Using Regression Analysis for Automated Material Selection in Smart Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

2.1. The General Methodology

2.2. The Direct Problem

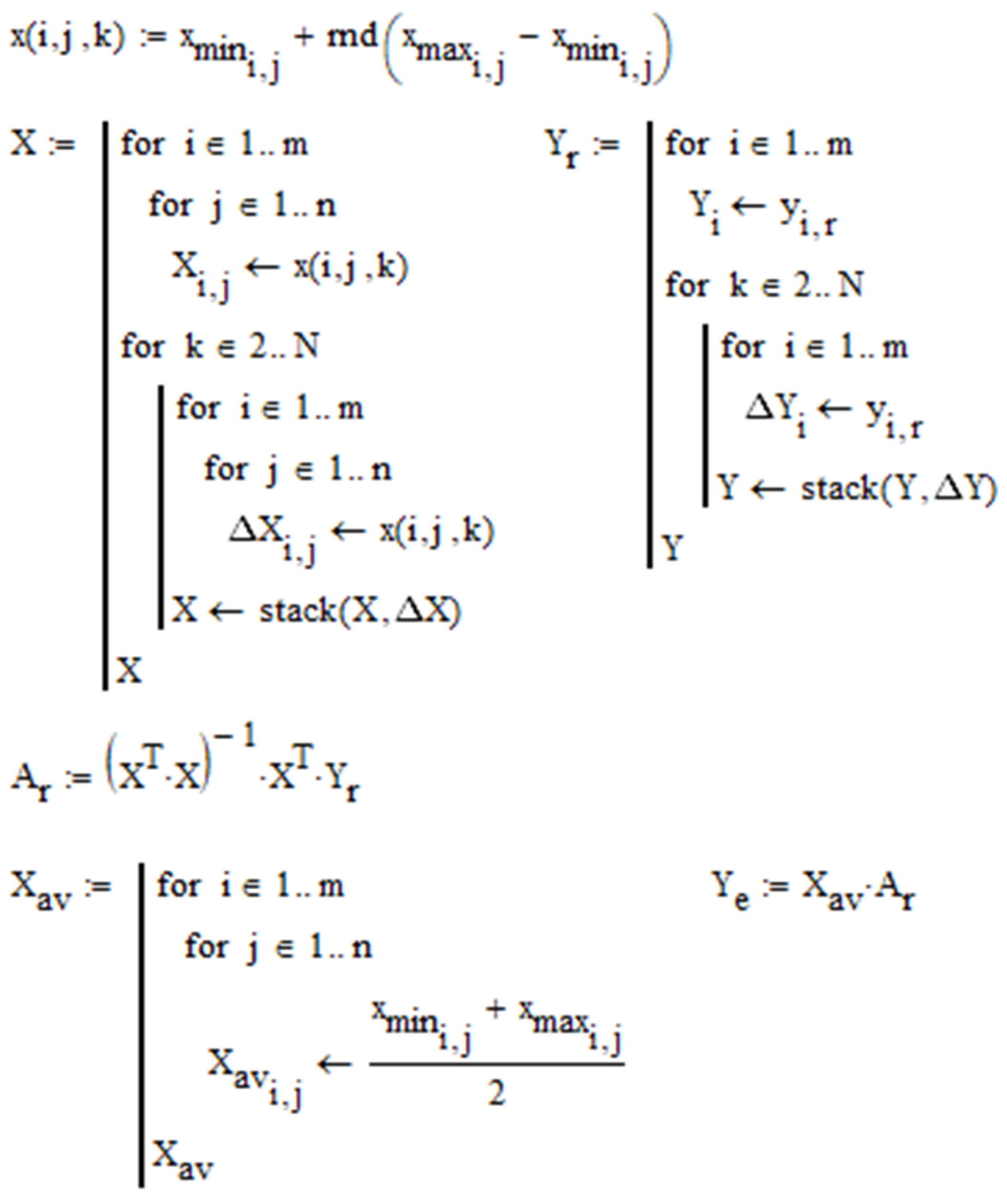

2.3. The Inverse Problem

2.4. Estimation Accuracy

3. Results

3.1. Regression Dependencies

3.2. Rational Choice of the Material

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Harisha, M.S.; Ramesh, D.K.; Jayalakshmi, N. A study on design modification and validation by static and dynamic load analysis of SAE-1020 and 40C8 grade steel connecting rods of 4-stroke petrol engine. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2021; Volume 2316, p. 030027. [Google Scholar] [CrossRef]

