. Systematic Analysis of Artificial Intelligence in the Era of Industry 4.0. Journal of Management Analytics 10: 89–108. [Google Scholar] [CrossRef]

- Chenoy, Dilip, Shobha Mishra Ghosh, and Shiv Kumar Shukla. 2019. Skill Development for Accelerating the Manufacturing Sector: The Role of ‘new-Age’ Skills for ‘Make in India’. International Journal of Training Research 17: 112–30. [Google Scholar] [CrossRef]

- Culot, Giovanna, Guido Nassimbeni, Guido Orzes, and Marco Sartor. 2020. Behind the Definition of Industry 4.0: Analysis and Open Questions. International Journal of Production Economics 226: 107617. [Google Scholar] [CrossRef]

- Davies, Ron. 2015. Industry 4.0 Digitalization for Productivity and Growth. Available online: https://policycommons.net/artifacts/1335939/industry-40/1942749/ (accessed on 19 December 2023).

- Devkota, Niranjan, Sharad Rajbhandari, Udaya Raj Poudel, and Seeprata Parajuli. 2022. Obstacles of Implementing Industry 4.0 in Nepalese Industries and Way-Forward. International Journal of Finance Research 2: 286–95. [Google Scholar] [CrossRef]

- Dregger, Johannes, Jonathan Niehaus, Peter Ittermann, Hartmut Hirsch-Kreinsen, and Michael Ten Hompel. 2016. The Digitization of Manufacturing and Its Societal Challenges: A Framework for the Future of Industrial Labor. Paper presented at the 2016 IEEE International Symposium on Ethics in Engineering, Science and Technology (ETHICS), Vancouver, BC, Canada, May 13–14. [Google Scholar]

- D’souza, Brayal, Shreyas Suresh Rao, Chepudira Ganapathy Muthana, Reshmi Bhageerathy, Nikitha Apuri, Varalakshmi Chandrasekaran, Deena Prabhavathi, and Sapna Renukaradhya. 2021. ROTA: A System for Automated Scheduling of Nursing Duties in a Tertiary Teaching Hospital in South India. Health Informatics Journal 27. [Google Scholar] [CrossRef]

- Dutta, Sunasir. 2017. Creating in the Crucibles of Nature’s Fury: Associational Diversity and Local Social Entrepreneurship after Natural Disasters in California, 1991–2010. Administrative Science Quarterly 62: 443–83. [Google Scholar] [CrossRef]

- Echchakoui, Saïd, and Noureddine Barka. 2020. Industry 4.0 and Its Impact in Plastics Industry: A Literature Review. Journal of Industrial Information Integration 20: 100172. [Google Scholar] [CrossRef]

- Ehsan, Shah Md Azimul. 2021. Artificial Intelligence and the Future of Labor Market in Bangladesh. In Global Encyclopedia of Public Administration, Public Policy, and Governance. Cham: Springer, pp. 1–9. [Google Scholar] [CrossRef]

- Erboz, Gizem. 2017. How to Define Industry4.0: The Main Pillars of Industry 4.0. In Managerial Trends in the Development of Enterprises in Globalization Era. Edited by I. Kosiciarova and Z. Kadekova. 761-67. Tr A Hlinku2, Nitra, 94976. Slovakia: Slovak Univ Agriculture Nitra. Available online: https://www.researchgate.net/publication/326557388_How_To_Define_Industry_40_Main_Pillars_Of_Industry_40 (accessed on 18 January 2024).

- Freund, Lucas, and Salah Al-Majeed. 2021. Managing Industry 4.0 Integration—The Industry 4.0 Knowledge & Framework. Logforum 17: 569–86. [Google Scholar]

- Gadre, Monika, and Aruna Deoskar. 2021. Interpretations and Impact of New Education Policy 2020 on Indian Higher Education for Industry 4.0. Pacific Business Review International 14: 93–105. Available online: https://www.researchgate.net/publication/355668078_Interpretations_and_Impact_of_New_Education_Policy_2020_on_Indian_Higher#fullTextFileContent (accessed on 18 January 2024).

