Similitude for the Dynamic Characteristics of Dual-Rotor System with Bolted Joints

Abstract

:1. Introduction

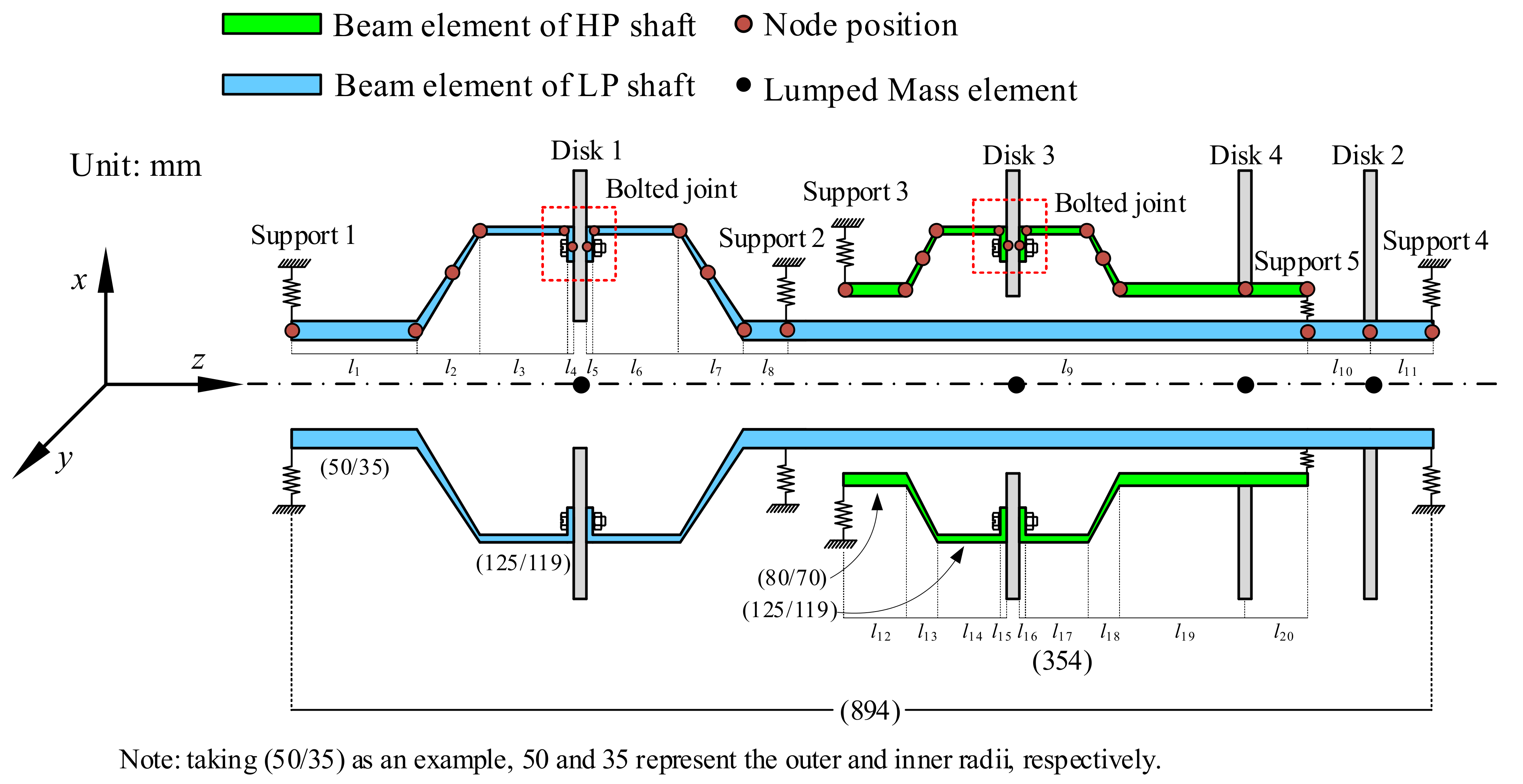

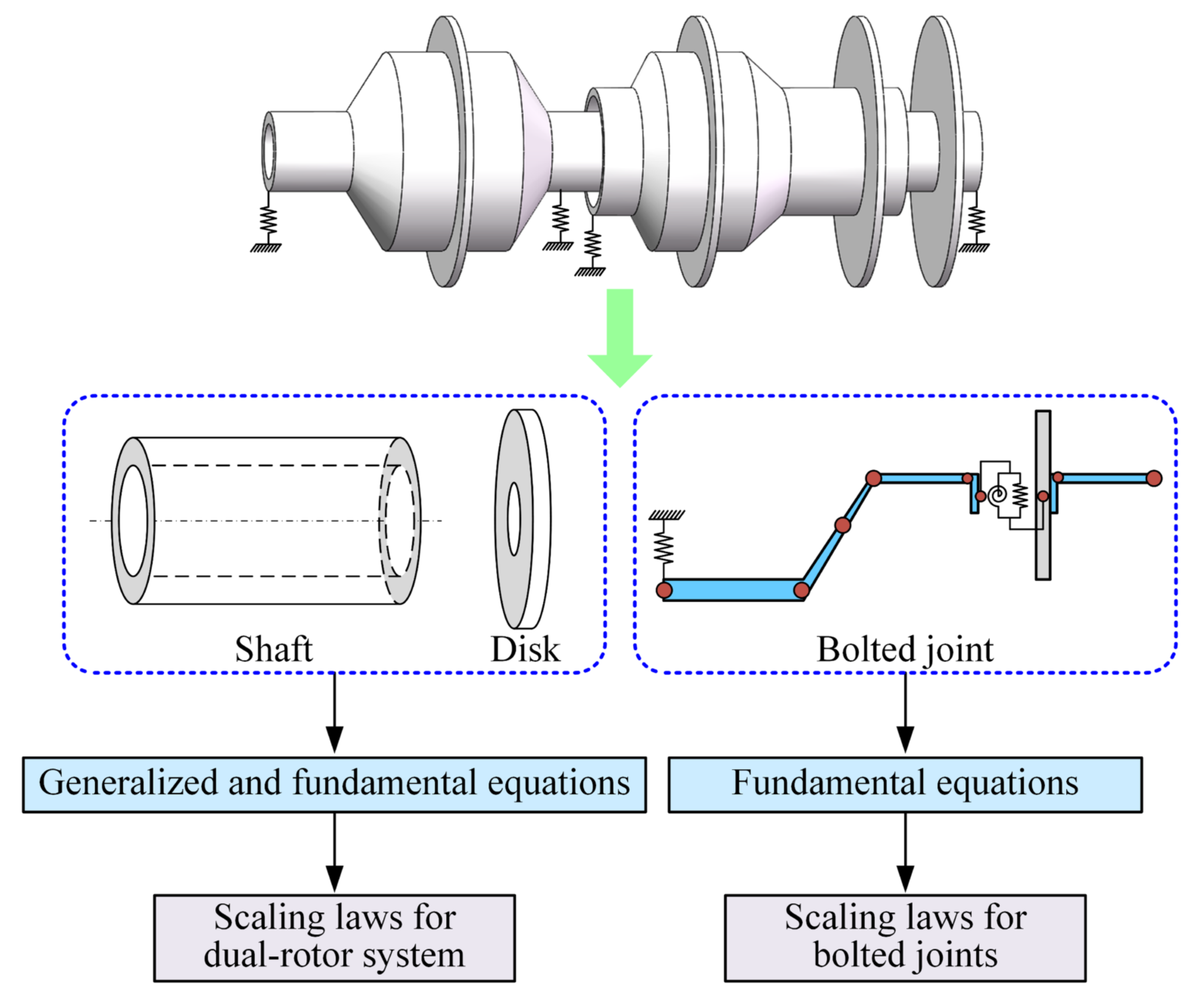

2. Dynamic Model of the Dual-Rotor System with Bolted Joints

2.1. Dual-Rotor System Model

2.2. Bolted Joint Model