- Dulucheanu, C.; Severin, T.L.; Cerlinca, D.A.; Irimescu, L. Structures and mechanical properties of some dual-phase steels with low manganese content. Metals 2022, 12, 189. [Google Scholar] [CrossRef]

- Bakhoum, E.S.; Brown, D.C. An automated decision support system for sustainable selection of structural materials. Int. J. Sustain. Eng. 2015, 8, 80–92. [Google Scholar] [CrossRef]

- Kolesnyk, V.; Peterka, J.; Alekseev, O.; Neshta, A.; Xu, J.; Lysenko, B.; Sahul, M.; Martinovic, J.; Hrbal, J. Application of ANN for analysis of hole accuracy and drilling temperature when drilling CFRP/Ti alloy stacks. Materials 2022, 15, 1940. [Google Scholar] [CrossRef] [PubMed]

- Mafokwane, S.Z.; von Kallon, D.V. Material Selection of a Tri-adjustable Automated Heavy-duty Handling System Designed on Industry 4.0 Principles. In Proceedings of the 2nd South American Conference on Industrial Engineering and Operations Management, IEOM 2021, São Paulo, Brazil, 5–8 April 2021; pp. 1606–1607. [Google Scholar]

- Ivchenko, O.; Ivanov, V.; Trojanowska, J.; Zhyhylii, D.; Ciszak, O.; Zaloha, O.; Pavlenko, I.; Hladyshev, D. Method for an effective selection of tools and cutting conditions during precise turning of non alloy quality steel C45. Materials 2022, 15, 505. [Google Scholar] [CrossRef] [PubMed]

- Kazemzadeh Azad, S.; Akış, T. Automated selection of optimal material for pressurized multi-layer composite tubes based on an evolutionary approach. Neural Comput. Appl. 2018, 29, 405–416. [Google Scholar] [CrossRef]

- Jghamou, A.; Lahbabi, S.; Riane, F. Automated Decisional Process for Material and Equipment Selection: Application to the Selection of Material for Water Pipes. In Proceedings of the 11th Annual International Conference on Industrial Engineering and Operations Management, IEOM 2021, Singapore, 7–11 May 2021; pp. 5872–5883. [Google Scholar]

- Akhmedzyanov, D.A.; Kishalov, A.E.; Markina, K.V. Automated Selection of the Material a Fan Blade PS-90A. In Proceedings of the 30th Congress of the International Council of the Aeronautical Sciences, ICAS 2016, Daejeon, Korea, 25–30 September 2016; p. 126186. [Google Scholar]

- Srinivasan, S.; Kane, R.D.; Skogsberg, J.W. Automated material selection and equipment specification system for oil and gas production: Concept, development, implementation. NACE-Int. Corros. Conf. Ser. 2003, 2003, 135912. [Google Scholar]

- Veldenz, L.; di Francesco, M.; Giddings, P.; Kim, B.C.; Potter, K. Material selection for automated dry fiber placement using the analytical hierarchy process. Adv. Manuf. Polym. Compos. Sci. 2018, 4, 83–96. [Google Scholar] [CrossRef] [Green Version]

- Panchuk, V.; Onysko, O.; Kotwica, K.; Barz, C.; Borushchak, L. Prediction of the accuracy of the tapered thread profile. J. Eng. Sci. 2021, 8, B1–B6. [Google Scholar] [CrossRef]

- Seo, S.; Tucker, S.; Newton, P. Automated material selection and environmental assessment in the context of 3D building modelling. J. Green Build. 2007, 2, 51–61. [Google Scholar] [CrossRef]

- Trehern, W.; Ortiz-Ayala, R.; Atli, K.C.; Arroyave, R.; Karaman, I. Data-driven shape memory alloy discovery using artificial intelligence materials selection (AIMS) framework. Acta Mater. 2022, 228, 117751. [Google Scholar] [CrossRef]