- Ghislieri, Chiara, Monica Molino, and Claudio G. Cortese. 2018. Work and Organizational Psychology Looks at the Fourth Industrial Revolution: How to Support Workers and Organizations? Frontiers in Psychology 9: 1–6. [Google Scholar] [CrossRef]

- Ghobakhloo, Morteza. 2020. Industry 4.0, Digitization, and Opportunities for Sustainability. Journal of Cleaner Production 252: 119869. [Google Scholar] [CrossRef]

- Goswami, Mohit, and Yash Daultani. 2022. Make-in-India and Industry 4.0: Technology Readiness of Select Firms, Barriers and Socio-Technical Implications. TQM Journal 34: 1485–505. [Google Scholar] [CrossRef]

- Gusenbauer, Michael, and Neal R Haddaway. 2020. Which Academic Search Systems Are Suitable for Systematic Reviews or Meta-analyses? Evaluating Retrieval Qualities of Google Scholar, PubMed, and 26 Other Resources. Research Synthesis Methods 11: 181–217. [Google Scholar] [CrossRef]

- Hammer, Anita, and Suparna Karmakar. 2021. Automation, AI and the Future of Work in India. Employee Relations 43: 1327–41. [Google Scholar] [CrossRef]

- Harris, Joshua D., Carmen E. Quatman, Maurice M Manring, Robert A Siston, and David C Flanigan. 2014. How to Write a Systematic Review. The American Journal of Sports Medicine 42: 2761–68. [Google Scholar] [CrossRef]

- Hasan, Md. Zahid, Avijit Mallik, and Jia-Chi Tsou. 2021. Learning Method Design for Engineering Students to Be Prepared for Industry 4.0: A Kaizen Approach. Higher Education Skills and Work-Based Learning 11: 182–98. [Google Scholar] [CrossRef]

- Hill, Jonathan, Andrew J Thomas, R. K. Mason-Jones, and Sherien El-Kateb. 2018. The Implementation of a Lean Six Sigma Framework to Enhance Operational Performance in an MRO Facility. Production & Manufacturing Research 6: 26–48. [Google Scholar] [CrossRef]

- Hiremath, Nandeesh V., Amiya Kumar Mohapatra, and Anil Subbarao Paila. 2021. A Study on Digital Learning, Learning and Development Interventions and Learnability of Working Executives in Corporates. American Journal of Business 36: 35–61. [Google Scholar]

- Hizam-Hanafiah, Mohd, Mansoor Ahmed Soomro, and Nor Liza Abdullah. 2020. Industry 4.0 Readiness Models: A Systematic Literature Review of Model Dimensions. Information 11: 364. [Google Scholar] [CrossRef]

- Holm, Jacob Rubæk, and Edward Lorenz. 2022. The Impact of Artificial Intelligence on Skills at Work in Denmark. New Technology, Work and Employment 37: 79–101. [Google Scholar] [CrossRef]

- Hoque, Imranul, and Md. Shahinuzzaman. 2021. Task Performance and Occupational Health and Safety Management Systems in the Garment Industry of Bangladesh. International Journal of Workplace Health Management 14: 369–85. [Google Scholar] [CrossRef]

- Horváth, Dóra, and Roland Zs Szabó. 2019. Driving Forces and Barriers of Industry 4.0: Do Multinational and Small and Medium-Sized Companies Have Equal Opportunities? Technological Forecasting and Social Change 146: 119–32. [Google Scholar] [CrossRef]

- Hossain, Sourav, Sanjida Hassan, and Rubayet Karim. 2023. Assessment of Critical Barriers to Industry 4.0 Adoption in Manufacturing Industries of Bangladesh: An ISM-Based Study. Brazilian Journal of Operations & Production Management 20: 1797. [Google Scholar] [CrossRef]

- Husin, Mohd Heikal, Noor Farizah Ibrahim, Nor Athiyah Abdullah, Sharifah Mashita Syed-Mohamad, Nur Hana Samsudin, and Leonard Tan. 2022. The Impact of Industrial Revolution 4.0 and the Future of the Workforce: A Study on Malaysian IT Professionals. Social Science Computer Review 41: 1671–90. [Google Scholar] [CrossRef]

- Imran, Muhammad, Waseem ul Hameed, and Adnan ul Haque. 2018. Influence of Industry 4.0 on the Production and Service Sectors in Pakistan: Evidence from Textile and Logistics Industries. Social Sciences 7: 246. [Google Scholar] [CrossRef]

- Imrana, Syed Muhammad, Syed Mumtaz Ali Kazmib, Farva Jawadc, and Iqra Ghousd. 2021. The Impact of Human Capital on Innovation: Empirical Evidence from South Asian Association for Regional Cooperation (SAARC). International Journal of Innovation, Creativity and Change 15. Available online: https://www.ijicc.net/images/Vol_15/Iss_8/15919_Imran_2021_E_R.pdf (accessed on 18 January 2024).