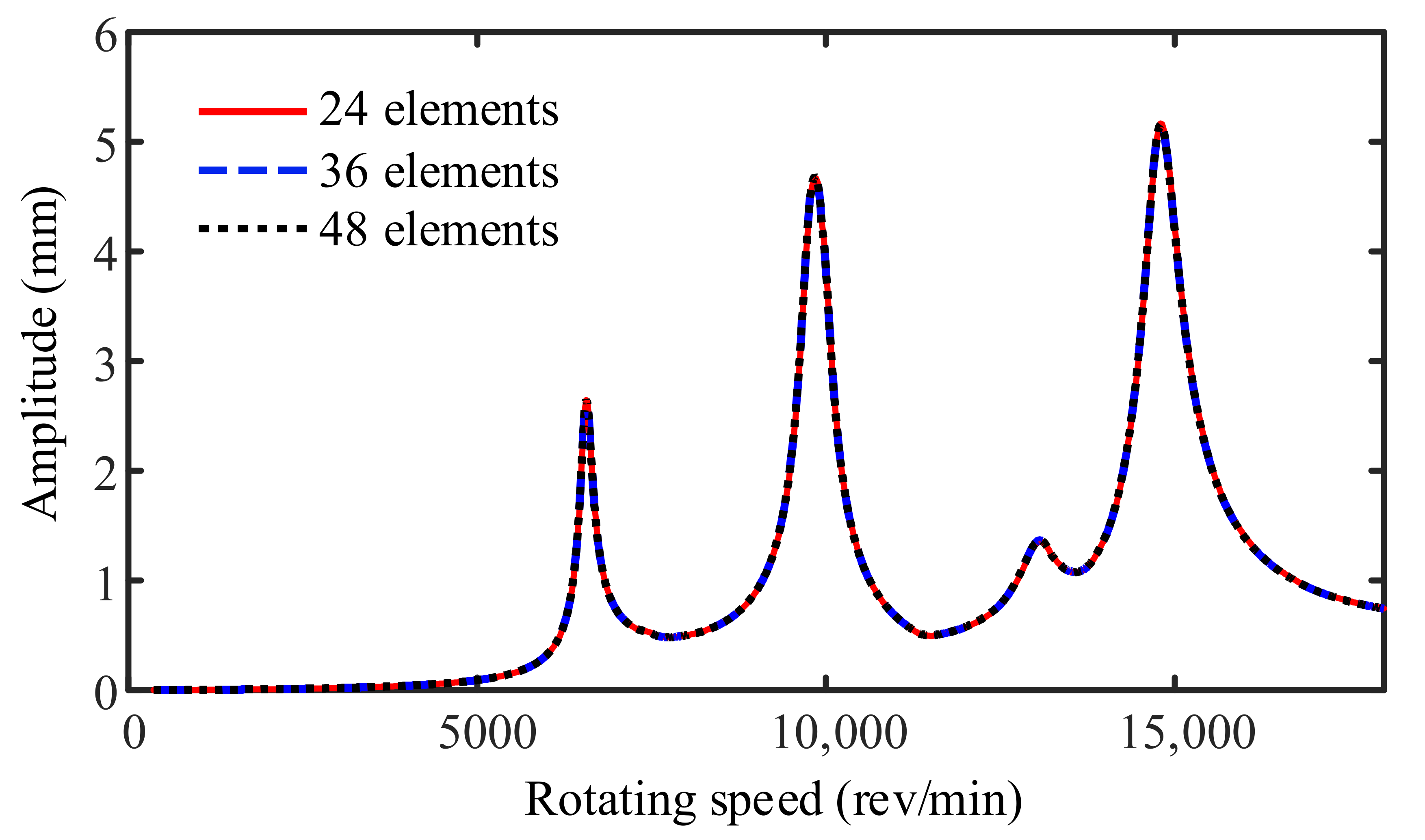

2.3. Convergence Analysis

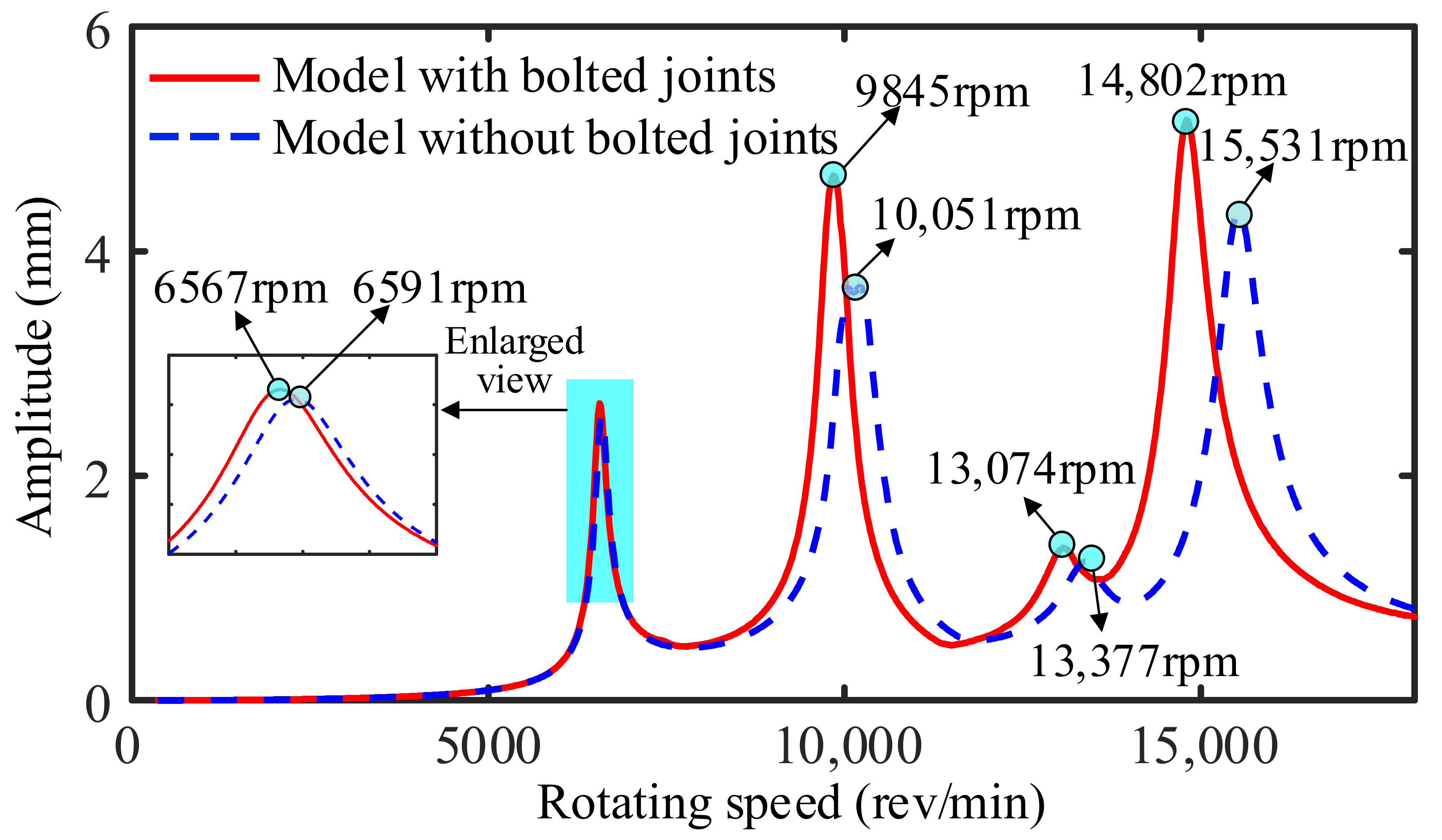

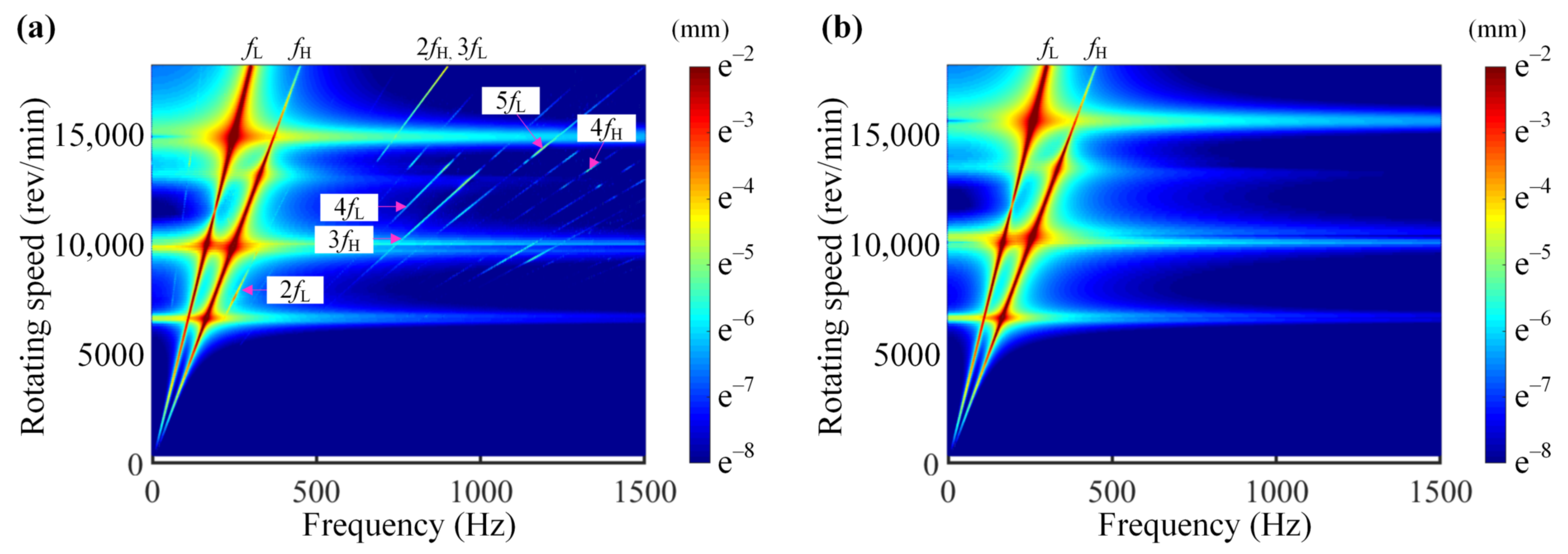

2.4. Comparison of the Dual-Rotor System with and without Bolted Joints

3. Scaling Relationships for the Dual-Rotor System with Bolted Joints