- Li, S.; Li, S.; Liu, D.; Zou, R.; Yang, Z. Hardness prediction of high entropy alloys with machine learning and material descriptors selection by improved genetic algorithm. Comput. Mater. Sci. 2022, 205, 111185. [Google Scholar] [CrossRef]

- Lai, C.-C.; Boyd, R.; Svensson, P.-O.; Höglund, C.; Robinson, L.; Birch, J.; Hall-Wilton, R. Effect of substrate roughness and material selection on the microstructure of sputtering deposited boron carbide thin films. Surf. Coat. Technol. 2022, 433, 128160. [Google Scholar] [CrossRef]

- Chatterjee, S.; Chakraborty, S. A multi-attributive ideal-real comparative analysis-based approach for piston material selection. OPSEARCH 2022, 59, 207–228. [Google Scholar] [CrossRef]

- Del Rosario, Z. Precision materials indices: Materials selection with statistically rigorous reliability analysis. AIAA J. 2022, 60, 578–586. [Google Scholar] [CrossRef]

- Kumar, D.; Marchi, M.; Alam, S.B.; Kavka, C.; Koutsawa, Y.; Rauchs, G.; Belouettar, S. Multi-criteria decision making under uncertainties in composite materials selection and design. Compos. Struct. 2022, 279, 114680. [Google Scholar] [CrossRef]

- Jahan, F.; Soni, M.; Parveen, A.; Waseem, M. Application of combined compromise solution method for material selection. In Proceedings of the International Conference on Advancement in Materials, Manufacturing and Energy Engineering, ICAMME 2021, Online, 18–20 February 2021; pp. 379–387. [Google Scholar] [CrossRef]

- Toledo, H.; Martínez-Gómez, J.; Nicolalde, J.F. Selection of rear axle tip alternative material of a car by multi-criteria means. Int. J. Math. Oper. Res. 2022, 21, 46–66. [Google Scholar] [CrossRef]

- Foong, F.M.; Thein, C.K.; Yurchenko, D. Structural optimisation through material selections for multi-cantilevered vibration electromagnetic energy harvesters. Mech. Syst. Signal Process. 2022, 162, 108044. [Google Scholar] [CrossRef]

- Izonin, I.; Tkachenko, R.; Gregus, M.; Zub, K.; Tkachenko, P. A GRNN-based approach towards prediction from small datasets in medical application. Proc. Comput. Sci. 2021, 184, 242–249. [Google Scholar] [CrossRef]

- Altun, O.; Zhang, D.; Siqueira, R.; Wolniak, P.; Mozgova, I.; Lachmayer, R. Identification of dynamic loads on structural component with artificial neural networks. Proc. Manuf. 2020, 52, 181–186. [Google Scholar] [CrossRef]

- Boyacı, A.Ç.; Tüzemen, M.Ç. Multi-criteria decision-making approaches for aircraft-material selection problem. Int. J. Mater. Prod. Technol. 2022, 64, 45–68. [Google Scholar] [CrossRef]

- Takemura, K. Escaping from Bad Decisions a Behavioral Decision-Theoretic Perspective; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Kwak, S.; Kim, J.; Ding, H.; Xu, X.; Chen, R.; Guo, J.; Fu, H. Using multiple regression analysis to predict directionally solidified TiAl mechanical property. J. Mater. Sci. Technol. 2022, 104, 285–291. [Google Scholar] [CrossRef]

- Kangishwar, S.; Radhika, N.; Sheik, A.A.; Chavali, A.; Hariharan, S. A comprehensive review on polymer matrix composites: Material selection, fabrication, and application. Polym. Bull. 2022, in press. [Google Scholar] [CrossRef]

- Sadowski, A.J.; Rotter, J.M.; Reinke, T.; Ummenhofer, T. Statistical analysis of the material properties of selected structural carbon steels. Struct. Saf. 2015, 53, 26–35. [Google Scholar] [CrossRef]