- International Monetary Fund. 2023. World Economic Outlook: Navigating Global Divergences. Washington, DC. Available online: https://www.imf.org/en/Publications/WEO/Issues/2023/10/10/world-economic-outlook-october-2023 (accessed on 19 December 2023).

- Iqbal, Mohammed Masum, K M Anwarul Islam, Nurul Mohammad Zayed, Tahrima Haque Beg, and Shahiduzzaman Khan Shahi. 2021. Impact of Artificial Intelligence and Digital Economy on Industrial Revolution 4: Evidence from Bangladesh. American Finance & Banking Review 6: 42–55. [Google Scholar] [CrossRef]

- Javeed, Iram. 2023. The Impact of Industry 4.0 on Employability and the Skills Required in India. Global Economics Science 4: 1–10. [Google Scholar] [CrossRef]

- Islam, A.Y.M. Atiquil, Khurshid Ahmad, Muhammad Rafi, and Zheng Jian Ming. 2021. Performance-Based Evaluation of Academic Libraries in the Big Data Era. Journal of Information Science 47: 458–71. [Google Scholar] [CrossRef]

- Islam, Tarikul, Subhas Chandra Mukhopadhyay, and Nagender Kumar Suryadevara. 2017. Smart Sensors and Internet of Things: A Postgraduate Paper. IEEE Sensors Journal 17: 577–84. [Google Scholar] [CrossRef]

- Jadhav, Abhijitkumar Anandrao, Deepali Aanandrao Suryawanshi, Sandeep Sureshrao Ahankari, and Sanjay Bhaskar Zope. 2022. A Technology-Enabled Assessment and Attainment of Desirable Competencies. Education for Chemical Engineers 39: 67–83. [Google Scholar] [CrossRef]

- Jain, Vineet, and Puneeta Ajmera. 2021. Modelling the Enablers of Industry 4.0 in the Indian Manufacturing Industry. International Journal of Productivity and Performance Management 70: 1233–62. [Google Scholar] [CrossRef]

- Jain, Vineet, and Puneeta Ajmera. 2022. Modelling the Barriers of Industry 4.0 in India Using Fuzzy TISM. International Journal of Business Performance Management 23: 347–72. [Google Scholar] [CrossRef]

- Jain, Vineet, Puneeta Ajmera, and Joao Paulo Davim. 2022. SWOT Analysis of Industry 4.0 Variables Using AHP Methodology and Structural Equation Modelling. Benchmarking-An International Journal 29: 2147–76. [Google Scholar] [CrossRef]

- Jaiswal, Akanksha, C. Joe Arun, and Arup Varma. 2022. Rebooting Employees: Upskilling for Artificial Intelligence in Multinational Corporations. The International Journal of Human Resource Management 33: 1179–208. [Google Scholar] [CrossRef]

- Jamil, Sadia. 2022. Evolving Newsrooms and the Second Level of Digital Divide: Implications for Journalistic Practice in Pakistan. Journalism Practice 17: 1864–81. [Google Scholar] [CrossRef]

- Jha, Pratiksha. 2021. Digitization and Industry 4.0 Practices: An Exploratory Study on SMEs in India. SSRN Electronic Journal, 1–8. [Google Scholar] [CrossRef]

- Jony, Sheikh Saifur Rahman, Tsuyoshi Kano, Ryotaro Hayashi, Norihiko Matsuda, and M. Sohel Rahman. 2022. An Exploratory Study of Online Job Portal Data of the ICT Sector in Bangladesh: Analysis, Recommendations and Preliminary Implications for ICT Curriculum Reform. Education Sciences 12: 423. [Google Scholar] [CrossRef]

- Joshi, Seema. 2021. Rising Importance of Remote Learning in India in the Wake of COVID-19: Issues, Challenges and Way Forward. World Journal of Science Technology and Sustainable Development 18: 44–63. [Google Scholar] [CrossRef]

- Kadir, Bzhwen A., Ole Broberg, and Carolina Souza da Conceição. 2019. Current Research and Future Perspectives on Human Factors and Ergonomics in Industry 4.0. Computers and Industrial Engineering 137: 106004. [Google Scholar] [CrossRef]

- Kagermann, Henning, Wolf-Dieter Lukas, and Wolfgang Wahlster. 2011. Industrie 4.0: Mit Dem Internet Der Dinge Auf Dem Weg Zur 4. Industriellen Revolution. VDI Nachrichten 13: 2–3. Available online: https://www-live.dfki.de/fileadmin/user_upload/DFKI/Medien/News_Media/Presse/Presse-Highlights/vdinach2011a13-ind4.0-Internet-Dinge.pdf (accessed on 17 January 2024).