3.1. Scaling Relationships for Dual-Rotor System

3.2. Scaling Relationships for Bolted Joints

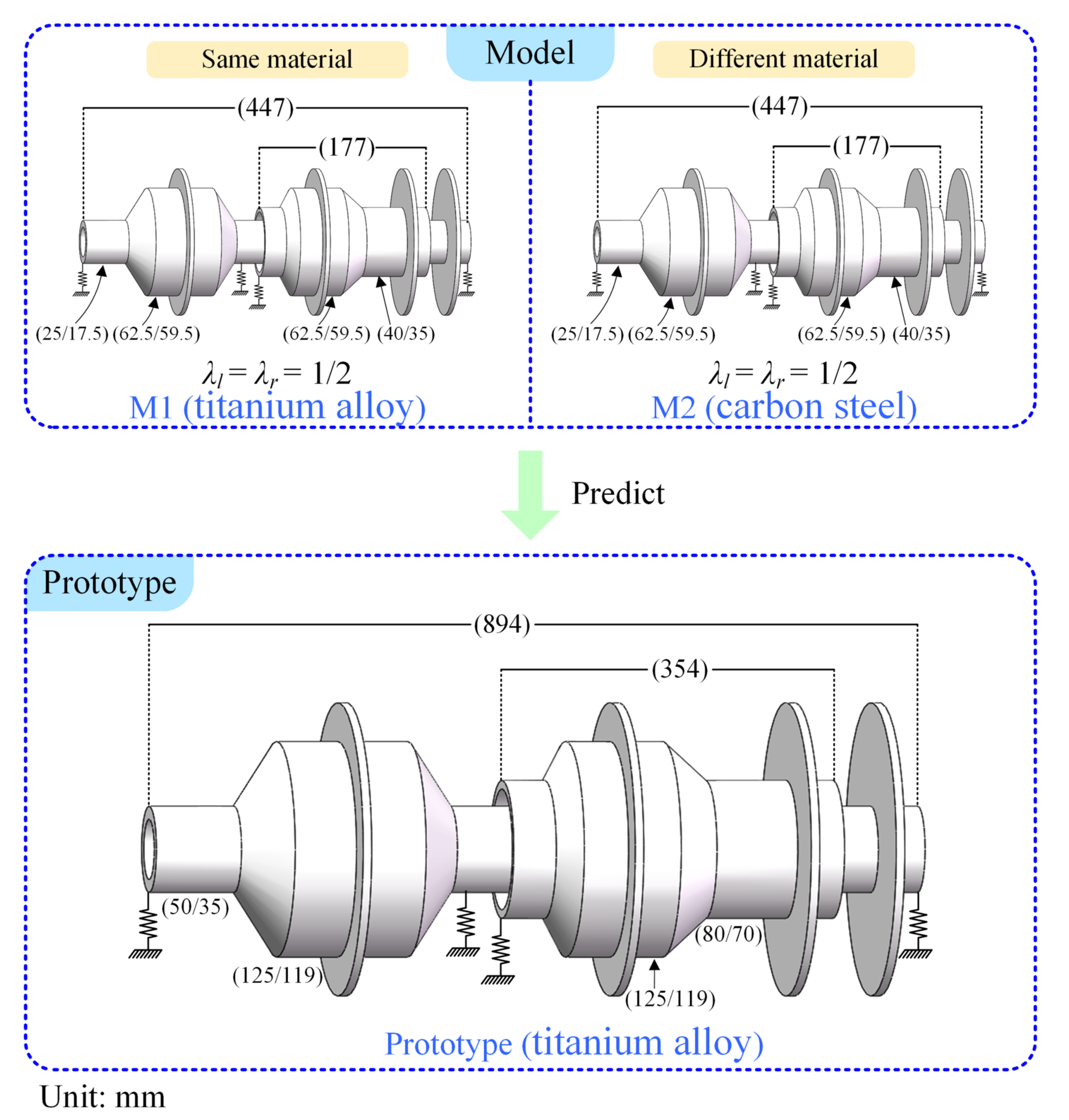

4. Verification of the Scaling Relationships

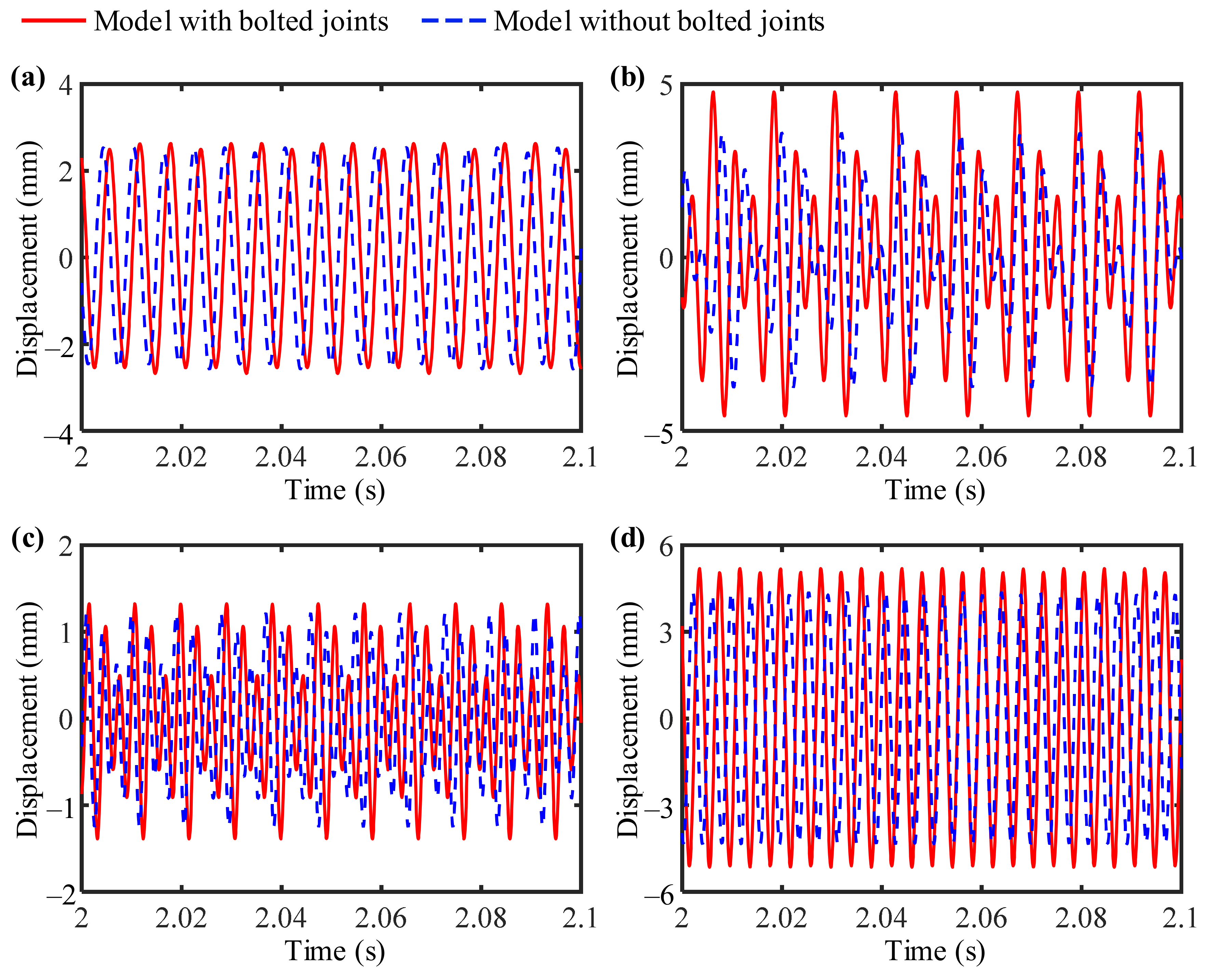

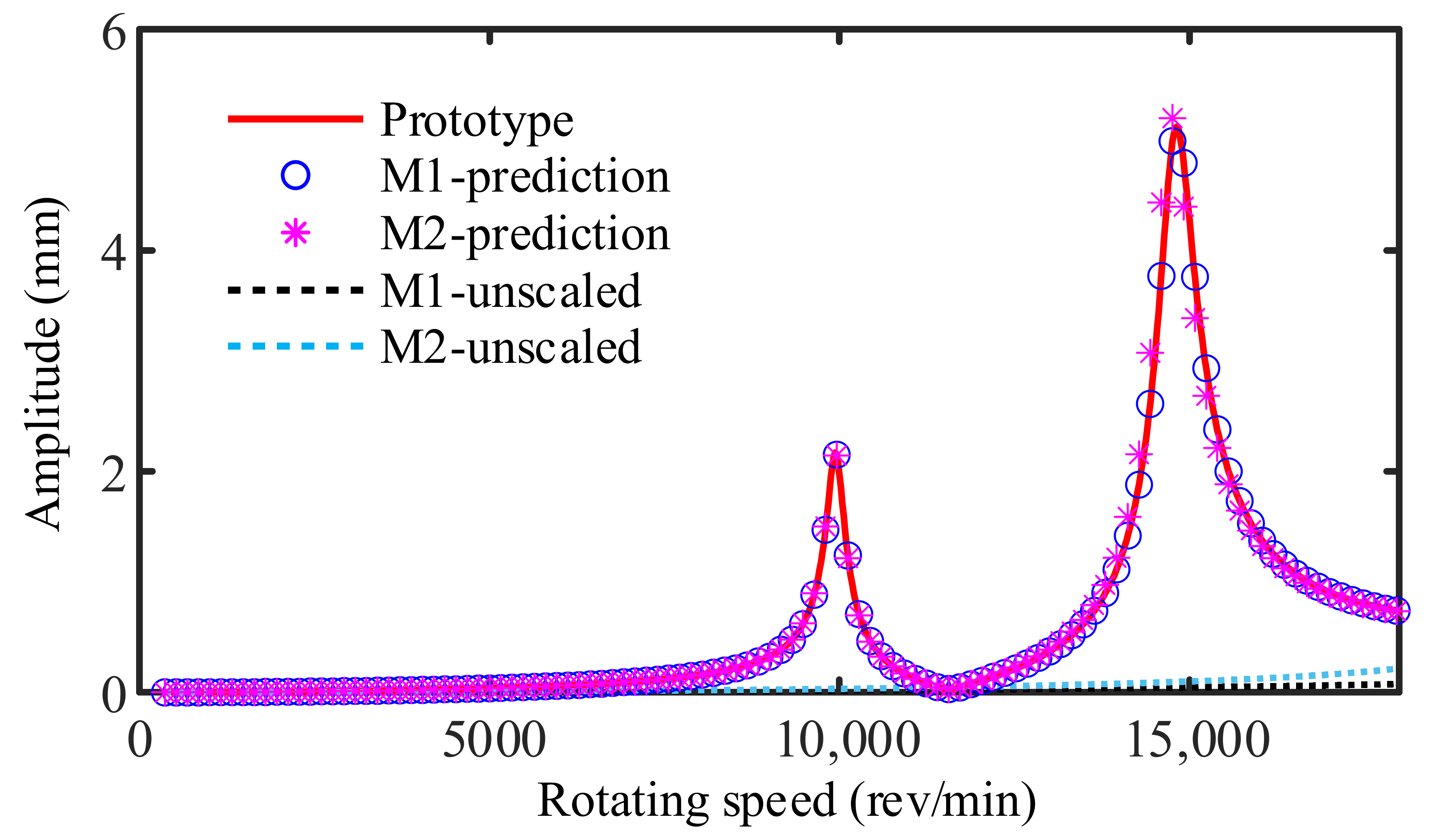

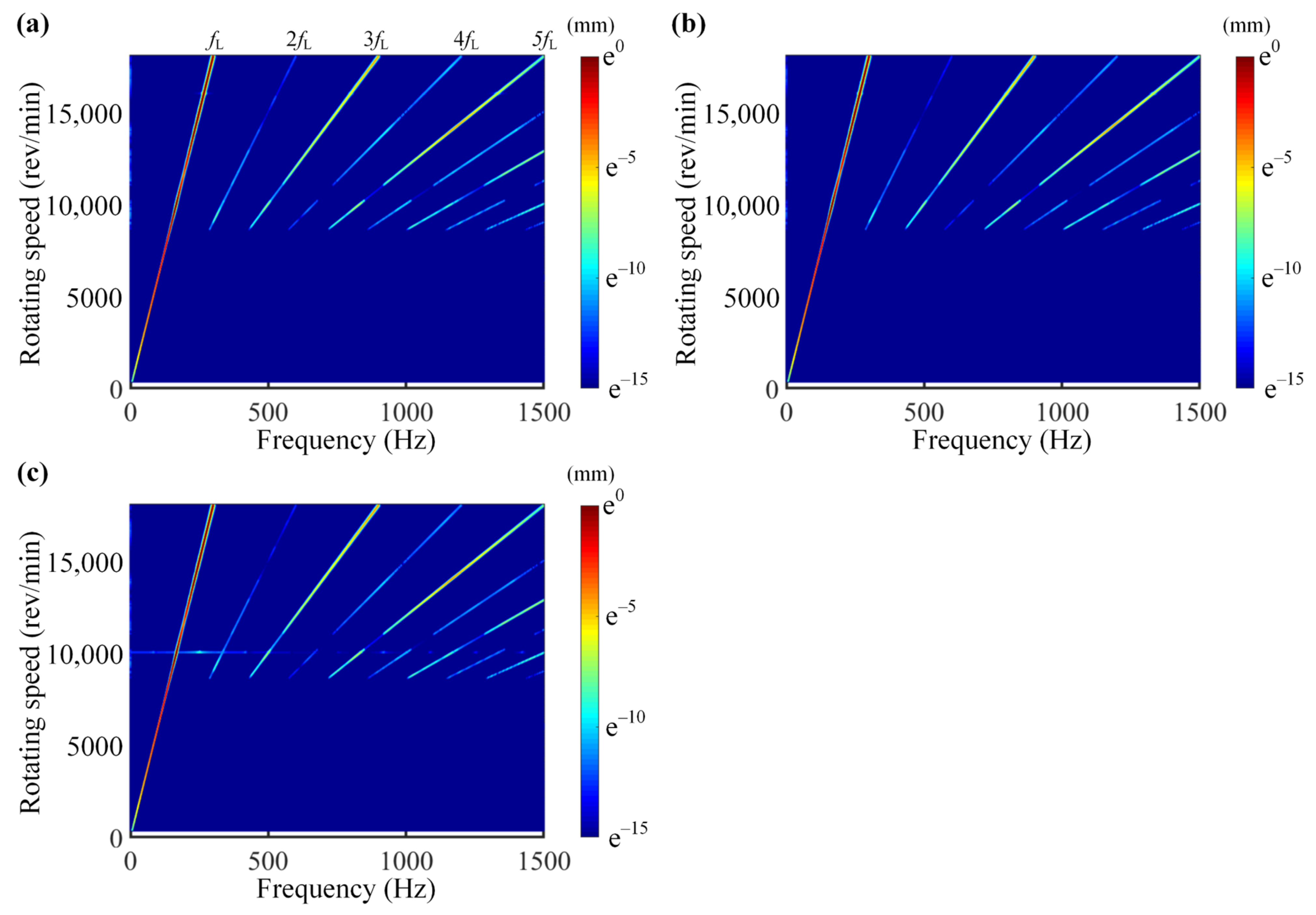