- Tian, P.; Zhu, G.; Kang, Y. Effect of Carbon content on microstructure, properties and texture of ultra-thin hot rolled strip produced by endless roll technology. Materials 2021, 14, 6174. [Google Scholar] [CrossRef]

- Salman, A.; Djavanroodi, F. Variability of chemical analysis of reinforcing bar produced in Saudi Arabia. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 348, p. 012015. [Google Scholar] [CrossRef]

- Gandy, D. Carbon Steel Handbook; EPRI: Palo Alto, CA, USA, 2007. [Google Scholar]

- Hosford, W.F. Iron and Steel; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar] [CrossRef]

- Davis, J.R. Mechanical Properties of Carbon and Alloy Steels, 2nd ed.; ASM International: Russell Township, OH, USA, 1998. [Google Scholar] [CrossRef]

- Phelps, C. Carbon Steel: Microstructure, Mechanical Properties and Applications; Nova Science Publishers: Hauppauge, NY, USA, 2019. [Google Scholar]

- Islam, T.; Rashed, H.M.M.A. Classification and application of plain carbon steels. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Angelo, P.C.; Ravisankar, B. Introduction to Steels: Processing, Properties, and Applications, 1st ed.; Taylor & Francis Group: Abingdon, UK, 2019. [Google Scholar]

- Lv, Z.; Qian, L.; Liu, S.; Zhan, L.; Qin, S. Preparation and mechanical behavior of ultra-high strength low-carbon steel. Materials 2020, 13, 459. [Google Scholar] [CrossRef] [Green Version]

- Johnson, O.T.; Ogunmuyiwa, E.N.; Ude, A.U.; Gwangwavac, N.; Addo-Tenkorang, R. Mechanical properties of heat-treated medium carbon steel in renewable and biodegradable oil. Proc. Manuf. 2019, 35, 229–235. [Google Scholar] [CrossRef]

- Kim, B.; Sietsma, J.; Santofimia, M.J. The role of silicon in carbon partitioning processes in martensite/austenite microstructures. Mater. Des. 2017, 127, 336–345. [Google Scholar] [CrossRef]

- Salvetr, P.; Nový, Z.; Gokhman, A.; Kotous, J.; Zmeko, J.; Motyčka, P.; Dlouhý, J. Influence of Si and Cu content on tempering and properties of 54SiCr6 steel. Manuf. Technol. 2020, 20, 516–520. [Google Scholar] [CrossRef]

- Kučerová, L.; Jirková, H.; Volkmannová, J.; Vrtáček, J. Effect of aluminium and manganese contents on the microstructure development of forged and annealed TRIP steel. Manuf. Technol. 2018, 18, 605–610. [Google Scholar] [CrossRef]

- Salvetr, P.; Gokhman, A.; Nový, Z.; Motyčka, P.; Kotous, J. Effect of 1.5 wt% Copper addition and various contents of silicon on mechanical properties of 1.7102 medium carbon steel. Materials 2021, 14, 5244. [Google Scholar] [CrossRef]

- Duriagina, Z.A.; Tkachenko, R.O.; Trostianchyn, A.M.; Lemishka, I.A.; Kovalchuk, A.M.; Kulyk, V.V.; Kovbasyuk, T.M. Determination of the best microstructure and titanium alloy powders properties using neural network. J. Achiev. Mater. Manuf. Eng. 2018, 87, 23–30. [Google Scholar] [CrossRef]

- Kusy, M.; Kowalski, P. Weighted probabilistic neural network. Inf. Sci. 2018, 430, 65–76. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, R.; Gupta, A.K. Experimental investigation of WEDM process through integrated desirability and machine learning technique on implant material. J. Mech. Behav. Mater. 2021, 30, 38–48. [Google Scholar] [CrossRef]

- Izonin, I.; Tkachenko, R.; Gregus, M.; Duriagina, Z.; Shakhovska, N. PNN-SVM approach of Ti-based powder’s properties evaluation for biomedical implants production. CMC-Comput. Mater. Contin. 2022, 71, 5933–5947. [Google Scholar] [CrossRef]