- Kagermann, Henning, Wolfgang Wahlster, and Johannes Helbig. 2013. Recommendations for Implementing the Strategic Initiative Industrie 4.0: Final Report of the Industrie 4.0 Working Group. Berlin, Germany: Available online: https://www.din.de/resource/blob/76902/e8cac883f42bf28536e7e8165993f1fd/recommendations-for-implementing-industry-4-0-data.pdf (accessed on 17 January 2024).

- Kanji, Repaul, and Rajat Agrawal. 2020. Exploring the Use of Corporate Social Responsibility in Building Disaster Resilience through Sustainable Development in India: An Interpretive Structural Modelling Approach. Progress in Disaster Science 6: 100089. [Google Scholar] [CrossRef]

- Kar, Sudatta, Arpan K. Kar, and M. P. Gupta. 2021. Industrial Internet of Things and Emerging Digital Technologies-Modeling Professionals’ Learning Behavior. IEEE Access 9: 30017–34. [Google Scholar] [CrossRef]

- Karki, Samrakshya, and Bonaventura Hadikusumo. 2023. Machine Learning for the Identification of Competent Project Managers for Construction Projects in Nepal. Construction Innovation-England 23: 1–18. [Google Scholar] [CrossRef]

- Karuppusami, Gandhinathan, and R. Gandhinathan. 2006. Pareto Analysis of Critical Success Factors of Total Quality Management: A Literature Review and Analysis. The TQM Magazine 18: 372–85. [Google Scholar] [CrossRef]

- Katekar, Vikrant, and Sandip S Deshmukh. 2021. En Route for the Accomplishment of SDG-7 in South Asian Countries: A Retrospective Study. Strategic Planning for Energy and the Environment 40: 195–230. [Google Scholar] [CrossRef]

- Kattimani, Shivaputrappa Fakkirappa, and Ramesh R. Naik. 2013. Evaluation of Librarianship and ICT Skills of Library and Information Professionals Working in the Engineering College Libraries in Karnataka, India: A Survey. Program-Electronic Library and Information Systems 47: 344–68. [Google Scholar] [CrossRef]

- Klingenberg, Cristina Orsolin, Marco Antônio Viana Borges, and José Antônio do Vale Antunes. 2022. Industry 4.0: What Makes It a Revolution? A Historical Framework to Understand the Phenomenon. Technology in Society 70: 102009. [Google Scholar] [CrossRef]

- Kowalikova, Petra, Petr Polak, and Roman Rakowski. 2020. The Challenges of Defining the Term “Industry 4.0”. Society 57: 631–36. [Google Scholar] [CrossRef]

- Kumar, Surendra. 2019. Artificial Intelligence Divulges Effective Tactics of Top Management Institutes of India. Benchmarking-An International Journal 26: 2188–204. [Google Scholar] [CrossRef]

- Lane, Marguerita, and Anne Saint-Martin. 2021. The Impact of Artificial Intelligence on the Labour Market: What Do We Know So Far? OECD Social, Employment and Migration Working Papers, No. 256. Paris: OECD Publishing. [Google Scholar] [CrossRef]

- Leong, Wai Yie, Joon Huang Chuah, and Tee Boon Tuan. 2020. The Nine Pillars of Technologies for Industry 4.0. Selangor: Institution of Engineering and Technology, p. 576. [Google Scholar] [CrossRef]

- Li, Ling. 2022. Reskilling and Upskilling the Future-Ready Workforce for Industry 4.0 and beyond. Information Systems Frontiers, 1–21. [Google Scholar] [CrossRef]

- Madhavan, Meena, Sutee Wangtueai, Mohammed Ali Sharafuddin, and Thanapong Chaichana. 2022. The Precipitative Effects of Pandemic on Open Innovation of SMEs: A Scientometrics and Systematic Review of Industry 4.0 and Industry 5.0. Journal of Open Innovation: Technology, Market, and Complexity 8: 152. [Google Scholar] [CrossRef]

- Maisiri, Whisper, Hasan Darwish, and Liezl van Dyk. 2019. An Investigation of Industry 4.0 Skills Requirements. South African Journal of Industrial Engineering 30: 90–105. [Google Scholar] [CrossRef]