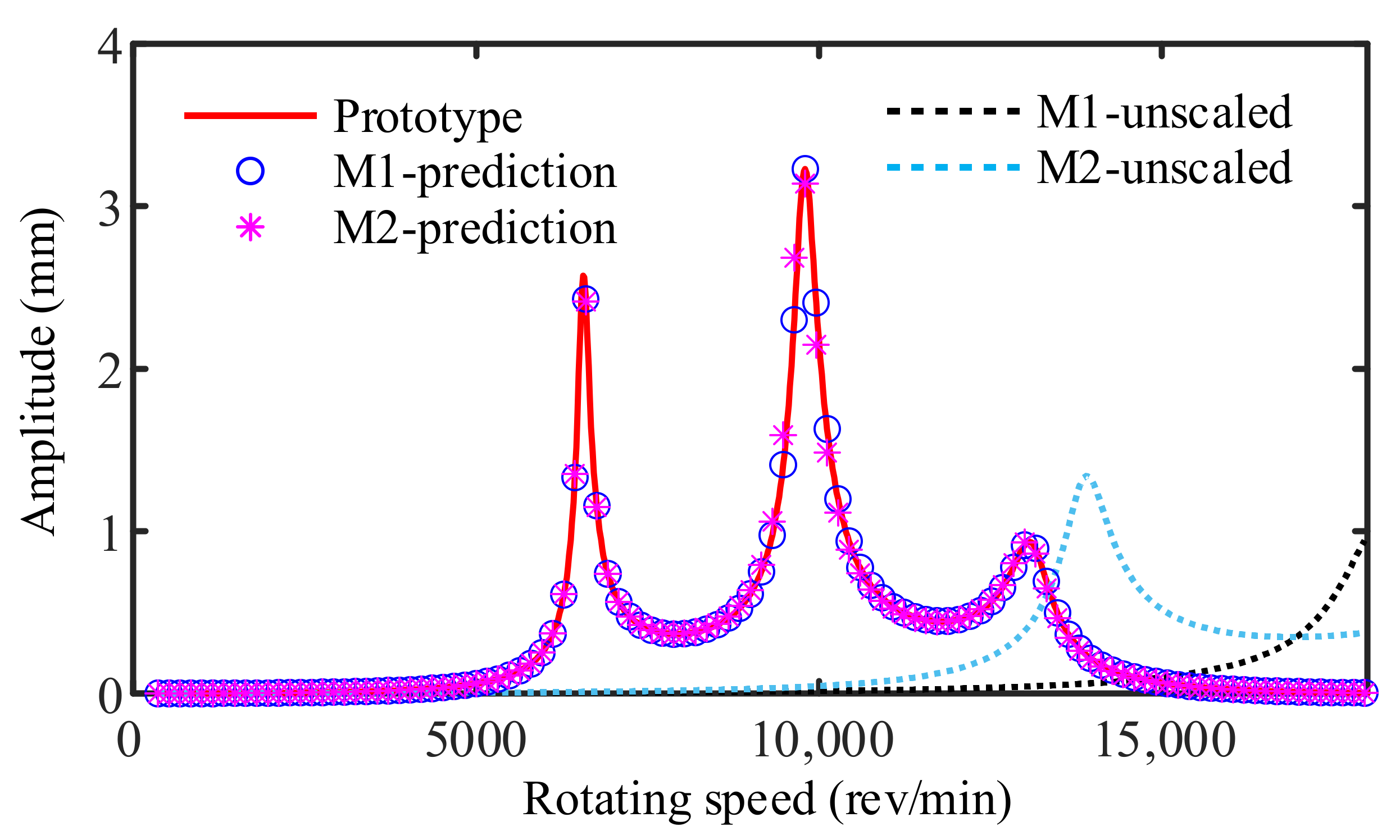

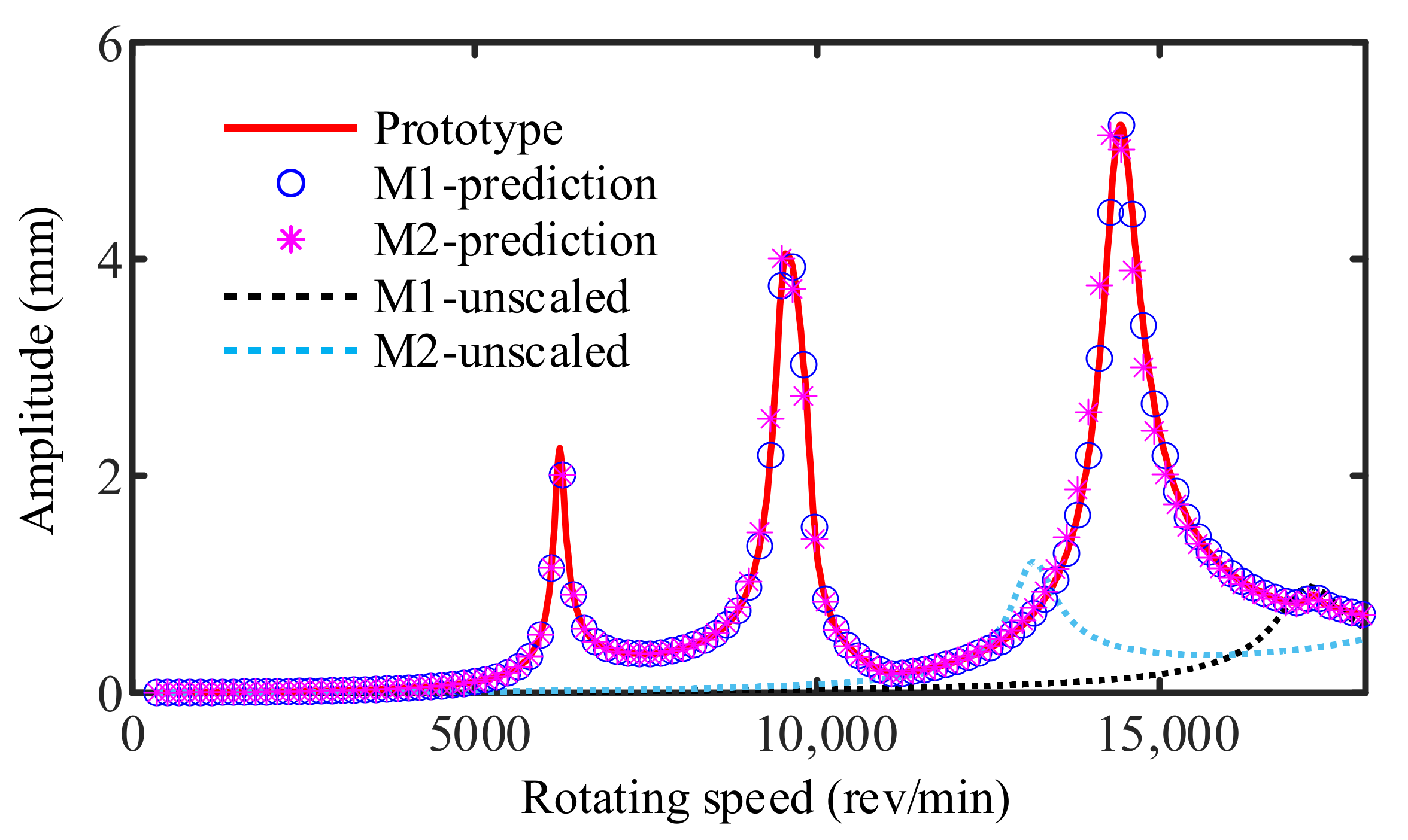

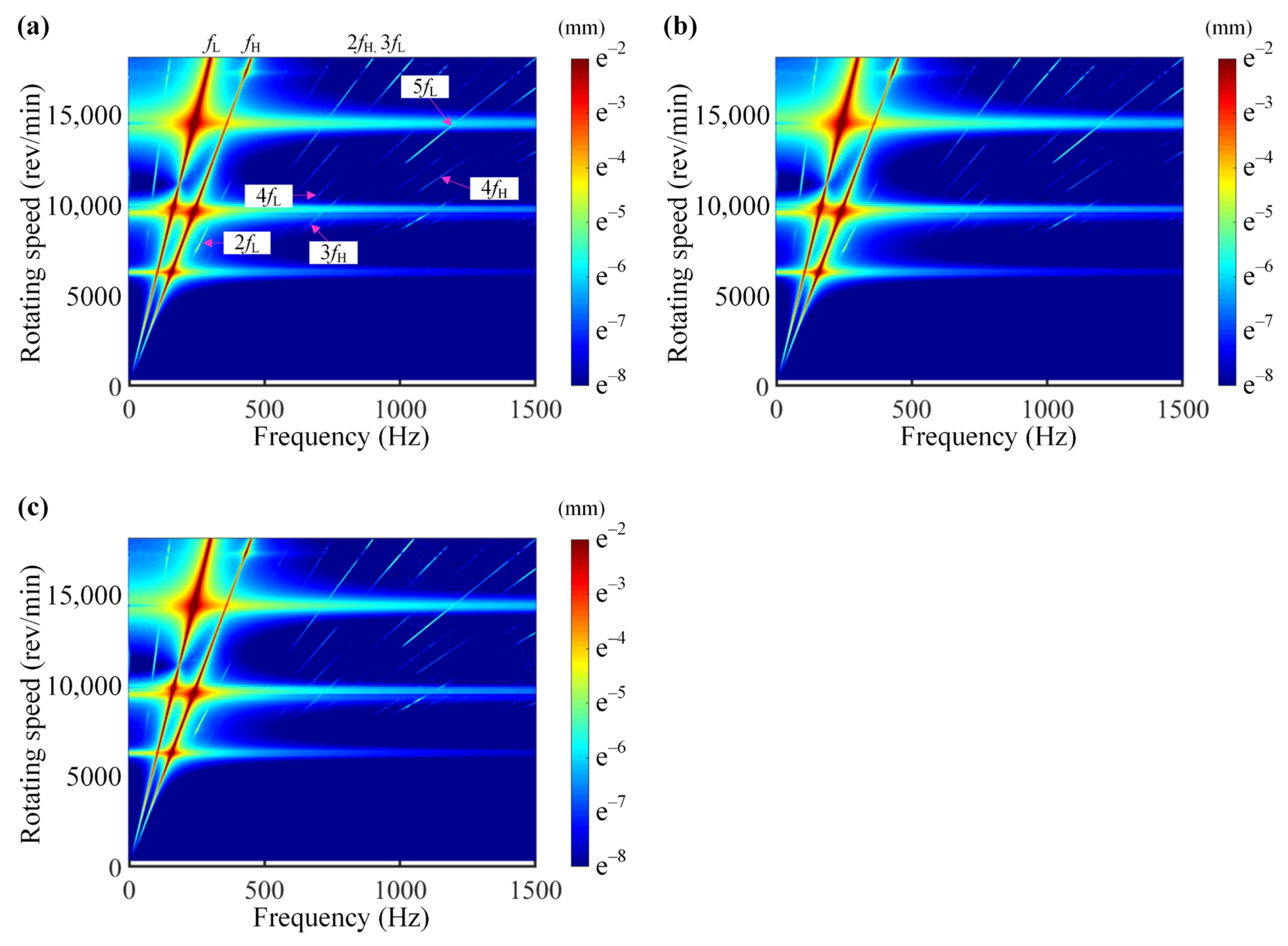

4.1. Case 1: LP Rotor Excitation

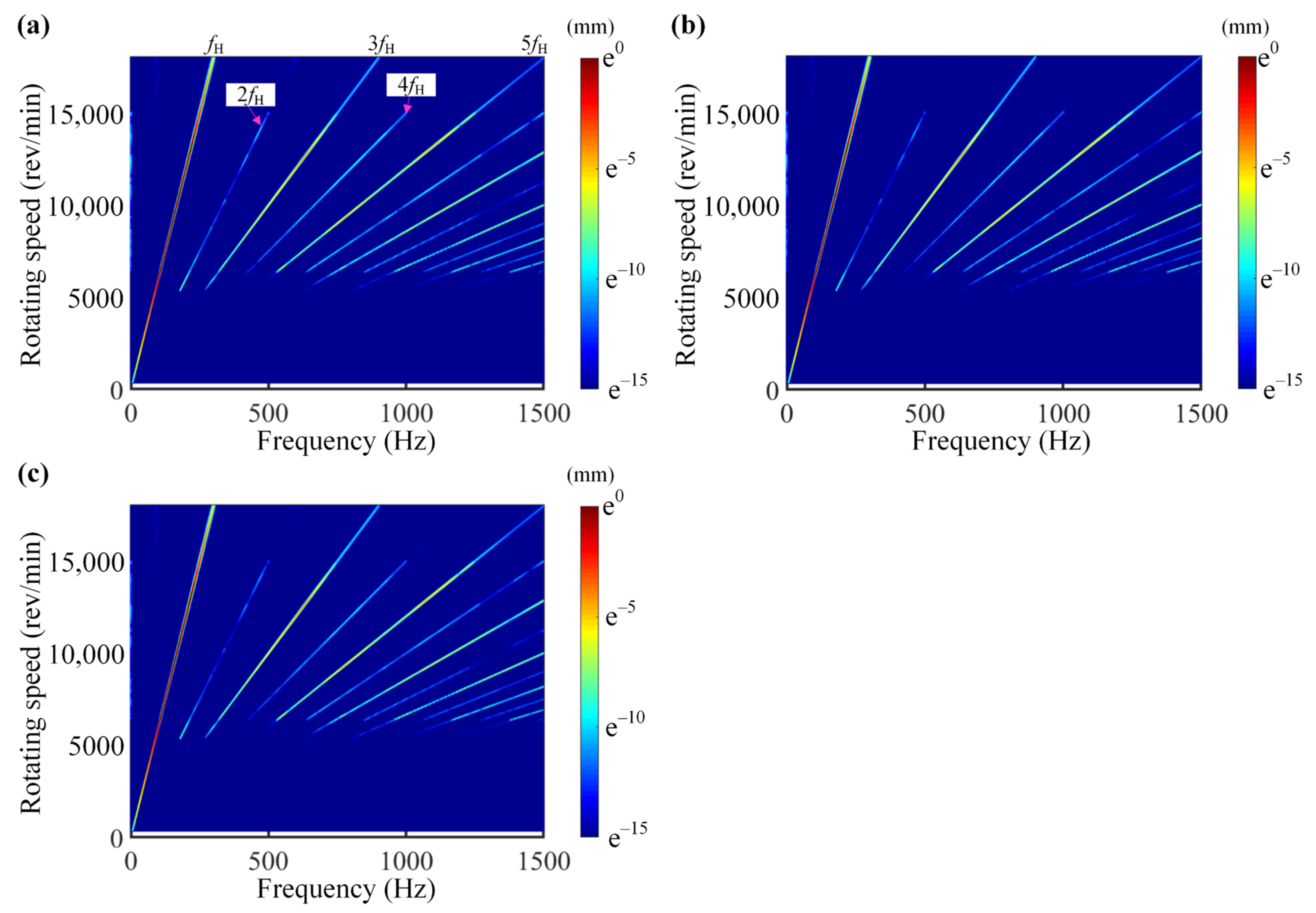

4.2. Case 2: HP Rotor Excitation

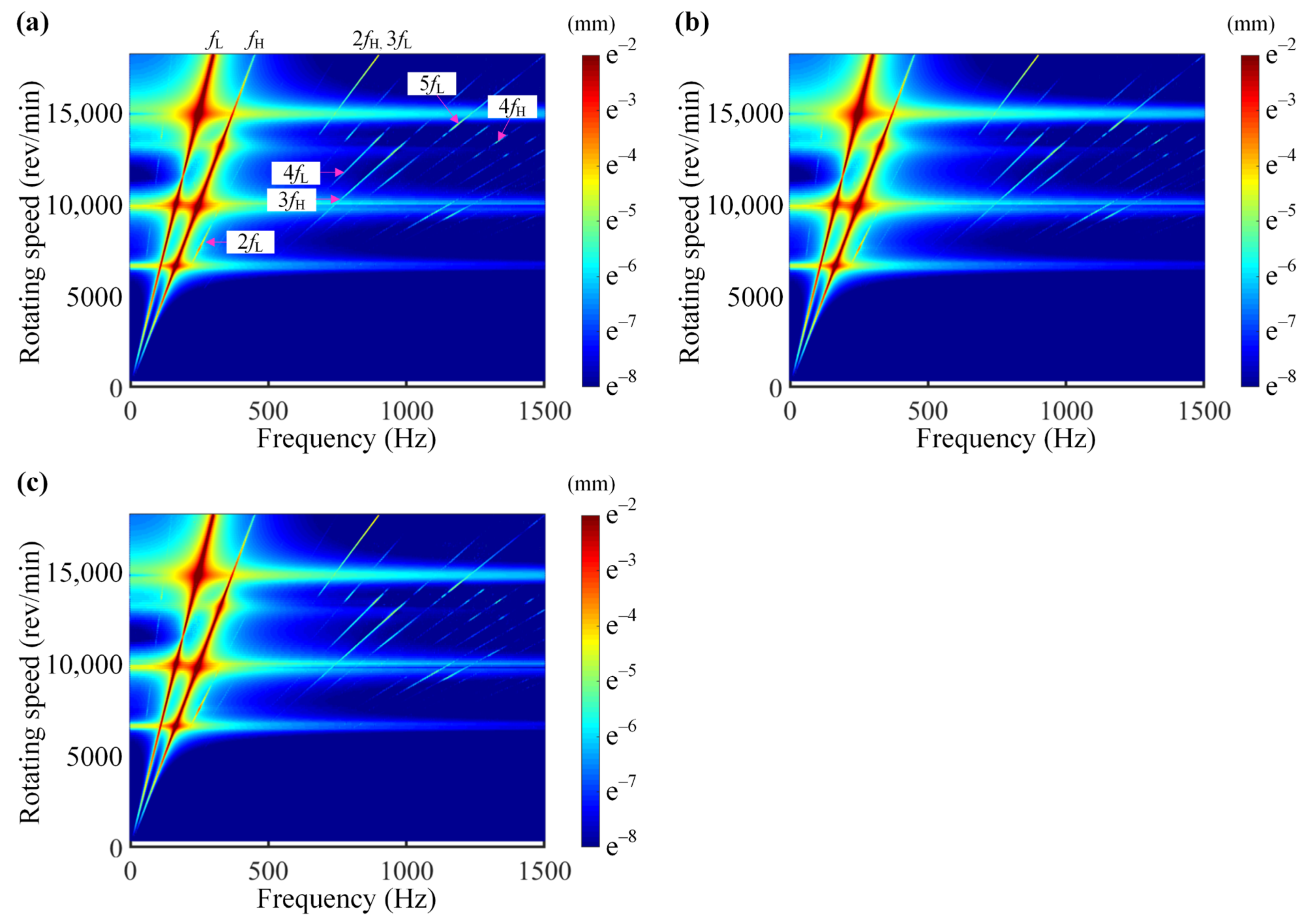

4.3. Case 3: Two Frequency Excitations

4.4. Case 4: Counter-Rotation

5. Conclusions

- The scaling relationships are developed by generalized and fundamental equations of substructures (shaft, disk, and bolted joint). The scaling factors of geometric dimensions, support parameters, critical speed, and vibration displacement are derived and can be used to design scaled models. However, as for STAGE and EM, the governing equations of the whole structure are required when deriving scaling relationships. Thus, the scaling relationships developed in this paper can reduce the calculation effort and provide the possibility for the application of complex structures.