- Xie, X.; Bennett, J.; Saha, S.; Lu, Y.; Cao, J.; Liu, W.K.; Gan, Z. Mechanistic data-driven prediction of as-built mechanical properties in metal additive manufacturing. Comput. Mater. 2021, 7, 86. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | Cr | Other * | |||

|---|---|---|---|---|---|---|---|---|

| x1 | x2 | x3 | x4 | x5 | ||||

| Min | Max | Min | Max | Min | Max | |||

| AISI 1010 | 0.07 | 0.14 | 0.17 | 0.37 | 0.35 | 0.65 | 0.15 | 0.66 |

| AISI 1015 | 0.12 | 0.19 | 0.25 | |||||

| AISI 1020 | 0.17 | 0.24 | ||||||

| AISI 1025 | 0.22 | 0.30 | 0.50 | 0.80 | ||||

| AISI 1030 | 0.27 | 0.35 | ||||||

| AISI 1035 | 0.32 | 0.40 | ||||||

| AISI 1040 | 0.37 | 0.45 | ||||||

| AISI 1045 | 0.42 | 0.50 | ||||||

| AISI 1050 | 0.47 | 0.55 | ||||||

| AISI 1055 | 0.52 | 0.60 | ||||||

| AISI 1060 | 0.57 | 0.65 | ||||||

| Maximum value of X<j> ** | 0.65 | 0.37 | 0.80 | 0.25 | 0.66 | |||

| Steel | Conditional Yield Strength σ0.2, MPa | Ultimate Tensile Strength, σB, MPa | Relative Elongation- at-Break, δr, % | Relative Narrowing, ψ, % | Fatigue Limit, σ−1, MPa | Brinell Hardness, HB, kgf/mm2 |

|---|---|---|---|---|---|---|

| y1 | y2 | y3 | y4 | y5 | y6 | |

| AISI 1010 | 260 | 420 | 32 | 69 | 187 | 143 |

| AISI 1015 | 215 | 420 | 33 | 70 | 176 | 152 |

| AISI 1020 | 245 | 470 | 29 | 72 | 206 | 161 |

| AISI 1025 | 300 | 530 | 27 | 68 | 223 | 177 |

| AISI 1030 | 415 | 585 | 23 | 65 | 255 | 163 |

| AISI 1035 | 470 | 660 | 19 | 67 | 302 | 189 |

| AISI 1040 | 485 | 730 | 17 | 62 | 323 | 208 |

| AISI 1045 | 495 | 725 | 15 | 55 | 331 | 197 |

| AISI 1050 | 490 | 710 | 15 | 55 | 421 | 200 |

| AISI 1055 | 540 | 800 | 14 | 48 | 377 | 239 |

| AISI 1060 | 590 | 920 | 12 | 50 | 373 | 229 |

| Maximum value of Y<l> * | 590 | 920 | 33 | 72 | 421 | 239 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pavlenko, I.; Piteľ, J.; Ivanov, V.; Berladir, K.; Mižáková, J.; Kolos, V.; Trojanowska, J. Using Regression Analysis for Automated Material Selection in Smart Manufacturing. Mathematics 2022, 10, 1888. https://doi.org/10.3390/math10111888

Pavlenko I, Piteľ J, Ivanov V, Berladir K, Mižáková J, Kolos V, Trojanowska J. Using Regression Analysis for Automated Material Selection in Smart Manufacturing. Mathematics. 2022; 10(11):1888. https://doi.org/10.3390/math10111888

Chicago/Turabian StylePavlenko, Ivan, Ján Piteľ, Vitalii Ivanov, Kristina Berladir, Jana Mižáková, Vitalii Kolos, and Justyna Trojanowska. 2022. "Using Regression Analysis for Automated Material Selection in Smart Manufacturing" Mathematics 10, no. 11: 1888. https://doi.org/10.3390/math10111888

APA StylePavlenko, I., Piteľ, J., Ivanov, V., Berladir, K., Mižáková, J., Kolos, V., & Trojanowska, J. (2022). Using Regression Analysis for Automated Material Selection in Smart Manufacturing. Mathematics, 10(11), 1888. https://doi.org/10.3390/math10111888