- Manda, More Ickson, and Soumaya Ben Dhaou. 2019. Responding to the Challenges and Opportunities in the 4th Industrial Revolution in Developing Countries. Paper presented at the 12th International Conference on Theory and Practice of Electronic Governance, Melbourne, Australia, April 3–5; pp. 244–53. [Google Scholar] [CrossRef]

- Mazhar, Saman, Ali Sher, Azhar Abbas, Abdul Ghafoor, and Guanghua H. Lin. 2022. Empowering Shepreneurs to Achieve the Sustainable Development Goals: Exploring the Impact of Interest-Free Start-up Credit, Skill Development and ICTs Use on Entrepreneurial Drive. Sustainable Development 30: 1235–51. [Google Scholar] [CrossRef]

- Mehta, Balwant Singh, and Ishwar Chandra Awasthi. 2019. Industry 4.0 and Future of Work in India. FIIB Business Review 8: 9–16. [Google Scholar] [CrossRef]

- Mezina, T. V., A. V. Zozulya, P. V. Zozulya, T. F. Chernova, and A. V. Pletnyova. 2022. Impact of Industry 4.0 on the Economy and Production. Vestnik Universiteta 2: 71–76. [Google Scholar] [CrossRef]

- Moher, David, Alessandro Liberati, Jennifer Tetzlaff, Douglas G Altman, and PRISMA Group*. 2009. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. Annals of Internal Medicine 151: 264–69. [Google Scholar] [CrossRef]

- Mohiuddin, Muhammad, Md. Samim Al Azad, Selim Ahmed, Slimane Ed-Dafali, and Mohammad Nurul Hasan Reza. 2022. Evolution of Industry 4.0 and Its Implications for International Business. In Global Trade in the Emerging Business Environment. London: IntechOpen. [Google Scholar]

- Mukherjee, Arpita, and Divya Satija. 2020. Regional Cooperation in Industrial Revolution 4.0 and South Asia: Opportunities, Challenges and Way Forward. South Asia Economic Journal 21: 76–98. [Google Scholar] [CrossRef]

- Nizami, Nausheen, Tulika Tripathi, and Meha Mohan. 2022. Transforming Skill Gap Crisis into Opportunity for Upskilling in India’s IT-BPM Sector. Indian Journal of Labour Economics 65: 845–62. [Google Scholar] [CrossRef]

- Nudurupati, Sai Sudhakar, Pawan Budhwar, Raja Phani Pappu, Soumyadeb Chowdhury, Mukesh Kondala, Ayon Chakraborty, and Sadhan Kumar Ghosh. 2022. Transforming Sustainability of Indian Small and Medium-Sized Enterprises through Circular Economy Adoption. Journal of Business Research 149: 250–69. [Google Scholar] [CrossRef]

- Oesterreich, Thuy Duong, and Frank Teuteberg. 2016. Understanding the Implications of Digitisation and Automation in the Context of Industry 4.0: A Triangulation Approach and Elements of a Research Agenda for the Construction Industry. Computers in Industry 83: 121–39. [Google Scholar] [CrossRef]

- Page, Matthew J., Joanne E. McKenzie, Patrick M. Bossuyt, Isabelle Boutron, Tammy C. Hoffmann, Cynthia D. Mulrow, Larissa Shamseer, Jennifer M. Tetzlaff, Elie A. Akl, and Sue E. Brennan. 2021. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. International Journal of Surgery 88: 105906. [Google Scholar] [CrossRef]

- Park-Poaps, Haesun, Md. Sadaqul Bari, and Zafar Waziha Sarker. 2021. Bangladeshi Clothing Manufacturers’ Technology Adoption in the Global Free Trade Environment. Journal of Fashion Marketing and Management 25: 354–70. [Google Scholar] [CrossRef]

- Pathak, Saurabh, and Bhawna Sharma. 2022. Artificial Intelligence for Improving Employee Engagement in South Asian Banking Industry: A Systematic Literature Review. NeuroQuantology 20: 17. [Google Scholar]

- Pereira, Gustavo Bernardi, Adriana de Paula Lacerda Santos, and Marcelo Gechele Cleto. 2018. Industry 4.0: Glitter or Gold? A Systematic Review. Brazilian Journal of Operations & Production Management 15: 247–53. [Google Scholar] [CrossRef]

- Perez Perales, David, Faustino Alarcon Valero, and Andres Boza Garcia. 2018. Industry 4.0: A Classification Scheme. In Closing the Gap between Practice and Research in Industrial Engineering. Edited by E. Viles, M. Ormazabal and A. Lleo. Lecture Notes in Management and Industrial Engineering. Cham: Springer International Publishing Ag, pp. 343–50. [Google Scholar] [CrossRef]