- The effect of bolted joints on the dual-rotor system is considered. It is found that the bolted joints reduce the critical speed and lead to the emergence of frequency multiplication. Thus, the bolted joints need to be considered in similitude analysis. Aiming at this issue, the scaling relationships derived in this paper take the nonlinear stiffness of bolted joint into account for the first time.

- For the case of LP rotor excitation or HP rotor excitation, only the resonance and frequency components of the LP rotor or HP rotor can be found. As for two frequency excitations, both the resonance and frequency components of LP and HP rotors can be observed. Besides, the critical speeds decrease slightly under the case of counter-rotation. The predicted results of scaled models are compared with the results of the prototype in these cases. The results for all working conditions show that the derived scaling relationships can accurately predict the critical speeds, vibration responses, and frequency components of the prototype, even though different materials and the nonlinearity introduced by bolted joints are considered.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Roman symbols | |

| CH, CL | damping matrices of HP and LP rotors |

| cs, ks | damping and stiffness of shaft |

| E | Young’s modulus of shaft |

| e1-4 | eccentricities of disks 1–4 |

| fH, fL | rotating frequencies of HP and LP rotors |

| GH, GL | gyroscopic matrices of HP and LP rotors |

| g | gravitational acceleration |

| I | area moment of inertia of shaft |

| k, l | node numbers of the intershaft support |

| kθ1, kθ2 | stiffness of bolted joint at the first and second stages |

| kin | stiffness matrix of the intershaft support |

| KH, KL | stiffness matrices of HP and LP rotors |

| KJ | stiffness matrix of joint element |

| ld, ls | thickness of disk and length of shaft |

| M | internal bending moment of shaft |

| MH, ML | mass matrices of HP and LP rotors |

| m1-4 | mass of disks 1–4 |

| Q | shear force |

| QH, QL | force vectors of high- and low-pressure rotors |

| qJ | generalized displacement vector of joint element |

| R | ratio of rotational speed between HP and LP rotors |

| rd, rs | radii of disk and shaft |

| rLi, rLo | inner and outer radii of left end of shaft element |

| rRi, rRo | inner and outer radii of right end of shaft element |

| t | time |

| uH, uL | displacement vectors of HP and LP rotors |

| x1-28, y1-28 | displacements of nodes 1–28 in x and y directions |

| xJ, yJ | displacements of joint element in x and y directions |

| xd, ys | displacements of disk and shaft |

| Greek symbols | |

| θx1-28, θy1-28 | rotations of nodes 1–28 in x and y directions |

| θxJ, θyJ | rotations of joint element in x and y directions |

| λρ, λE | scaling factors of density and Young’s modulus |

| λl, λr, λe | scaling factors of length, radius, and eccentricity |

| λω, λΩ, λt, λx | scaling factors of critical speed, rotating speed, time, and displacement |

| λxH, λxL | scaling factors of displacement of HP and LP rotors |

| λk, λc, λkθ | scaling factors of support stiffness, damping, and bolted joint stiffness |

| λkin | scaling factor of stiffness of intershaft support |

| ρd, ρs | densities of disk and shaft |

| ϕ0, ϕ | critical rotation angle and relative rotation angle between the flange and disk |

| ΩH, ΩL | rotating speeds of HP and LP rotors |

Appendix A

| Parameter (m) | Value | Parameter (m) | Value | |||

|---|---|---|---|---|---|---|

| rLi | rLo | rRi | rRo | |||

| Length of shaft element l1 | 0.100 | Radii of shaft element l1 | 0.035 | 0.050 | 0.035 | 0.050 |

| Length of shaft element l2 | 0.050 | Radii of shaft element l2 | 0.035 | 0.050 | 0.119 | 0.125 |

| Length of shaft element l3, l6 | 0.070 | Radii of shaft element l3, l6 | 0.119 | 0.125 | 0.119 | 0.125 |

| Length of shaft element l4, l5 | 0.002 | Radii of shaft element l4, l5 | 0.105 | 0.125 | 0.105 | 0.125 |

| Length of shaft element l7 | 0.050 | Radii of shaft element l7 | 0.119 | 0.125 | 0.035 | 0.050 |

| Length of shaft element l8, l10, l11 | 0.050 | Radii of shaft element l8, l10, l11 | 0.035 | 0.050 | 0.035 | 0.050 |

| Length of shaft element l9 | 0.400 | Radii of shaft element l9 | 0.035 | 0.050 | 0.035 | 0.050 |

| Length of shaft element l12, l20 | 0.050 | Radii of shaft element l12, l20 | 0.070 | 0.080 | 0.070 | 0.080 |

| Length of shaft element l13 | 0.025 | Radii of shaft element l13 | 0.070 | 0.080 | 0.119 | 0.125 |

| Length of shaft element l14, l17 | 0.050 | Radii of shaft element l14, l17 | 0.119 | 0.125 | 0.119 | 0.125 |

| Length of shaft element l15, l16 | 0.002 | Radii of shaft element l15, l16 | 0.105 | 0.125 | 0.105 | 0.125 |

| Length of shaft element l18 | 0.025 | Radii of shaft element l18 | 0.119 | 0.125 | 0.070 | 0.080 |

| Length of shaft element l19 | 0.100 | Radii of shaft element l19 | 0.070 | 0.080 | 0.070 | 0.080 |

| Parameter (m) | Value | Parameter (m) | Value |

|---|---|---|---|

| Mass of disks 1 and 2 (kg) | 7.22 | Moment of inertia of disks 1 and 2 (kg.m2) | 0.11 |

| Mass of disk 3 (kg) | 6.56 | Moment of inertia of disk 3 (kg.m2) | 0.11 |

| Mass of disk 4 (kg) | 6.15 | Moment of inertia of disk 4 (kg.m2) | 0.11 |

| Support stiffness k1, k2, k3, k4 (N/m) | 2 × 107 | Support damping c1, c2, c3, c4, c5 (N/m) | 500 |

| Support stiffness kin (N/m) | 4 × 107 | Density (kg/m3) | 4350 |

| Elastic modulus (GPa) | 105 | Poisson ratio | 0.26 |

References

- Yu, P.C.; Zhang, D.Y.; Ma, Y.H.; Hong, J. Dynamic modeling and vibration characteristics analysis of the aero-engine dual-rotor system with Fan blade out. Mech. Syst. Sig. Process. 2018, 106, 158–175. [Google Scholar] [CrossRef]

- Wang, N.F.; Jiang, D.X. Vibration response characteristics of a dual-rotor with unbalance-misalignment coupling faults: Theoretical analysis and experimental study. Mech. Mach. Theory 2018, 125, 207–219. [Google Scholar] [CrossRef]

- Sun, G.; Palazzolo, A.; Provenza, A.; Lawrence, C.; Carney, K. Long duration blade loss simulations including thermal growths for dual-rotor gas turbine engine. J. Sound Vib. 2008, 316, 147–163. [Google Scholar] [CrossRef]

- Bab, S.; Najafi, M.; Fathi Sola, J.; Abbasi, A. Annihilation of non-stationary vibration of a gas turbine rotor system under rub-impact effect using a nonlinear absorber. Mech. Mach. Theory 2019, 139, 379–406. [Google Scholar] [CrossRef]

- Hong, J.; Chen, X.Q.; Wang, Y.F.; Ma, Y.H. Optimization of dynamics of non-continuous rotor based on model of rotor stiffness. Mech. Syst. Sig. Process. 2019, 131, 166–182. [Google Scholar] [CrossRef]

- Liu, S.G.; Ma, Y.H.; Zhang, D.Y.; Hong, J. Studies on dynamic characteristics of the joint in the aero-engine rotor system. Mech. Syst. Sig. Process. 2012, 29, 120–136. [Google Scholar] [CrossRef]

- Asl, M.E.; Niezrecki, C.; Sherwood, J.; Avitabile, P. Vibration prediction of thin-walled composite I-beams using scaled models. Thin Walled Struct. 2017, 113, 151–161. [Google Scholar] [CrossRef] [Green Version]

- Asl, M.E.; Niezrecki, C.; Sherwood, J.; Avitabile, P. Experimental and theoretical similitude analysis for flexural bending of scaled-down laminated I-beams. Compos. Struct. 2017, 176, 812–822. [Google Scholar] [CrossRef]

- Kasivitamnuay, J.; Singhatanadgid, P. Scaling laws for displacement of elastic beam by energy method. Int. J. Mech. Sci. 2017, 128, 361–367. [Google Scholar] [CrossRef]

- Kasivitamnuay, J.; Singhatanadgid, P. Scaling laws for static displacement of linearly elastic cracked beam by energy method. Theor. Appl. Fract. Mech. 2018, 98, 157–166. [Google Scholar] [CrossRef]

- Coutinho, C.P.; Baptista, A.J.; Rodriges, J.D. Modular approach to structural similitude. Int. J. Mech. Sci. 2018, 135, 294–312. [Google Scholar] [CrossRef]

- Yazdi, A.A. Study nonlinear vibration of cross- ply laminated plates using scale models. Polym. Composite. 2014, 35, 752–758. [Google Scholar] [CrossRef]

- Rezaeepazhand, J.; Yazdi, A.A. Similitude requirements and scaling laws for flutter prediction of angle-ply composite plates. Compos. Part B: Eng. 2011, 42, 51–56. [Google Scholar] [CrossRef]

- Frostig, Y.; Simitses, G.J. Similitude of sandwich panels with a soft core in buckling. Compos. Part B: Eng. 2004, 35, 599–608. [Google Scholar] [CrossRef]

- Singhatanadgid, P.; Songkhla, A.N. An experimental investigation into the use of scaling laws for predicting vibration responses of rectangular thin plates. J. Sound Vib. 2008, 311, 314–327. [Google Scholar] [CrossRef]

- De Rosa, S.; Franco, F. A scaling procedure for the response of an isolated system with high modal overlap factor. Mech. Syst. Sig. Process. 2008, 22, 1549–1565. [Google Scholar] [CrossRef]

- Franco, F.; Robin, O.; Ciappi, E.; De Rosa, S.; Berry, A.; Petrone, G. Similitude laws for the structural response of flat plates under a turbulent boundary layer excitation. Mech. Syst. Sig. Process. 2019, 129, 590–613. [Google Scholar] [CrossRef]

- Mazzariol, L.M.; Alves, M. Similarity laws of structures under impact load: Geometric and material distortion. Int. J. Mech. Sci. 2019, 157, 633–647. [Google Scholar] [CrossRef]

- Petrone, G.; Manfredonia, M.; De Rosa, S.; Franco, F. Structural similitudes of stiffened cylinders. Math. Mech. Solids 2019, 24, 527–541. [Google Scholar] [CrossRef]

- Rezaeepazhand, J.; Simitses, G.J.; Starnes, J.H. Design of scaled down models for predicting shell vibration response. J. Sound Vib. 1996, 195, 301–311. [Google Scholar] [CrossRef]

- Rezaeepazhand, J.; Simitses, G.J.; Starnes, J.H. Scale models for laminated cylindrical shells subjected to axial compression. Compos. Struct. 1996, 34, 371–379. [Google Scholar] [CrossRef]

- Ungbhakorn, V.; Wattanasakulpong, N. Structural similitude and scaling laws of anti-symmetric cross-ply laminated cylindrical shells for buckling and vibration experiments. Int. J. Struct. Stab. Dyn. 2007, 7, 609–627. [Google Scholar] [CrossRef]

- De Rosa, S.; Franco, F.; Polito, T. Structural similitudes for the dynamic response of plates and assemblies of plates. Mech. Syst. Sig. Process. 2011, 25, 969–980. [Google Scholar] [CrossRef]

- De Rosa, S.; Franco, F. On the use of the asymptotic scaled modal analysis for time-harmonic structural analysis and for the prediction of coupling loss factors for similar systems. Mech. Syst. Sig. Process. 2010, 24, 455–480. [Google Scholar] [CrossRef]

- De Rosa, S.; Franco, F.; Polito, T. Partial scaling of finite element models for the analysis of the coupling between short and long structural wavelengths. Mech. Syst. Sig. Process. 2015, 52–53, 722–740. [Google Scholar] [CrossRef]

- You, C.; Yasaee, M.; Dayyani, I. Structural similitude design for a scaled composite wing box based on optimised stacking sequence. Compos. Struct. 2019, 226, 111255. [Google Scholar] [CrossRef]

- Song, Y.Y.; Wu, J.; Yu, G.; Huang, T. Dynamic characteristic prediction of a 5-DOF hybrid machine tool by using scale model considering the geometric distortion of bearings. Mech. Mach. Theory 2020, 145, 103679. [Google Scholar] [CrossRef]

- Wu, J.J. Prediction of lateral vibration characteristics of a full-size rotor-bearing system by using those of its scale models. Finite Elem. Anal. Des. 2007, 43, 803–816. [Google Scholar] [CrossRef]

- Li, L.; Luo, Z.; He, F.X.; Sun, K.; Yan, X.L. An improved partial similitude method for dynamic characteristic of rotor systems based on Levenberg–Marquardt method. Mech. Syst. Sig. Process. 2022, 165, 108405. [Google Scholar] [CrossRef]

- Casaburo, A.; Petrone, G.; Franco, F.; De Rosa, S. A review of similitude methods for structural engineering. Appl. Mech. Rev. 2019, 71, 30802. [Google Scholar] [CrossRef] [Green Version]

- Rezaeepazhand, J.; Simitses, G.J.; Starnes, J.H. Use of scaled-down models for predicting vibration response of laminated plates. Compos. Struct. 1995, 30, 419–426. [Google Scholar] [CrossRef]

- Yazdi, A.A.; Rezaeepazhand, J. Structural similitude for flutter of delaminated composite beam-plates. Compos. Struct. 2011, 93, 1918–1922. [Google Scholar] [CrossRef]

- Ungbhakorn, V.; Singhatanadgid, P. A scaling law for vibration response of laminated doubly curved shallow shells by energy approach. Mech. Adv. Mater. Struc. 2009, 16, 333–344. [Google Scholar] [CrossRef]

- De Rosa, S.; Franco, F.; Li, X.; Polito, T. A similitude for structural acoustic enclosures. Mech. Syst. Sig. Process. 2012, 30, 330–342. [Google Scholar] [CrossRef]

- De Rosa, S.; Franco, F.; Meruane, V. Similitudes for the structural response of flexural plates. Proc. IMechE Part C J. Mech. Eng. Sci. 2016, 230, 174–188. [Google Scholar] [CrossRef] [Green Version]

- Adams, C.; Bos, J.; Slomski, E.M.; Melz, T. Scaling laws obtained from a sensitivity analysis and applied to thin vibrating structures. Mech. Syst. Sig. Process. 2018, 110, 590–610. [Google Scholar] [CrossRef]

- Qin, Z.Y.; Han, Q.K.; Chu, F.L. Analytical model of bolted disk–drum joints and its application to dynamic analysis of jointed rotor. Proc. IMechE Part C J. Mech. Eng. Sci. 2014, 228, 646–663. [Google Scholar] [CrossRef]

- Li, Y.Q.; Luo, Z.; Liu, J.X.; Ma, H.; Yang, D.S. Dynamic modeling and stability analysis of a rotor-bearing system with bolted-disk joint. Mech. Syst. Sig. Process. 2021, 158, 107778. [Google Scholar] [CrossRef]

- Shanmugam, A.; Padmanabhan, C. A fixed–free interface component mode synthesis method for rotordynamic analysis. J. Sound Vib. 2006, 297, 664–679. [Google Scholar] [CrossRef]

- Li, C.F.; Qiao, R.H.; Tang, Q.S.; Miao, X.Y. Investigation on the vibration and interface state of a thin-walled cylindrical shell with bolted joints considering its bilinear stiffness. Appl. Acoust. 2021, 172, 107580. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| kθ1 (N∙m/rad) | 3.16 × 107 |

| kθ2 (N∙m/rad) | 2.70 × 106 |

| ϕ0 (rad) | 1.42 × 10−5 |

| Model | λl (λr) | λρ | λE | λc | λk | λω (λΩ) | λt | λx (λe) | λkθ |

|---|---|---|---|---|---|---|---|---|---|

| M1 | 0.5 | 1 | 1 | 0.25 | 0.5 | 2 | 0.5 | 0.5 | 0.125 |

| M2 | 0.5 | 1.8 | 2 | 0.47 | 1 | 2.11 | 0.47 | 0.45 | 0.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Luo, Z.; He, F.; Qin, Z.; Li, Y.; Yan, X. Similitude for the Dynamic Characteristics of Dual-Rotor System with Bolted Joints. Mathematics 2022, 10, 3. https://doi.org/10.3390/math10010003

Li L, Luo Z, He F, Qin Z, Li Y, Yan X. Similitude for the Dynamic Characteristics of Dual-Rotor System with Bolted Joints. Mathematics. 2022; 10(1):3. https://doi.org/10.3390/math10010003

Chicago/Turabian StyleLi, Lei, Zhong Luo, Fengxia He, Zhaoye Qin, Yuqi Li, and Xiaolu Yan. 2022. "Similitude for the Dynamic Characteristics of Dual-Rotor System with Bolted Joints" Mathematics 10, no. 1: 3. https://doi.org/10.3390/math10010003

APA StyleLi, L., Luo, Z., He, F., Qin, Z., Li, Y., & Yan, X. (2022). Similitude for the Dynamic Characteristics of Dual-Rotor System with Bolted Joints. Mathematics, 10(1), 3. https://doi.org/10.3390/math10010003