- Phethean, Christopher, Elena Simperl, Thanassis Tiropanis, Ramine Tinati, and Wendy Hall. 2016. The Role of Data Science in Web Science. IEEE Intelligent Systems 31: 102–7. [Google Scholar] [CrossRef]

- Piccarozzi, Michela, Barbara Aquilani, and Corrado Gatti. 2018. Industry 4.0 in Management Studies: A Systematic Literature Review. Sustainability 10: 3821. [Google Scholar] [CrossRef]

- Pollock, Alex, and Eivind Berge. 2018. How to Do a Systematic Review. International Journal of Stroke 13: 138–56. [Google Scholar] [CrossRef]

- Pranckutė, Raminta. 2021. Web of Science (WoS) and Scopus: The Titans of Bibliographic Information in Today’s Academic World. Publications 9: 12. [Google Scholar] [CrossRef]

- Puriwat, Wilert, and Suchart Tripopsakul. 2020. Preparing for Industry 4.0—Will Youths Have Enough Essential Skills? An Evidence from Thailand. International Journal of Instruction 13: 89–104. [Google Scholar] [CrossRef]

- Rad, Fakhreddin F, Pejvak Oghazi, Maximilian Palmie, Koteshwar Chirumalla, Natallia Pashkevich, Pankaj C Patel, and Setayesh Sattari. 2022. Industry 4.0 and Supply Chain Performance: A Systematic Literature of the Benefits, Challenges, and Critical Success Factors of 11 Technologies. Industrial Marketing Management 105: 268–93. [Google Scholar] [CrossRef]

- Rahman, Noorul Shaiful Fitri Abdul, Abdelsalam Adam Hamid, Taih-Cherng Lirn, Khalid Al Kalbani, and Bekir Sahin. 2022. The Adoption of Industry 4.0 Practices by the Logistics Industry: A Systematic Review of the Gulf Region. Cleaner Logistics and Supply Chain 5: 100085. [Google Scholar] [CrossRef]

- Raj, Alok, Gourav Dwivedi, Ankit Sharma, Ana Beatriz de Sousa Jabbour, and Sonu Rajak. 2020. Barriers to the Adoption of Industry 4.0 Technologies in the Manufacturing Sector: An Inter-Country Comparative Perspective. International Journal of Production Economics 224: 107546. [Google Scholar] [CrossRef]

- Rajamanickam, Srinivasan. 2016. Exploring Landscapes in Regional Convergence. In Handbook of Research on Global Indicators of Economic and Political Convergence. Pennsylvania: IGI Global, pp. 474–510. [Google Scholar]

- Reddy, Narasimha D. 2020. Future of Work and Emerging Challenges to the Capabilities of the Indian Workforce. Indian Journal of Labour Economics 63: 199–224. [Google Scholar] [CrossRef]

- Rehman, Hafiz Mudassir, Au Yong Hui Nee, Choong Yuen Onn, and Mobashar Rehman. 2021. Barriers to Adoption of Industry 4.0 in Manufacturing Sector. Paper presented at the 2021 International Conference on Computer & Information Sciences (ICCOINS), Kuching, Malaysia, July 13–15. [Google Scholar]

- Rethlefsen, Melissa L, Shona Kirtley, Siw Waffenschmidt, Ana Patricia Ayala, David Moher, Matthew J Page, and Jonathan B Koffel. 2021. PRISMA-S: An Extension to the PRISMA Statement for Reporting Literature Searches in Systematic Reviews. Systematic Reviews 10: 1–19. [Google Scholar] [CrossRef]

- Rodrigues, Gonçalo, Bruno Carvalho, Andreia Reigoto, Ana Elias, Pedro Batista, Sandra Jardim, and Nuno Madeira. 2017. Training at Instituto Politécnico de Tomar: Skill Alignment to Respond to the Industry 4.0 Challenges. Superavit 2: 65–75. [Google Scholar] [CrossRef]

- Rodriguez, Leonardo, Fabian Quint, Dominic Gorecky, David Romero, and Héctor R Siller. 2015. Developing a Mixed Reality Assistance System Based on Projection Mapping Technology for Manual Operations at Assembly Workstations. Procedia Computer Science 75: 327–33. [Google Scholar] [CrossRef]

- Ross, Philip, and Kasia Maynard. 2021. Towards a 4th Industrial Revolution. Intelligent Buildings International 13: 159–61. [Google Scholar] [CrossRef]